Vacuum NISSAN 300ZX 1984 Z31 Electrical System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 116, PDF Size: 3.42 MB

Page 49 of 116

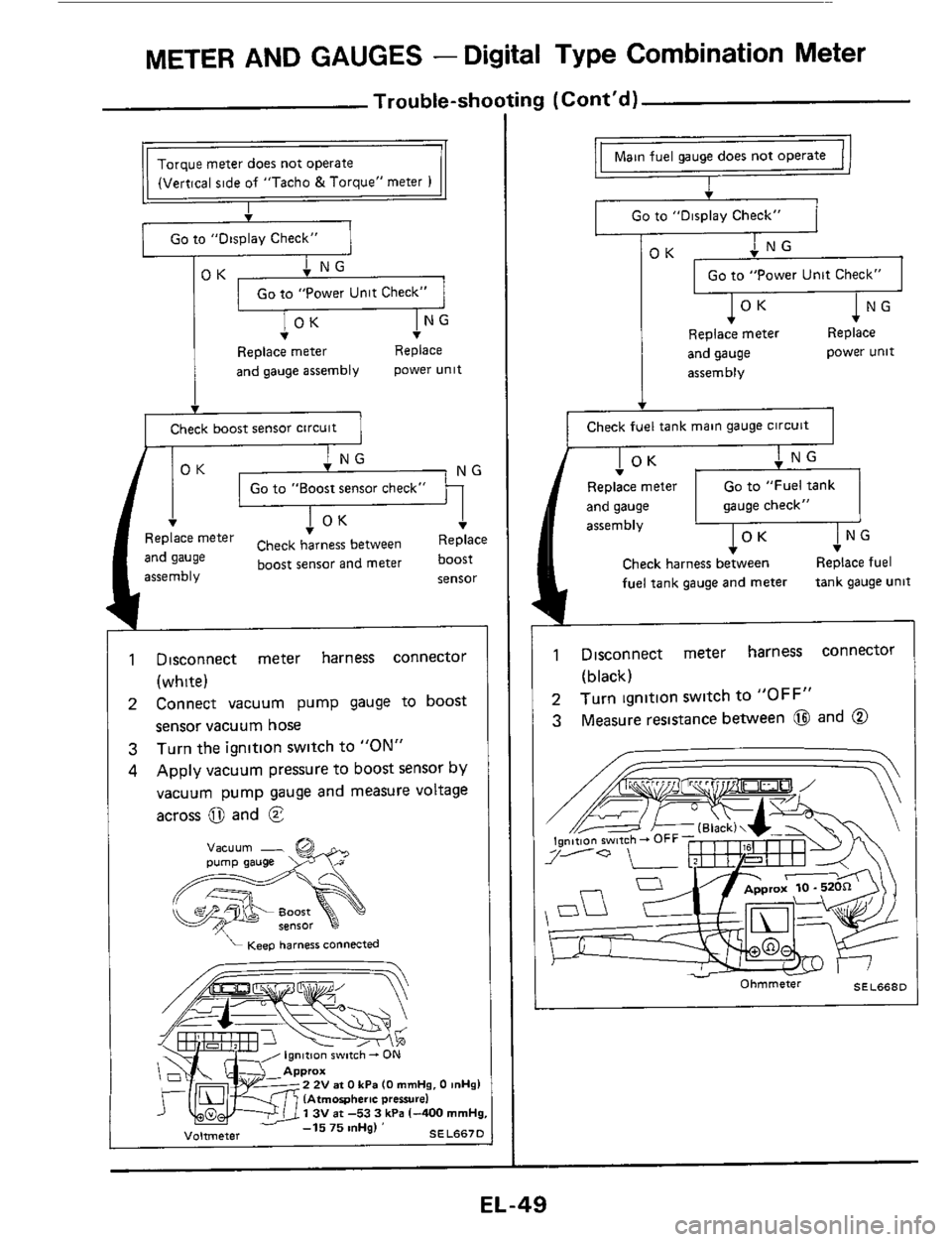

METER AND GAUGES - Digital Type Combination Meter

Trouble-st

Torque meter does not operate

1 Go to "Display Check" I

Go to "Power Unit Check"

v

Replace meter Replace

and gauge assembly power unit

I

I Check boost sensor circuit I

boost sensor and meter boost

sensor

1 Disconnect meter harness connector

2 Connect vacuum pump gauge to boost

3

4

(white)

sensor vacuum hose

Turn the ignition switch to "ON"

Apply vacuum pressure to boost sensor by

vacuum pump gauge and measure voltage

across

0 and

Vacuum -

~eep harness connected

J wu 1 3v at-53 3kPa 1-400 mmH

SEL667 Voltmeter -15 75 mHg) '

rg (Cont'd)

Main fuel gauge does not operate

I

Go to "Display Check"

Go to "Power Unit Check"

Replace meter Replace

and gauge power unit

assembly

Check fuel tank main gauge clrcult

I OK

Replace meter

and gauge

assembly Go to "Fuel tank

gauge check"

.

