ESP MITSUBISHI SPYDER 1990 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1246 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL. .

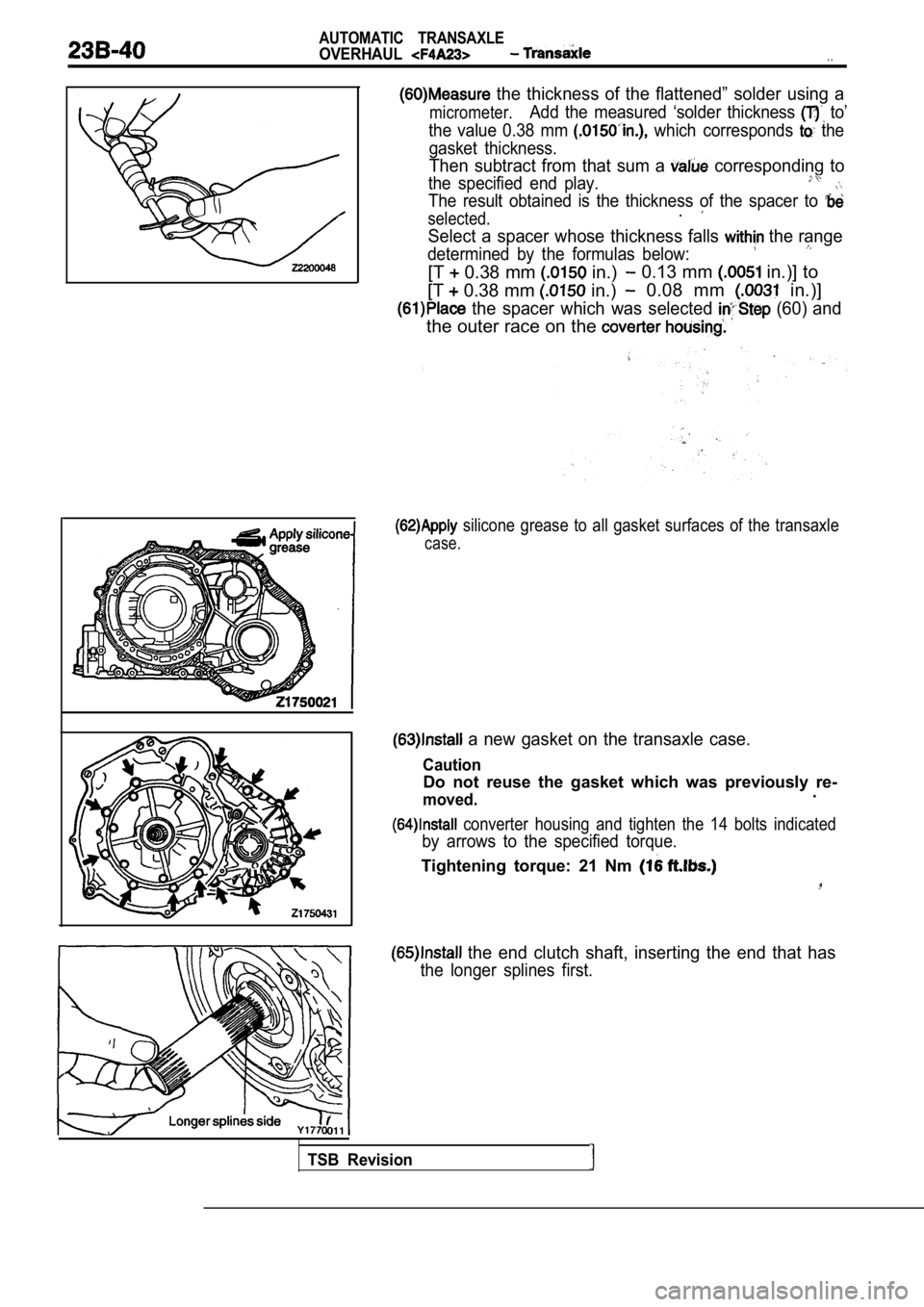

the thickness of the flattened” solder using a

micrometer.Add the measured ‘solder thickness to’

the value 0.38 mm

which corresponds the

gasket thickness.

Then subtract from that sum a corresponding to

the specified end play.

The result obtained is the thickness of the spacer to

selected..

Select a spacer whose thickness falls the range

determined by the formulas below:

[T 0.38 mm in.) 0.13 mm in.)] to

[T

0.38 mm in.) 0.08 mm in.)]

the spacer which was selected (60) and

the outer race on the

silicone grease to all gasket surfaces of the tran saxle

case.

a new gasket on the transaxle case.

Caution

Do not reuse the gasket which was previously re-

moved..

converter housing and tighten the 14 bolts indicat ed

by arrows to the specified torque.

Tightening torque: 21 Nm

the end clutch shaft, inserting the end that has

the longer splines first.

TSB Revision

Page 1286 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

General

Precautions to be taken when disassembling and the

Because the automatic transaxle is of component parts of especially high degree of

precision, these parts should be very carefully han dled during disassembly and assembly so as not

to scar or scratch them.

A rubber mat should be placed on the and it should always be kept clean.

During disassembly, cloth gloves or shop towels, sh ould not be used.

such items must be used,

either use articles made of nylon, or use paper tow els.

All disassembled parts must be thoroughly cleaned.

Metal parts may be cleaned with ordinary but must thoroughly air dried.

Clean the clutch disc, resin thrust plate and rubbe r parts by using ATF (automatic transmission fluid) ,

being very careful that dust, dirt, etc. do not adhere to them.

Do not reuse gaskets, oil seals, or, rubber parts.

