differential MITSUBISHI SPYDER 1990 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 989 of 2103

MANUAL TRANSAXLE . .

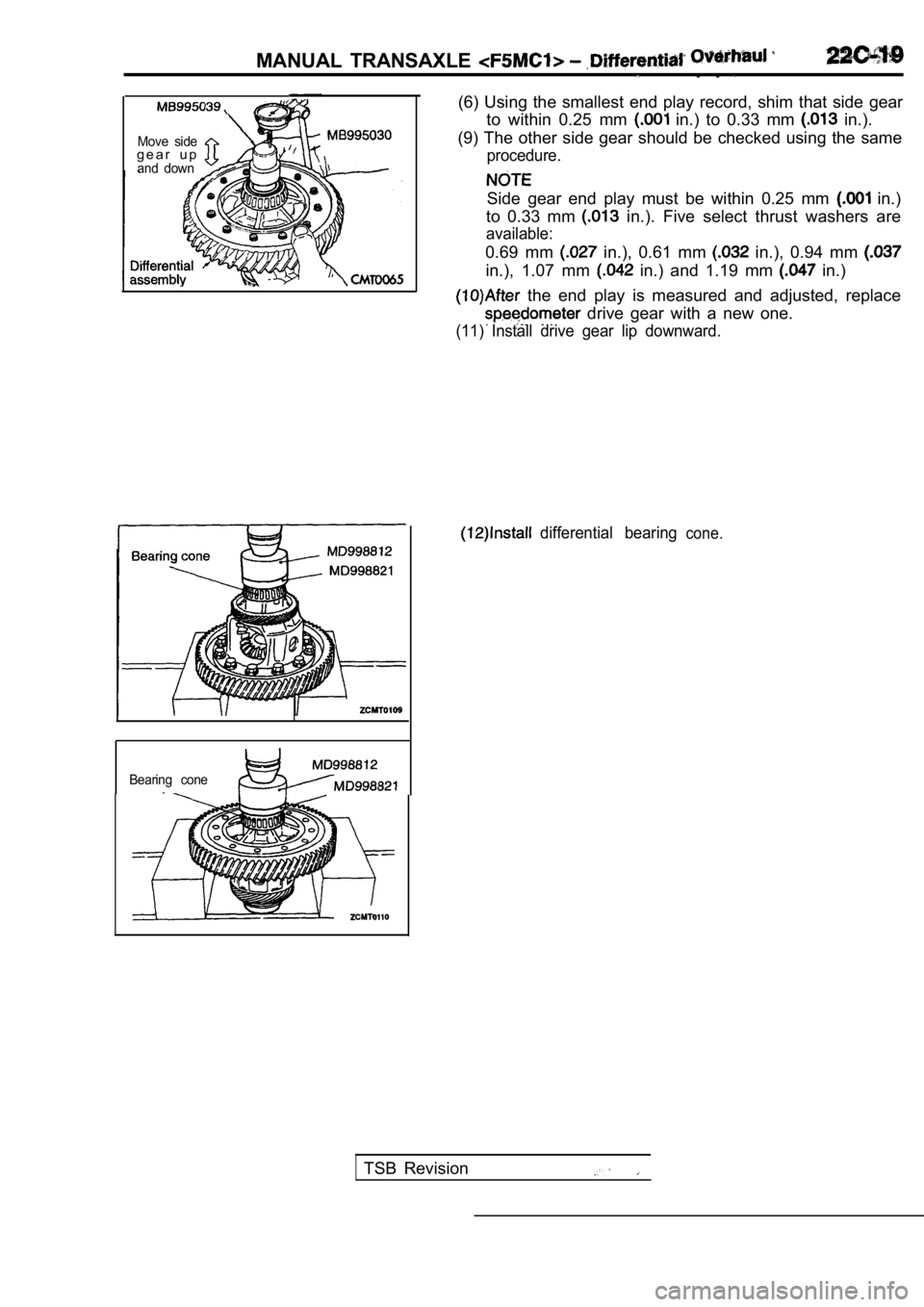

Move sideg e a r u pand down

Bearing cone.(6) Using the smallest end play record, shim that s

ide gear

to within 0.25 mm

in.) to 0.33 mm in.).

(9) The other side gear should be checked using the same

procedure.

Side gear end play must be within 0.25 mm in.)

to 0.33 mm

in.). Five select thrust washers are

available:

0.69 mm in.), 0.61 mm in.), 0.94 mm

in.), 1.07 mm in.) and 1.19 mm in.)

the end play is measured and adjusted, replace

drive gear with a new one.

(11) Install drive gear lip downward.

differential bearingcone.

TSB Revision

Page 992 of 2103

Shifter Rails Overhaul/

MANUAL

SHIFTER

Disassemble the transaxle case using the procedures’

provided in this group.

(2) Remove shifter rails from the

(3) To service the shift rail, remove the retaining

the reverse shift lever arm. Remove the

“shift fork

roll pin and remove the

shift fork.

Remove the shift lug roll pin and remove the shift lug.’

Replace parts as necessary.

(4) To service the

shift rail, remove the roll pin retaining’

the

shift fork. Remove the shift fork.,, Remove the

shift lug roll pin and remove shift lug. Replace pa rts as,

necessary.

(5) To service the shift rail, remove roll pin retaining,

the shift fork. Remove the shift replace parts

as necessary.

GEAR CASE

The sealant used to seal the transaxle case halves is Loctite

51817 or equivalent. The sealant used for the bearing end

plate cover is Loctite

or equivalent.

