belt MITSUBISHI SPYDER 1990 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 164 of 2103

11

Crankshaft,

ENGINE OVERHAUL Drive Plate .

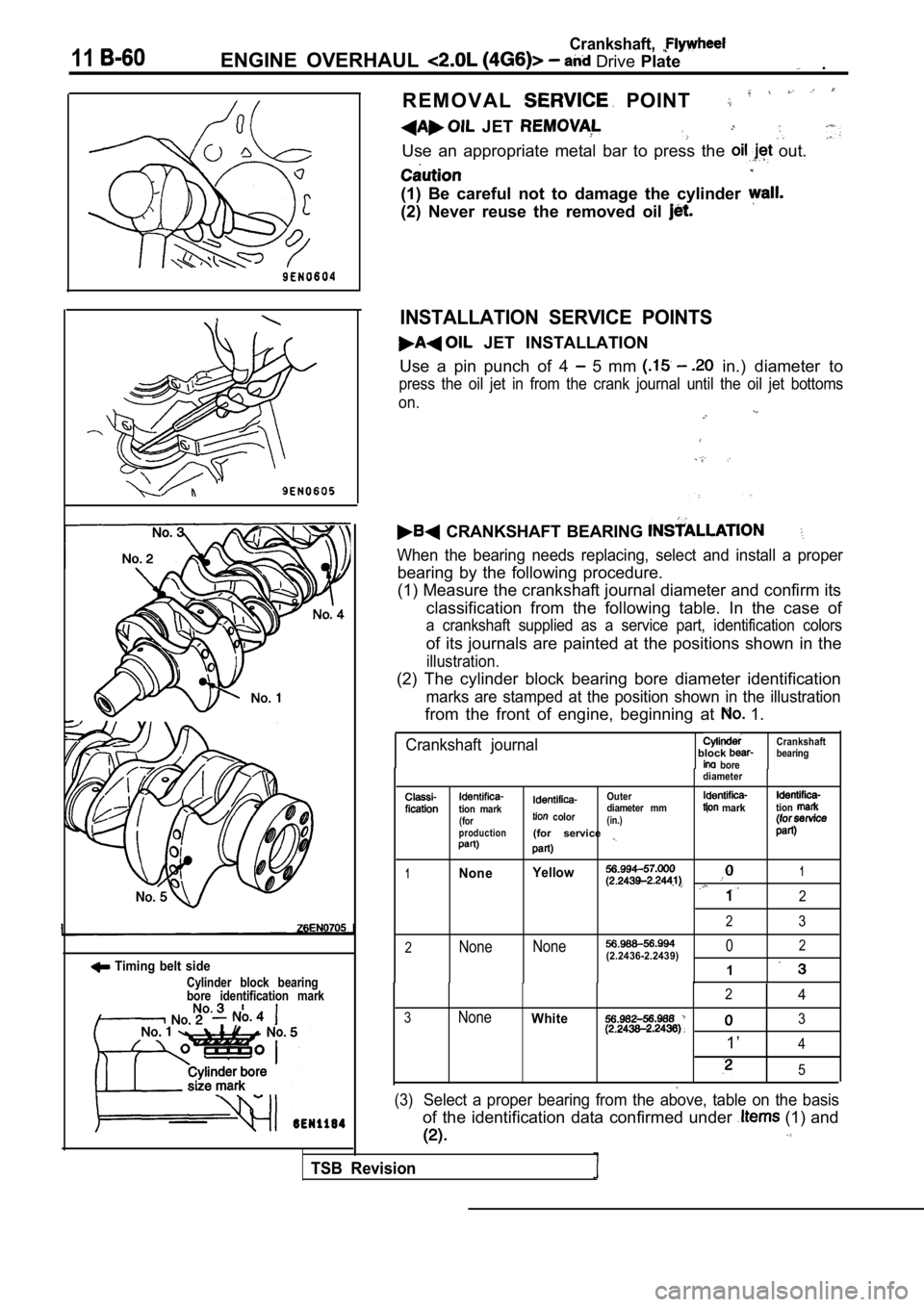

Timing belt side

Cylinder block bearing

bore identification mark

R E M O V A L POINT

JET

Use an appropriate metal bar to press the out.

(1) Be careful not to damage the cylinder

(2) Never reuse the removed oil

INSTALLATION SERVICE POINTS

JET INSTALLATION

Use a pin punch of 4

5 mm in.) diameter to

press the oil jet in from the crank journal until t he oil jet bottoms

on.

CRANKSHAFT BEARING

When the bearing needs replacing, select and instal l a proper

bearing by the following procedure.

(1) Measure the crankshaft journal diameter and confirm its

classification from the following table. In the cas e of

a crankshaft supplied as a service part, identification colors

of its journals are painted at the positions shown in the

illustration.

(2) The cylinder block bearing bore diameter identi fication

marks are stamped at the position shown in the illustration

from the front of engine, beginning at 1.

