ECU MITSUBISHI SPYDER 1990 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1234 of 2103

AUTOMATIC TRANSAXLEOVERHAUL Transaxle

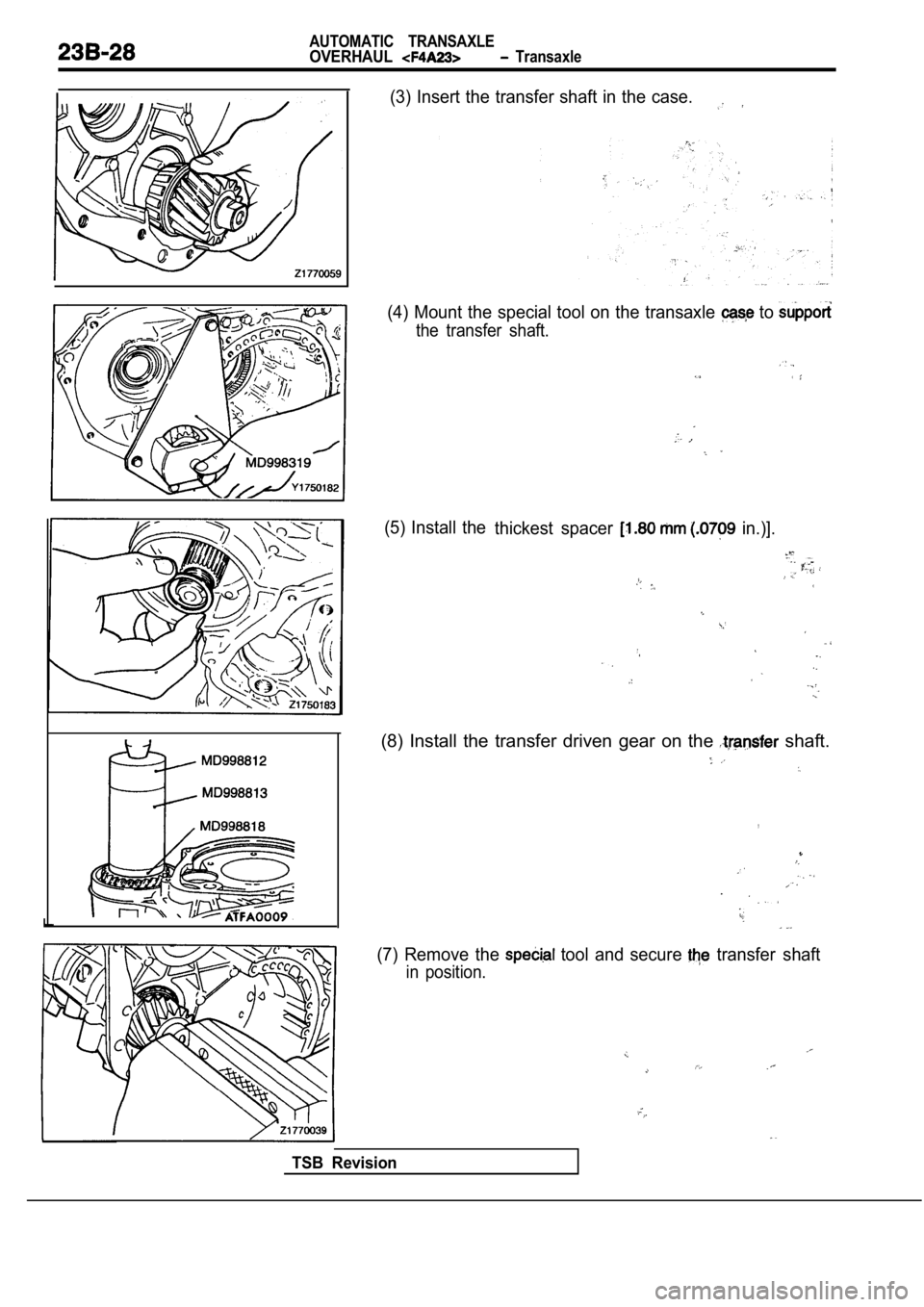

(3) Insert the transfer shaft in the case.

(4) Mount the special tool on the transaxle to

the transfer shaft.

(5) Install thethickest spacer in.)].

(8) Install the transfer driven gear on the shaft.

,

(7) Remove the tool and secure transfer shaft

in position.

TSB Revision

Page 1237 of 2103

OVERHAUL.

