belt MITSUBISHI SPYDER 1990 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 99 of 2103

E N G I N E

(3) Install the timing belt so as not to be’

the sprockets, by the

Cautidn ,

If the timing belt is to be it that

the mark indicates the

,

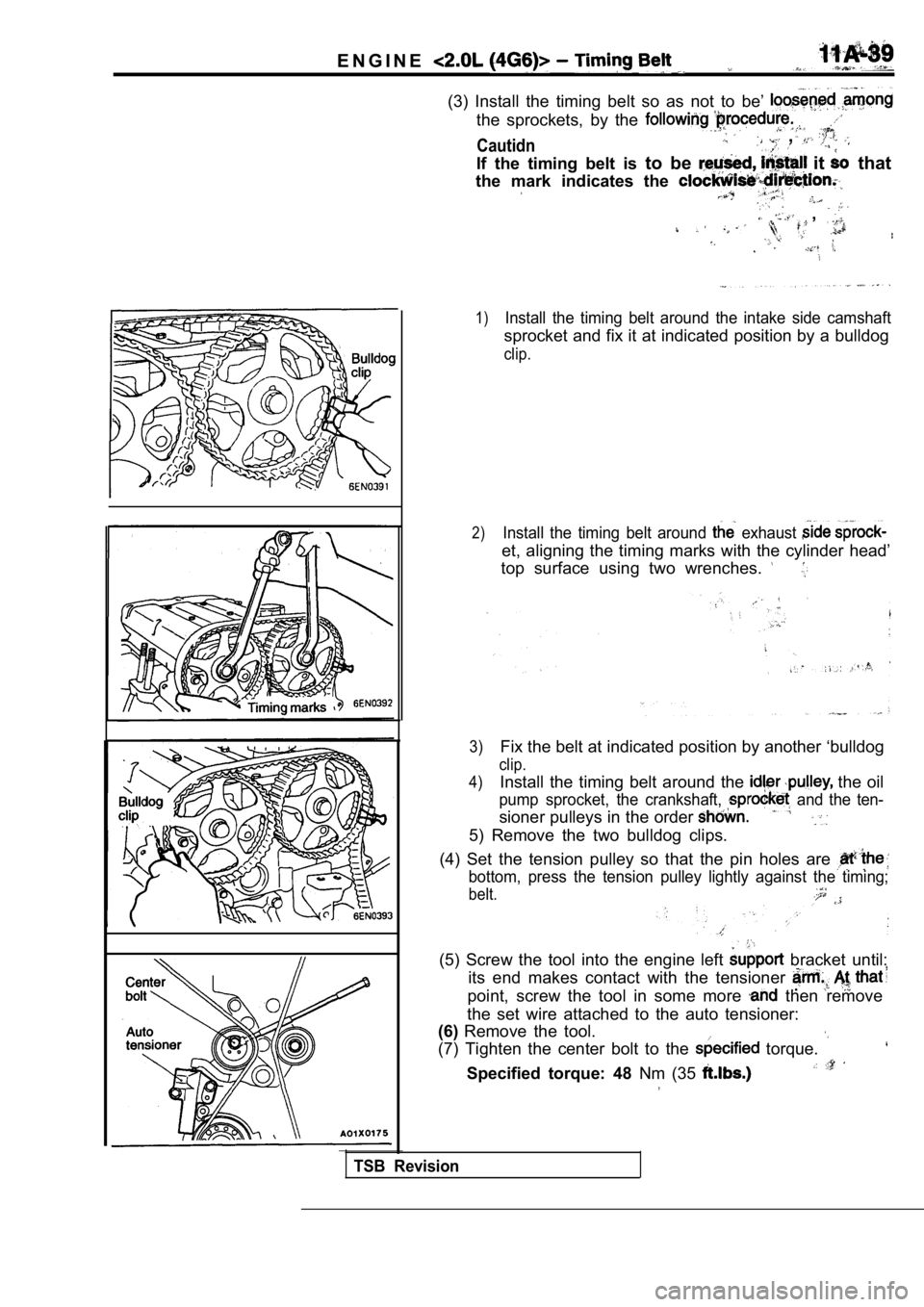

1)Install the timing belt around the intake side cams haft

sprocket and fix it at indicated position by a bulldog

clip.

2)Install the timing belt around exhaust

et, aligning the timing marks with the cylinder hea d’

top surface using two wrenches.

3)Fix the belt at indicated position by another ‘bull dog

clip.

4)

Install the timing belt around the the oil

pump sprocket, the crankshaft, and the ten-

sioner pulleys in the order

5) Remove the two bulldog clips.

(4) Set the tension pulley so that the pin holes ar e

bottom, press the tension pulley lightly against the timing;

belt.

(5) Screw the tool into the engine left bracket until:

its end makes contact with the tensioner

point, screw the tool in some more then remove

the set wire attached to the auto tensioner:

(6) Remove the tool.

(7) Tighten the center bolt to the

torque.

