differential MITSUBISHI SPYDER 1990 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1124 of 2103

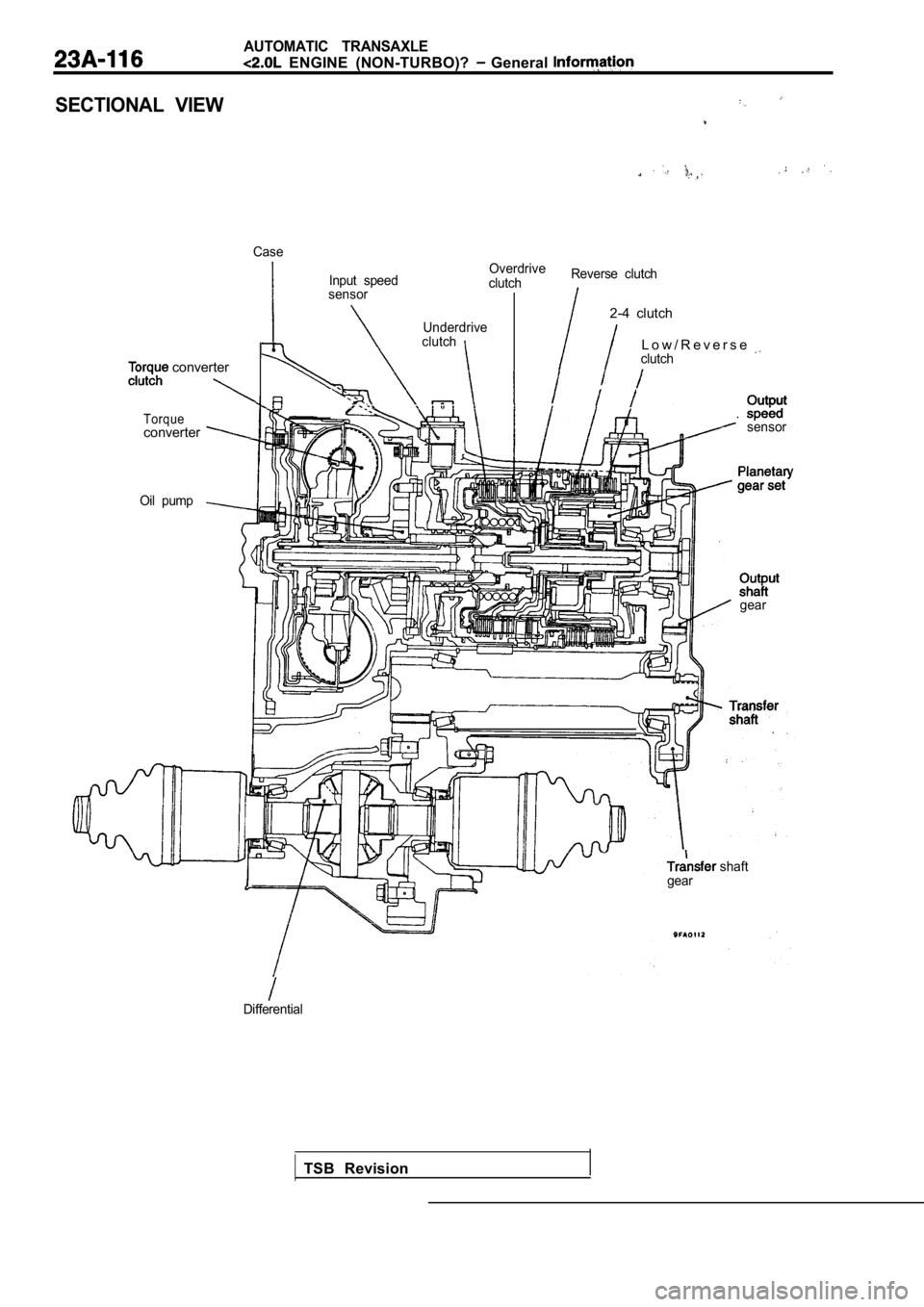

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)? General

SECTIONAL VIEW

Case

Input speedOverdrive

clutch Reverse clutch

sensor

2-4 clutchUnderdrive

clutch

L o w / R e v e r s eclutch converter

Torqueconverter

.sensor

Oil pump

TSB Revision

shaft

gear

gear

Differential

Page 1207 of 2103

.