Crankshaft journalblock bore

diameter Crankshaft

bearing

tion mark(for

production

Outer

color diameter mm(in.)(for service

marktion

1None

Yellow1

2

23

2None

None02(2.2436-2.2439)

1

24

3NoneWhite3

1’4

5

(3)Select a proper bearing from the above, table on th

e basis

of the identification data confirmed under (1) and

TSB Revision

Page 165 of 2103

![MITSUBISHI SPYDER 1990 Service Service Manual E N G I N E O V E R H A U L

ed

(for No. tion mark

Upper and lower (for No.3)

Identification

mark

1

Shank length

[Example]

(1) If the measured value of a crankshaft

diameter is b MITSUBISHI SPYDER 1990 Service Service Manual E N G I N E O V E R H A U L

ed

(for No. tion mark

Upper and lower (for No.3)

Identification

mark

1

Shank length

[Example]

(1) If the measured value of a crankshaft

diameter is b](/img/19/57345/w960_57345-164.png)

E N G I N E O V E R H A U L

ed

(for No. tion mark

Upper and lower (for No.3)

Identification

mark

1

Shank length

[Example]

(1) If the measured value of a crankshaft

diameter is between 56.994 mm (2.2439

2.2441 in.), the journal is in the’

case the is also replaced by a

spare part, check the identification colors of the

journals painted on the

crankshaft. If the color’

is yellow, for example,.

journal is classified as

(2)

check the cylinder block bearing hole

mark stamped on the cylinder block.

If it is “O”, read the “Bearing identification column

to find the identification mark of the bearing to b e

used. In this case, it is “1”.

(4)

the bearings oil groove to the cylinder

block.

(5) Install the bearings having no oil to the bearing

caps.

CAP B E A R I N G C A P B O L T

INSTALLATION

(1) Install the bearing caps so that their arrows directed

to the timing belt side.

(2) Before installing the bearing cap bolts, check that the

shank length of each bolt meets the limit.

limit

is exceeded, replace the bolt.

(A): Max. 71.1 mm (2.79 in.)

(3) Apply engine oil to the threaded portion and be aring sur-

face of the bolt.

(4) Tighten the bolts to 25 Nm (16

in the specified

tightening sequence.

(5) Make a paint mark on the head of each bolt.

(6) Make a paint mark on the bearing cap at the pos ition

to from the paint mark made on the bolt in

the direction of tightening the bolt.

(7) According to the specified tightening sequence, give a

to turn to each bolt and make sure that the

paint mark on the bolt and that on the cap are in a lignment.

Caution

(1) If

thebolt is turned less than proper

performance may not be expected.

tightening the bolt, therefore, be careful to

a sufficient turn to it.

( 2 ) I f t h e b o l t i s

loosen the bolt completely and then retlghten

by repeating the tightening procedure from step

TSB Revision

Page 171 of 2103

CONTENTS

CAMSHAFT AND CAMSHAFT OIL

SEAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

CRANKSHAFT FRONT OIL SEAL. . . . . . . . . .25

CRANKSHAFT PULLEY. . . . . . . . . . . . . . . . . . .19

CRANKSHAFT REAR OIL SEAL

. . . . . . . . . .

CYLINDER HEAD GASKET. . . . . . . . . . . . . . . .29

ENGINE ASSEMBLY. . . . . . . . . . . . . . . . . . . . . .14

GENERAL INFORMATION. . . . . . . . . . . . . . . . . .2

OIL PAN AND OIL SCREEN . . . . . . . . . . . . . . .24

ON-VEHICLE SERVICE

. . . . . . . . . . . . . . . . . . . . .8

Basic idle Speed Adjustment. . . . . . . . . . . . . . . . . . . . . Refer to GROUP

Compression Pressure Check. . . . . . . . . ..

Curb Speed Check . . . . . . . . . ...

Drive Tension

Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mixture Check . . . . . . . . . . . . . . . . .. . . . . . ..

Ignition Timing Check. . . . . . . . .....................

Lash Adjuster Check . . . . . . . . . . . . . . . . .

......

. . . . .

Manifold Check . . . . . . . . . . . . .13

SEALANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SERVICE SPECIFICATIONS. . . . . . . . . . . . . . . . .3

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . .4

TIMING BELT. . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . .

