sensor MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 673 of 2103

1.4

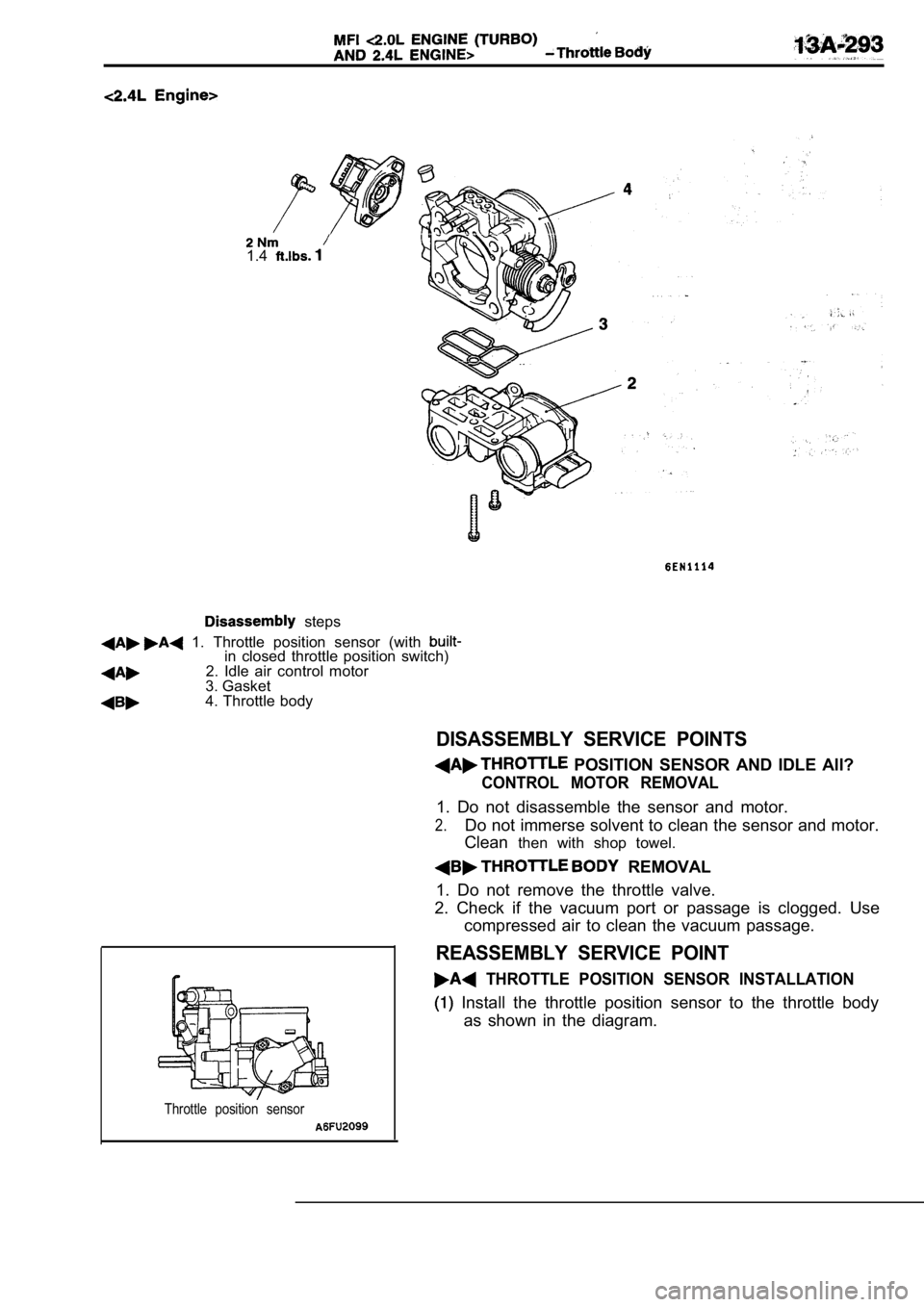

steps

1. Throttle position sensor (with in closed throttle position switch)2. Idle air control motor

3. Gasket

4. Throttle body

DISASSEMBLY SERVICE POINTS

POSITION SENSOR AND IDLE All?

CONTROL MOTOR REMOVAL

1. Do not disassemble the sensor and motor.

2.Do not immerse solvent to clean the sensor and moto r.

Clean then with shop towel.

REMOVAL

1. Do not remove the throttle valve.

2. Check if the vacuum port or passage is clogged. Use

compressed air to clean the vacuum passage.

REASSEMBLY SERVICE POINT

THROTTLE POSITION SENSOR INSTALLATION

Install the throttle position sensor to the thrott le body

as shown in the diagram.