,

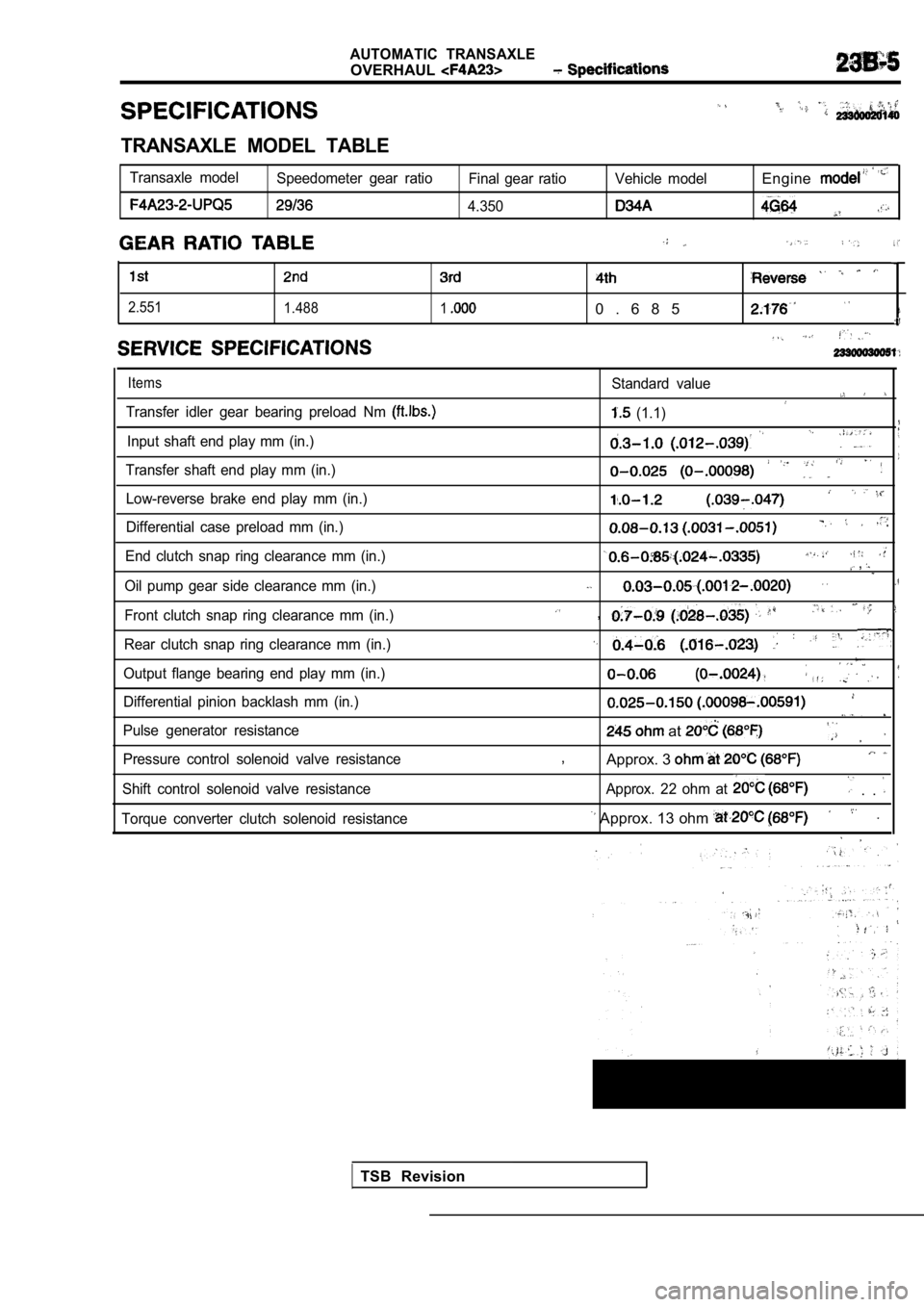

GEAR AND TRANSFER DRIVE

GEAR SET . . . .

. . . . . . . . . . . . . . . . . . . . . . . .62

DIFFERENTIAL

. . . . . . . . . . . . . . . . . . . . . . . . . . . .64

DRIVE SHAFT OIL SEAL . . . . . . . . . . . . . . . . . .70

END CLUTCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

FRONT CLUTCH. . . . . . . . . . . . . . . . . . . . . . . . . .51

GENERAL INFORMATION. . . . . . . . . . . . . . . . . .2

SERVO. . . . . . . . . . . . . . . . . . . . . . .68

LOW-REVERSE BRAKE. . . . . . . . . . . . . . . . . .67

OIL PUMP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

PLANETARY GEAR

. . . . . . . . . . . . . . . . . . . . . . .59

REAR CLUTCH. . . . . . . . . . . . . . . . . . . . . . . . . . .54

SPECIAL. . . . . ... . . . . . . . . . . . .. . ...... ....

SPECIFICATIONS. . . . . . . . . . . . . .. .. . . ........ .

Gear Ratio Table. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Plates, Snap Rings and

Spacers for Adjustment. . . . . . . . . . . . . . . . . . . . . .6

Service Specifications. . . . . . . . . . . . . . . . . . . . . . . .5

Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . .9

Transaxle Model Table. . . . . . . . . . . . . . . . . . . . . . .5

Valve Body Spring Identification . . . . . . . . . . . . . . .6

SPEEDOMETER GEAR. . . . . . . . . . . . . . . . . . .

TRANSAXLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

TRANSFER DRIVEN GEAR . . . . . . . . . . . . . . .

TRANSFER SHAFT

. . . . . . . . . . . . . . . . . . . . . . .71

VALVE BODY. . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Page 1209 of 2103