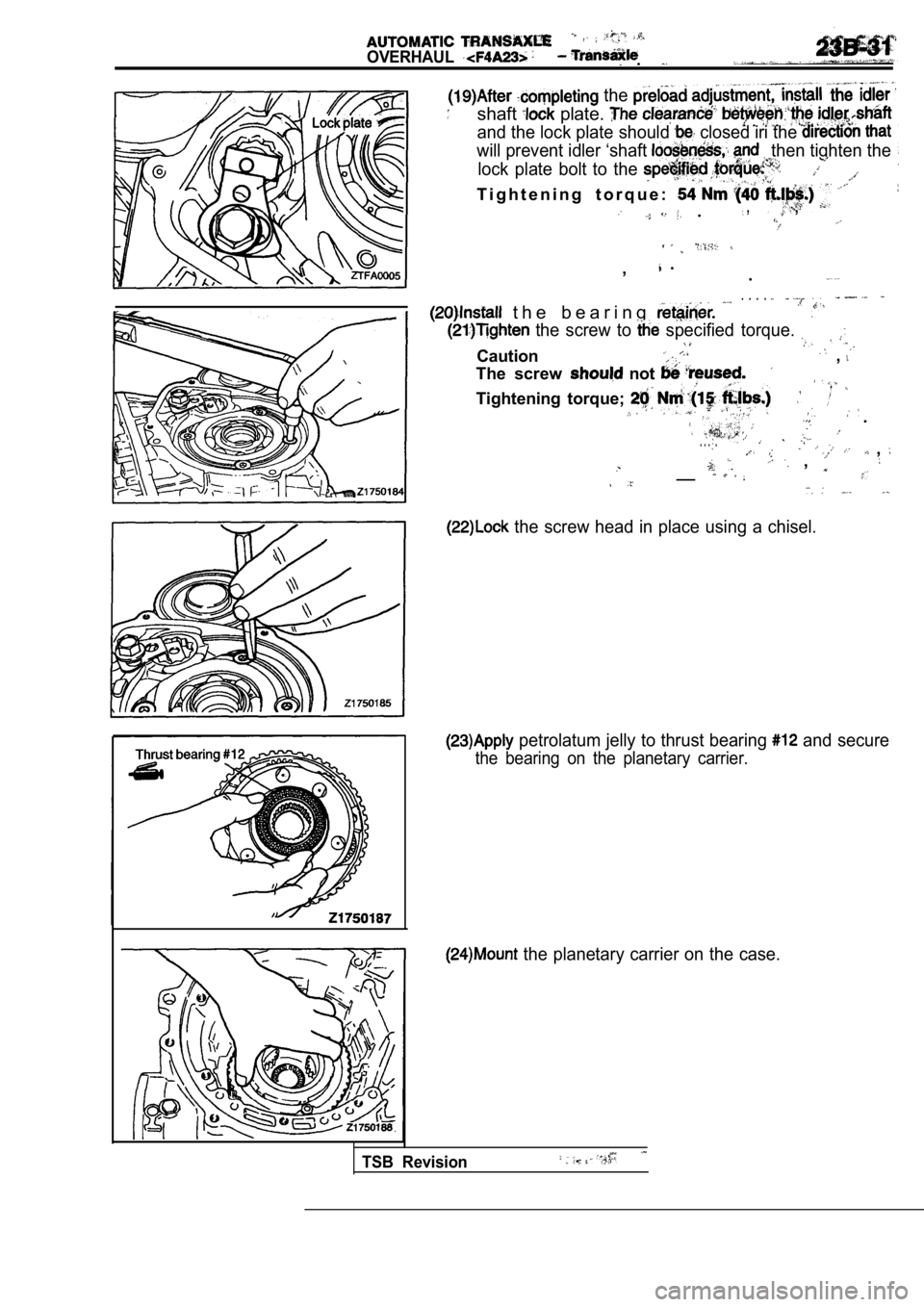

the

shaft plate.

and the lock plate should closed iri the

will prevent idler ‘shaft then tighten the

lock plate bolt to the

T i g h t e n i n g t o r q u e :

. , ,

, . .

t h e b e a r i n g

. . . .

the screw to specified torque.

Caution,

The screw not

Tightening torque;

.

. . . . , , __

the screw head in place using a chisel.

petrolatum jelly to thrust bearing and secure

the bearing on the planetary carrier.

the planetary carrier on the case.