The components that are left in the gear cases when the

gear train is pulled out are the:

Axle shaft seals

Output bearing race and retainer Input bearing and sleeve

Differential bearing cones

Shifter rail bushings ,

Shifter shafts

Shifter shaft seals

Shifter shaft bushings

Rear bearing oil feed trough

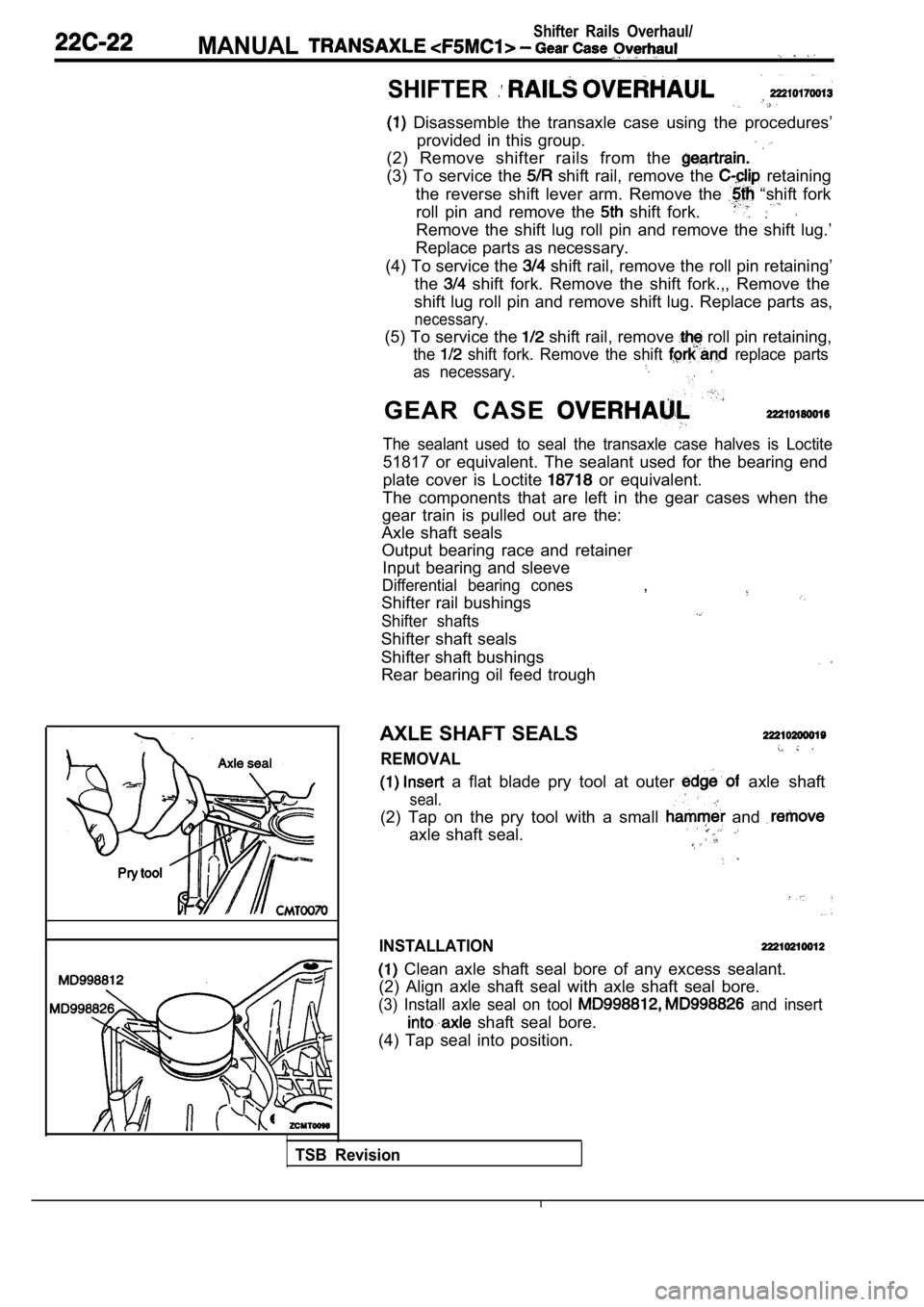

AXLE SHAFT SEALS

REMOVAL

a flat blade pry tool at outer axle shaft

seal.

(2) Tap on the pry tool with a small and

axle shaft seal.

INSTALLATION

Clean axle shaft seal bore of any excess sealant.

(2) Align axle shaft seal with axle shaft seal bore .

(3) Install axle seal on tool and insert

shaft seal bore.

(4) Tap seal into position.