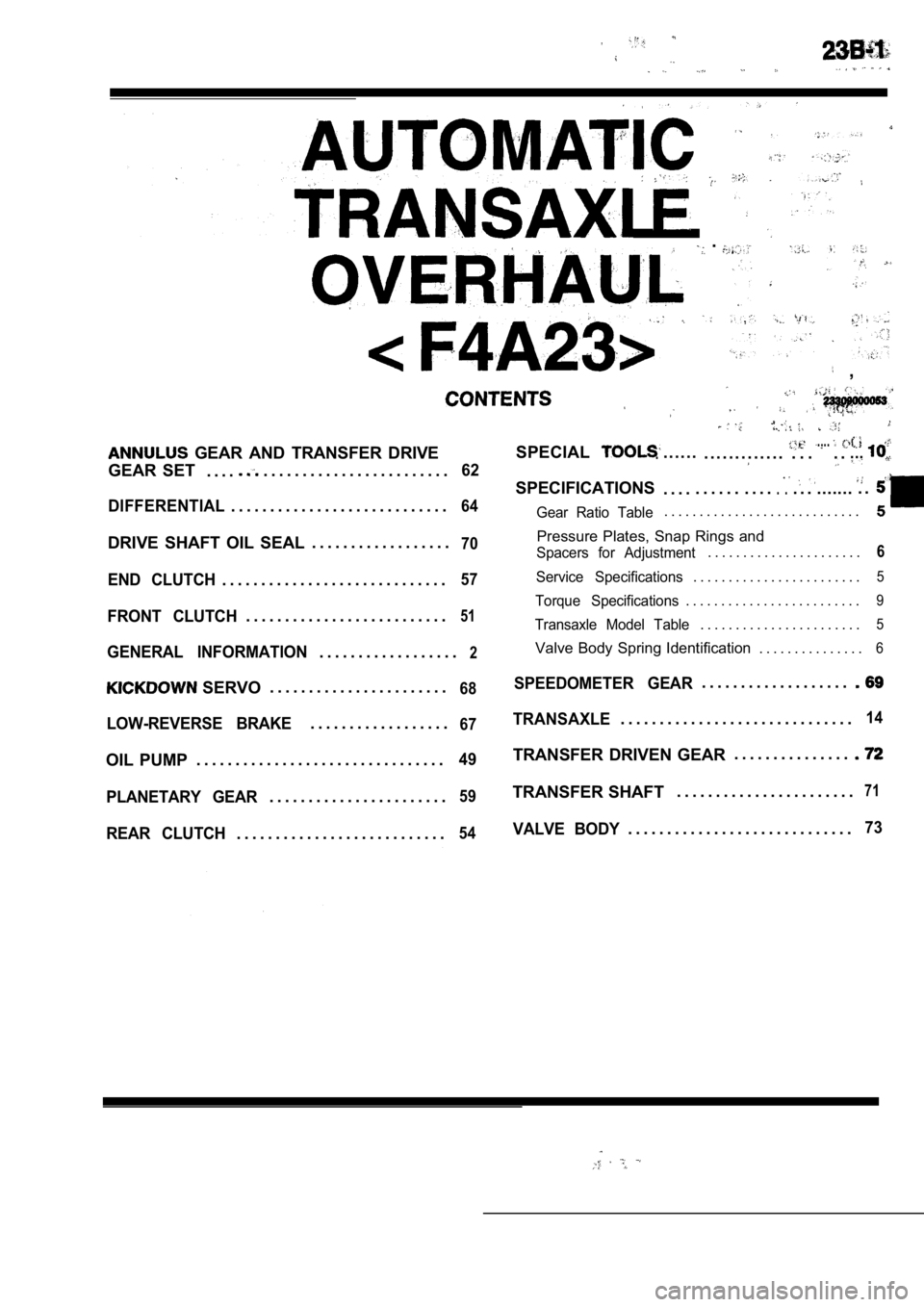

AUTOMATIC TRANSAXLE

OVERHAUL Information

Torqueconverter

Front

clutch Rear

clutch

Oil pump

brake

I

TSB Revision

Transferdrive

Transferdriven gear

Differential

Page 1211 of 2103

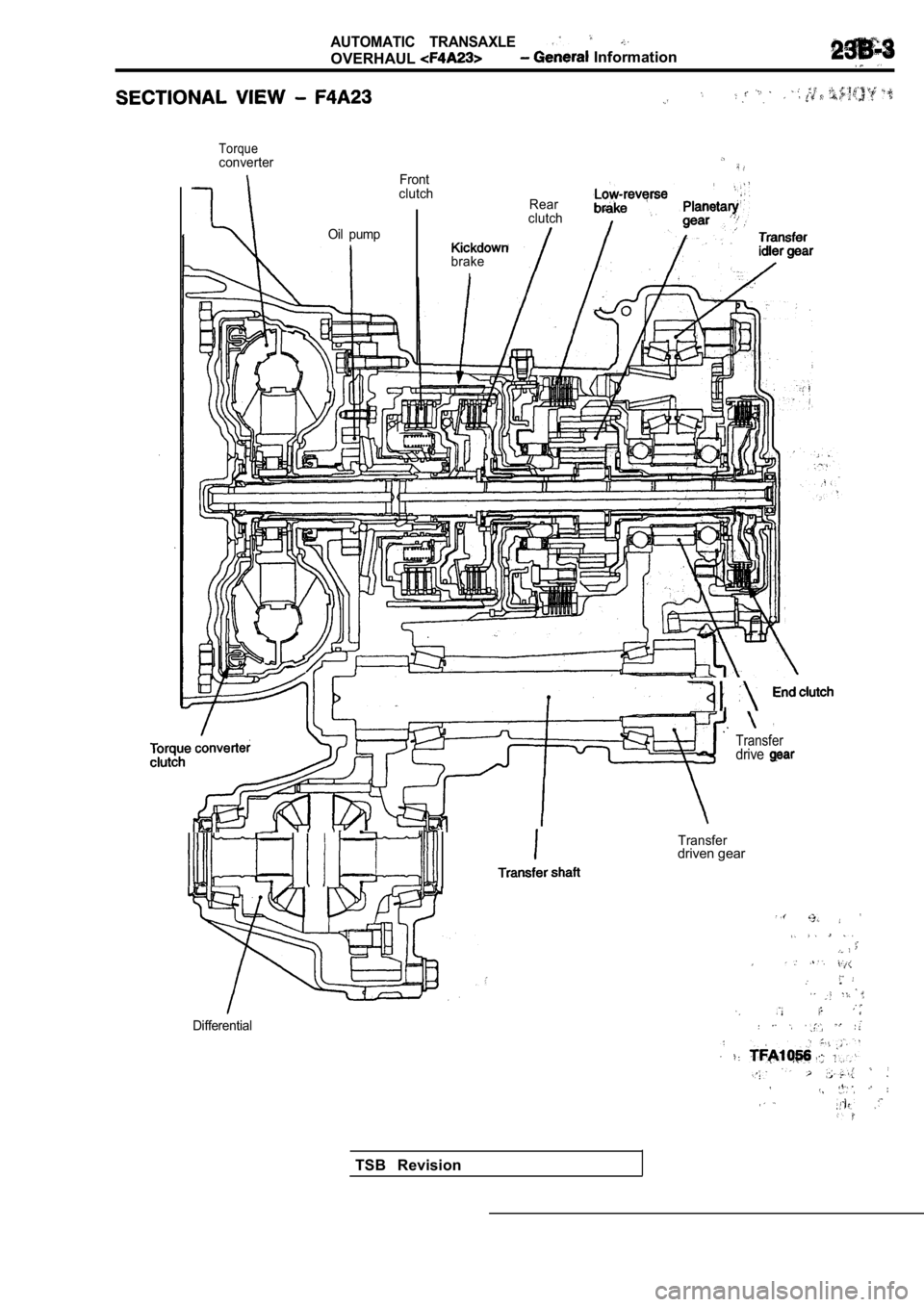

AUTOMATIC TRANSAXLE

OVERHAUL

TRANSAXLE MODEL TABLE

Transaxle modelSpeedometer gear ratio Final gear ratio Vehicle modelEngine

4.350

2.551

1.488 10 . 6 8 5

ItemsStandard value

Transfer idler gear bearing preload Nm

Input shaft end play mm (in.)

Transfer shaft end play mm (in.) Low-reverse brake end play mm (in.)

