NISSAN 300ZX 1984 Z31 Manual Transmission Workshop Manual

300ZX 1984 Z31

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/575/w960_575-0.png

NISSAN 300ZX 1984 Z31 Manual Transmission Workshop Manual

Trending: length, lock, ECO mode, transmission fluid, tow, recommended oil, ECU

Page 1 of 34

MANUAL TRANSMISSION

I

CONTENTS

REMOVAL AND INSTALLATION ...... ...... .... MT-2

ON-VEHICLE SERVICE

. . .. .. _. MT- 3

MAJOR OVERHAUL - FS5W71C. ... ...... ........ Mi- 4

DISASSEMBLY - FS5W71C ....... .. MT- 7

REPAIR FOR COMPONENT PARTS-FS5W71C ..... MT- a

ASSEMBLY - FS5W71C ...... , . . MT-18

5-SPEED TRANSMISSION [Model BW T-5 (FS5R90AIl

... MT-20

Rear extension

.. ... ..... ...... MT-23

Case cover

. . ......... ......... MT-23

Transmission case

. . ... .... MT-24

Gearstkshafts

.... .. .. .. ... MT-27

Replacement of

oil seals .... ..... MT-28

Replacement

of bearings . .I. ....... . MT-29

SPECIAL SERVICE TOOLS .... MT-33

SERVICE DATA AND SPECIFICATIONS (S D S ) .. MT-30

Page 2 of 34

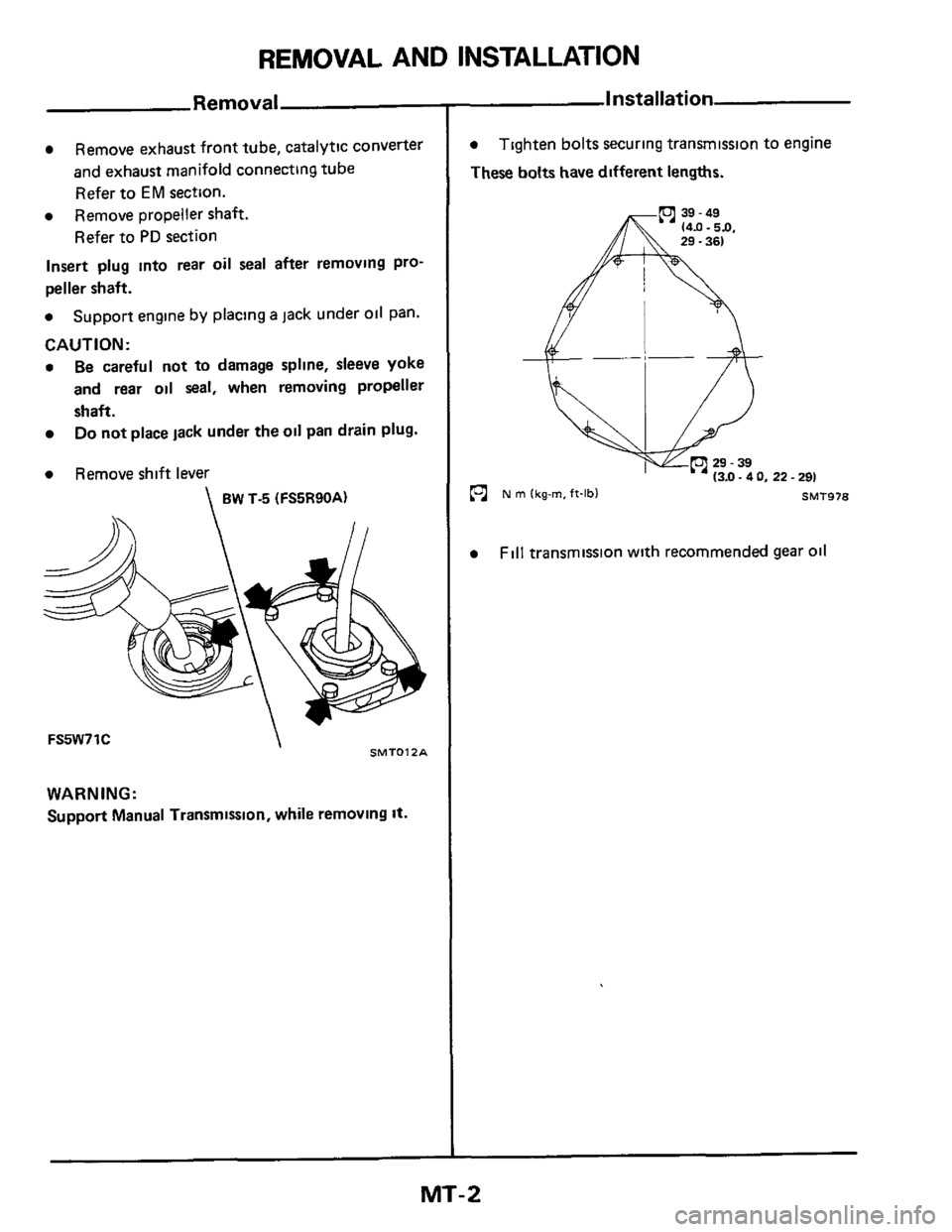

REMOVAL AND INSTALLATION

Remove exhaust front tube, catalytic converter

and exhaust manifold connecting tube

Refer to

EM section.

a Remove propeller shaft.

Refer to

PD section

Insert plug into rear oil seal after removing pro-

peller shaft.

a Support engine by placing a jack under oil pan.

CAUTION:

a Be careful not to damage spline, sleeve yoke

and rear oil seal, when removing propeller

shaft.

Do not place lack under the oil pan drain plug.

