sensor MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 870 of 2103

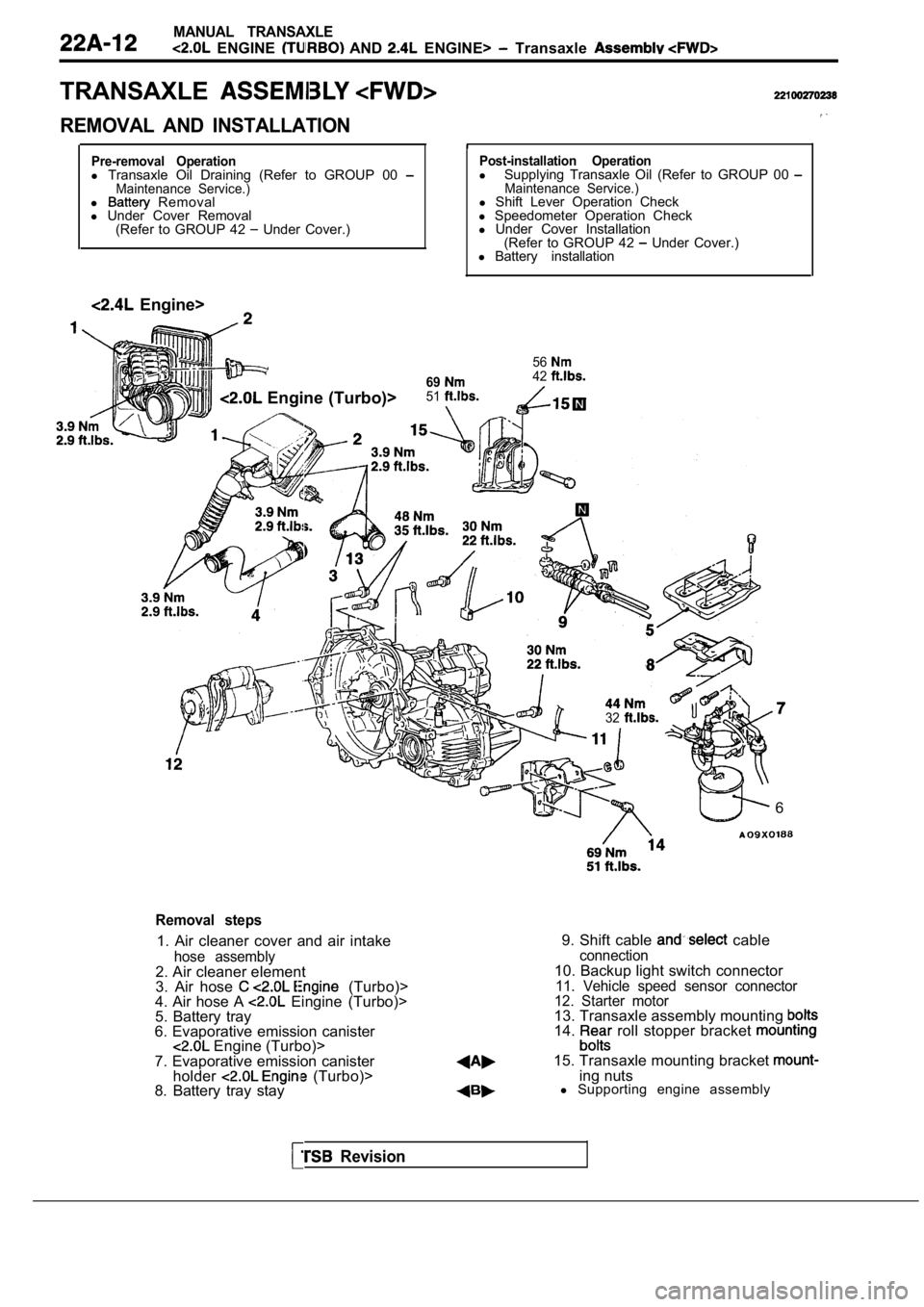

MANUAL TRANSAXLE

ENGINE AND ENGINE> Transaxle

TRANSAXLE

REMOVAL AND INSTALLATION

Pre-removal Operationl Transaxle Oil Draining (Refer to GROUP 00 Maintenance Service.)l Removal

l Under Cover Removal

(Refer to GROUP 42

Under Cover.)

Engine>

Post-installation Operationl Supplying Transaxle Oil (Refer to GROUP 00 Maintenance Service.)l Shift Lever Operation Check

l Speedometer Operation Check

l Under Cover Installation

(Refer to GROUP 42

Under Cover.)

l Battery installation

56

6942

Engine (Turbo)>51

32

6

Removal steps

1. Air cleaner cover and air intake

hose assembly2. Air cleaner element

3. Air hose (Turbo)>

4. Air hose A Eingine (Turbo)>

5. Battery tray

6. Evaporative emission canister

Engine (Turbo)>

7. Evaporative emission canister holder

(Turbo)>

8. Battery tray stay 9. Shift cable

cableconnection10. Backup light switch connector11. Vehicle speed sensor connector

