differential MITSUBISHI SPYDER 1990 Service Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1288 of 2103

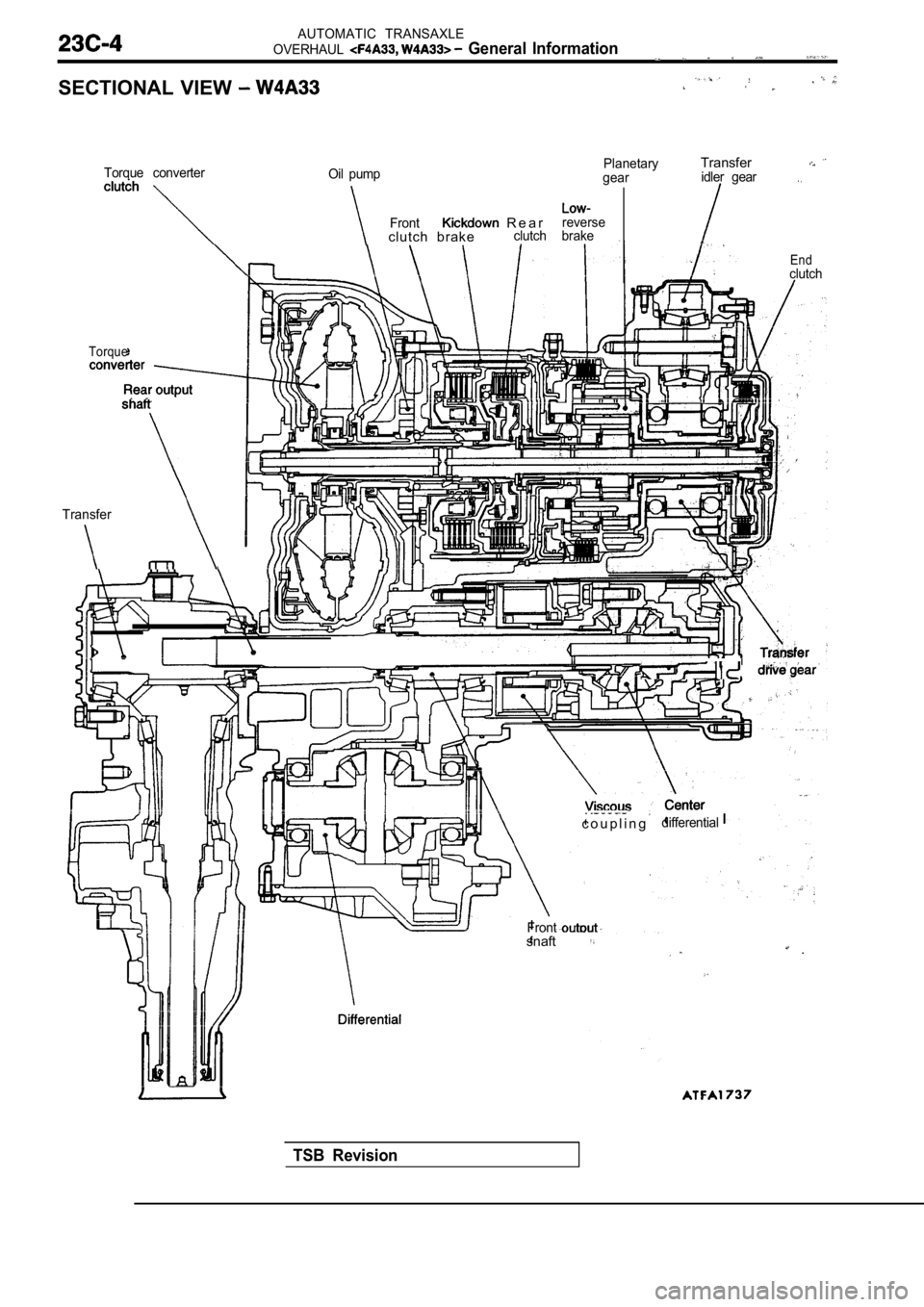

AUTOMATIC TRANSAXLE

OVERHAUL

General Information

SECTIONAL VIEW

Torque converter Oil pump

Front R e a r

clutch brakeclutch

Torque

Transfer

Planetary

gearTransferidler gear

reverse

brake

Endclutch

TSB Revision

c o u p l i n g

Front

differential

snaft.