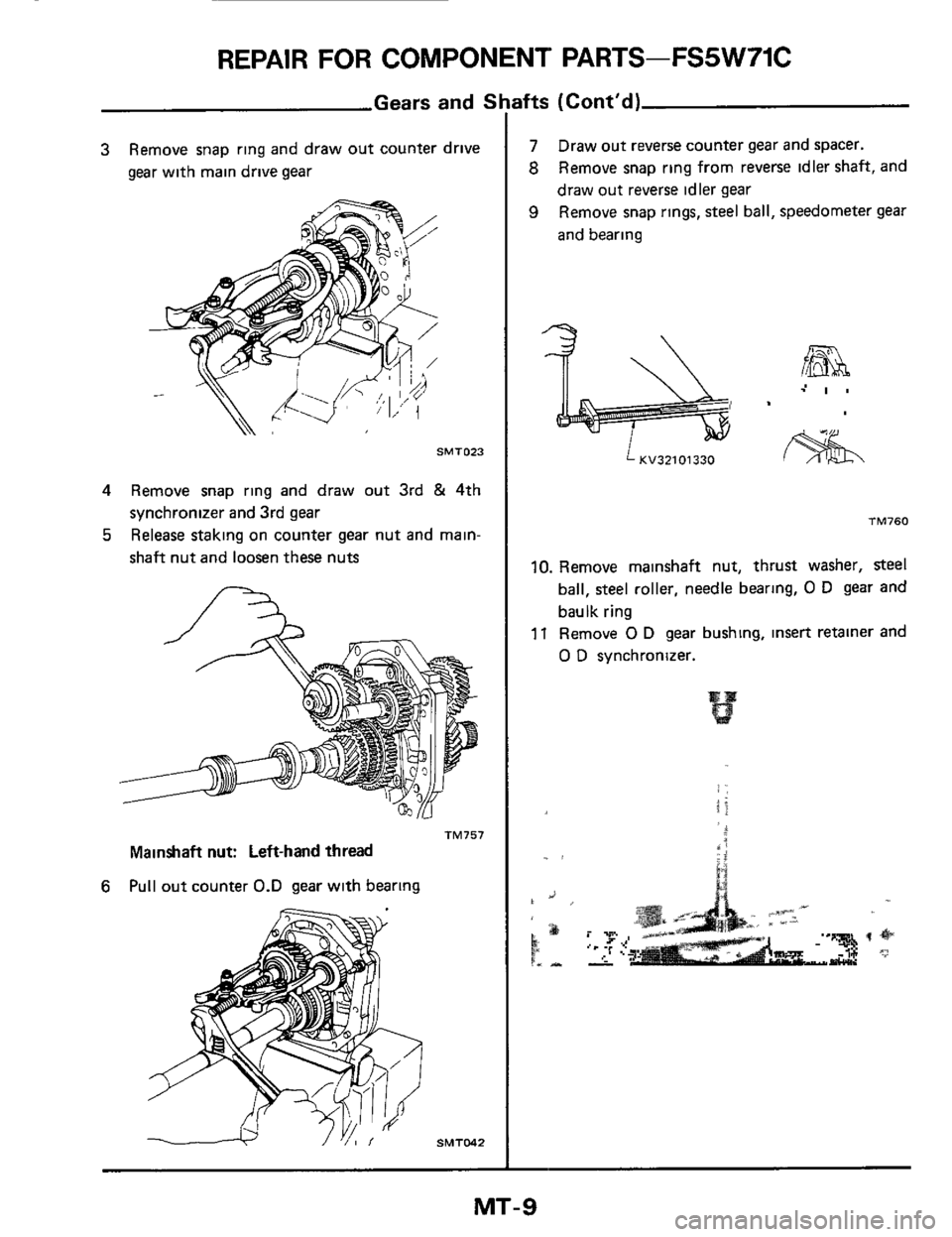

a Remove shift lever

BW T-5 (FS5R90A)

SMTOlZA FS5W71C

WARNING:

Support Manual Transmission, while removing It.

Installation

a

These bolts have different lengths.

