GENERAL ± How to Use This Manual00-2

HOW TO USE THIS MANUAL00100010210

SCOPE OF MAINTENANCE, REPAIR

AND SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning

procedures for the inspection, maintenance, repair

and servicing of the subject model. Note, however,

that for engine and transmission-related component

parts, this manual covers only on-vehicle

inspections, adjustments, and the removal and

installation procedures for major components.

For detailed information concerning the inspection,

checking, adjustment, disassembly and reassembly

of the engine, transmission and major components

after they have been removed from the vehicle,

please refer to separate manuals covering the

engine and the transmission.

ON-VEHICLE SERVICE

ªOn-vehicle Serviceº is procedures for performing

inspections and adjustments of particularly

important locations with regard to the construction

and for maintenance and servicing, but other

inspection (for looseness, play, cracking, damage,

etc.) must also be performed.

INSPECTION

Under this title are presented inspection and

checking procedures to be performed by using

special tools and measuring instruments and by

feeling, but, for actual maintenance and servicing

procedures, visual inspections should always be

performed as well.

DEFINITION OF TERMS

STANDARD VALUE

Indicates the value used as the standard for judging

the quality of a part or assembly on inspection

or the value to which the part or assembly is

corrected and adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a

part or assembly on inspection and means the

maximum or minimum value within which the part

or assembly must be kept functionally or in strength.

It is a value established outside the range of

standard value.

REFERENCE VALUE

Indicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be

completed in a shorter time).

CAUTION

Indicates the presentation of information particularly

vital to the worker during the performance of

maintenance and servicing procedures in order to

avoid the possibility of injury to the worker, or

damage to component parts, or a reduction of

component or vehicle function or performance, etc.

INDICATION OF TIGHTENING TORQUE

The tightening torque shown in this manual is a

basic value with a tolerance of +10% except the

following cases when the upper and lower limits

of tightening torque are given.

(1) The tolerance of the basic value is within +10%.

(2) Special bolts or the like are in use.

(3) Special tightening methods are used.

GENERAL ± How to Use This Manual00-3

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.

M/T: Indicates the manual transmission, or models equipped with the manual transmission.

A/T: Indicates the automatic transmission, or models equipped with the automatic transmission.

SOHC: Indicates an engine with the single overhead camshaft, or a model equipped with such

an engine.

MPI: Indicates the multi-point injection, or engines equipped with the multi-point injection.

DIESEL: Indicates a diesel engine, or models equipped with such an engine.

2WD: Indicates the rear wheel-drive vehicles.

4WD: Indicates the 4 wheel-drive vehicles.