Specified torque: 48 Nm (35

TSB Revision

Page 100 of 2103

E N G I N E Belt

Auto tensioner

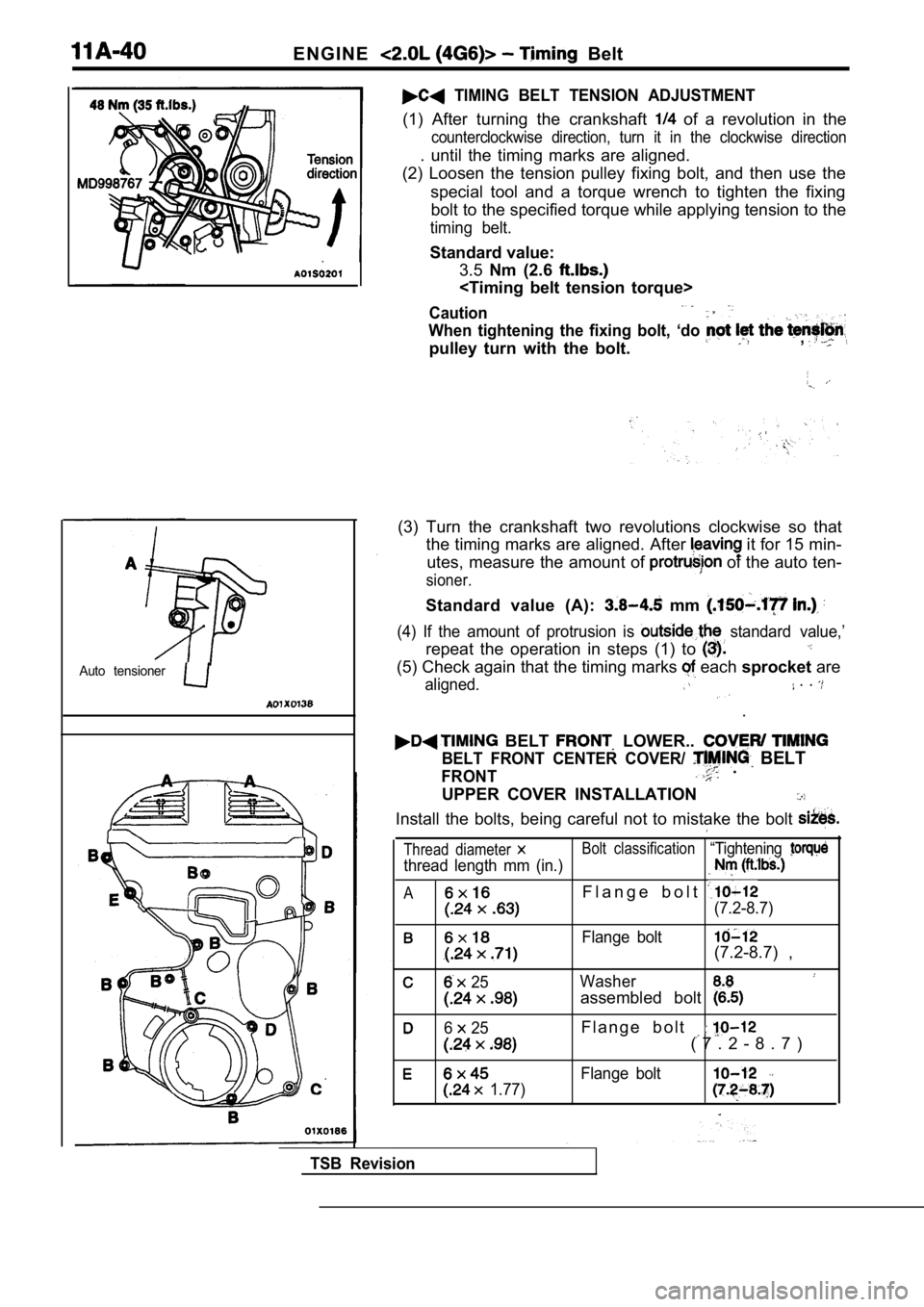

TIMING BELT TENSION ADJUSTMENT

(1) After turning the crankshaft of a revolution in the

counterclockwise direction, turn it in the clockwise direction

. until the timing marks are aligned.

(2) Loosen the tension pulley fixing bolt, and then use the

special tool and a torque wrench to tighten the fix ing

bolt to the specified torque while applying tension to the

timing belt.

Standard value:

3.5 Nm (2.6

Caution

When tightening the fixing bolt, ‘do

pulley turn with the bolt.,

(3) Turn the crankshaft two revolutions clockwise s o that

the timing marks are aligned. After

it for 15 min-

utes, measure the amount of

of the auto ten-

sioner.

Standard value (A): mm

(4) If the amount of protrusion is standard value,’

repeat the operation in steps (1) to

(5) Check again that the timing marks each sprocket are

aligned. . .

.

BELT LOWER..

BELT FRONT CENTER COVER/ BELT

FRONT .

UPPER COVER INSTALLATION

Install the bolts, being careful not to mistake the bolt

Thread diameter Bolt classification“Tightening

thread length mm (in.)

AF l a n g e b o l t

(7.2-8.7)

Flange bolt(7.2-8.7) ,

25Washer

assembled bolt

6 25F l a n g e b o l t

( 7 . 2 - 8 . 7 )

Flange bolt

1.77)