TSB Revision

Page 994 of 2103

MANUAL TRANSAXLE Case

I \Differential

ing

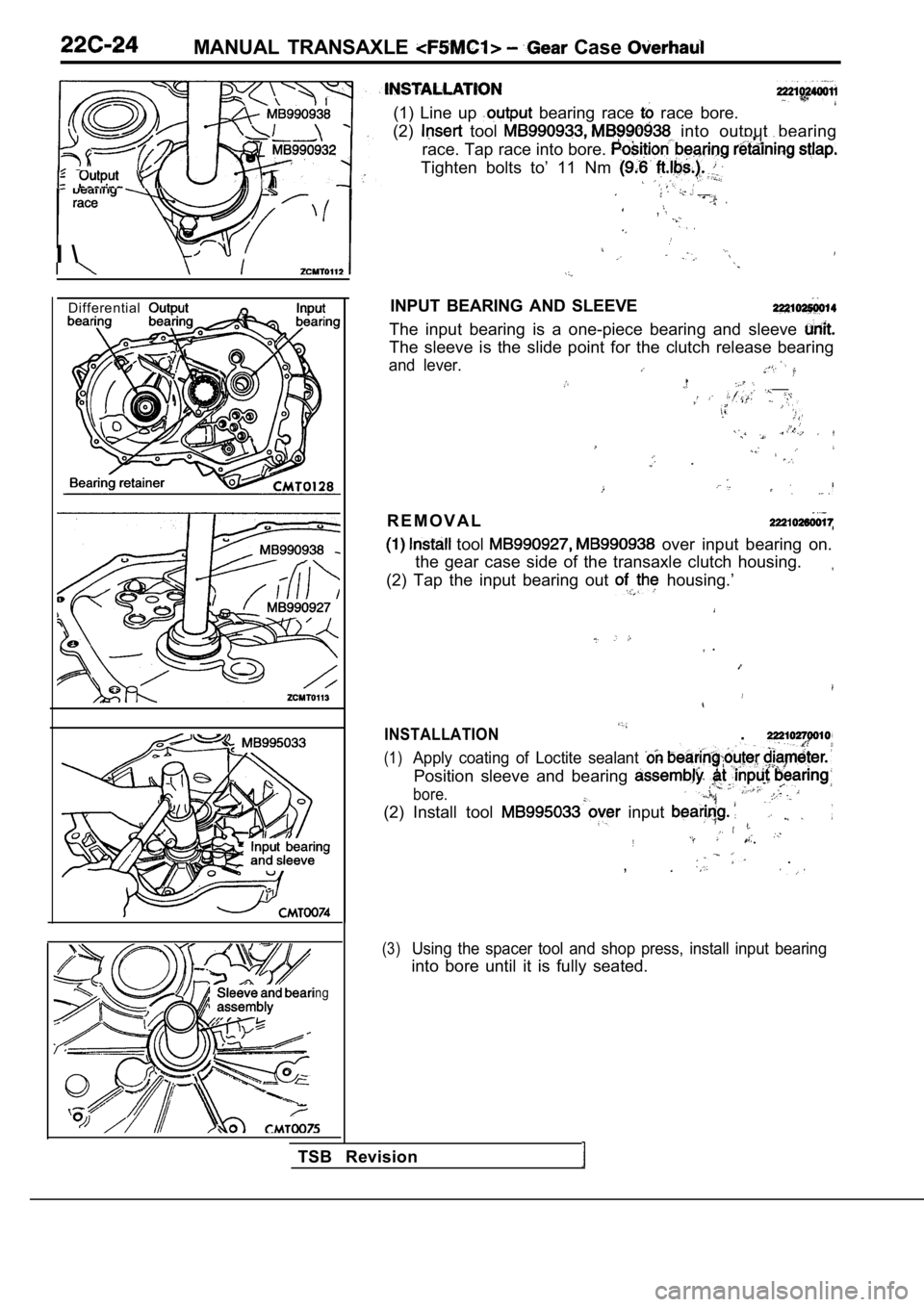

(1) Line up bearing race race bore.

(2) tool into output bearing

race. Tap race into bore.

Tighten bolts to’ 11 Nm

__

,

INPUT BEARING AND SLEEVE

The input bearing is a one-piece bearing and sleeve

The sleeve is the slide point for the clutch release bearing

and lever.

__

R E M O V A L

tool over input bearing on.

the gear case side of the transaxle clutch housing.

(2) Tap the input bearing out housing.’

INSTALLATION.

(1)Apply coating of Loctite sealant

Position sleeve and bearing

bore.

(2) Install tool input

.

.

,

(3)Using the spacer tool and shop press, install input bearing

into bore until it is fully seated.