Replace such parts with new ones at every reassembl y. The oil’ gauge need not

be replaced.

Do not use grease other than petrolatum jelly.

Apply ATF to friction components, rotating

and sliding parts before installation.

A new clutch disc should be immersed in ATF for at least two hours before installation.

Do not apply sealer or adhesive to gaskets.

When a bushing must be replaced, replace the assemb ly in which it is incorporated:,

If the transaxle main unit is damaged, also disasse

mble and clean the ‘cooler system.,

TSB Revision

Page 1325 of 2103

AUTOMATIC

OVERHAUL Transaxle

A

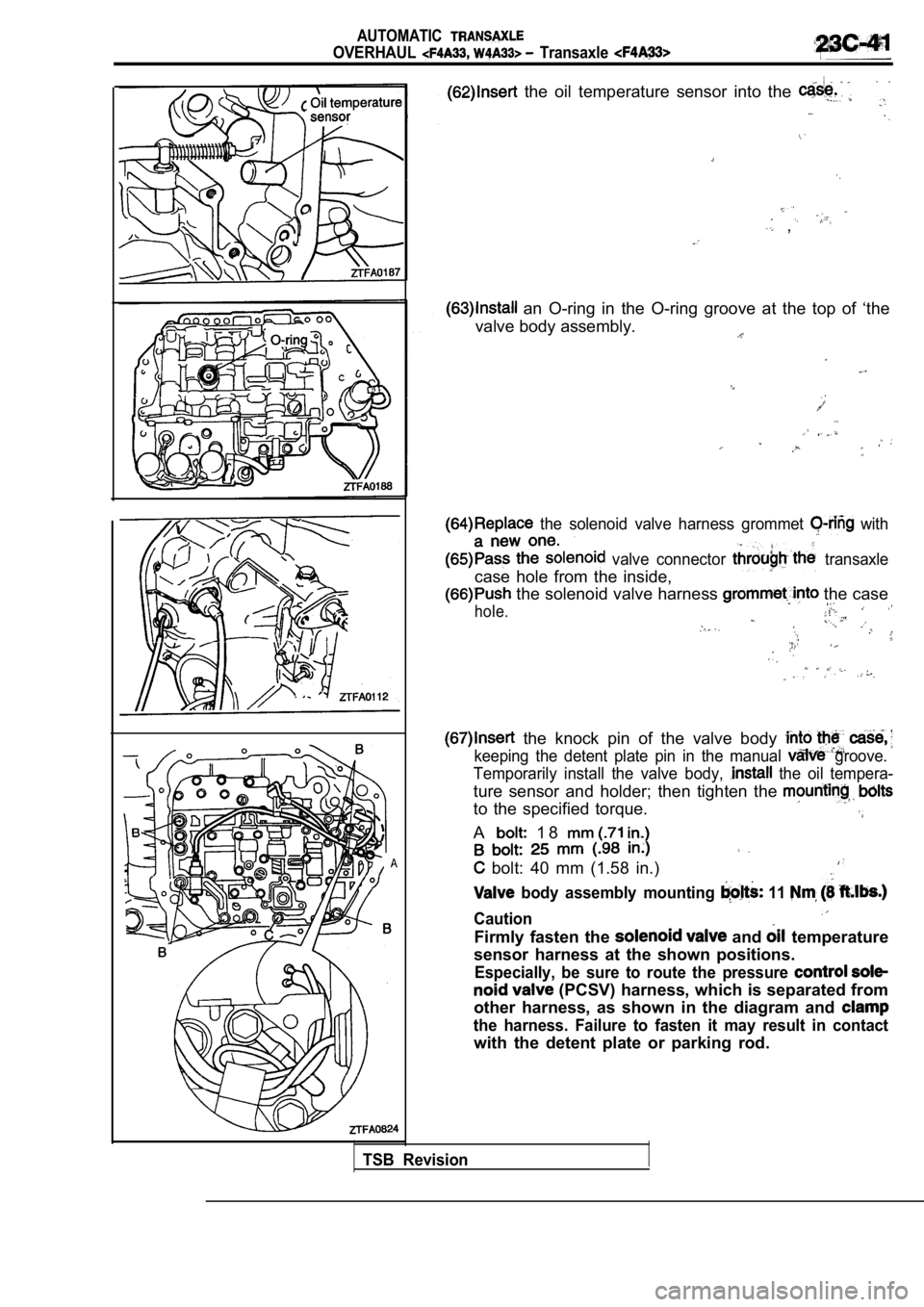

the oil temperature sensor into the

,

an O-ring in the O-ring groove at the top of ‘the

valve body assembly.

the solenoid valve harness grommet with

valve connector transaxle

case hole from the inside,

the solenoid valve harness the case

hole.

the knock pin of the valve body

keeping the detent plate pin in the manual groove.

Temporarily install the valve body,

the oil tempera-

ture sensor and holder; then tighten the

to the specified torque.

A 1 8

bolt: 40 mm (1.58 in.)

body assembly mounting 11

Caution

Firmly fasten the and temperature

sensor harness at the shown positions.

Especially, be sure to route the pressure

(PCSV) harness, which is separated from

other harness, as shown in the diagram and

the harness. Failure to fasten it may result in con tact

with the detent plate or parking rod.