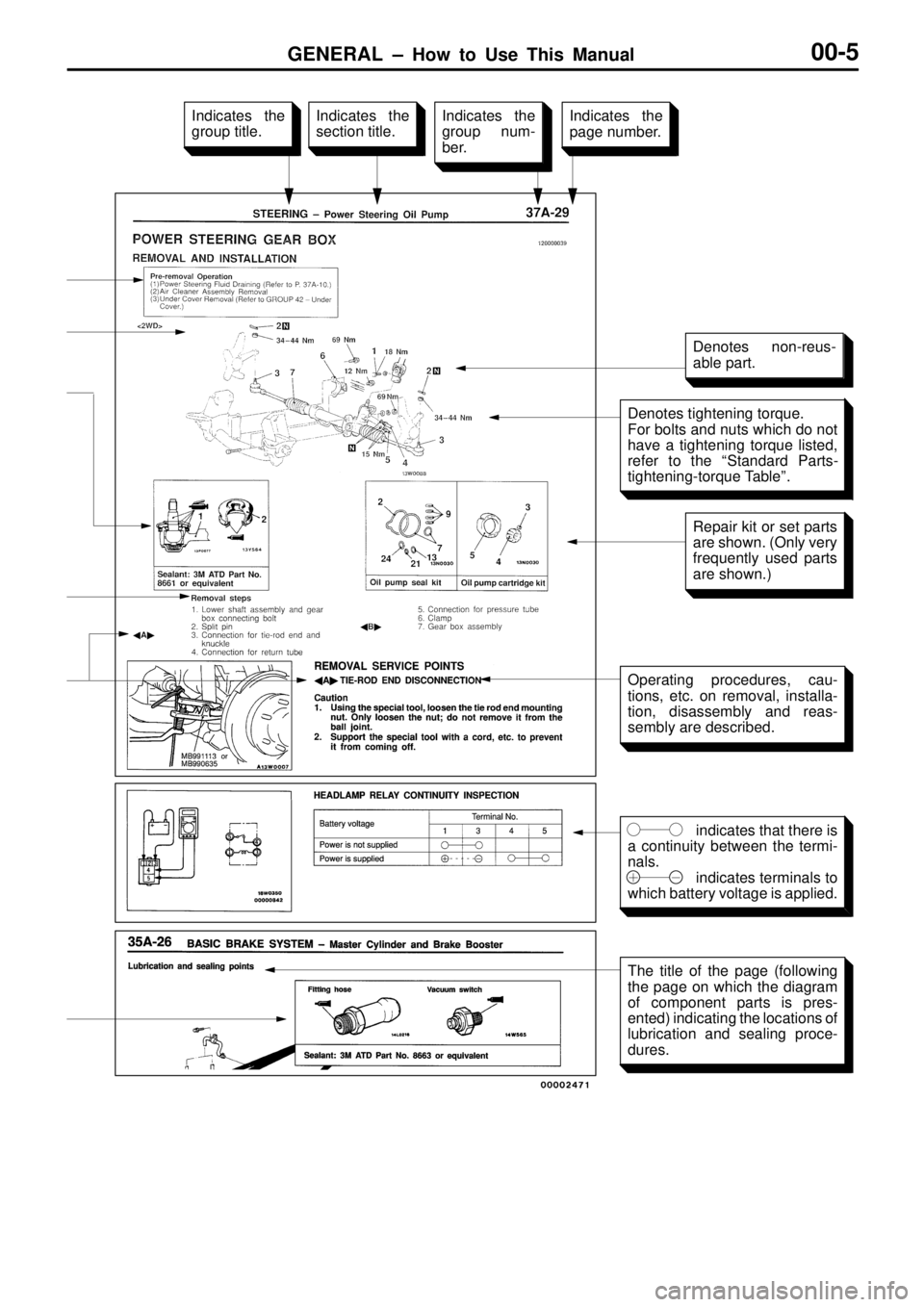

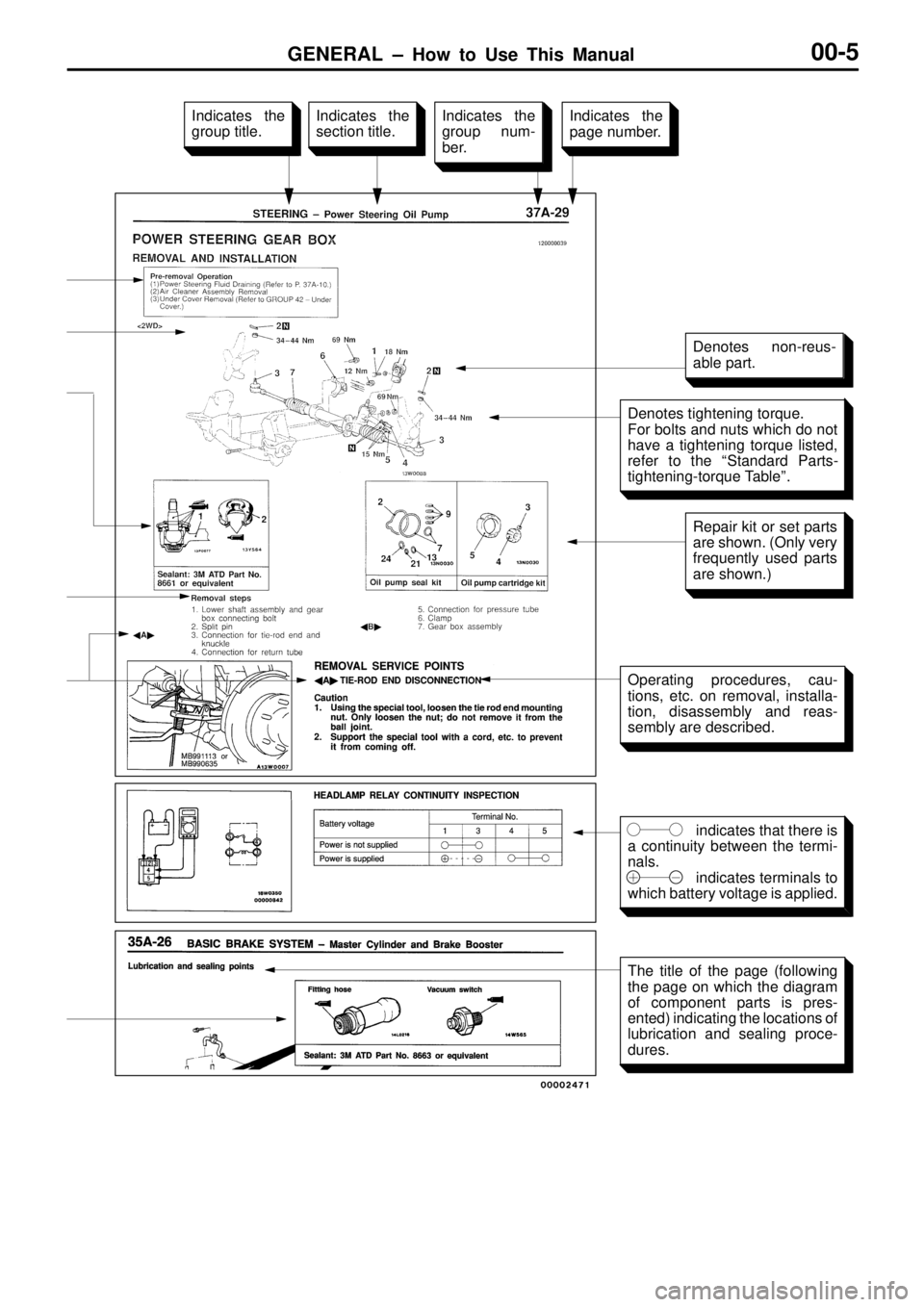

i

n dic a te s th at th ere is

a c o ntin uit y b etw een th e te rm i-

n als .