7

Page 173 of 2103

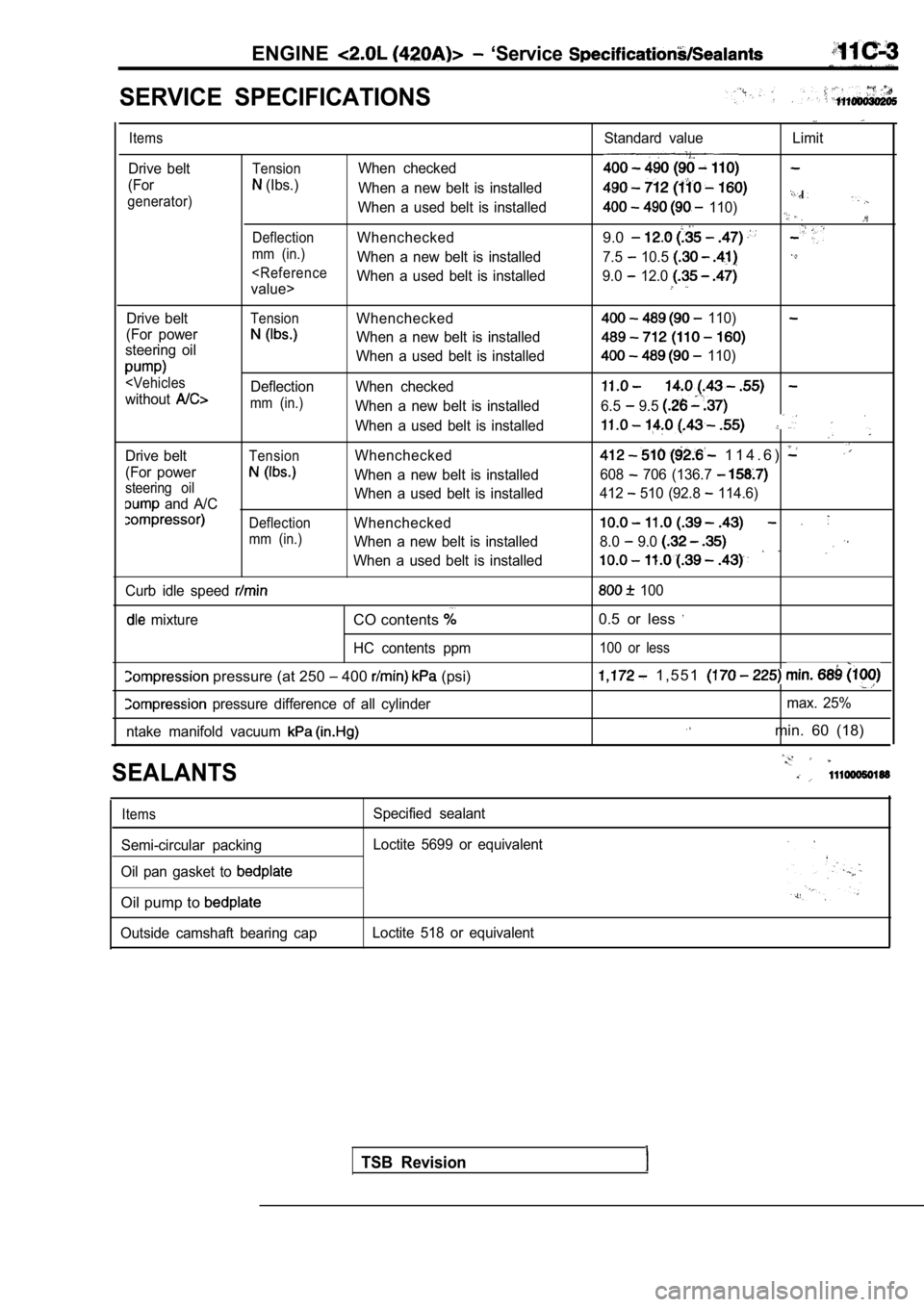

ENGINE ‘Service

SERVICE SPECIFICATIONS

Items

Drive belt

(For

generator)

Standard value Limit

TensionWhen checked

(Ibs.) When a new belt is installed

When a used belt is installed

110)

DeflectionWhenchecked9.0

mm (in.)When a new belt is installed 7.5 10.5

Drive beltTensionWhenchecked

(For power

When a new belt is installed

steering oil

When a used belt is installed

mm (in.)When a new belt is installed

When a used belt is installed

Drive belt

TensionWhenchecked

(For power

When a new belt is installedsteering oil

and A/C When a used belt is installed

DeflectionWhenchecked

mm (in.)When a new belt is installed

When a used belt is installed

Curb idle speed

mixtureCO contents

HC contents ppm

pressure (at 250 400 (psi)

pressure difference of all cylinder

ntake manifold vacuum

110)

110)

6.5 9.5

1 1 4 . 6 )

608 706 (136.7

412 510 (92.8 114.6)

8.0 9.0

100

0.5 or less

100 or less

1 , 5 5 1

max. 25%

min. 60 (18)

