headlamp NISSAN 300ZX 1984 Z31 Electrical System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 116, PDF Size: 3.42 MB

Page 1 of 116

ELECTRICAL SYSTEM

I

SECTION EL

CONTENTS

HOW TO READ DIAGRAMS

STANDARDIZED RELAY

POWER SUPPLY ROUTING

BATTERY.

.. ..

STARTING SYSTEM .

STARTING SYSTEM -Starter -

CHARGING SYSTEM .

CHARGING SYSTEM - Alternator

COMB IN AT1 ON SWITCH

INSTRUMENT SWITCH

HEADLAMP

EXTERIOR LAMP,

INTERIOR LAMP

.

..

..

..

..

..

... ......

..

.. ....

..

.. ...

EL- 2

EL- 3

EL- 4

EL- 6

EL- 9

EL-

10

EL- 15

EL- 17

EL- 23

EL- 25

EL- 26

EL- 34

EL- 38

METER AND GAUGES - Digital Type Combination Meter . . EL- 41

METER AND GAUGES - Digital Type Combination Gauge . .. .. EL- 57

METER AND GAUGES - Needle Type Combination Meter .. . EL- 65

METER AND GAUGES

- Needle Type Combination Gauge.. .... EL- 68

WARNING LAMPS AND CHIME. .......... ... .... EL- 71

VOICE WARNING SYSTEM

... ... EL- 76

TIME CONTROL SYSTEM ... EL- 81

WIPER AND WASHER .... .... ... ... . EL- 89

HORN, CIGARETTE LIGHTER, CLOCK . . ......... EL- 92

REAR WINDOW DEFOGGER

... .. ... ....... EL- 93

AUDIO AND POWER ANTENNA

,. . .... .. . EL- 95

AUTOMATIC SPEED CONTROL DEVICE (AS

C D ) . ... , . EL- 97

LOCATION OF ELECTRICAL UNITS

... .. .. .. EL-104

HARNESS LAYOUT

. . .. .. .. . EL-107

Page 26 of 116

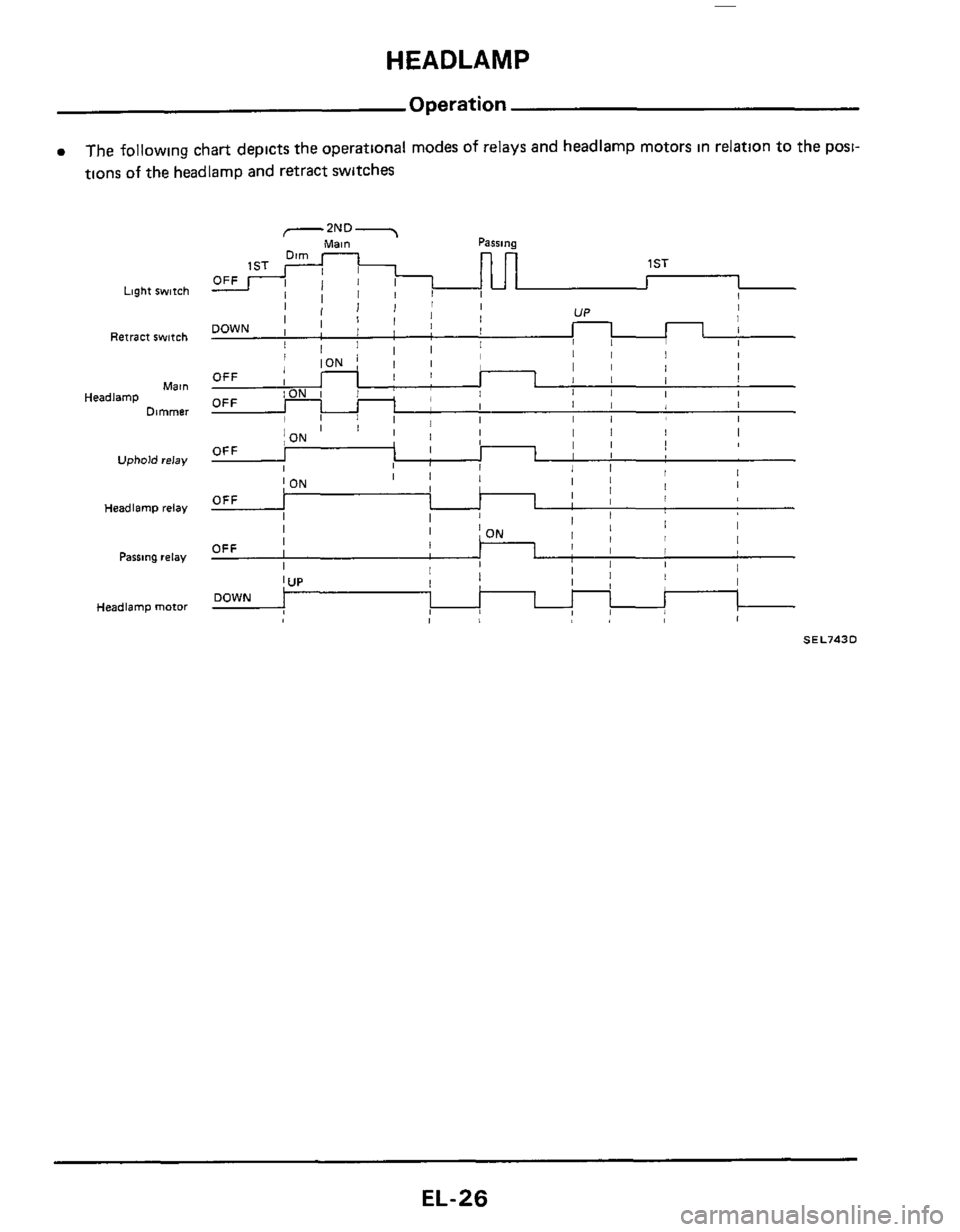

HEADLAMP

Operation

0 The following chart depicts the operational modes of relays and headlamp motors in relation to the posi-

nons

of the headlamD and retract switches

Light switch

Retract switch

Mal”

Dimmer Headlamp

Uphold relay

Headlamp relay

Pasrlng relay

Headlamp mofor

Parsing -2ND 7 Main

nn

1 ST

I I I

I I I I I , I , , 1 I 1 I , I I OFF 1 1 I I I I 1 I I OFF I I 1 I I I I I I II I I

UP

II 111

I

Ill I I I !

I j ON

I I

I ON

I I I I

I

OFF I

I I

I I I 1 I I1 1 I 1

I/ OFF

I I 1, I !I I OFF ~

I I UP DOWN

SEL743D

EL-26

Page 27 of 116

-

BATTERY TI RFI AV 1 7

THEFT WARNING

r --, I II

I

"$ 7; '/' '

PASSING RELAY

k=a-J \-UPHOLD RELAY

I

1V.