12. Starter motor

13. Transaxle assembly mounting 14. roll stopper bracket

15. Transaxle mounting bracket ing nuts

l Supporting engine assembly

Revision

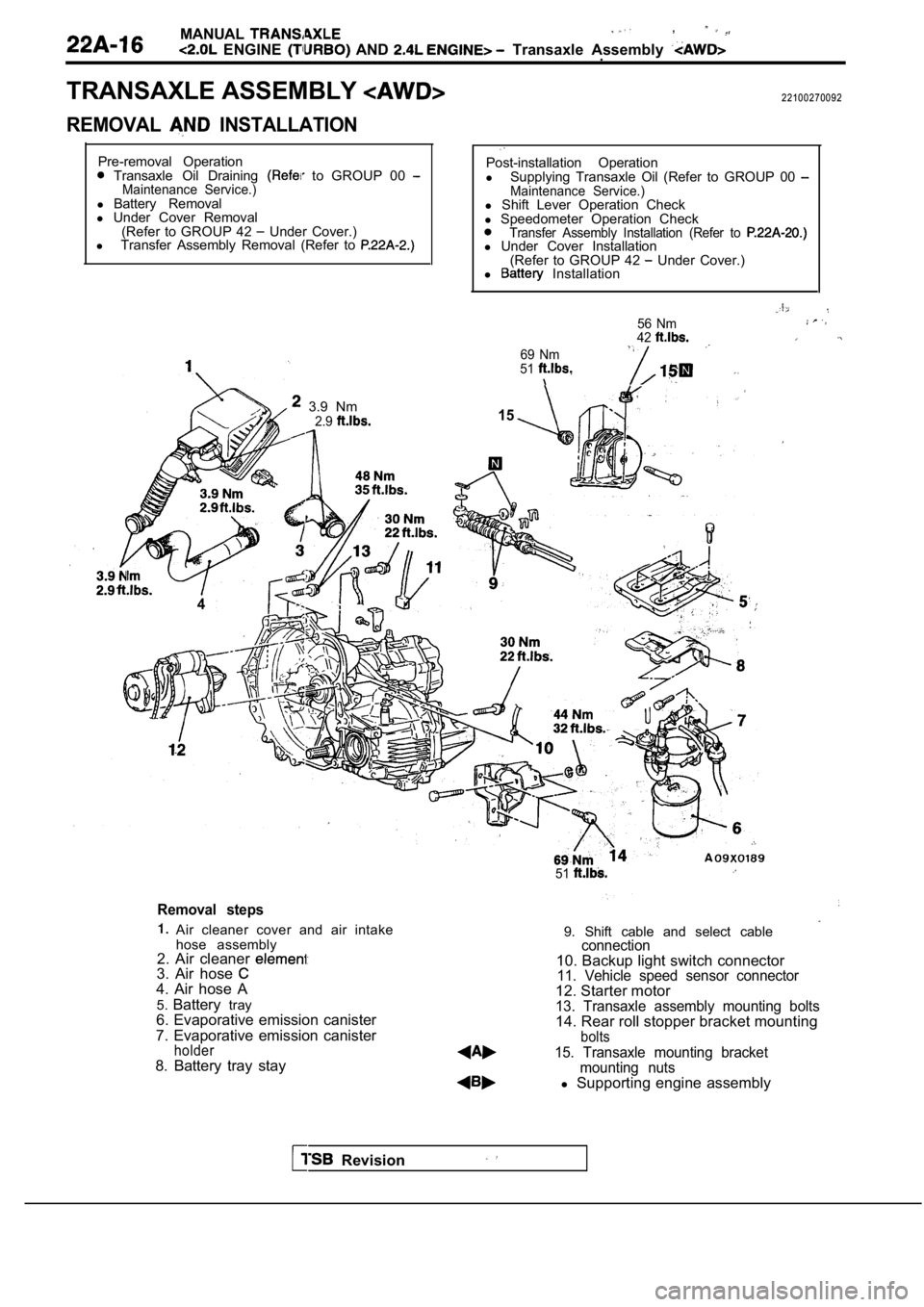

Page 874 of 2103

MANUAL ,

ENGINE AND Transaxle Assembly .

TRANSAXLE ASSEMBLY

REMOVAL INSTALLATION

22100270092

Pre-removal Operation

Transaxle Oil Draining to GROUP 00 Maintenance Service.)l Battery Removal

l Under Cover Removal

(Refer to GROUP 42

Under Cover.)

l Transfer Assembly Removal (Refer to

3.9 Nm

4

2.9

Post-installation Operation

l Supplying Transaxle Oil (Refer to GROUP 00

Maintenance Service.)l Shift Lever Operation Check

l Speedometer Operation Check

Transfer Assembly Installation (Refer to l Under Cover Installation

(Refer to GROUP 42 Under Cover.)

l Installation

69 Nm

51

56 Nm

42

15

51

Removal steps

Air cleaner cover and air intake

hose assembly

2. Air cleaner

3. Air hose 4. Air hose A

5. Battery tray

6. Evaporative emission canister

7. Evaporative emission canister

holder8. Battery tray stay 9. Shift cable and select cable

connection10. Backup light switch connector11. Vehicle speed sensor connector12. Starter motor13. Transaxle assembly mounting bolts14. Rear roll stopper bracket mountingbolts