TSB Revision

Page 1241 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL Transaxle

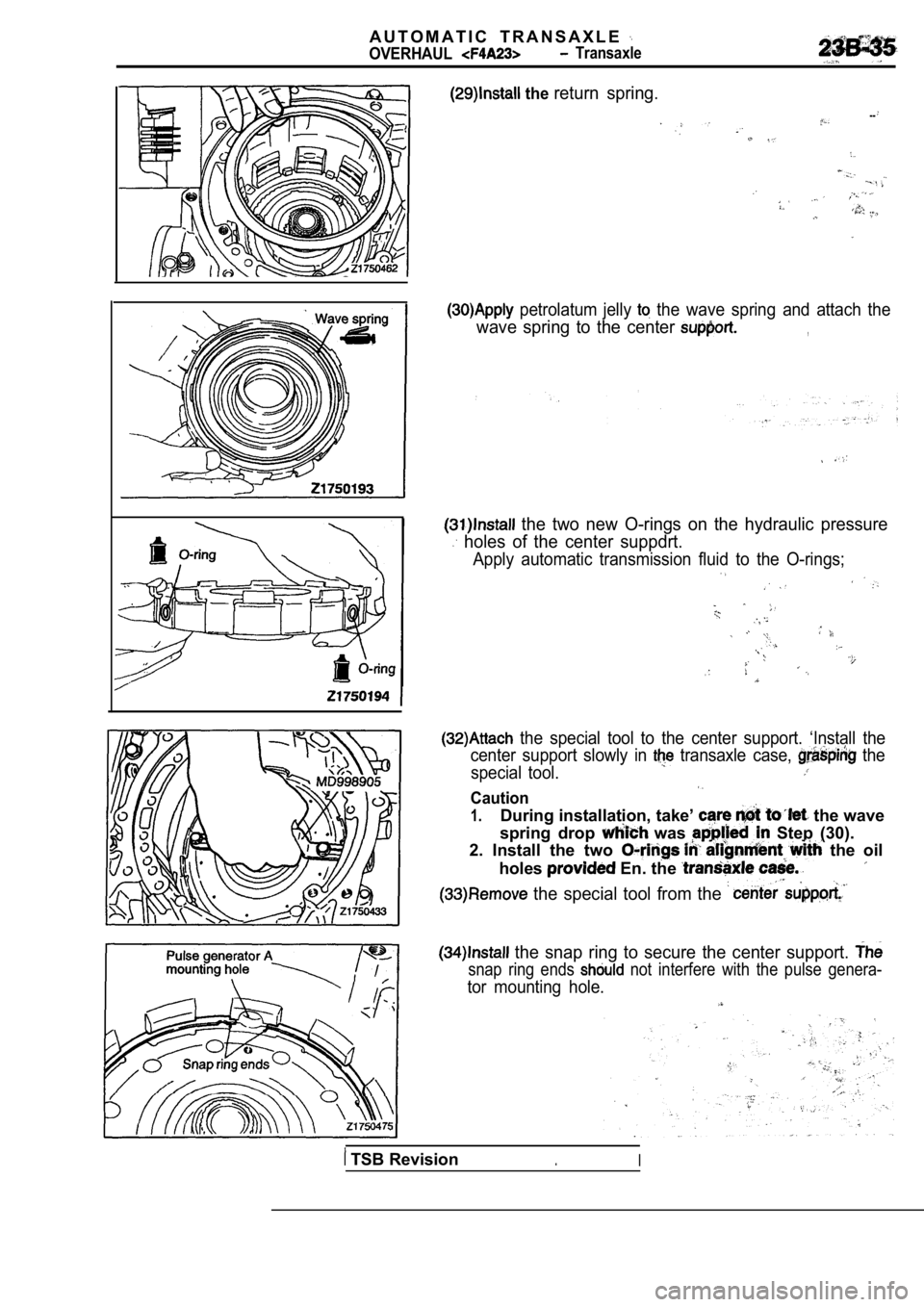

the return spring.

--

petrolatum jelly the wave spring and attach the

wave spring to the center ,

the two new O-rings on the hydraulic pressure

holes of the center suppdrt.

Apply automatic transmission fluid to the O-rings;

the special tool to the center support. ‘Install the

center support slowly in

transaxle case, the

special tool.

Caution

1.During installation, take’ the wave

spring drop

was Step (30).

2. Install the two

the oil

holes

En. the

the special tool from the

the snap ring to secure the center support.

snap ring ends not interfere with the pulse genera-

tor mounting hole.

TSB Revision.I

Page 1250 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

I

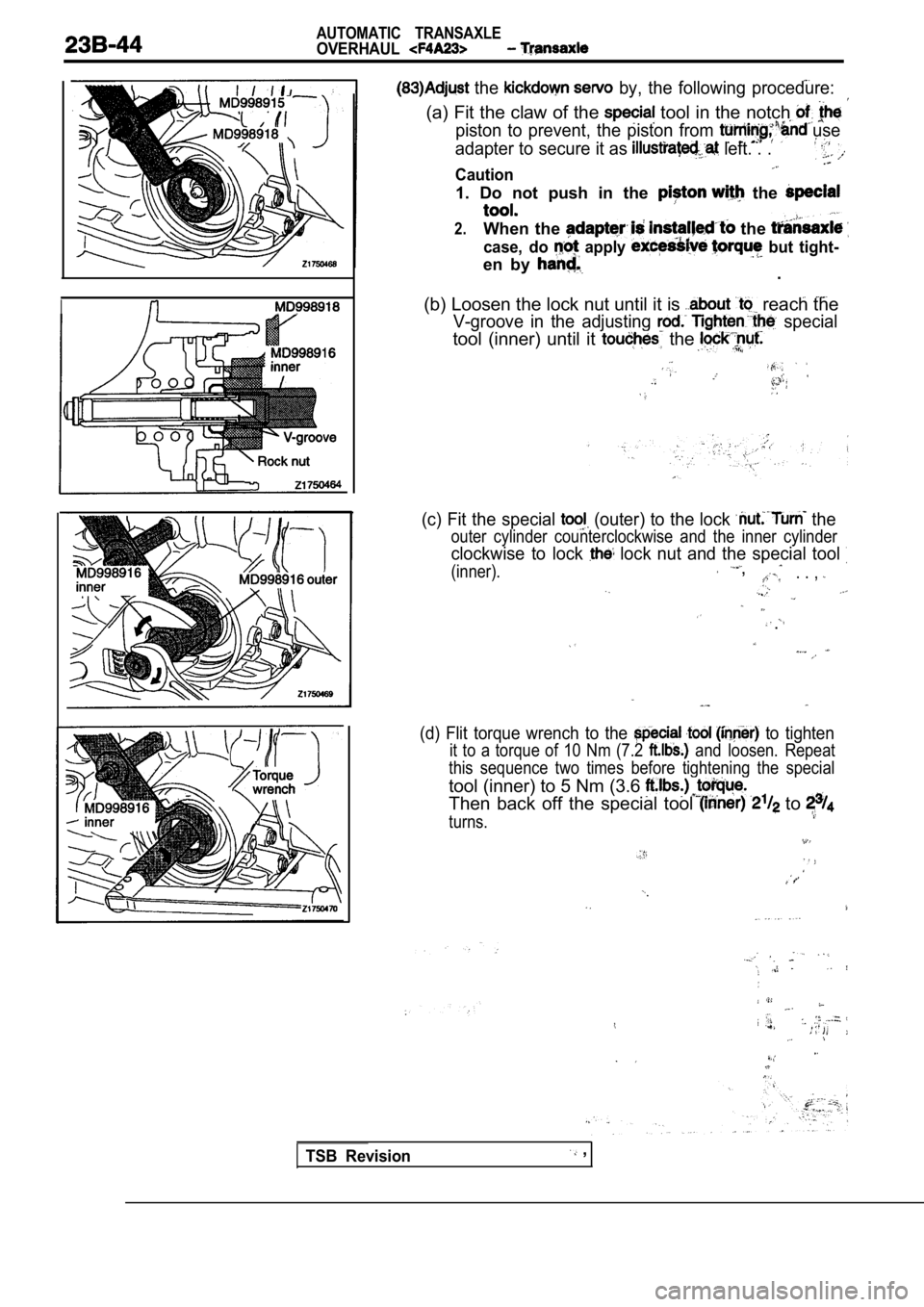

the by, the following procedure:

(a) Fit the claw of the tool in the notch

piston to prevent, the piston from use

adapter to secure it as

left. . .