Differential case preload mm (in.)

End clutch snap ring clearance mm (in.)

Oil pump gear side clearance mm (in.)

Front clutch snap ring clearance mm (in.)

Rear clutch snap ring clearance mm (in.)

Output flange bearing end play mm (in.)

Differential pinion backlash mm (in.)

Pulse generator resistance

Pressure control solenoid valve resistance

Shift control solenoid valve resistance

Torque converter clutch solenoid resistance

(1.1)

,

,

at

, Approx. 3

Approx. 22 ohm at . .

Approx. 13 ohm

TSB Revision

Page 1214 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL Specifications

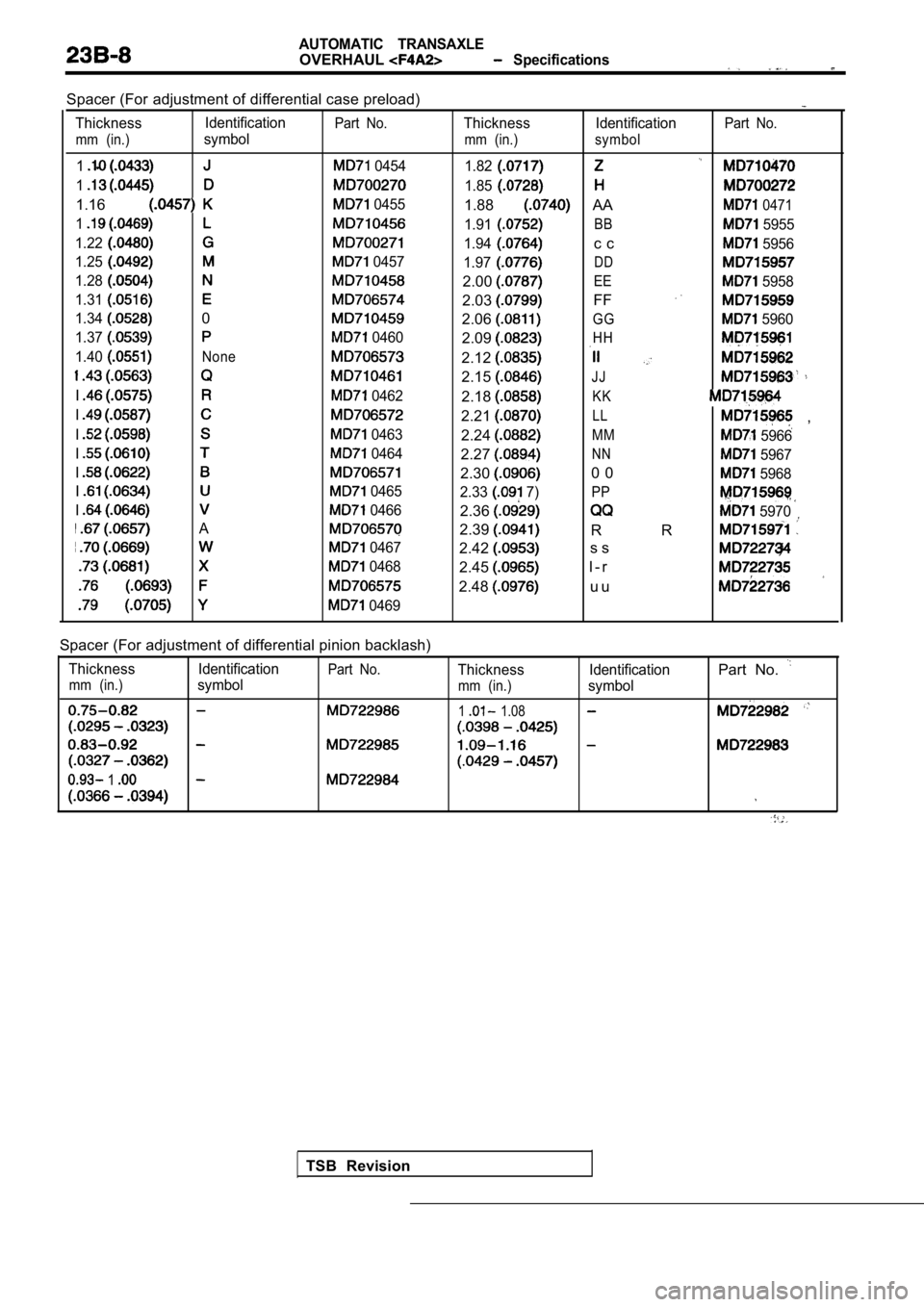

Spacer (For adjustment of differential case preload)

ThicknessIdentificationPart No.Thickness IdentificationPart No.

mm (in.)

symbolmm (in.) symbol

1 0454 1.82

11.85

1.16 04551.88 AA 0471

11.91BB 5955

1.22

1.94c c 5956

1.25

0457 1.97D D

1.282.00EE 5958

1.31

2.03FF

1.3402.06GG 5960

1.37

04602.09HH

1.40None2.12

2.15JJ

I 04622.18KK

I2.21LL

I 04632.24MM

,

5966

I

04642.27N N 5967

I

2.300 0 5968

I 0465 2.33 7)PP

I 04662.36 5970

A2.39R R

04672.42s s

04682.45l - r

2.48u u

0469

Spacer (For adjustment of differential pinion backl ash)

Thickness IdentificationPart No.Thickness IdentificationPart No. mm (in.)symbolmm (in.)symbol

