ESP MITSUBISHI SPYDER 1990 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 518 of 2103

ENGINE

AND ENGINE> G e n e r a l

ENGINE (TURBO) AND ENGINE>13199910319

GENERAL INFORMATIONThe

Fuel Injection System consists

of sensors which detect the engine conditions,

the ENGINE CONTROL MODULE (ECM) which

controls the system based on signals from these

sensors, and actuators which operate under

the control of the ECM.

FUEL INJECTION CONTROL

The injector drive times and injector timing are

controlled so that the optimum air/fuel mixture

is supplied to the engine to correspond to the

continually-changing engine operation condi-

tions.

A single injector is mounted at the intake port

of each cylinder. Fuel is sent under pressure

from the fuel tank by the fuel pump, with the

pressure regulated by the fuel pressure regula-

tor. The regulated fuel is distributed to each

of the injectors.

Fuel injection is normally carried out once for

each cylinder for every two rotations of the

IDLE AIR CONTROL The idle speed is kept at the optimum speed

by controlling the amount of air that bypasses

the throttle valve in accordance with changes

in idling conditions and engine load during id-

ling.

The ECM drives the idle air control (IAC) motor

to keep the engine running at the pre-set idle

target speed in accordance with the engine

IGNITION TIMING CONTROL

The ignition power transistor located in the igni-

tion primary circuit turns ON and OFF to control

the primary current flow to the ignition coil.

This controls the ignition timing in order to pro-

vide the optimum ignition timing with respect The ECM carries out activities such as fuel

injection control, idle air control and ignition

timing control.

In addition, the ECM is equipped with several

diagnostic test modes which simplify trouble-

shooting when a problem develops.

. .

crankshaft. The firing is This

is called

The provides a richer

air/fuel mixture by carrying out “open-loop” con-

trol when the engine is cold or operating under high load

in order to maintain engine

performance. In addition, when the engine is warm or operat-

ing under normal conditions, the ECM controls

the air/fuel mixture by using the heated oxygen

sensor signal to carry out “closed-loop” control

in order to obtain the theoretical air/fuel mixture

ratio that provides the maximum cleaning per-

formance from the three way catalyst.

coolant temperature and air conditioning load.

In addition, when the air’ conditioning switch

is turned off and on while the

is

the motor operates to adjust the throttle

valve bypass air amount in accordance with

the engine load conditions in order to avoid

fluctuations in the engine speed.

to the engine operating conditions. The ignition

timing is determined by the ECM from the en-

gine speed, intake air volume, engine coolant

temperature and atmospheric pressure.

TSB Revision

Page 519 of 2103

ENGINE (TURBO)

ENGINE>

DIAGNOSTIC TEST MODEl When an abnormality is detected in one

of the sensors or actuators related to emis-

sion control, the CHECK

FUNCTION INDICATOR LAMP illuminates

as a warning to the driver.

l When an abnormality is detected in one

of the’ sensors or actuators, a

OTHER CONTROL FUNCTIONS

1. Fuel Pump Control

Turns the fuel pump relay ON current

is supplied to the fuel pump while the engine

is cranking or running.

2. A/C Compressor Clutch Relay Control Turns the A/C compressor clutch ON and

OFF.

3. Fan Relay Control

The radiator fan and condenser fan speeds

are controlled in response to the engine

coolant temperature and vehicle speed.

4. Fuel

Control

Supplies current to fuel pressure solenoid

coil to raise the fuel pressure so that the

fuel does not vaporize when the engine

is started while it is warm.

trouble code ‘the,,

normality is output.

lThe RAM data inside the that

to the sensors and actuators can be read’

by

scan’ tool.

addition, the actuators can be controlled

under certain

5. Charge Control

Controls the intake charge pressure by con-

trolling the duty of the turbocharger

gate solenoid!

6. Intake Pressure Gauge’ Control Indicates the intake charge pressure on

the

7. Generator Output Current Control

Prevents generator output current from in-

creasing idle speed from

dropping at times such as when the head-

lights are turned on.

8.Evaporative Emission Purge Solenoid Con-

trol Engine (TURBO)>

Refer to

17.

Evaporative Emission Purge Solenoid Con-

trol GROUP 17.

