ECU MITSUBISHI SPYDER 1990 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1107 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> Lock

LOCK

I N S T A L L A T I O N

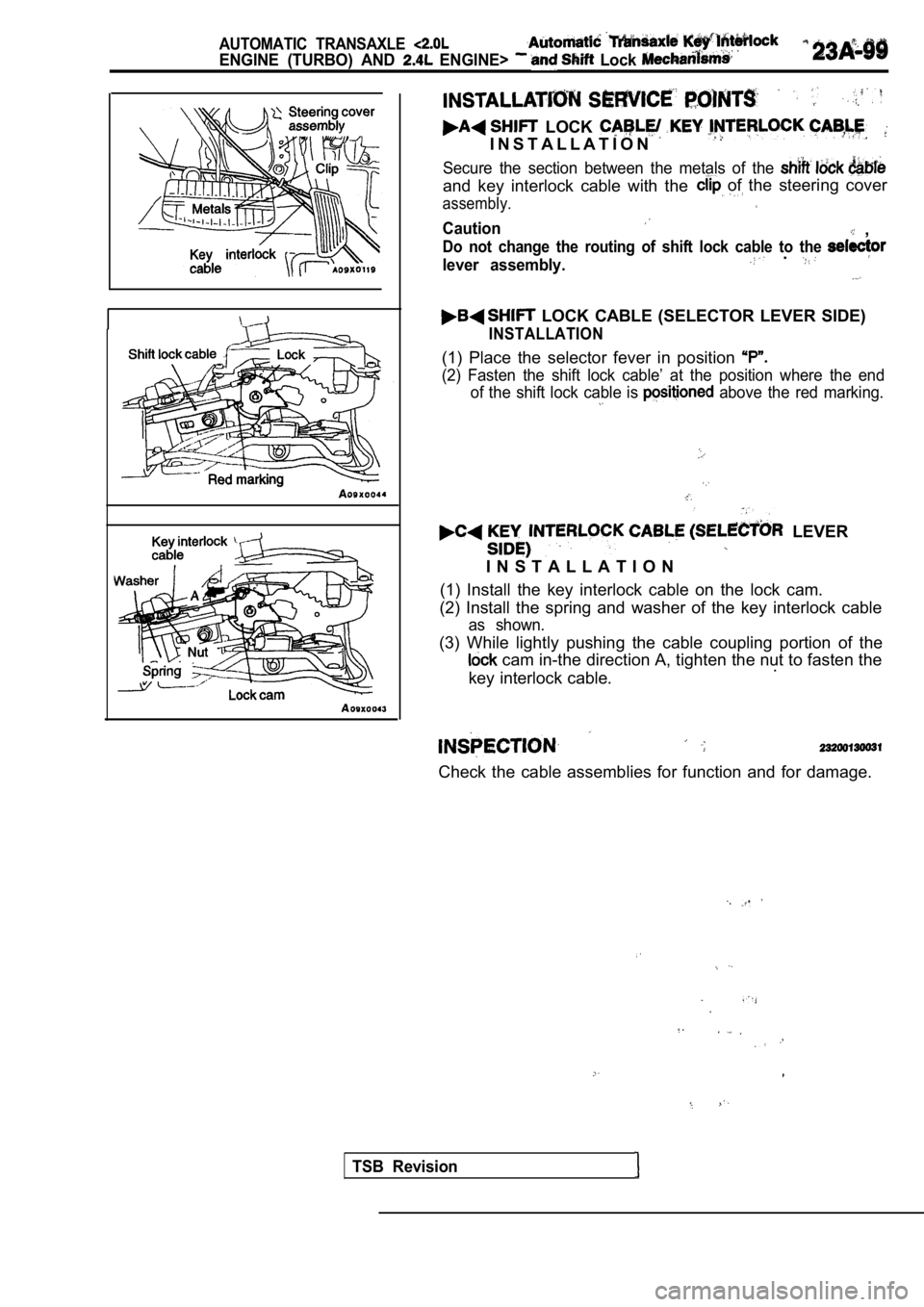

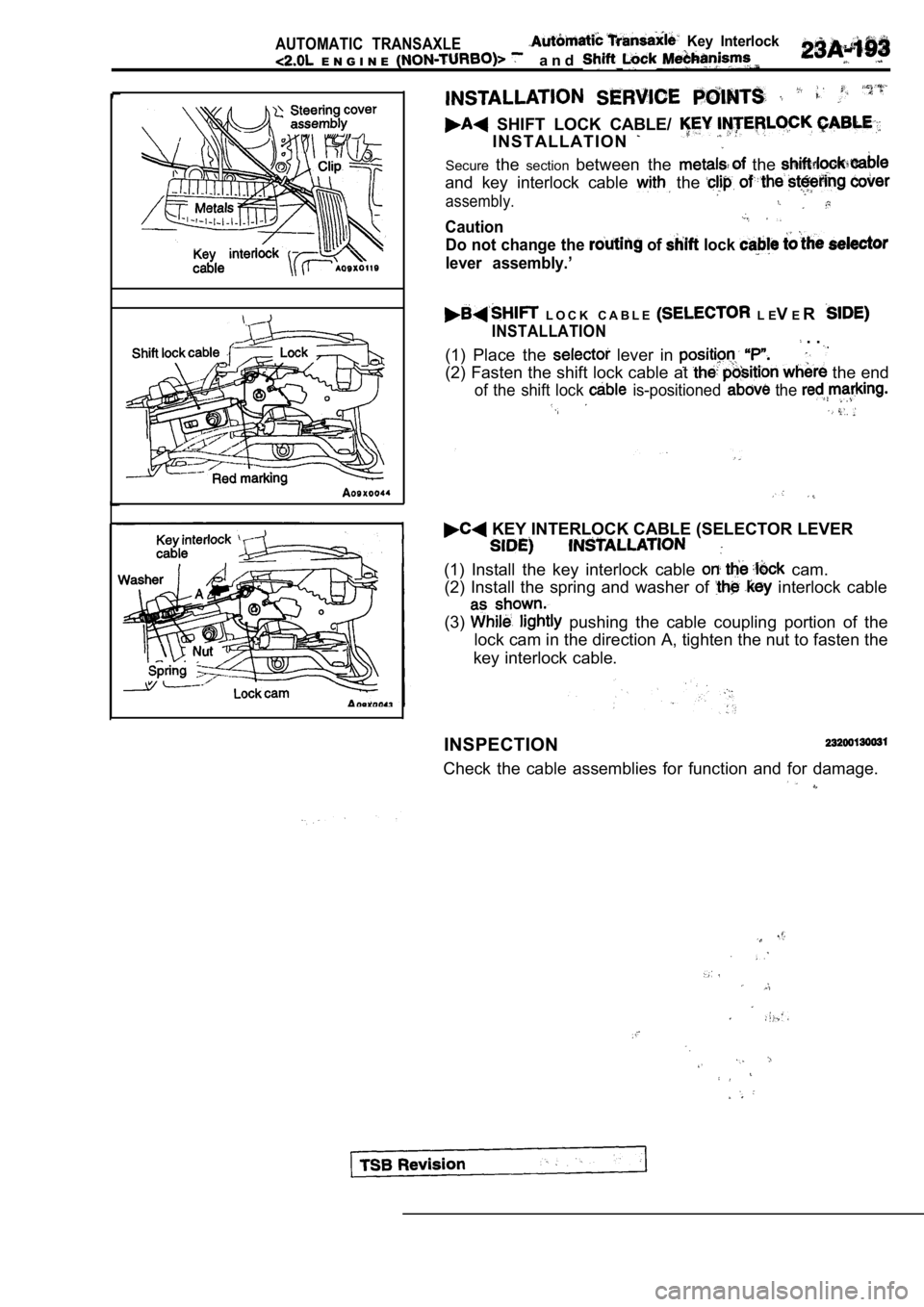

Secure the section between the metals of the

and key interlock cable with the of the steering cover

assembly.

Caution ,

Do not change the routing of shift lock cable to the

lever assembly. .

LOCK CABLE (SELECTOR LEVER SIDE)

INSTALLATION

(1) Place the selector fever in position

(2) Fasten the shift lock cable’ at the position where the end

of the shift lock cable is

above the red marking.

LEVER

I N S T A L L A T I O N

(1) Install the key interlock cable on the lock cam .

(2) Install the spring and washer of the key interl ock cable

as shown.

(3) While lightly pushing the cable coupling portio n of the

cam in-the direction A, tighten the nut to fasten the

key interlock cable. .

Check the cable assemblies for function and for dam

age.

TSB Revision

Page 1113 of 2103

AUTOMATIC TRANSAXLE . .