in dic a te s te rm in als to

w hic h b atte ry v o lt a ge is a pplie d. I

n dic a te s th e

s e ctio n tit le . I

n dic a te s th e

g ro up n um -

b er. I

n dic a te s th e

p age n um ber. I

n dic a te s th e

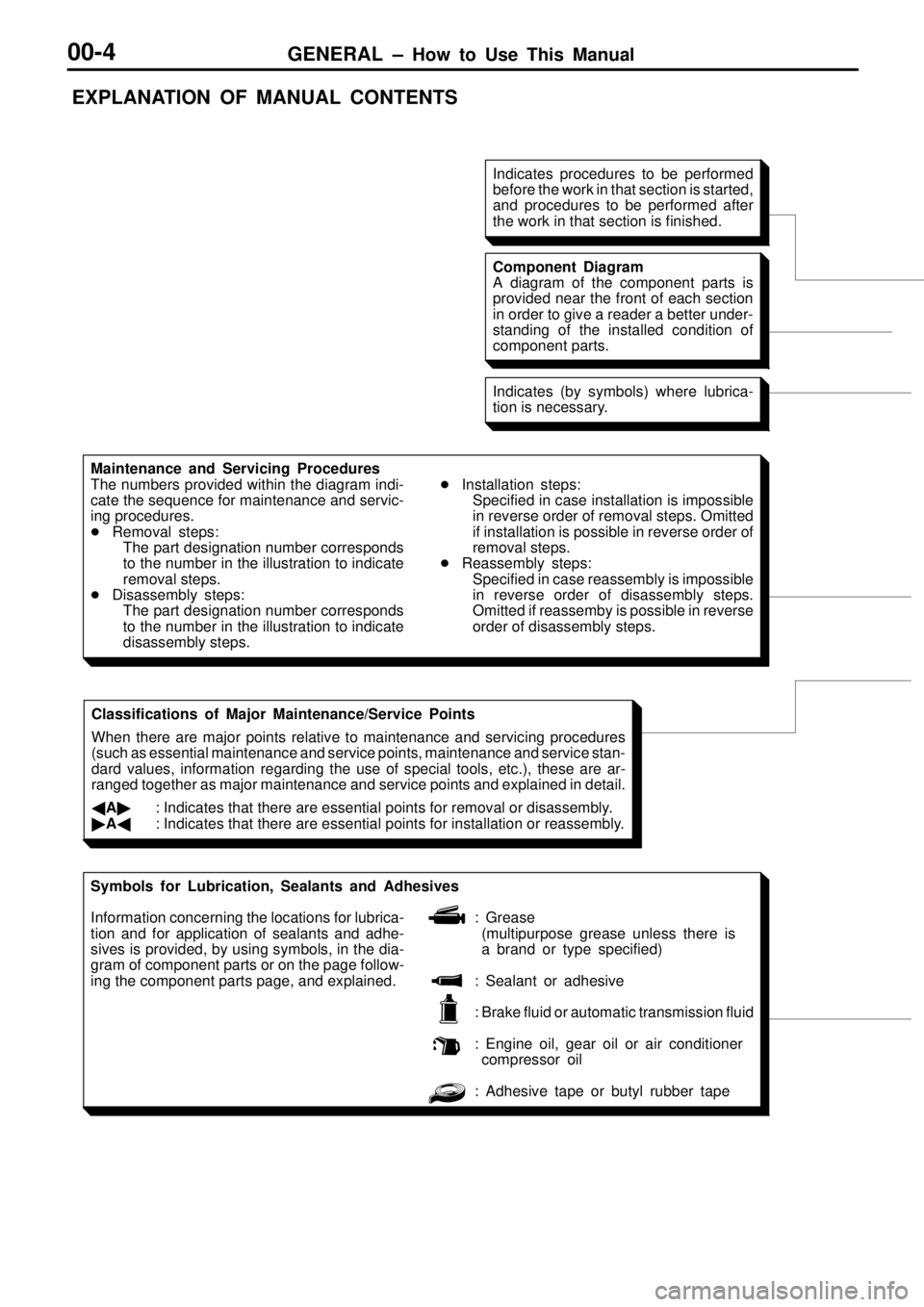

g ro up tit le . D

enote s n on-re us-

a ble p art. R

epair k it o r s e t p arts

a re s h ow n. ( O nly v e ry

f r e quently u se d p arts

a re s h ow n.) O

pera tin g p ro ce dure s, c a u-

t io ns, e tc . o n r e m ova l, in sta lla -

t io n, d is a sse m bly a nd r e as-

s e m bly a re d escrib ed. T

he tit le o f th e p age ( fo llo w in g

t h e p age o n w hic h th e d ia gra m

o f c o m ponent p arts is p re s-

e nte d) in dic a tin g th e lo ca tio ns o f

l u bric a tio n a nd s e alin g p ro ce -

d ure s.