9. EGR Solenoid’ Control

Refer to GROUP

,,

,

TSB Revision

Page 531 of 2103

ENGINE (TURBO)

AND

ENGINE>

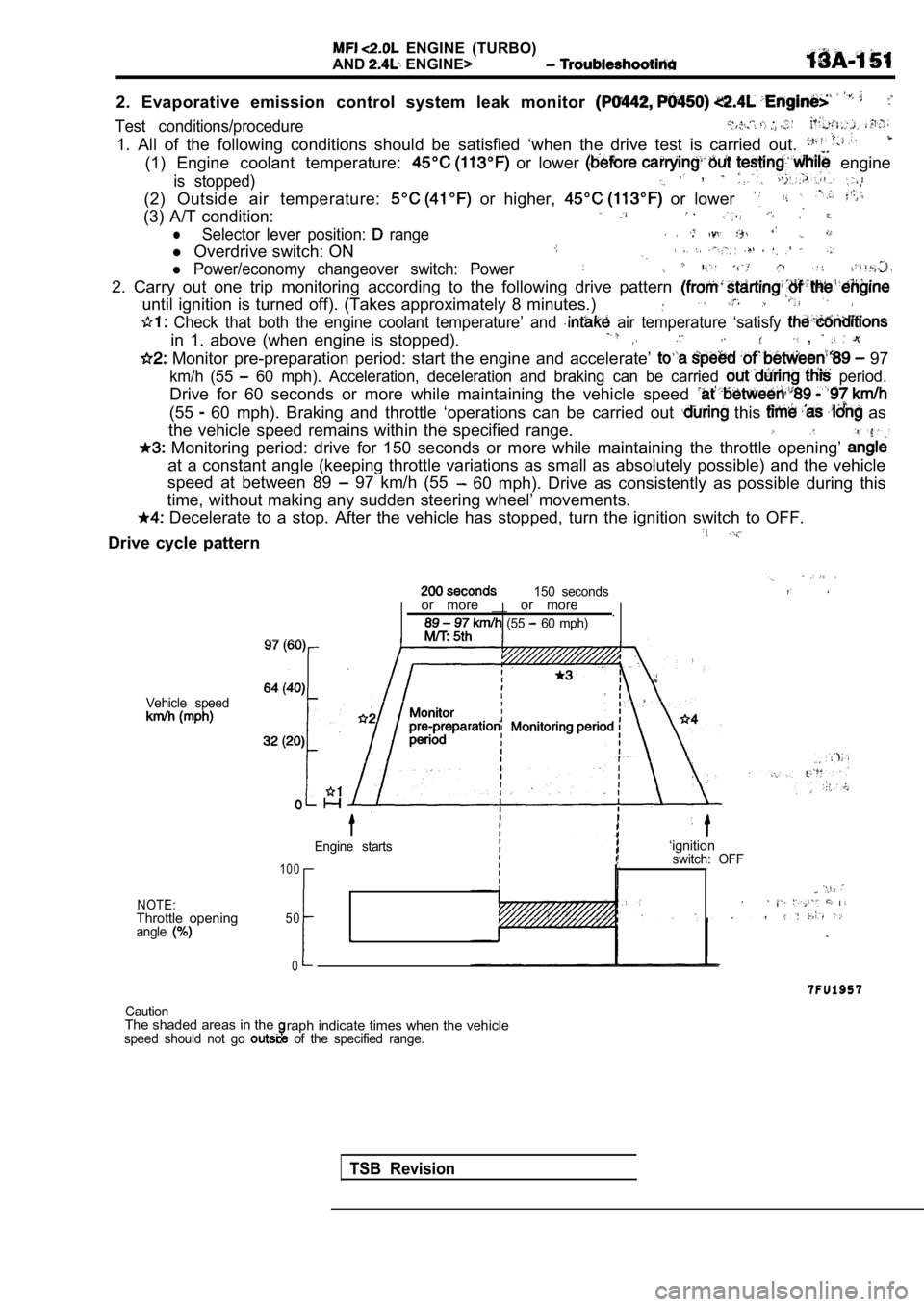

2. Evaporative emission control system leak monitor

Test conditions/procedure , . .

1. All of the following conditions should be satisfied ‘when the drive test is carried out.

(1) Engine coolant temperature: or lower engine

is stopped) ,

(2) Outside air temperature: or higher, or lower

(3) A/T condition: .

lSelector lever position: range .

l Overdrive switch: ON

l Power/economy changeover switch: Power

2. Carry out one trip monitoring according to the f ollowing drive pattern

until ignition is turned off). (Takes approximately 8 minutes.)