Page 1291 of 2103

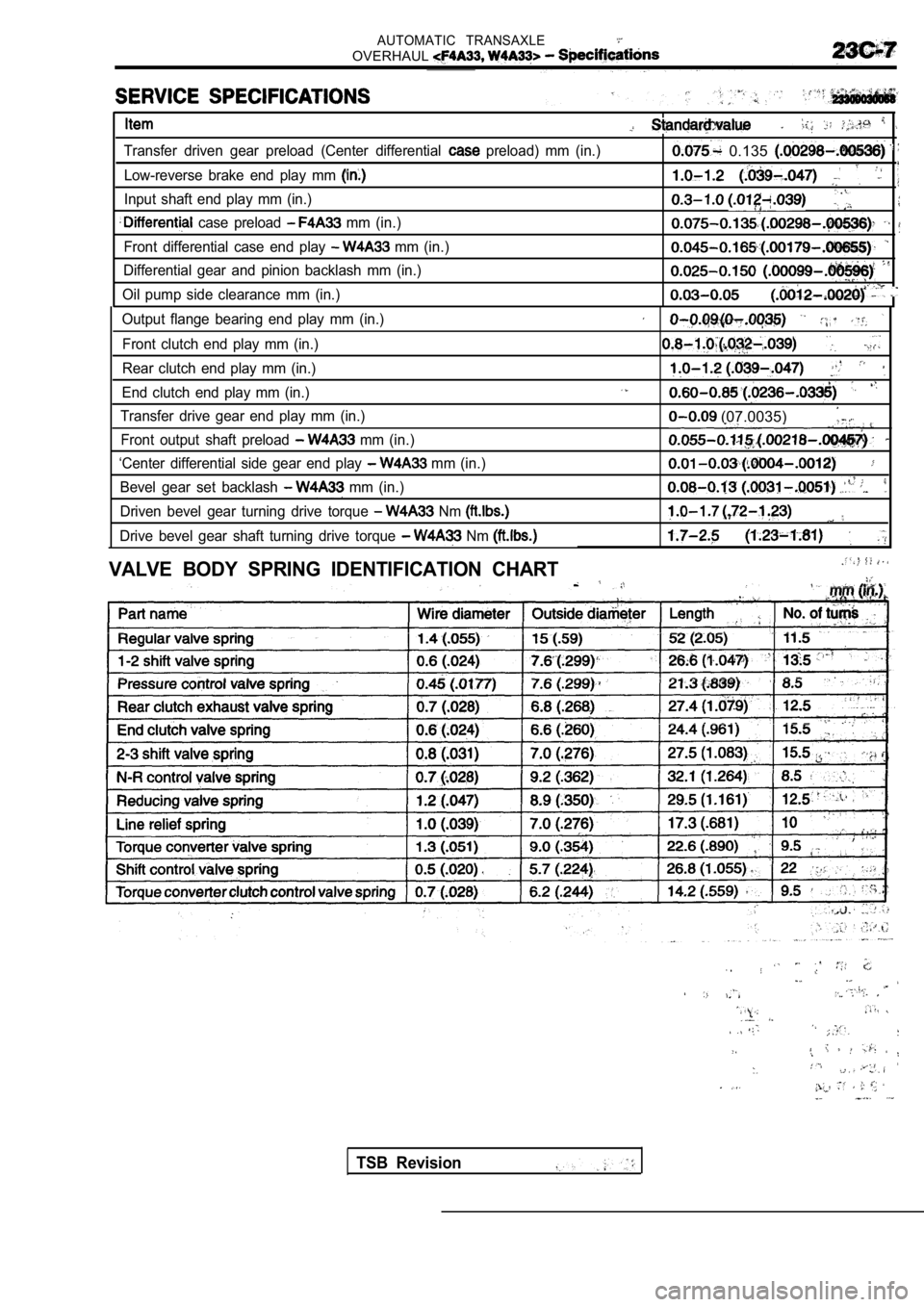

AUTOMATIC TRANSAXLE

OVERHAUL

Transfer driven gear preload (Center differential preload) mm (in.) 0.135

Low-reverse brake end play mm

Input shaft end play mm (in.)

case preload mm (in.)

Front differential case end play mm (in.)

Differential gear and pinion backlash mm (in.)

Oil pump side clearance mm (in.)

Output flange bearing end play mm (in.)Front clutch end play mm (in.)

Rear clutch end play mm (in.)

End clutch end play mm (in.)

Transfer drive gear end play mm (in.)

Front output shaft preload

mm (in.)

‘Center differential side gear end play

mm (in.)

Bevel gear set backlash

mm (in.)

Driven bevel gear turning drive torque

Nm

Drive bevel gear shaft turning drive torque Nm

(07.0035)