TSB Revision

Page 995 of 2103

MANUAL TRANSAXLE Case

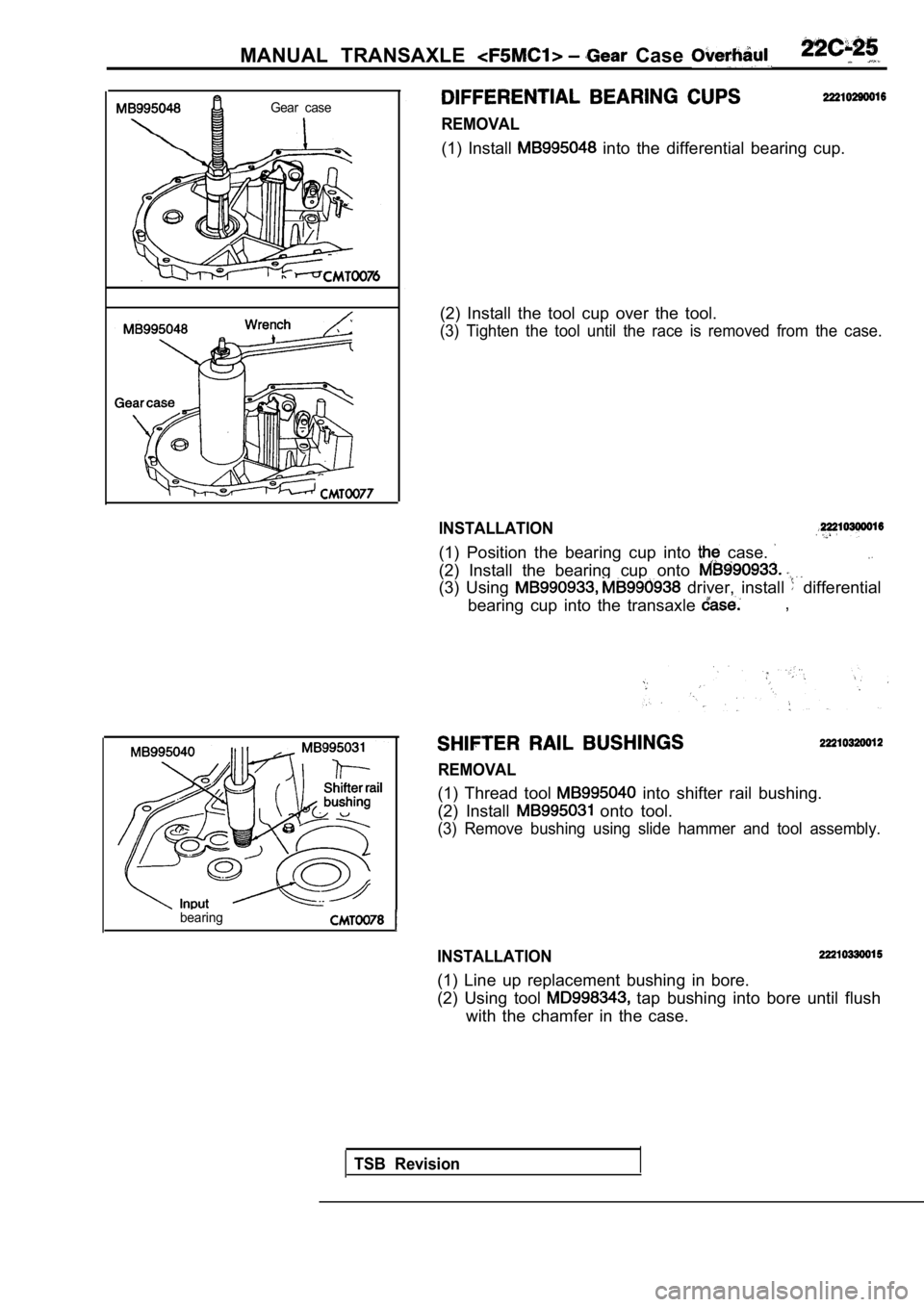

Gear case

REMOVAL

(1) Install into the differential bearing cup.

(2) Install the tool cup over the tool.

(3) Tighten the tool until the race is removed from the case.

INSTALLATION

(1) Position the bearing cup into case.

(2) Install the bearing cup onto

(3) Using driver, install differential

bearing cup into the transaxle

,

REMOVAL

(1) Thread tool into shifter rail bushing.

(2) Install

onto tool.

(3) Remove bushing using slide hammer and tool asse mbly.

bearing

INSTALLATION

(1) Line up replacement bushing in bore.

(2) Using tool

tap bushing into bore until flush

with the chamfer in the case.