TSB Revision

Page 1356 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL -Transaxle

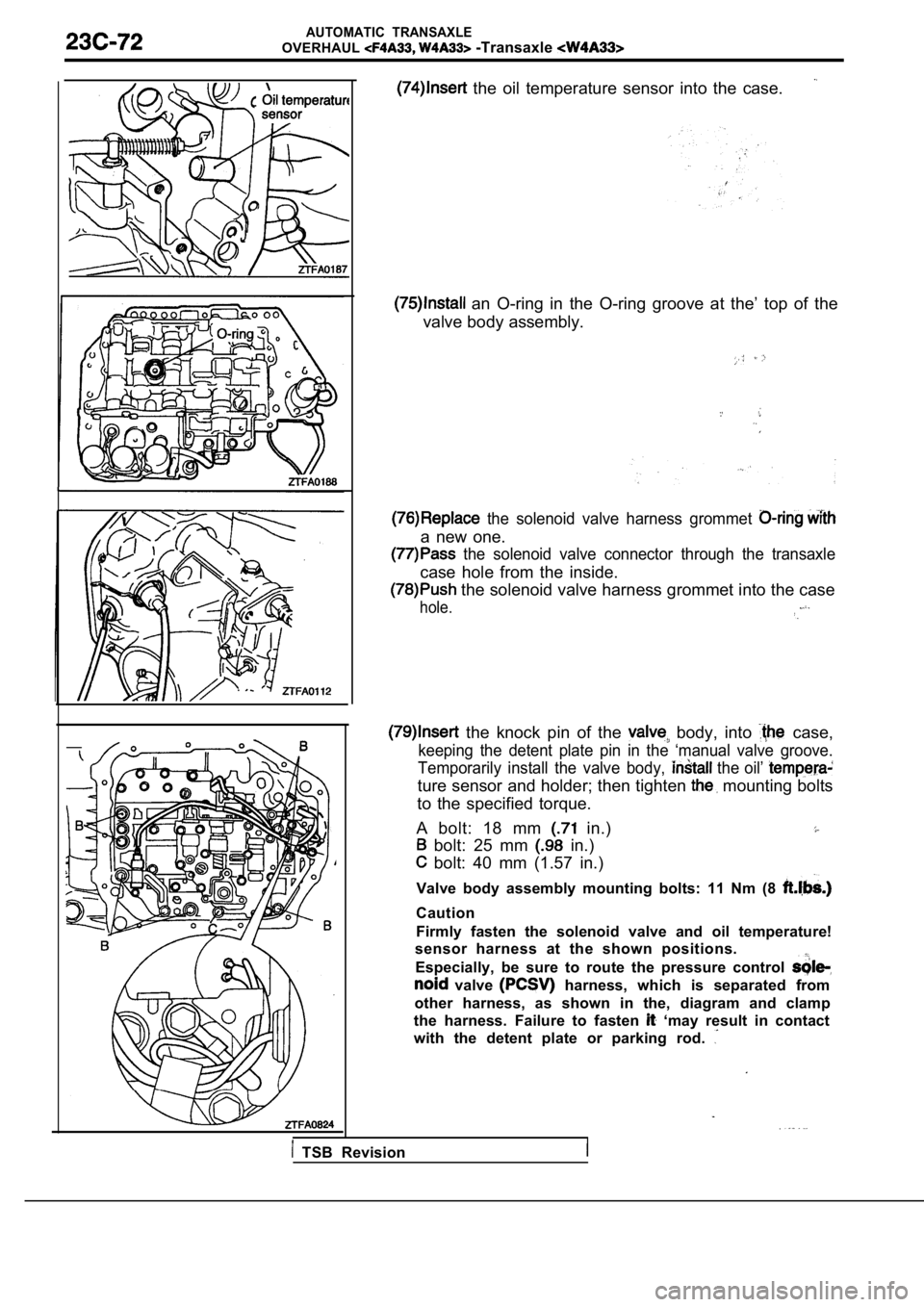

the oil temperature sensor into the case.

an O-ring in the O-ring groove at the’ top of the

valve body assembly.

the solenoid valve harness grommet

a new one.

the solenoid valve connector through the transaxle

case hole from the inside.

the solenoid valve harness grommet into the case

hole.

the knock pin of the body, into case,

keeping the detent plate pin in the ‘manual valve g roove.

Temporarily install the valve body,

the oil’

ture sensor and holder; then tighten mounting bolts

to the specified torque.

A bolt: 18 mm

in.)

bolt: 25 mm in.)

bolt: 40 mm (1.57 in.)

Valve body assembly mounting bolts: 11 Nm (8

Caution

Firmly fasten the solenoid valve and oil temperatur e!

sensor harness at the shown positions.

Especially, be sure to route the pressure control

valve harness, which is separated from

other harness, as shown in the, diagram and clamp

the harness. Failure to fasten

‘may result in contact

with the detent plate or parking rod.