VALVE BODY SPRING IDENTIFICATION CHART

TSB Revision

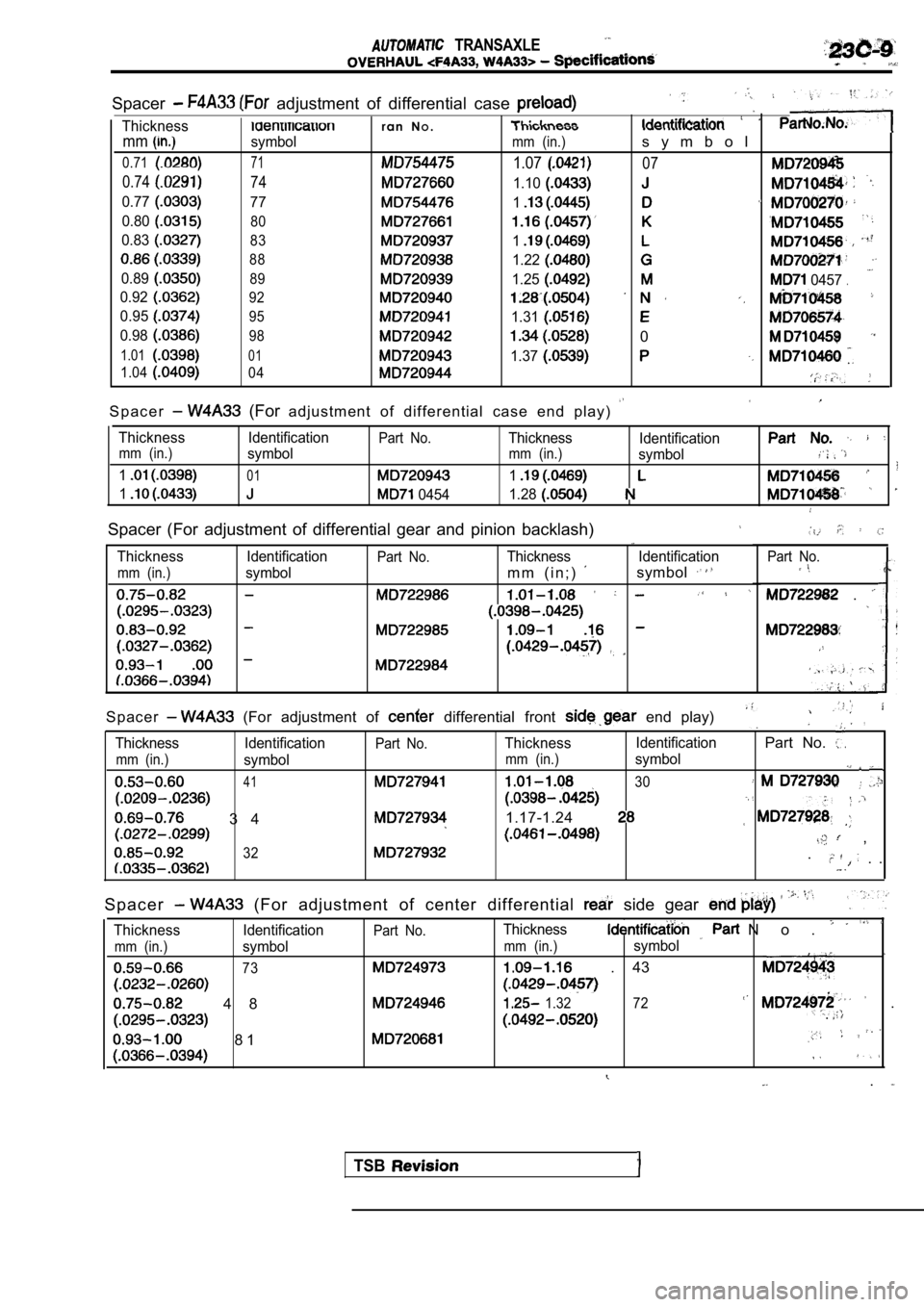

Page 1293 of 2103

TRANSAXLE

Spacer adjustment of differential case

Thickness

mmsymbol

0.7171

0.7474

0.7777

0.80

80

0.8383

88

0.8989

0.9292

0.9595

0.9898

1.0101

1.0404

r a n N O.

mm (in.)s y m b o l

1.0707

1.10

1

1

1.22

.1.25 0457

1.31

0

1.37

S p a c e r (For a d j u s t m e n t o f d i f f e r e n t i a l c a s e e n d p l a y )

Thickness

mm (in.)

1

1

Identification

symbol

01

Part No.

0454 Thickness

mm (in.)

1

1.28

Identification

symbol

Spacer (For adjustment of differential gear and pin ion backlash)

Thickness Identification

mm (in.)symbol

Part No.Thickness Identification

m m ( i n ; ) symbol

Part No.

.

S p a c e r (For adjustment of differential front end play)

Part No.

,

Thickness IdentificationPart No.ThicknessIdentification

mm (in.)symbolmm (in.)symbol

4130

3 4 1.17-1.24

,

32.. .

S p a c e r (For adjustment of center differential side gear

Thickness IdentificationPart No.Thickness N o .

mm (in.)symbolmm (in.)symbol

73. 43

4 8 1.32 72 .

.

8 1

.