1 1.08

1

TSB Revision

Page 1215 of 2103

AUTOMATIC

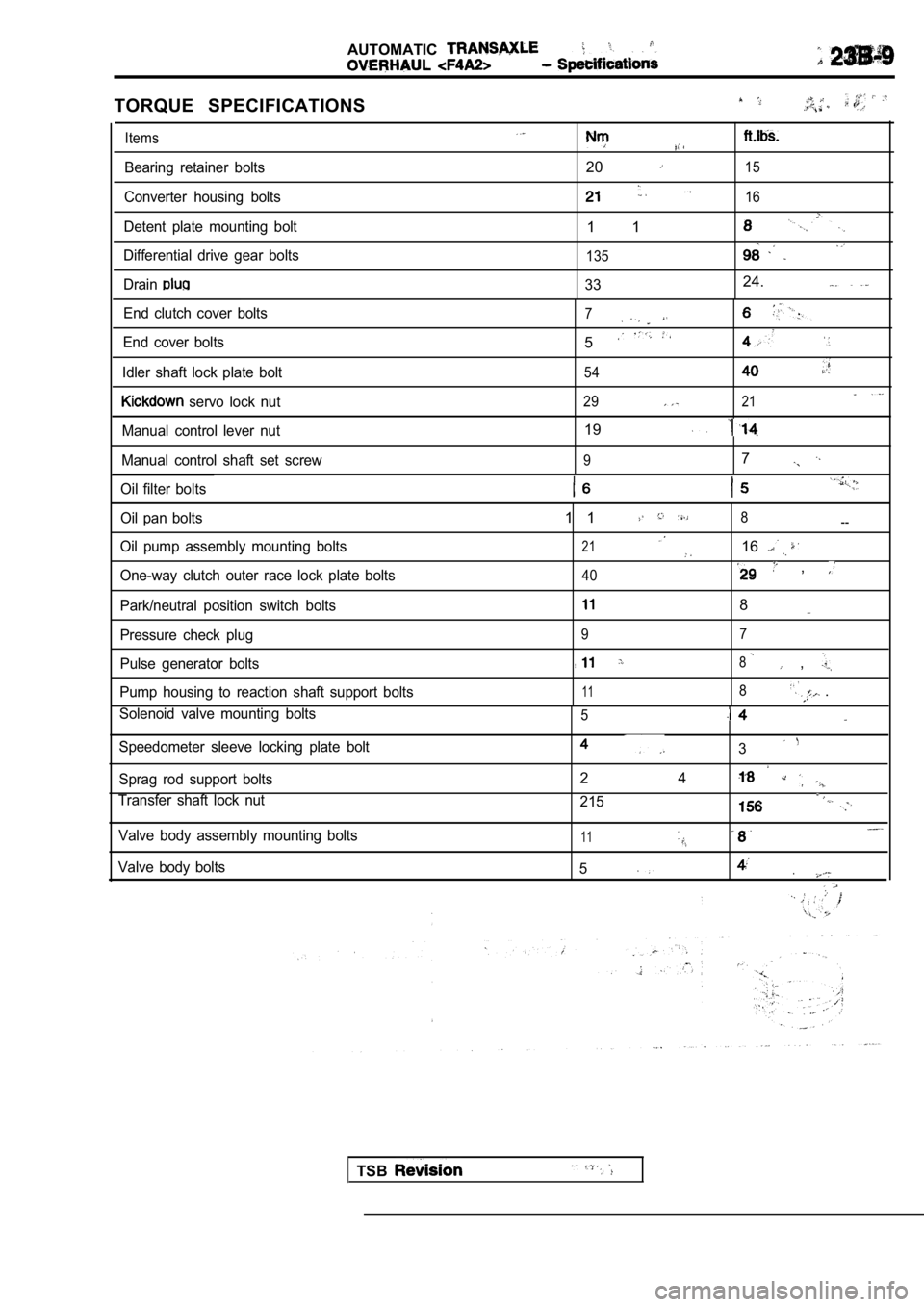

TORQUE SPECIFICATIONS

Items

Bearing retainer bolts2015

Converter housing bolts16

Detent plate mounting bolt1 1

Differential drive gear bolts135

Drain3324.

End clutch cover bolts

End cover bolts

Idler shaft lock plate bolt

servo lock nut

7

5

54

2921

Manual control lever nut19

Manual control shaft set screw97

Oil filter bolts

Oil pan bolts

Oil pump assembly mounting bolts

One-way clutch outer race lock plate bolts

Park/neutral position switch bolts

Pressure check plug

Pulse generator bolts

Pump housing to reaction shaft support bolts1 18--

21

16

40 ,

8

9 7

8 ,

118 .