ENGINE (TURBO) AND ENGINE> Assembly

Front roll

stopper

bracket

ber

DRIVE PLATE

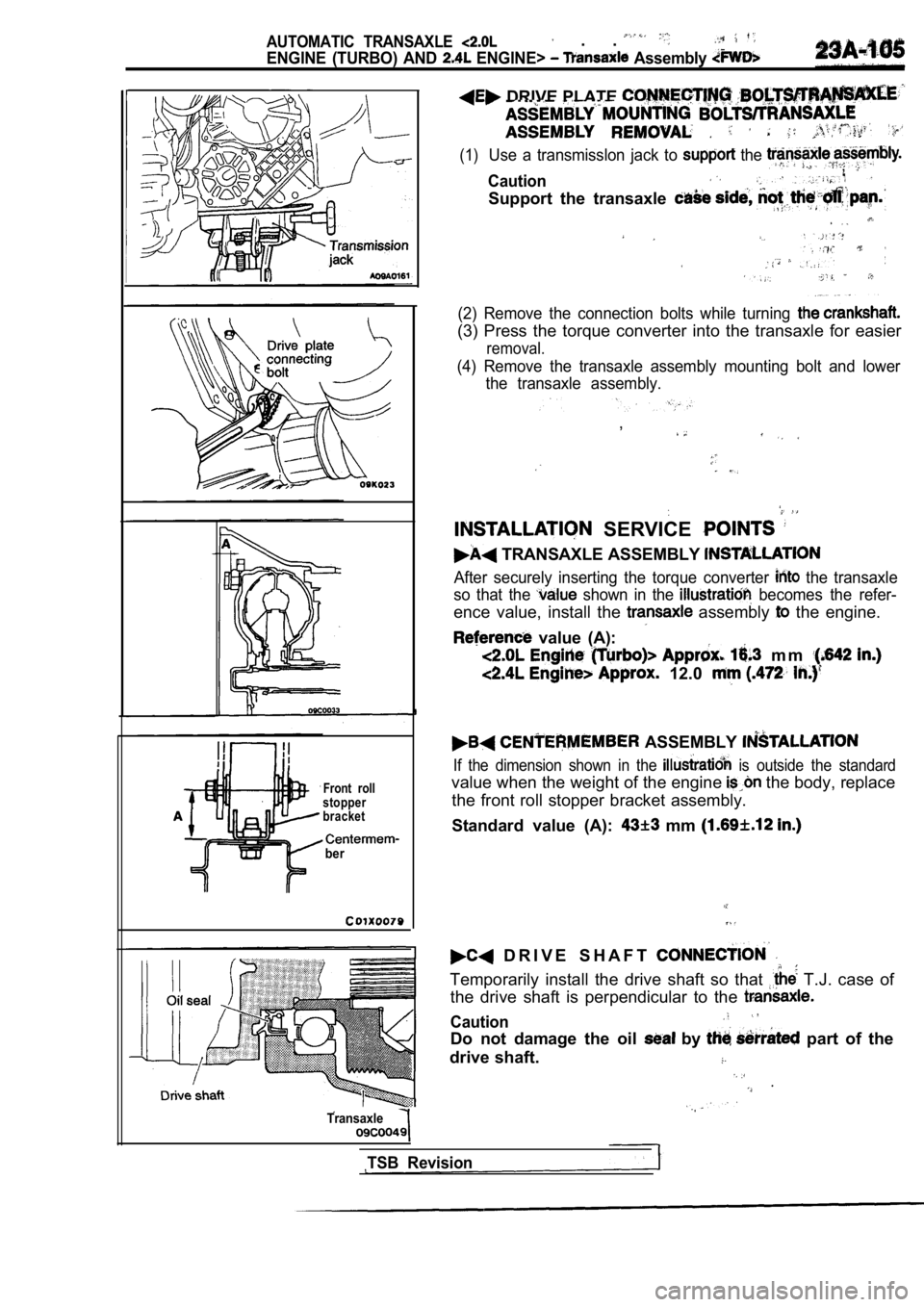

(1)Use a transmisslon jack to the ,,Caution

Support the transaxle

(2) Remove the connection bolts while turning

(3) Press the torque converter into the transaxle f or easier

removal.

(4) Remove the transaxle assembly mounting bolt and lower

the transaxle assembly.

,

SERVICE

TRANSAXLE ASSEMBLY

After securely inserting the torque converter the transaxle

so that the

shown in the becomes the refer-

ence value, install the assembly the engine.

value (A):

m m

12.0

ASSEMBLY

If the dimension shown in the is outside the standard