TSB

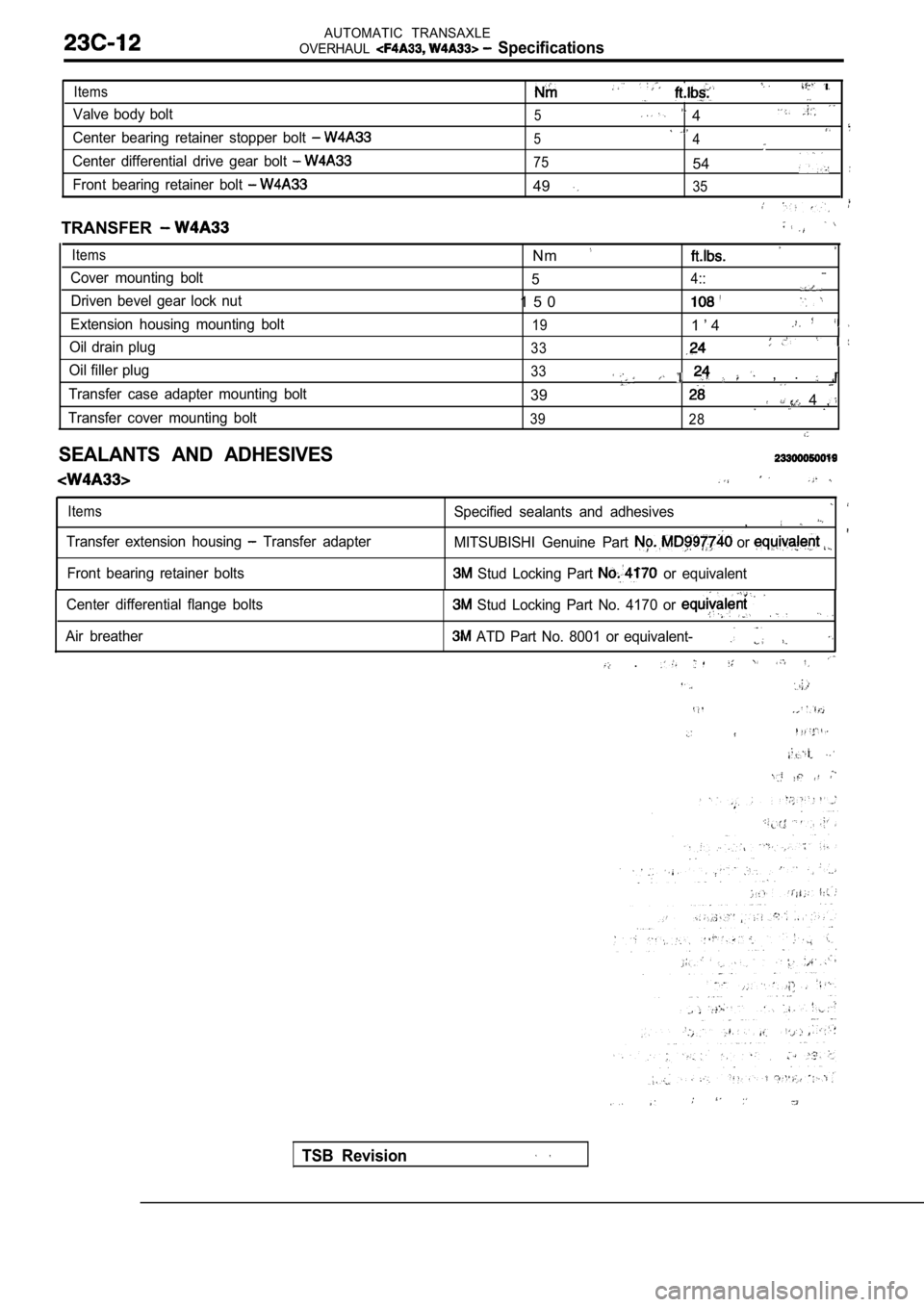

Page 1296 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

Specifications

Items

Valve body bolt

Center bearing retainer stopper bolt

Center differential drive gear bolt

Front bearing retainer bolt

5 4

54

7554

4935

TRANSFER

Items

Cover mounting bolt Driven bevel gear lock nut

Extension housing mounting bolt

Oil drain plug

Oil filler plug

Transfer case adapter mounting bolt

Transfer cover mounting bolt

Nm_ _54::

1 5 0

191 ’ 4

33

33 , .

39 4 ,

39 28

SEALANTS AND ADHESIVES

Items

Transfer extension housing Transfer adapter Specified sealants and adhesives

,

MITSUBISHI Genuine Part or

Front bearing retainer bolts Stud Locking Part or equivalent

Center differential flange bolts

Air breather

Stud Locking Part No. 4170 or

ATD Part No. 8001 or equivalent-

.

TSB Revision

Page 1305 of 2103

A U T O M A T I C T R A N S A X L E

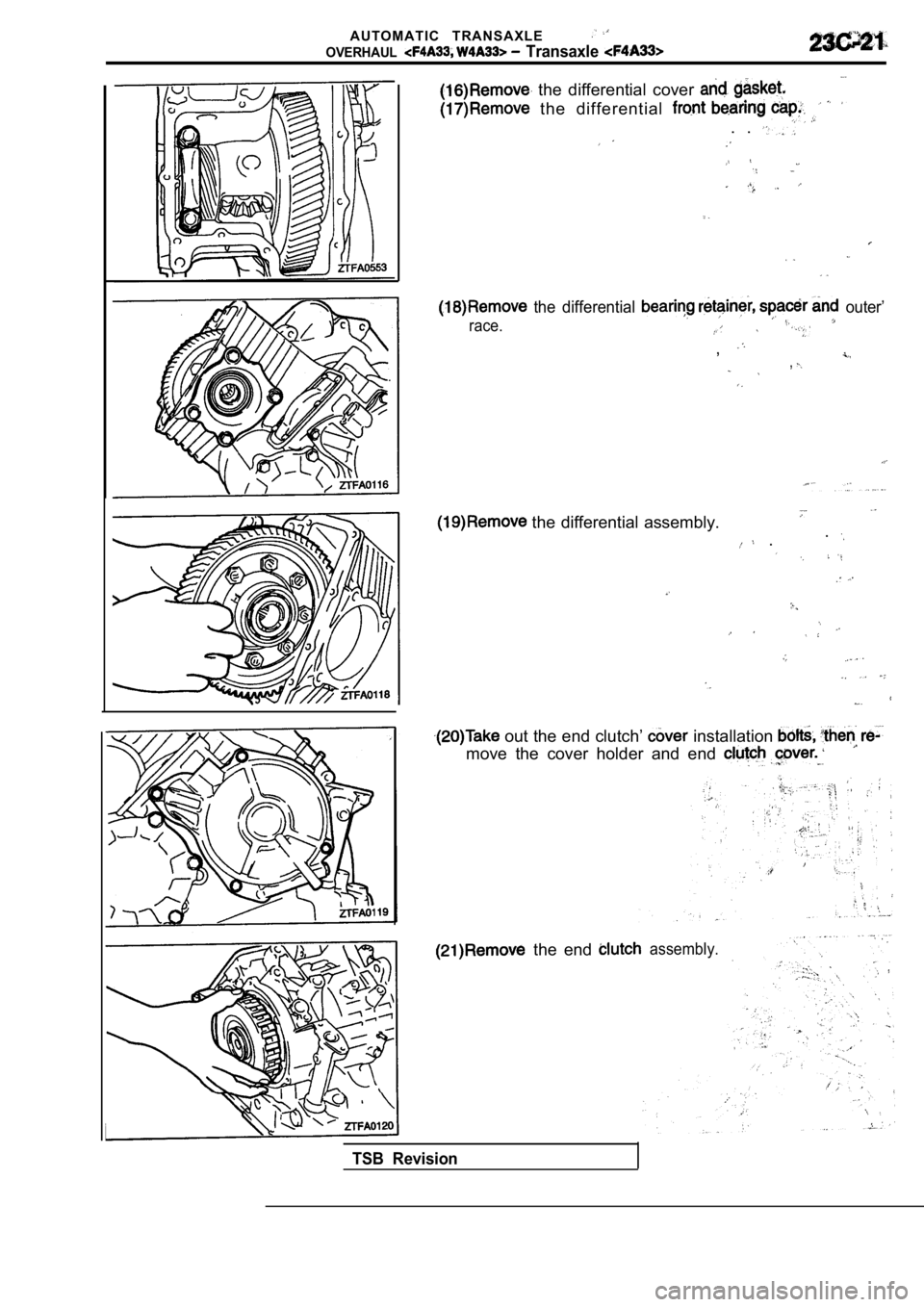

OVERHAUL Transaxle

the differential cover

the differential

. .

the differential outer’

race.