@ Wnihoul headlamp warning

0 Wnh headlamp warning

Page 28 of 116

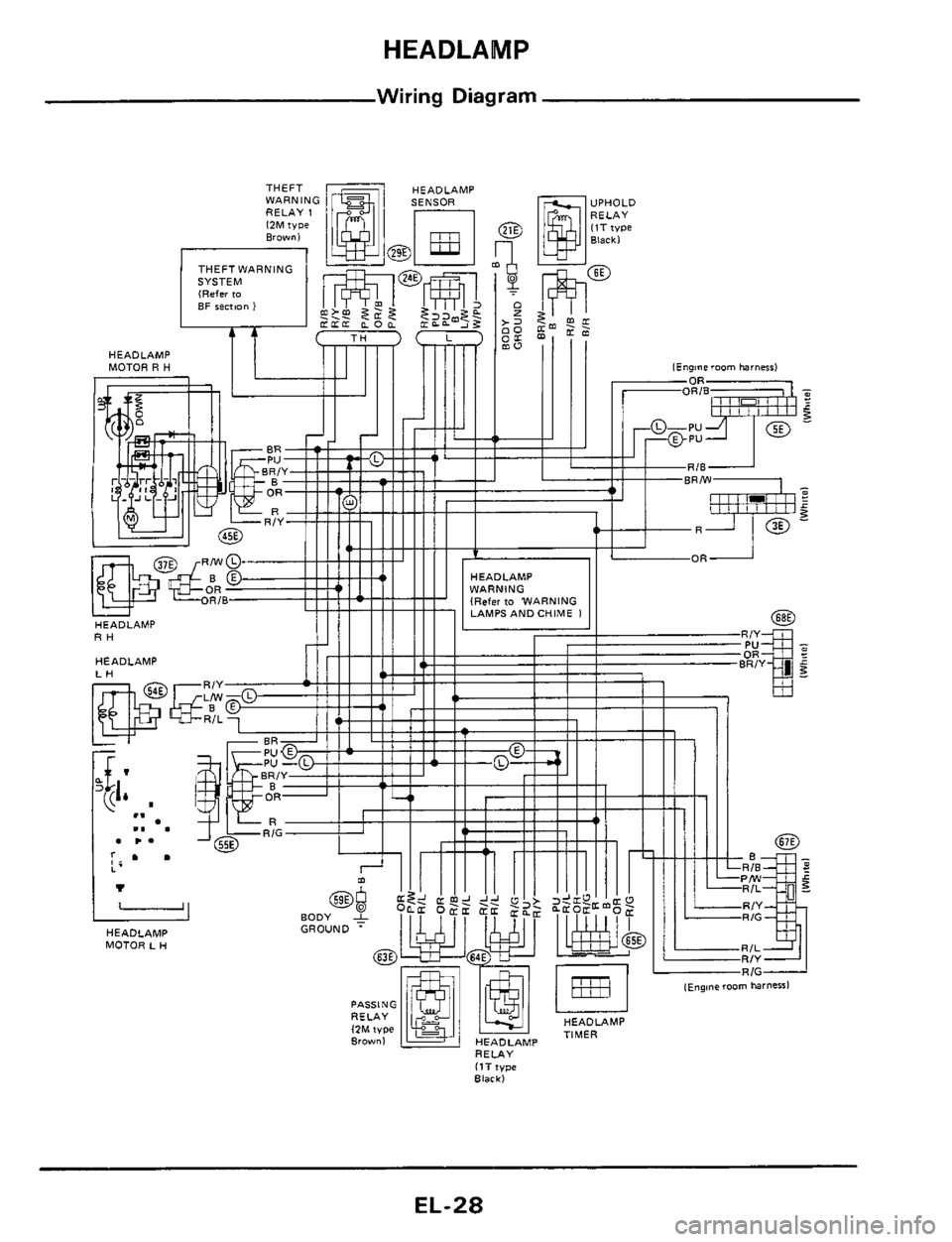

HEADLAMP

Wiring Diagram

HEADLAMP

MOTOR R H

RH

HEADLAMP

HEADLAMP

MOTOR L H

HEADLAMP

RELAY

ItT type Black)

EL-28

Page 30 of 116