Check harness between Replace fuel

fuel tank gauge and meter

tank gauge unit

1 Disconnect meter harness Connector

(black)

Turn ignition switch to

"OFF" 2

3 Measure resistance between @ and @

e

Ohmmeter SEL6680

EL-49

Page 53 of 116

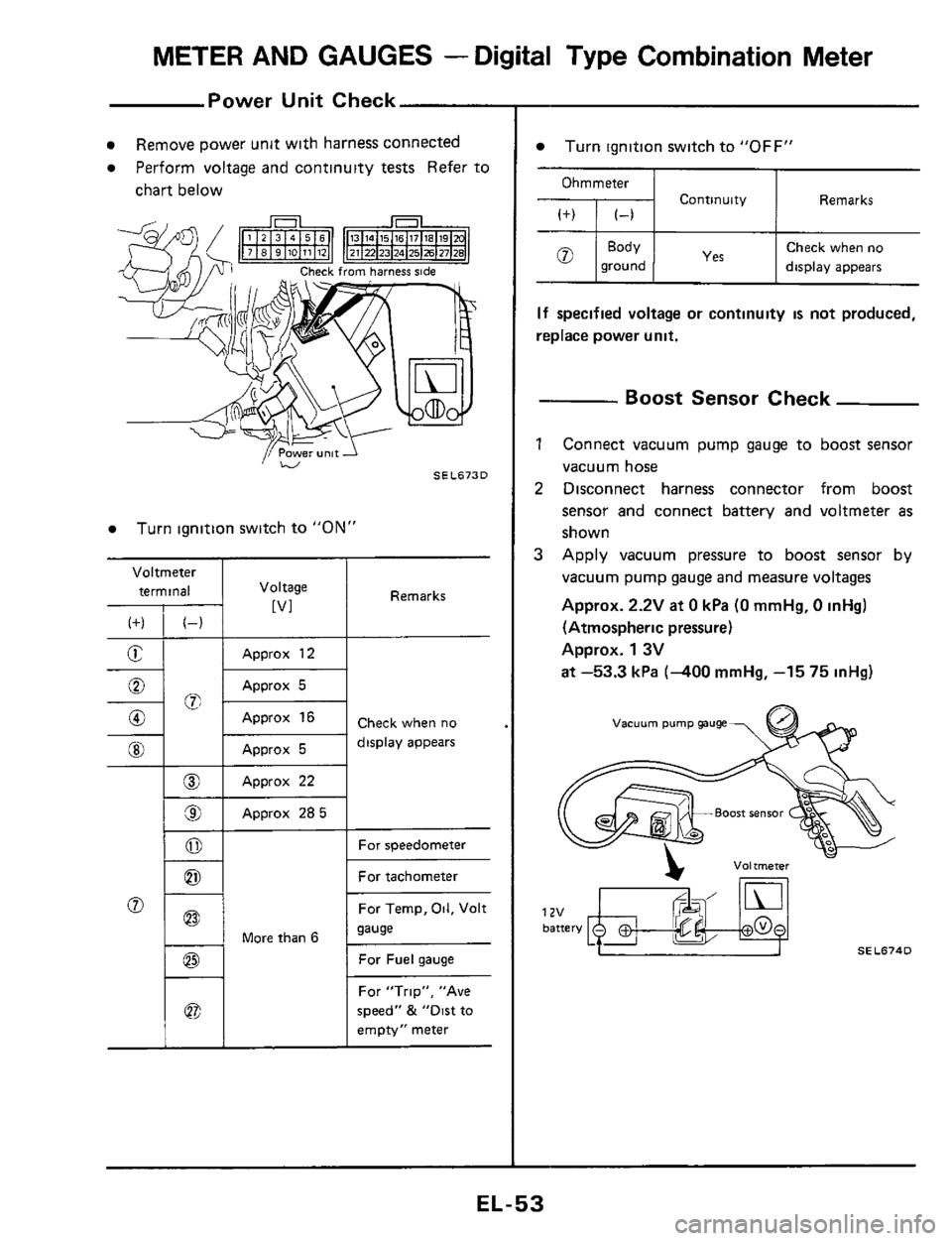

METER AND GAUGES - Digital Type Combination Meter

Power Unit Check

Voltmeter

terminal

(f) (-)

E -

-%; 0

0

@I

__

@

9

0

0

Remove power unit with harness connected

Perform voltage and continuity tests Refer to

chart below

I Voltage

[VI

Approx 12

Approx 5

Approx 16

Approx 5

Approx 22

Approx 285

Turn ignition switch to "ON"

1 - 1 More than 6

Remarks

Check when no

display appears

For speedometer

For tachometer

For Temp,

Oil, Volt

sause

For Fuel gauge

For "Trip", "Ave

speed"

& "Dirt to

empty" meter

Turn ignition switch to "OFF"

Ohmmeter

Continuity Remarks

Check when no

ground display appears

If specified voltage or continuity is not produced,

replace power unit.