15. Transaxle mounting bracket

mounting nuts

l Supporting engine assembly

Revision

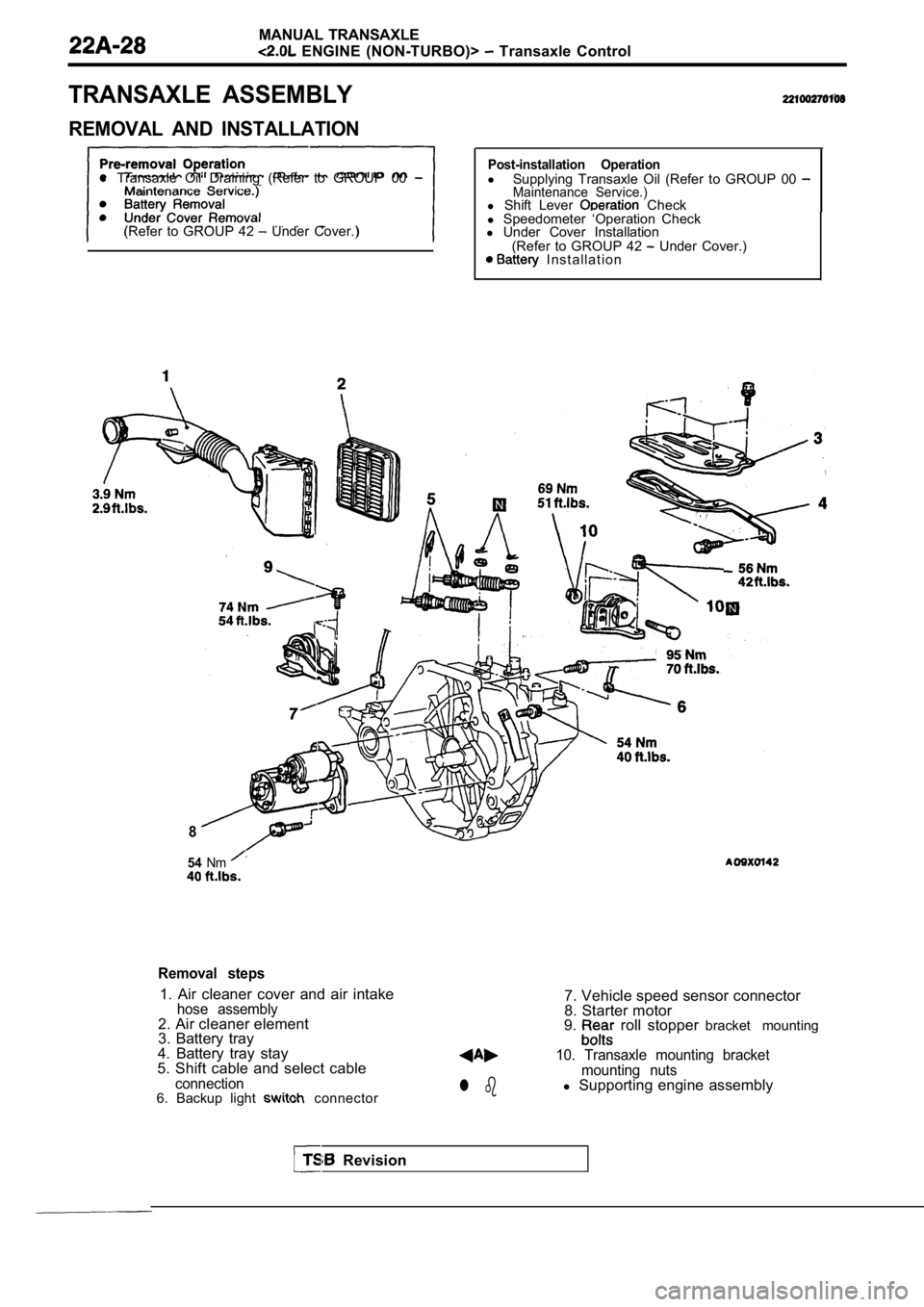

Page 886 of 2103

MANUAL TRANSAXLE

ENGINE (NON-TURBO)> Transaxle Control

TRANSAXLE ASSEMBLY

REMOVAL AND INSTALLATION

l Transaxle Oil Draining (Refer to GROUP 00

(Refer to GROUP 42 Under Cover.)

Post-installation Operationl

Supplying Transaxle Oil (Refer to GROUP 00 Maintenance Service.)l Shift Lever Check

l Speedometer ‘Operation Check

l Under Cover Installation

(Refer to GROUP 42

Under Cover.) I n s t a l l a t i o n

8

54Nm

Removal steps

1. Air cleaner cover and air intakehose assembly2. Air cleaner element

3. Battery tray

4. Battery tray stay

5. Shift cable and select cable

connection6. Backup light connectorl b

7. Vehicle speed sensor connector

8. Starter motor

9.