,,

the differential assembly.. .

out the end clutch’ installation

move the cover holder and end

the end assembly.

TSB Revision

Page 1312 of 2103

-Transaxle

Differential

bearing

retainer

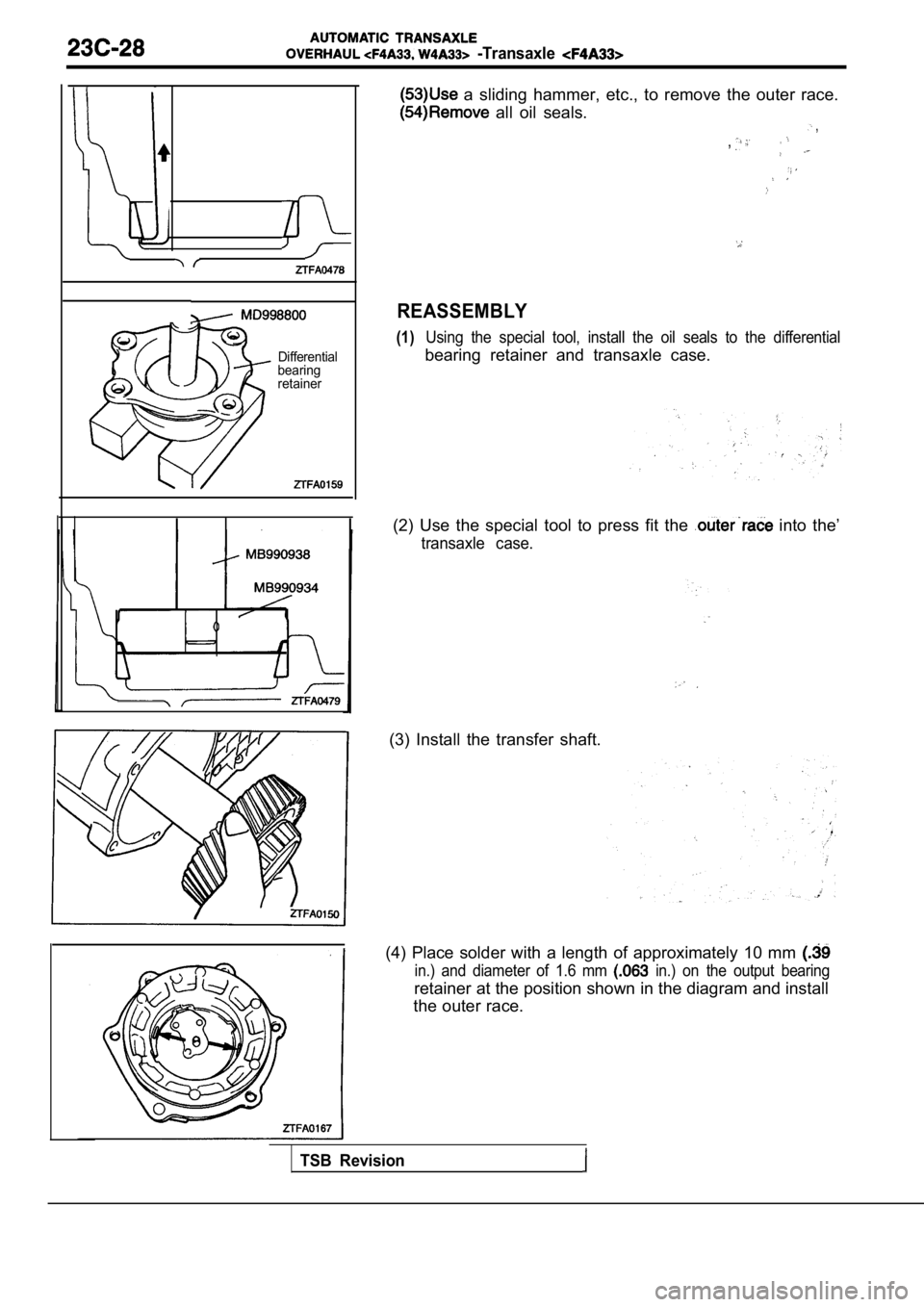

a sliding hammer, etc., to remove the outer race.

all oil seals. ,

,

REASSEMBLY

(1)Using the special tool, install the oil seals to th e differential

bearing retainer and transaxle case.

(2) Use the special tool to press fit the

into the’

transaxle case.

(3) Install the transfer shaft.

(4) Place solder with a length of approximately 10 mm

in.) and diameter of 1.6 mm in.) on the output bearing

retainer at the position shown in the diagram and install

the outer race.