- Boost Sensor Check

1 Connect vacuum pump gauge to boost sensor

vacuum hose

2 Disconnect harness connector from boost

sensor and connect battery and voltmeter

as

shown

3 Apply vacuum pressure to boost sensor by

vacuum pump gauge and measure voltages

Approx.

2.2V at 0 kPa (0 mmHg, 0 inHg)

(Atmospheric pressure)

Approx.

1 3V

at -53.3 kPa (-400 mmHg, -15 75 inHg)

vacuum pump gauge

SEL674D

EL-53

Page 99 of 116

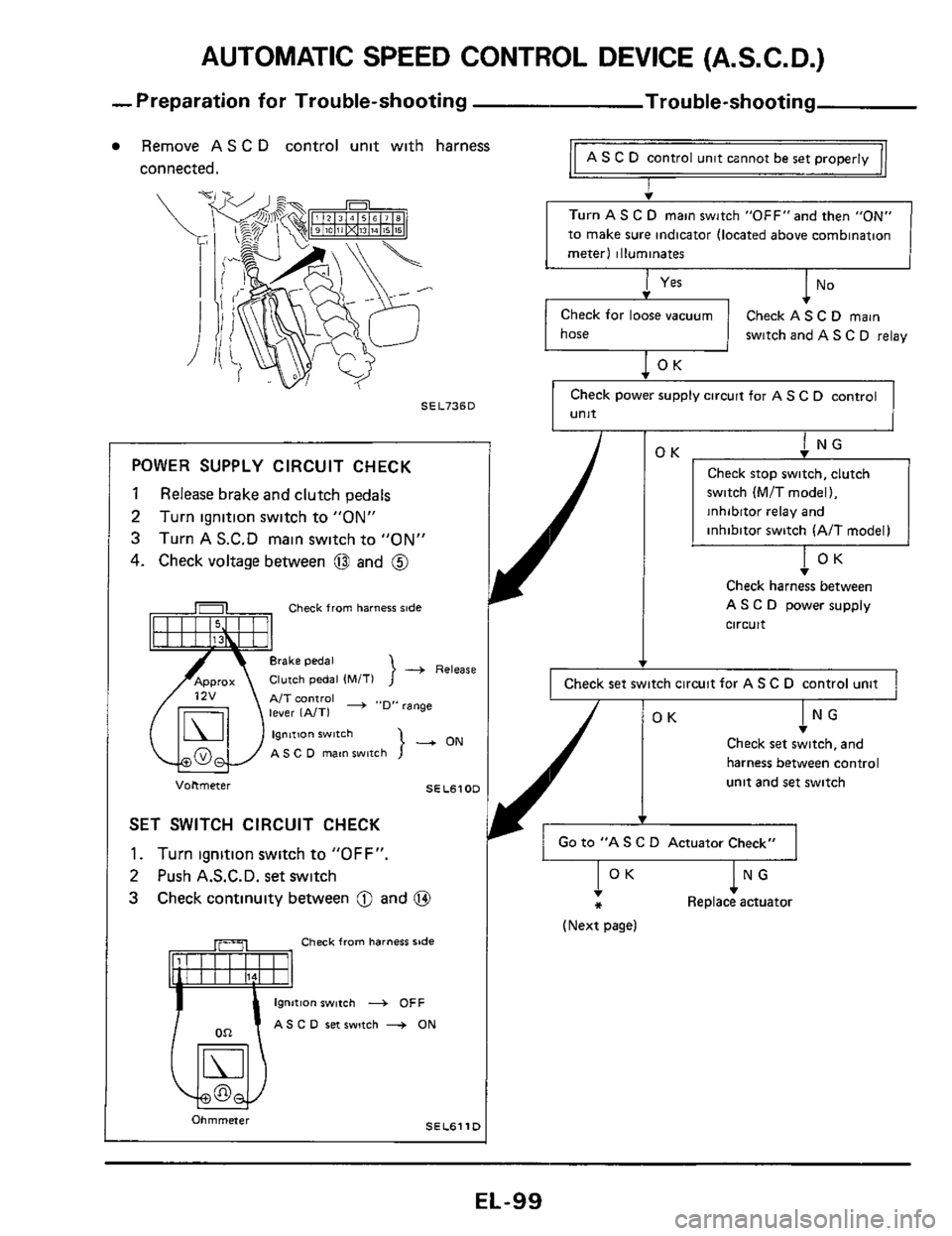

AUTOMATIC SPEED CONTROL DEVICE (A.S.C.D.)