Throttle position sensor

Page 674 of 2103

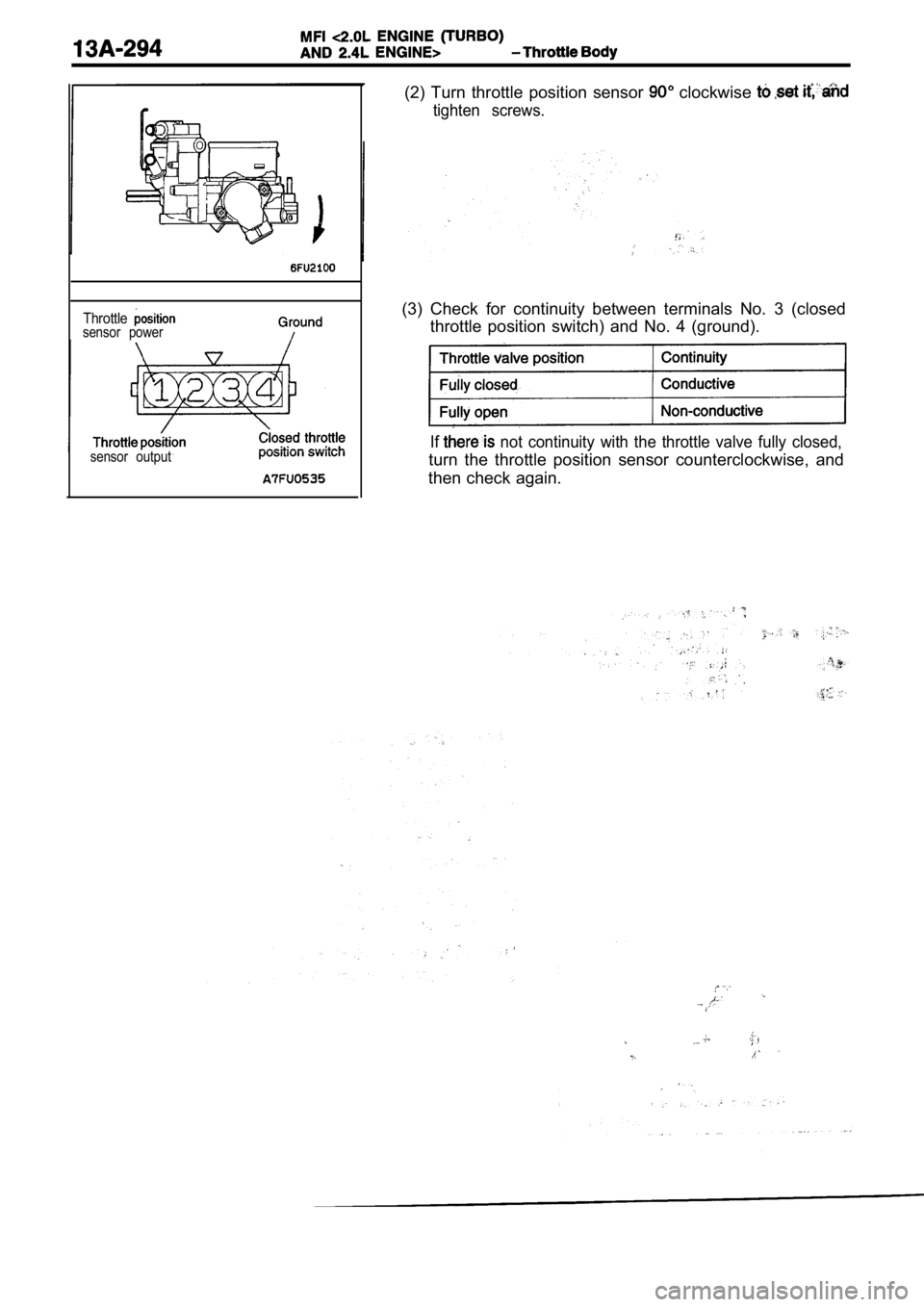

Throttlesensor powersensor output

(2) Turn throttle position sensor clockwise

tighten screws.

(3) Check for continuity between terminals No. 3 (c losed

throttle position switch) and No. 4 (ground).

If not continuity with the throttle valve fully close d,

turn the throttle position sensor counterclockwise, and

then check again.

