sensor MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 728 of 2103

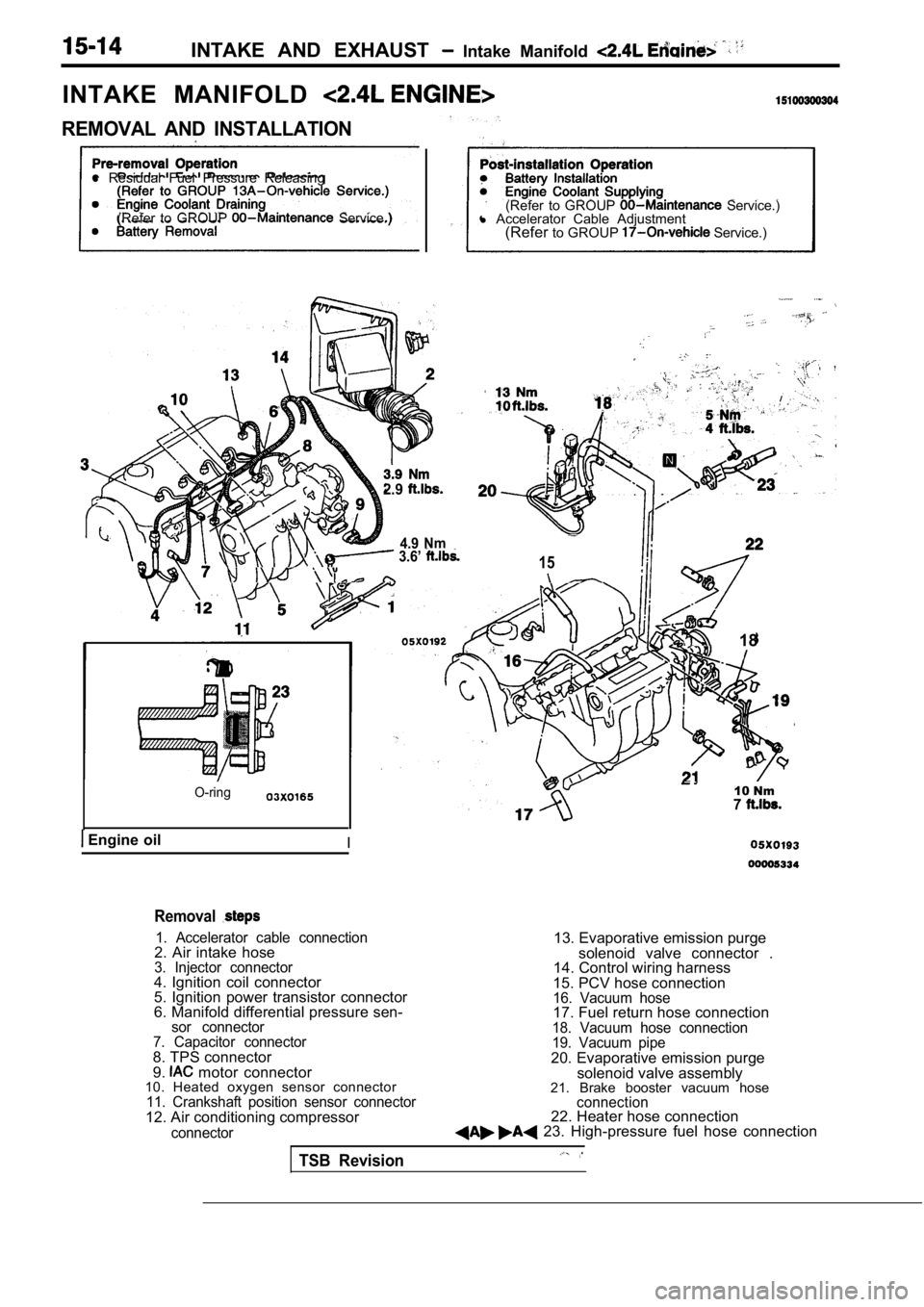

INTAKE AND EXHAUST Intake Manifold

INTAKE MANIFOLD

REMOVAL AND INSTALLATION

l Residual Fuel Pressure Releasing

(Refer to GROUP

Service.) (Refer to GROUP Service.)

l Accelerator Cable Adjustment

(Refer to GROUP

Service.)

2.9

4.9 Nm 3.6’ 15

O-ring

Engine oilI

18

10 Nm7

Removal

1. Accelerator cable connection2. Air intake hose3. Injector connector4. Ignition coil connector

5. Ignition power transistor connector

6. Manifold differential pressure sen-

sor connector

7. Capacitor connector

8. TPS connector

9. motor connector

10. Heated oxygen sensor connector

11. Crankshaft position sensor connector12. Air conditioning compressor

connector

13. Evaporative emission purge

solenoid valve connector .