SEALANTS

Items

Semi-circular packing

Oil pan gasket to

Oil pump to

Outside camshaft bearing cap Specified sealant

Loctite 5699 or equivalent

Loctite 518 or equivalent

TSB Revision

Page 177 of 2103

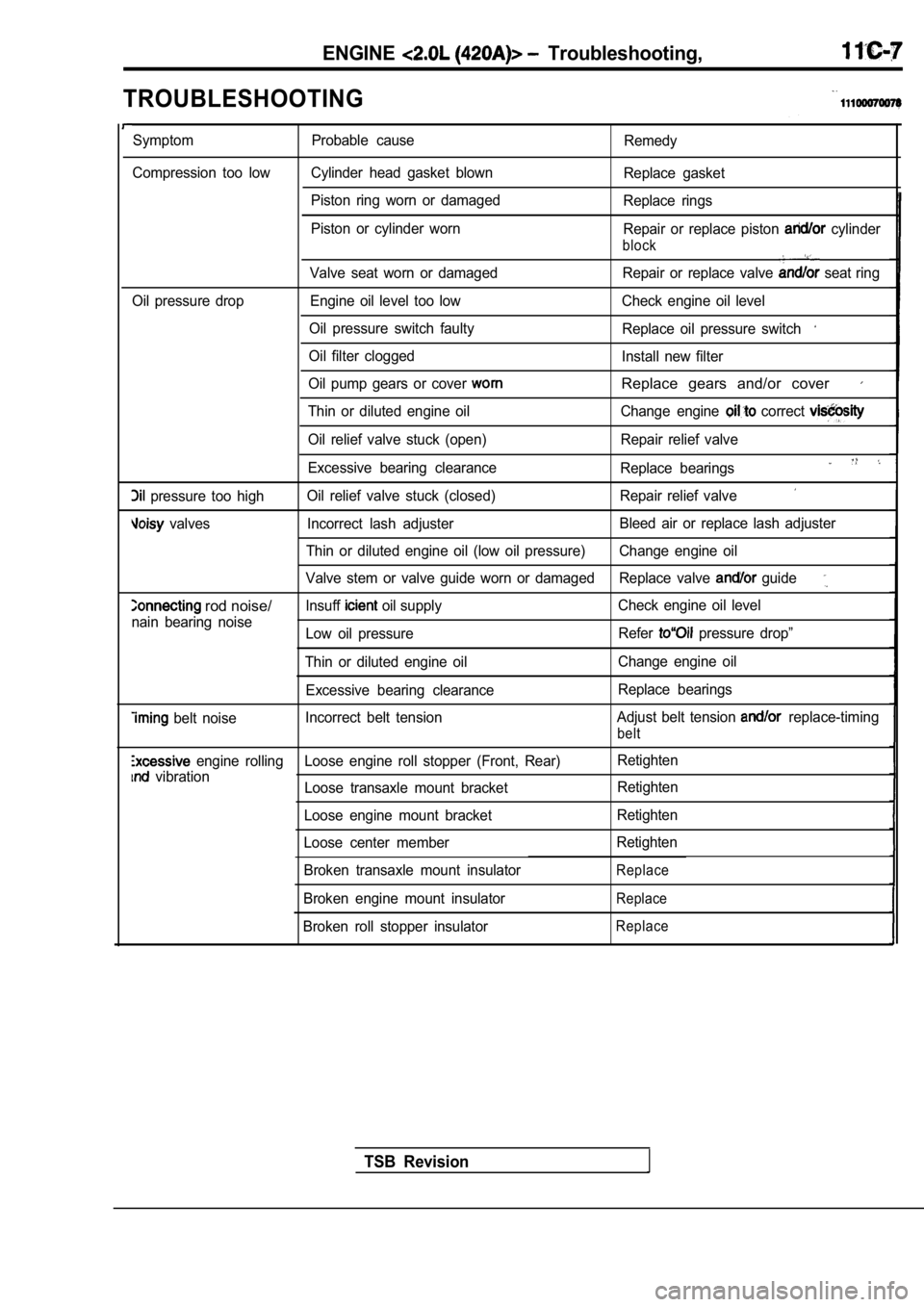

ENGINE Troubleshooting,

TROUBLESHOOTING

Symptom Probable causeRemedy

Compression too low Cylinder head gasket blown Replace gasket

Piston ring worn or damaged Replace rings

Piston or cylinder worn Repair or replace piston

cylinder

block

Valve seat worn or damaged Repair or replace valve seat ring

Oil pressure drop Engine oil level too low Check engi ne oil level

Oil pressure switch faulty Replace oil pressure switch

Oil filter clogged

Install new filter

Oil pump gears or cover

Replace gears and/or cover

Thin or diluted engine oil Change engine correct

Oil relief valve stuck (open) Repair relief valve

Excessive bearing clearance Replace bearings

pressure too highOil relief valve stuck (closed) Repair relief valve

valves Incorrect lash adjuster Bleed air or replace lash adjuster

Thin or diluted engine oil (low oil pressure) Change engine oil

Valve stem or valve guide worn or damaged Replace va lve

guide

rod noise/lnsuff oil supplyCheck engine oil level

nain bearing noise Low oil pressure Refer

pressure drop”