Tighten bolts securing transmission to engine

22.291

SMT978

Fill transmission with recommended gear oil

MT-2

Page 3 of 34

ON-VEHICLE SERVICE

0 Rear extension oil seal.

I

MT-3

Page 4 of 34

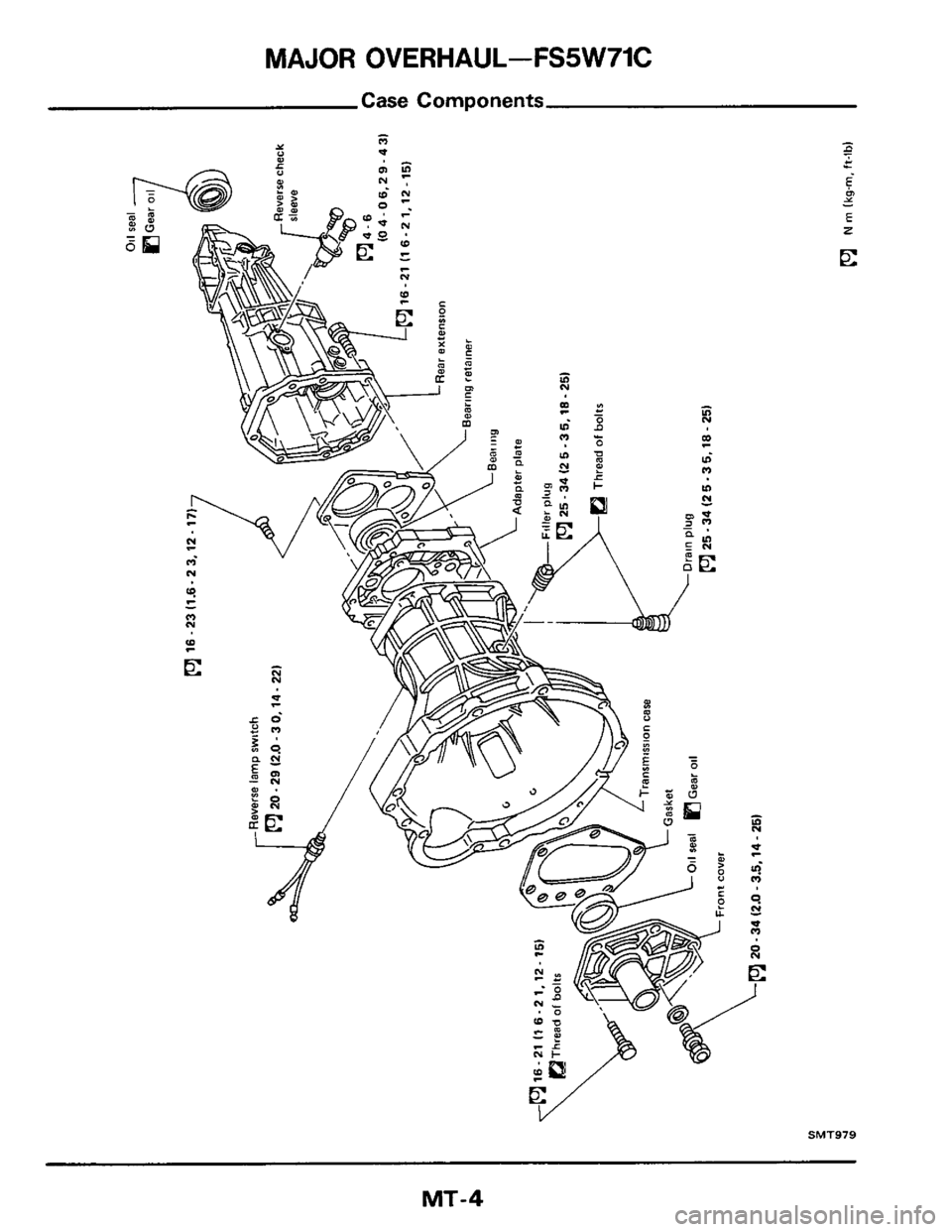

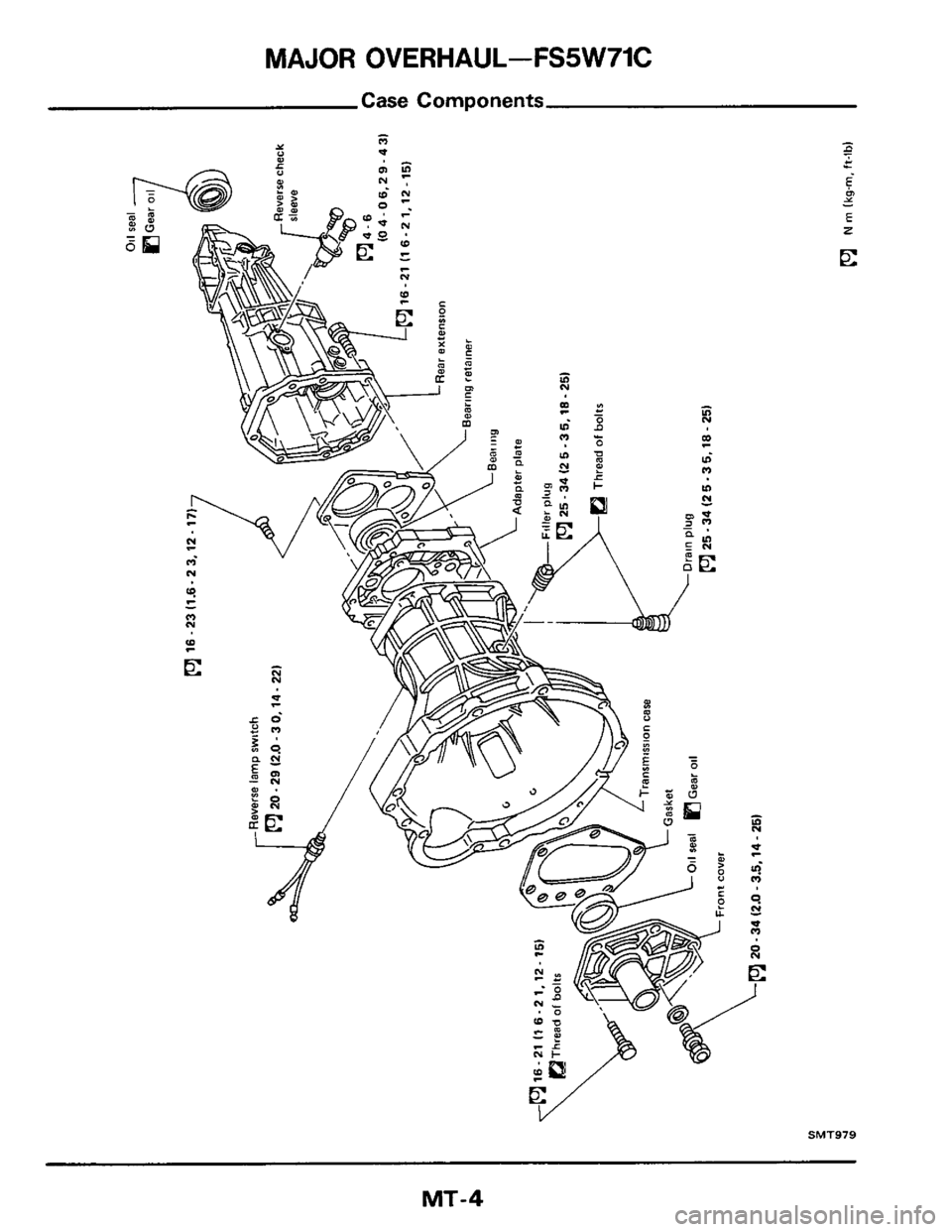

MAJOR OVERHAUL-FS5W71C

Case Components

MT-4

Page 5 of 34