value when the weight of the engine the body, replace

the front roll stopper bracket assembly.

Standard value (A):

mm

D R I V E S H A F T

Temporarily install the drive shaft so that T.J. case of

the drive shaft is perpendicular to the

Caution

Do not damage the oil by part of the

drive shaft.

Transaxle

TSB Revision

Page 1116 of 2103

.AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> Transaxle Assembly

,

Cord

N i t

TSB Revision

REMOVAL SERVICE POINTS

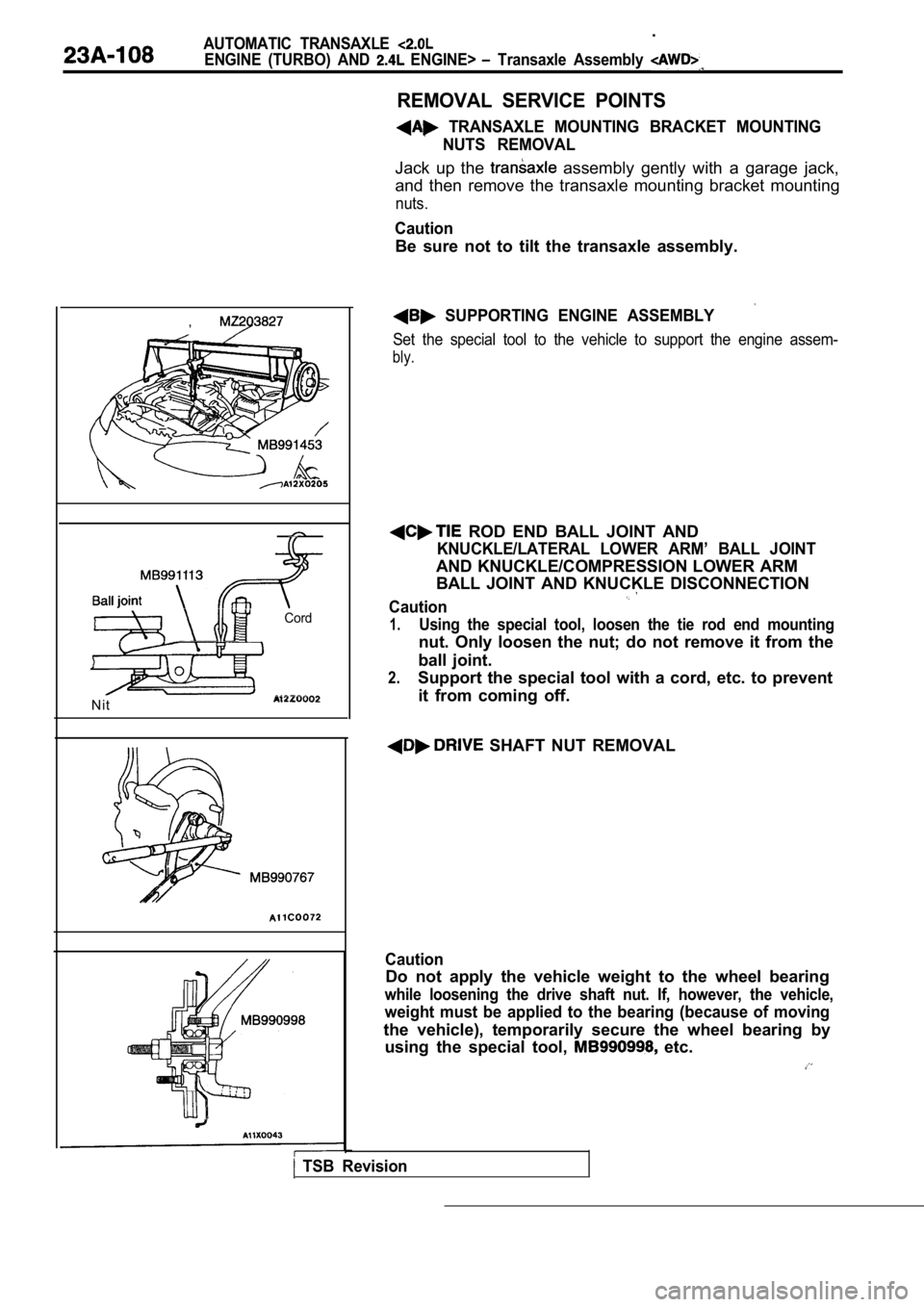

TRANSAXLE MOUNTING BRACKET MOUNTINGNUTS REMOVAL

Jack up the assembly gently with a garage jack,

and then remove the transaxle mounting bracket moun ting

nuts.