-Preparation for Trouble-shooting Trouble-shooting

Remove AS C D control unit with harness AS C D control unit cznnot be set properly connected. I

Turn AS C D main switch "0FF"and then "ON"

to make sure indicator (located above combination

meter1 illuminates

Check for loose vacuum Check AS C D main

[-I switch and AS C D relay

Check power supply circuit for

A S C D control

unit SEL736D

Check stop switch. clutch

switch (MIT model).

inhibitor relay and

inhibitor switch (AIT model) POWER SUPPLY CIRCUIT CHECK

1 Release brake and clutch pedals

2 Turn ignition switch to "ON"

3 Turn A S.C.D main switch to "ON"

4. Check voltage between 0 and @ v Check harness between

AS C D power supply Check from harness side

-+ Release

A/T control -+ ..D" range

AS C D main wnch }-ON IOK Checksets:and

harness between control

unit and

set switch Voltmeter SELSlOD

SET SWITCH CIRCUIT CHECK

1. Turn ignition switch to "OFF". Go to "A S C D Actuator Check" -

2 Push A.S.C.D. set switch

3 Check continuity between 0 and @

Check from harness side

tion switch 4 OFF

C 0 ret switch + ON

SELBllD Ohmmeter

I

circuit

I Check set switch circuit for AS C D control unit 1

lNG Replace actuator !OK *

(Next page)