TSB Revision

Page 101 of 2103

ENGINE Timing

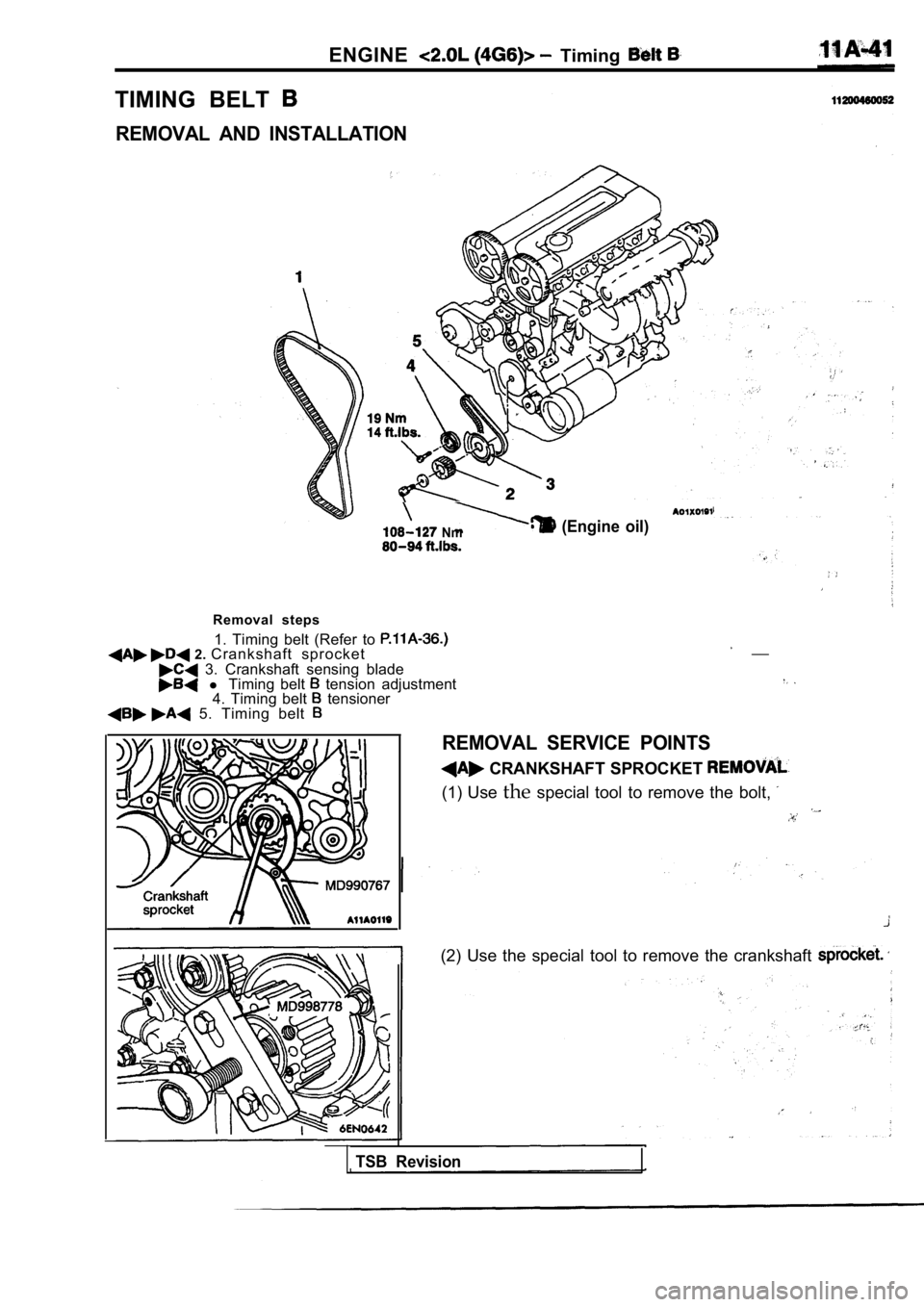

TIMING BELT

REMOVAL AND INSTALLATION

(Engine oil) Nm

Removal steps1. Timing belt (Refer to

2. Crankshaft sprocket 3. Crankshaft sensing blade l Timing belt tension adjustment

4. Timing belt tensioner 5. Timing belt

__

REMOVAL SERVICE POINTS

CRANKSHAFT SPROCKET

(1) Use thespecial tool to remove the bolt,

(2) Use the special tool to remove the crankshaft

TSB Revision

Page 102 of 2103

ENGINE Timing Belt

CounterbalanceBelt tension side

Timingmarks

Belt tension side tension side

installation bolt

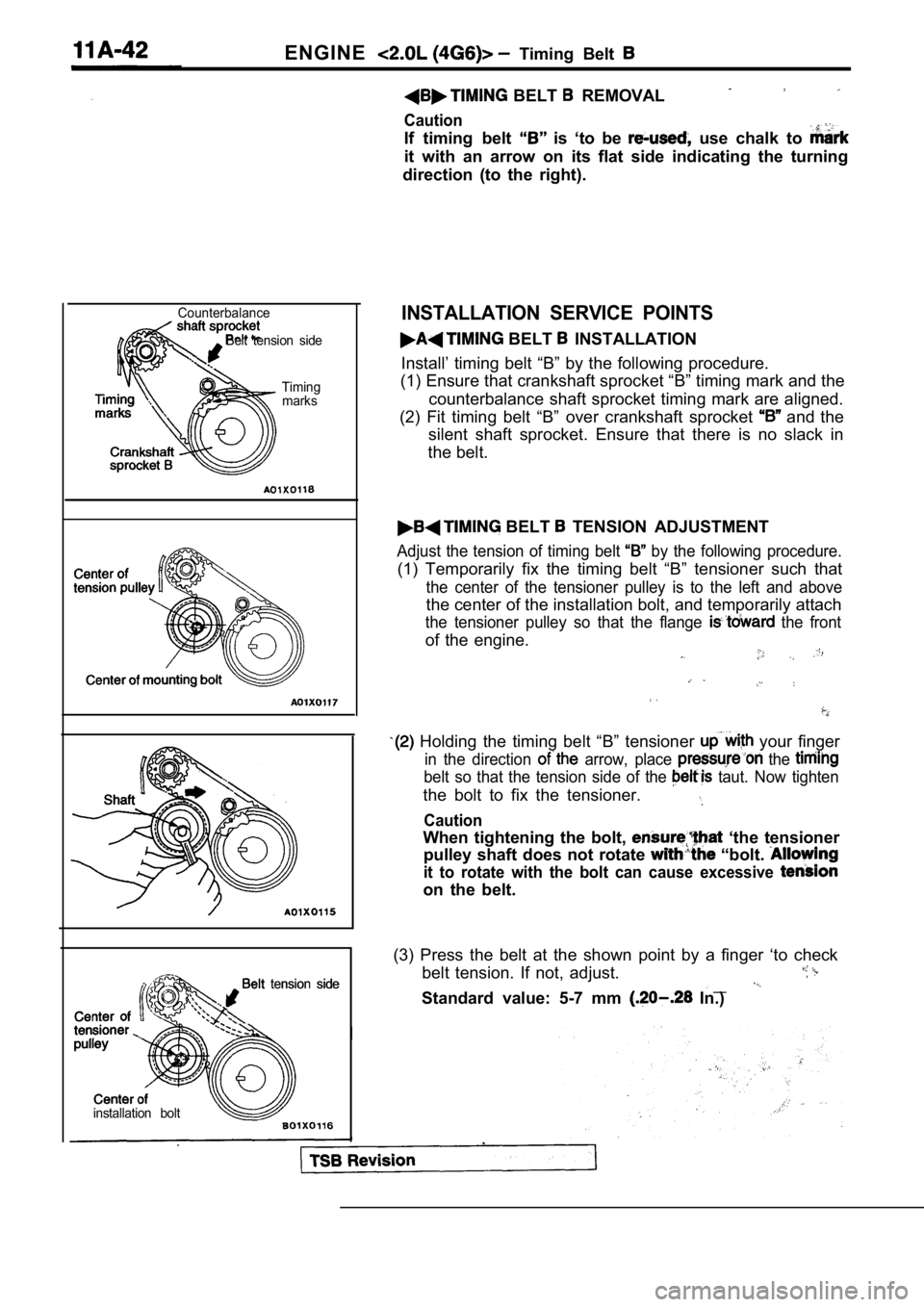

BELT REMOVAL

Caution

If timing belt is ‘to be use chalk to

it with an arrow on its flat side indicating the tu rning

direction (to the right).

INSTALLATION SERVICE POINTS

BELT INSTALLATION

Install’ timing belt “B” by the following procedure .

(1) Ensure that crankshaft sprocket “B” timing mark and the

counterbalance shaft sprocket timing mark are align ed.

(2) Fit timing belt “B” over crankshaft sprocket

and the

silent shaft sprocket. Ensure that there is no slac k in

the belt.

BELT TENSION ADJUSTMENT

Adjust the tension of timing belt by the following procedure.

(1) Temporarily fix the timing belt “B” tensioner s uch that

the center of the tensioner pulley is to the left and above

the center of the installation bolt, and temporarily attach

the tensioner pulley so that the flange the front

of the engine.

Holding the timing belt “B” tensioner your finger

in the direction arrow, place the

belt so that the tension side of the taut. Now tighten

the bolt to fix the tensioner.

Caution

When tightening the bolt, ‘the tensioner

pulley shaft does not rotate

“bolt.

it to rotate with the bolt can cause excessive

on the belt.

(3) Press the belt at the shown point by a finger ‘ to check

belt tension. If not, adjust.