14. Control wiring harness

15. PCV hose connection

16. Vacuum hose17. Fuel return hose connection18. Vacuum hose connection

19. Vacuum pipe

20. Evaporative emission purge solenoid valve assembly

21. Brake booster vacuum hose

connection22. Heater hose connection 23. High-pressure fuel hose connection

TSB Revision

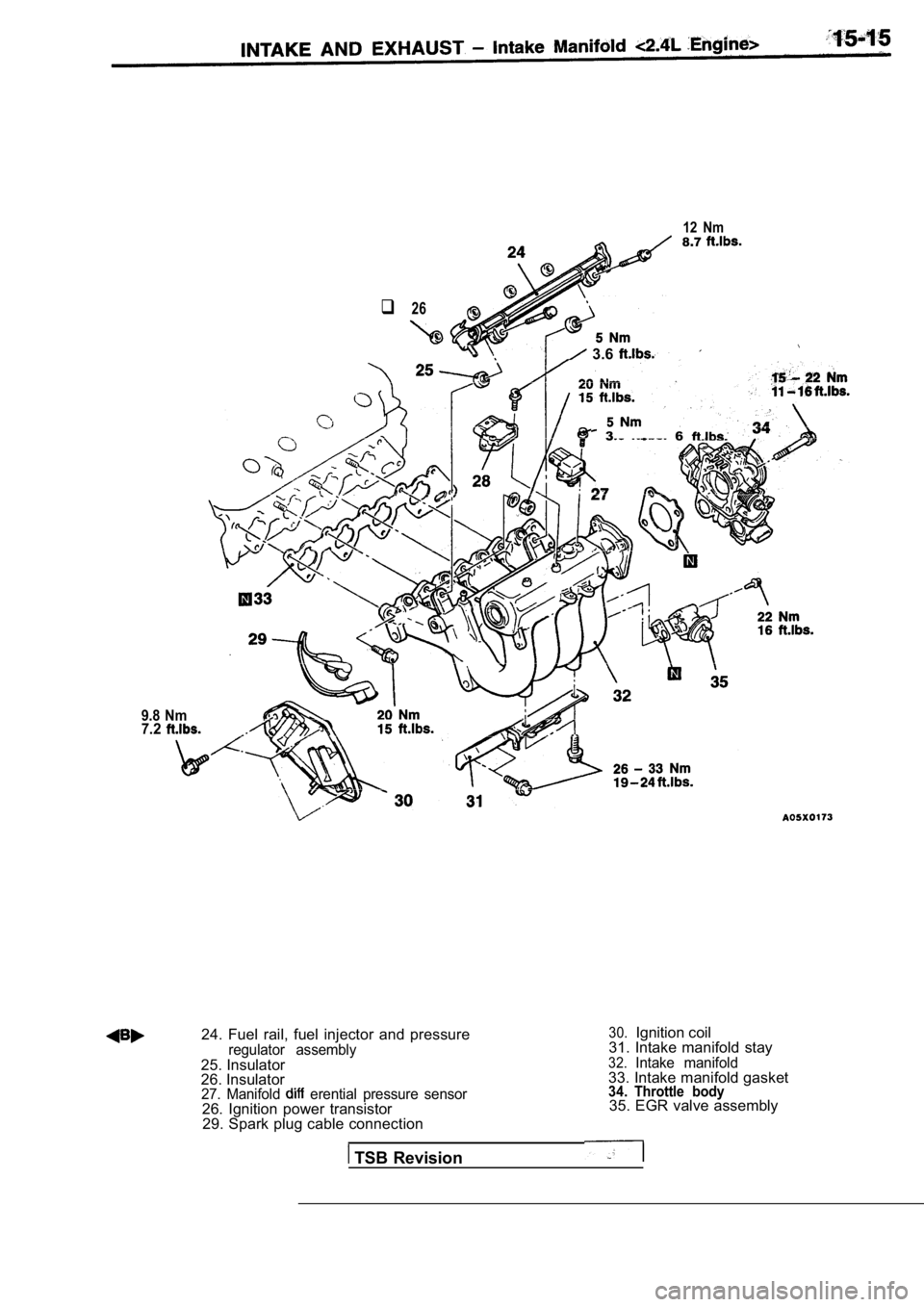

Page 729 of 2103

12 Nm8.7

q 26

3.6

9.8 Nm7.2

3 . 6

24. Fuel rail, fuel injector and pressureregulator assembly25. Insulator

26. Insulator

27. Manifold erential pressure sensor26. Ignition power transistor29. Spark plug cable connection

TSB Revision

30.Ignition coil

31. Intake manifold stay

32.Intake manifold33. Intake manifold gasket34. Throttle body35. EGR valve assembly