roll stopper bracket mounting

10. Transaxle mounting bracket

mounting nuts

l Supporting engine assembly

Revision

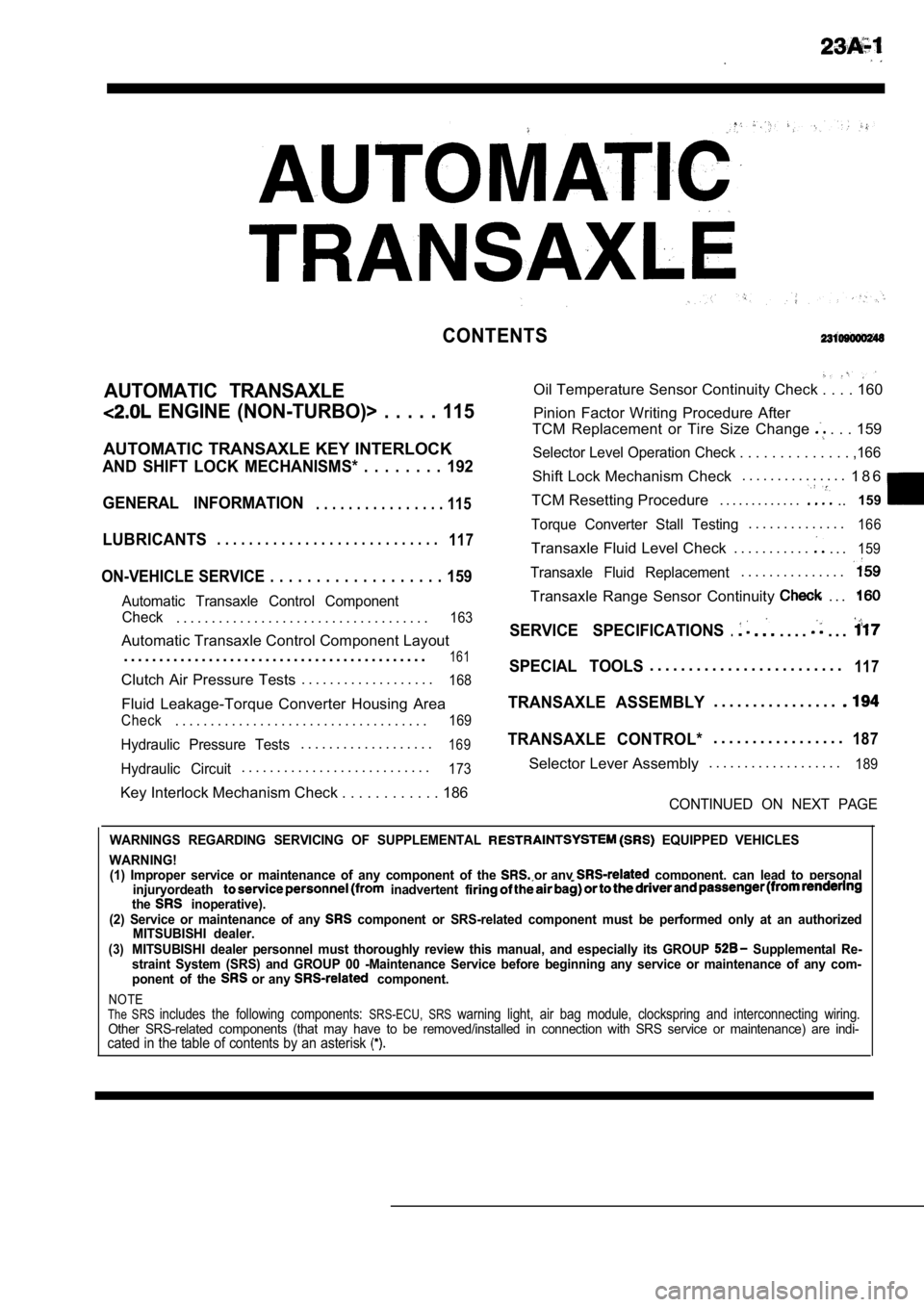

Page 1009 of 2103

CONTENTS

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> . . . . . 115

AUTOMATIC TRANSAXLE KEY INTERLOCK

AND SHIFT LOCK MECHANISMS* . . . . . . . . 192

GENERAL INFORMATION

. . . . . . . . . . . . . . . . 115

LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . .117

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . 159

Automatic Transaxle Control Component

Oil Temperature Sensor Continuity Check . . . . 160

Pinion Factor Writing Procedure After

TCM Replacement or Tire Size Change

. . . 159

Selector Level Operation Check . . . . . . . . . . . . . . ,166

Shift Lock Mechanism Check. . . . . . . . . . . . . . .

1 8 6

TCM Resetting Procedure . . . . . . . . . . . . .

..159

Torque Converter Stall Testing. . . . . . . . . . . . . .166

Transaxle Fluid Level Check . . . . . . . . . . .. . .159

Transaxle Fluid Replacement. . . . . . . . . . . . . . .

Transaxle Range Sensor Continuity . . .

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163SERVICE SPECIFICATIONS.. . . .. . .Automatic Transaxle Control Component Layout

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

161SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . .117Clutch Air Pressure Tests . . . . . . . . . . . . . . . . . . .168

Fluid Leakage-Torque Converter Housing Area

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Hydraulic Pressure Tests. . . . . . . . . . . . . . . . . . .169

Hydraulic Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . .173

TRANSAXLE ASSEMBLY. . . . . . . . . . . . . . . .

TRANSAXLE CONTROL*. . . . . . . . . . . . . . . . .187

Selector Lever Assembly. . . . . . . . . . . . . . . . . . .189

Key Interlock Mechanism Check . . . . . . . . . . .

. 186CONTINUED ON NEXT PAGE

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL EQUIPPED VEHICLES

WARNING! (1) Improper service or maintenance of any componen t of the

or any component, can lead to personal

injuryordeath inadvertent the inoperative).

(2) Service or maintenance of any component or SRS-related component must be perform ed only at an authorized

MITSUBISHI dealer.

(3)MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP Supplemental Re-

straint System (SRS) and GROUP 00 -Maintenance Serv ice before beginning any service or maintenance of any com-

ponent of the

or any component.

NOTEThe SRS includes the following components: SRS-ECU, SRS warning light, air bag module, clockspring and inte rconnecting wiring.Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are indi-cated in the table of contents by an asterisk

Page 1016 of 2103

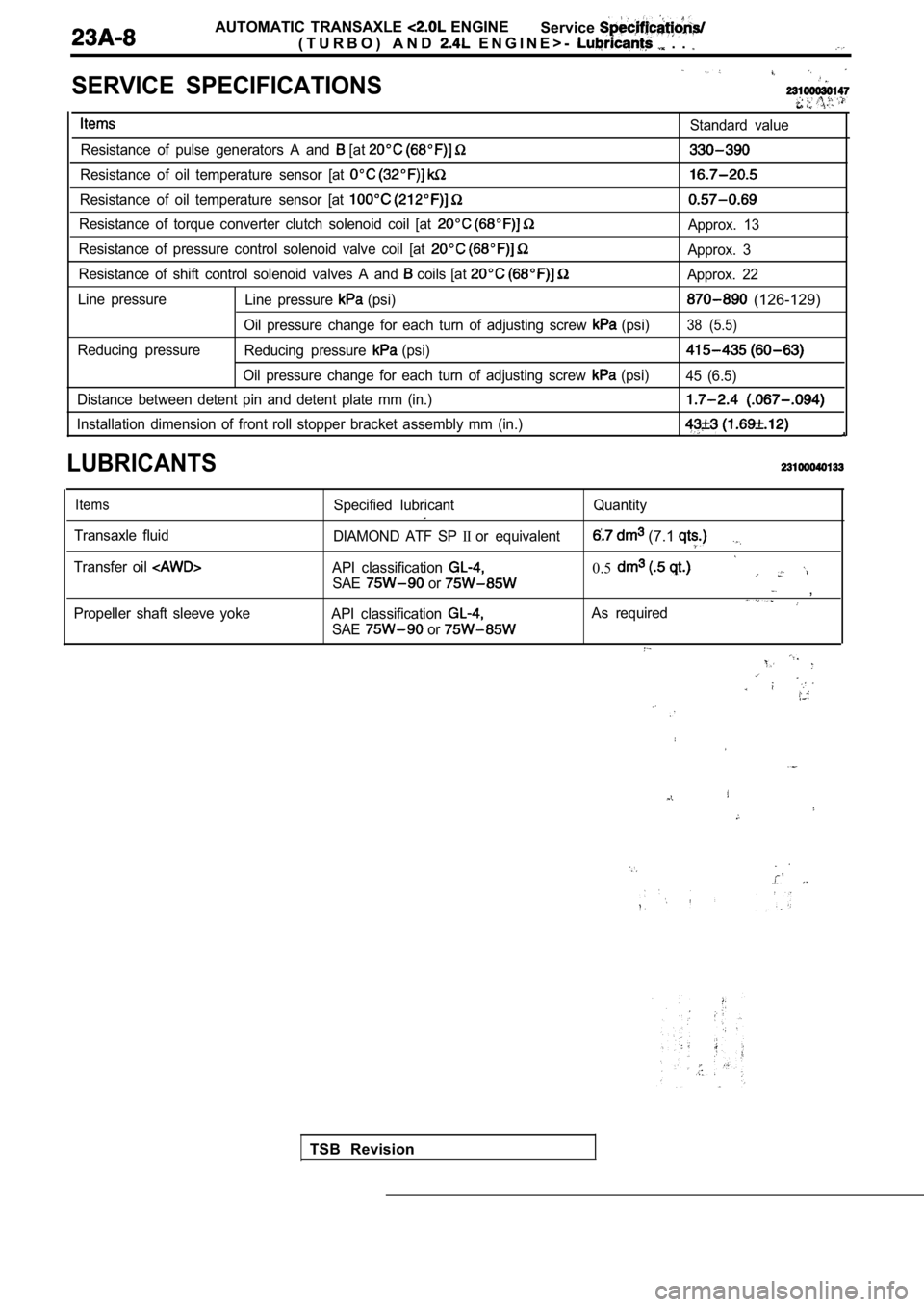

AUTOMATIC TRANSAXLE ENGINEService

( T U R B O ) A N D E N G I N E > - . .