__Standard value: 5-7 mm In.)

Page 103 of 2103

ENGINE Timing Belt

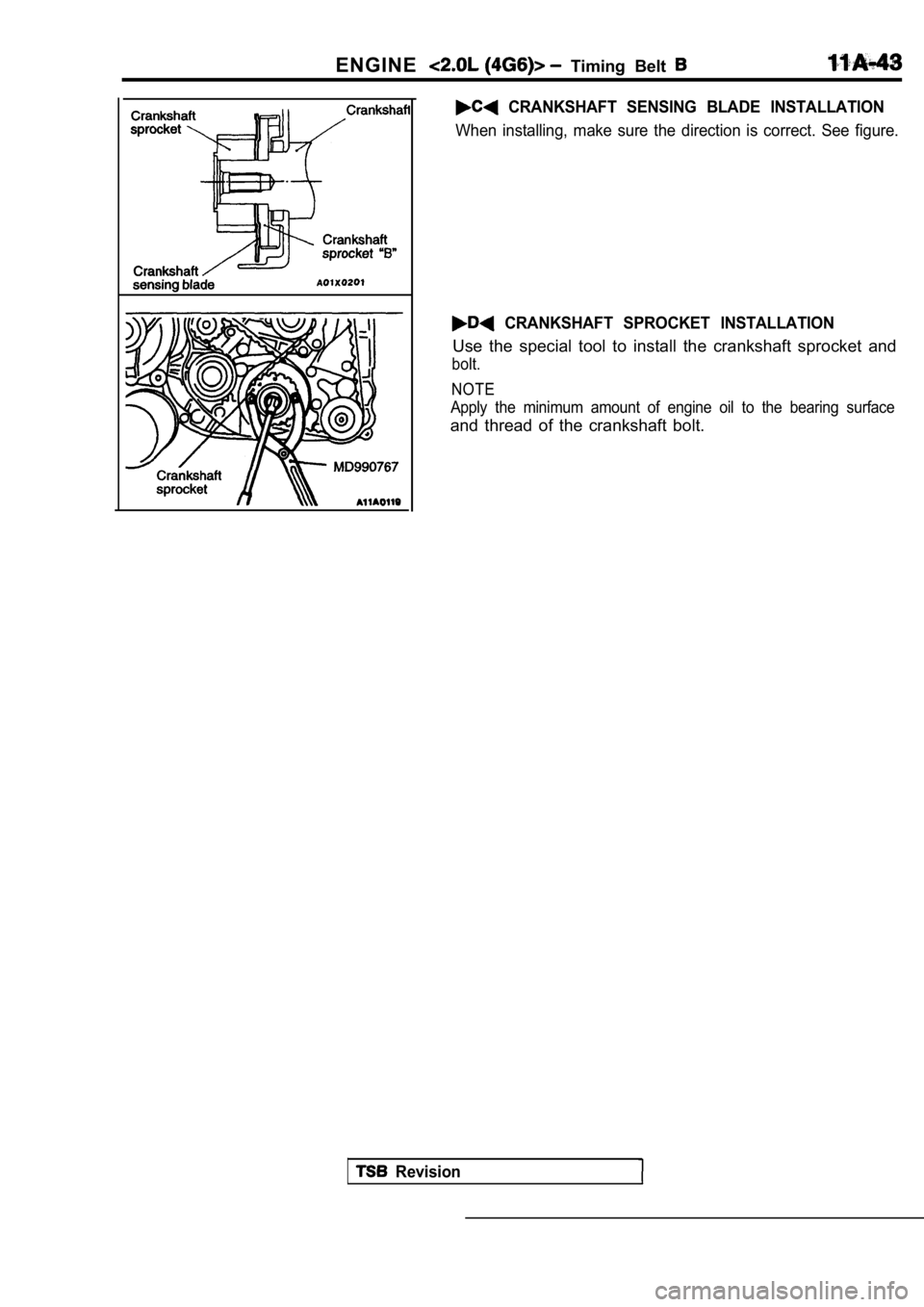

CRANKSHAFT SENSING BLADE INSTALLATION

When installing, make sure the direction is correct. See figure.

CRANKSHAFT SPROCKET INSTALLATION

Use the special tool to install the crankshaft spro cket and

bolt.

NOTE

Apply the minimum amount of engine oil to the beari ng surface

and thread of the crankshaft bolt.

Revision

Page 105 of 2103

CONTENTS

BRACKET65

CRANKSHAFT, FLYWHEEL ANDDRIVE PLATE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

CYLINDER HEAD AND VALVES . . . . . . . . . . . 36

EXHAUST MANIFOLD AND

WATER PUMP. . . . . . . * . . . . . . . . . . . . . . . . . . . .29

FRONT CASE, COUNTERBALANCE

SHAFT AND OIL PAN . . . . . . . . . . . . . . . . . . . . . 42

FUEL AND EMISSION CONTROL

PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

GENERAL INFORMATION. . . . . . . . . . . . . . . . . .2

General Specifications . . . . . . . . . . . . . . . . . . , . . . . .2

GENERATOR IGNITION SYSTEM. . . . .11

INTAKE MANIFOLD. . . . . . . . . . . . . . . . . . . . . .

PISTON AND CONNECTING ROD..

. . . . . . . .51

ROCKER ARMS AND CAMSHAFT. . . . . . . .

SPECIAL TOOLS

. . . . . . . . . . . . . . . . . . . . . . . . . . .8

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . .3

Rework Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . .4

Sealant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . ..

Service Specifications. . . . . . . . . . . . . . . . . . . ....3

Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . .5

TIMING BELT

. . . . . . . . . . . . . . . . . .. . . . . . . . .