EL-99

Page 101 of 116

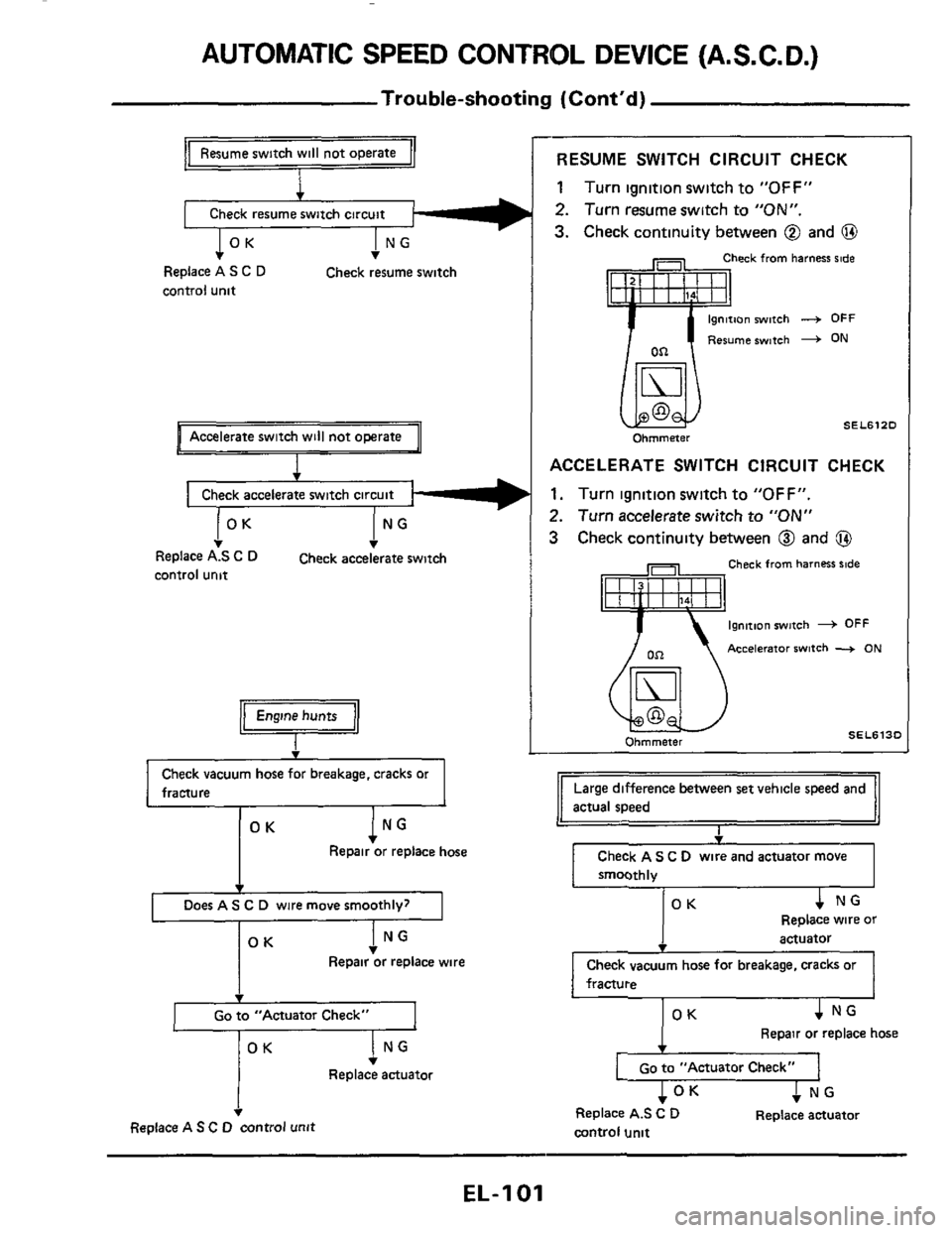

AUTOMATIC SPEED CONTROL DEVICE (A.S.C. D.)

Trouble-shooting (Cont'd)