GENERAL ± How to Use Troubleshooting/Inspection Service Points00-6

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE

POINTS

00100020091

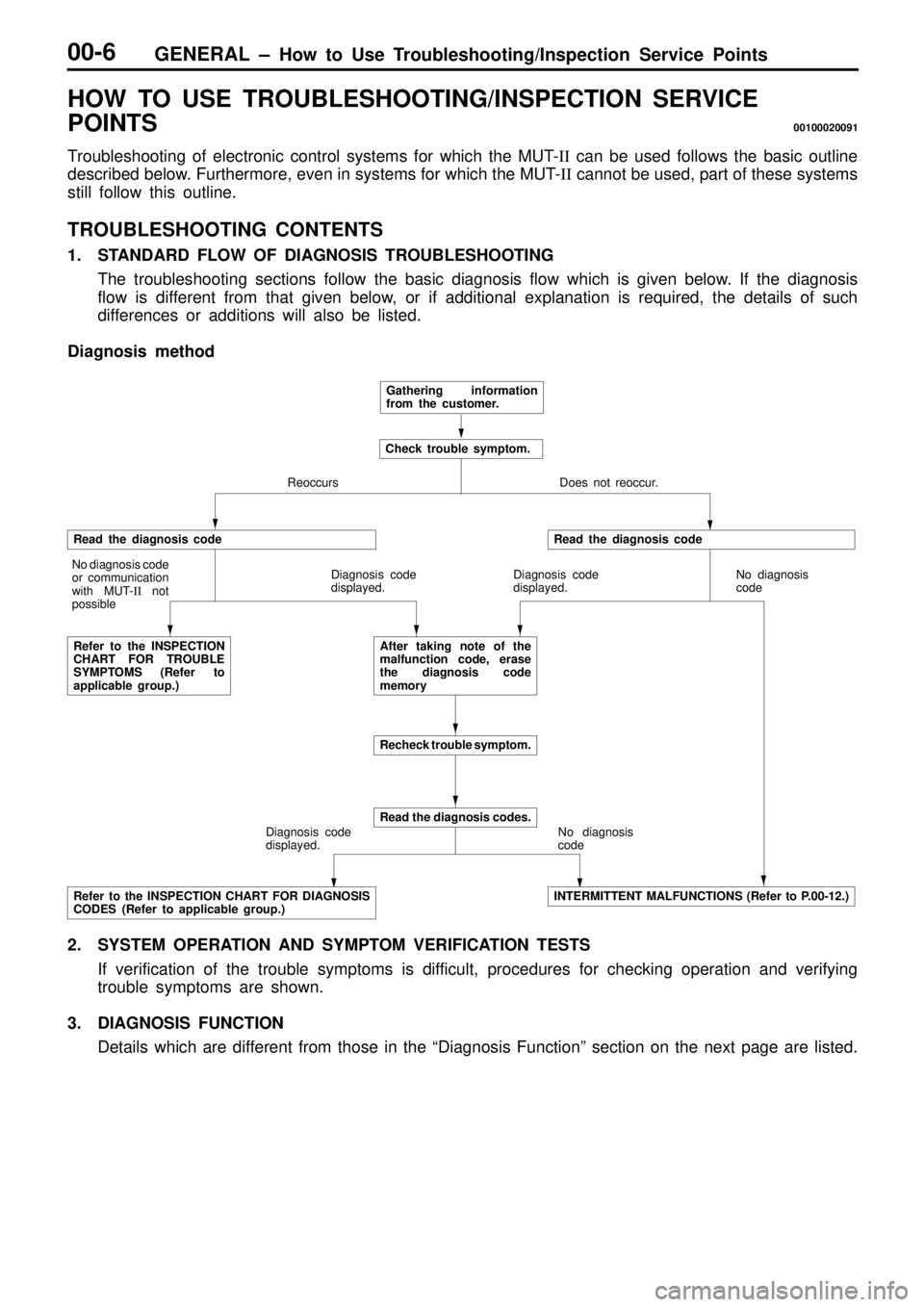

Troubleshooting of electronic control systems for which the MUT-II can be used follows the basic outline

described below. Furthermore, even in systems for which the MUT-II cannot be used, part of these systems

still follow this outline.