TSB Revision

Page 1522 of 2103

FRONT AXLE Drive Shaft

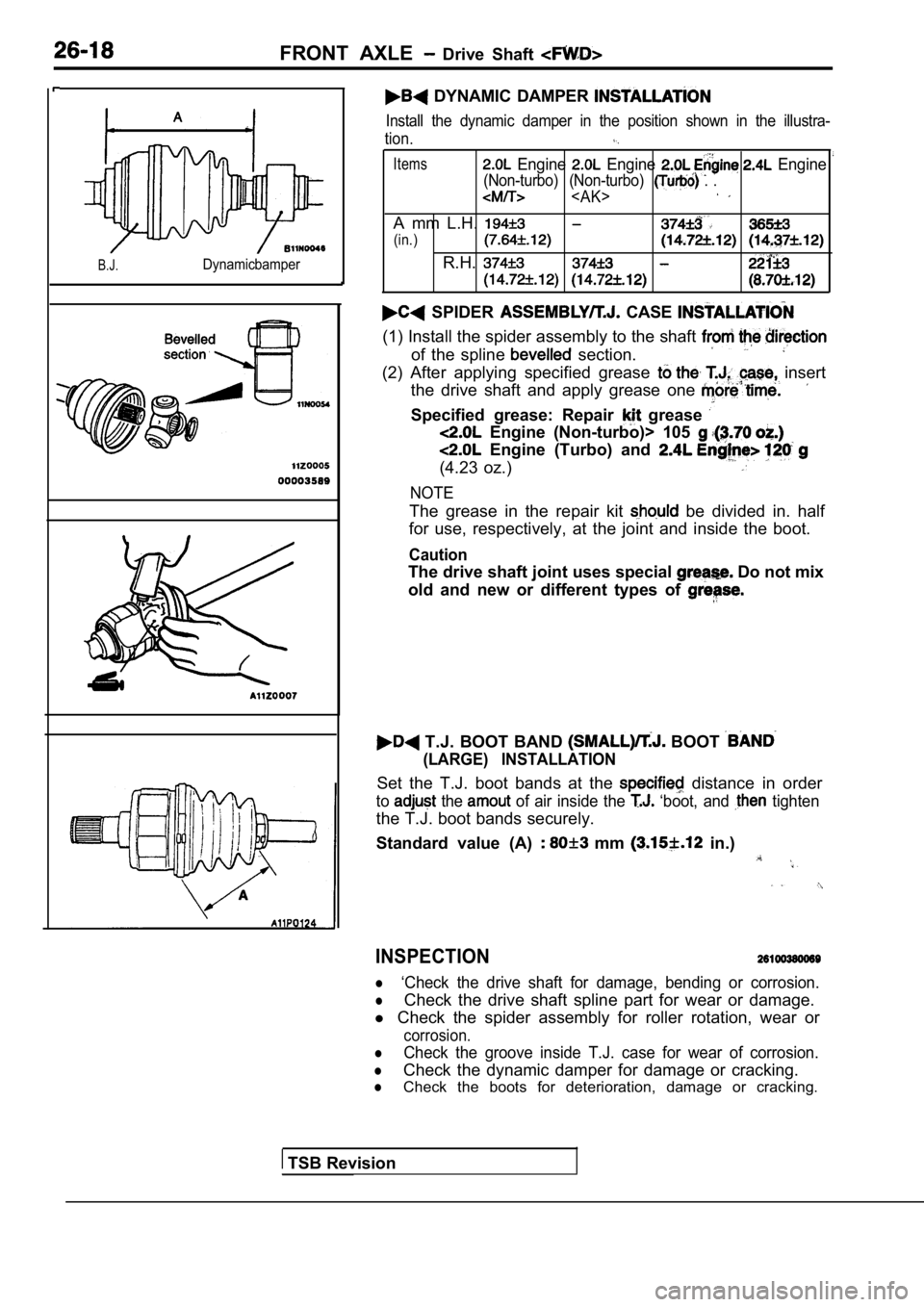

B.J.Dynamicbamper

DYNAMIC DAMPER

Install the dynamic damper in the position shown in the illustra-

tion.

Items Engine Engine Engine

(Non-turbo) (Non-turbo) . .

A mm L.H.

(in.)

R.H.

SPIDER CASE

(1) Install the spider assembly to the shaft

of the spline section.

(2) After applying specified grease insert

the drive shaft and apply grease one

Specified grease: Repair grease

Engine (Non-turbo)> 105

Engine (Turbo) and

(4.23 oz.)

NOTE

The grease in the repair kit be divided in. half

for use, respectively, at the joint and inside the boot.

Caution

The drive shaft joint uses special Do not mix

old and new or different types of

T.J. BOOT BAND BOOT

(LARGE) INSTALLATION

Set the T.J. boot bands at the distance in order

to the of air inside the ‘boot, and tighten

the T.J. boot bands securely.

Standard value (A)

mm in.)

INSPECTION

l‘Check the drive shaft for damage, bending or corro sion.

lCheck the drive shaft spline part for wear or damage.

l Check the spider assembly for roller rotation, wear or

corrosion.

lCheck the groove inside T.J. case for wear of corro sion.

lCheck the dynamic damper for damage or cracking.

lCheck the boots for deterioration, damage or cracking.