TSB Revision

Page 1323 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL

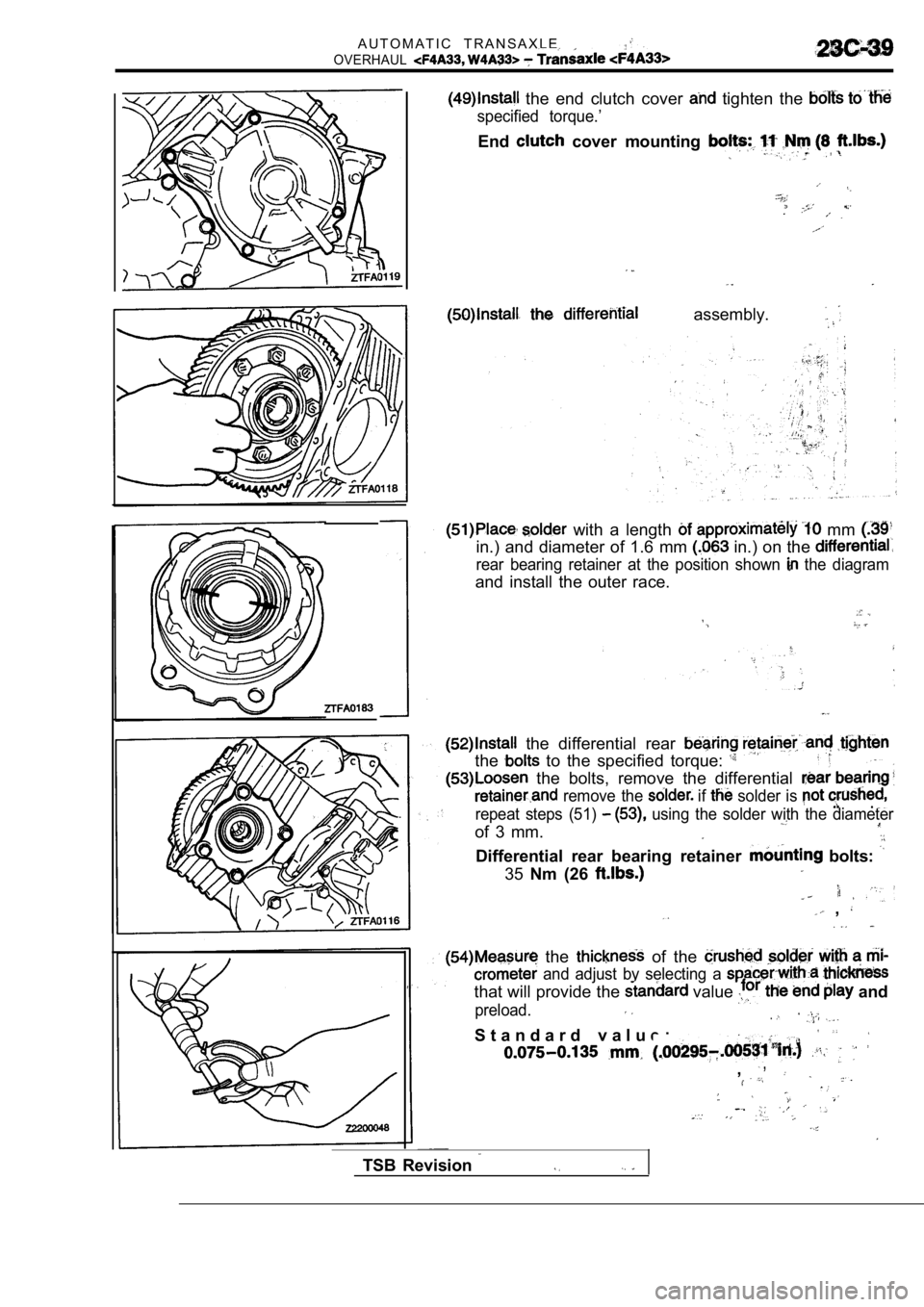

the end clutch cover tighten the

specified torque.’

End cover mounting

assembly.

with a length mm

in.) and diameter of 1.6 mm in.) on the

rear bearing retainer at the position shown the diagram

and install the outer race.

the differential rear

the to the specified torque:

the bolts, remove the differential

remove the if solder is

repeat steps (51) using the solder with the diameter

of 3 mm.

Differential rear bearing retainer bolts:

35Nm (26

,

the of the

and adjust by selecting a

that will provide the value and

preload..

S t a n d a r d v a l u e :