Page 732 of 2103

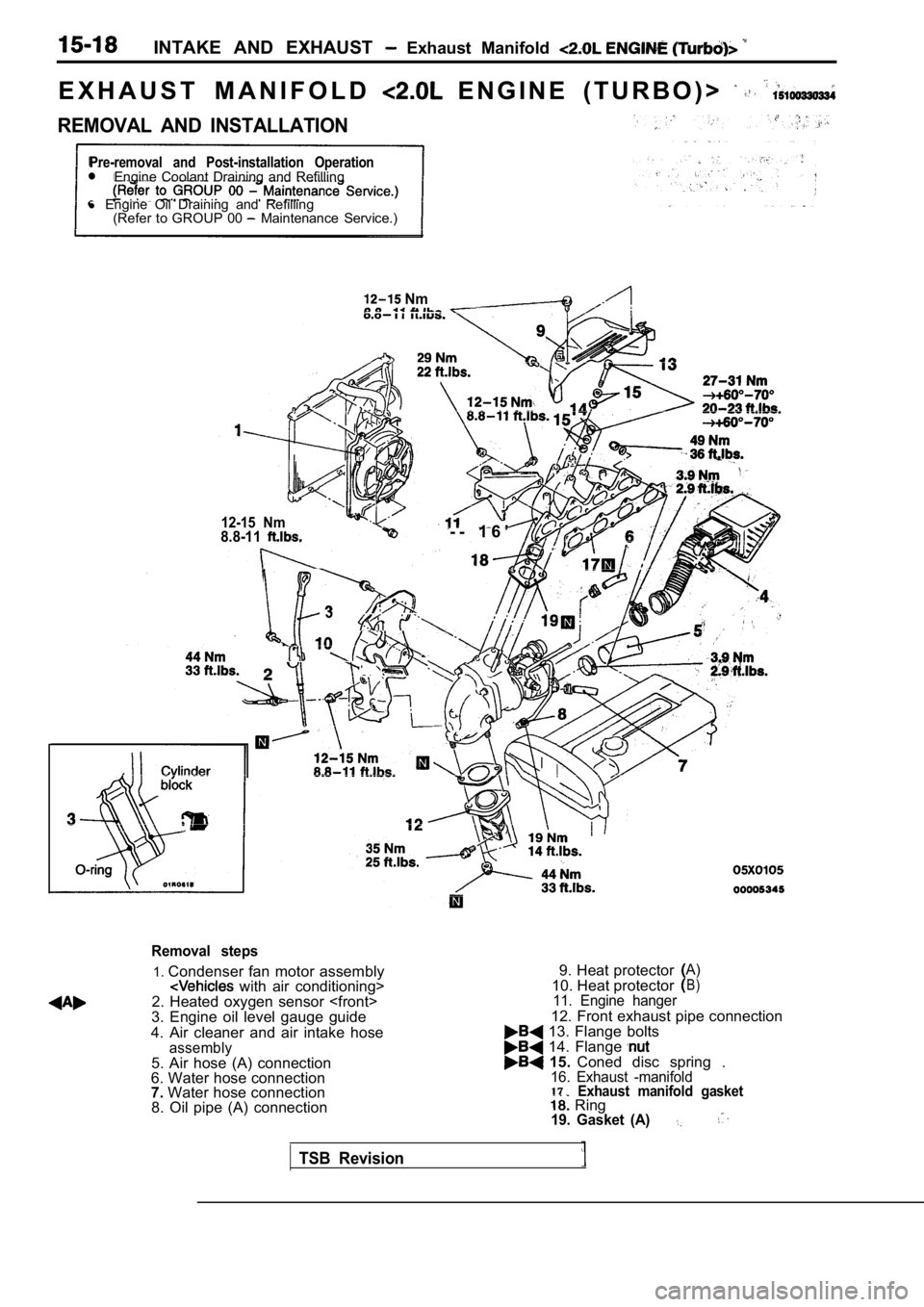

INTAKE AND EXHAUST Exhaust Manifold

E X H A U S T M A N I F O L D E N G I N E ( T U R B O ) >

REMOVAL AND INSTALLATION

Pre-removal and Post-installation OperationEngine Coolant Draining and Refilling

l Engine Oil Draining and Refilling

(Refer to GROUP 00

Maintenance Service.)

Nm

12-15 Nm8.8-11- - 1 6 ’

3

. .

Removal steps

1. Condenser fan motor assembly with air conditioning>

2. Heated oxygen sensor

3. Engine oil level gauge guide

4. Air cleaner and air intake hose

assembly5. Air hose (A) connection

6. Water hose connection

7. Water hose connection

8. Oil pipe (A) connection 9. Heat protector

A)

10. Heat protectorB)

11. Engine hanger

12. Front exhaust pipe connection 13. Flange bolts 14. Flange 15.

Coned disc spring .16. Exhaust -manifold17.Exhaust manifold gasket Ring19. Gasket (A)