TSB Revision

Page 1533 of 2103

FRONT AXLE Drive Shaft

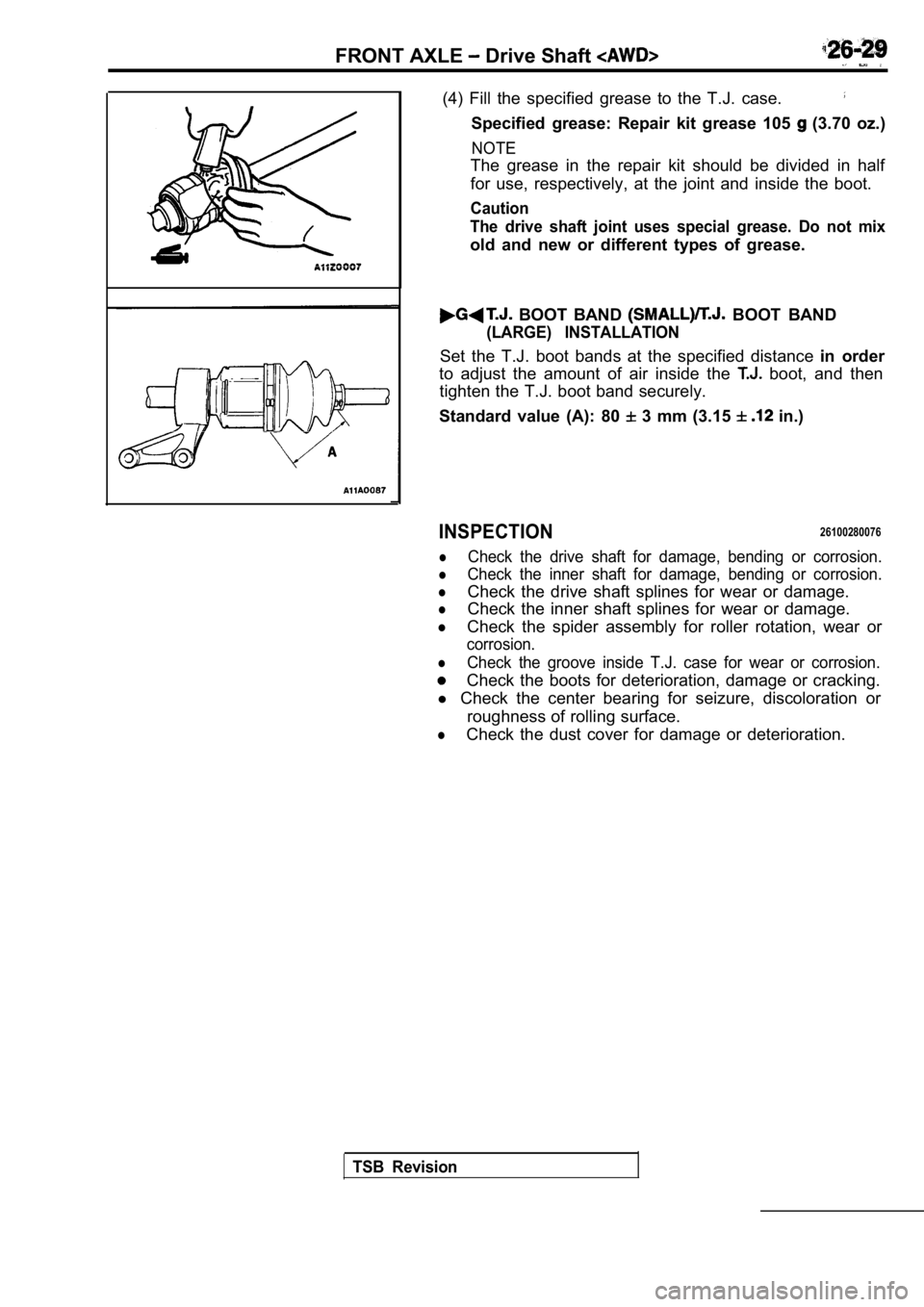

(4) Fill the specified grease to the T.J. case.

Specified grease: Repair kit grease 105 (3.70 oz.)

NOTE

The grease in the repair kit should be divided in half

for use, respectively, at the joint and inside the boot.

Caution

The drive shaft joint uses special grease. Do not m ix

old and new or different types of grease.

BOOT BAND BOOT BAND

(LARGE) INSTALLATION

Set the T.J. boot bands at the specified distance in order

to adjust the amount of air inside the

boot, and then

tighten the T.J. boot band securely.

Standard value (A): 80

3 mm (3.15 in.)

INSPECTION26100280076

lCheck the drive shaft for damage, bending or corros ion.

lCheck the inner shaft for damage, bending or corros ion.

lCheck the drive shaft splines for wear or damage.

lCheck the inner shaft splines for wear or damage.

lCheck the spider assembly for roller rotation, wear or

corrosion.

lCheck the groove inside T.J. case for wear or corro sion.

Check the boots for deterioration, damage or cracking.

l Check the center bearing for seizure, discoloration or

roughness of rolling surface.

lCheck the dust cover for damage or deterioration.