Caution

1. Do not push in the the

2.When the the

case, do apply but tight-

en by .

(b) Loosen the lock nut until it is reach the

V-groove in the adjusting special

tool (inner) until it the

(c) Fit the special (outer) to the lock the

outer cylinder counterclockwise and the inner cylin der

clockwise to lock lock nut and the special tool

(inner). ,. . ,

.

(d) Flit torque wrench to the to tighten

it to a torque of 10 Nm (7.2 and loosen. Repeat

this sequence two times before tightening the speci al

tool (inner) to 5 Nm (3.6

Then back off the special tool to

turns.

TSB Revision ,

Page 1251 of 2103

AUTOMATIC

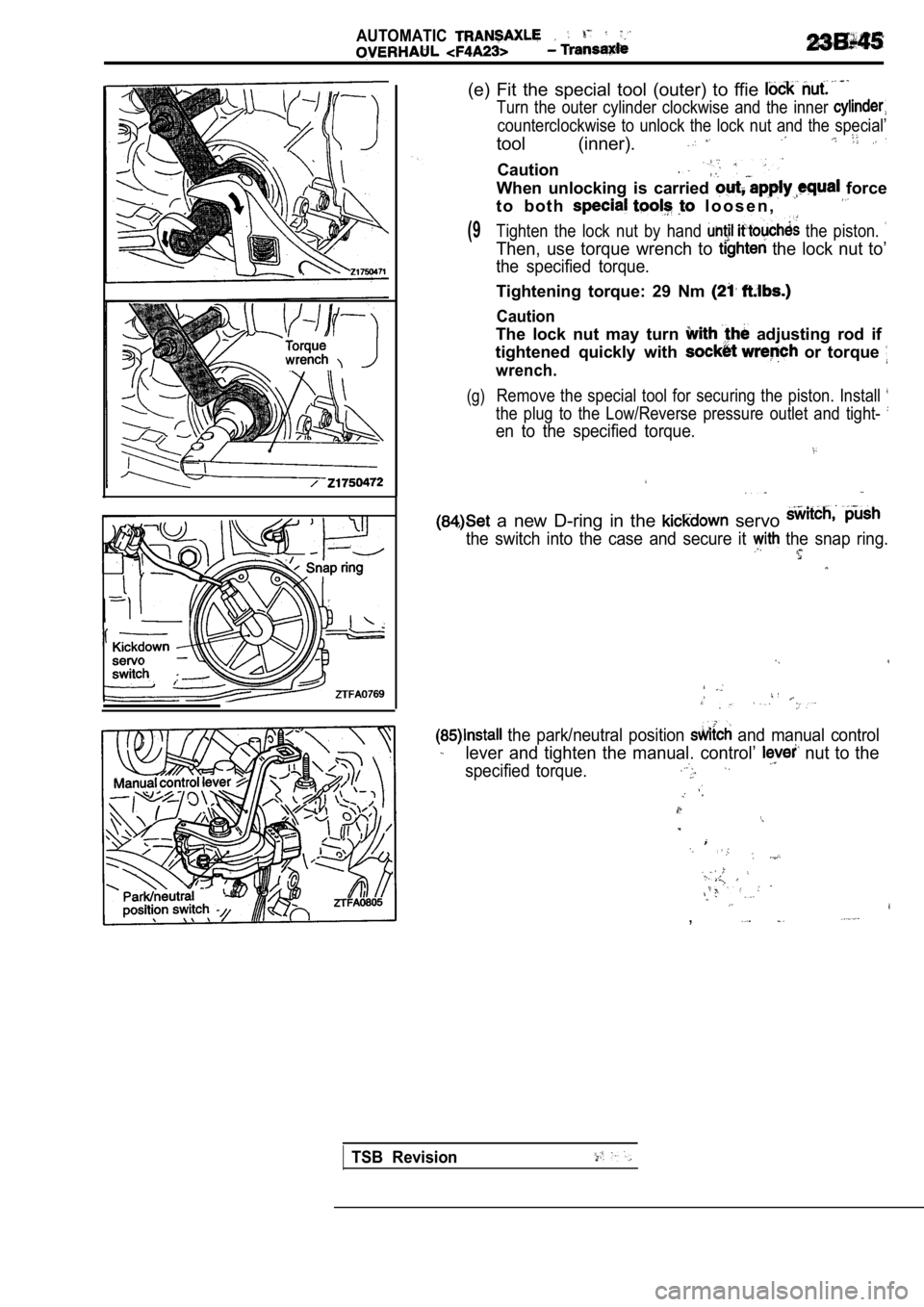

(e) Fit the special tool (outer) to ffie

Turn the outer cylinder clockwise and the inner

counterclockwise to unlock the lock nut and the special’

tool (inner).