,

Page 109 of 2103

ENGINE OVERHAUL

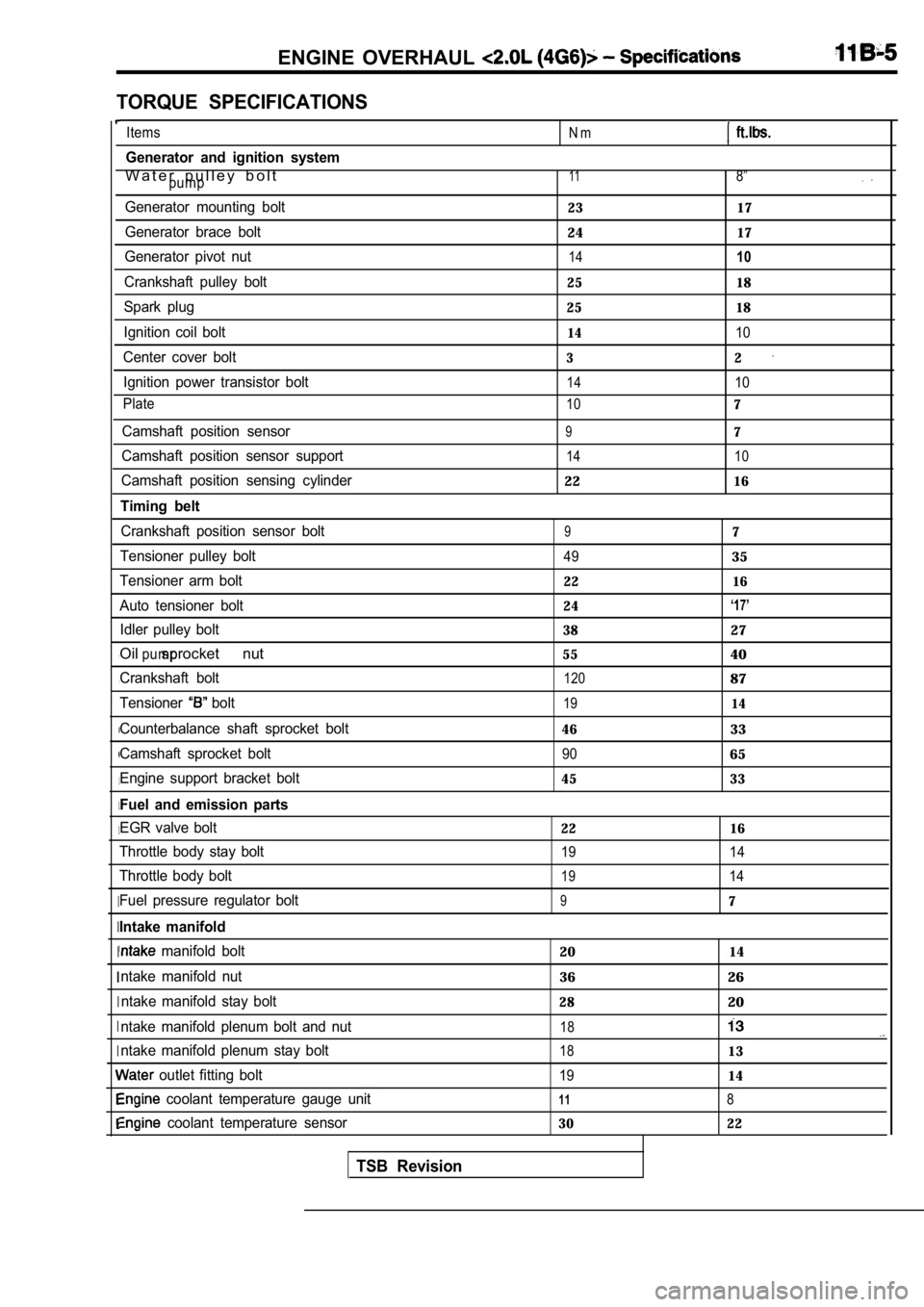

TORQUE SPECIFICATIONS

, ,

I

I I

I

I I

I

I

I I

Items

Generator and ignition system

W a t e r p u l l e y b o l tpump

Generator mounting bolt

Generator brace bolt

Generator pivot nut

Crankshaft pulley bolt

Spark plug

Ignition coil bolt

Center cover bolt Ignition power transistor bolt

Plate

Camshaft position sensor

Camshaft position sensor support

Camshaft position sensing cylinder

Timing belt

Crankshaft position sensor bolt

Tensioner pulley bolt

Tensioner arm bolt

Auto tensioner bolt Idler pulley bolt

Oil sprocket nutpump

Crankshaft bolt

Tensioner

bolt

Counterbalance shaft sprocket bolt

Camshaft sprocket bolt

Engine support bracket bolt

Fuel and emission parts

EGR valve bolt

Throttle body stay bolt

Throttle body bolt

Fuel pressure regulator bolt

Intake manifold

manifold bolt

ntake manifold nut ntake manifold stay bolt

ntake manifold plenum bolt and nut

ntake manifold plenum stay bolt

outlet fitting bolt

coolant temperature gauge unit

coolant temperature sensor

TSB Revision

N m

118”

23 17

2417

1410

25 18

25 18

1410

32

1410

107

97

14 10

2216

97

4935

22 16

24

‘17’