TSB Revision

Page 1560 of 2103

R E A R A X L E

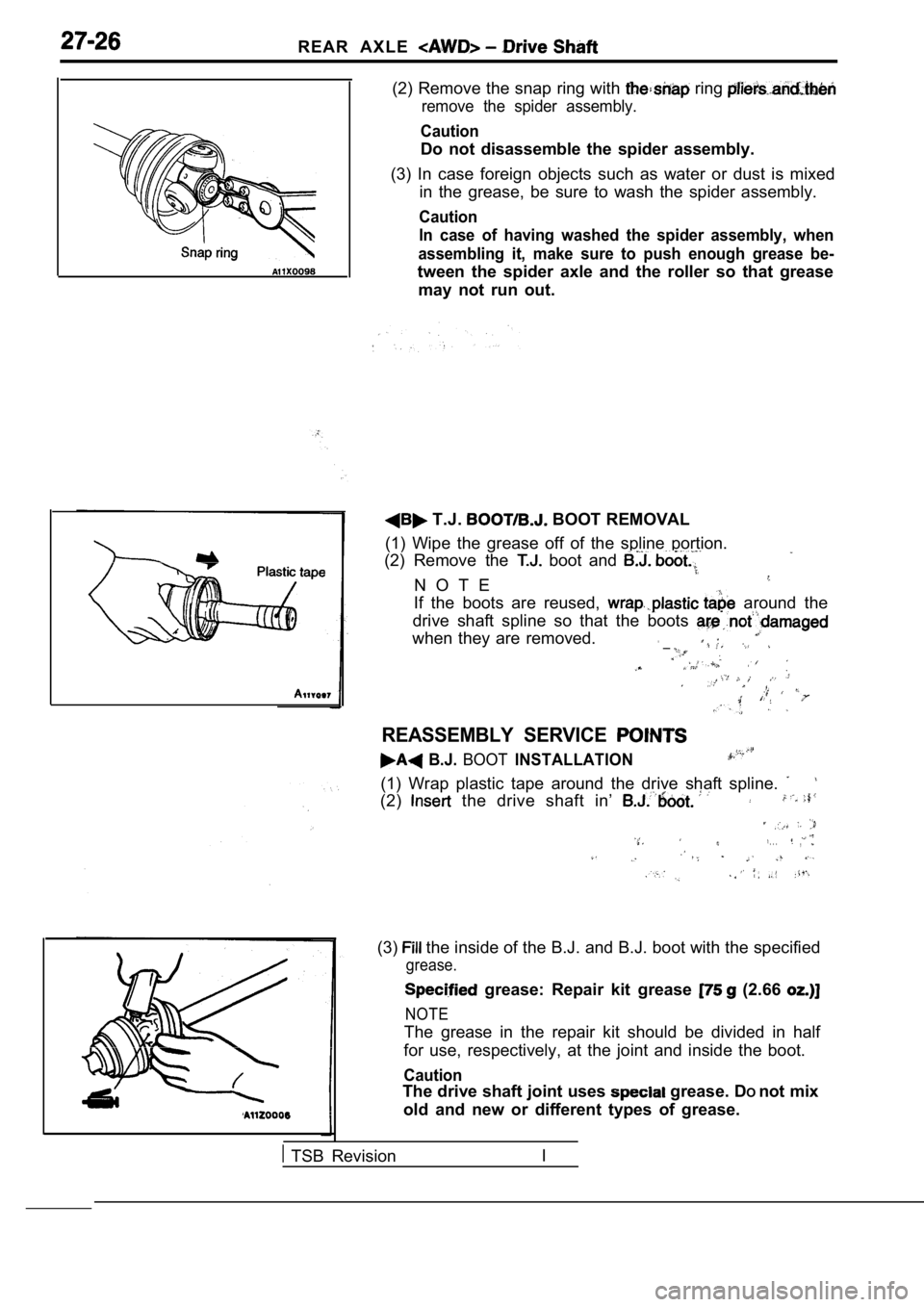

(2) Remove the snap ring with ring

remove the spider assembly.

Caution

Do not disassemble the spider assembly.

(3) In case foreign objects such as water or dust i s mixed

in the grease, be sure to wash the spider assembly.

Caution

In case of having washed the spider assembly, when

assembling it, make sure to push enough grease be-

tween the spider axle and the roller so that grease may not run out.

T.J. BOOT REMOVAL

(1) Wipe the grease off of the spline portion.

(2) Remove the

boot and

N O T E

If the boots are reused, around the

drive shaft spline so that the boots

when they are removed. __

REASSEMBLY SERVICE

B.J. BOOTINSTALLATION

(1) Wrap plastic tape around the drive shaft spline .

(2) the drive shaft in’

. . .,

(3) the inside of the B.J. and B.J. boot with the specified

grease.

grease: Repair kit grease (2.66

NOTE

The grease in the repair kit should be divided in h alf

for use, respectively, at the joint and inside the boot.

Caution

The drive shaft joint uses grease. DOnot mix

old and new or different types of grease.