,,

TSB Revision

Page 1324 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

-Transaxle

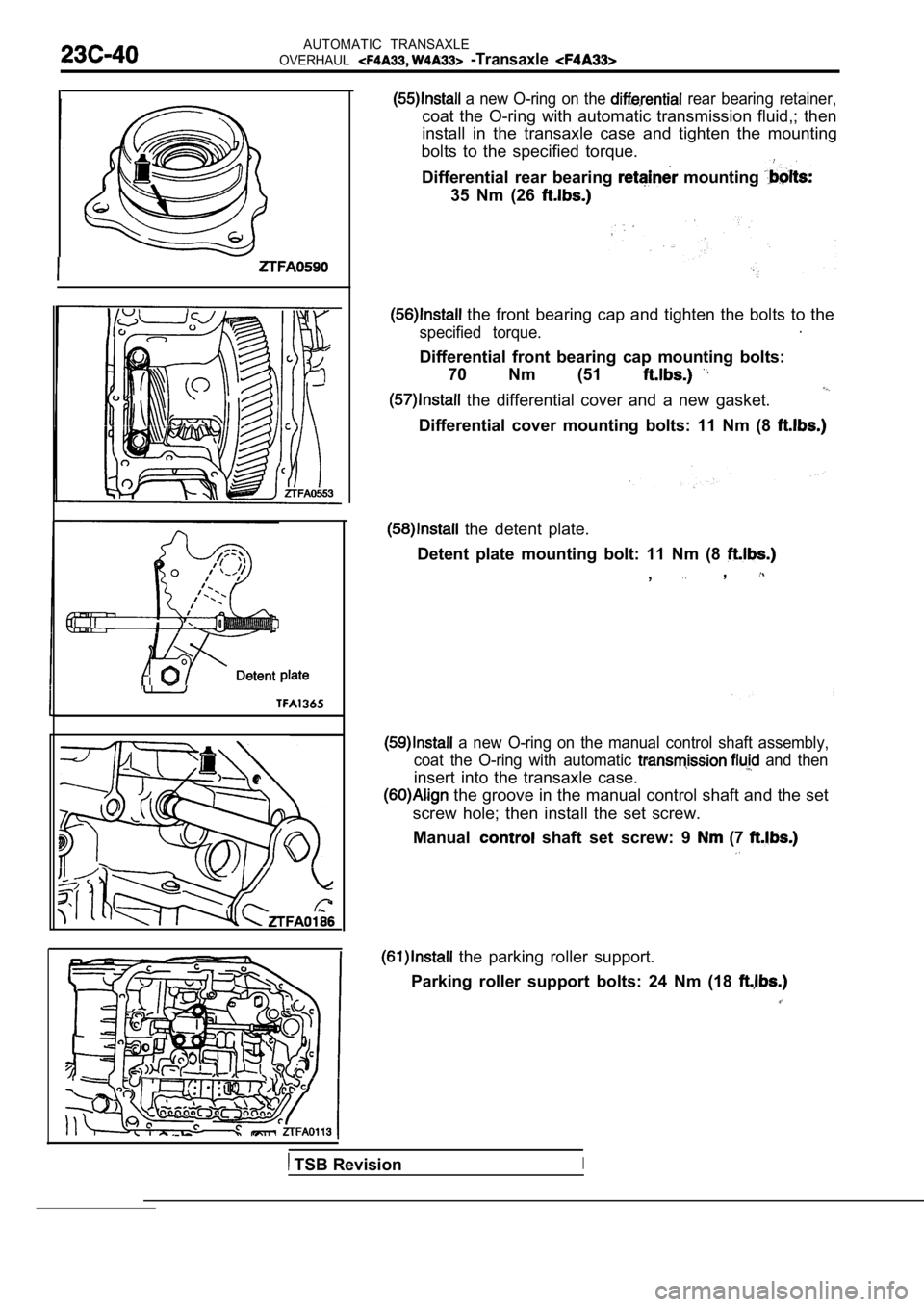

a new O-ring on the rear bearing retainer,

coat the O-ring with automatic transmission fluid,; then

install in the transaxle case and tighten the mount ing

bolts to the specified torque.

Differential rear bearing

mounting

35 Nm (26

the front bearing cap and tighten the bolts to the

specified torque..

Differential front bearing cap mounting bolts: 70 Nm (51

the differential cover and a new gasket.

Differential cover mounting bolts: 11 Nm (8

the detent plate.

Detent plate mounting bolt: 11 Nm (8

,,

a new O-ring on the manual control shaft assembly,

coat the O-ring with automatic

and then

insert into the transaxle case.

the groove in the manual control shaft and the set

screw hole; then install the set screw.

Manual

shaft set screw: 9 (7

the parking roller support.