SERVICE SPECIFICATIONS

Standard value

Resistance of pulse generators A and

[at

Resistance of oil temperature sensor [at

Resistance of oil temperature sensor [at

Resistance of torque converter clutch solenoid coil [at Approx. 13

Resistance of pressure control solenoid valve coil [at

Approx. 3

Resistance of shift control solenoid valves A and

coils [at Approx. 22

Line pressure Line pressure

(psi) (126-129)

Oil pressure change for each turn of adjusting scre w (psi)38 (5.5)

Reducing pressure

Reducing pressure (psi)

Oil pressure change for each turn of adjusting scre w (psi)

45 (6.5)

Distance between detent pin and detent plate mm (in .)

Installation dimension of front roll stopper bracket assembly mm (in.)

LUBRICANTS

Items

Transaxle fluid

Transfer oil

Propeller shaft sleeve yoke Specified lubricant

Quantity

DIAMOND ATF SP

IIor equivalent (7.1

API classification 0.5SAE or ,

API classification As required

SAE

or

TSB Revision

Page 1020 of 2103

AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND

ENGINE> Troubleshooting

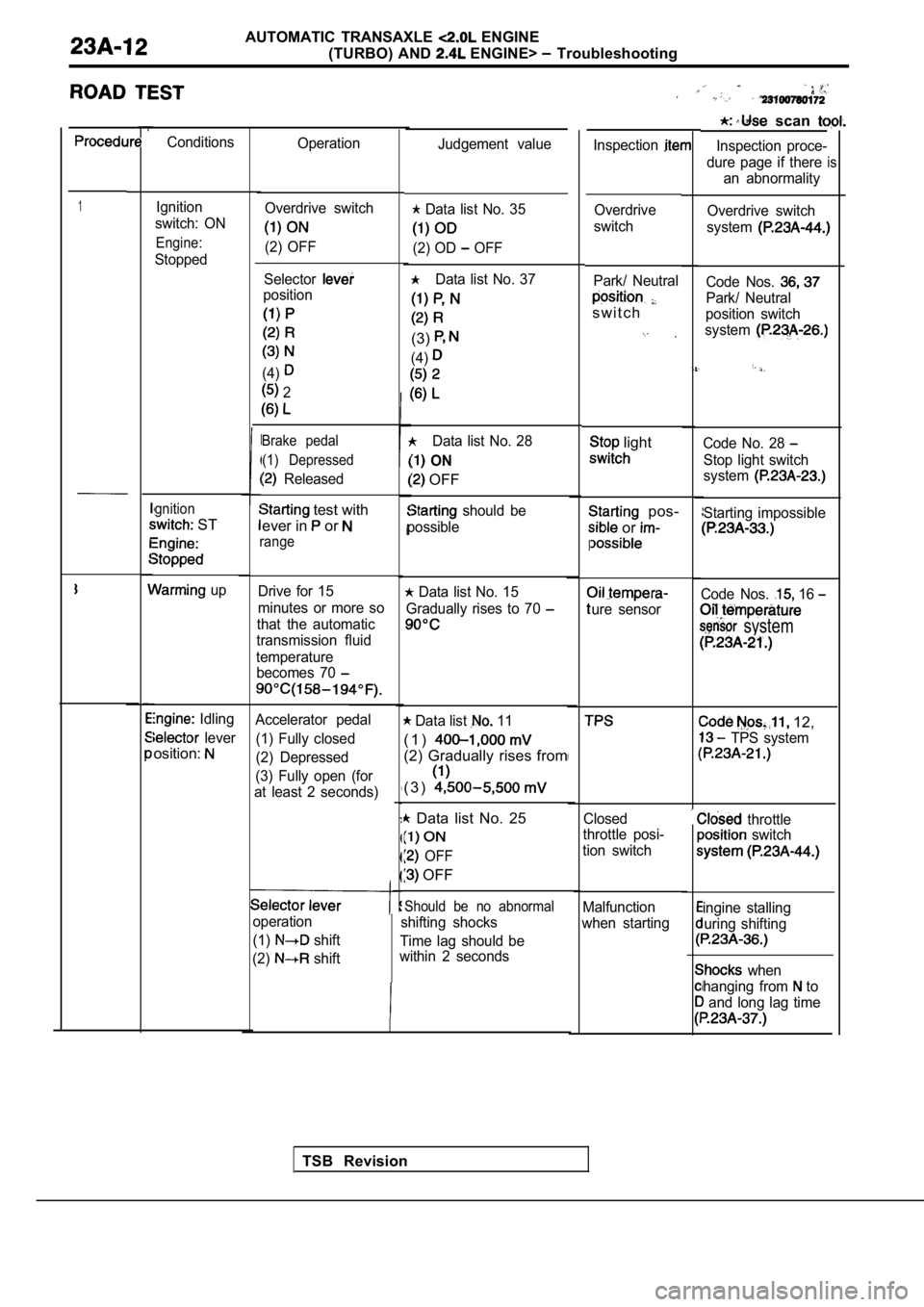

scan

Inspection proce-

dure page if there an abnormality

is

Conditions Operation

Inspection

1Ignition

switch: ON

Engine:

Stopped

gnition

ST

up

Idling

lever

osition:

Judgement value

Overdrive switch

system

Code Nos.