Check that both the engine coolant temperature’ an d air temperature ‘satisfy

in 1. above (when engine is stopped). ,

Monitor pre-preparation period: start the engine and accelerate’ 97

km/h (55 60 mph). Acceleration, deceleration and braking ca n be carried period.

Drive for 60 seconds or more while maintaining the vehicle speed

(55 60 mph). Braking and throttle ‘operations can be carried out this as

the vehicle speed remains within the specified rang e.

Monitoring period: drive for 150 seconds or more w hile maintaining the throttle opening’

at a constant angle (keeping throttle variations as small as absolutely possible) and the vehicle

speed at between 89

97 km/h (55 60 mph). Drive as consistently as possible during this

time, without making any sudden steering wheel’ mov ements.

Decelerate to a stop. After the vehicle has stopped, turn the ignition switch to OFF.

Drive cycle pattern

150 seconds

Vehicle speed

NOTE:Throttle openingangle

or more __ or more

.

(55 60 mph)

Engine starts

1 0 0

50

0

I

‘ignitionswitch: OFF

,

CautionThe shaded areas in theraph indicate times when the vehiclespeed should not go of the specified range.

TSB Revision

Page 534 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

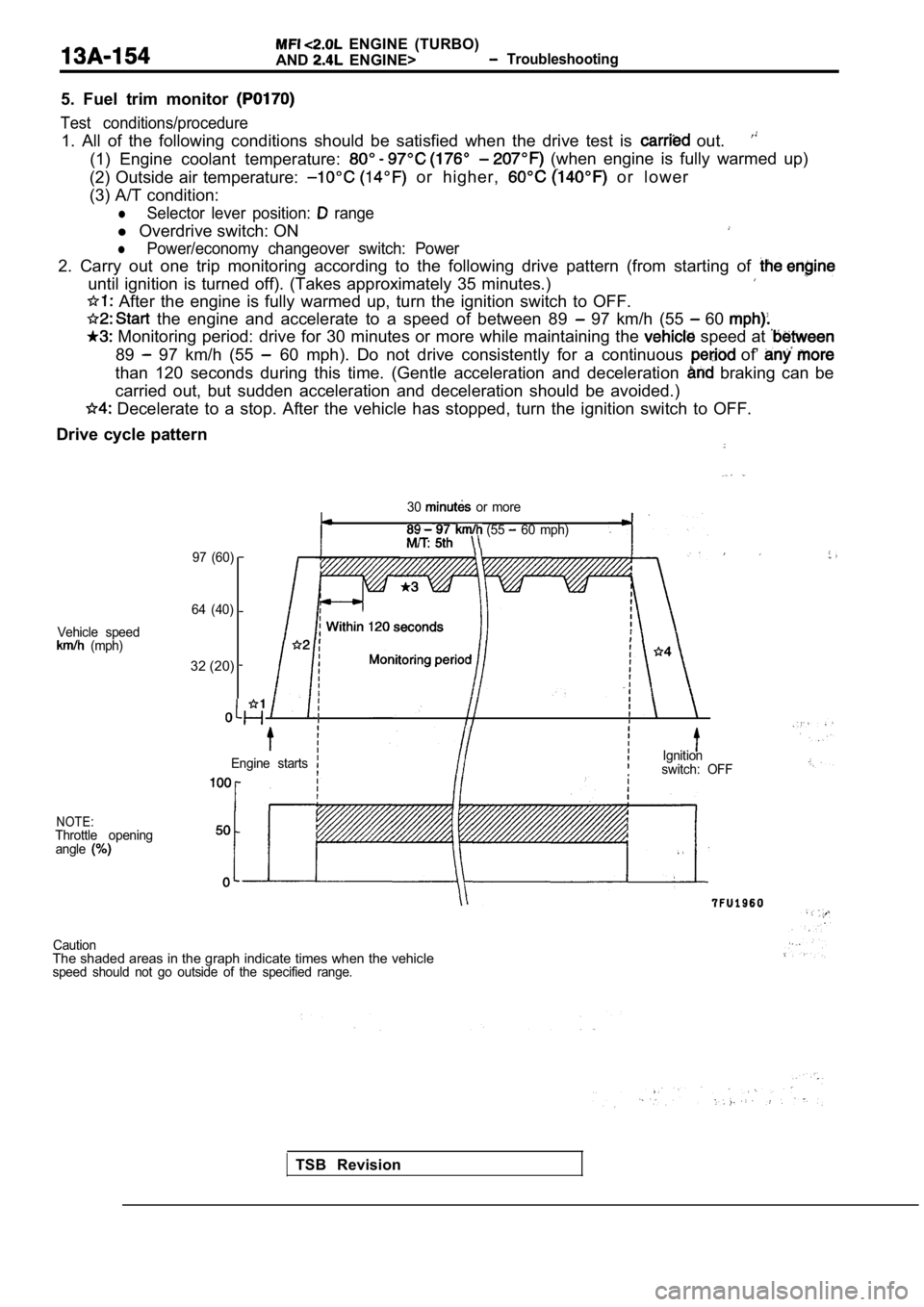

5. Fuel trim monitor

Test conditions/procedure

1. All of the following conditions should be satisf ied when the drive test is out.

(1) Engine coolant temperature: (when engine is fully warmed up)

(2) Outside air temperature:

or higher, o r l o w e r

(3) A/T condition:

lSelector lever position: range

l Overdrive switch: ON

lPower/economy changeover switch: Power

2. Carry out one trip monitoring according to the f ollowing drive pattern (from starting of

until ignition is turned off). (Takes approximately 35 minutes.)

After the engine is fully warmed up, turn the igni tion switch to OFF.

the engine and accelerate to a speed of between 89 97 km/h (55 60

Monitoring period: drive for 30 minutes or more while maintaining the speed at

89 97 km/h (55 60 mph). Do not drive consistently for a continuous of’