Thin or diluted engine oil Change engine oil

Excessive bearing clearance Replace bearings

belt noiseIncorrect belt tension

Adjust belt tension replace-timing

belt

engine rolling Loose engine roll stopper (Front, Re

ar)Retighten

vibration

Loose transaxle mount bracket Retighten

Loose engine mount bracket Retighten

Loose center member Retighten

Broken transaxle mount insulator

Replace

Broken engine mount insulatorReplace

Broken roll stopper insulatorReplace

TSB Revision

Page 178 of 2103

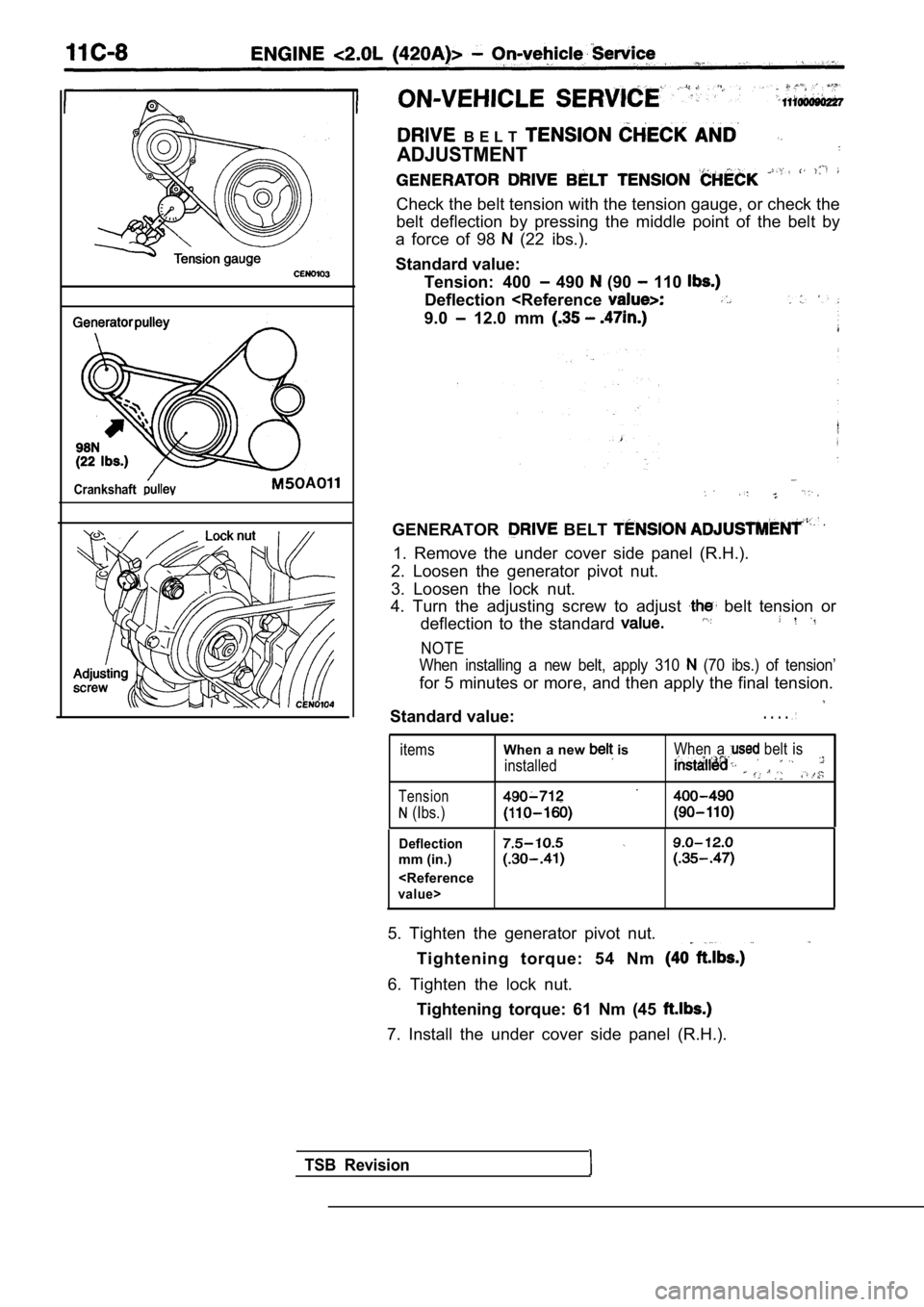

Crankshaft

B E L T

ADJUSTMENT

Check the belt tension with the tension gauge, or check the

belt deflection by pressing the middle point of the belt by

a force of 98

(22 ibs.).

Standard value: Tension: 400

490 (90 110

Deflection

GENERATOR BELT

1. Remove the under cover side panel (R.H.).

2. Loosen the generator pivot nut.

3. Loosen the lock nut.

4. Turn the adjusting screw to adjust

belt tension or

deflection to the standard

NOTE

When installing a new belt, apply 310

(70 ibs.) of tension’

for 5 minutes or more, and then apply the final ten sion.

Standard value:. . . .

items

Tension

(Ibs.)

When a new is

installed

When a belt is

Deflection

mm (in.)

5. Tighten the generator pivot nut.

Tightening torque: 54 Nm

6. Tighten the lock nut.Tightening torque: 61 Nm (45

7. Install the under cover side panel (R.H.).

TSB Revision

Page 179 of 2103

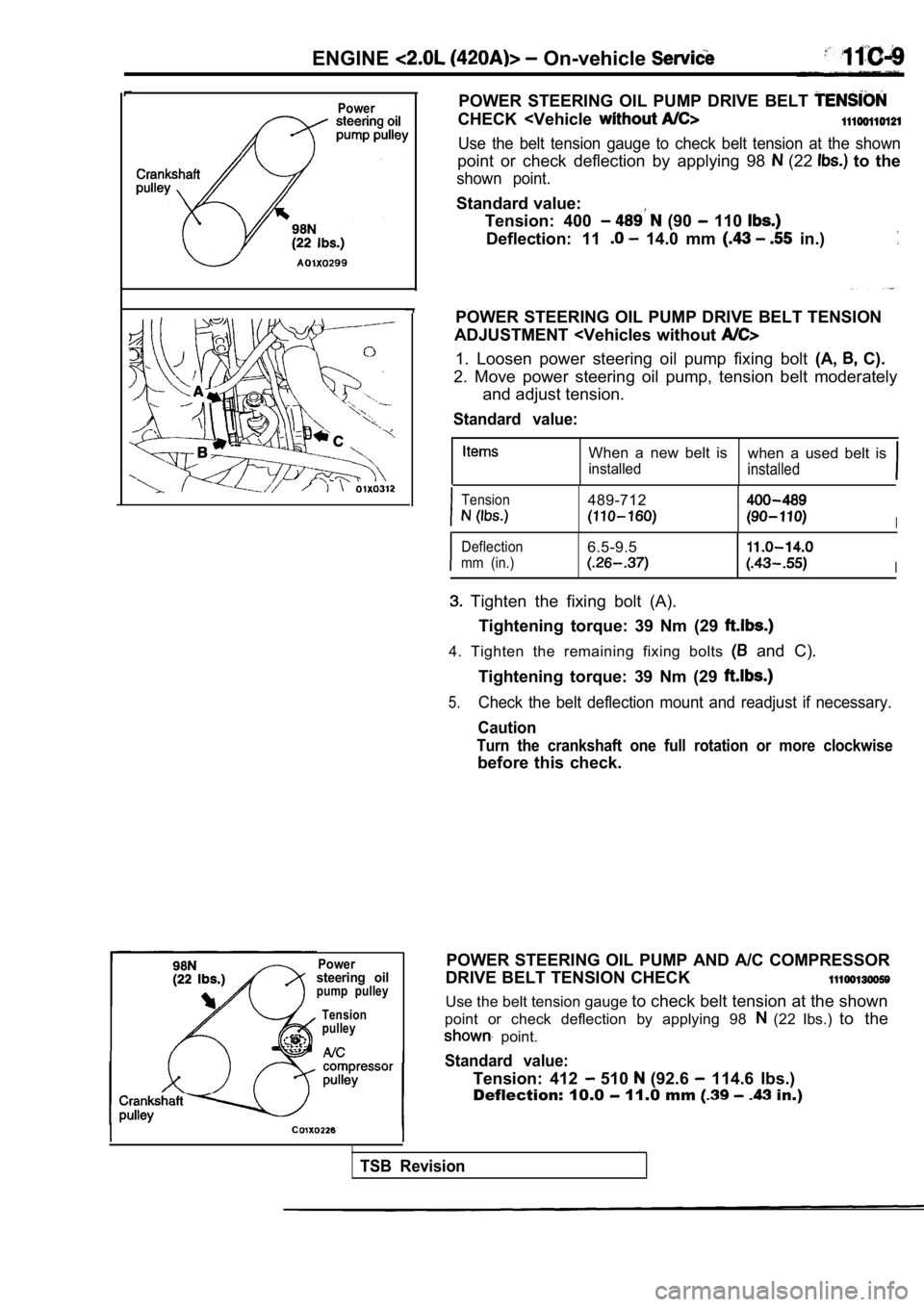

ENGINE On-vehicle

Power

Powersteering oilpump pulleyTension

pulley

POWER STEERING OIL PUMP DRIVE BELT

CHECK

point or check deflection by applying 98 (22 to the

shown point.