Page 678 of 2103

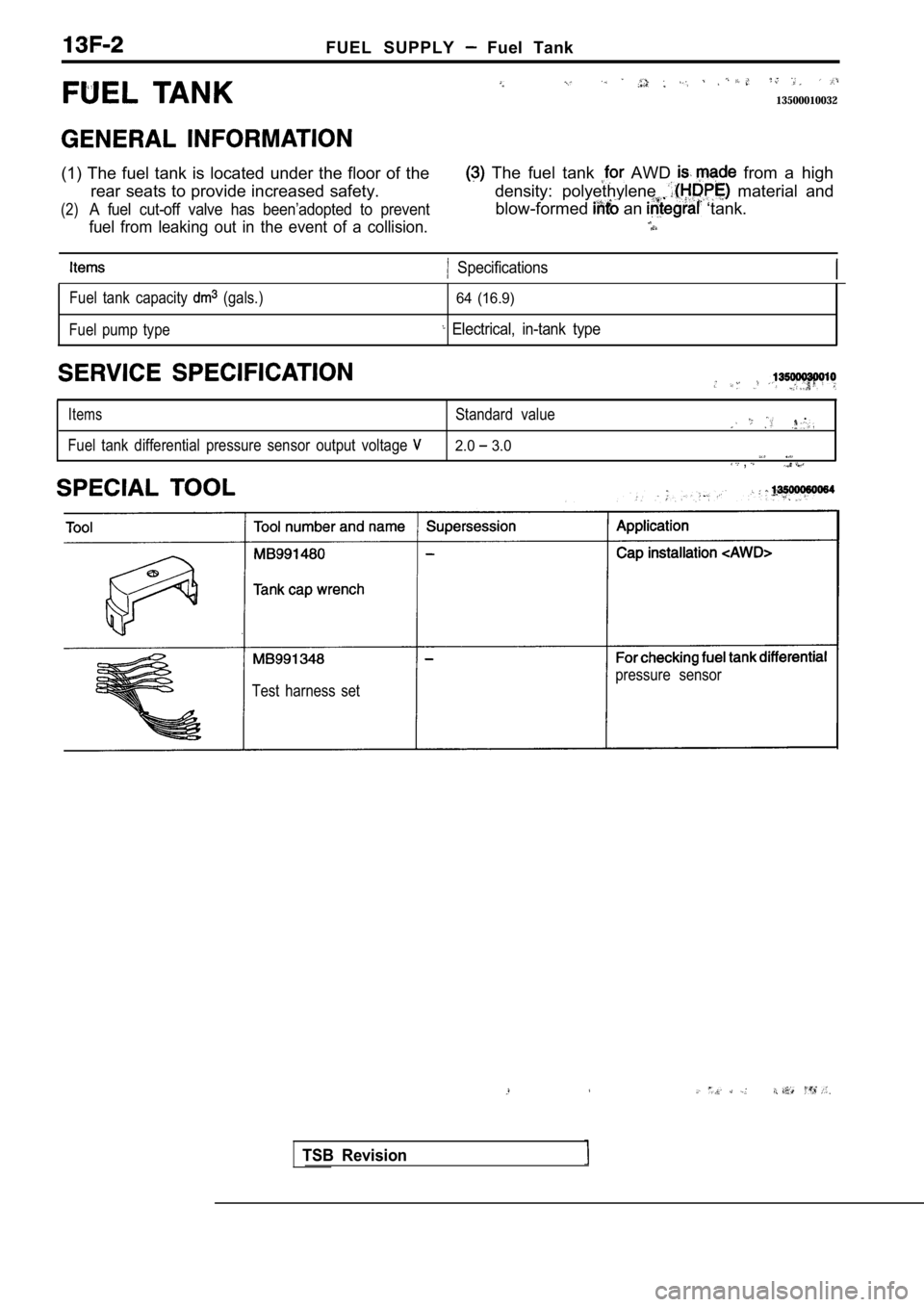

FUEL SUPPLY Fuel Tank

13500010032

(1) The fuel tank is located under the floor of the The fuel tank AWD from a high

rear seats to provide increased safety. density: pol yethylene

material and

(2)A fuel cut-off valve has been’adopted to preventblow-formed an ‘tank.

fuel from leaking out in the event of a collision.

Specifications

Fuel tank capacity (gals.)

Fuel pump type64 (16.9)

Electrical, in-tank type

ItemsStandard value.

Fuel tank differential pressure sensor output volta ge 2.0 3.0 ,

Test harness set pressure sensor

TSB Revision

Page 682 of 2103

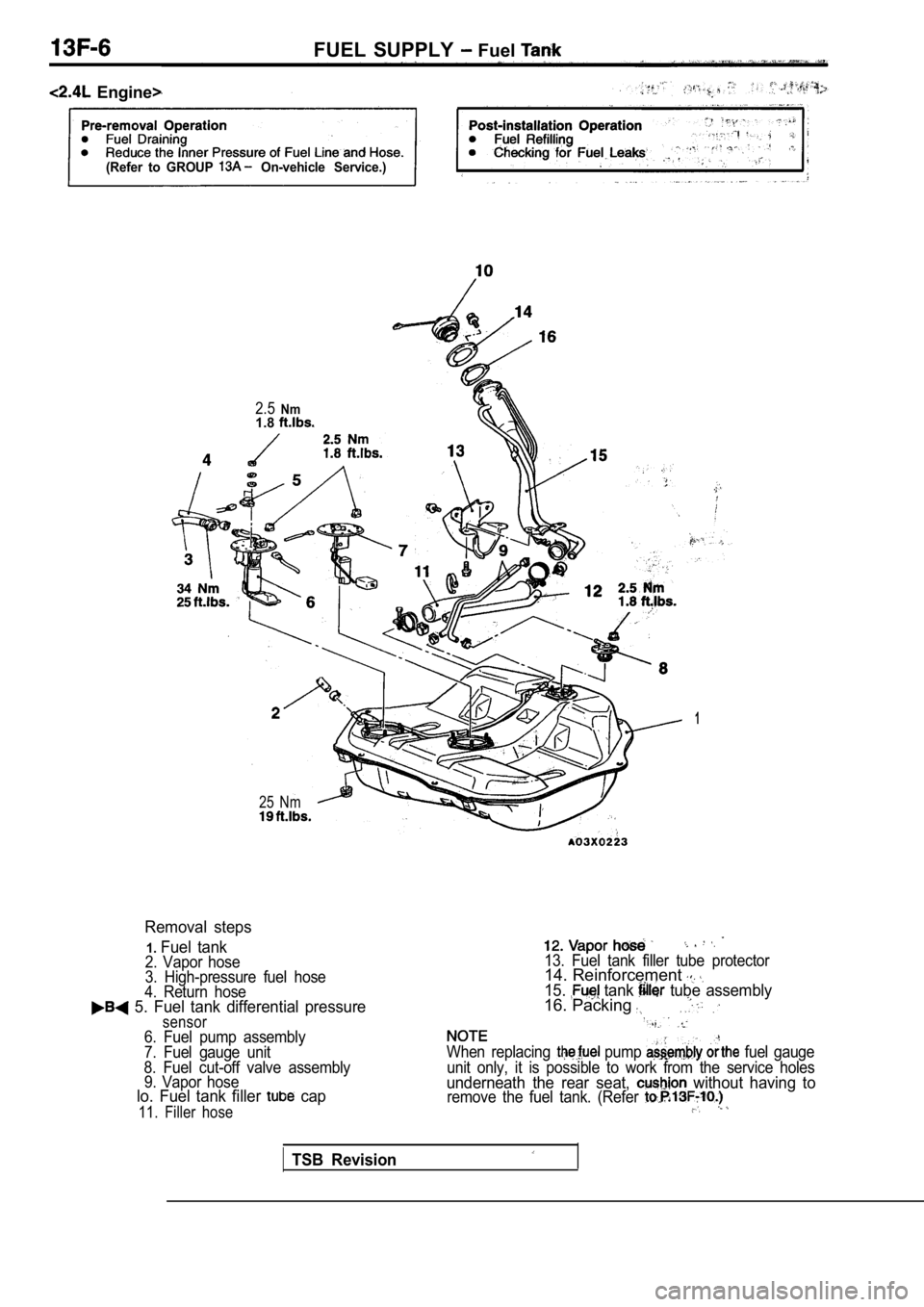

Engine>FUEL SUPPLY

Fuel

(Refer to GROUP On-vehicle Service.)