TSB Revision

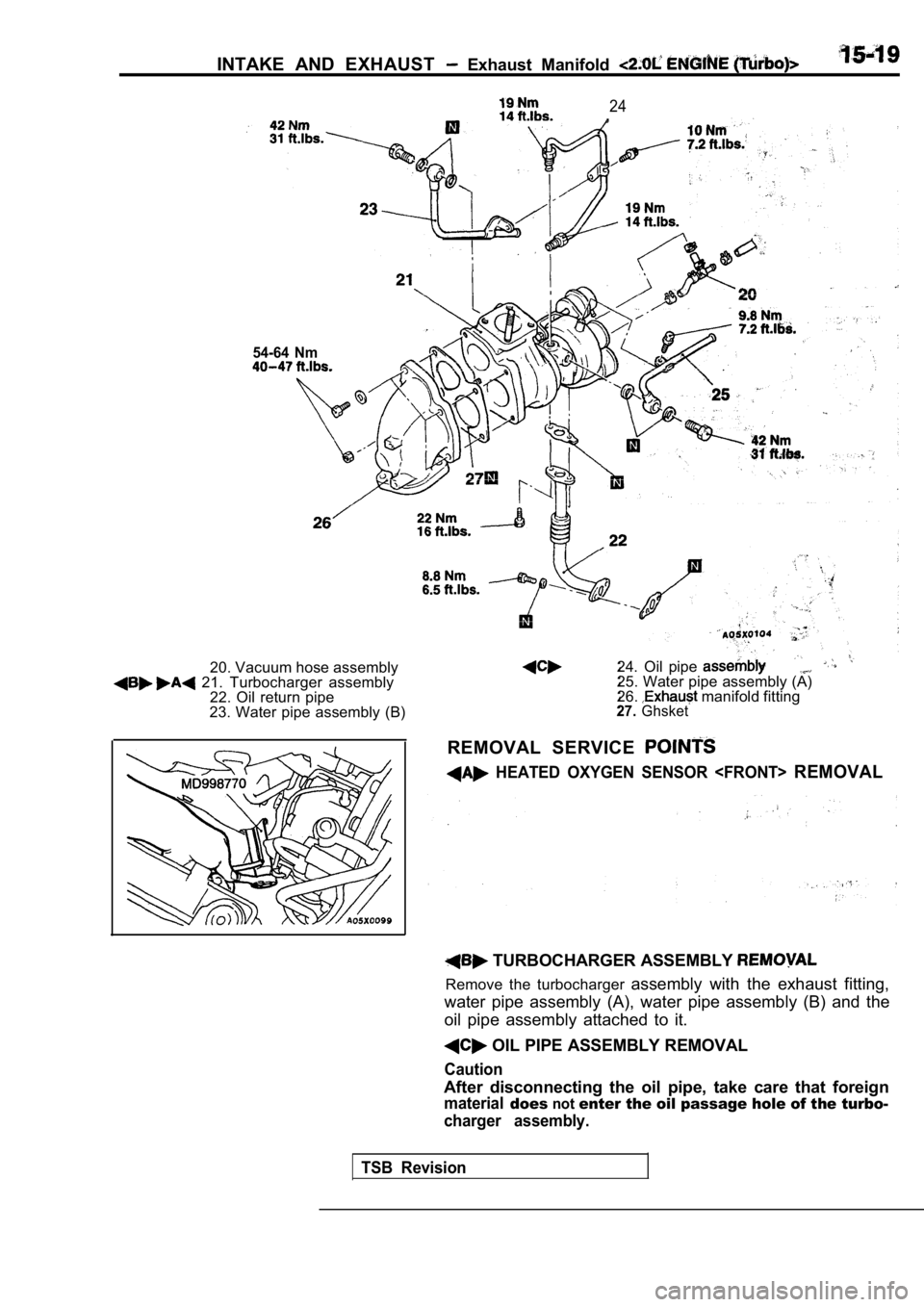

Page 733 of 2103

INTAKE AND EXHAUST Exhaust Manifold

24 ,

54-64 Nm

20. Vacuum hose assembly 21. Turbocharger assembly22. Oil return pipe

23. Water pipe assembly (B) 24. Oil pipe 25. Water pipe assembly (A)

26. manifold fitting27.Ghsket

REMOVAL SERVICE

HEATED OXYGEN SENSOR

TSB Revision

TURBOCHARGER ASSEMBLY

Remove the turbocharger

assembly with the exhaust fitting,

water pipe assembly (A), water pipe assembly (B) an d the

oil pipe assembly attached to it.

OIL PIPE ASSEMBLY REMOVAL

Caution

After disconnecting the oil pipe, take care that fo reign

materialdoesnotenter the oil passage hole of the turbo-

charger assembly.