Resume switch will not operate

Replace AS C D

control unit Check resume switch

h Accelerate switch will not owrate 11

Check accelerate switch circuit

v v Replace AS C D

control unit Check accelerate swttch

Engine hunts

Q

Check vacuum hose for breakage, cracks or

fracture

OK lNG Repair or replace hose

v

Does AS C D wire move smoothlv7

I NG v OK

Repair or replace wire

I

I Go to "Actuator Check" I

OK lNG Replace actuator

.I

Replace A S C D control unlt

RESUME SWITCH CIRCUIT CHECK

1 Turn ignition switch to "OFF"

2. Turn resume switch to "ON".

3. Check continuity between @ and 0

heck from harness side

on witch -+ OFF

M 0 h rn rn el e r SEL6120

ACCELERATE SWITCH CIRCUIT CHECK

1. Turn ignition switch to "OFF".

2. Turn accelerate switch to "ON"

3 Check continuity between @ and @

Check from harness %de

ignition switch + OFF

Accelerator witch -+ ON

SEL6130 Ohmmeter -

Large difference between set vehicle speed and

actual speed

I v

Check AS C D wire and actuator move

smoothlv

1 NG Replace wire 01

actuator

Check vacuum hose for breakage, cracks or

I fracture

4 NG

I OK Repair or replace hose

I Go to "Actuator Check" 1

4 NG

Replace actuator c OK Replace A.S C D

control unit

EL-I 01

Page 102 of 116

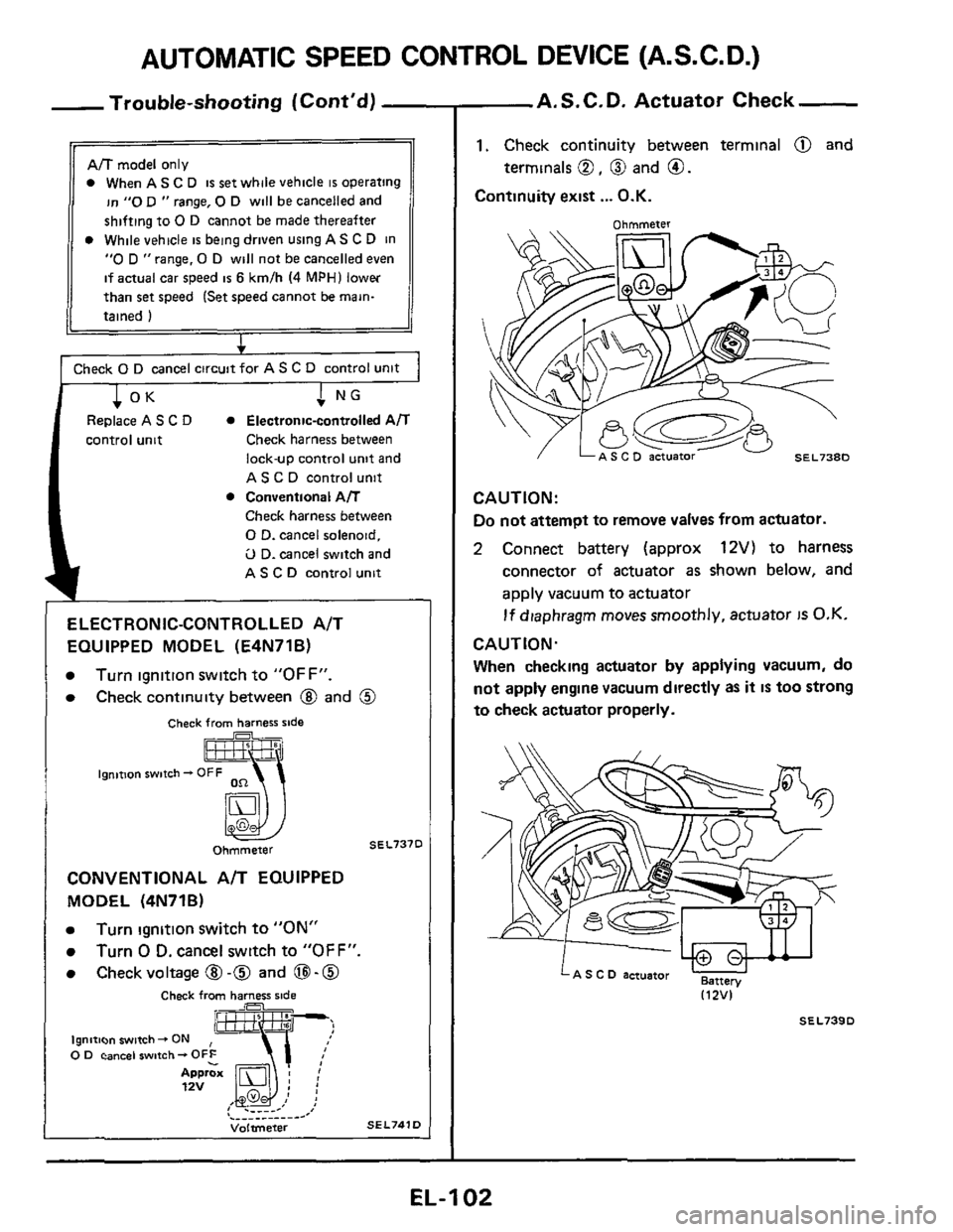

AUTOMATIC SPEED CONTROL DEVICE (A.S.C.D.)

- Trouble-shooting (Cont'd)

AIT model only

0 When A S C D is set while vehicle is operating

in

"0 D " range, 0 D will be cancelled and

shifting to

0 D cannot be made thereafter

0 While vehicle is being driven using AS C D in

"0 D "range, 0 D will not be cancelled even

if actual car speed is 6 kmlh (4 MPH) lower

than

set speed (Set speed cannot be main-

tained

)

1 Check 0 D cancel circuit for AS C D control unit I

Replace A S C D 0 Electroniccontrolled A/T

control unit Check harness between

lock-up control unit and

AS C D control unit

Check harness between

0 D. cancel solenoid.

i) D. cancel switch and

AS C D control unit

0 Conventional Ail

I

ELECTRONIC-CONTROLLED A/T

EQUIPPED MODEL (E4N71B)

Turn ignition switch to "OFF".

Check continuity between @ and @

Check from harness slde . .~

ignmon switch - OFF

SEL737D Ohmmeter

CONVENTIONAL A/T EQUIPPED

MODEL (4N71B)

Turn ignition switch to "ON"

Turn 0 D. cancel switch to "OFF".

Check voltage @ -0 and 0-0

Check from harness side A '- b9ndt'~~n~~~~i~hO_N 0 Fihz L

Approx 12v ,I { .__. _- I .__.__.__.- -' Volmeter SEL741D

A.S.C.D. Actuator Check

1. Check continuity between terminal @ and

Continuity exist

... O.K.

terminals 0, @ and 0.

CAUTION:

Do

not attempt to remove valves from actuator.

2 Connect battery (approx 12V) to harness

connector

of actuator as shown below, and

apply vacuum to actuator

If diaphragm moves smoothly, actuator IS O.K.

CAUTION.

When checking actuator by applying vacuum, do

not apply engine vacuum directly

as it IS too strong

to check actuator properly.