2.5Nm1.8

25 Nm

Removal steps

1.Fuel tank2. Vapor hose

3. High-pressure fuel hose

4. Return hose

5. Fuel tank differential pressuresensor6. Fuel pump assembly

7. Fuel gauge unit

8. Fuel cut-off valve assembly 9. Vapor hose

lo. Fuel tank filler cap

11. Filler hose

1

13. Fuel tank filler tube protector14. Reinforcement 15. tank tube assembly16. Packing

When replacing pump fuel gauge

unit only, it is possible to work from the service holes

underneath the rear seat, without having toremove the fuel tank. (Refer

TSB Revision

Page 683 of 2103

FUEL SUPPLY Fuel Tank

Pre-removal Operation

Pressure of Fuel (Refer to GROUP On-vehicle Service.) Il . . . . .

and Hose.

Post-installation Operationl Propeller Installation to GROUP 25 Propeller

Fuel Leaks

Propeller Shaft.)

13

Nm

.

13

25

4936

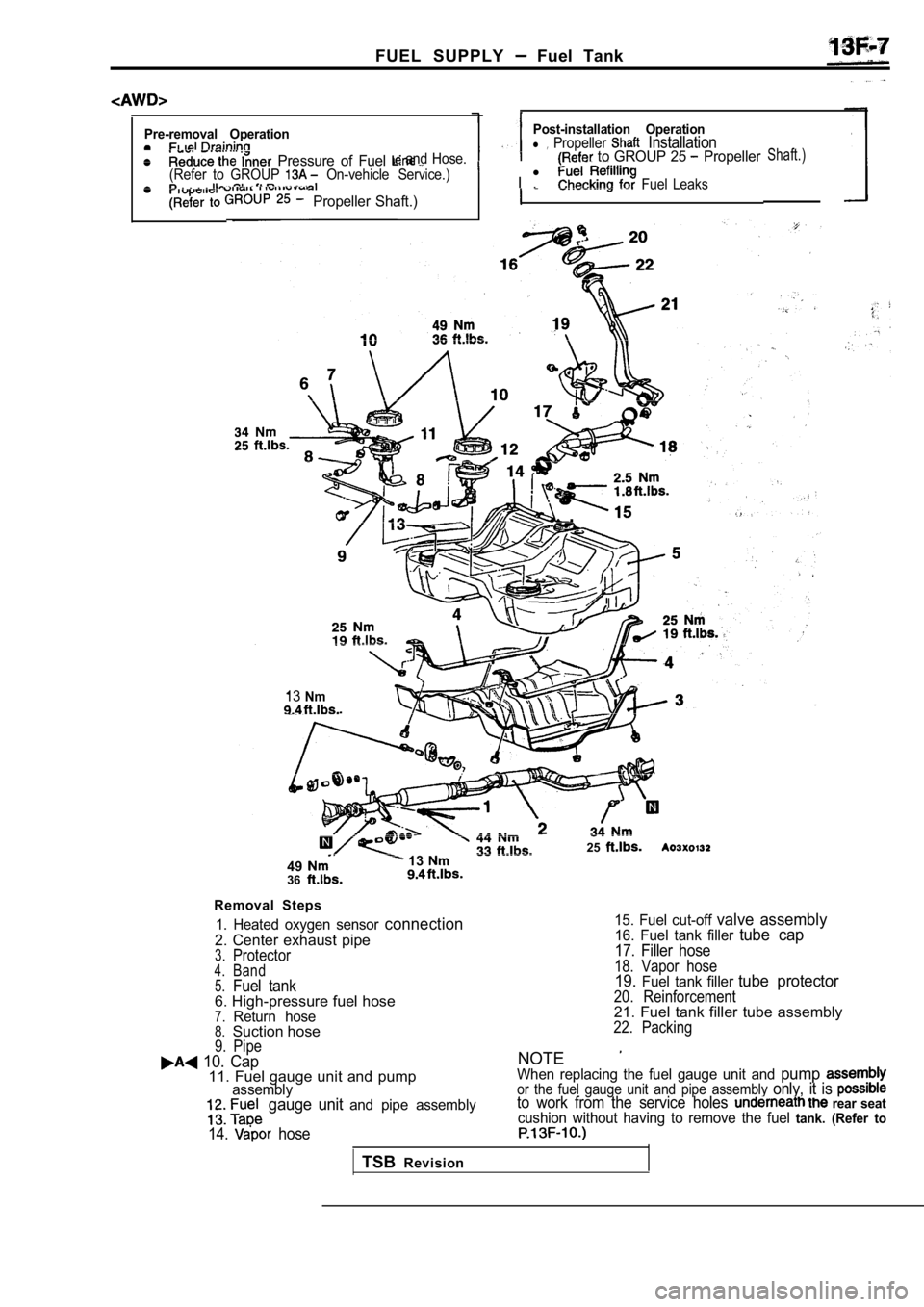

Removal Steps

1. Heated oxygen sensor connection

2. Center exhaust pipe

3.Protector4.Band5.Fuel tank6. High-pressure fuel hose7.Return hose8.Suction hose9. Pipe 10. Cap11. Fuel gauge unit and pumpassembly gauge unit and pipe assembly

14. hose

TSB

Revision

Shaft.)

15. Fuel cut-off valve assembly16. Fuel tank filler tube cap

17. Filler hose

18. Vapor hose19.Fuel tank filler tube protector

20. Reinforcement21. Fuel tank filler tube assembly

22. Packing

NOTEWhen replacing the fuel gauge unit and pumpor the fuel gauge unit and pipe assembly only, it is to work from the service holes rear seatcushion without having to remove the fuel tank. (Refer to