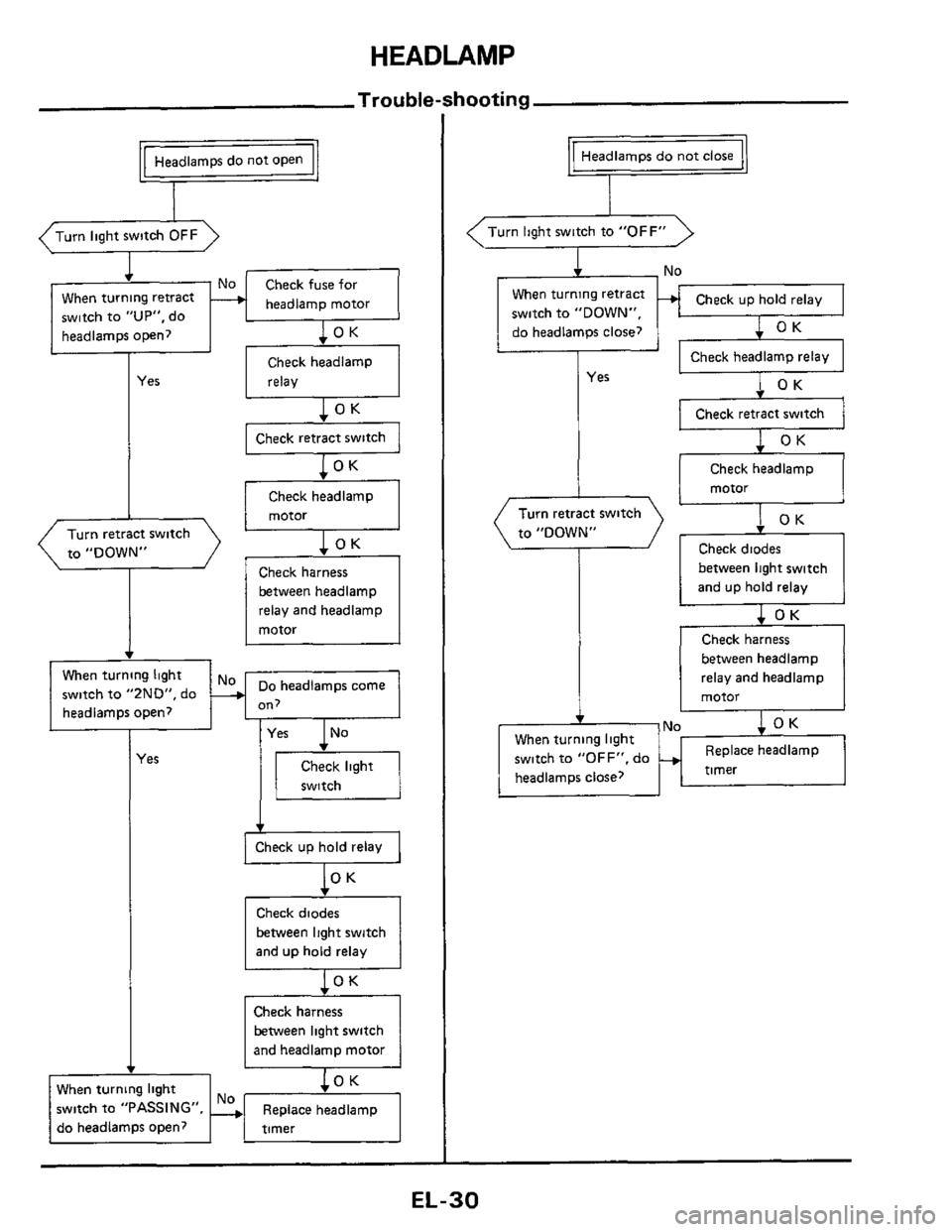

HEADLAMP

Trouble-shooting

Check diodes

between light switch

and up hold relay

1 OK

Check harness

between headlamp

relay and headlamp

motor

headlamp motor When turning retract

switch to

"UP", do

headlamps open?