Caution

Be sure not to tilt the transaxle assembly.

SUPPORTING ENGINE ASSEMBLY

Set the special tool to the vehicle to support the engine assem-

bly.

ROD END BALL JOINT AND

KNUCKLE/LATERAL LOWER ARM’ BALL JOINT

AND KNUCKLE/COMPRESSION LOWER ARM

BALL JOINT AND KNUCKLE DISCONNECTION

Caution

1.Using the special tool, loosen the tie rod end moun ting

nut. Only loosen the nut; do not remove it from the

ball joint.

2.Support the special tool with a cord, etc. to preve nt

it from coming off.

SHAFT NUT REMOVAL

Caution

Do not apply the vehicle weight to the wheel bearin g

while loosening the drive shaft nut. If, however, the vehicle,

weight must be applied to the bearing (because of m oving

the vehicle), temporarily secure the wheel bearing by

using the special tool,

etc.

Page 1118 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> Transaxle Assembly

Front roll

I - -

stopper

bracket

Centermember

Washer

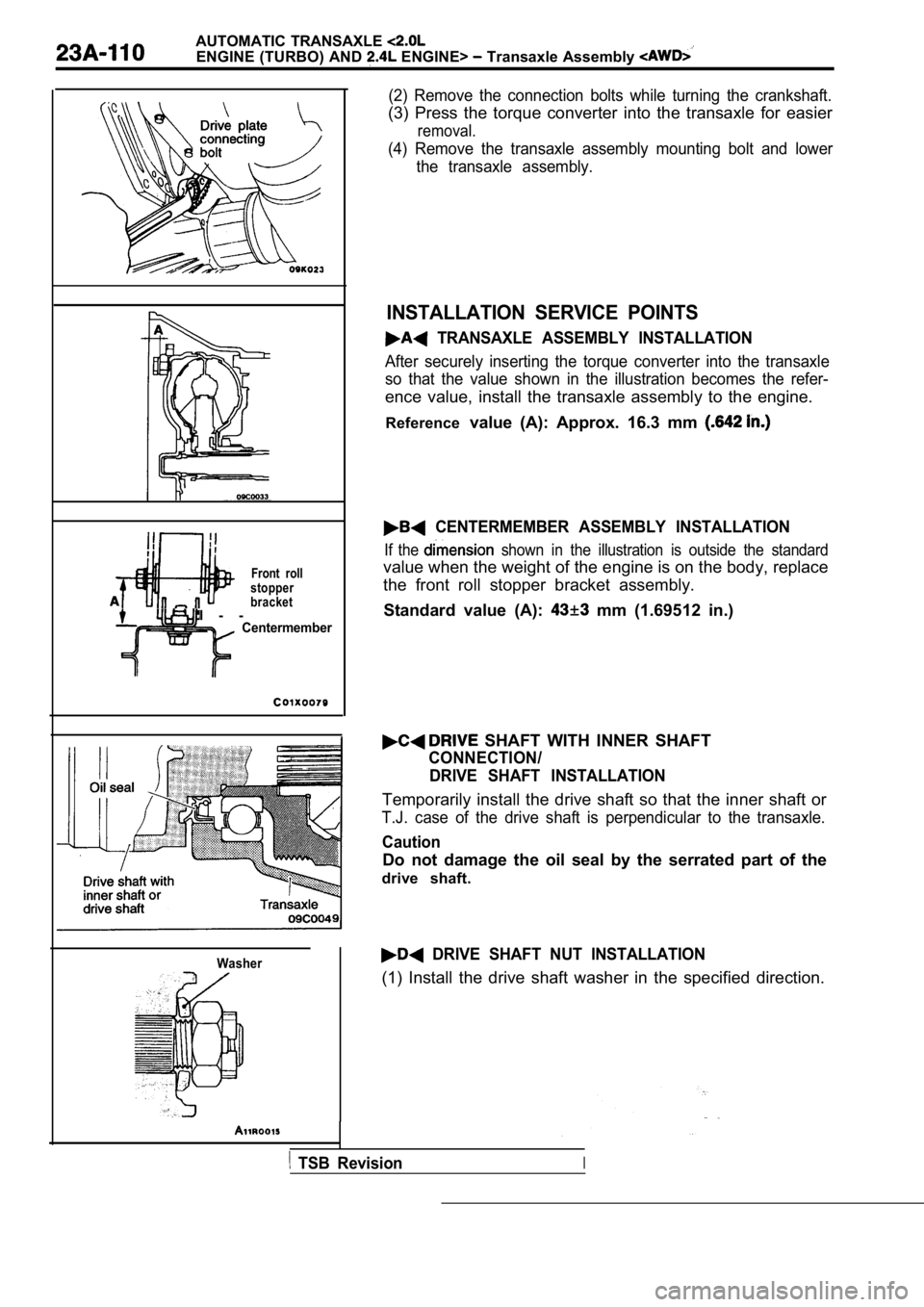

(2) Remove the connection bolts while turning the crankshaft.