Caution

When unlocking is carried force

t o b o t h

l o o s e n ,

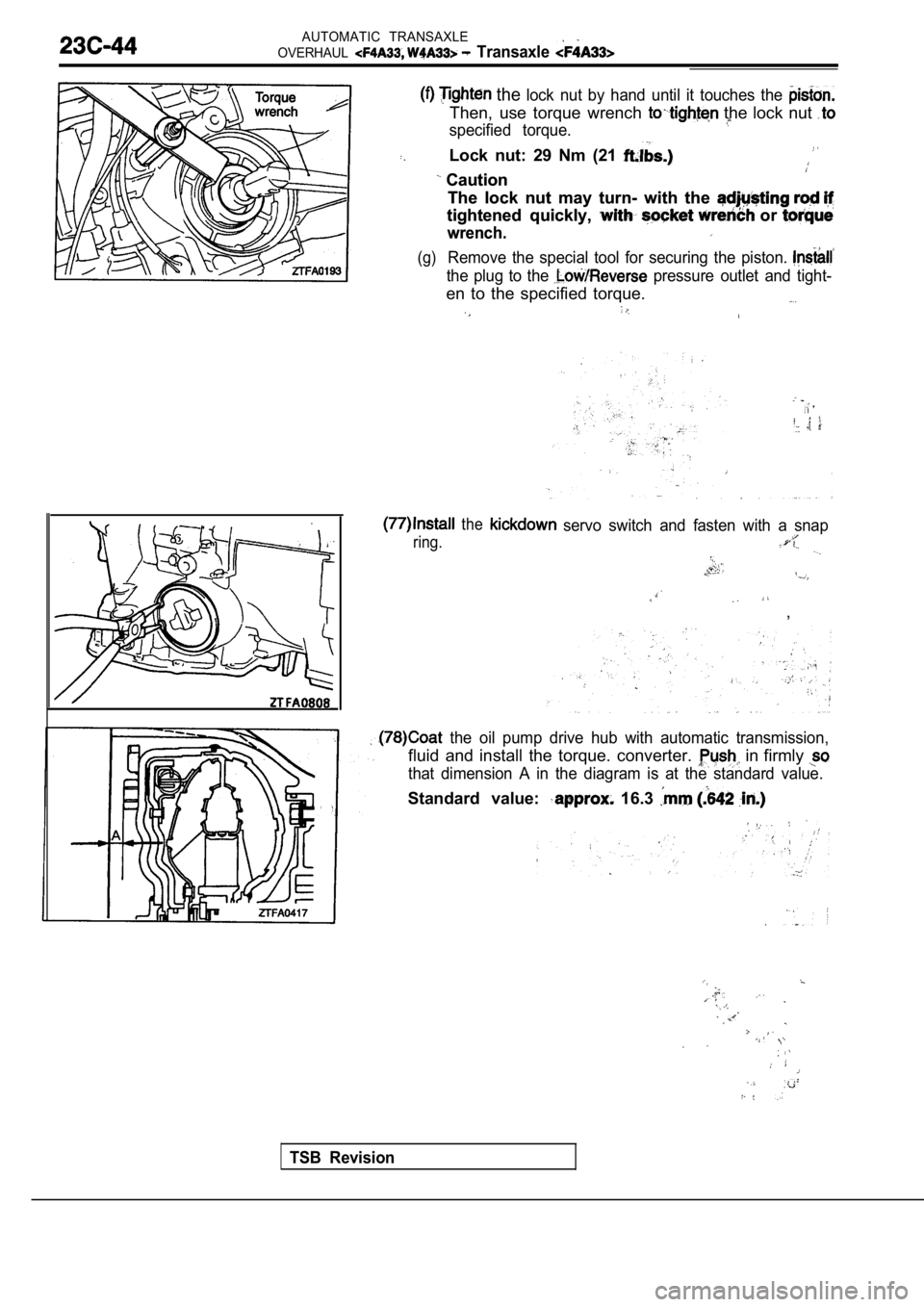

(9Tighten the lock nut by hand the piston.

Then, use torque wrench to the lock nut to’

the specified torque.

Tightening torque: 29 Nm

Caution

The lock nut may turn adjusting rod if

tightened quickly with

or torque

wrench.

(g)Remove the special tool for securing the piston. In stall

the plug to the Low/Reverse pressure outlet and tig ht-

en to the specified torque.

a new D-ring in the servo

the switch into the case and secure it the snap ring.

the park/neutral position and manual control

lever and tighten the manual. control’ nut to the

specified torque.