than 120 seconds during this time. (Gentle acceleration and deceleration braking can be

carried out, but sudden acceleration and decelerati on should be avoided.)

Decelerate to a stop. After the vehicle has stopped, turn the ignition switch to OFF.

Drive cycle pattern

30 or more

(55 60 mph)

Vehicle speed

(mph)

NOTE:Throttle opening angle

97 (60)

64 (40)

32 (20)

Engine startsIgnitionswitch: OFF

CautionThe shaded areas in the graph indicate times when t he vehiclespeed should not go outside of the specified range.

TSB Revision

Page 537 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

DIAGNOSTIC BY TEST

(INCREASED SENSITIVITY)

When mode II is selected using the MUT-II, the chec k

engine/malfunction indicator lamp illuminates at the point when

the ECM detects a problem (except if the related

to emissions), and at the same time the correspondi ng

diagnostic trouble codes are stored.

Furthermore, in the case of comprehensive component

electrical faults (opens/shorts), the time from the occurrence

of the fault to the storing of the DTC is compresse d (4 seconds

1 second).

As a result of this, checking of the trouble symptoms

checking after have been completed are both made

easier.

Once mode II has been selected, it is necessary

ignition switch to OFF or to use the MUT-II to

I once more before mode I operation can resumed.

However, all

readiness test and frame

data will be erased after returning to mode

so this

should be recorded beforehand if necessary.

(1) Using the scan tool, changeover the diagnostic test mode

of the engine control module to DIAGNOSTIC TEST

MODE II. (INCREASED SENSITIVITY)

(2) Road test the vehicle.

(3) Read the diagnostic trouble code in the same ma nner

as “READ OUT OF DIAGNOSTIC TROUBLE CODE” and

repair the malfunctioning part.

(4) Turn off the ignition

NOTE

Turning OFF the ignition switch will cause the engi ne

control module to changeover the ECM from the diagn ostic

test mode II to the diagnostic test

Revision

Page 538 of 2103

ENGINE

A N D E N G I N E > .