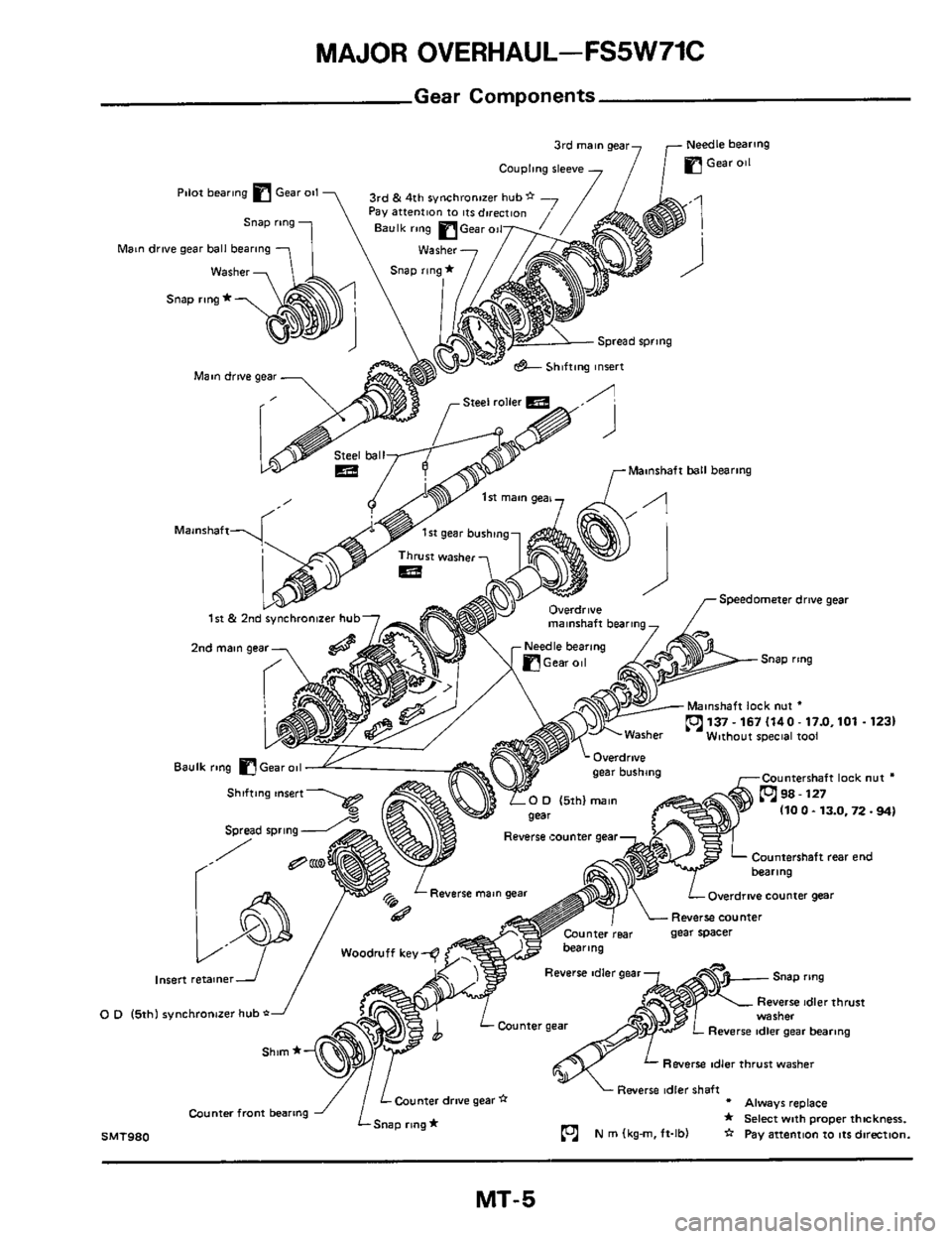

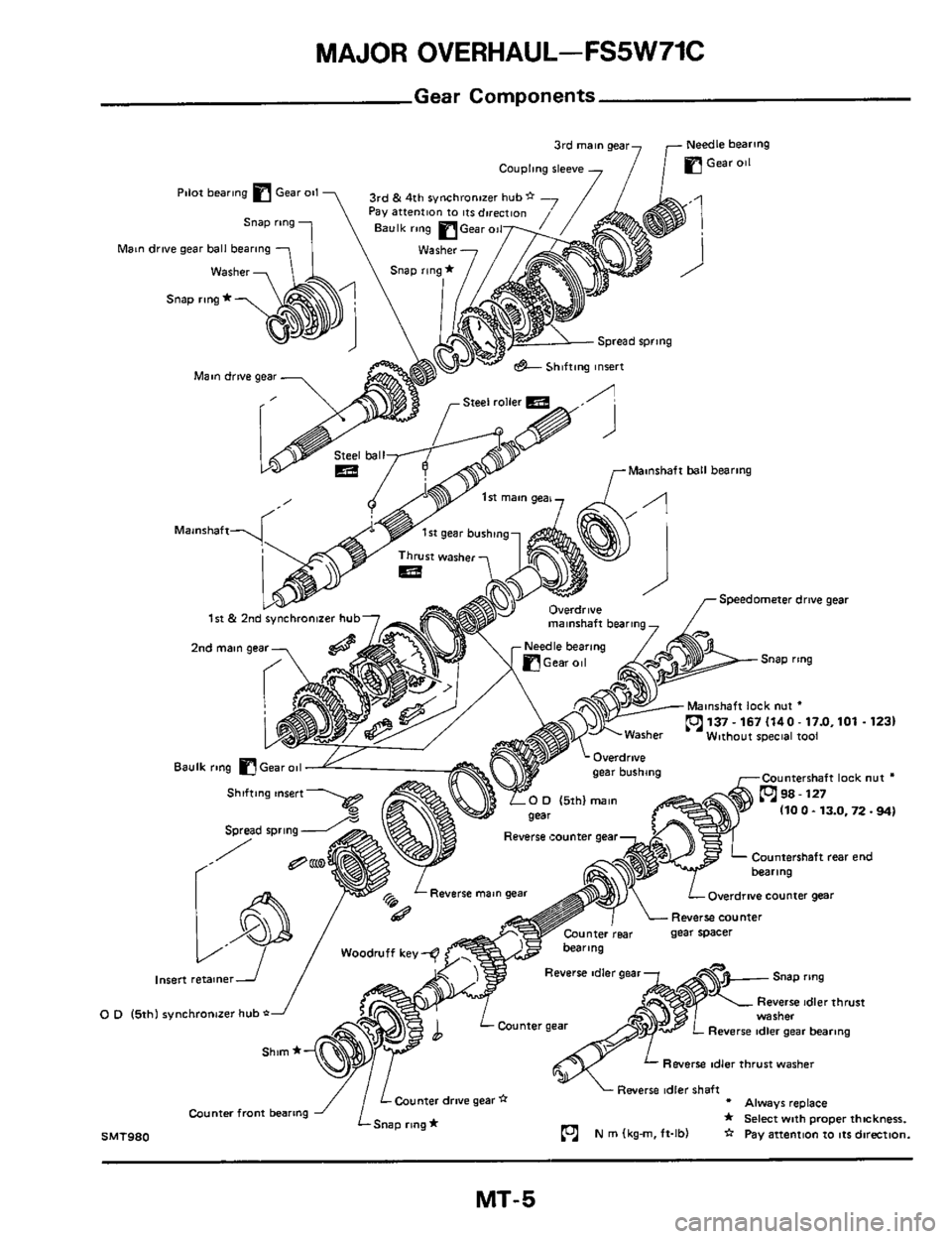

MAJOR OVERHAUL-FS5W71C

Gear Components

3rd main gear Needle bearing

Coupling sleeve 7 TmGearoiI

3rd & 4th synchroi Pay attention to ~ts

Pilot bearing Gear 011

Baulk ring Gear uu

Man drive gear ball bearing -,

Snap rc )

Mainshaft

I

2nd main gear- @A?