TSB Revision I

Page 1561 of 2103

REAR AXLE Drive Shaft

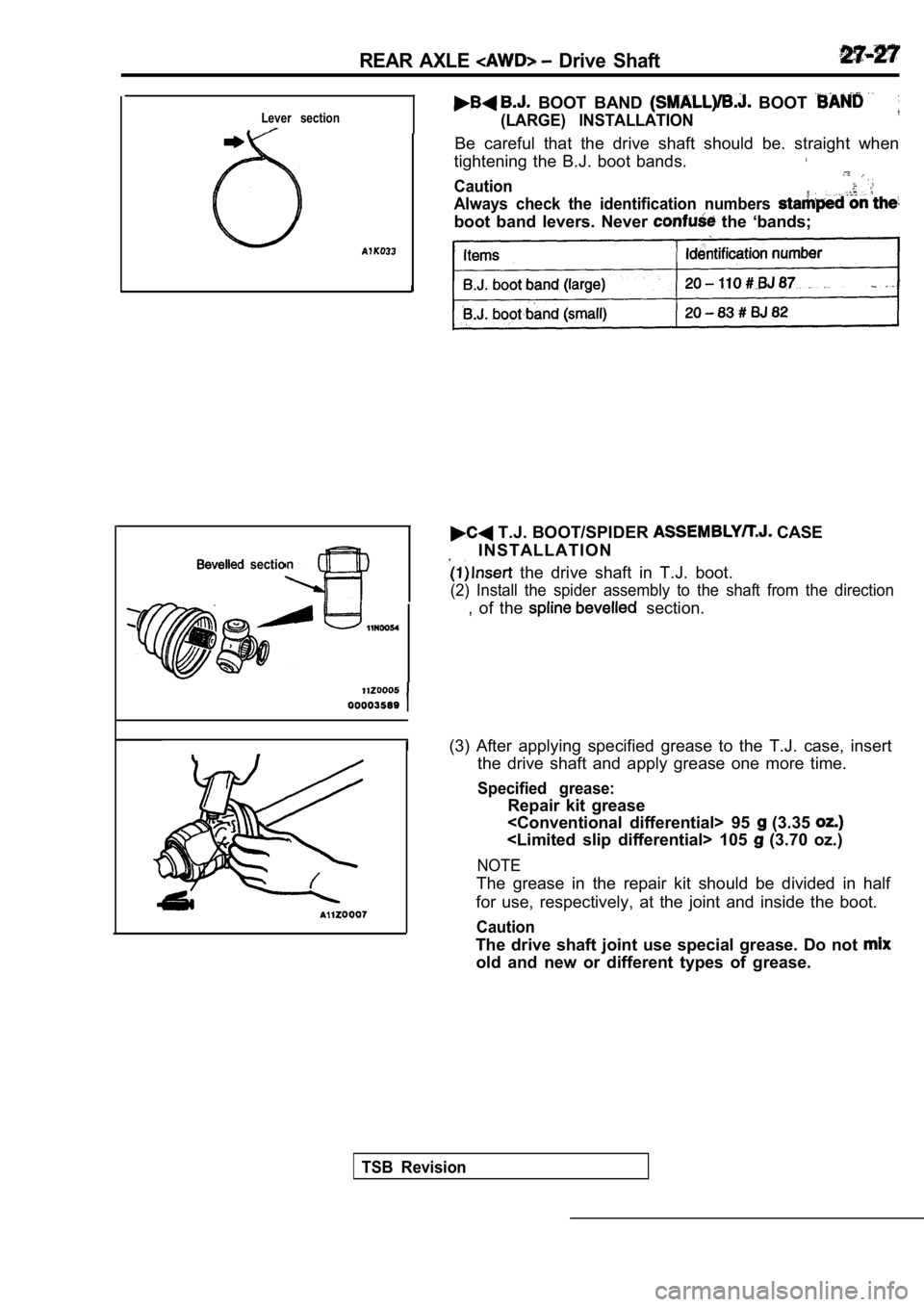

Lever section.

BOOT BAND BOOT

(LARGE) INSTALLATION

Be careful that the drive shaft should be. straight when

tightening the B.J. boot bands.

Caution

Always check the identification numbers

boot band levers. Never the ‘bands;

section

I

T.J. BOOT/SPIDER CASE

I N S T A L L A T I O N

the drive shaft in T.J. boot.

(2) Install the spider assembly to the shaft from t he direction

, of the section.

(3) After applying specified grease to the T.J. cas e, insert

the drive shaft and apply grease one more time.

Specified grease:

Repair kit grease

(3.35

NOTE

The grease in the repair kit should be divided in h alf

for use, respectively, at the joint and inside the boot.

Caution

The drive shaft joint use special grease. Do not

old and new or different types of grease.

TSB Revision

Page 1578 of 2103

REAR AXLE Differential

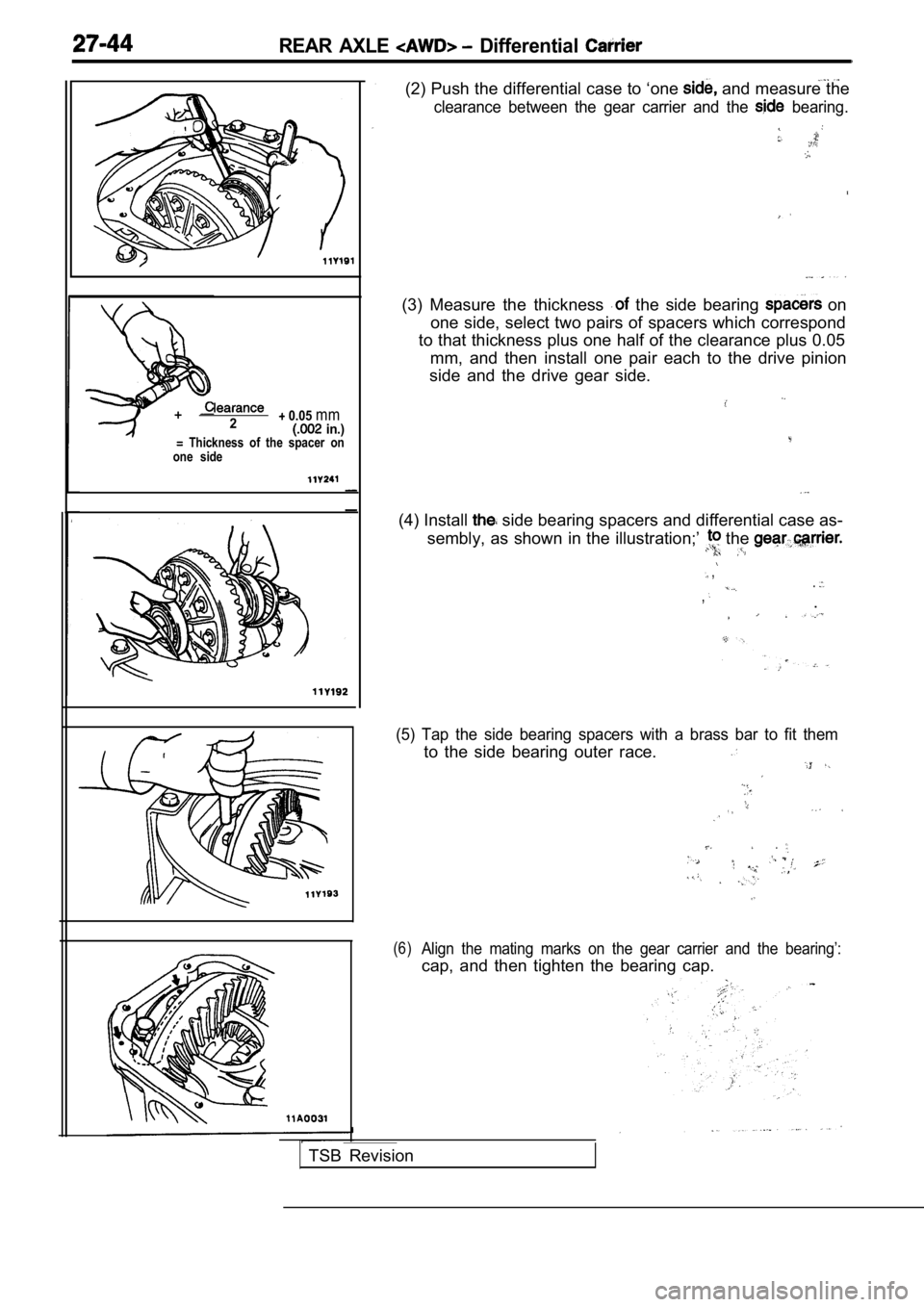

2 0.05 mm in.) Thickness of the spacer on

one side

(2) Push the differential case to ‘one and measure the

clearance between the gear carrier and the bearing.