Park/ Neutral

position switch

system

Code No. 28

Stop light switch

system

Starting impossible

Code Nos. 16

system

12,

TPS system

throttle switch

ingine stalling

uring shifting

when

hanging from

to

and long lag time

Overdrive switch

(2) OFF

Data list No. 35

(2) OD OFF

Data list No. 37

(3)

(4)

Data list No. 28

ON

OFF

should be

possible Overdrive

switch

Selector

position

(4)

2

Park/ Neutral

s w i t c h

Brake pedal (1) Depressed

Released

light

pos-

or

I

ure sensor

test with

ever in

or

range

Drive for 15

minutes or more so

that the automatic

transmission fluid

temperature becomes 70 Data list No. 15

Gradually rises to 70

Accelerator pedal

(1) Fully closed

(2) Depressed

(3) Fully open (for

at least 2 seconds) Data list 11

( 1 )

(2) Gradually rises from

( 3 )

Data list No. 25

OFF

OFF

Closed

throttle posi-

tion switch

Should be no abnormal

shifting shocks

Time lag should be

within 2 seconds Malfunction

when starting

operation

(1)

shift

(2)

shift

TSB Revision

Page 1022 of 2103

AUTOMATIC TRANSAXLE

(TURBO) AND ENGINE> , .

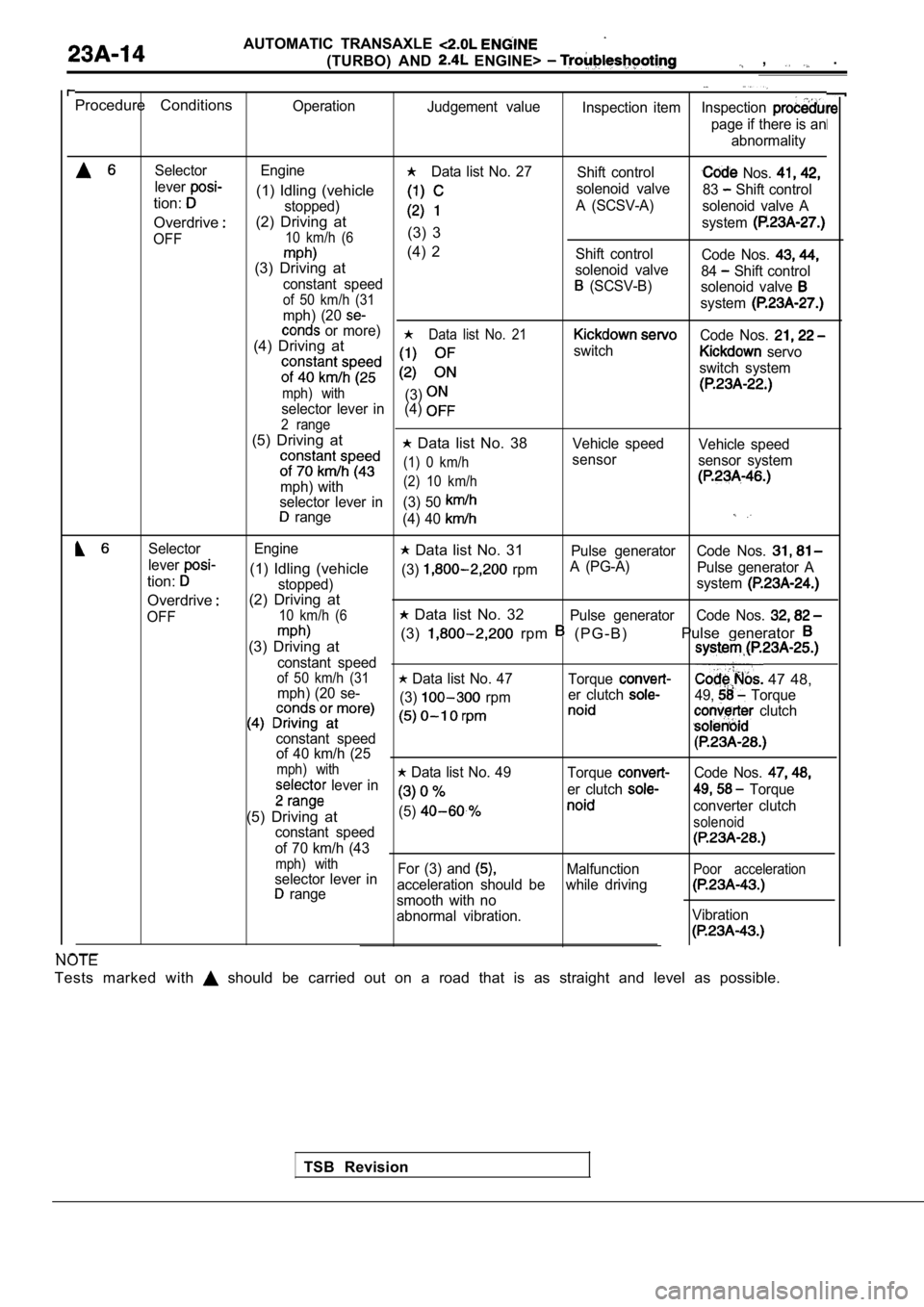

Procedure ConditionsOperationJudgement valueInspection item Inspectionre

page if there is anI

abnormality

Selector EngineData list No. 27Shift control

lever

solenoid valve

Nos.

(1) Idling (vehicle83 Shift controltion:stopped)

Overdrive(2) Driving at

A (SCSV-A) solenoid valve A

system

OFF10 km/h (6(3) 3

(4) 2Shift control(3) Driving atCode Nos. solenoid valve 84 Shift control

constant speed (SCSV-B) solenoid valve of 50 km/h (31

mph) (20 system

or more)(4) Driving atData list No. 21Code Nos.

switch servo

switch system

mph) with(3)selector lever in

2 range

(4)

(5) Driving at Data list No. 38Vehicle speed Vehicle speed

(1) 0 km/hsensorsensor system

mph) with

(2) 10 km/h

selector lever in (3) 50 range (4) 40

Selector Engine Data list No. 31leverPulse generator Code Nos.

tion:(1) Idling (vehicle(3) rpmA (PG-A)

Pulse generator A

stopped) system

Overdrive(2) Driving at

OFF10 km/h (6 Data list No. 32Pulse generator Code Nos.