Solenoid valve mounting bolts5

Speedometer sleeve locking plate bolt3

Sprag rod support bolts

Transfer shaft lock nut2 4

215

Valve body assembly mounting bolts

Valve body bolts11

.5

TSB

Page 1220 of 2103

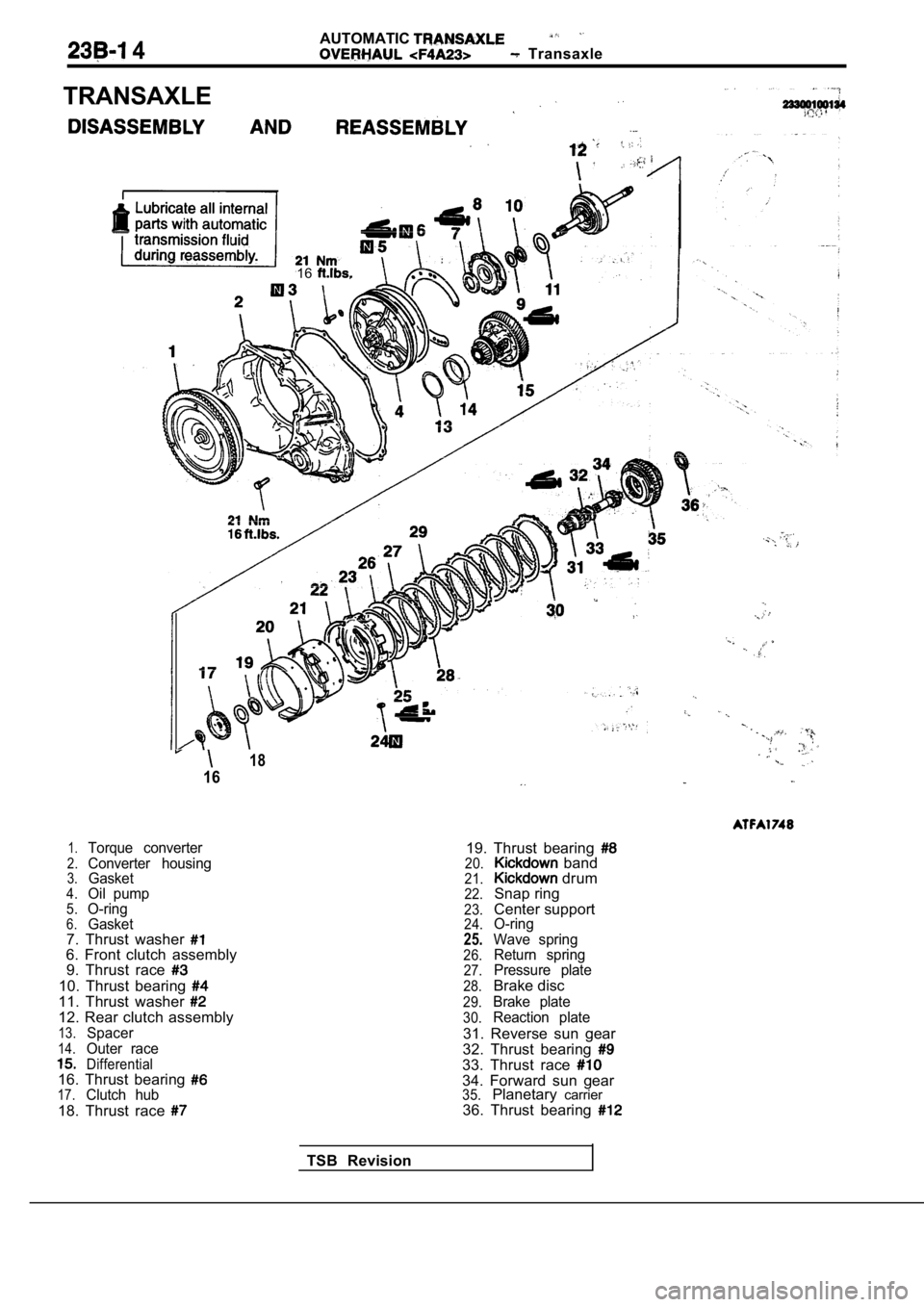

4AUTOMATIC Transaxle

TRANSAXLE

16

18

16

1.Torque converter

2.Converter housing3.Gasket4.Oil pump5.O-ring6.Gasket7. Thrust washer 6. Front clutch assembly 9. Thrust race

10. Thrust bearing

11. Thrust washer

12. Rear clutch assembly

13.Spacer

14.Outer race

Differential16. Thrust bearing 17.Clutch hub

18. Thrust race

19. Thrust bearing 20. band

21. drum

22.Snap ring

23.Center support24.O-ring

25.Wave spring

26.Return spring

27.Pressure plate

28.Brake disc

29.Brake plate

30.Reaction plate

31. Reverse sun gear

32. Thrust bearing

33. Thrust race

34. Forward sun gear35.Planetary carrier

36. Thrust bearing

TSB Revision

Page 1270 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL Differential.