LA s c D actuator B,m, 112VI

SEL739D

EL-I 02

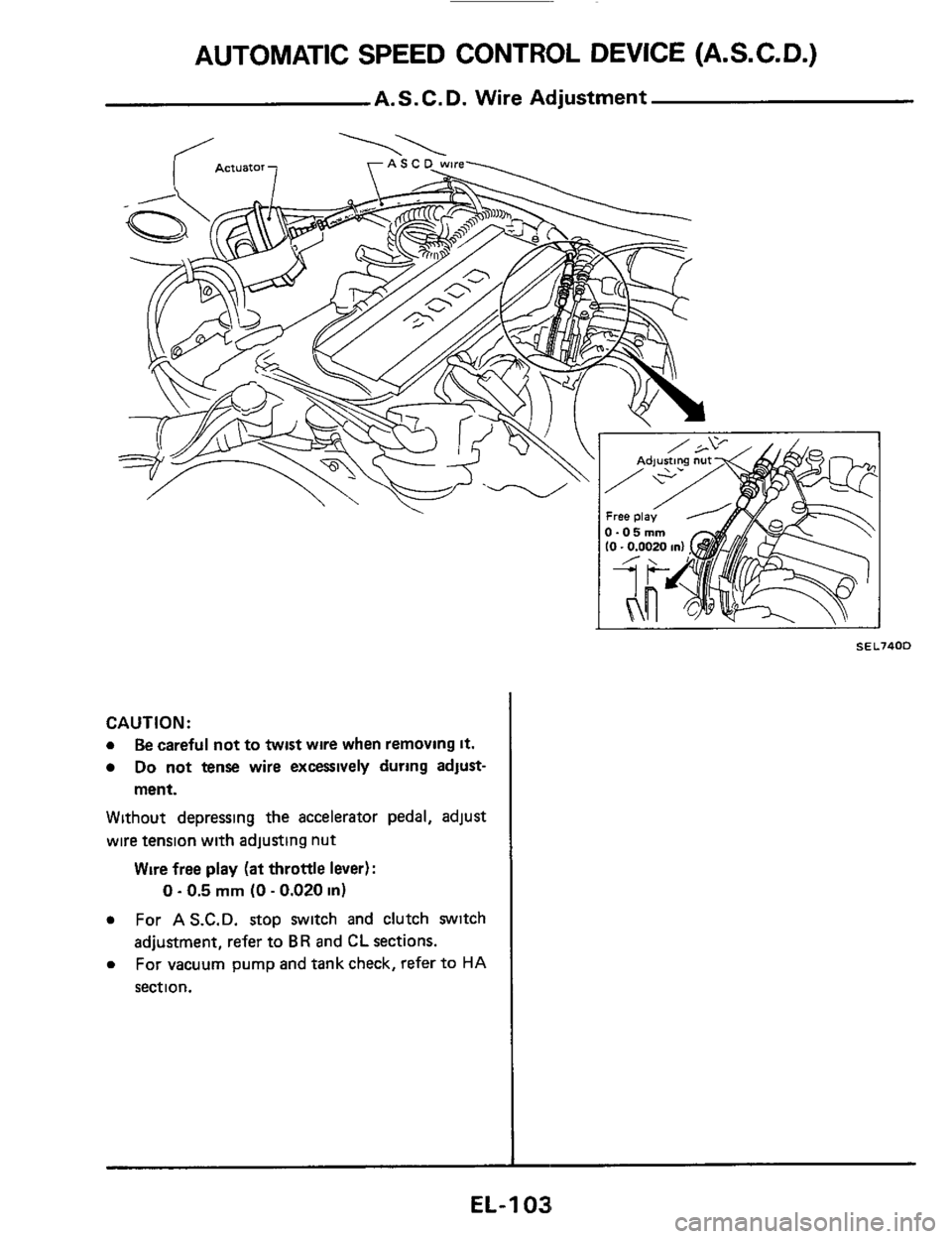

Page 103 of 116

SEL740D

CAUTION:

a Be careful not to twist wire when removing it.

Do not tense wire excessively during adjust-

ment.

Without depressing the accelerator pedal, adjust

wire tension with adjusting nut

Wire free play (at throttle lever):

0 - 0.5 mm (0 - 0.020 in)

a For A S.C.D. stop switch and clutch switch

adjustment, refer to

BR and CL sections.

a For vacuum pump and tank check, refer to HA

sect ion.