(3) Driving at(3) rpm ( P G - B )

Pulse generator

constant speedof 50 km/h (31 Data list No. 47

Torque 47 48,mph) (20 se-

er clutch (3) rpm49, Torque

clutch

constant speed

of 40 km/h (25

mph) with Data list No. 49 lever in TorqueCode Nos.

er clutch Torque

(5) Driving at(5)converter clutch

constant speed

solenoid

of 70 km/h (43

mph) withselector lever in For (3) and MalfunctionPoor acceleration

range

acceleration should be while drivingsmooth with no

abnormal vibration.

Vibration

TSB Revision

NOTE

Tests marked with

should be carried out on a road that is as straigh t and level as possible.

Page 1027 of 2103

AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND

ENGINE> Troubleshooting

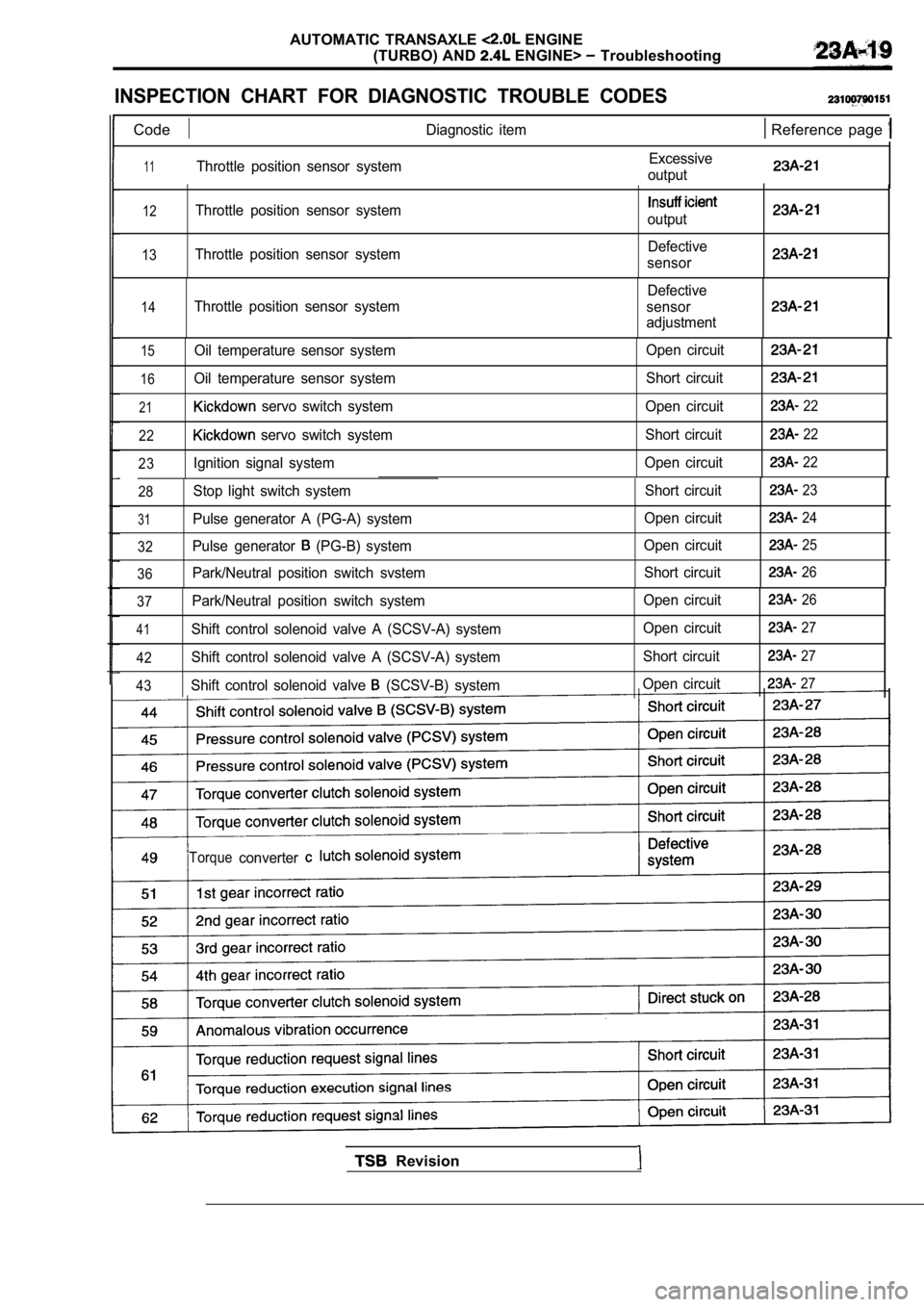

INSPECTION CHART FOR DIAGNOSTIC TROUBLE CODES

CodeDiagnostic item Reference page

11Throttle position sensor system Excessive

output

12Throttle position sensor systemoutput

13Throttle position sensor system Defective

sensor

14Throttle position sensor system Defective

sensor

adjustment

15

16

21

22

23

Oil temperature sensor system

Oil temperature sensor system

servo switch system

servo switch system

Ignition signal system Open circuit

Short circuit

Open circuit

Short circuit

Open circuit

22

22

22

28

31

32

36

Stop light switch system

Pulse generator A (PG-A) system

Pulse generator

(PG-B) system

Park/Neutral position switch svstem Short circuit

Open circuit

Open circuit Short circuit

23

24

25

26

Torque

converter

37

41

42

43

Park/Neutral position switch system

Shift control solenoid valve A (SCSV-A) system

Shift control solenoid valve A (SCSV-A) system

Shift control solenoid valve

(SCSV-B) system Open circuit

Open circuit

Short circuit

Open circuit

26

27

27

27

Revision

Page 1029 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND ENGINE>

Code No. Throttle position sensor system Probable cause

[Comment] of the throttle If the TPS output becomes 4.6 or more at idle, T MITSUBISHI SPYDER 1990 Service Repair Manual AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND ENGINE>

Code No. Throttle position sensor system Probable cause

[Comment] of the throttle If the TPS output becomes 4.6 or more at idle, T](/img/19/57345/w960_57345-1028.png)

AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND ENGINE>

Code No. Throttle position sensor system Probable cause

[Comment] of the throttle If the TPS output becomes 4.6 or more at idle, TPS output is excessive, and of connector

trouble code No. 11 is output. If the TPS output be comes 0.2 or less at times other than l of idling, TPS output is insufficient and diagnostic t rouble code No. 12 is output. If the TPS output

and the target value inside the TCM do not match ev en after compensation is carried out while

the engine is idling, the TPS sensor is defective and diagnostic trouble code No. 13 is output.