TSB Revision

Page 1003 of 2103

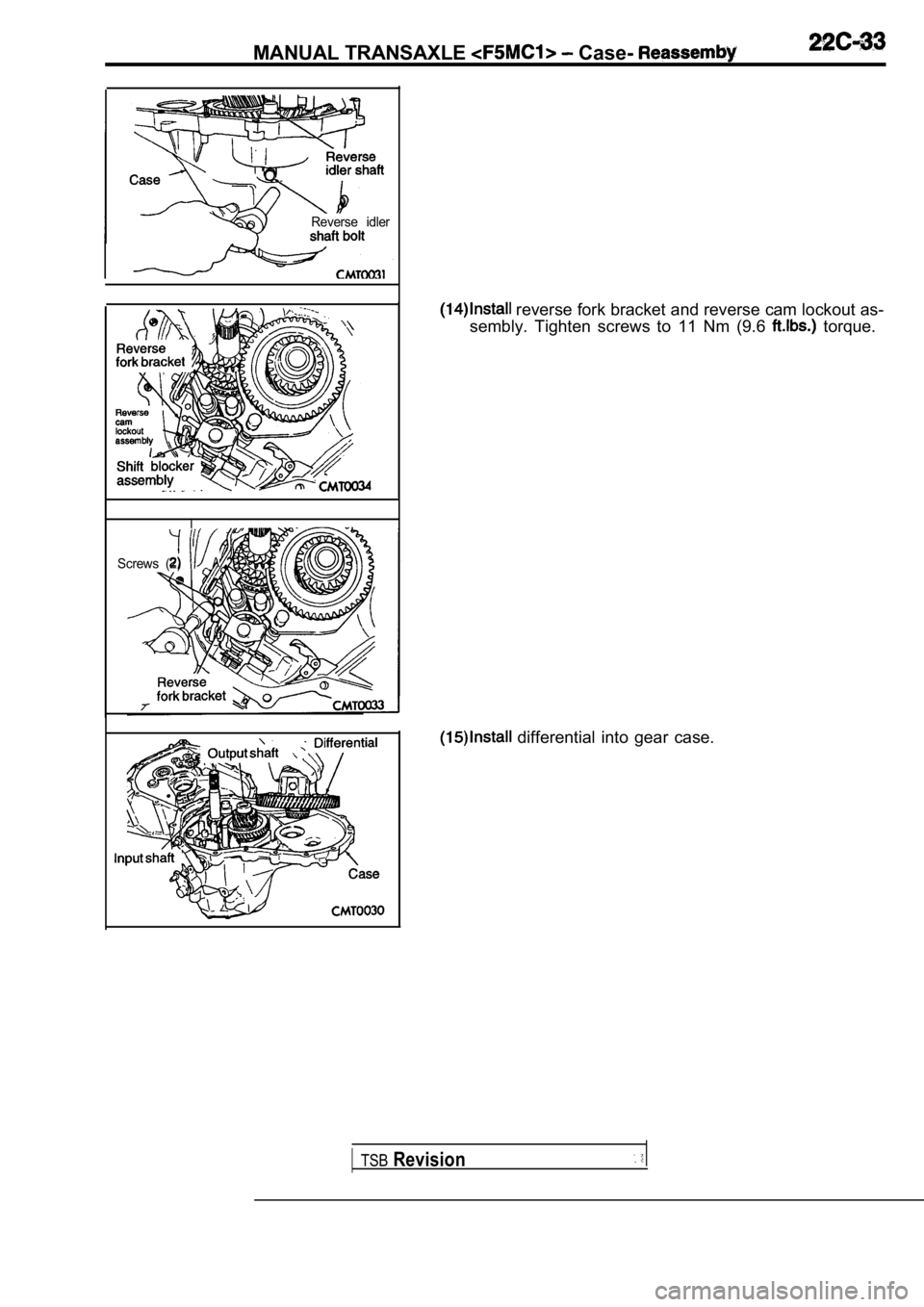

MANUAL TRANSAXLE Case-

Reverse idler

Screws (2)A

TSBRevision

reverse fork bracket and reverse cam lockout as-

sembly. Tighten screws to 11 Nm (9.6

torque.

differential into gear case.

Page 1004 of 2103

TRANSAXLE

G E N E R A L R U L E S O N

(3)

(4)

Take extreme care when removing, and installing bearing

cups and cones. Use only

arbor for installation,

as a hammer may not properly* align the

or cone. Burrs or nicks on the bearing

give a end

play reading while gauging. for proper shims. Impro perly

seated bearing cups and cones are subject to low mi leage’

failure.

Bearing cups and ‘cones should be replaced if they

signs of pitting or heat distress., If distress seen on’

either the cup or bearing rollers, both cone must

be replaced.

Bearing preload and drag torque specifications

maintained to avoid premature’

(original) bearing may lose up to drag

torque offer break in. All bearing, adjustments

made with no other component

mesh.

Replace bearings as a pair. For

bearing is defective, replace both differential.

If one input shaft bearing is defective; ‘replace b oth input

s h a f t b e a r i n g s .