Check headlamp

Yes relay

Check headlamp

motor

Turn retract switch

to "DOWN"

between headlamp

relay and headlamp

motor

v

When turning light

r switch to "ZND", do

-No When turning light

switch to "OFF". do

headlamps close? ~

on, I headlampsopen? I I

Replace

headlamp

timer -.

-

I

(es

switch

Check up hold relay 1 I

lo

Check diodes

between light switch

and up hold relay

OK

between light switch

and headlamp motor

When turning light

switch to "PASSING", Replace headlamp

do headlamps open?

Headlamps do not close

F

(Turn light switch to "OFF"

c - No

When turning retract

switch to "DOWN",

do headlamps close?

I - Check headlamp relay

Yes

Check retract switch

Check headlamp

EL-30

Page 32 of 116

HEADLAMP

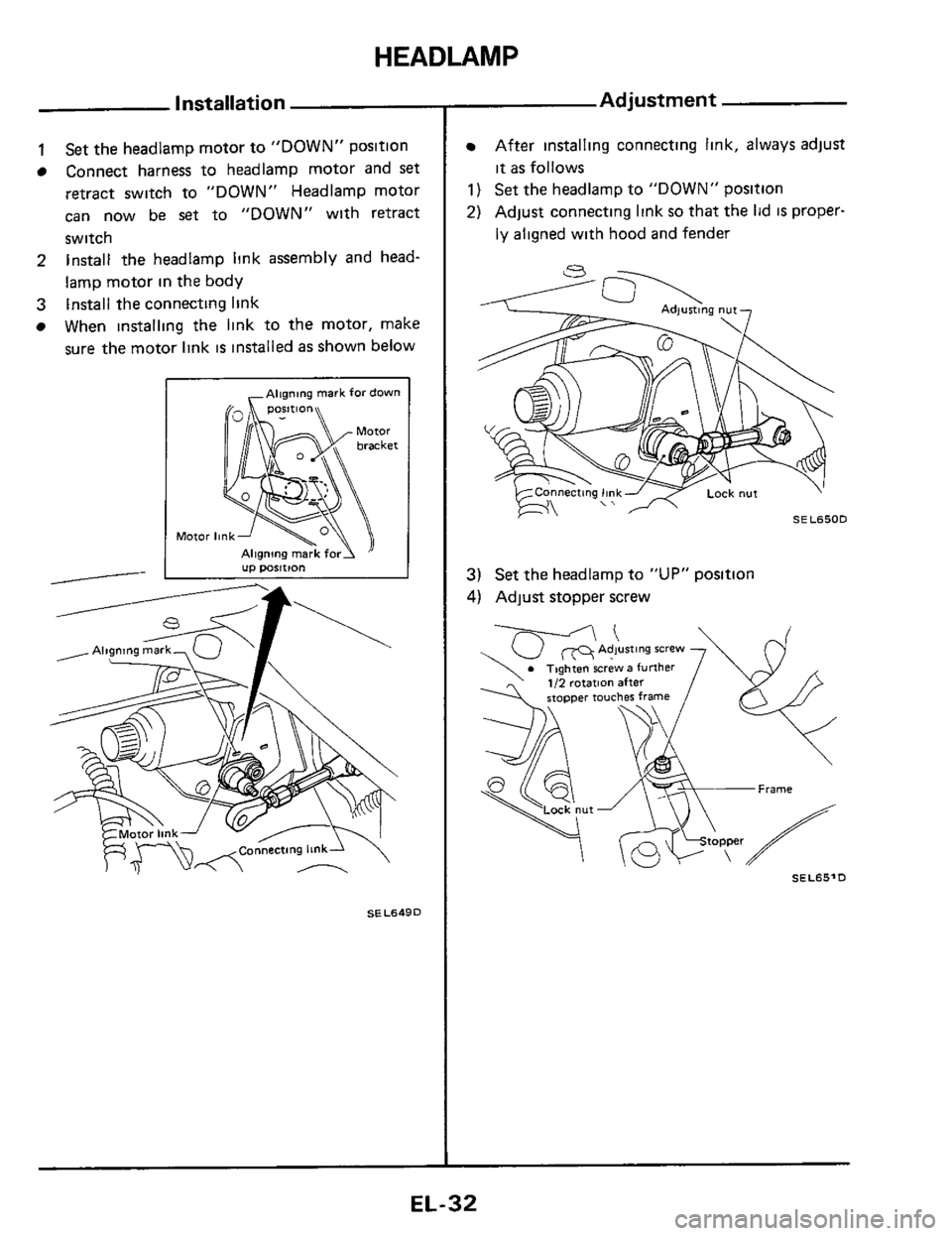

Installation

1 Set the headlamp motor to "DOWN" position

Connect harness

to headlamp motor and set

retract switch to "DOWN" Headlamp motor

can now be

set to "DOWN" with retract

switch Install the headlamp link assembly and head-

lamp motor in the body

When installing the link to the motor, make

sure the motor link is installed as shown below

2

