overheating MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 48 of 2103

GENERAL Maintenance

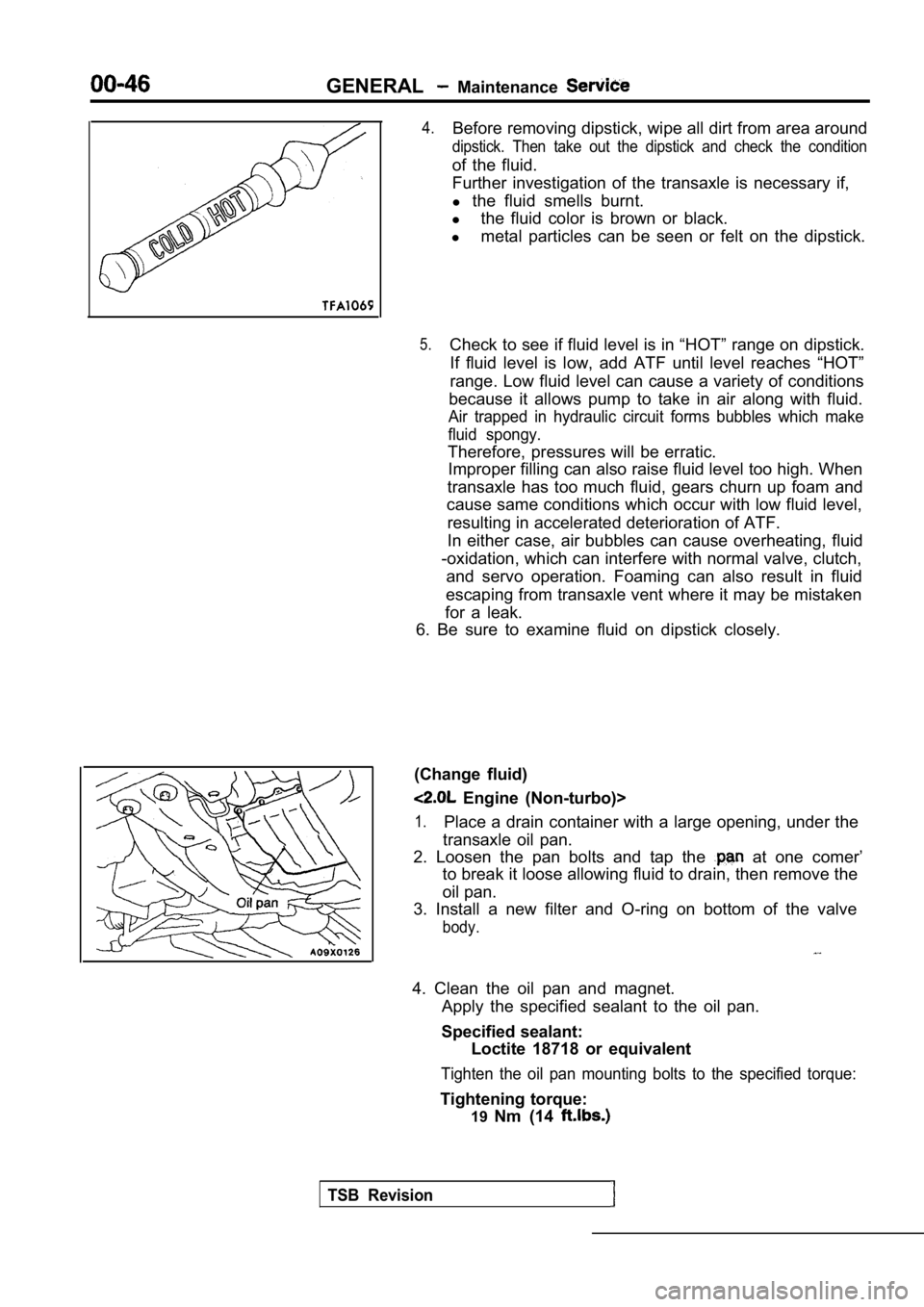

4.Before removing dipstick, wipe all dirt from area around

dipstick. Then take out the dipstick and check the condition

of the fluid.

Further investigation of the transaxle is necessary if,

l the fluid smells burnt.

l the fluid color is brown or black.

l metal particles can be seen or felt on the dipstick .

5.Check to see if fluid level is in “HOT” range on dipstick.

If fluid level is low, add ATF until level reaches “HOT”

range. Low fluid level can cause a variety of condi tions

because it allows pump to take in air along with fl uid.

Air trapped in hydraulic circuit forms bubbles which make

fluid spongy.

Therefore, pressures will be erratic. Improper filling can also raise fluid level too hig h. When

transaxle has too much fluid, gears churn up foam a nd

cause same conditions which occur with low fluid le vel,

resulting in accelerated deterioration of ATF.

In either case, air bubbles can cause overheating, fluid

-oxidation, which can interfere with normal valve, clutch,

and servo operation. Foaming can also result in flu id

escaping from transaxle vent where it may be mistak en

for a leak.

6. Be sure to examine fluid on dipstick closely.

(Change fluid)

Engine (Non-turbo)>

1.Place a drain container with a large opening, under the

transaxle oil pan.

2. Loosen the pan bolts and tap the

at one comer’

to break it loose allowing fluid to drain, then rem ove the

oil pan.

3. Install a new filter and O-ring on bottom of the valve

body.

4. Clean the oil pan and magnet.

Apply the specified sealant to the oil pan.

Specified sealant: Loctite 18718 or equivalent

Tighten the oil pan mounting bolts to the specified torque:

Tightening torque:

19Nm (14

TSB Revision

Page 1655 of 2103

B R A K E S Y S T E M 7 .

FRONT DISC BRAKE ROTOR CHECK

35100270047

Caution

To maintain safe braking performance, the disc brak e rotors must be kept within allowable service

specifications.

Before re-finishing or re-processing the brake disc surface, the following conditions should be checke d.

Inspection itemsRemarks

Scratches, rust, saturated lining lIf the vehicle is not driven for a the of the

and weardiscs that are not in contact with lining will beco me rusty, causing

noise and shudderin.lIf grooves resultingrom excessive disc wear and scratches arenot removed prior to installing a new pad assembly, there will tarily be inappropriate contact between the disc and the lining (pad).

Run-out or drift

Excessive run-out or drift of the discs will increa se the pedal depression

resistance due to piston knock-back.

Change in thickness (parallelism)

If the thickness of the disc changes, this will cau se pedal pulsation,

shuddering and surging.

Inset or warping (flatness)

Overheating and improper handling while servicing w ill cause inset or

warping.

TSB Revision