TROUBLESHOOTING CONTENTS

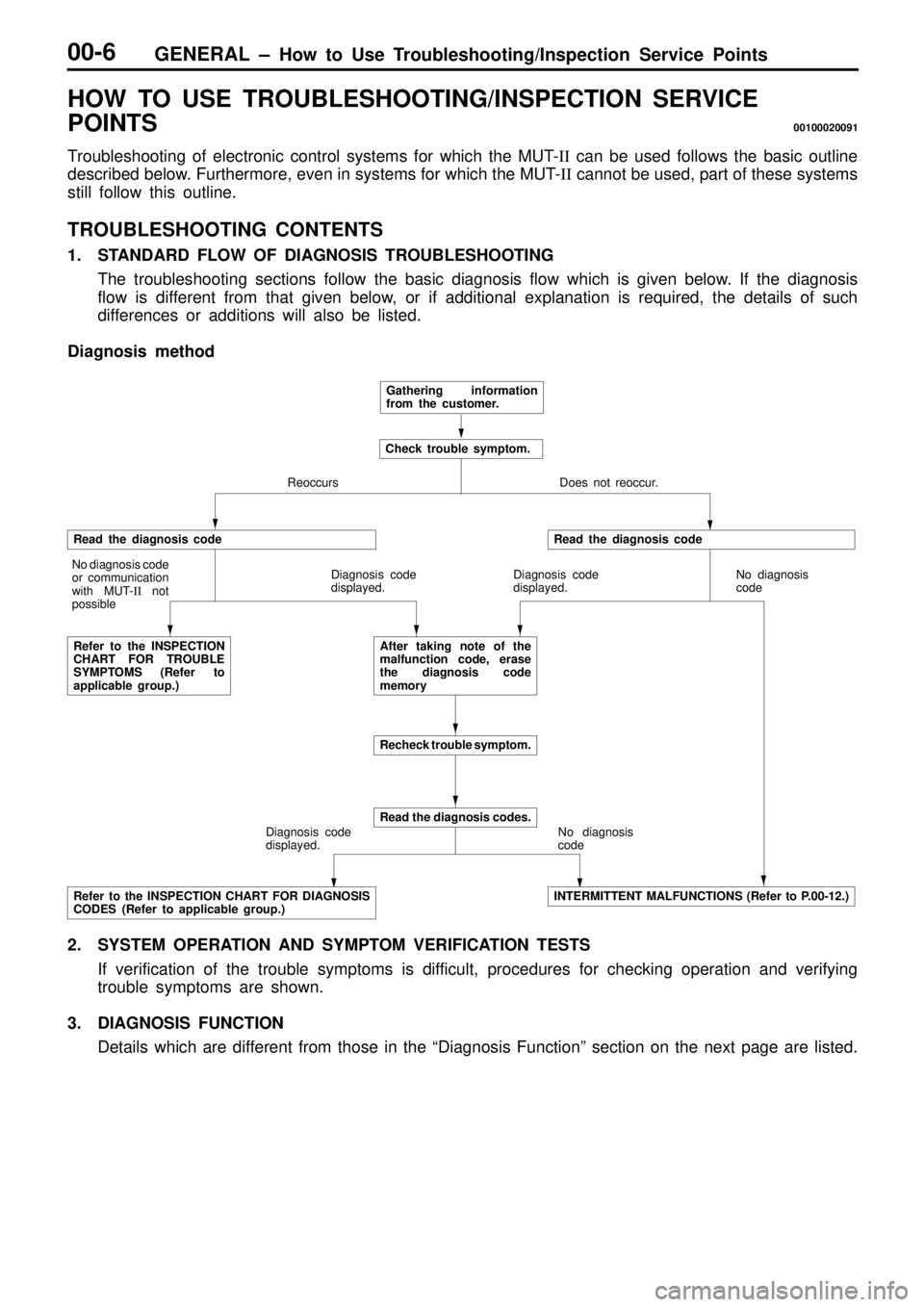

1. STANDARD FLOW OF DIAGNOSIS TROUBLESHOOTING

The troubleshooting sections follow the basic diagnosis flow which is given below. If the diagnosis

flow is different from that given below, or if additional explanation is required, the details of such

differences or additions will also be listed.

Diagnosis method

Gathering information

from the customer.

Check trouble symptom.

Reoccurs Does not reoccur.

Read the diagnosis code

No diagnosis code

or communication

with MUT-II not

possible

Refer to the INSPECTION

CHART FOR TROUBLE

SYMPTOMS (Refer to

applicable group.)Diagnosis code

displayed.

Read the diagnosis code

Diagnosis code

displayed.No diagnosis

code

After taking note of the

malfunction code, erase

the diagnosis code

memory

Recheck trouble symptom.

Diagnosis code

displayed.

Read the diagnosis codes.

No diagnosis

code

Refer to the INSPECTION CHART FOR DIAGNOSIS

CODES (Refer to applicable group.)INTERMITTENT MALFUNCTIONS (Refer to P.00-12.)

2. SYSTEM OPERATION AND SYMPTOM VERIFICATION TESTS

If verification of the trouble symptoms is difficult, procedures for checking operation and verifying

trouble symptoms are shown.