3 Install the connecting link

,Aligning mark fordown

Motor

SEL649D

Adjustment

After installing connecting link, always adjust

it as follows

1) Set the headlamp to "DOWN" positlon

2) Adjust connecting link so that the lid IS proper-

ly aligned with hood and fender

3) Set the headlamp to "UP" position

4) Adjust stopper screw

SEL65'D

EL-32

Page 33 of 116

HEADLAMP

0

0

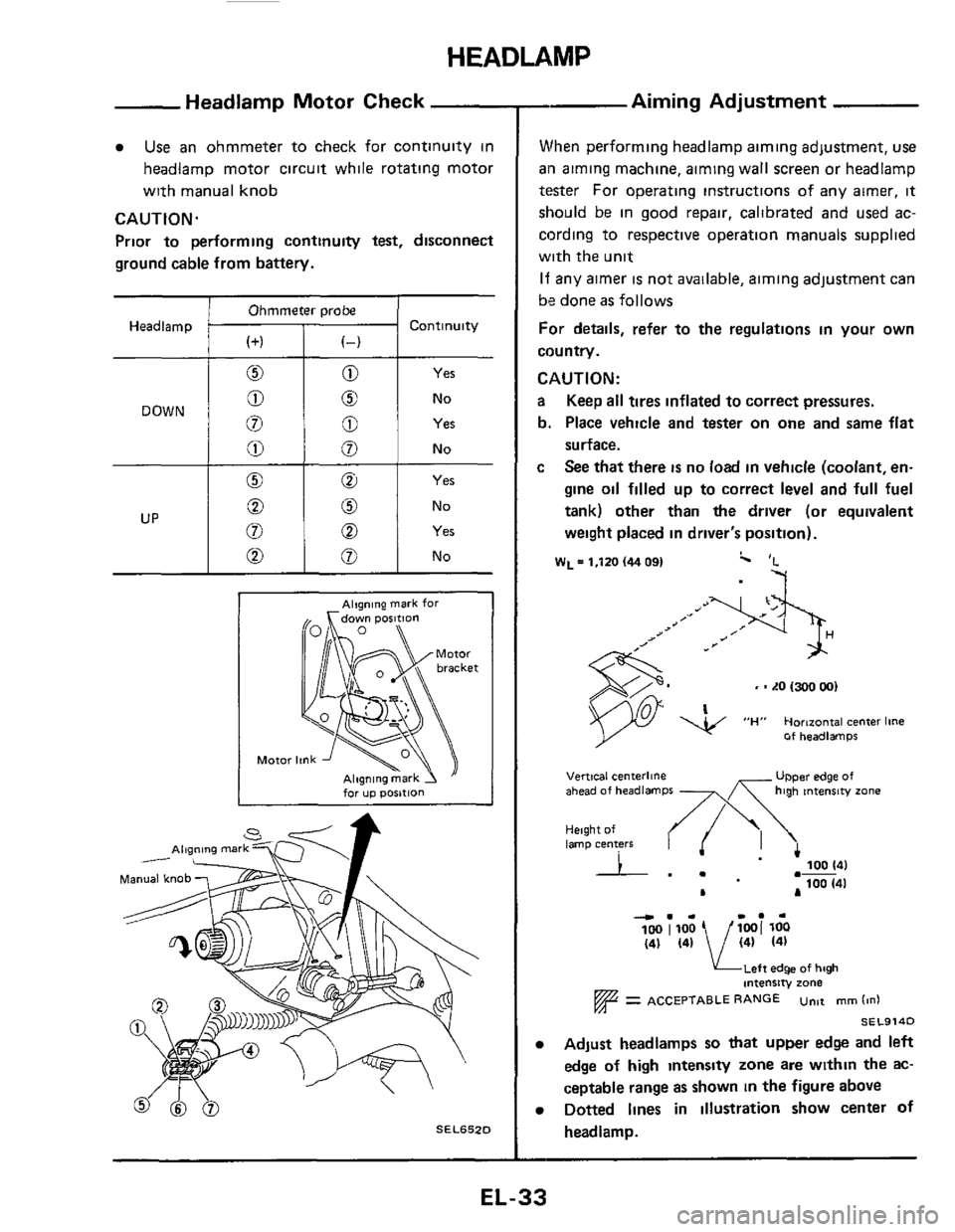

Headlamp Motor Check

0 No

8 Yes

Use an ohmmeter to check for continuity in

headlamp motor circuit while rotating motor

with manual knob

CAUTION.

Prior to performing continuity test, disconnect

ground cable from battery.

Ohmmeter probe

Headlamp Continuity

Yes

No

Alqning mark for

for up posltlon

SEL652D

- Aiming Adjustment

When performing headlamp aiming adjustment, use

ail aiming machine, aiming wall screen or headlamp

tester For operating instructions of any airner, it

should be in good repair, calibrated and used ac-

cording to respective operation manuals supplied

with the unit

If any aimer is not available, aiming adjustment can

be done

as follows

For details, refer to the regulations in your own

country.