(3) Press the torque converter into the transaxle for easier

removal.

(4) Remove the transaxle assembly mounting bolt and lower

the transaxle assembly.

INSTALLATION SERVICE POINTS

TRANSAXLE ASSEMBLY INSTALLATION

After securely inserting the torque converter into the transaxle

so that the value shown in the illustration becomes the refer-

ence value, install the transaxle assembly to the engine.

Reference value (A): Approx. 16.3 mm

CENTERMEMBER ASSEMBLY INSTALLATION

If the shown in the illustration is outside the standard

value when the weight of the engine is on the body, replace

the front roll stopper bracket assembly.

Standard value (A):

mm (1.69512 in.)

SHAFT WITH INNER SHAFT

CONNECTION/ DRIVE SHAFT INSTALLATION

Temporarily install the drive shaft so that the inn er shaft or

T.J. case of the drive shaft is perpendicular to th e transaxle.

Caution

Do not damage the oil seal by the serrated part of the

drive shaft.

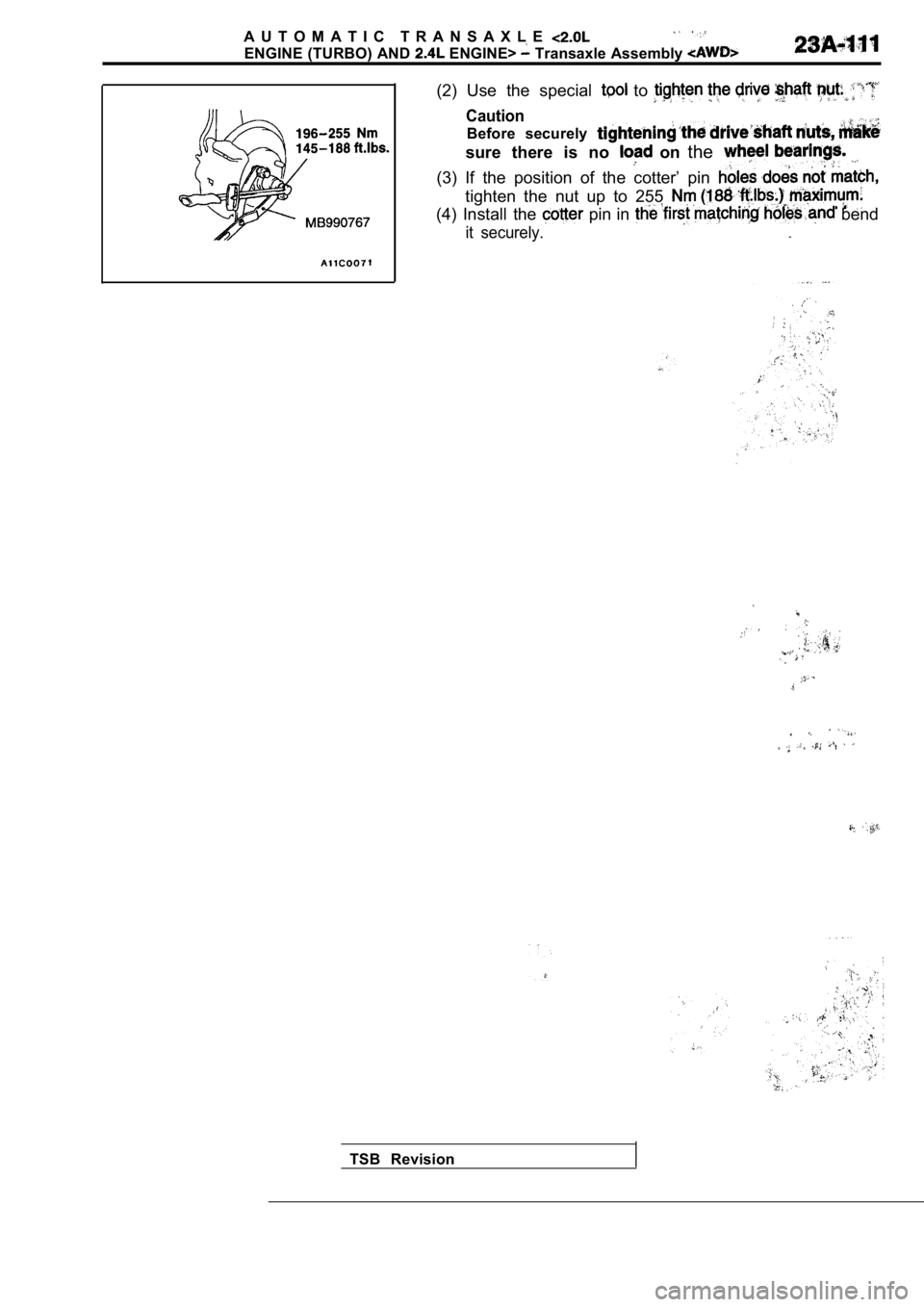

DRIVE SHAFT NUT INSTALLATION

(1) Install the drive shaft washer in the specified direction.

TSB RevisionI

Page 1119 of 2103

A U T O M A T I C T R A N S A X L E

ENGINE (TURBO) AND ENGINE> Transaxle Assembly

(2) Use the special to

Caution

Before securely

sure there is no on the

(3) If the position of the cotter’ pin

tighten the nut up to 255

(4) Install the pin in bend

it securely.