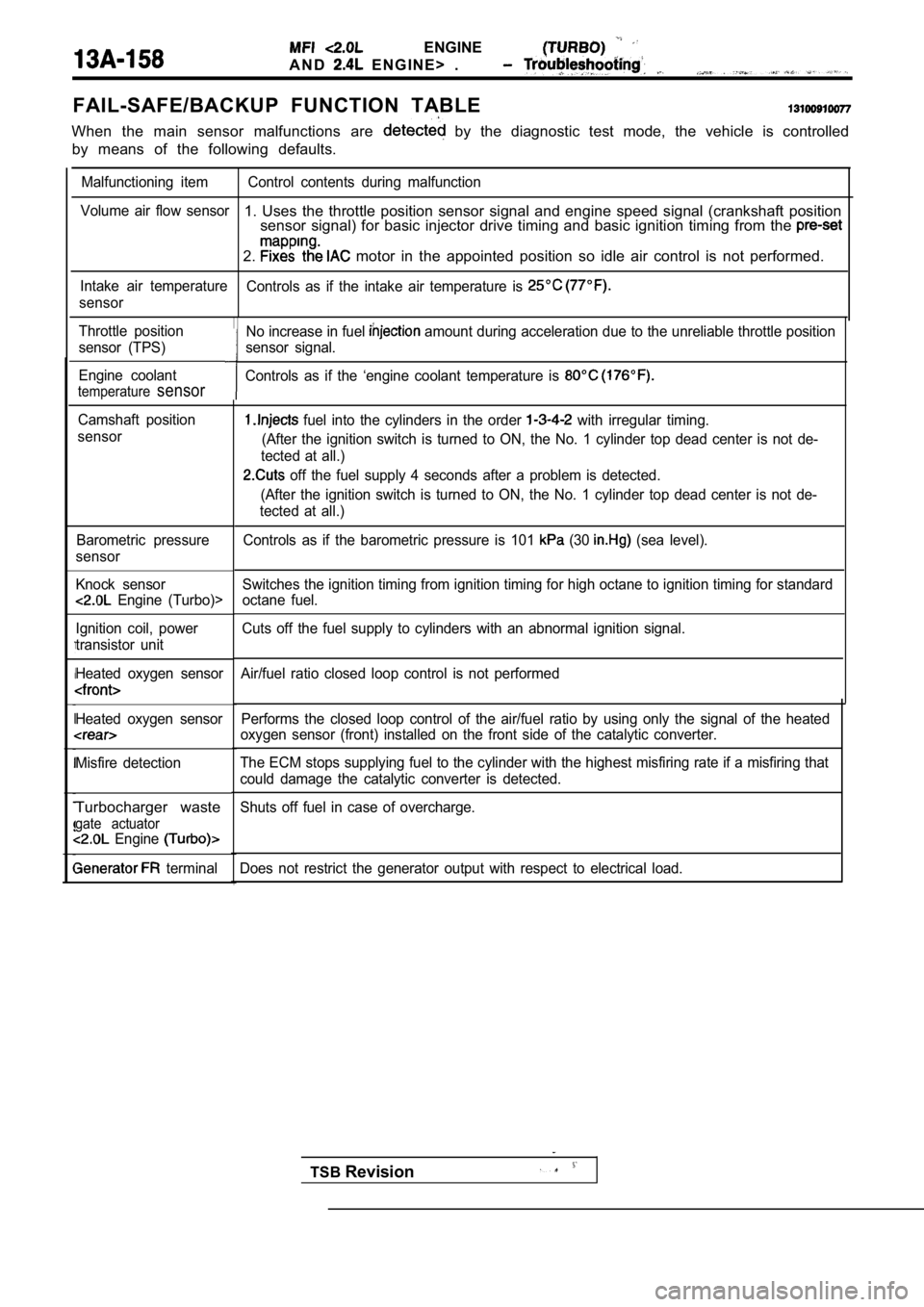

FAIL-SAFE/BACKUP FUNCTION TABLE

When the main sensor malfunctions are by the diagnostic test mode, the vehicle is controlled

by means of the following defaults.

Malfunctioning item Control contents during malfunct ion

Volume air flow sensor

1. Uses the throttle position sensor signal and eng ine speed signal (crankshaft position

sensor signal) for basic injector drive timing and basic ignition timing from the

2. motor in the appointed position so idle air contro l is not performed.

Intake air temperature

Controls as if the intake air temperature is

sensor

Throttle position

sensor (TPS)

Engine coolant

temperaturesensor

Camshaft position

sensor

Barometric pressure

sensor

Knock sensor

Engine (Turbo)>

Ignition coil, power

transistor unit

Heated oxygen sensor

Heated oxygen sensor

Misfire detection

Turbocharger waste

gate actuator Engine

terminal Performs the closed loop control of the air/fuel ra

tio by using only the signal of the heated

oxygen sensor (front) installed on the front side o f the catalytic converter.

The ECM stops supplying fuel to the cylinder with t he highest misfiring rate if a misfiring that

could damage the catalytic converter is detected.

Shuts off fuel in case of overcharge.

Does not restrict the generator output with respect to electrical load.

No increase in fuel amount during acceleration due to the unreliable throttle position

sensor signal.

Controls as if the ‘engine coolant temperature is

fuel into the cylinders in the order with irregular timing.