(3) Measure the thickness the side bearing on

one side, select two pairs of spacers which corresp ond

to that thickness plus one half of the clearance pl us 0.05

mm, and then install one pair each to the drive pin ion

side and the drive gear side.

(4) Install side bearing spacers and differential case as-

sembly, as shown in the illustration;’

the

, .

,.

(5) Tap the side bearing spacers with a brass bar t o fit them

to the side bearing outer race.

(6)Align the mating marks on the gear carrier and the bearing’:

cap, and then tighten the bearing cap.

TSB Revision

Page 1610 of 2103

FRONT SUSPENSION Shock Absorber

Damper foinstallation

of the body

REASSEMBLY. SERVICE

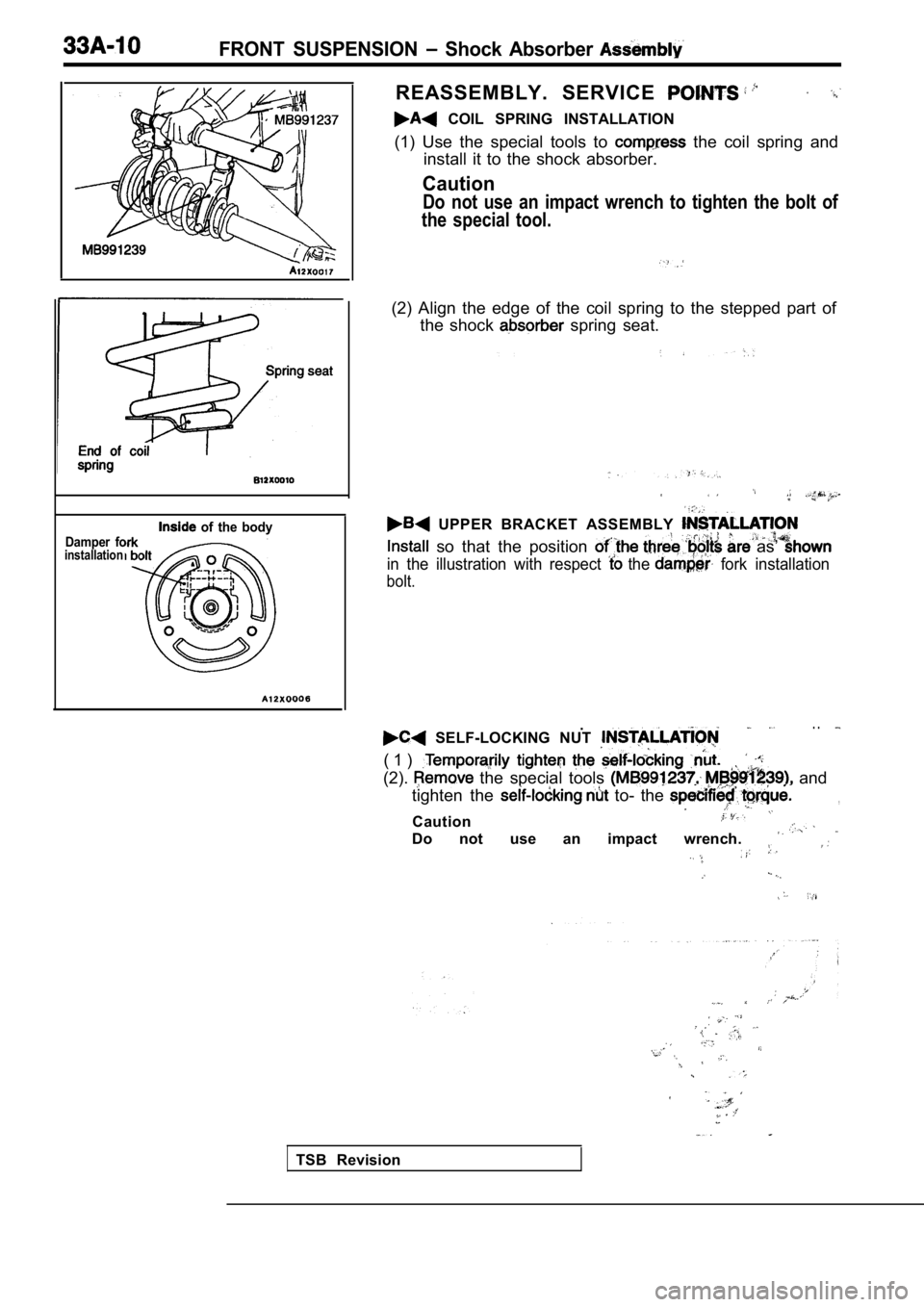

COIL SPRING INSTALLATION

(1) Use the special tools to

the coil spring and

install it to the shock absorber.

Caution

Do not use an impact wrench to tighten the bolt of

the special tool.

(2) Align the edge of the coil spring to the steppe d part of

the shock

spring seat.

UPPER BRACKET ASSEMBLY

so that the position as’

in the illustration with respect the fork installation

bolt.

. SELF-LOCKING NUT . .

( 1 )

(2). the special tools and

tighten the

to- the ,

Caution

Do not use an impact wrench.

TSB Revision