TSB Revision

Page 1136 of 2103

AUTOMATIC TRANSAXLE ENGINE (NON -TURBO )> Troubleshooting

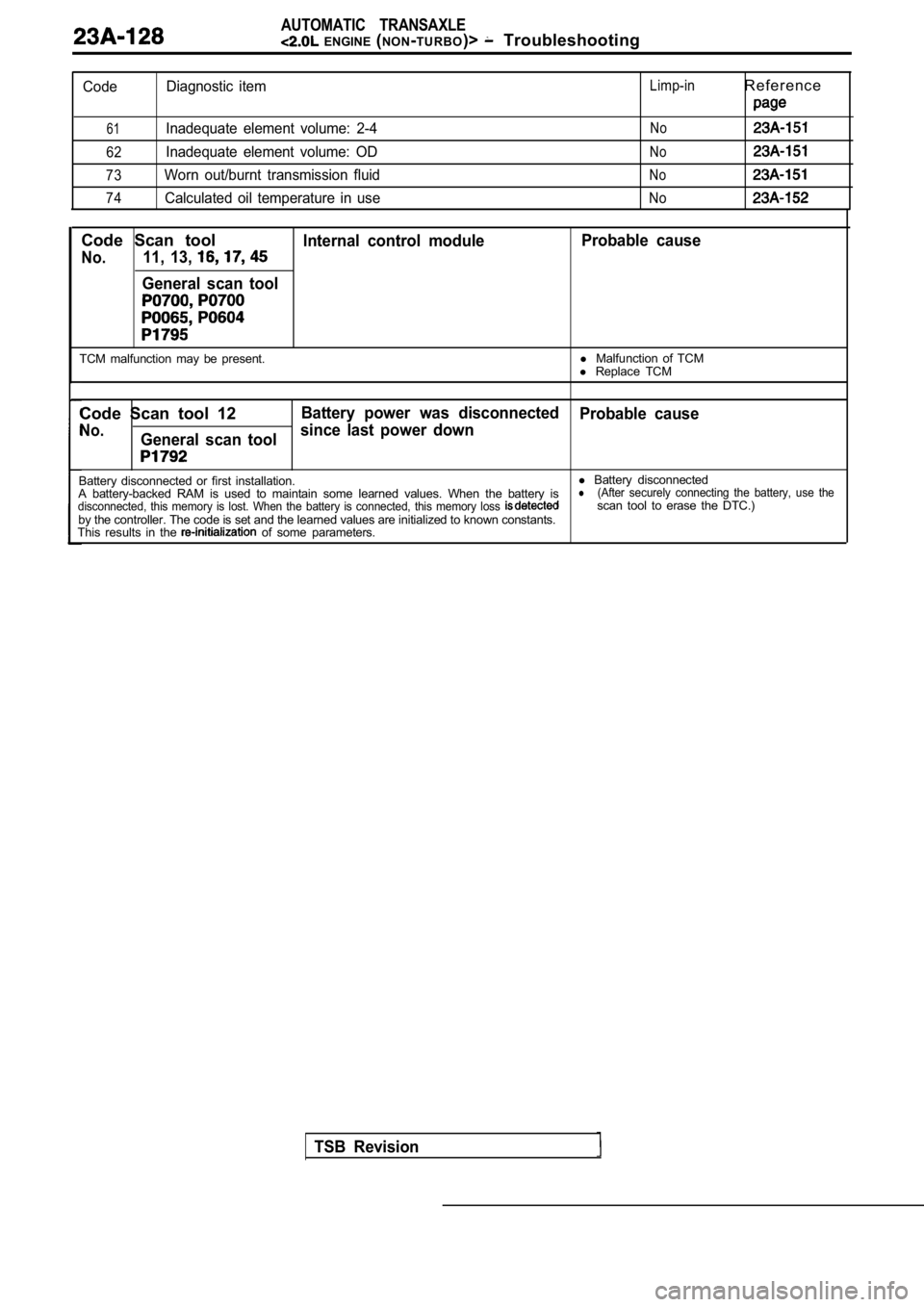

Code Diagnostic item

61Inadequate element volume: 2-4

62Inadequate element volume: OD

73Worn out/burnt transmission fluid

74Calculated oil temperature in use

Limp-in

No

No

No

No

R e f e r e n c e

Code Scan toolInternal control module Probable cause

No.11, 13,

General scan tool

TCM malfunction may be present. l

Malfunction of TCM

l Replace TCM

Code Scan tool 12

No.

Battery power was disconnected Probable cause

General scan tool since last power down

Battery disconnected or first installation.

l

Battery disconnected

A battery-backed RAM is used to maintain some learn ed values. When the battery isl(After securely connecting the battery, use the

disconnected, this memory is lost. When the battery is connected, this memory loss scan tool to erase the DTC.)

by the controller. The code is set and the learned values are initialized to known constants.

This results in the

of some parameters.