Page 736 of 2103

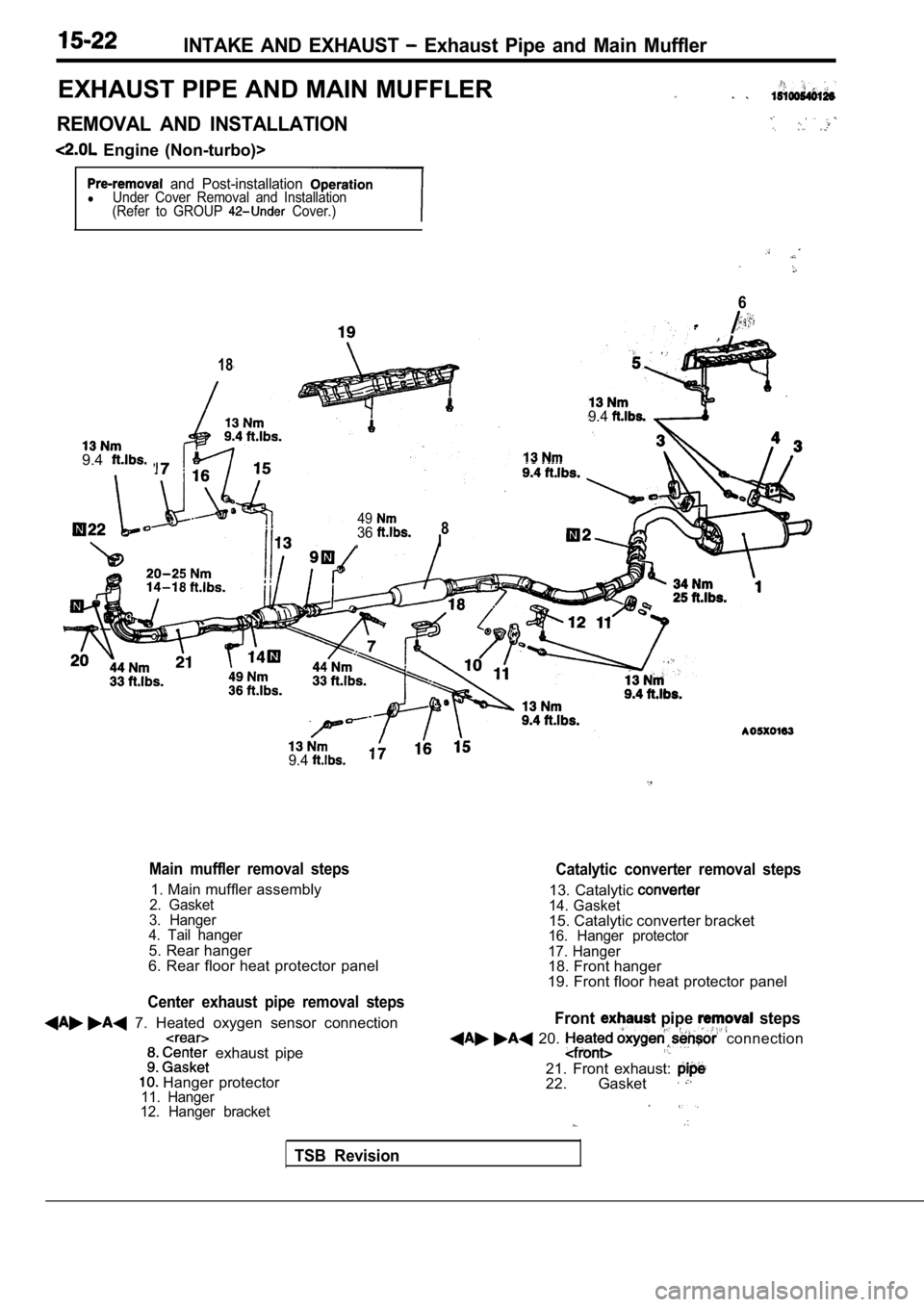

INTAKE AND EXHAUST Exhaust Pipe and Main Muffler

EXHAUST PIPE AND MAIN MUFFLER

REMOVAL AND INSTALLATION

Engine (Non-turbo)>

and Post-installationlUnder Cover Removal and Installation

(Refer to GROUP Cover.)

18

9.4 ,

4936,8I

6

9.4

9.4

Main muffler removal steps Catalytic converter removal steps

1. Main muffler assembly2. Gasket13. Catalytic 14. Gasket

3. Hanger

4. Tail hanger15. Catalytic converter bracket

5. Rear hanger16. Hanger protector

6. Rear floor heat protector panel17. Hanger18. Front hanger

Center exhaust pipe removal steps

7. Heated oxygen sensor connection

exhaust pipe

Hanger protector11. Hanger

12. Hanger bracket

TSB Revision

19. Front floor heat protector panel

Front pipe steps

20. connection

21. Front exhaust:22. Gasket

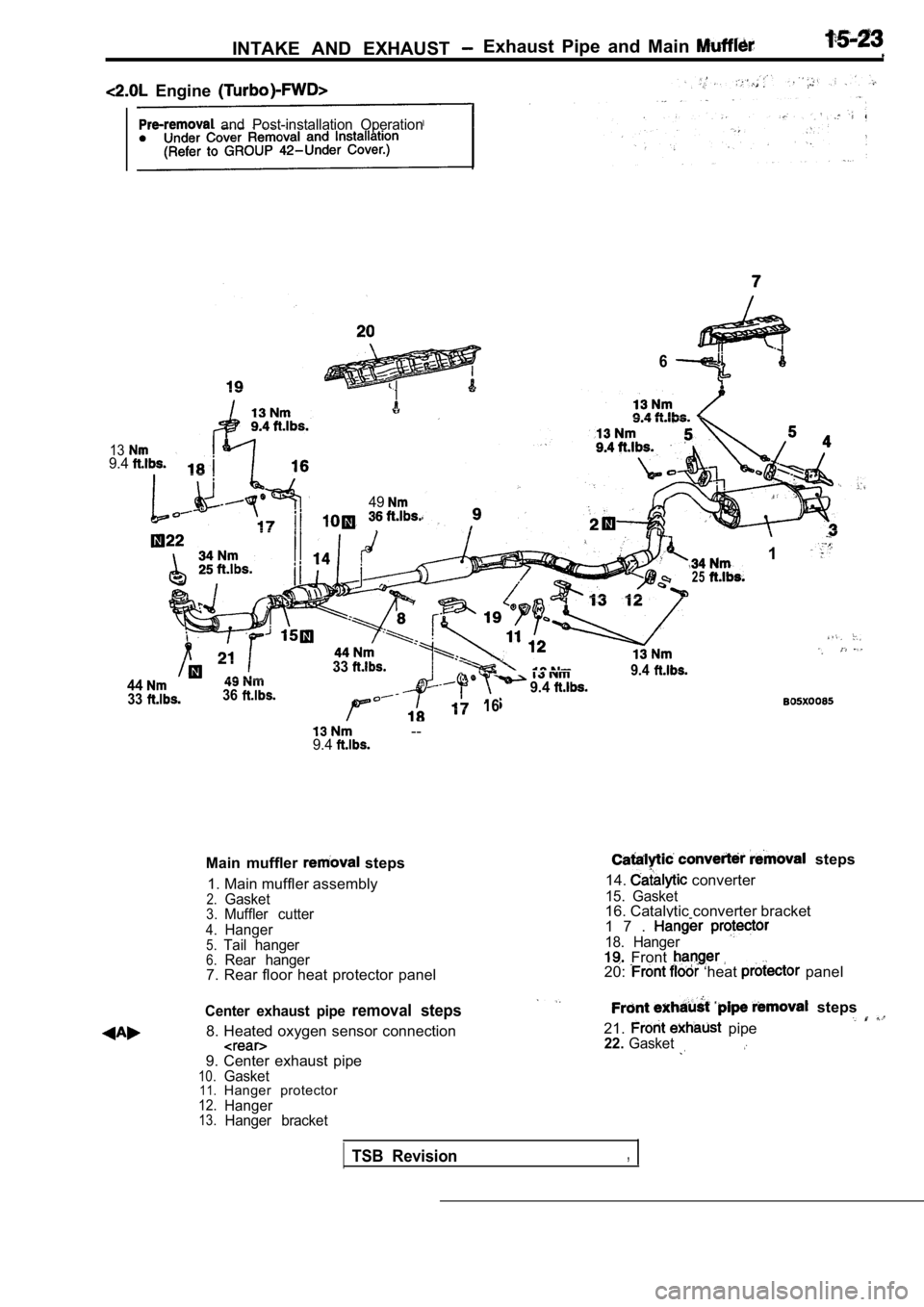

Page 737 of 2103

INTAKE AND EXHAUST Exhaust Pipe and Main

Engine

and Post-installation Operation

139.4

49

6

25

1

443336

33

9.4

16

9.4

--9.4

Main muffler steps

1. Main muffler assembly

2.Gasket3.Muffler cutter

4.Hanger5.Tail hanger6.Rear hanger7. Rear floor heat protector panel

Center exhaust pipe removal steps

8. Heated oxygen sensor connection

9. Center exhaust pipe10.Gasket11.Hanger protector12.Hanger13.Hanger bracket

steps

14.

converter

15. Gasket16. Catalytic converter bracket

1 7 .