Standard value:

Tension: 400

(90 110

Deflection: 11 14.0 mm in.)

POWER STEERING OIL PUMP DRIVE BELT TENSION

ADJUSTMENT

2. Move power steering oil pump, tension belt moder ately

and adjust tension.

Standard value:

When a new belt is when a used belt is

installedinstalled

Tension489-712

I

Deflection6.5-9.5

mm (in.)I

Tighten the fixing bolt (A).

Tightening torque: 39 Nm (29

4. Tighten the remaining fixing bolts and C).

Tightening torque: 39 Nm (29

5.Check the belt deflection mount and readjust if nec essary.

Caution

Turn the crankshaft one full rotation or more clock wise

before this check.

POWER STEERING OIL PUMP AND A/C COMPRESSOR

DRIVE BELT TENSION CHECK

Use the belt tension gauge to check belt tension at the shown

point or check deflection by applying 98

(22 Ibs.) to the

point.

Standard value:

Tension: 412 510 (92.6 114.6 Ibs.)

Deflection: 10.0

11.0 mm in.)

TSB Revision

Page 180 of 2103

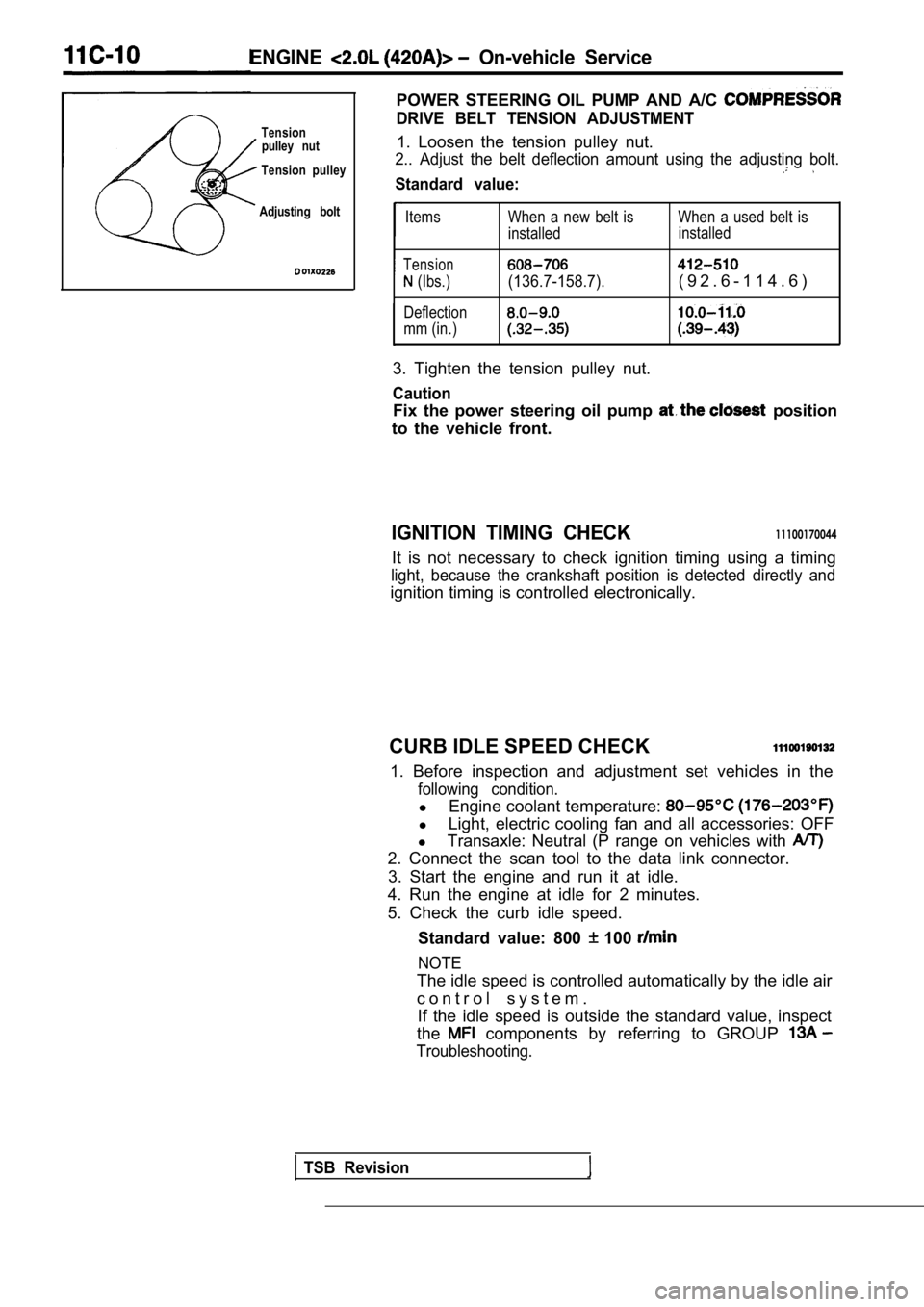

ENGINE On-vehicle Service

POWER STEERING OIL PUMP AND A/C

DRIVE BELT TENSION ADJUSTMENTTensionpulley nut1. Loosen the tension pulley nut.