Mainshaft ball bearing r

Speedometer drive geai

Snap ring

1st 8 2nd synchronizer hub

Counterrhaft lock nut *

110 0 - 13.0,12.94)

Reverse ~ounter gear

Countershaft rear end

Reverse main gear Overdrive counter gear

gear spacer

Reverse idler gear

Reverse idler thrust

lnsen retainer

Reverse idler gear bearing

0 D (5th) synchronaer hub *

Rwerre idler thrust washer

Reverse idler shaft * Always replace

* Select with proper thickness. SMT980 N m (kg-m, ft-lb) * pay anemon to Itsdlrectlon.

counter front bearing

MT- 5

Page 6 of 34

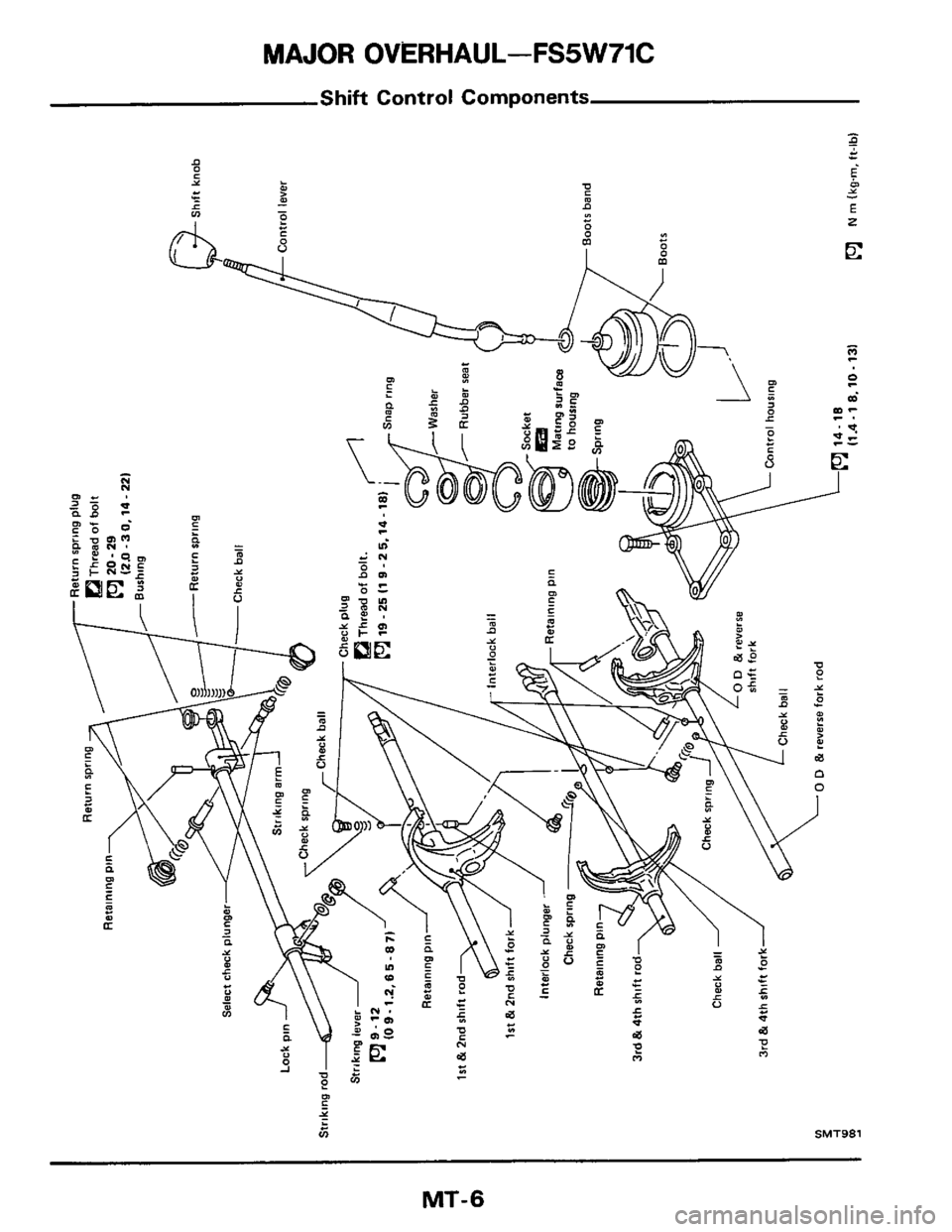

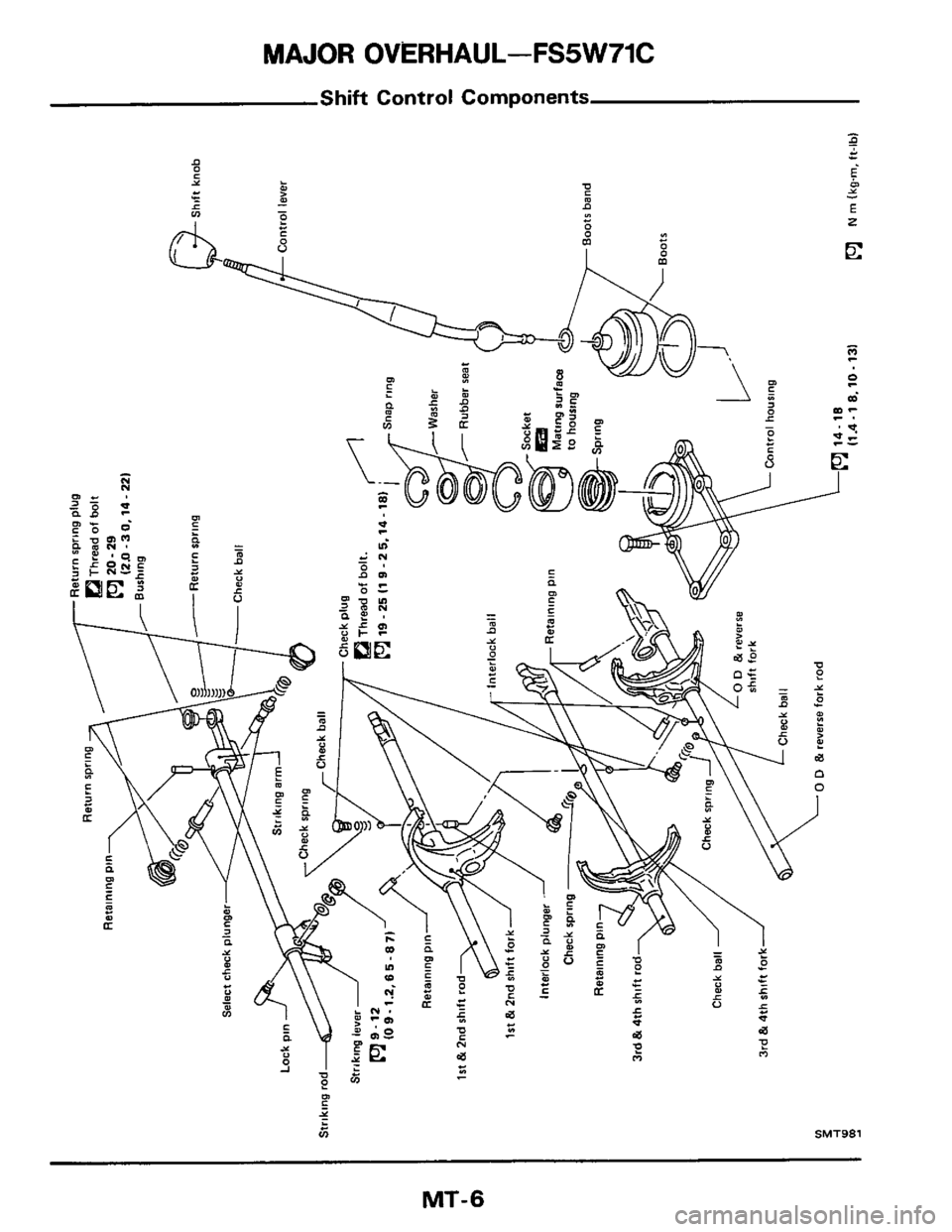

MAJOR OVERHAUL-FS5W71C

Shift Control Components

Page 7 of 34

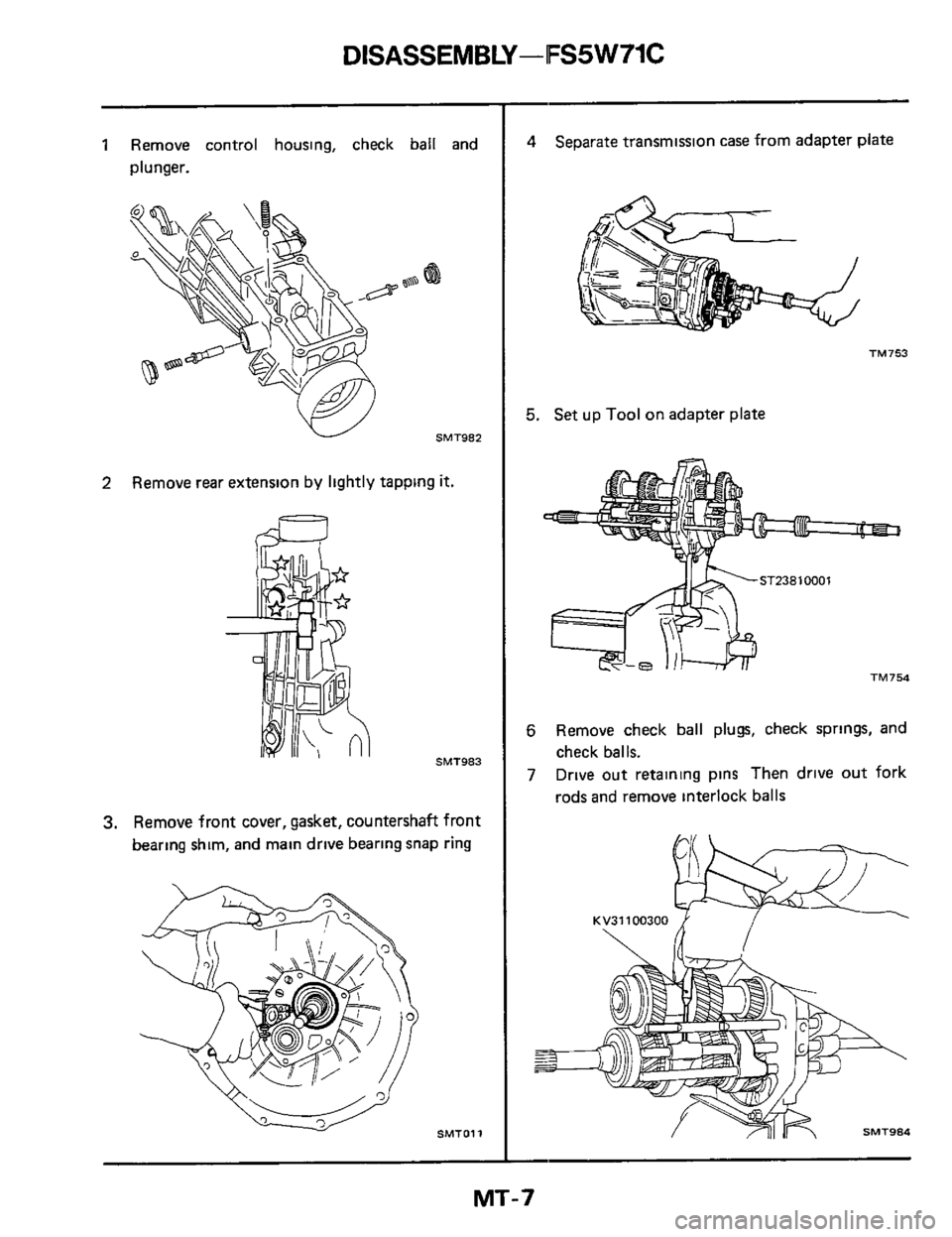

DlSASSEMBLY-IFS5W71C

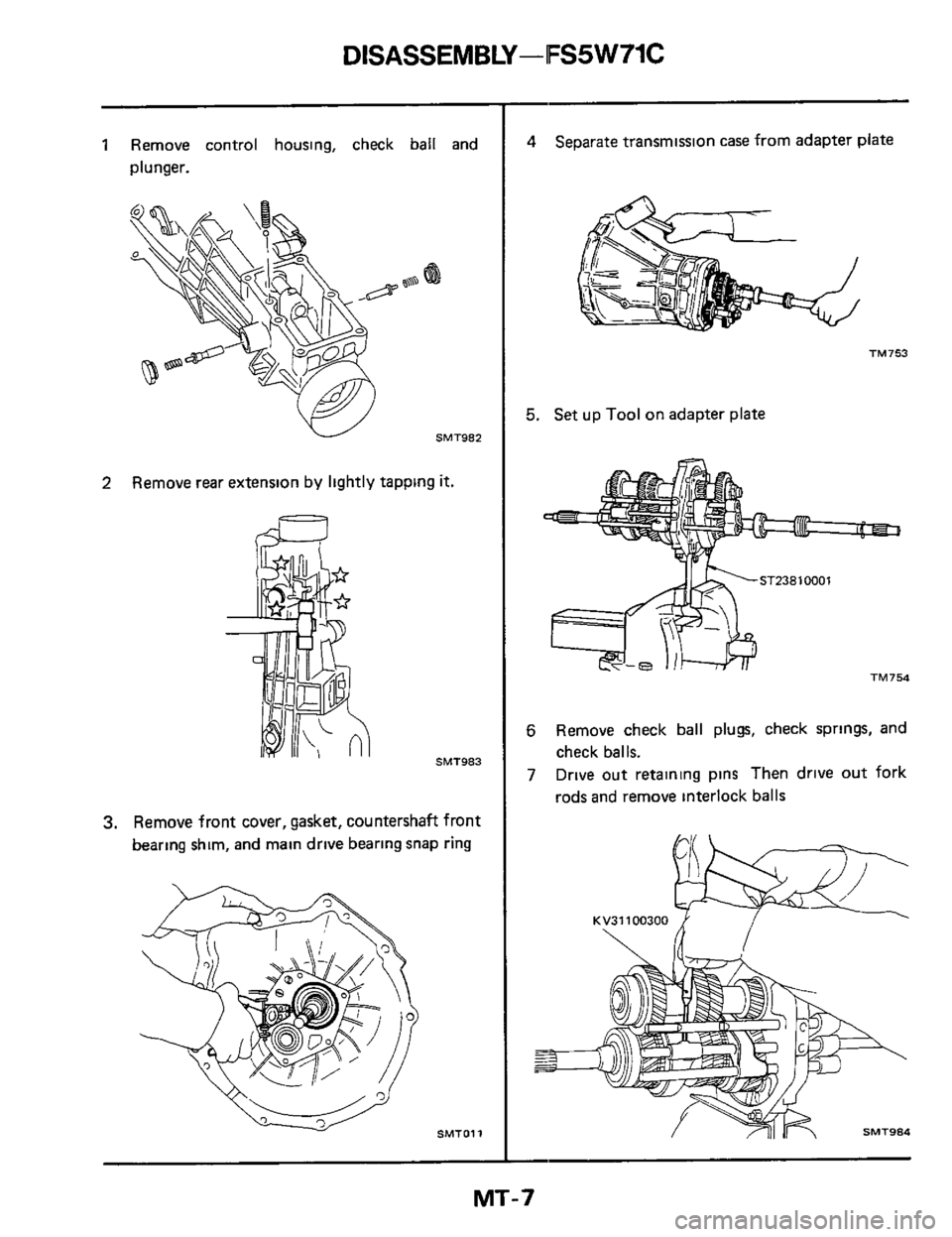

1 Remove control housing, check ball and

plunger.

W SMT982

2 Remove rear extension by lightly tapping it.

60

SMT983

3. Remove front cover, gasket, countershaft front

bearing shim, and main drive bearing snap ring

SMTOll

4 Separate transmission case from adapter plate

TM753

5. Set up Tool on adapter plate

TM754

6 Remove check ball plugs, check springs, and

7 Drive out retaining pins Then drive out fork

check balls.