18. Hanger Front .20: ‘heat panel

steps

21.

pipe22.Gasket

TSB Revision,

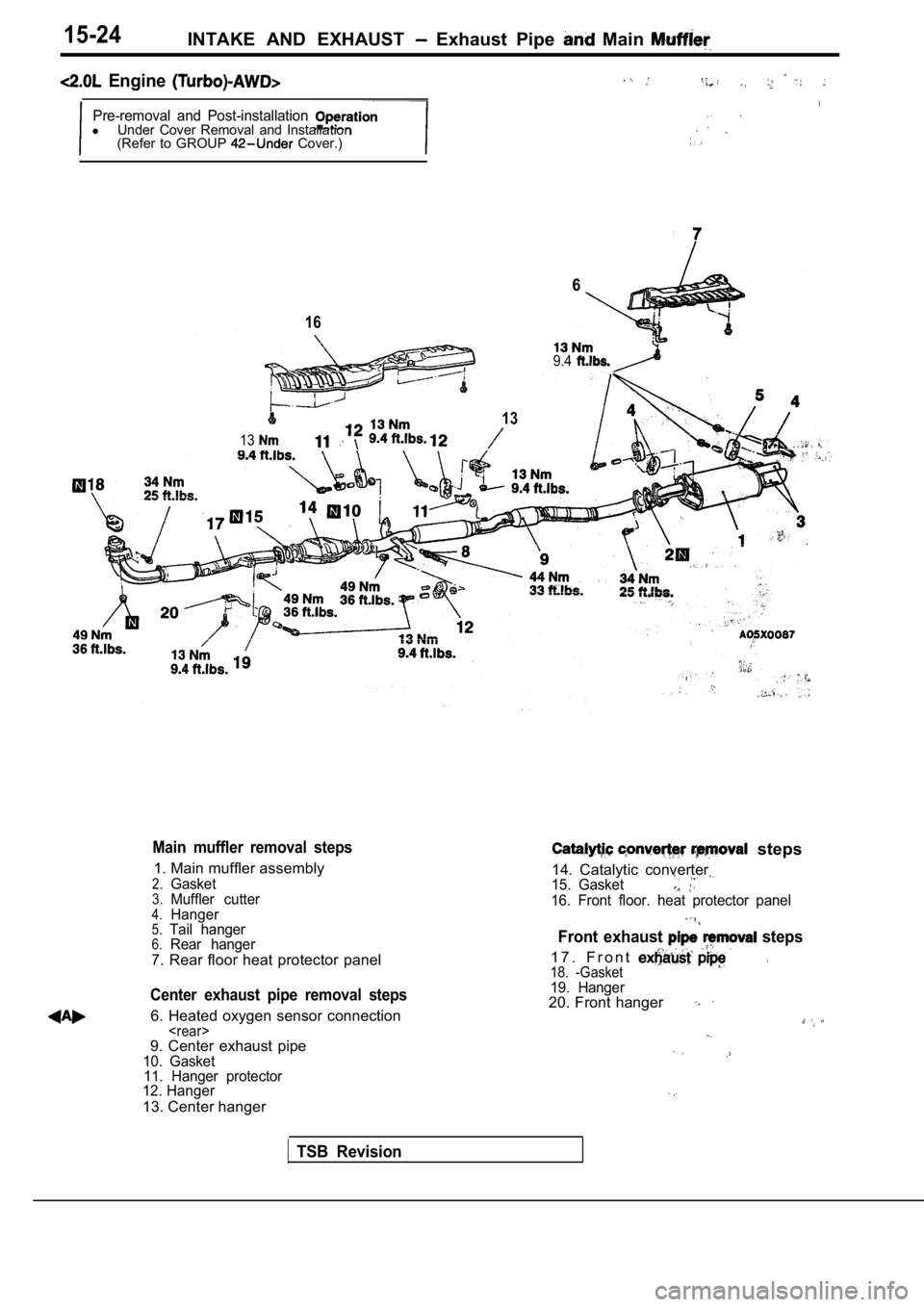

Page 738 of 2103

15-24INTAKE AND EXHAUST Exhaust Pipe Main

Engine

Pre-removal and Post-installationlUnder Cover Removal and Installation

(Refer to GROUP Cover.)