Page 684 of 2103

FUEL SUPPLY Fuel Tank

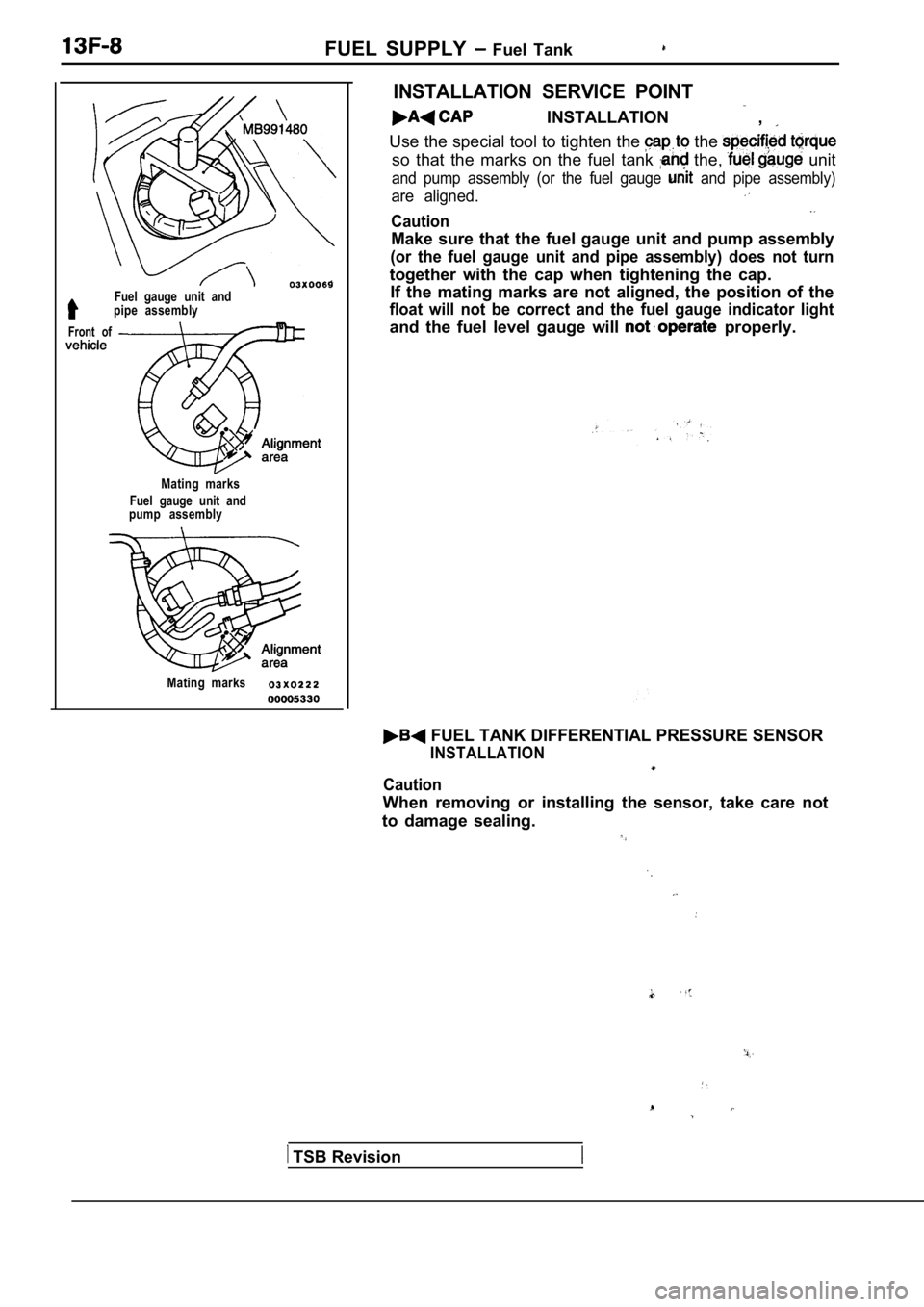

Fuel gauge unit and

pipe assembly

Front of

Mating marks

Fuel gauge unit and

pump assembly

Mating marks

INSTALLATION SERVICE POINT

INSTALLATION ,

Use the special tool to tighten the the

so that the marks on the fuel tank the, unit

and pump assembly (or the fuel gauge and pipe assembly)

are aligned.

Caution

Make sure that the fuel gauge unit and pump assembl y

(or the fuel gauge unit and pipe assembly) does not turn

together with the cap when tightening the cap.

If the mating marks are not aligned, the position o f the

float will not be correct and the fuel gauge indicator light

and the fuel level gauge will properly.

FUEL TANK DIFFERENTIAL PRESSURE SENSOR

INSTALLATION

Caution

When removing or installing the sensor, take care n ot

to damage sealing.