CAUTION:

a Keep all tires inflated to correct pressures.

b. Place vehicle and tester on

one and same flat

surface.

c See that there is no load in vehicle (coolant, en-

gine oil filled up to correct level and full fuel

tank) other than

the driver (or equivalent

weight placed in driver's position).

W~=l,ltO(4409I c 'L

-7

, - LO 1300 001

Of headlamps

UPper edge of Vertical centerline ahead of headlamps -x high tntenrw zone

Height of lamp centers I .- 100 141

100 (41 .-

L A

4.. I.. 100 1100 1001 loo (41 (41 / (41 (41

KLeft edge of high intensity zone

= ACCEPTABLE RANGE untt mm (in1

SEL914D

Adjust headlamps so that upper edge and left

edge

of high intensty zone are within the ac-

ceptable range as shown

in the figure above

Dotted lines in illustration show center of

headlamp.

EL-33

Page 37 of 116

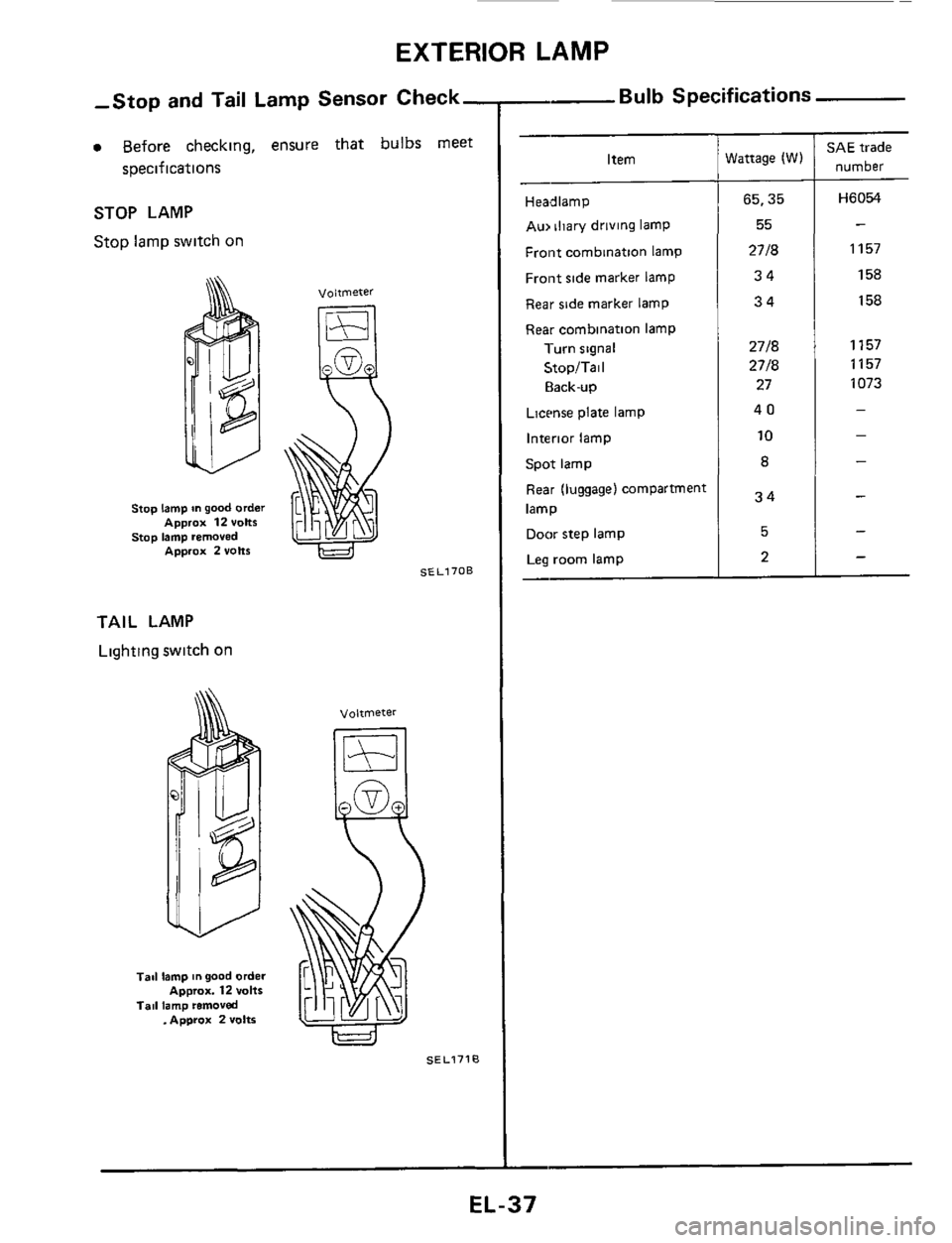

EXTERIOR LAMP

-

Item

-

Headlamp

Au, iliary driving lamp

Front combination lamp

Front side marker lamp