,

TSB Revision

Page 1282 of 2103

AUTO T R A N S A X L E

OVER

2 1 7 5 0 3 3 3

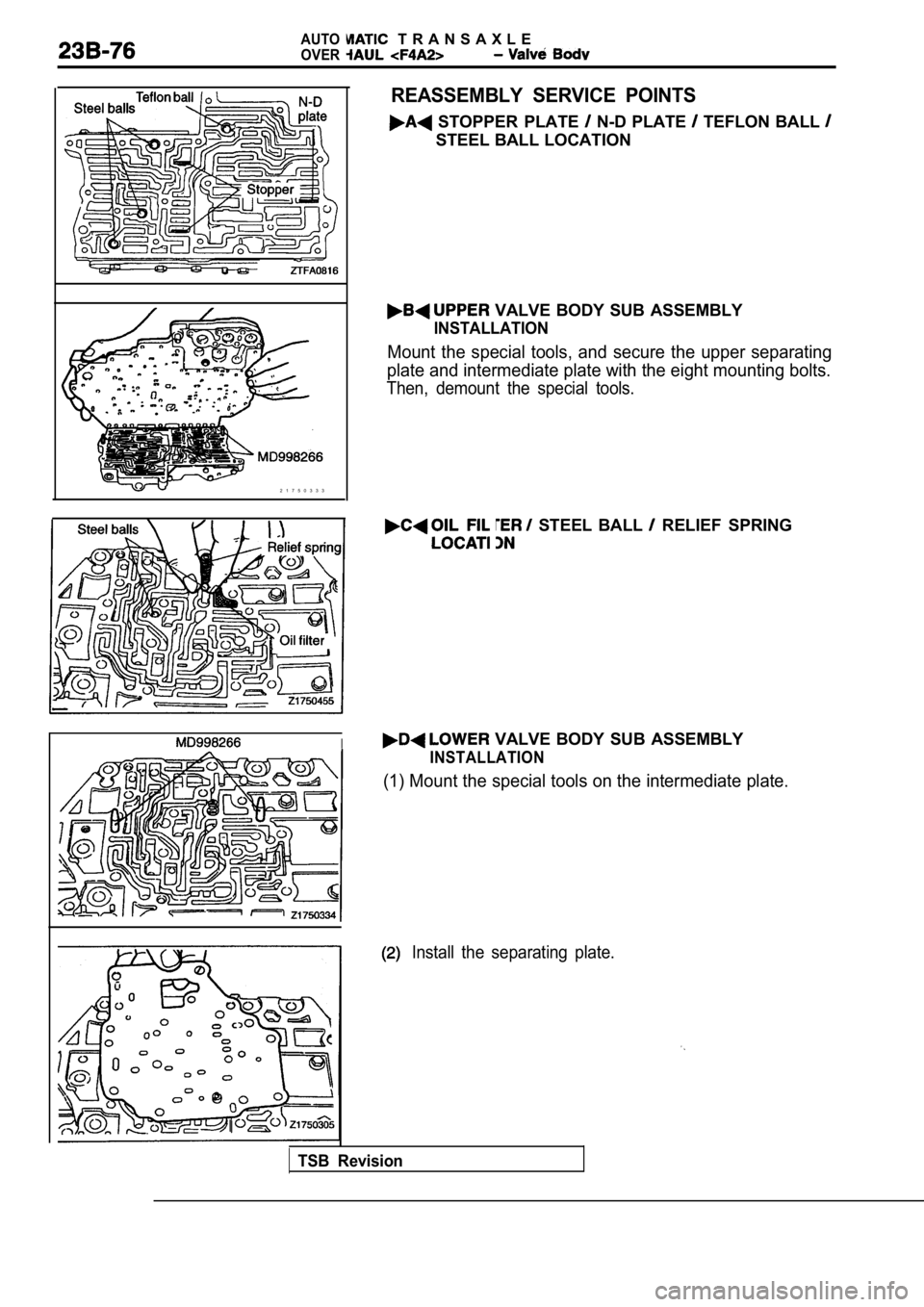

REASSEMBLY SERVICE POINTS

STOPPER PLATE N-D PLATE TEFLON BALL

STEEL BALL LOCATION

VALVE BODY SUB ASSEMBLY

INSTALLATION

Mount the special tools, and secure the upper separating

plate and intermediate plate with the eight mountin g bolts.

Then, demount the special tools.

I

STEEL BALL RELIEF SPRING

VALVE BODY SUB ASSEMBLY

INSTALLATION

(1) Mount the special tools on the intermediate plate.

Install the separating plate.

TSB Revision

Page 1283 of 2103

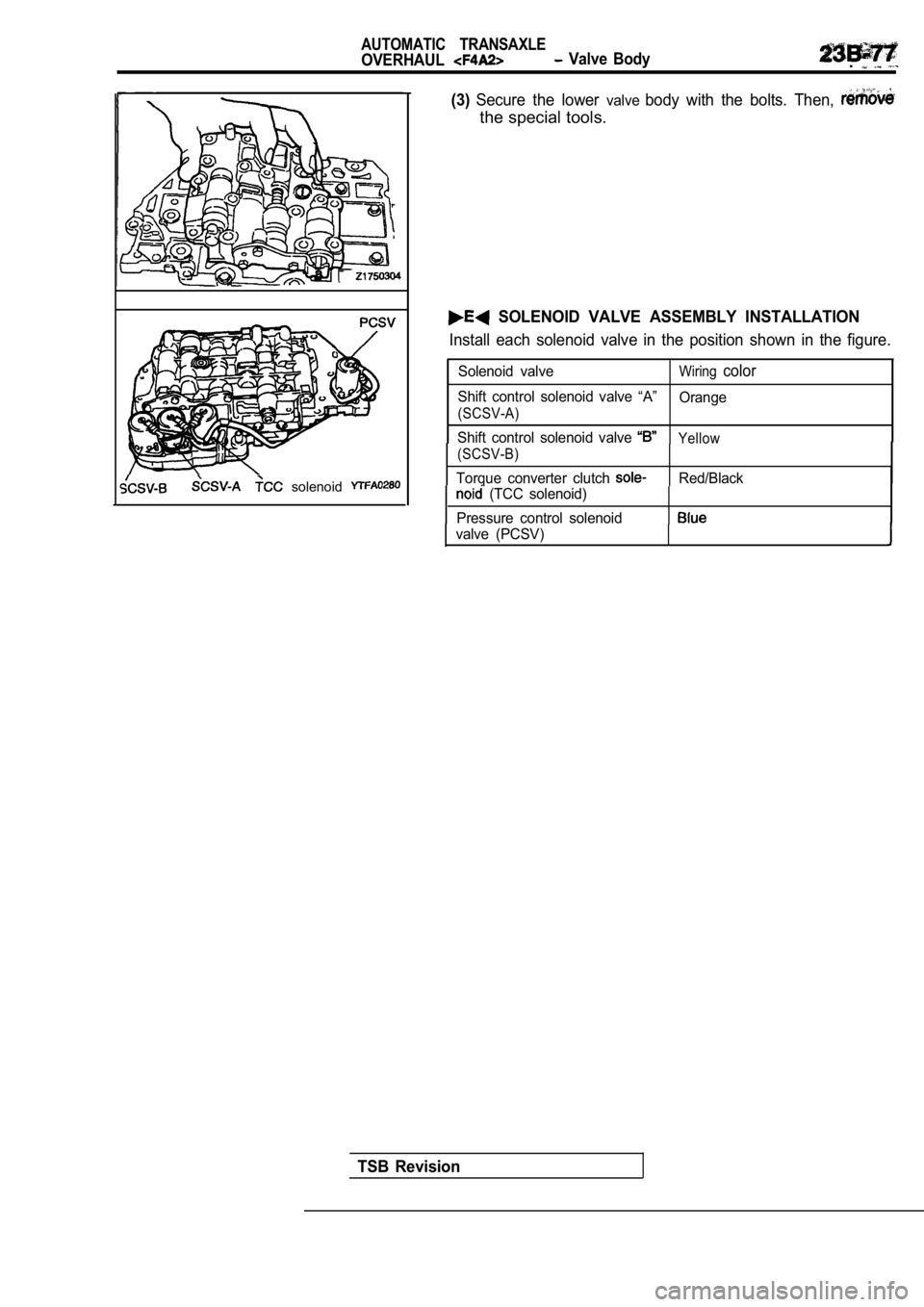

solenoid

AUTOMATIC TRANSAXLE

OVERHAUL Valve Body.