(After the ignition switch is turned to ON, the No. 1 cylinder top dead center is not de-

tected at all.)

off the fuel supply 4 seconds after a problem is d etected.

(After the ignition switch is turned to ON, the No. 1 cylinder top dead center is not de-

tected at all.)

Controls as if the barometric pressure is 101

(30 (sea level).

Switches the ignition timing from ignition timing f or high octane to ignition timing for standard

octane fuel.

Cuts off the fuel supply to cylinders with an abnor mal ignition signal.

Air/fuel ratio closed loop control is not performed

TSB Revision

Page 542 of 2103

![MITSUBISHI SPYDER 1990 Service Owners Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Volume Air Flow Circuit Malfunction

[Comment]Background

lWhile the engine is running, the volume air flow se nsor outputs a MITSUBISHI SPYDER 1990 Service Owners Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Volume Air Flow Circuit Malfunction

[Comment]Background

lWhile the engine is running, the volume air flow se nsor outputs a](/img/19/57345/w960_57345-541.png)

ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Volume Air Flow Circuit Malfunction

[Comment]Background

lWhile the engine is running, the volume air flow se nsor outputs a signal which

corresponds to the volume of air flow.

lThe engine control module checks whether the freque ncy of this signal output by the

volume air flow sensor while the engine is running is at or above the set value.

Check Area, Judgement Criteria

1. Check Area

Engine is not lower than 500

Judgement CriterialSensor output frequency has continued to be 3.3 Hz or lower for 4 sec.

2. Check Area l Throttle position sensor voltage is 2

or lower. Engine speed is not higher than 2000

Judgement CriterialSensor freauencv has continued to be 1000 Hz or hiaher fo r 4 sec. EnginelSensor output frequency has continued to be 800 Hz or higher for 4 sec. Engine>

3. Check Area

l Throttle position sensor voltage is 1.5 or higher.

l Engine speed is 2000 or higher.

Judgement CriterialSensor output frequency is Hz or lower for 4 seconds.

Measure at the volume air flow Check the volume air flow sensor

sensor connector A-l 02. circuit. (Refer to

l Connect the connector. (Use PROCEDURE 47.)

the test harness:

1. Voltage between 3 and ground(Engine: idling)OK: 2.2-3.2 2. Voltage between 7 and ground OK: (Engine: idling)

6 - 9

OK

Replace the ECM.

(Ignition switch: ON)

O K : 6 - 9

TSB Revision

Check the following connector

Probable cause

lVolume air, flow lOpen or shorted sensor or loose connector Engine control module failed

Check trouble symptom.

N G

Repair

Replacethevolumeairflowsensor.

, Check trouble

Repair

Replace the ECM.

Page 543 of 2103

![MITSUBISHI SPYDER 1990 Service Owners Manual ENGINE ( T U R B O )

AND ENGINE> Troubleshooting

Code No. Barometric Pressure Malfunction Probable cause ,

[ C o m m e n t ]BackgroundlThe barometric pressure sensor outputs a voltage wh

ich MITSUBISHI SPYDER 1990 Service Owners Manual ENGINE ( T U R B O )

AND ENGINE> Troubleshooting

Code No. Barometric Pressure Malfunction Probable cause ,

[ C o m m e n t ]BackgroundlThe barometric pressure sensor outputs a voltage wh

ich](/img/19/57345/w960_57345-542.png)

ENGINE ( T U R B O )

AND ENGINE> Troubleshooting

Code No. Barometric Pressure Malfunction Probable cause ,

[ C o m m e n t ]BackgroundlThe barometric pressure sensor outputs a voltage wh

ich corresponds to the barometricpressure.

Barometric pressure sensor failedlOpen or shorted barometric or loose connectorl Engine control module failedl The engine control module checks whether this volta ge is within a specified range.

Check Area l 60

or more have passed since the starting sequence wa s completed.

l Battery voltage is not lower than 8 V.

Judgement CriterialSensor output voltage has continued to be 4.5 or higher [corresponding to a barometricpressure of 114 (17 psi) or higher] for 4 sec. ,

or

lSensor output voltage has continued to be 1.95 or lower a barometricpressure of 50 (7.4 psi) or lower] for 4 sec.

theECM and the barometric

NGMeasure at the volume air flow

sensor connector

lDisconnect the connector, andmeasure at the harness side.lVoltage between 1 and ground(Ignition switch: ON)

O K :

l Continuity between 5 andground

sor connector l Connect the connector. (Use

the test harness:

lVoltage between 2 and ground(Ignition switch: ON)

OK: 3.7-4.3

[Altitude: 0 (0 ft.)]