TSB Revision

Page 1154 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshooting

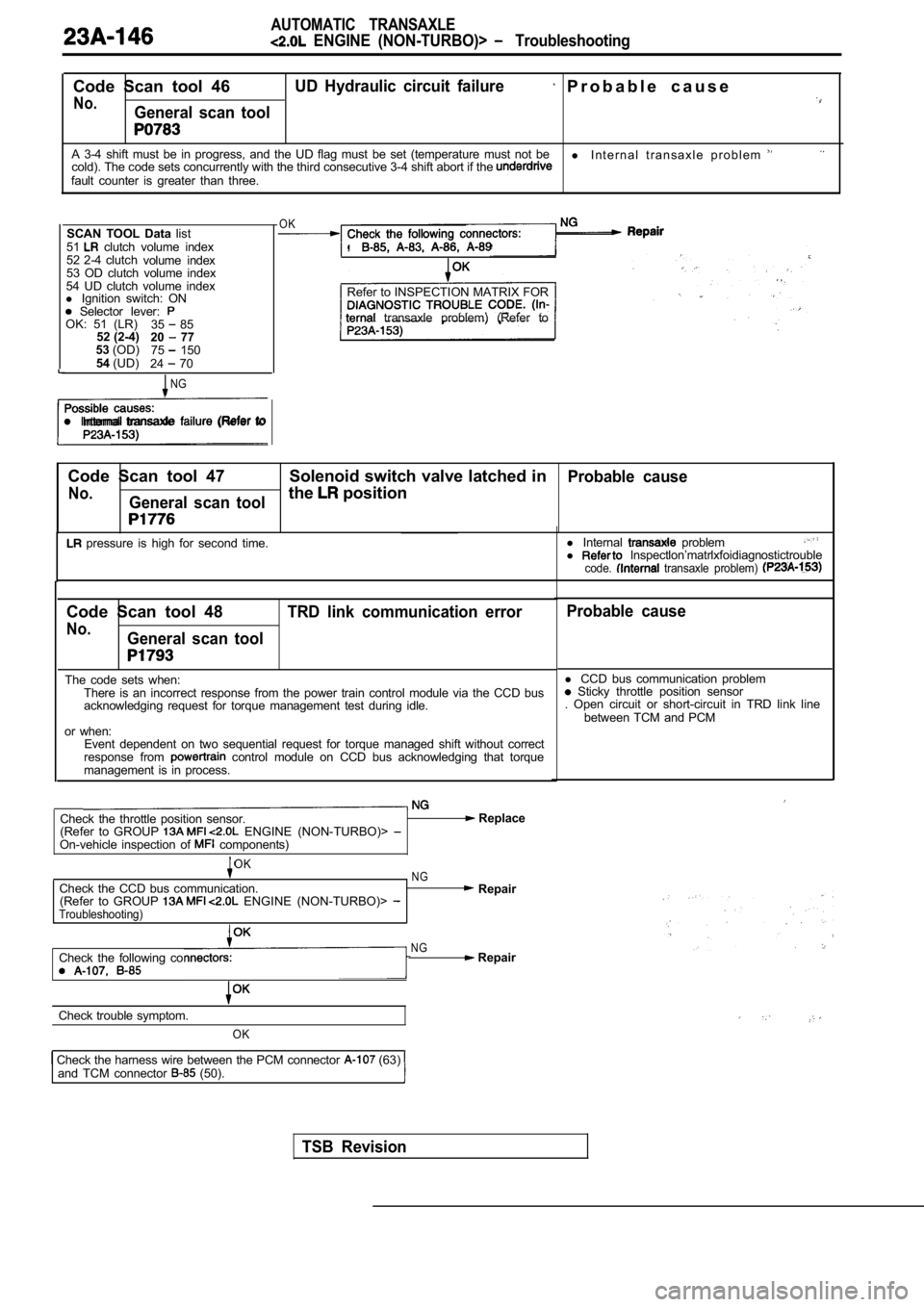

Code Scan tool 46UD Hydraulic circuit failure P r o b a b l e c a u s e

No.General scan tool

A 3-4 shift must be in progress, and the UD flag must be set (temperature must not be

l I n t e r n a l t r a n s a x l e p r o b l e m cold). The code sets concurrently with the third co nsecutive 3-4 shift abort if the fault counter is greater than three.

SCAN TOOL Data list

51

clutch volume index

52 2-4 clutch volume index

53 OD clutch volume index

54 UD clutch volume index

l Ignition switch: ON

Selector lever: OK: 51 (LR)

35 85

52 (2-4) 20 77

53 (OD)

75 150

54 (UD)

24 70

NG

l Internal transaxle (Refer to

OK

.

Refer to INSPECTION MATRIX FOR

transaxle problem) (Refer to

Code Scan tool 47 Solenoid switch valve latched in

Probable cause

No.General scan toolthe position

pressure is high for second time. l

Internal probleml lnspectlon’matrlxfoidiagnostictroublecode. transaxle problem)

Code Scan tool 48

No.General scan tool TRD link communication error

The code sets when:

There is an incorrect response from the power train control module via the CCD bus

acknowledging request for torque management test du ring idle.

or when: Event dependent on two sequential request for torqu e managed shift without correct

response from

control module on CCD bus acknowledging that torqu e

management is in process.

Check the throttle position sensor.

(Refer to GROUP ENGINE (NON-TURBO)> On-vehicle inspection of components)

Replace

OKNGCheck the CCD bus communication. Repair

(Refer to GROUP ENGINE (NON-TURBO)> Troubleshooting)

Check the following coNG Repair

Check trouble symptom.

OK

Check the harness wire between the PCM connector (63) and TCM connector (50).