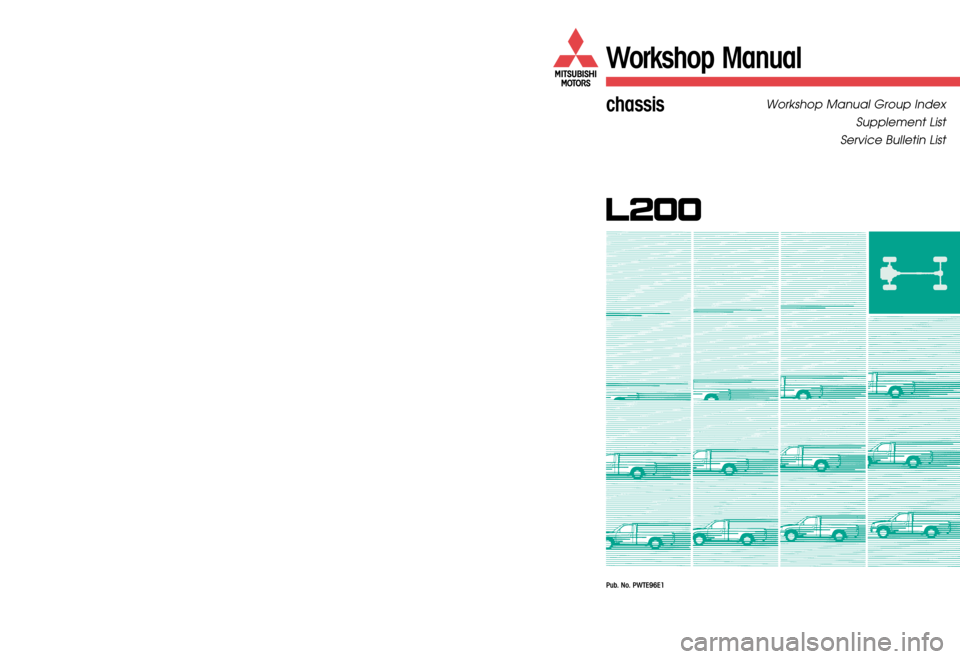

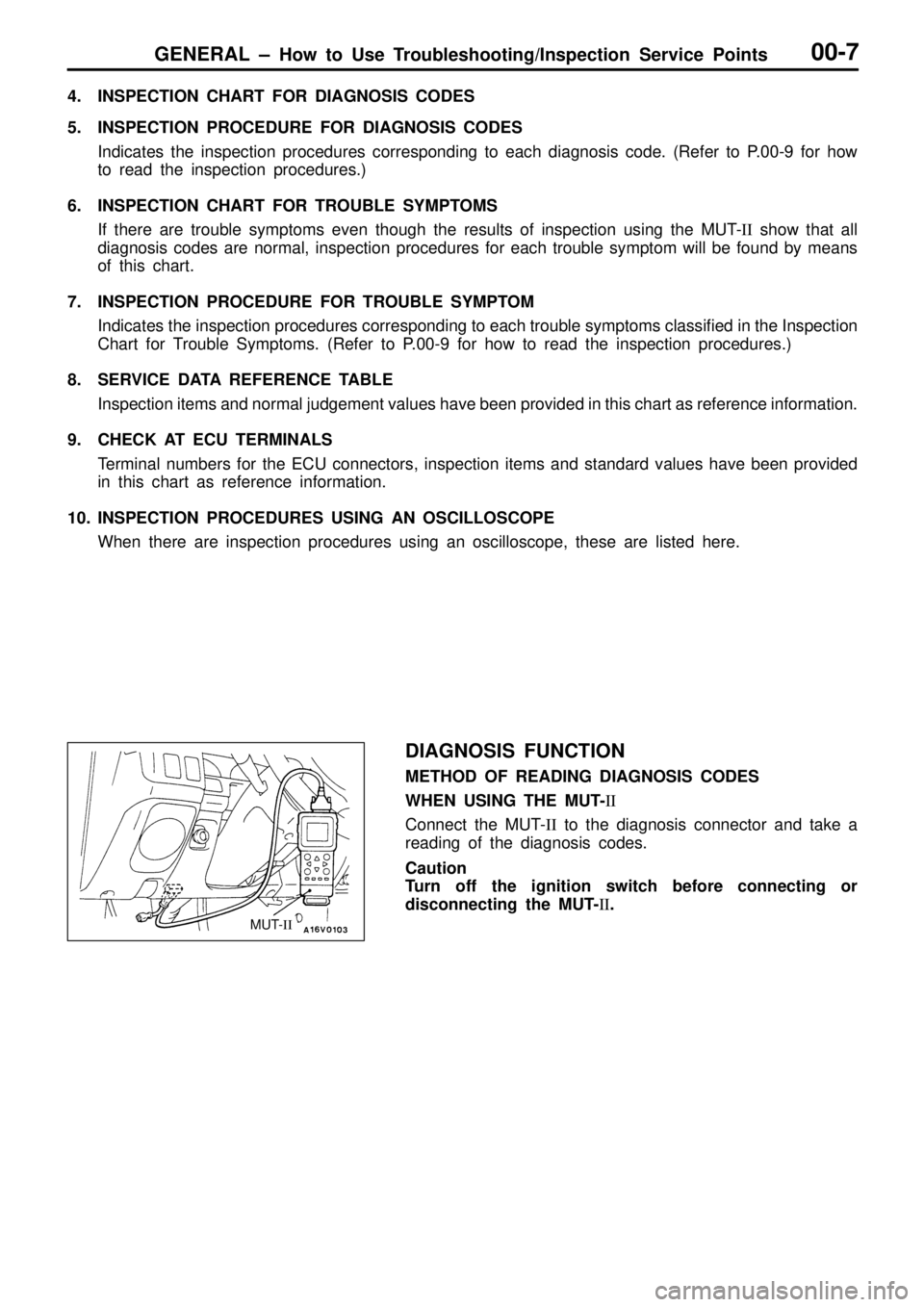

3. DIAGNOSIS FUNCTION

Details which are different from those in the ªDiagnosis Functionº section on the next page are listed.