Bearing cones must not be reused if

Turning torque readings should be while smooth-

ly rotating in either direction,,

TSB Revision

Page 1005 of 2103

Differential Bearing

MANUAL TRANSAXLE Preload Adjustment

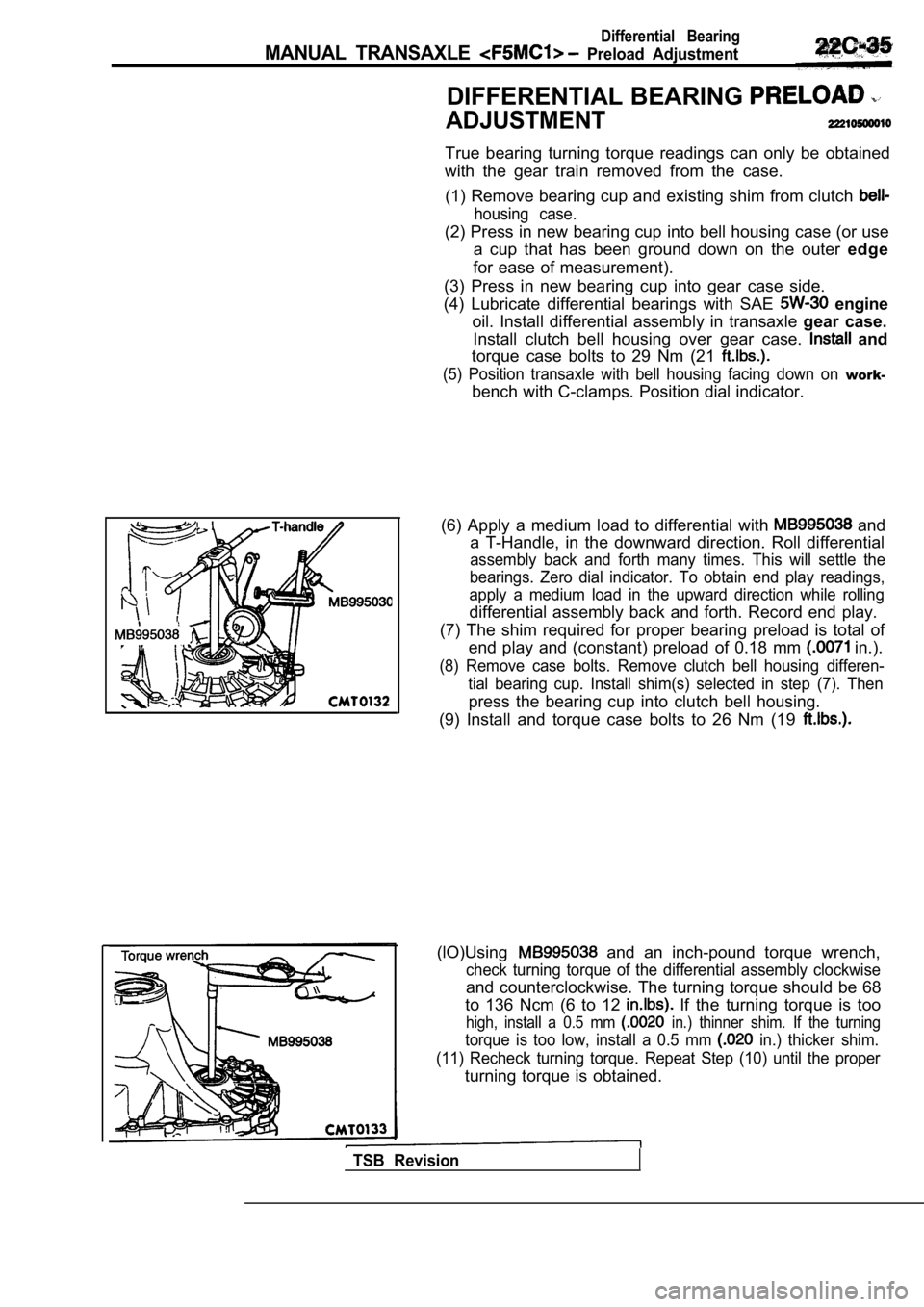

DIFFERENTIAL BEARING

ADJUSTMENT

True bearing turning torque readings can only be obtained

with the gear train removed from the case.

(1) Remove bearing cup and existing shim from clutc h

housing case.

(2) Press in new bearing cup into bell housing case (or use

a cup that has been ground down on the outer edge

for ease of measurement).

(3) Press in new bearing cup into gear case side.

(4) Lubricate differential bearings with SAE

engine

oil. Install differential assembly in transaxle gear case.

Install clutch bell housing over gear case.

and

torque case bolts to 29 Nm (21

(5) Position transaxle with bell housing facing dow n on work-

bench with C-clamps. Position dial indicator.

(6) Apply a medium load to differential with

and

a T-Handle, in the downward direction. Roll differe ntial

assembly back and forth many times. This will settl e the

bearings. Zero dial indicator. To obtain end play r eadings,

apply a medium load in the upward direction while r olling

differential assembly back and forth. Record end play.

(7) The shim required for proper bearing preload is total of

end play and (constant) preload of 0.18 mm

in.).

(8) Remove case bolts. Remove clutch bell housing d ifferen-

tial bearing cup. Install shim(s) selected in step (7). Then

press the bearing cup into clutch bell housing.

(9) Install and torque case bolts to 26 Nm (19

(lO)Using and an inch-pound torque wrench,

check turning torque of the differential assembly c lockwise

and counterclockwise. The turning torque should be 68

to 136 Ncm (6 to 12

If the turning torque is too

high, install a 0.5 mm in.) thinner shim. If the turning

torque is too low, install a 0.5 mm in.) thicker shim.

(11) Recheck turning torque. Repeat Step (10) until the proper

turning torque is obtained.

TSB Revision

Page 1011 of 2103

AUTOMATIC TRANSAXLE ENGINE . .

(TURBO) ENGINE> General Information’ .