Probable cause

l CCD bus communication problem Sticky throttle position sensor

. Open circuit or short-circuit in TRD link line

between TCM and PCM

TSB Revision

Page 1160 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshooting

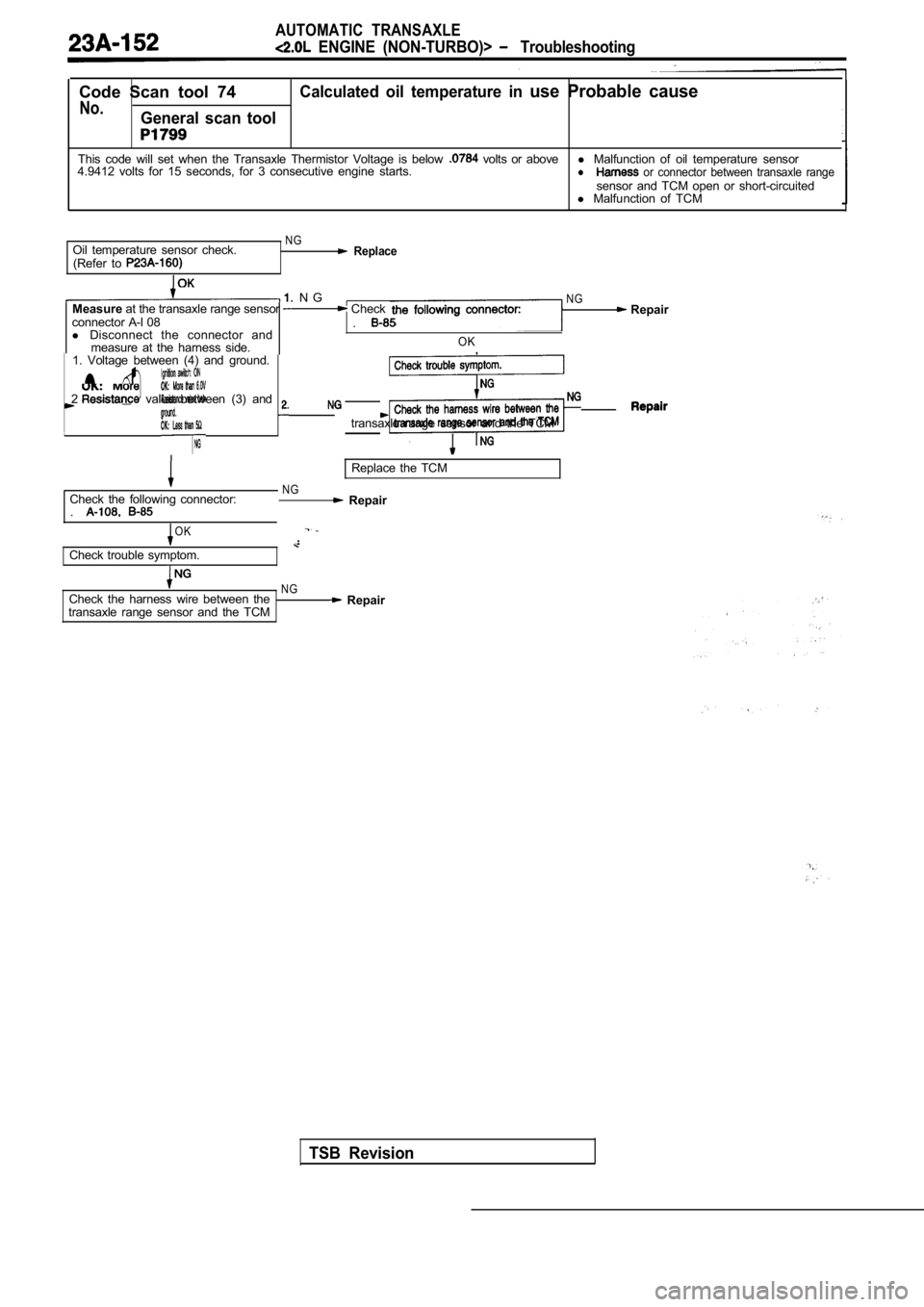

Code Scan tool 74Calculated oil temperature in use Probable cause

No.General scan tool

This code will set when the Transaxle Thermistor Voltage is below volts or abovel Malfunction of oil temperature sensor

4.9412 volts for 15 seconds, for 3 consecutive engi ne starts.l or connector between transaxle rangesensor and TCM open or short-circuited

l Malfunction of TCM

Oil temperature sensor check. (Refer to

NG Replace

N G

Measure at the transaxle range sensor Check

connector A-l 08 .

l Disconnect the connector and

measure at the harness side.OK

NG Repair

1. Voltage between (4) and ground.

l . 2 value between (3) and

transaxle range sensor and the TCM

Replace the TCM

Check the following connector: .NG Repair

OK

Check trouble symptom.

NGCheck the harness wire between the Repair

transaxle range sensor and the TCM

TSB Revision

Page 1198 of 2103

AUTOMATIC TRANSAXLE

E N G I N E ( N O N - T U R B O ) >Automatic

Transaxle KeyInterlock and Shift LockMechanisms

AUTOMATIC TRANSAXLE KEY INTERLOCK AND SHIFT LOCK

MECHANISMS

Caution: SRSBe careful not to subject the SRS-ECU to any shocksduring removal and installation of the key interloc kcable and shift lock cable.

NOTE

567I

8 ’

clipposition position

Key

interlock cable removal steps

1. Plug A

2. Plug

3. Hood release lever

4. Instrument panel under cover

5. Steering column lower cover

6. Center panel7. Cup holder assembly

8. Floor console assembly

9. Console side cover (L.H.)

10. Cover11. Cam and lever

12. Key interlock cable connection

13. Slide lever

14. Snap pin

15. Key interlock cable connection 19. Key interlock cable 11 Nm

8.3

Shift lock cable removal steps

1. Plug A

2. Plug

3. Hood release lever

4. Instrument panel under cover 6. Center panel

7. Cup holder assembly

8. Floor console assembly

9. Console side cover (L.H.)

16. Shift lock cable connection

17. Cotter pin

18. Shift lock cable connection

20. Shift lock cable

TSB Revision

Page 1199 of 2103

AUTOMATIC TRANSAXLE Key Interlock

E N G I N E a n d

SHIFT LOCK CABLE/

I N S T A L L A T I O N

Securethesection between the the

and key interlock cable the

assembly.

Caution

Do not change the of lock

lever assembly.’

L O C K C A B L E L EVER

INSTALLATION . .

(1) Place the

lever in

(2) Fasten the shift lock cable at the end

of the shift lock is-positioned the

KEY INTERLOCK CABLE (SELECTOR LEVER

(1) Install the key interlock cable cam.

(2) Install the spring and washer of

interlock cable

(3)

pushing the cable coupling portion of the

lock cam in the direction A, tighten the nut to fas ten the

key interlock cable.

INSPECTION

Check the cable assemblies for function and for dam age.