Tension pulley2.. Adjust the belt deflection amount using the adj usting bolt.

Standard value:

Adjusting boltItems

Tension

(Ibs.)

Deflection

mm (in.) When a new belt is When a used belt is

installed

installed(136.7-158.7).( 9 2 . 6 - 1 1 4 . 6 )

3. Tighten the tension pulley nut.

Caution

Fix the power steering oil pump position

to the vehicle front.

IGNITION TIMING CHECK11100170044

It is not necessary to check ignition timing using a timing

light, because the crankshaft position is detected directly and

ignition timing is controlled electronically.

CURB IDLE SPEED CHECK

1. Before inspection and adjustment set vehicles in the

following condition.

lEngine coolant temperature:

lLight, electric cooling fan and all accessories: OF F

l Transaxle: Neutral (P range on vehicles with

2. Connect the scan tool to the data link connector .

3. Start the engine and run it at idle.

4. Run the engine at idle for 2 minutes.

5. Check the curb idle speed.

Standard value: 800

100

NOTE

The idle speed is controlled automatically by the i dle air

c o n t r o l s y s t e m . If the idle speed is outside the standard value, in spect

the

components by referring to GROUP

Troubleshooting.

TSB Revision

Page 184 of 2103

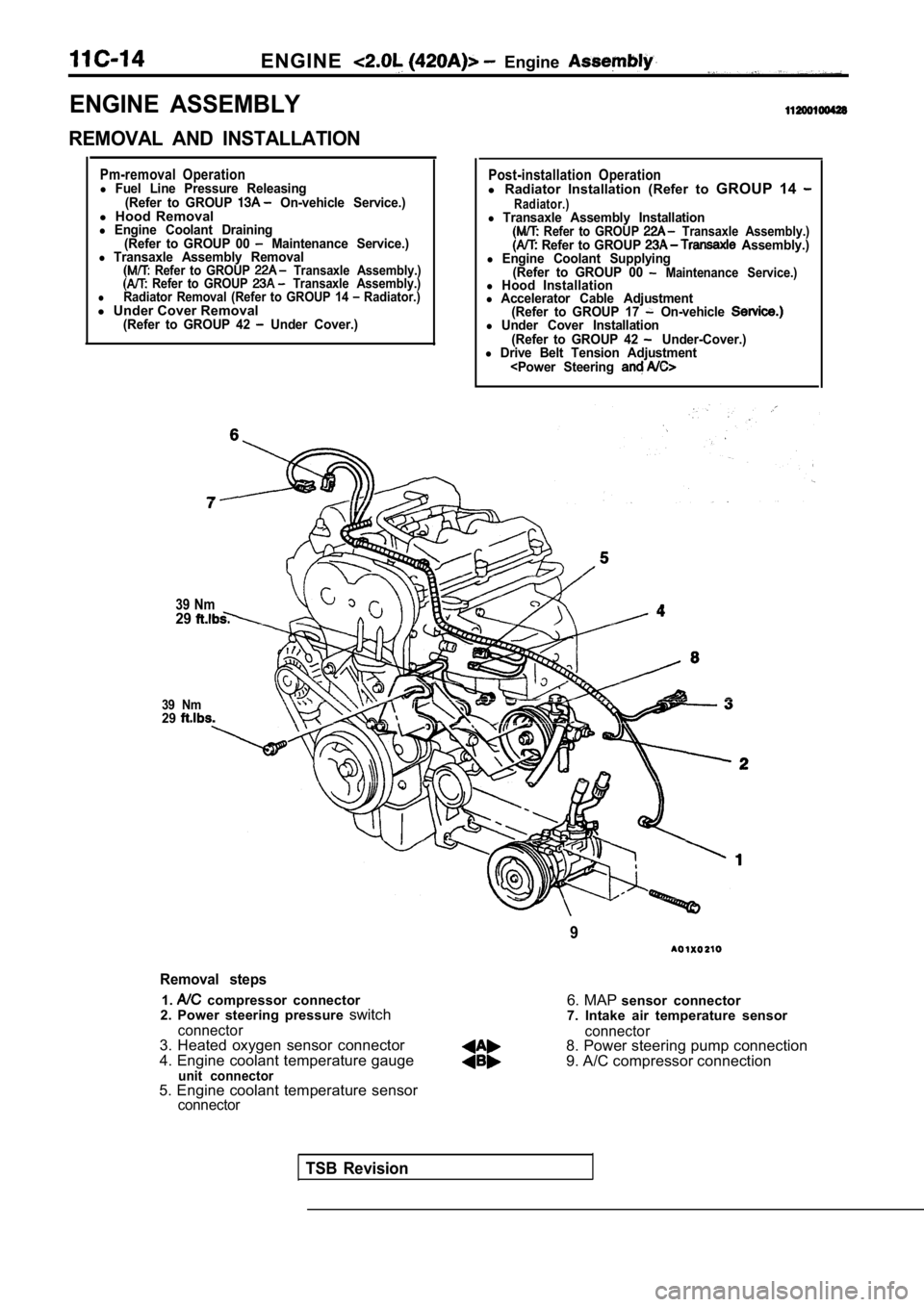

ENGINE Engine

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Pm-removal Operationl Fuel Line Pressure Releasing(Refer to GROUP On-vehicle Service.)l Hood Removall Engine Coolant Draining

(Refer to GROUP 00 Maintenance Service.)l Transaxle Assembly Removal Refer to GROUP Transaxle Assembly.) Refer to GROUP Transaxle Assembly.)lRadiator Removal (Refer to GROUP 14 Radiator.)l Under Cover Removal(Refer to GROUP 42 Under Cover.)