Rear side marker lamp

Rear cornbination lamp

1-urn signal

StopITail

Elack-up

Lictme plate lamp

Interior lamp

Spot lamp

Rear (luggage) compartment

lamp

Door step lamp

Leg room lamp

-

-Stop and Tail Lamp Sensor Check,

0 Before checking, ensure that bulbs meet Wattage (W)

65,35

55

2718 34

34

2718

2718

27

40

10

a

34

5

2

soecif ications

STOP LAMP

Stop lamp switch on

Stop lamp on good order

stop lamp removed Approx 12 volts

Approx 2volt6

voltmeter

SEL170B

TAIL LAMP

Lighting switch on

Tad lamp mgood order

Tail lamp removed ~pprox. 12 vans

. Approx 2 volts

SEL1710

- Bulb Specifications

SAE trade

number

Hi3054

-

1157

158 158

1157 1157

1073

-

-

-

-

-

-

EL-37

Page 75 of 116

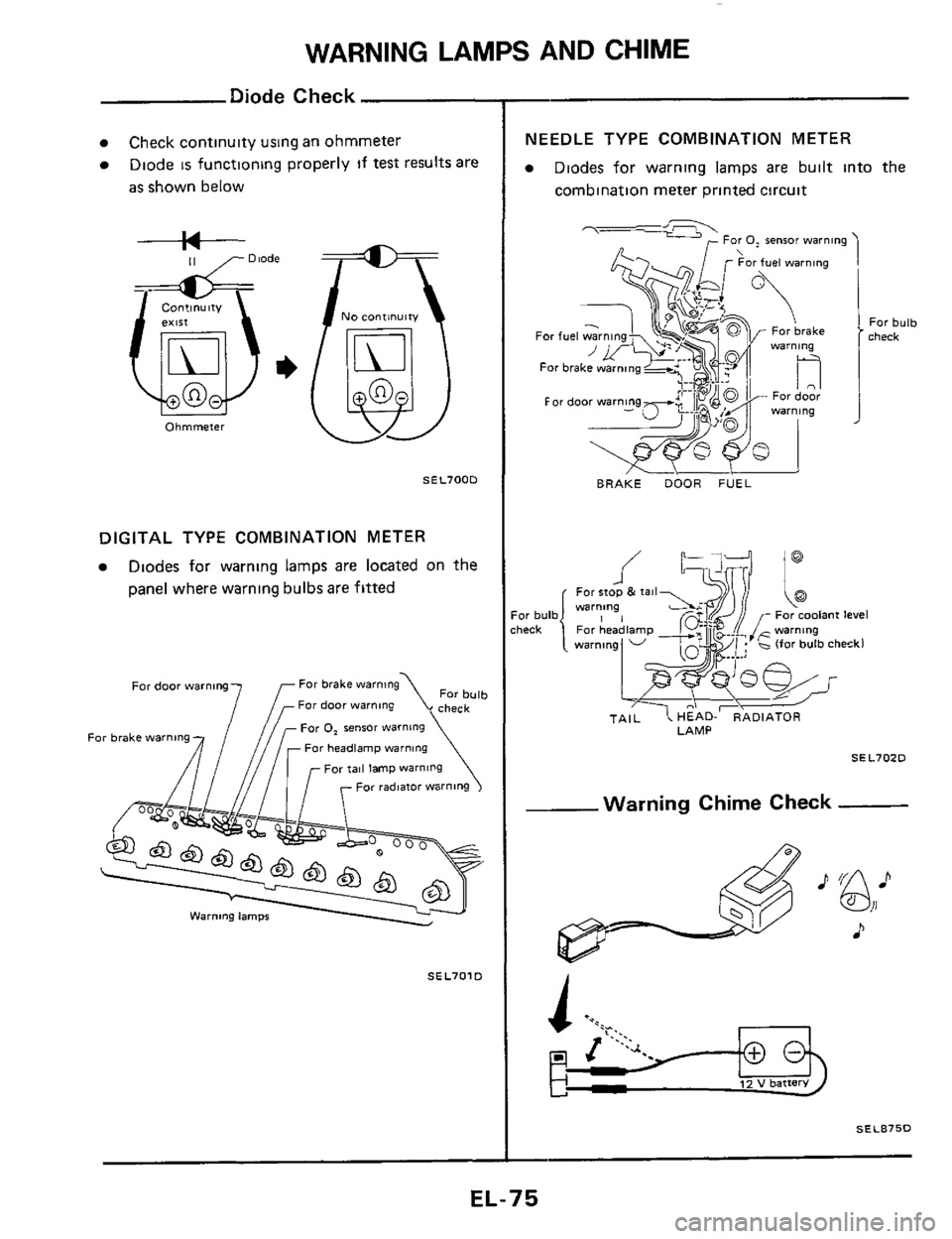

WARNING LAMPS AND CHIME

Diode Check

Check continuity using an ohmmeter

Diode

is functioning properly if test results are

as shown below

--I+-- 11 ,- Diode

Ohmmeter

NO continuity

@

SEL700D

DIGITAL TYPE COMBINATION METER