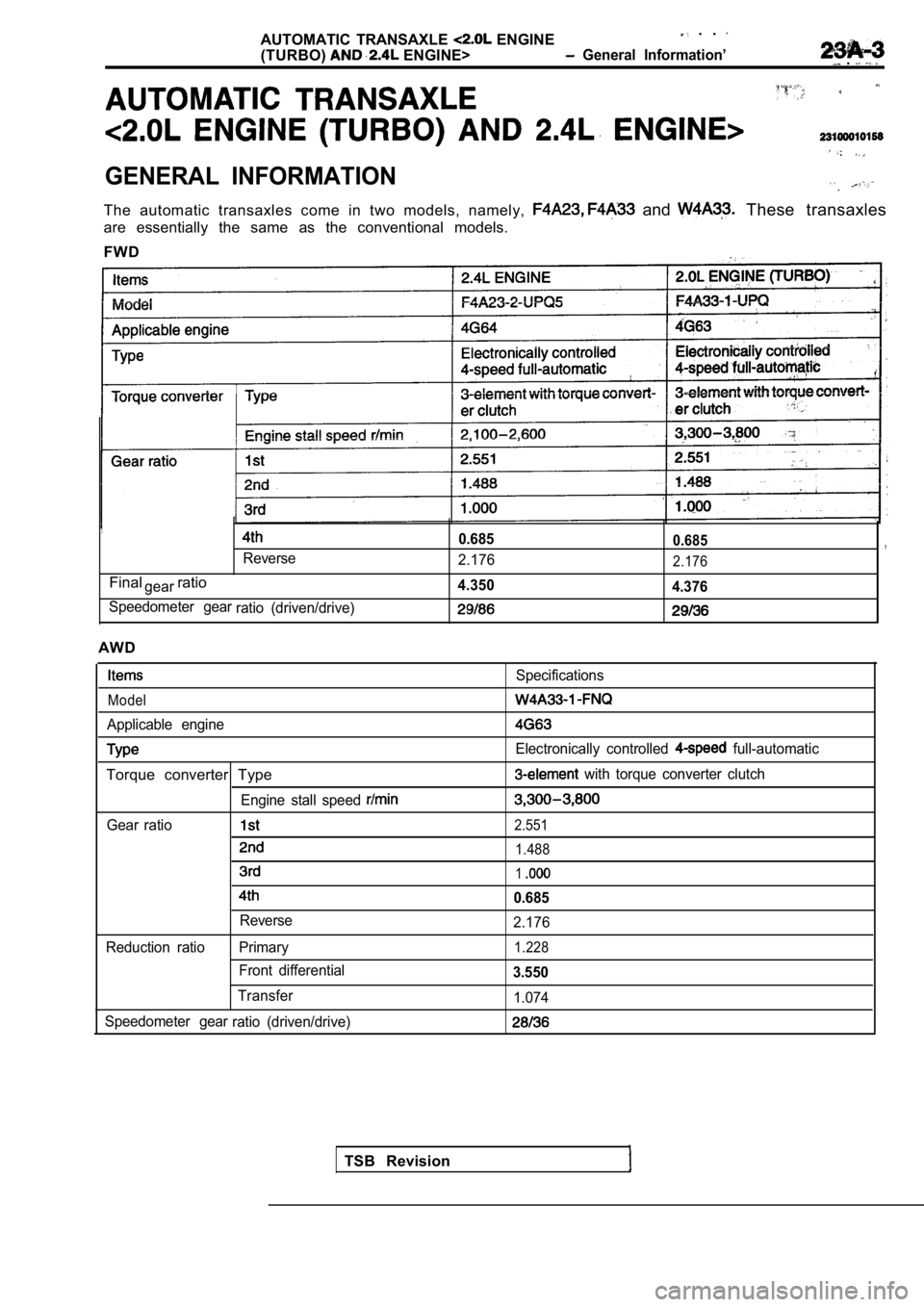

GENERAL INFORMATION

The automatic transaxles come in two models, namely, and These transaxles

are essentially the same as the conventional models .

FWD

Reverse

Final ratiogear

Speedometer gear ratio (driven/drive)

AWD

Model

Applicable engine

Torque converter Type

Engine stall speed

Gear ratio

Reverse

Reduction ratio Primary Front differential

Transfer

Speedometer gear ratio (driven/drive)

0.6850.685,

2.1762.176

4.350

4.376

Specifications

Electronically controlled full-automatic

with torque converter clutch

2.551

1.488

1

0.685

2.176

1.228

3.550

1.074

TSB Revision

Page 1013 of 2103

AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND ENGINE> General tnformation