EL-1 038

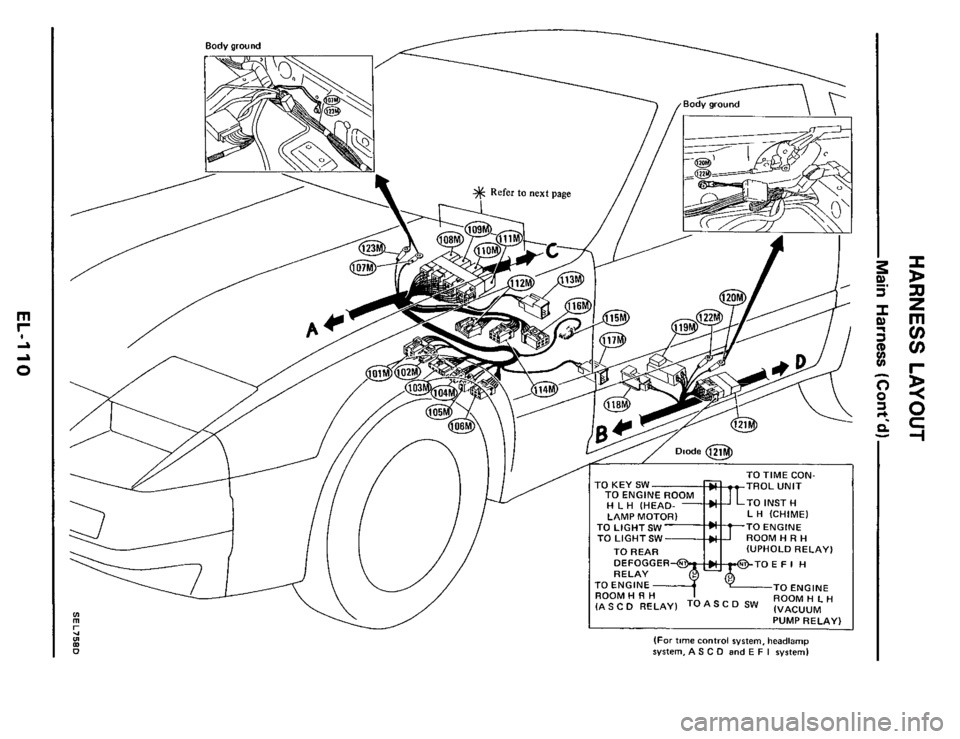

Page 110 of 116

,

TO TIME CON-

TROL UNIT

TO INST H LH (CHIME)

TO ENGINE

ROOM

H R H (UPHOLD RELAY)

TO ENGINE ROOM H L H IHEAO-

TO LIGHT SW TO LIGHT SW -

TO REAR

ro KEY sw

3OOM H R H A S C 0 RELAY1 To As sw (VACUUM ROOM H L H

PUMP RELAY)

(For time control system, headlamp system, AS C 0 and E F I system1

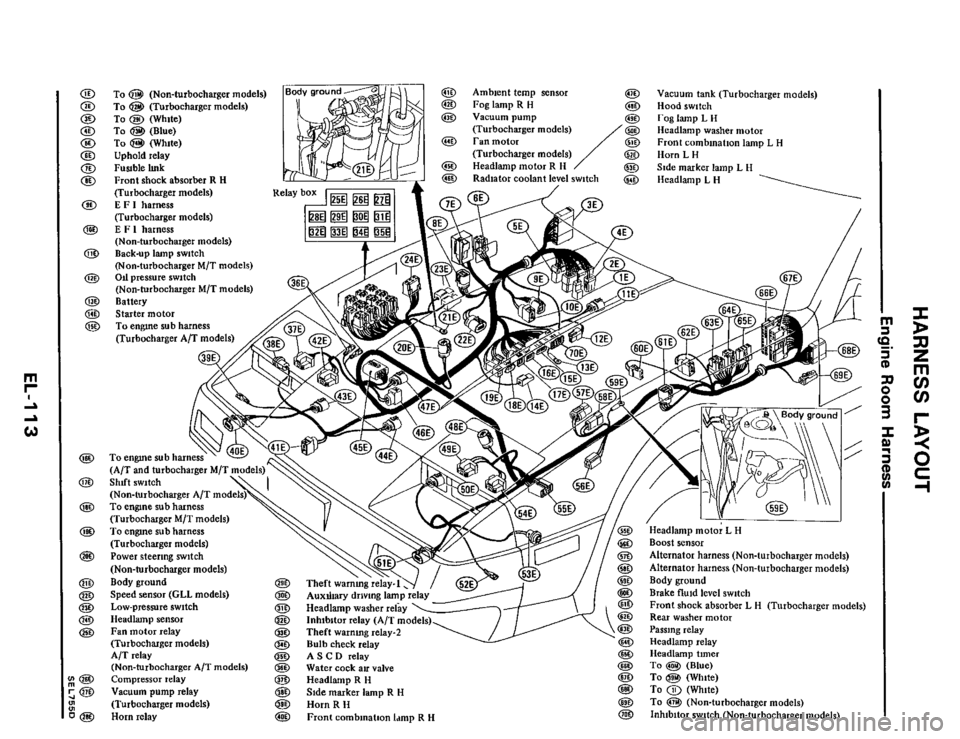

Page 113 of 116

@ To @ (Non-turbocharger models) 0 Ambient temp sensor 0 Vacuum tank (Turbocharger models)

0 To @I (Turbocharger models) 0 PoglampRH @ Hoodswitch

0 To @il White) @ Vacuumpump 0 I'oglampLH @ Hoadlamp washer motor

0 @D Horn L H

/ @ Side marker lamp L H

0 To @I (Blue) (Turbocharger models)

@ To @ White) 0 ranmotor

@ Uphold relay (Turbocharger models)

@ Fuublchk @ Headlamp motor R H

0 Front shock absorber R H @ Radiator coolant level switch 0 Hcadlamp L H

Front combmation lamp L H

A/T relay I @ AS C D relay (Non-turbocharger AIT models) @ Water cock an valve Compressor relay 0 Headlamp R H Vacuum pump relay @ Side marker lamp R H

(Turbocharger models) @ Horn RH Horn relay @ Front combination lamp R H

6 Headlamp tmer @ To @ (Blue) I@ To @ (White)

@Q To @ (White) @ To 0 (Non-turbocharger models)

@ Inhibitor switch (Non-turbocharger models)