If the TPS voltage becomes 0.2 or less or 1.2 or more while the engine is idling, the

TPS adjustment is defective and diagnostic trouble code No. 14 is output.

Check the throttle position sensor

NG Replace

(Refer to GROUP On-vehicle

Inspection of Components.)

OK

Check the following connectors:

l

OK

NG Repair

Check trouble symptom.

NG

Replace the TCM.

Code No. 15, 16 Oil temperature sensor system

[Comment] If the oil temperature sensor output is 4.4 or higher (oil temperature does not increase) evenafter driving for 10 minutes or more, there is an o pen circuit in the oil temperature sensor

and diagnostic trouble code No. 15 is output.

When the oil temperature sensor output is 0.2 or less (for 1 second or more), it is judgedthat there is a short-circuit in the oil temperatur e sensor and diagnostic trouble code No. 16is output.

Probable cause

o f o i l

l T C M

Oil temperature sensor check.

(Refer to NG Replace

OK

Measure at the oil temperature sensorconnectorl Disconnect the connector, and

measure at theconnector side.

l Voltage between terminal (1) and

ground (Ignition switch: ON)

l

Continuity between terminal (2) and

ground

OK:Continuity

OK

Check the following connector: Repair

, I .

Check the harness wire between con-

nectors of oil temperature sensor and

Replace the

l Repair

OK

Check trouble symptom.Check the harness wire between con-

TSB Revision

Page 1040 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> Troubleshooting

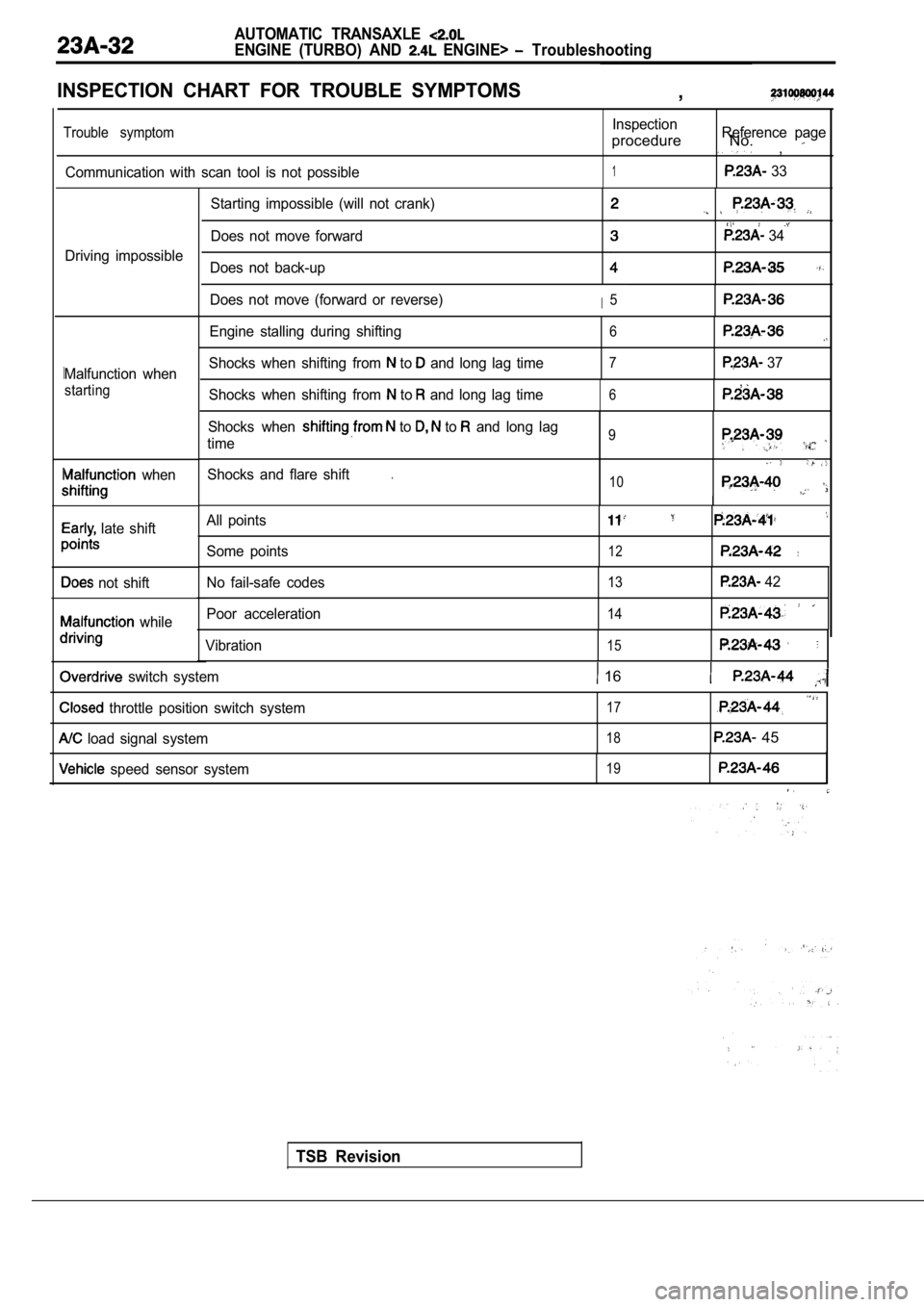

INSPECTION CHART FOR TROUBLE SYMPTOMS,

Malfunction when

starting

I

I

Engine stalling during shifting6

Shocks when shifting from to and long lag time7 37

Shocks when shifting from

to and long lag time6

when

Shocks when to to and long lag

time

Shocks and flare shift

.

late shiftAll points

Some points

not shift

while

No fail-safe codes13 42

Poor acceleration

14

Vibration

switch system 16

throttle position switch system17

load signal system18

speed sensor system

Trouble symptom

Communication with scan tool is not possible Inspection

procedure No. Reference page

,

1 33

Driving impossible Starting impossible (will not crank)

Does not move forward

Does not back-up

34

Does not move (forward or reverse)I5

TSB Revision

,

9

10

I I

12

15

45

19