TSB Revision

Page 685 of 2103

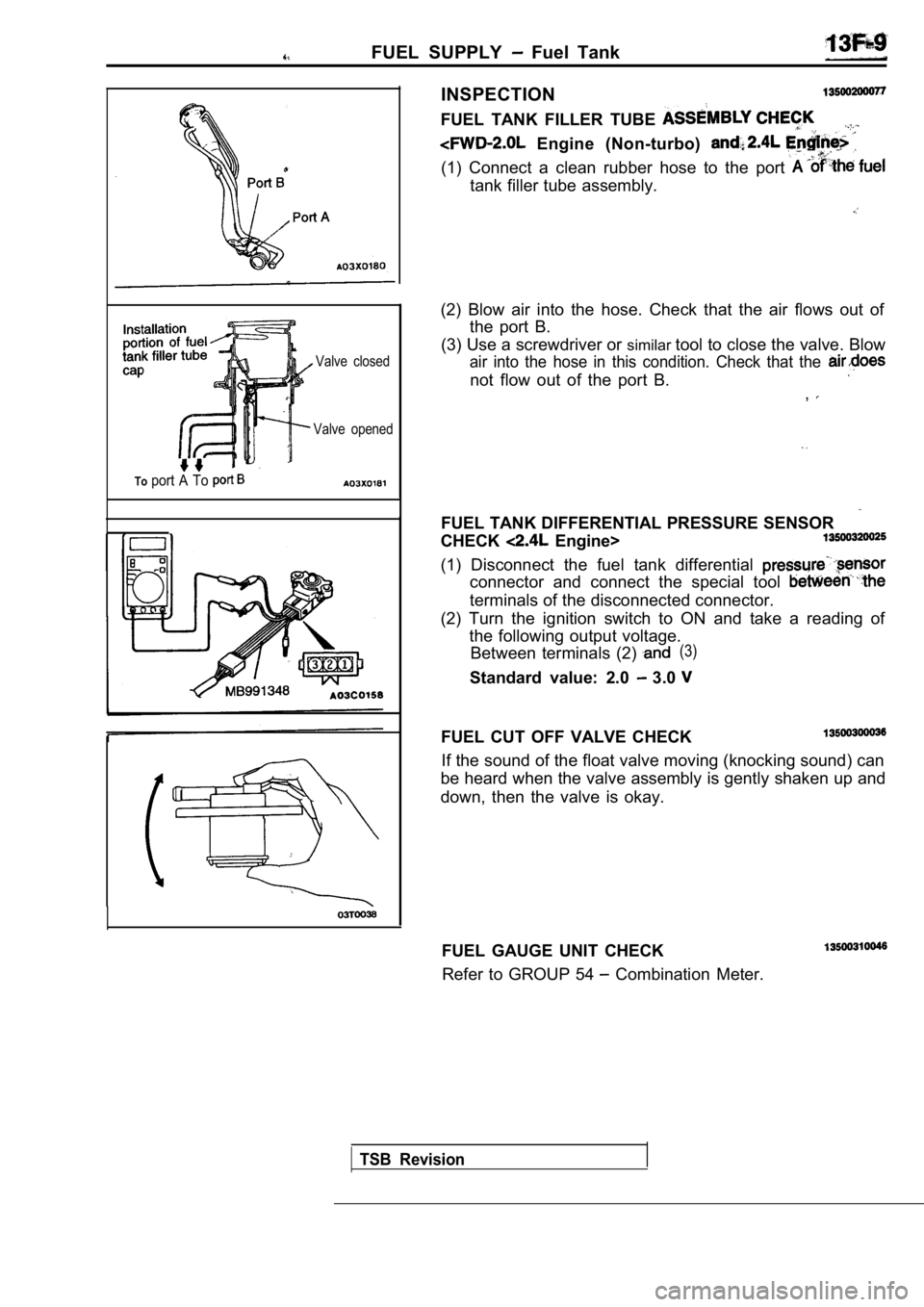

FUEL SUPPLY Fuel Tank

Valve closed

Valve opened

Toport A To

INSPECTION

FUEL TANK FILLER TUBE

Engine (Non-turbo)

(1) Connect a clean rubber hose to the port

tank filler tube assembly.

(2) Blow air into the hose. Check that the air flow s out of

the port B.

(3) Use a screwdriver or similartool to close the valve. Blow

air into the hose in this condition. Check that the

not flow out of the port B.,

FUEL TANK DIFFERENTIAL PRESSURE SENSOR

CHECK

Engine>

(1) Disconnect the fuel tank differential

connector and connect the special tool

terminals of the disconnected connector.

(2) Turn the ignition switch to ON and take a readi ng of

the following output voltage. Between terminals (2)

(3)

Standard value: 2.0 3.0

FUEL CUT OFF VALVE CHECK

If the sound of the float valve moving (knocking so und) can

be heard when the valve assembly is gently shaken u p and

down, then the valve is okay.

FUEL GAUGE UNIT CHECKRefer to GROUP 54

Combination Meter.