(3)Secure the lower valvebody with the bolts. Then,

the special tools.

SOLENOID VALVE ASSEMBLY INSTALLATION

Install each solenoid valve in the position shown in the figure.

Solenoid valveWiringcolor

Shift control solenoid valve “A”

Orange

(SCSV-A)

Shift control solenoid valve Yellow

(SCSV-B)

Torque converter clutch

(TCC solenoid)

Pressure control solenoid Red/Black

valve (PCSV)

TSB Revision

Page 1327 of 2103

.

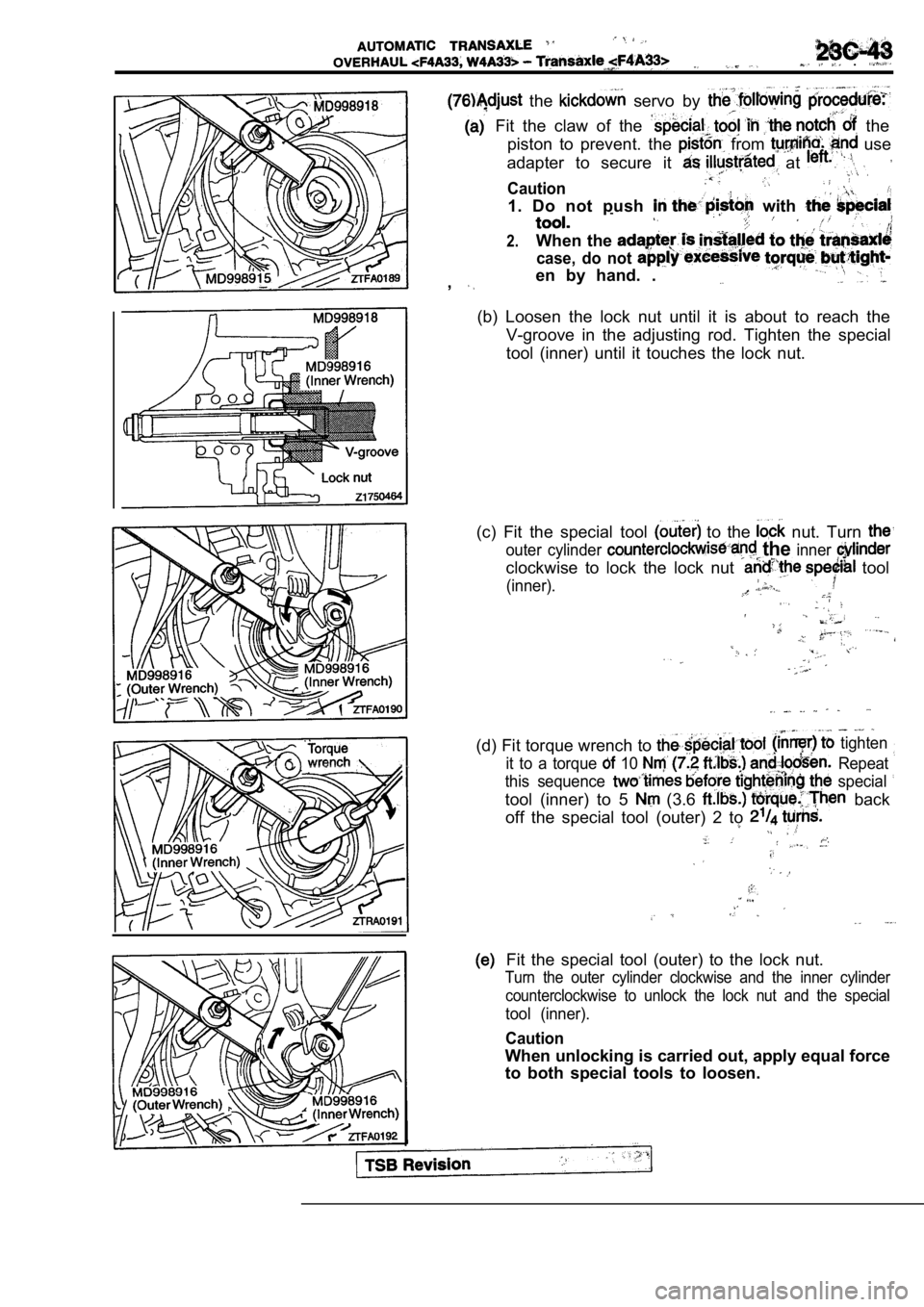

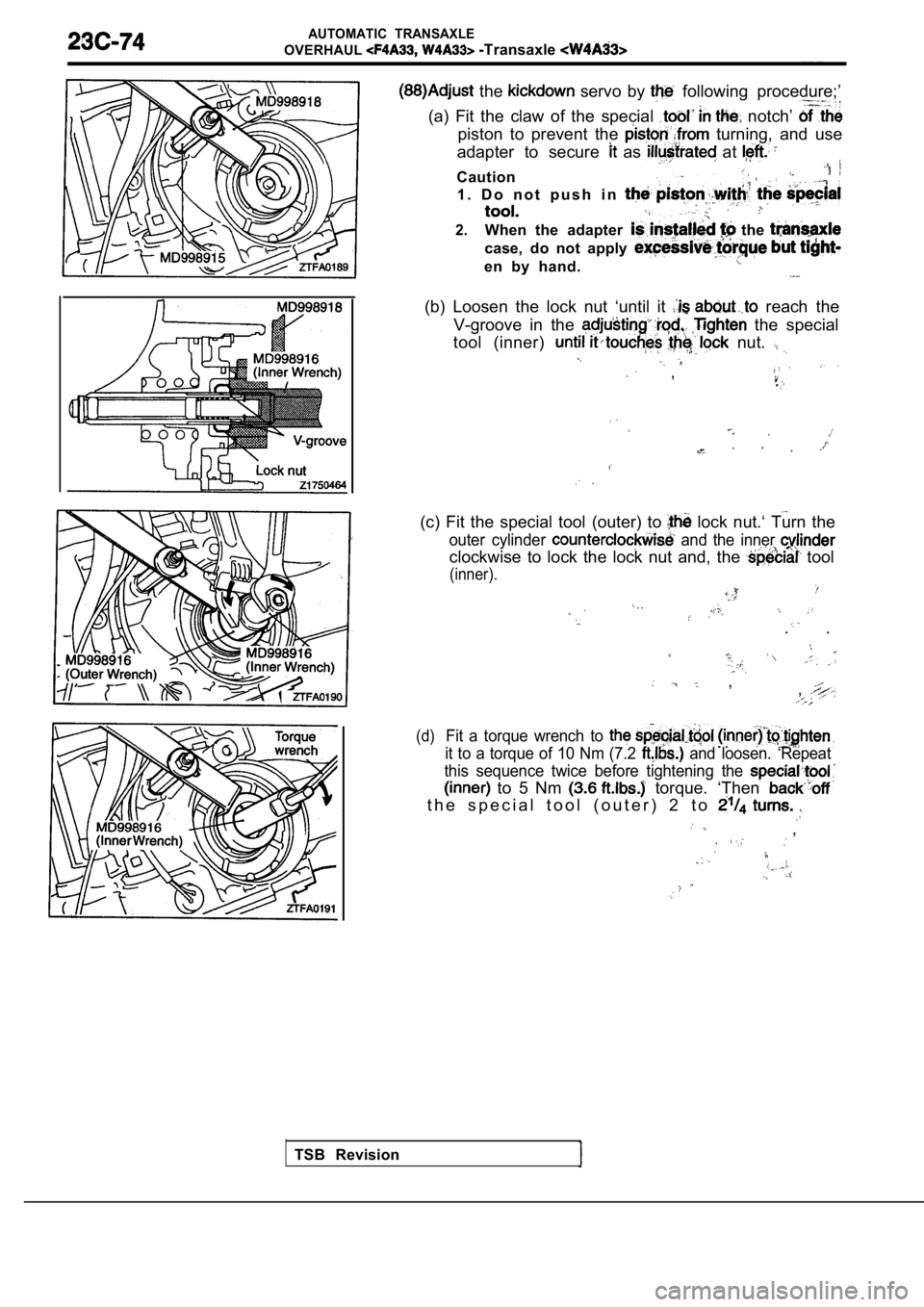

the servo by

Fit the claw of the the

piston to prevent. the

from use

adapter to secure it

at

Caution

1. Do not push with

2.When the

case, do not

en by hand. .,

(b) Loosen the lock nut until it is about to reach the

V-groove in the adjusting rod. Tighten the special

tool (inner) until it touches the lock nut.

(c) Fit the special tool

to the nut. Turn

outer cylinder the inner

clockwise to lock the lock nut tool

(inner).

(d) Fit torque wrench to tighten

it to a torque 10 Repeat

this sequence

special

tool (inner) to 5 (3.6 back

off the special tool (outer) 2 to

Fit the special tool (outer) to the lock nut.

Turn the outer cylinder clockwise and the inner cyl inder

counterclockwise to unlock the lock nut and the spe cial

tool (inner).

Caution

When unlocking is carried out, apply equal force

to both special tools to loosen.

Page 1328 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