3827

5540

12087

1914

4633

9065

45 33

22 16

19 14

1914

97

2014

3626

2820

18

1813

1914

118

30 22

Page 115 of 2103

ENGINE OVERHAUL and 11

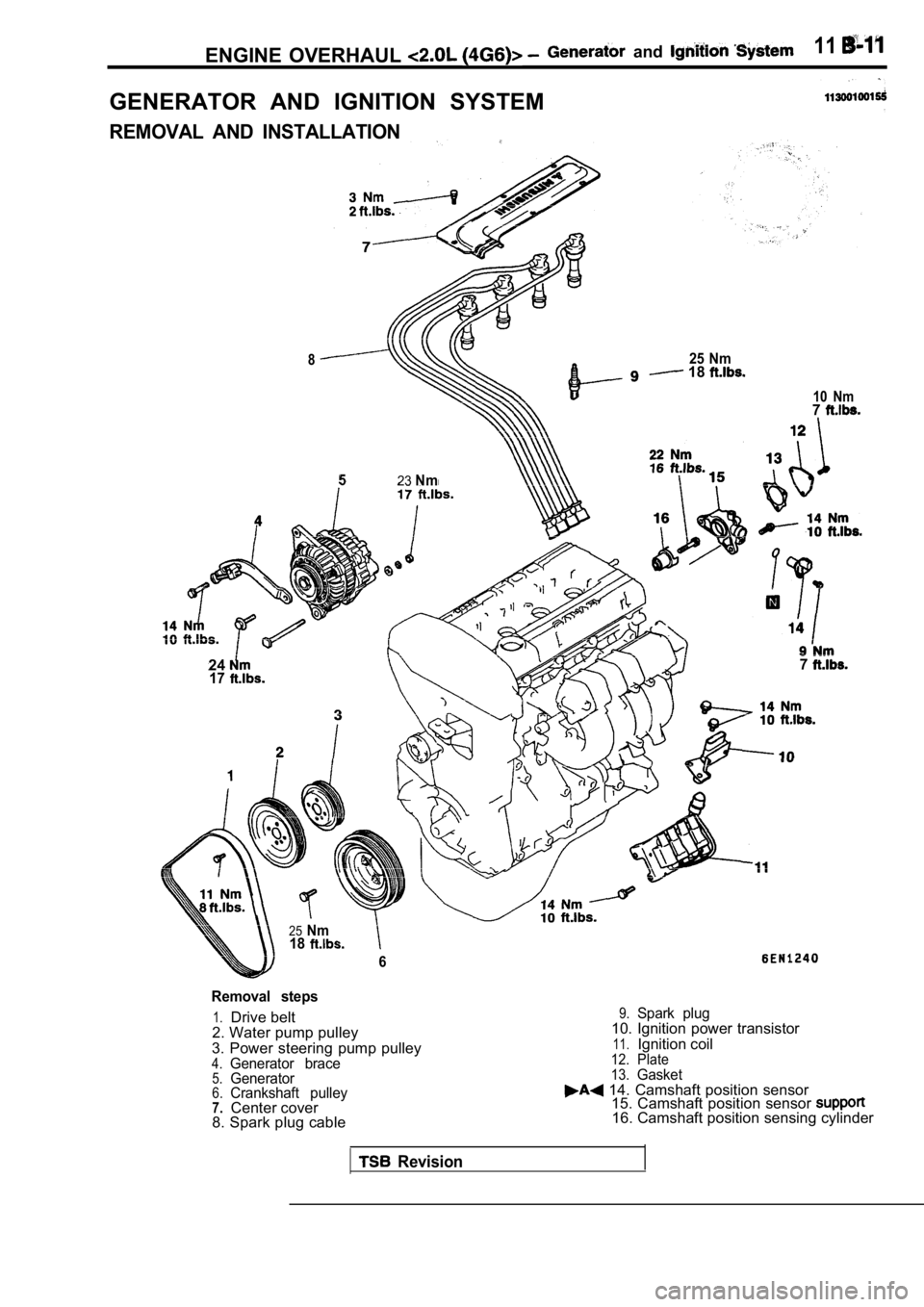

GENERATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION

825 Nm 18

523Nm

24177

25Nm18

6

10 Nm7

Removal steps

1.Drive belt

2. Water pump pulley

3. Power steering pump pulley

4.Generator brace5.Generator6.Crankshaft pulley7.Center cover

8. Spark plug cable

9.Spark plug10. Ignition power transistor

11.Ignition coil12. Plate

13.Gasket 14. Camshaft position sensor 15. Camshaft position sensor

16. Camshaft position sensing cylinder

Revision

Page 117 of 2103

ENGINE OVERHAUL

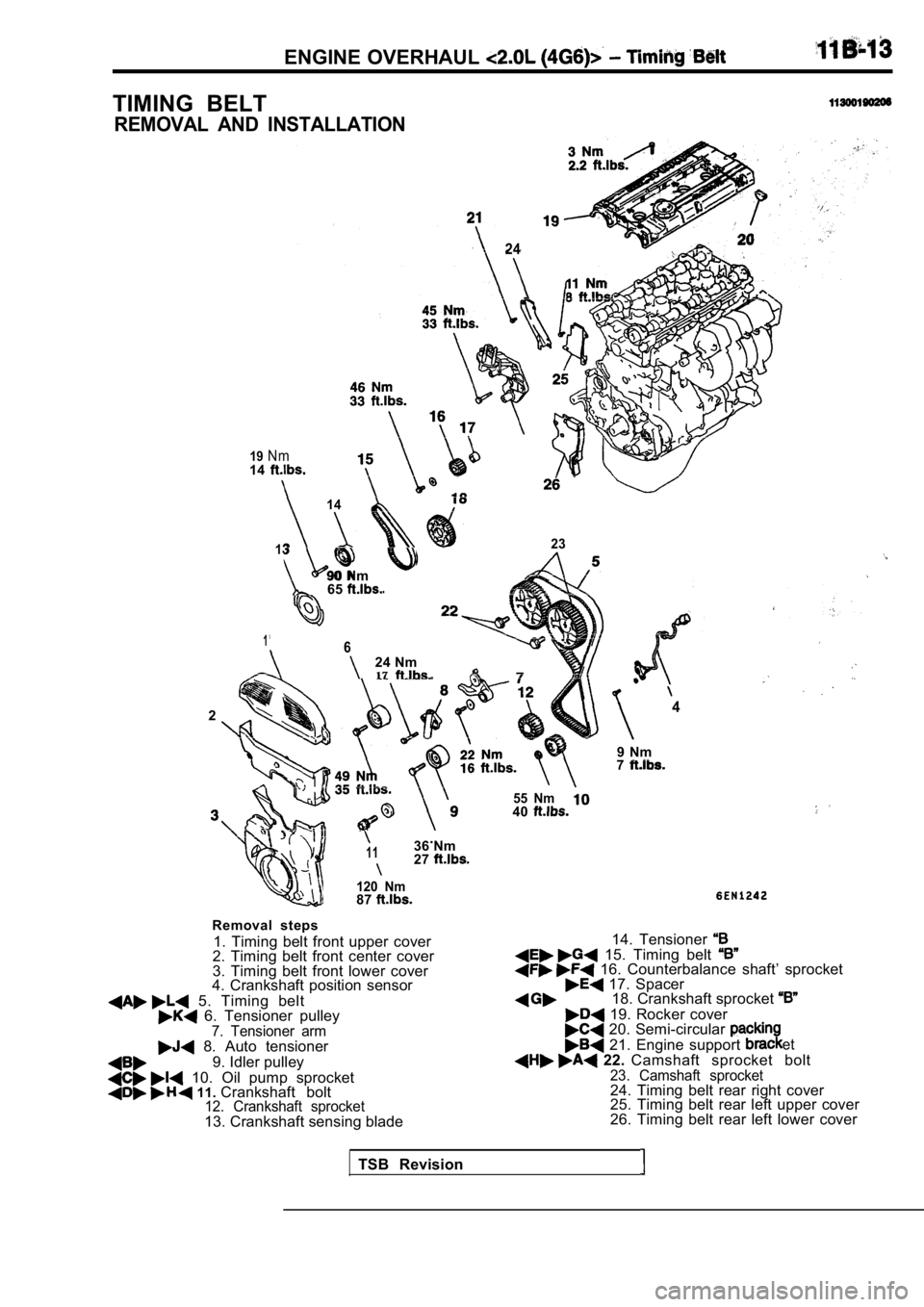

TIMING BELT

REMOVAL AND INSTALLATION

19N m

24

14

14

13

90 Nm65

23

1624 Nm17

24

9 Nm7

.1136 Nm27

120 Nm87

Removal steps

1. Timing belt front upper cover

2. Timing belt front center cover

3. Timing belt front lower cover

4. Crankshaft position sensor

5. Timing belt 6. Tensioner pulley7. Tensioner arm 8. Auto tensioner