Parking roller support bolts: 24 Nm (18

TSB RevisionI

Page 1331 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL -Transaxle

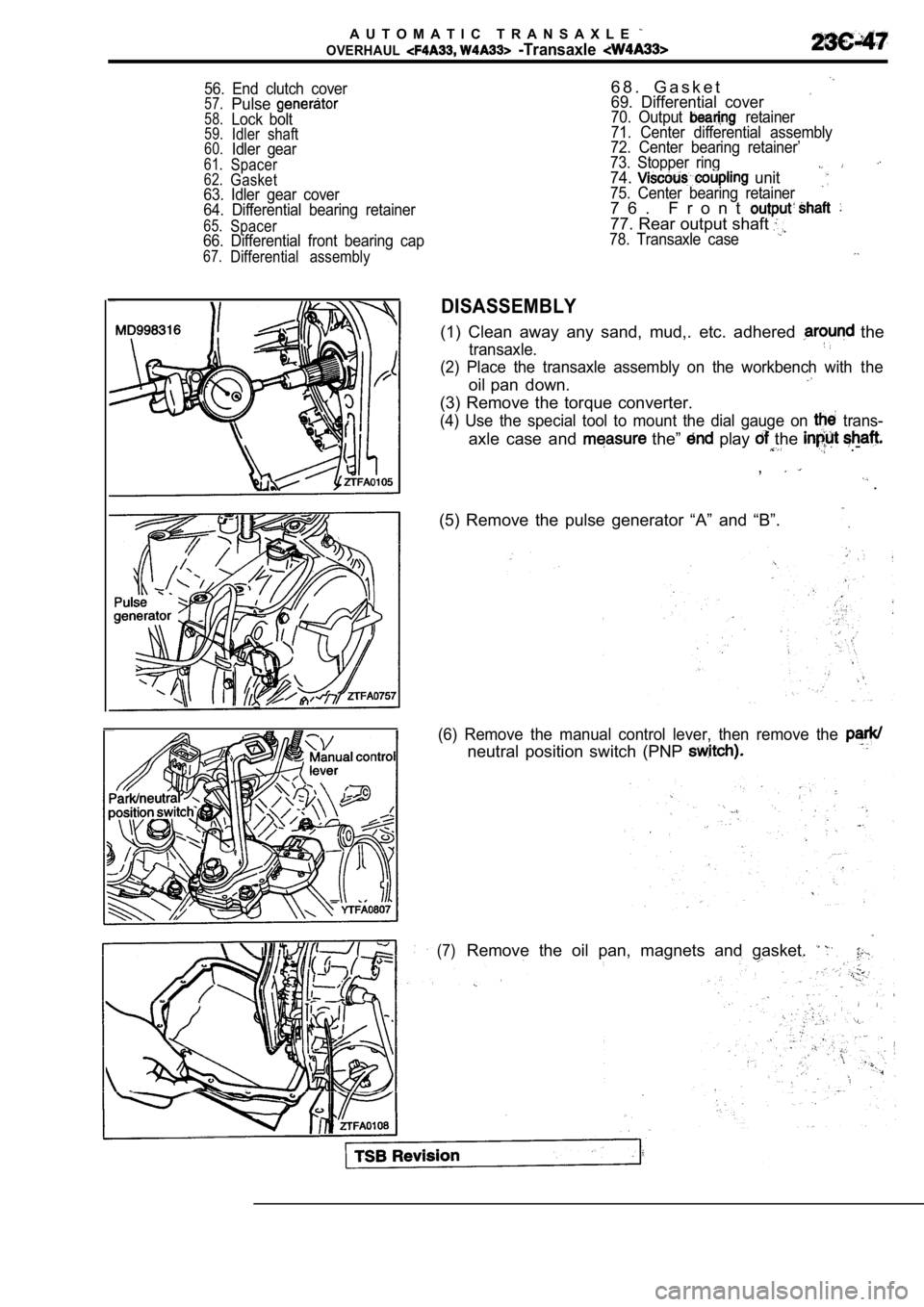

56. End clutch cover57.Pulse58.Lock bolt59.Idler shaft60.Idler gear61.Spacer62.Gasket63. Idler gear cover

64. Differential bearing retainer

65.Spacer66. Differential front bearing cap

67.Differential assembly

6 8 . G a s k e t69. Differential cover70. Output retainer

71. Center differential assembly

72. Center bearing retainer’

73. Stopper ring

74. unit75. Center bearing retainer7 6 . F r o n t

77. Rear output shaft 78. Transaxle case

DISASSEMBLY

(1) Clean away any sand, mud,. etc. adhered the

transaxle.

(2) Place the transaxle assembly on the workbench w ith the

oil pan down.

(3) Remove the torque converter.

(4) Use the special tool to mount the dial gauge on trans-

axle case and the” play the .-

,

.

(5) Remove the pulse generator “A” and “B”.

(6) Remove the manual control lever, then remove th e

neutral position switch (PNP

(7)Remove the oil pan, magnets and gasket.

Page 1333 of 2103

AUTOMATIC .

OVERHAUL

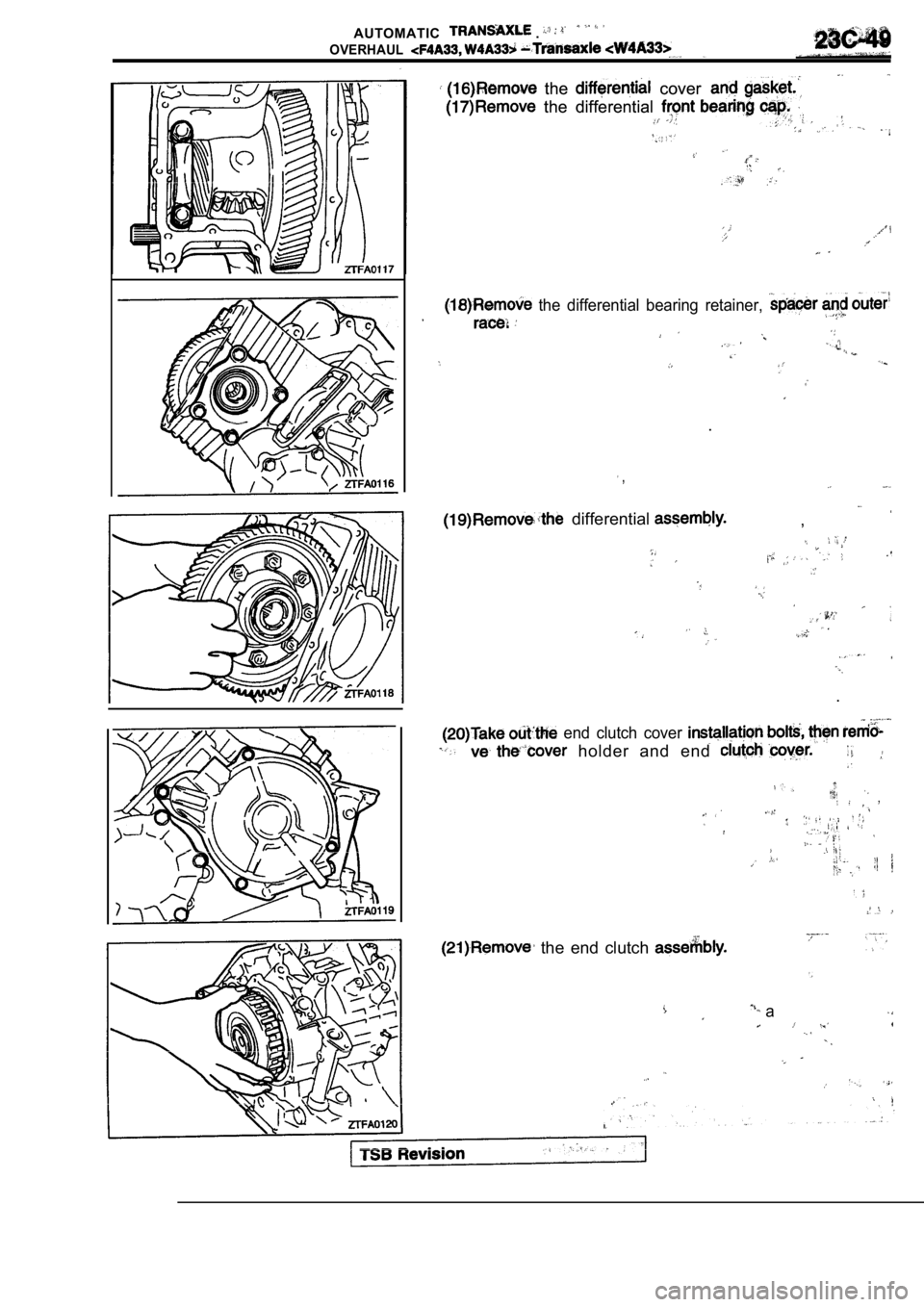

the cover the cover

the differential the differential

the differential bearing retainer,

.

,

differential,

.

end clutch cover

holder and end

the end clutch

a