Transaxle

the lock nut by hand until it touches the

Then, use torque wrench the lock nut

specified torque.

Lock nut: 29 Nm (21

Caution Caution

The lock nut may turn- with the The lock nut may turn- with the

tightened quickly, or tightened quickly, or

wrench.

wrench.

(g)Remove the special tool for securing the piston.

the plug to the pressure outlet and tight-

en to the specified torque.

ring. the

servo switch and fasten with a snap

,

the oil pump drive hub with automatic transmission

,

fluid and install the torque. converter. in firmly

that dimension A in the diagram is at the standard value.

Standard value: 16.3

TSB Revision

Page 1358 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL -Transaxle

the servo by following procedure;’

(a) Fit the claw of the special

notch’

piston to prevent the turning, and use

adapter to secure

as at

Caution

1 . D o n o t p u s h i n

2.When the adapter the

case, do not apply

en by hand.

TSB Revision (b) Loosen the lock nut ‘until it

reach the

V-groove in the

the special

tool (inner)

nut.

,

(c) Fit the special tool (outer) to lock nut.‘ Turn the

outer cylinder and the inner

clockwise to lock the lock nut and, the tool

(inner).

. .

. .

,,

(d)Fit a torque wrench to

it to a torque of 10 Nm (7.2 and loosen. ‘Repeat

this sequence twice before tightening the

to 5 Nm torque. ‘Then

t h e s p e c i a l t o o l ( o u t e r ) 2 t o

,