[Altitude: 1,200 (3,937

OK

at the ECM 3-56. Connect the connector. Voltage between 85 and ground (Ignition switch: ON)

OK: 3.7-4.3

[Altitude: 0 (0 ft.)]

I

[(Altitude: 1,200 (3,937ii.)]

Continuity

OKsure sensor connector.I

Check the following connector: Repair

A-i

OK

OK

Check trouble symptom.

NG

Replace the ECM.

N GCheck the harness wire between Repairthe ECM and the barometric pres-sure sensor connector.

OKOK

the ECM and the barometric pres- harness wire

sure sensor connector.

Repair

OK

the ECM.

TSB Revision1

Page 544 of 2103

![MITSUBISHI SPYDER 1990 Service Owners Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting,

Code No. Intake Air Temperature Circuit

[Comment]

Background

lThe intake air temperature sensor converts the intake air temperature to a voltag MITSUBISHI SPYDER 1990 Service Owners Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting,

Code No. Intake Air Temperature Circuit

[Comment]

Background

lThe intake air temperature sensor converts the intake air temperature to a voltag](/img/19/57345/w960_57345-543.png)

ENGINE (TURBO)

AND ENGINE> Troubleshooting,

Code No. Intake Air Temperature Circuit

[Comment]

Background

lThe intake air temperature sensor converts the intake air temperature to a voltage and

outputs it.

l The engine control module checks whether the voltag e is within a specified range.

Check Area

l 60

or more have passed since the starting sequence wa s completed.

Judgement CriterialSensor output voltage has continued to be 4.6 or higher [corresponding to an intake

air temperature of or lower] for 4 sec.

or

lSensor output voltage has continued to be 0.2 or lower [corresponding to an intake

air temperature of or higher] for 4 sec.

l Intake air temperature lOpen or shorted intake circuit, or loose l Engine control

Check the intake air temperature sor. (Refer to Replace the volume air flow sensor.

Measure at the volume air flow sensor

l

l a n d g r o u n d Check the wire between the RepairECM and the intake air temperaturesensor connector.

Replace the ECM.

Revision

Page 545 of 2103

![MITSUBISHI SPYDER 1990 Service Owners Manual ENGINE (TURBO)

AND ENGINE>

Code No. 5 Engine Coolant Temperature Circuit

Malfunction Probable

[Comment]l

Engine coolant temperature BackgroundlOpen shorted engine l theenginecoolanttemp MITSUBISHI SPYDER 1990 Service Owners Manual ENGINE (TURBO)

AND ENGINE>

Code No. 5 Engine Coolant Temperature Circuit

Malfunction Probable

[Comment]l

Engine coolant temperature BackgroundlOpen shorted engine l theenginecoolanttemp](/img/19/57345/w960_57345-544.png)

ENGINE (TURBO)

AND ENGINE>

Code No. 5 Engine Coolant Temperature Circuit

Malfunction Probable

[Comment]l

Engine coolant temperature BackgroundlOpen shorted engine l theenginecoolanttemperature and outputs it. sensor circuit, or l

The engine control module checks whether the voltag e is within a specified range.l

Engine control module In addition, it checks that the engine coolant temp erature (signal) does not drop while

the engine is warming up.

Check Area, Judgement Criteria

1. Check Area, Judgement Criteria

lSensor output voltage has continued to be 4.6 or higher [corresponding to an enginecoolant temperature of or lower] for 4 sec.

or

lSensor output voltage has continued to be 0.1 or lower [corresponding to an enginecoolant temperature of or higher] for 4 sec.

2. Check Area, Judgement CriterialSensor output voltage increased from a value lower than 1.6 to a value higher than1.6 [Engine coolant temperature decreases from a highe r than temperature to a lower than temperature.]lThen the sensor output voltage has continued to be 1.6 or higher for 5 min.

3. Check Area

lEngine coolant temperature is approximately immediately after engine

is started.

Judgement CriterialAbout 60 300 have passed for the engine coolant temperature to about after starting sequence was completed.

Measure at the engine coolant

temperature sensor connector

l Disconnect the connector, and

measure at the harness side.

l Voltage between 1 and ground

(Ignition switch: ON)

OK:

l Continuity between 2 and ground

OK: Continuity

Check trouble symptom.

NG

Replace the ECM.

Replace the

TSB Revision