TSB Revision

Page 721 of 2103

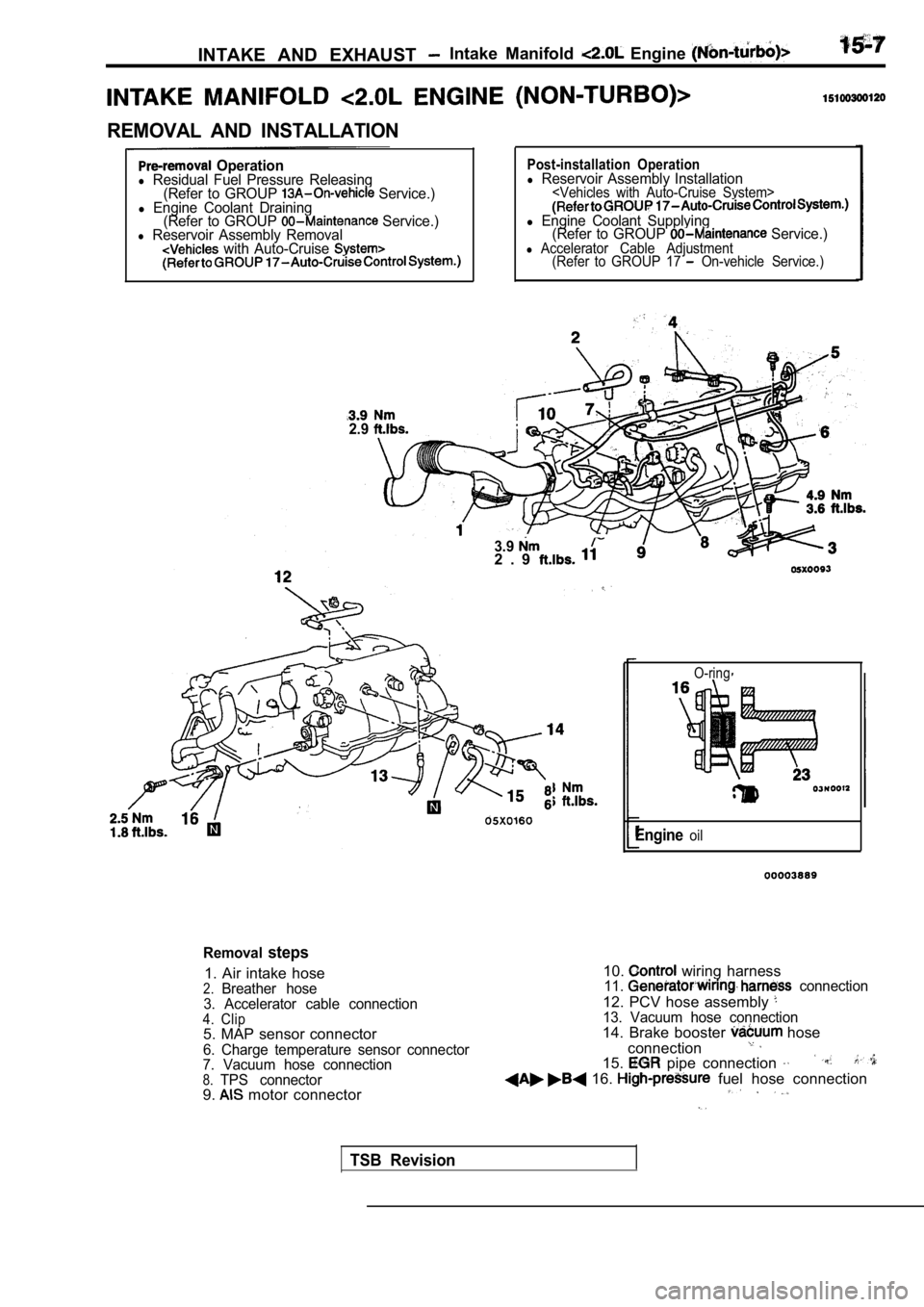

INTAKE AND EXHAUST Intake Manifold Engine

REMOVAL AND INSTALLATION

Operationl Residual Fuel Pressure Releasing(Refer to GROUP Service.)l Engine Coolant Draining(Refer to GROUP Service.)l Reservoir Assembly Removal with Auto-Cruise

2.9

Post-installation Operationl Reservoir Assembly Installation

l Engine Coolant Supplying (Refer to GROUP Service.)l Accelerator Cable Adjustment (Refer to GROUP 17 On-vehicle Service.)

3.92 . 9

O-ring

Engineoil

Removalsteps

1. Air intake hose2.Breather hose

3. Accelerator cable connection

4. Clip5. MAP sensor connector

6. Charge temperature sensor connector

7. Vacuum hose connection

8.TPS connector9. motor connector 10.

wiring harness11. connection

12. PCV hose assembly 13. Vacuum hose connection14. Brake booster hose

connection

15. pipe connection

16. fuel hose connection

TSB Revision

Page 725 of 2103

INTAKE AND EXHAUST Intake Manifold Engine

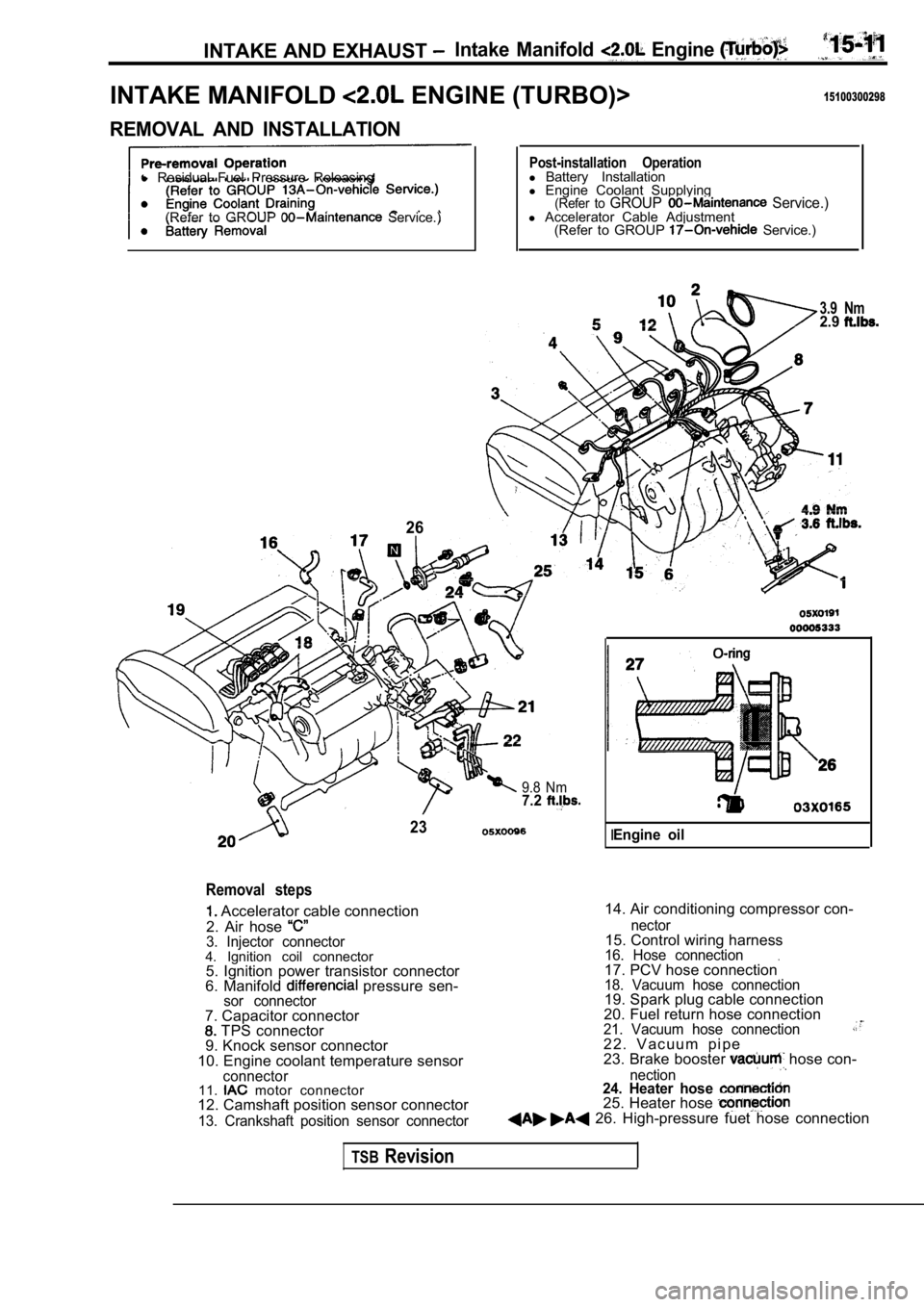

INTAKE MANIFOLD ENGINE (TURBO)>15100300298

REMOVAL AND INSTALLATION

l Residual Fuel Pressure Releasing

(Refer to GROUP

Service.)