Diodes for warning lamps are located on the

panel where warning bulbsare fitted

For bulb check

For brake warning

7f For door warning

Far door warning

For tail lamp warning

For radmtor warning

Far 0, sensor warning

Far headlamp warning For brake warning

SEL701D

-~

NEEDLE TYPE COMBINATION METER

Diodes for warning lamps are built into the

Combination meter printed circuit

7- For 0, sensor warning

BRAKE DOOR FUEL

For bulb check

LAMP

SEL70ZD

--Warning Chime Check

A

SEL875D

EL-75

Page 91 of 116

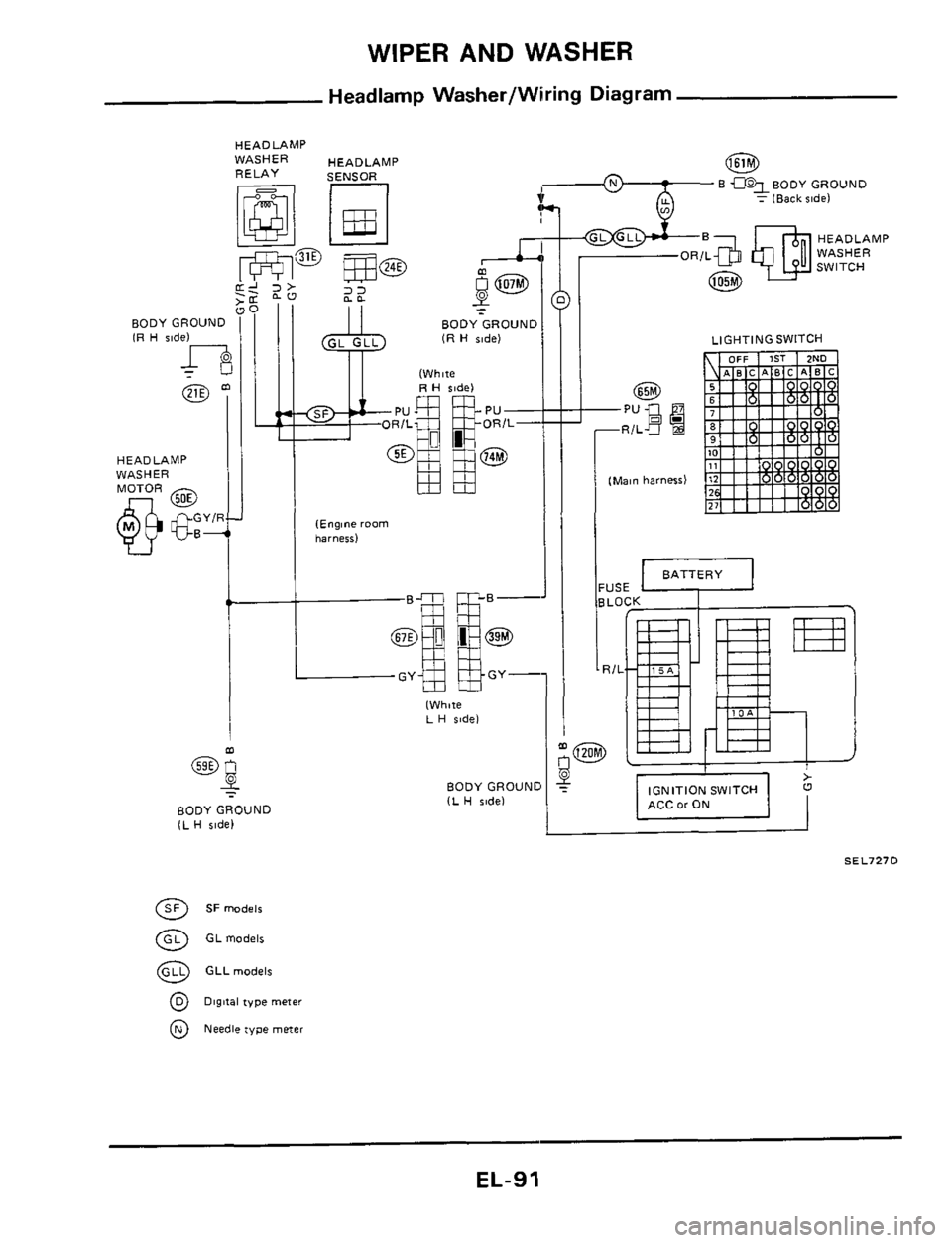

WIPER AND WASHER

Headlamp Washer/Wiring Diagram

HEADLAMP

RELAY

WASHER HEADLAMP @

: (Back ride)

HEADLAMP

WASHER

SWITCH

7

- 22 I1 BODY GROUND IR H ride)

HEADLAMP

WASHER

BODYGROUND (L H $#de)

@ GLmodelr

@ GLLrnodelr

@ Digital type meter

@ Needle type meiei

BODY GROl (R H ride)

II fWhw

(Engine room harnerr)

I LIGHTING SWITCH

J

(Main harness)

USE

7/1

w

II

IGNITION SWITCH I ACC or ON

I I

SEL727D

EL-91