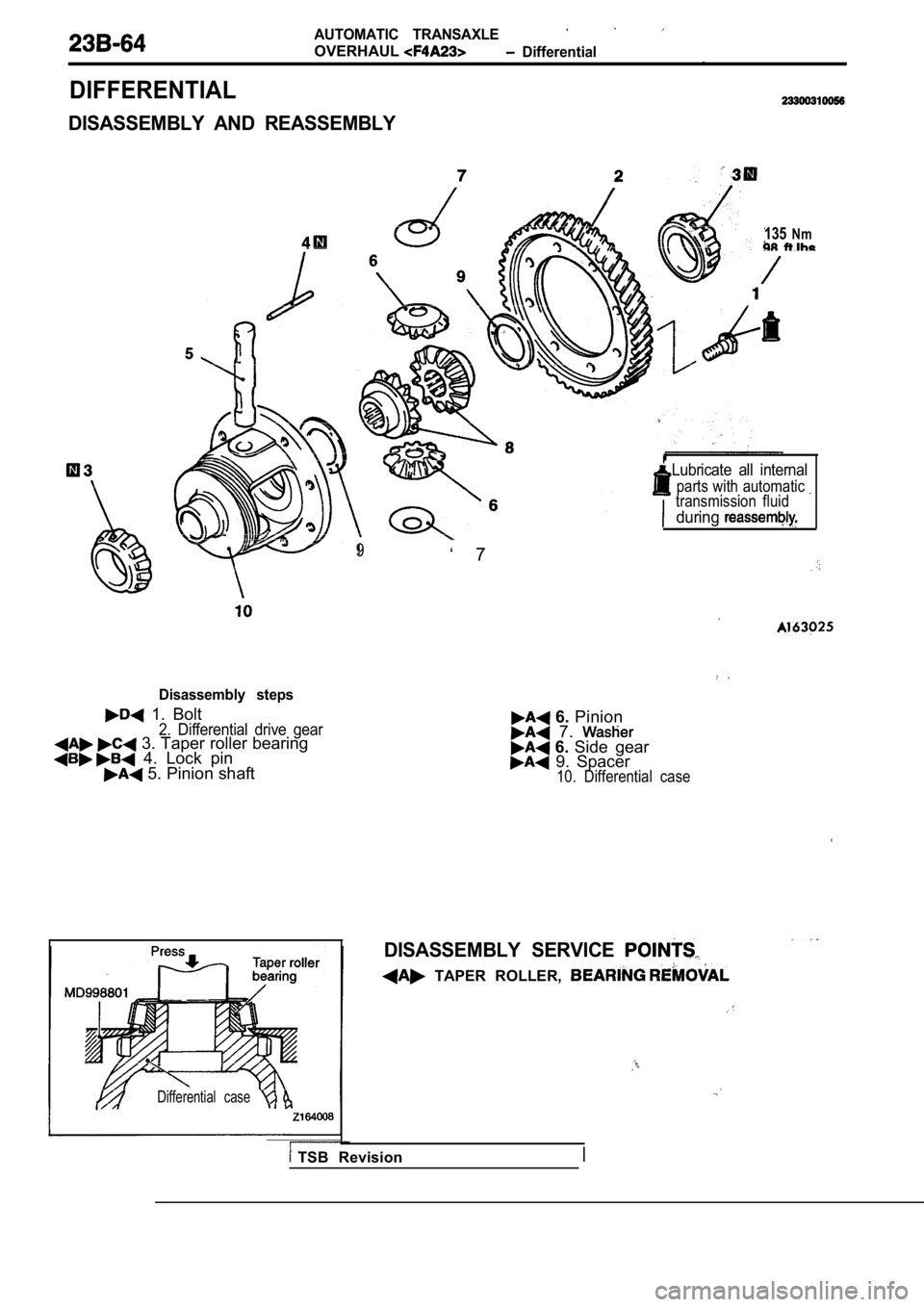

DIFFERENTIAL

DISASSEMBLY AND REASSEMBLY

135Nm

Lubricate all internal

parts with automatic transmission fluid

during

Disassembly steps

1. Bolt2. Differential drive gear 3. Taper roller bearing 4. Lock pin 5. Pinion shaft

Differential case

9‘ 7

6. Pinion 7. 6. Side gear 9. Spacer10. Differential case

DISASSEMBLY SERVICE

TAPER ROLLER,

TSB Revision

Page 1271 of 2103

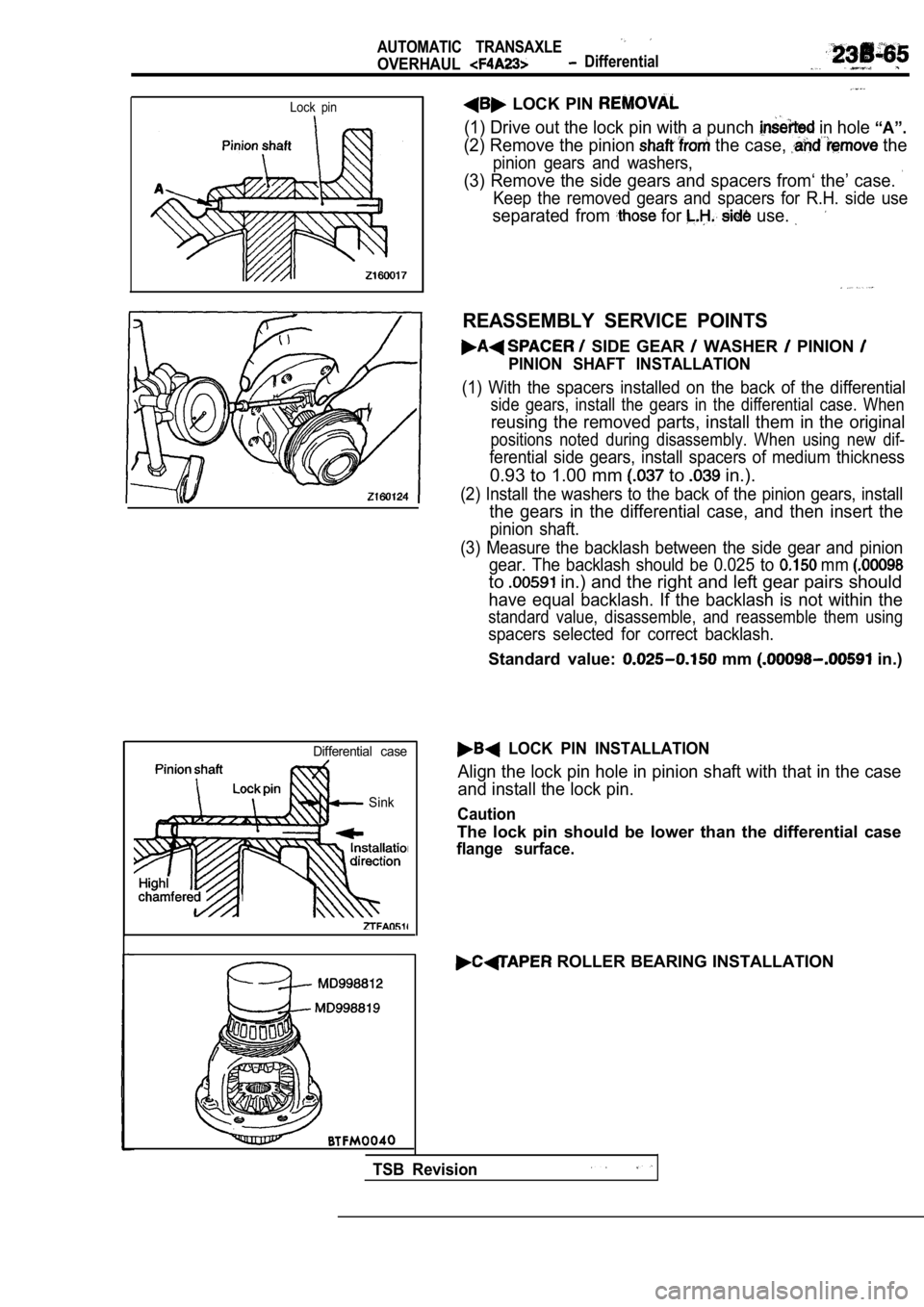

Lock pin

AUTOMATIC TRANSAXLE

OVERHAUL Differential

LOCK PIN

(1) Drive out the lock pin with a punch in hole “A”.

(2) Remove the pinion the case, the

pinion gears and washers,

(3) Remove the side gears and spacers from‘ the’ case.

Keep the removed gears and spacers for R.H. side us e

separated from for use.

REASSEMBLY SERVICE POINTS

SIDE GEAR WASHER PINION

PINION SHAFT INSTALLATION

(1) With the spacers installed on the back of the differential

side gears, install the gears in the differential case. When

reusing the removed parts, install them in the orig inal

positions noted during disassembly. When using new dif-

ferential side gears, install spacers of medium thickness

0.93 to 1.00 mm to in.).

(2) Install the washers to the back of the pinion gears, install

the gears in the differential case, and then insert the

pinion shaft.

(3) Measure the backlash between the side gear and pinion

gear. The backlash should be 0.025 to

mm

to in.) and the right and left gear pairs should

have equal backlash. If the backlash is not within the

standard value, disassemble, and reassemble them us ing

spacers selected for correct backlash.

Standard value: mm in.)