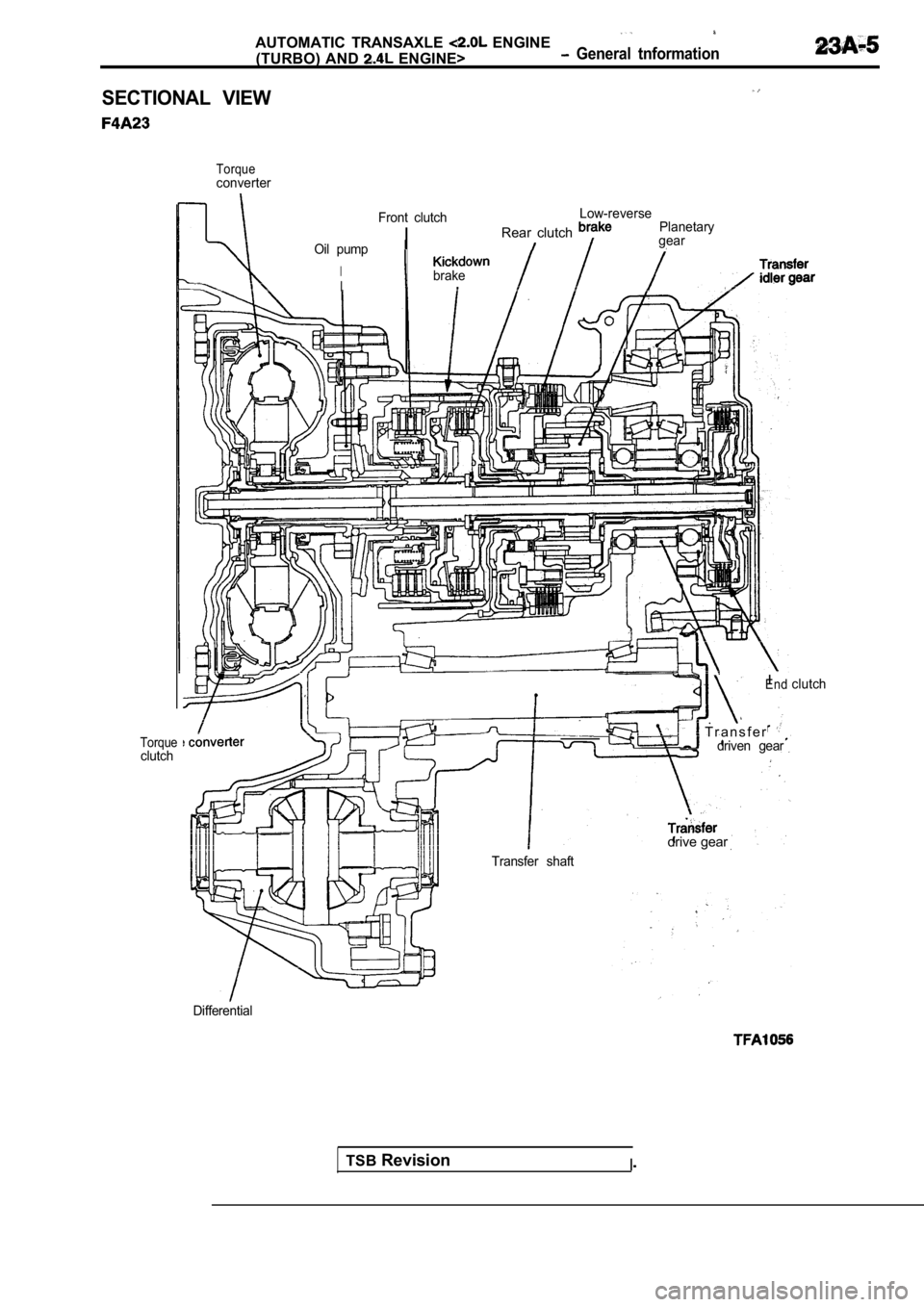

SECTIONAL VIEW

TorqueconverterOil pump

I

Front clutch

I

Low-reverse

Rear clutch Planetarygear

Ibrake

Torqueclutch

TSBRevisionI-

End

T r a n s f e rdriven gear

drive gear

Transfer shaft

Differential

clutch

Page 1015 of 2103

TRANSAXLE ENGINE

(TURBO) AND

ENGINE> General Information

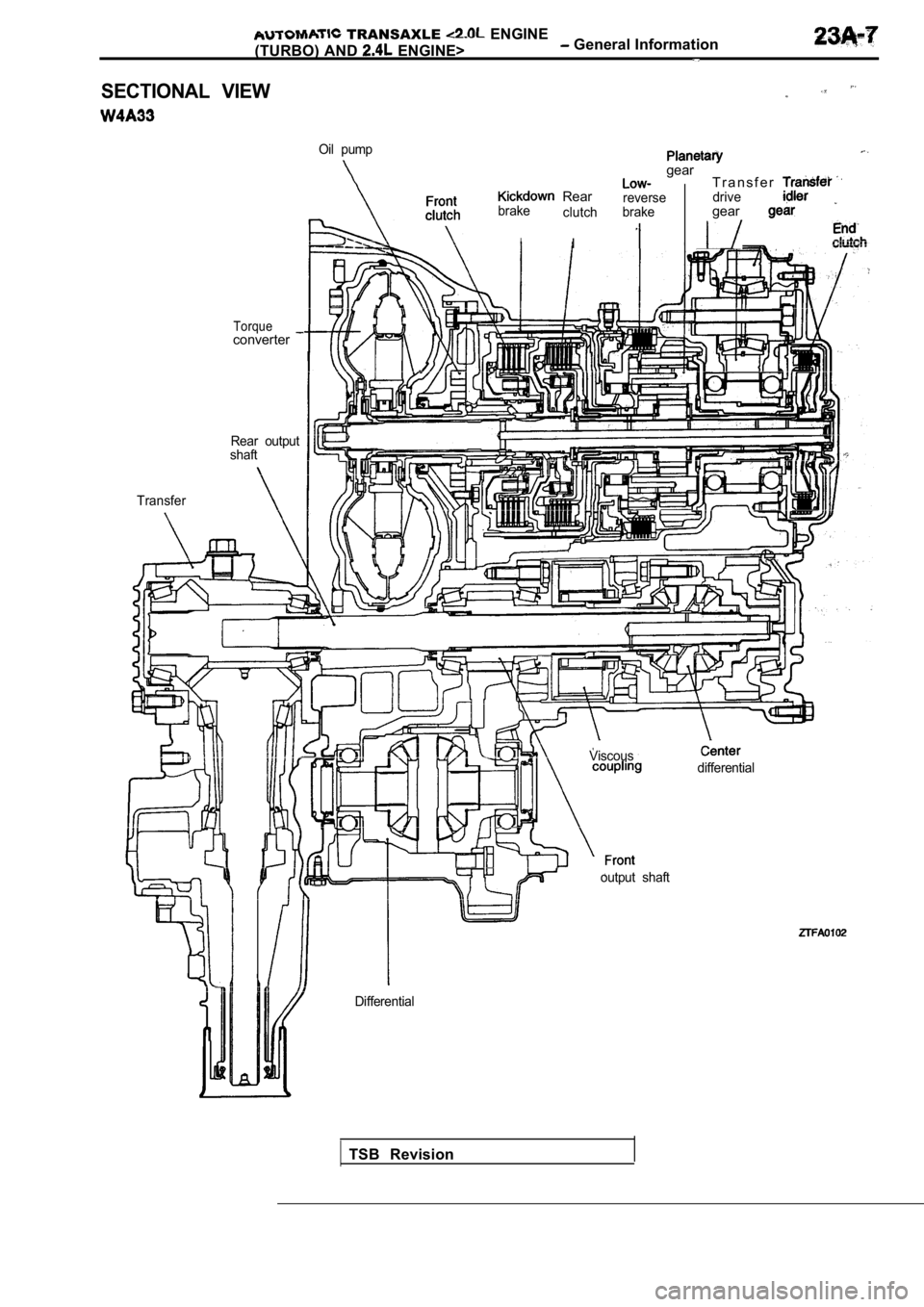

SECTIONAL VIEW

Torqueconverter

Rear output

shaft

Transfer Oil pump

gear

RearreverseT r a n s f e rdrive

brake clutchbrakegear

II

TSB Revision

differential

output shaft

Differential Viscous