16

13

13

6

9.4

Main muffler removal steps

1. Main muffler assembly

2.Gasket3.Muffler cutter4.Hanger5.Tail hanger6.Rear hanger

7. Rear floor heat protector panel

Center exhaust pipe removal steps

6. Heated oxygen sensor connection

11. Hanger protector

12. Hanger

13. Center hanger

steps

14. Catalytic converter

15. Gasket

16. Front floor. heat protector panel

Front exhaust steps

1 7 . F r o n t .18. -Gasket19. Hanger20. Front hanger

TSB Revision

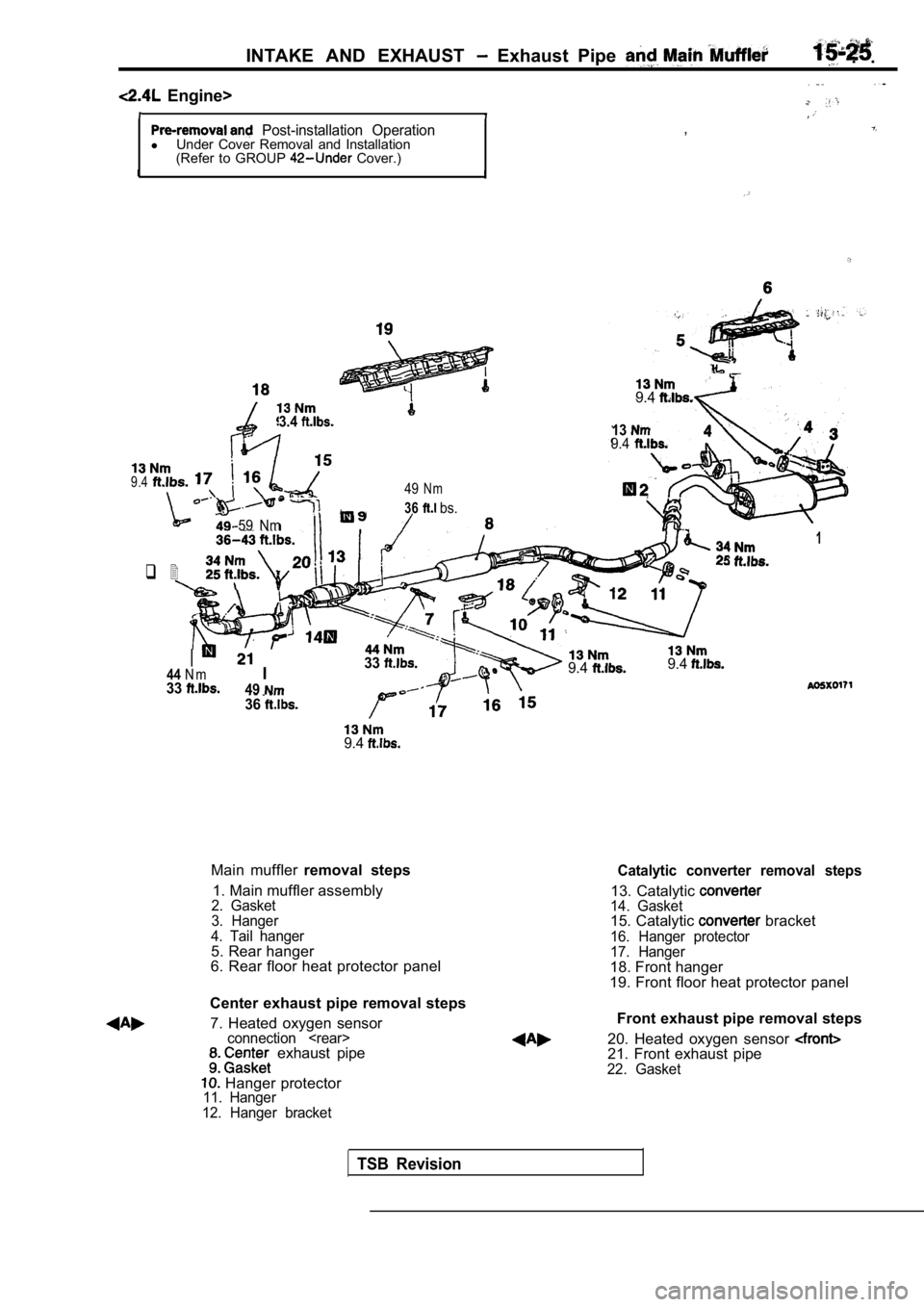

Page 739 of 2103

INTAKE AND EXHAUST Exhaust Pipe . .

Engine>

Post-installation OperationlUnder Cover Removal and Installation

(Refer to GROUP Cover.) ,

3.4

9.4

139.4

9.449N m

36 bs.