Differential case

Sink

I

LOCK PIN INSTALLATION

Align the lock pin hole in pinion shaft with that i n the case

and install the lock pin.

Caution

The lock pin should be lower than the differential case

flange surface.

ROLLER BEARING INSTALLATION

TSB Revision

Page 1285 of 2103

.

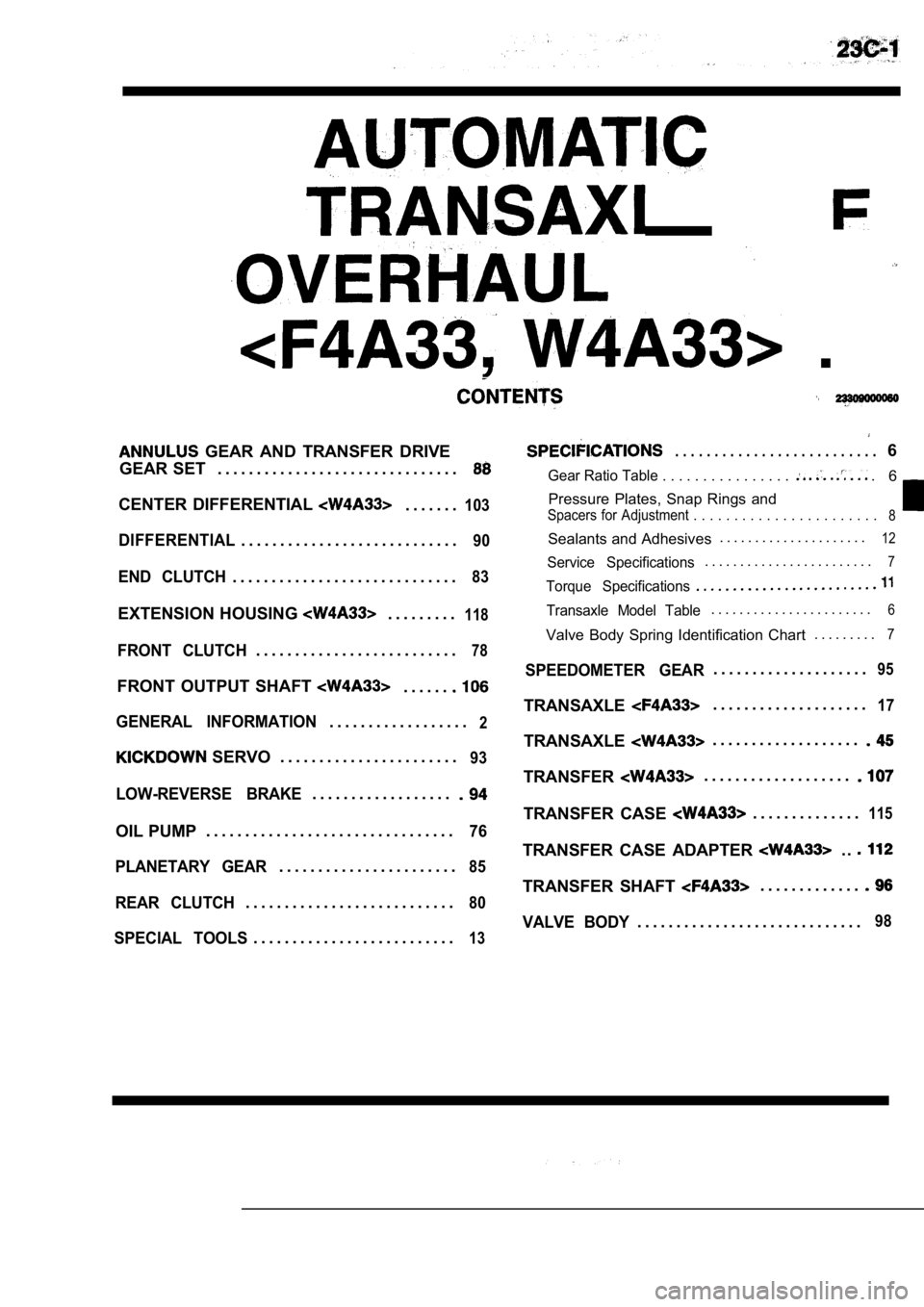

GEAR AND TRANSFER DRIVE

GEAR SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CENTER DIFFERENTIAL . . . . . . .103

DIFFERENTIAL. . . . . . . . . . . . . . . . . . . . . . . . . . . .90

END CLUTCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

EXTENSION HOUSING . . . . . . . . .118

FRONT CLUTCH. . . . . . . . . . . . . . . . . . . . . . . . . .78

FRONT OUTPUT SHAFT . . . . . .

GENERAL INFORMATION. . . . . . . . . . . . . . . . . .2

SERVO . . . . . . . . . . . . . . . . . . . . . . .93

LOW-REVERSE BRAKE. . . . . . . . . . . . . . . . . .

OIL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

PLANETARY GEAR

. . . . . . . . . . . . . . . . . . . . . . .85

REAR CLUTCH. . . . . . . . . . . . . . . . . . . . . . . . . . .80

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . .13

6. . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Ratio Table . . . . . . . . . . . . . . . . .6

Pressure Plates, Snap Rings and

Spacers for Adjustment . . . . . . . . . . . . . . . . . . . . . . .8

Sealants and Adhesives. . . . . . . . . . . . . . . . . . . . .12

Service Specifications. . . . . . . . . . . . . . . . . . . . . . . .7

Torque Specifications

Transaxle Model Table. . . . . . . . . . . . . . . . . . . . . . .6

Valve Body Spring Identification Chart

. . . . . . . . .7

SPEEDOMETER GEAR. . . . . . . . . . . . . . . . . . . .95

TRANSAXLE. . . . . . . . . . . . . . . . . . . .17

TRANSAXLE. . . . . . . . . . . . . . . . . . .

TRANSFER. . . . . . . . . . . . . . . . . . .

TRANSFER CASE . . . . . . . . . . . . . .115

TRANSFER CASE ADAPTER . .

TRANSFER SHAFT . . . . . . . . . . . . .

VALVE BODY. . . . . . . . . . . . . . . . . . . . . . . . . . . . .98