9. Idler pulley

10. Oil pump sprocket 11. Crankshaft bolt12. Crankshaft sprocket13. Crankshaft sensing blade

55 Nm40

14. Tensioner 15. Timing belt 16. Counterbalance shaft’ sprocket 17. Spacer18. Crankshaft sprocket

19. Rocker cover 20. Semi-circular

21. Engine support et

22. Camshaft sprocket bolt23. Camshaft sprocket24. Timing belt rear right cover

25. Timing belt rear left upper cover

26. Timing belt rear left lower cover

TSB Revision

Page 118 of 2103

OVERHAUL Timing. Belt

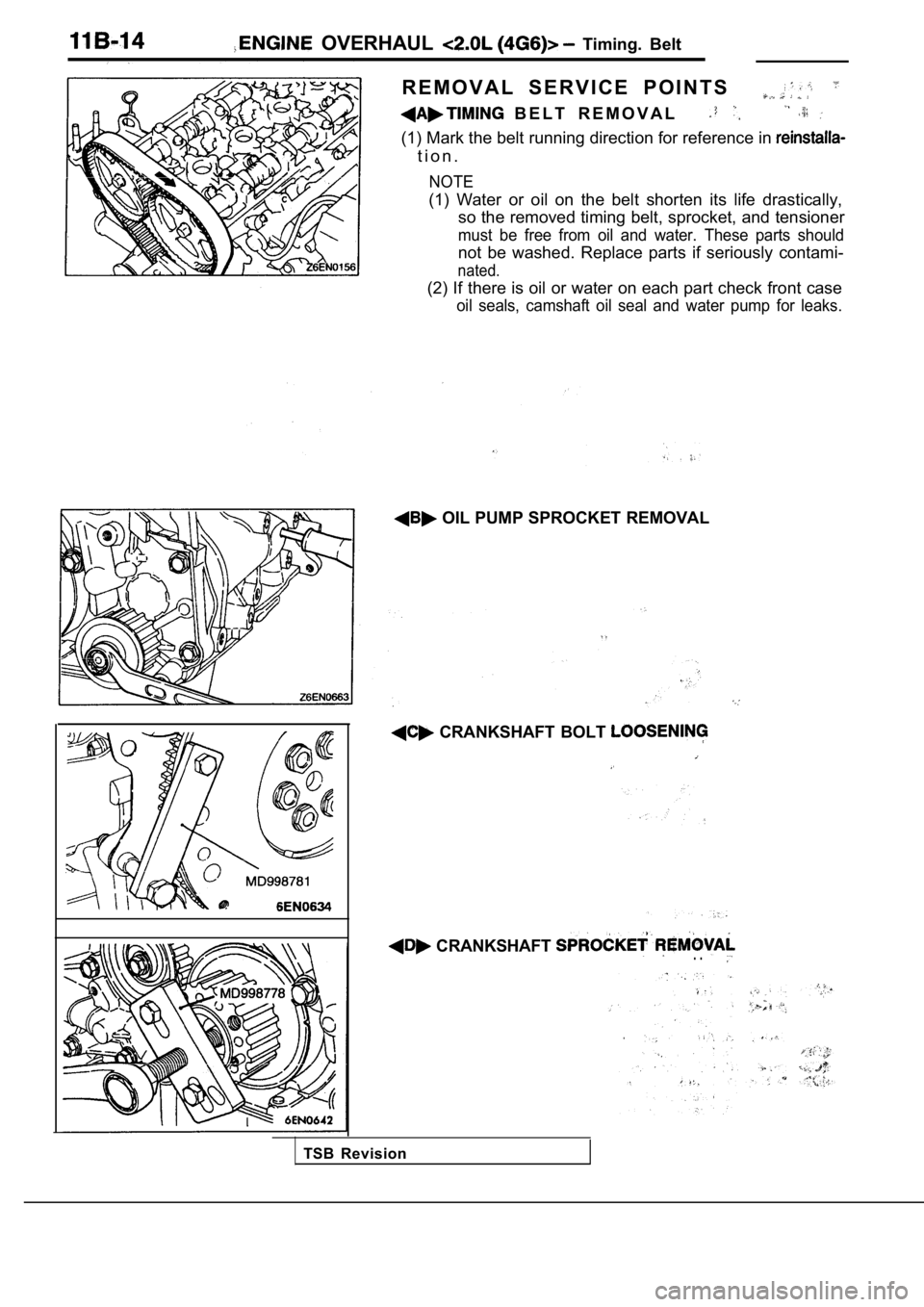

R E M O V A L S E R V I C E P O I N T S

B E L T R E M O V A L

(1) Mark the belt running direction for reference in

t i o n .

NOTE

(1) Water or oil on the belt shorten its life drast ically,

so the removed timing belt, sprocket, and tensioner

must be free from oil and water. These parts should

not be washed. Replace parts if seriously contami-

nated.

(2) If there is oil or water on each part check fro nt case

oil seals, camshaft oil seal and water pump for lea ks.

OIL PUMP SPROCKET REMOVAL

CRANKSHAFT BOLT

CRANKSHAFT . .

TSB Revision