26

Post-installation Operationl Battery Installation

l Engine Coolant Supplying

(Refer to GROUP Service.)l Accelerator Cable Adjustment

(Refer to GROUP Service.)

3.9 Nm2.9

9.8 Nm7.2

23

Removal steps

Accelerator cable connection

2. Air hose

3. Injector connector4. Ignition coil connector 5. Ignition power transistor connector

6. Manifold

pressure sen-sor connector

14. Air conditioning compressor con-

7. Capacitor connector

TPS connector

9. Knock sensor connector

10. Engine coolant temperature sensor

connector11. motor connector

12. Camshaft position sensor connector

13. Crankshaft position sensor connector nector

15. Control wiring harness16. Hose connection.17. PCV hose connection18. Vacuum hose connection19. Spark plug cable connection

20. Fuel return hose connection

21. Vacuum hose connection2 2 . V a c u u m p i p e

23. Brake booster hose con-

nection24. Heater hose 25. Heater hose 26. High-pressure fuet hose connection

IEngine oil

TSBRevision

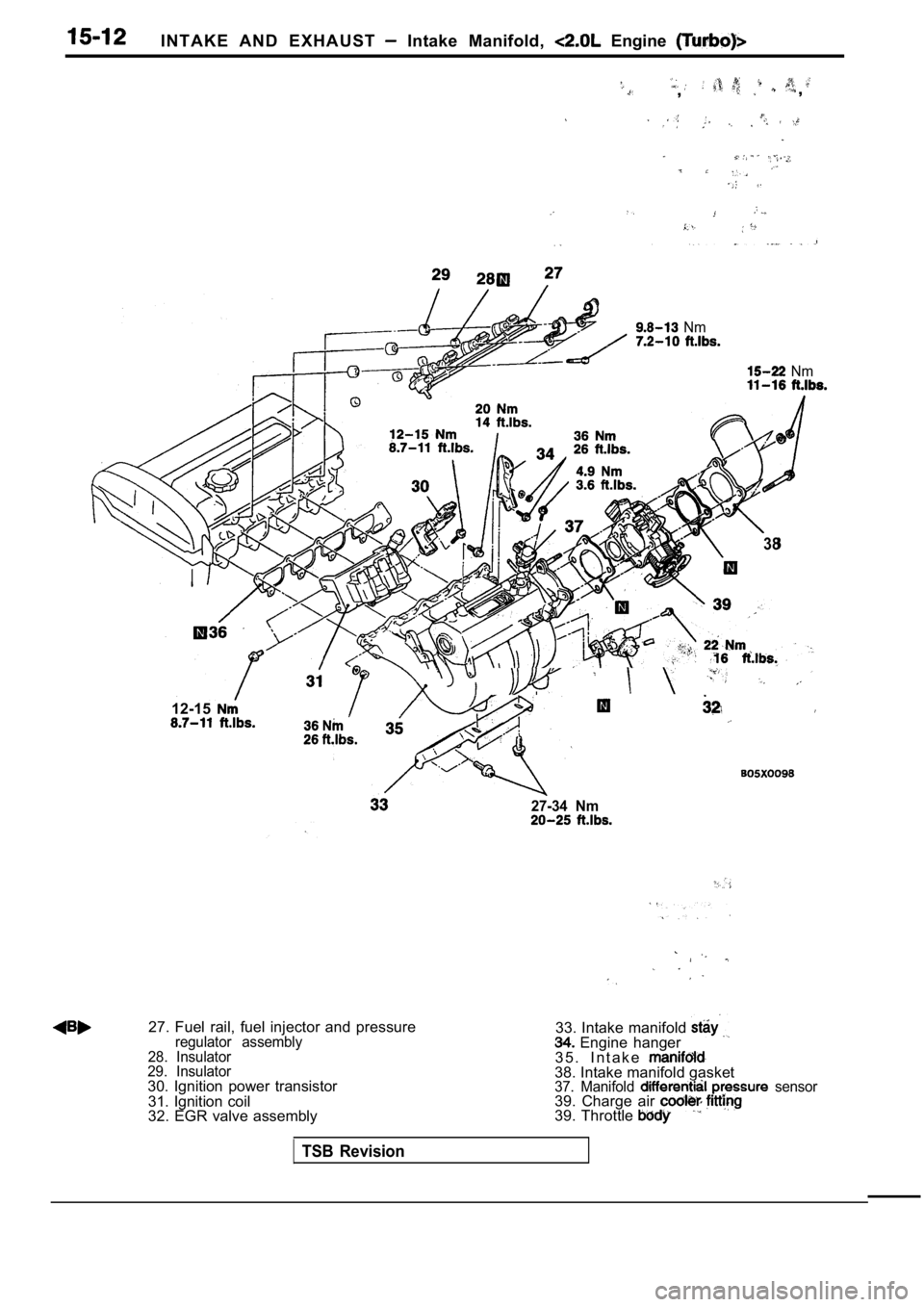

Page 726 of 2103

I N T A K E A N D E X H A U S T Intake Manifold, Engine

,,

Nm

Nm

12-15

38

27-34 Nm

27. Fuel rail, fuel injector and pressureregulator assembly

28. Insulator

29. Insulator

30. Ignition power transistor

31. Ignition coil

32. EGR valve assembly 33. Intake manifold

Engine hanger

3 5 . I n t a k e

38. Intake manifold gasket37. Manifold sensor39. Charge air 39. Throttle

TSB Revision