-59 Nm

q 2

9.4

Main muffler

removal steps

1. Main muffler assembly

2. Gasket

3. Hanger

4. Tail hanger

5. Rear hanger

6. Rear floor heat protector panel

Center exhaust pipe removal steps 7. Heated oxygen sensor

connection

Hanger protector11. Hanger

12. Hanger bracket

9.49.4

1

Catalytic converter removal steps

13. Catalytic 14. Gasket15. Catalytic bracket

16. Hanger protector

17. Hanger

18. Front hanger

19. Front floor heat protector panel

II3344N m334936

Front exhaust pipe removal steps

20. Heated oxygen sensor

21. Front exhaust pipe22. Gasket

TSB Revision

Page 740 of 2103

INTAKE AND Pipe and Main

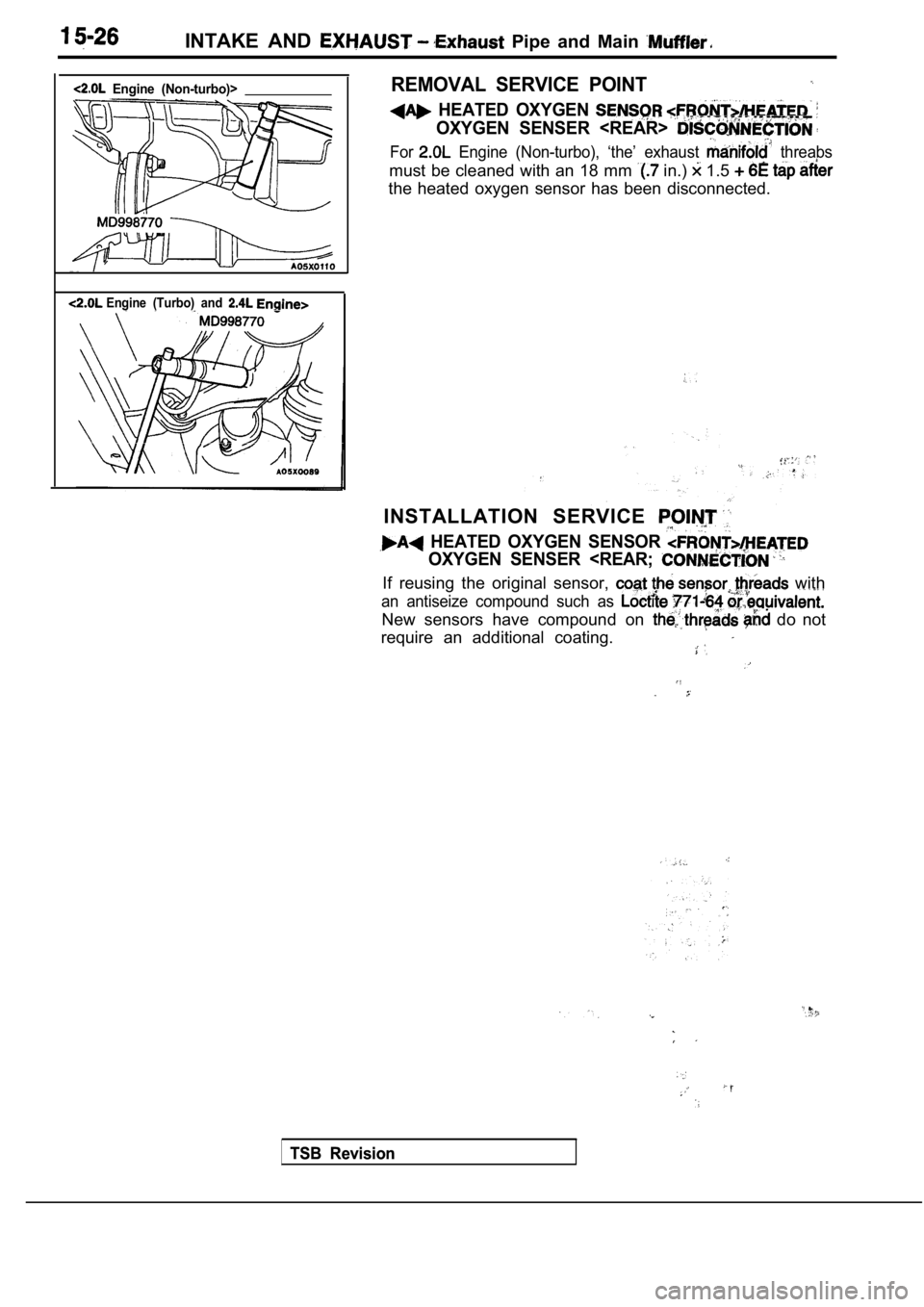

Engine (Non-turbo)>

Engine (Turbo) and

REMOVAL SERVICE POINT

HEATED OXYGEN

OXYGEN SENSER

For Engine (Non-turbo), ‘the’ exhaust threabs

must be cleaned with an 18 mm in.) 1.5

the heated oxygen sensor has been disconnected.

INSTALLATION SERVICE

HEATED OXYGEN SENSOR

OXYGEN SENSER

an antiseize compound such as

New sensors have compound on do not

require an additional coating.

TSB Revision

TSB Revision

Page 741 of 2103

CONTENTS

AUTO-CRUISE CONTROL SYSTEM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

AUTO-CRUISE CONTROL* . . . . . . . . . . . . . . 40

GENERAL INFORMATION . . . . . . . . . . . . . . . . 7

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . . 33

Auto-cruise Control Cable Check and

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

Auto-cruise Control Component Check . . . . . 37

Auto-cruise Control System Operation Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

SERVICE SPECIFICATIONS . . . . . . . . . . . . . 8

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . 8

TROUBLESHOOTING

ENGINE (NON-TURBO)> . . . . . . . . . . . 9

TROUBLESHOOTING

(TURBO) AND ENGINE> . . . . .

EMISSION CONTROL’ SYSTEM

. . . . .

CATALYTIC . . . . . . . . . . . . . .

General Information . . . . . . . . . . . . . . . . . . 57

EVAPORATIVE EMISSION .

SYSTEM. . . . . . . . . . . . . . . .

Air Conditioning . . . . . . . . . . . . . . . . . . . 52

Component Location

. . . . . . . . . . . . . . . . . .

Engine Coolant Temperature Sensor

Intake Air Temperature Sensor . . . . . . . . . . . . 52

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRA INT SYSTEM (SRS) EQUIPPED

WARNING!

(1) Improper serviceor maintenance of any component of the or any SRS-related can to injuryorcleathtoservicepersonnel (from inadvertentfiring the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly rev iew this manual, and especially its GROUP

Restraint System (SRS) and GROUP 00 Maintenance Service, before any service or maintenance of any

componentof the SRS or any SRS-related component.

NOTEJhe includes the following components: warning light, air bag module, clock components (that may have to be removed/installed in connection with or areIndicated in the table of contents by an asterisk