39 Nm29

39 Nm29

Post-installation Operationl Radiator Installation (Refer to GROUP 14 Radiator.)l Transaxle Assembly Installation Refer to GROUP Transaxle Assembly.) Refer to GROUP Assembly.)l Engine Coolant Supplying

(Refer to GROUP 00 Maintenance Service.)l Hood Installationl Accelerator Cable Adjustment(Refer to GROUP 17 On-vehicle l Under Cover Installation

(Refer to GROUP 42 Under-Cover.)l Drive Belt Tension Adjustment

Removal steps

1. compressor connector

2. Power steering pressure switch

connector3. Heated oxygen sensor connector

4. Engine coolant temperature gauge

unit connector

6. MAP sensor connector

7. Intake air temperature sensor

connector8. Power steering pump connection

9. A/C compressor connection

5. Engine coolant temperature sensor

connector

TSB Revision

Page 189 of 2103

ENGINE Crankshaft

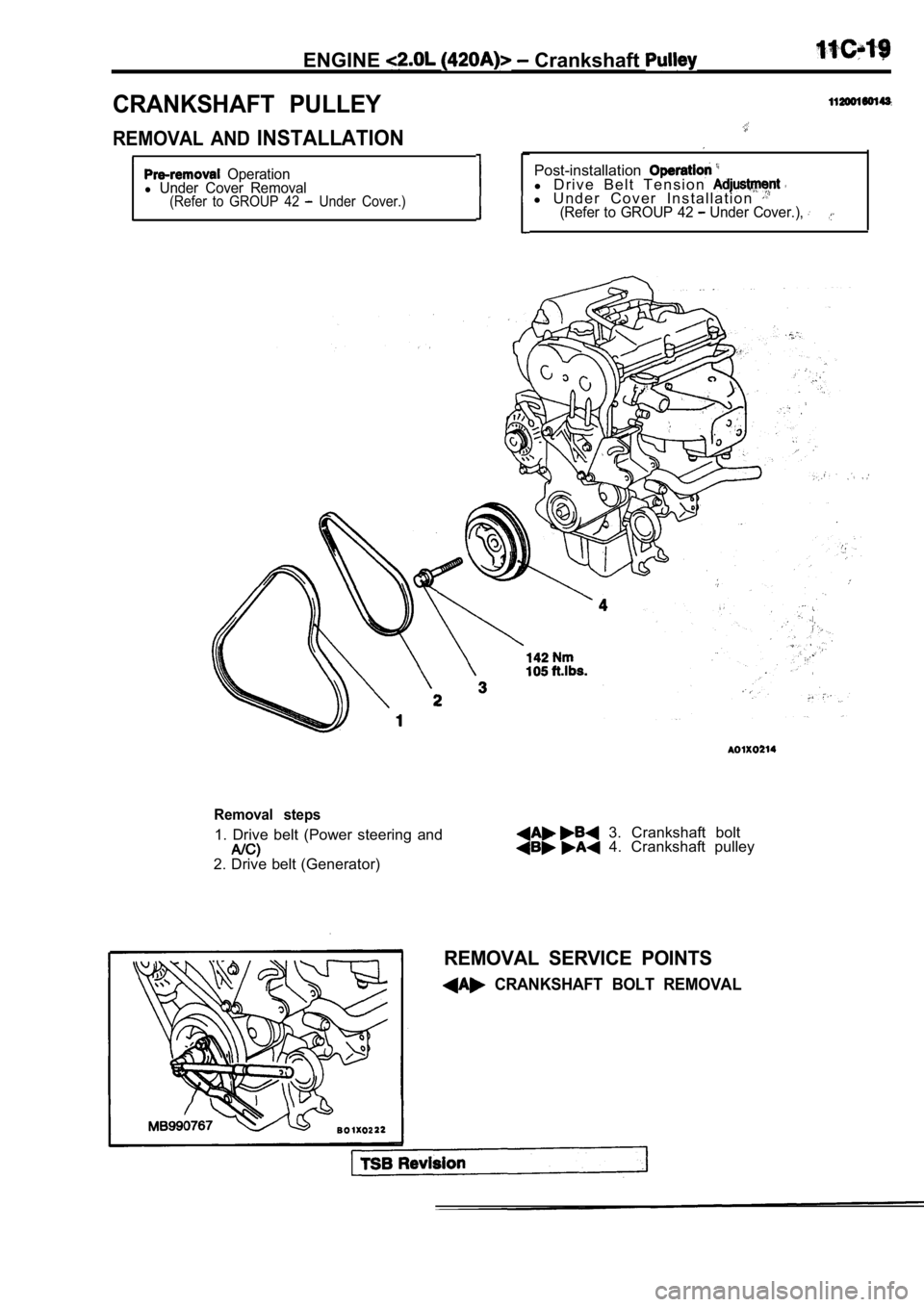

CRANKSHAFT PULLEY

REMOVAL AND INSTALLATION

Operationl Under Cover Removal(Refer to GROUP 42 Under Cover.)

Post-installationl D r i v e B e l t T e n s i o n l U n d e r C o v e r I n s t a l l a t i o n (Refer to GROUP 42 Under Cover.),

Removal steps

1. Drive belt (Power steering and

2. Drive belt (Generator)

3. Crankshaft bolt 4. Crankshaft pulley

REMOVAL SERVICE POINTS

CRANKSHAFT BOLT REMOVAL