rods and remove interlock balls

MT-7

Page 8 of 34

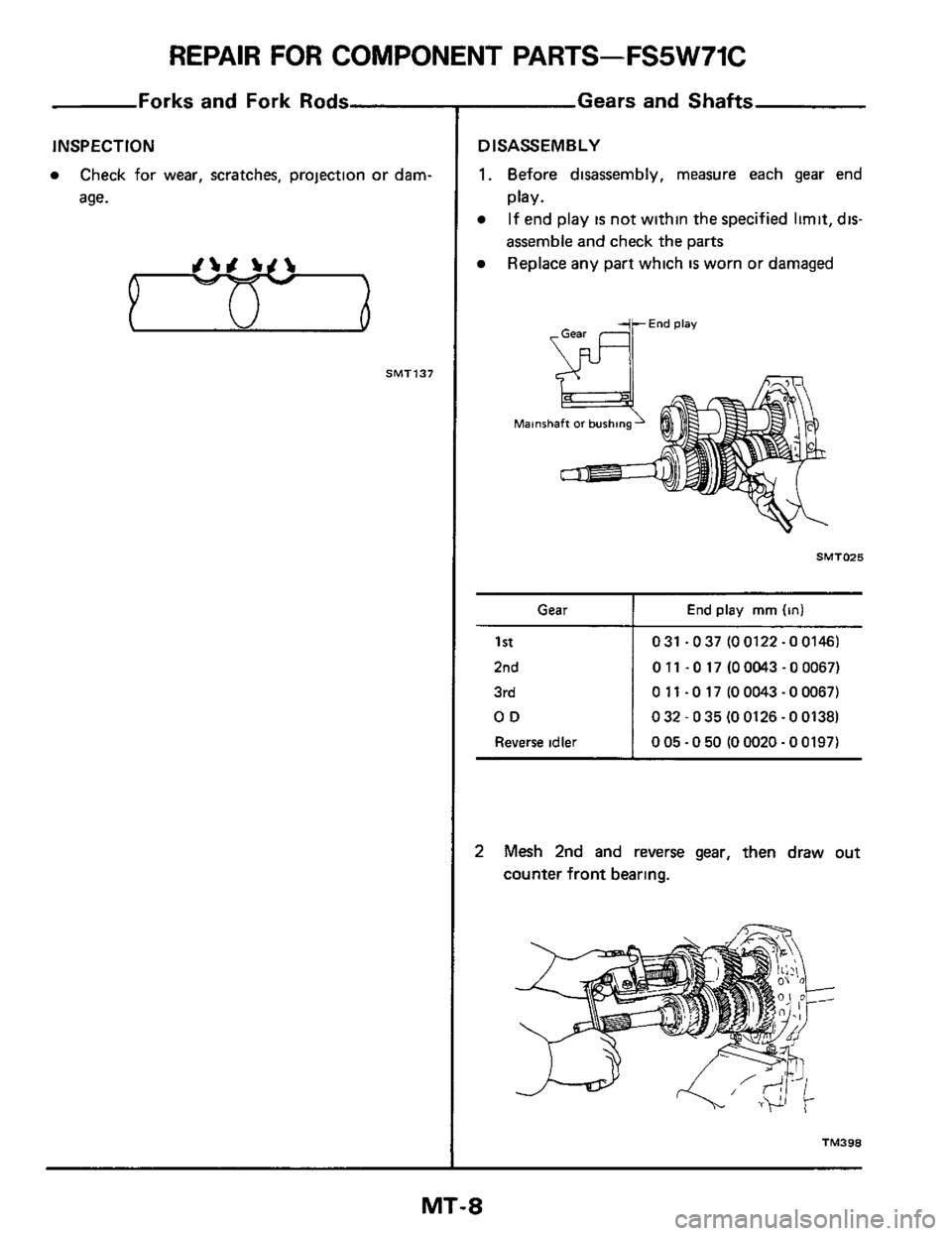

REPAIR FOR COMPONENT PARTS-FS5W71C

1 st

2nd

3rd

OD

Reverse idler

Forks and Fork Rods

031 .037 (00122 -0 01461

0 11 -0 17 (00043 -0 00671

0 11 - 0 17 (0 0043 - 0 00671

032-035(00126-00138~

0 05 - 0 50 (0 0020 - 0 01971

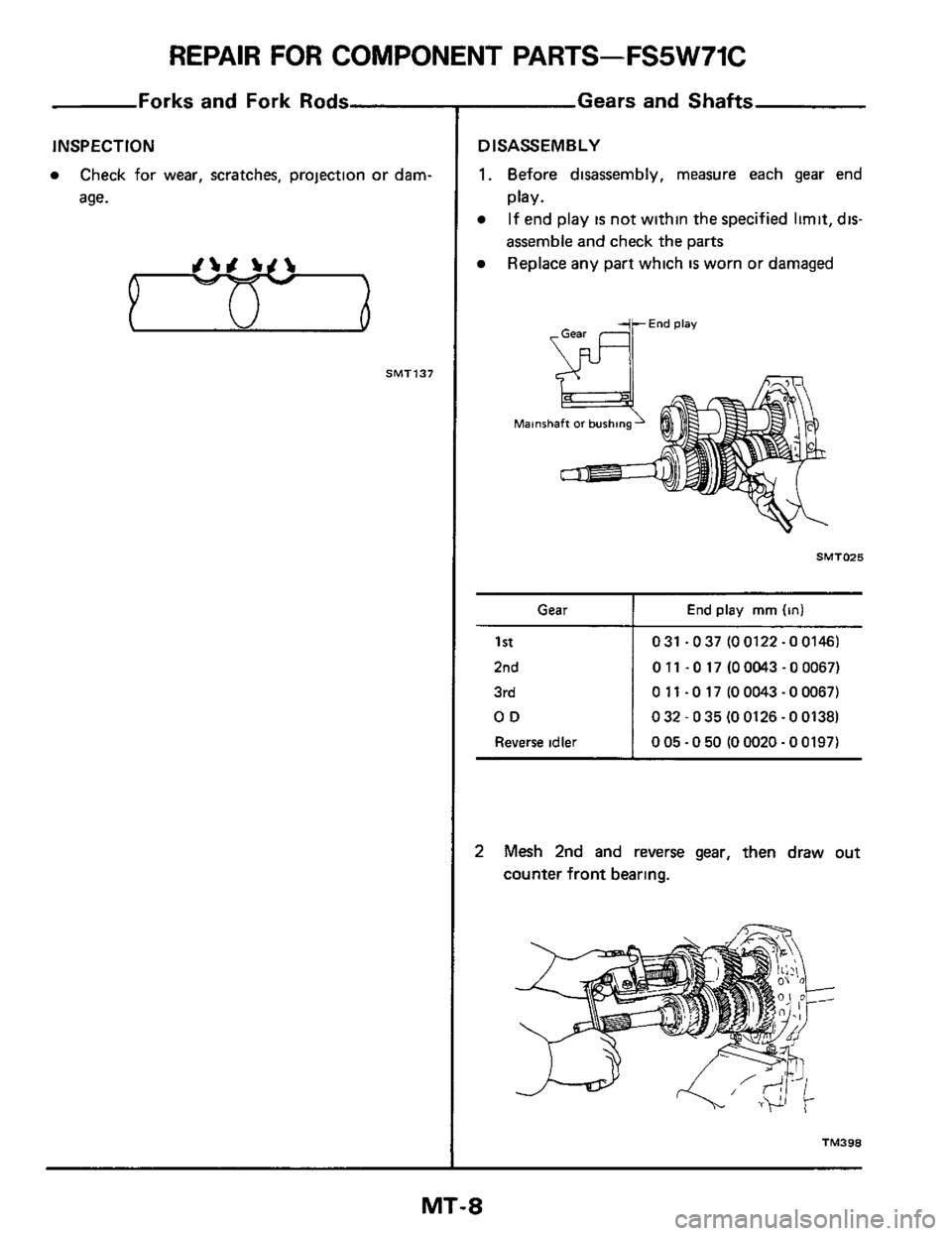

INSPECTION

Check for wear, scratches, projection or dam-

age.

SMT137

Gears and Shafts

D ISASSEMB LY

1.

0

Before disassembly, measure each gear end

If end play IS not within the specified limit, dis-

assemble and check the parts

Replace any part which

IS worn or damaged

play.

Mainshaft or bushing

WL

SMT025

Gear I End play mrn (in1

2 Mesh 2nd and reverse gear, then draw out

counter front bearing.

TM398

MT-8

Page 9 of 34

REPAIR FOR COMPONENT PARTS-FS5W71C

Gears and S

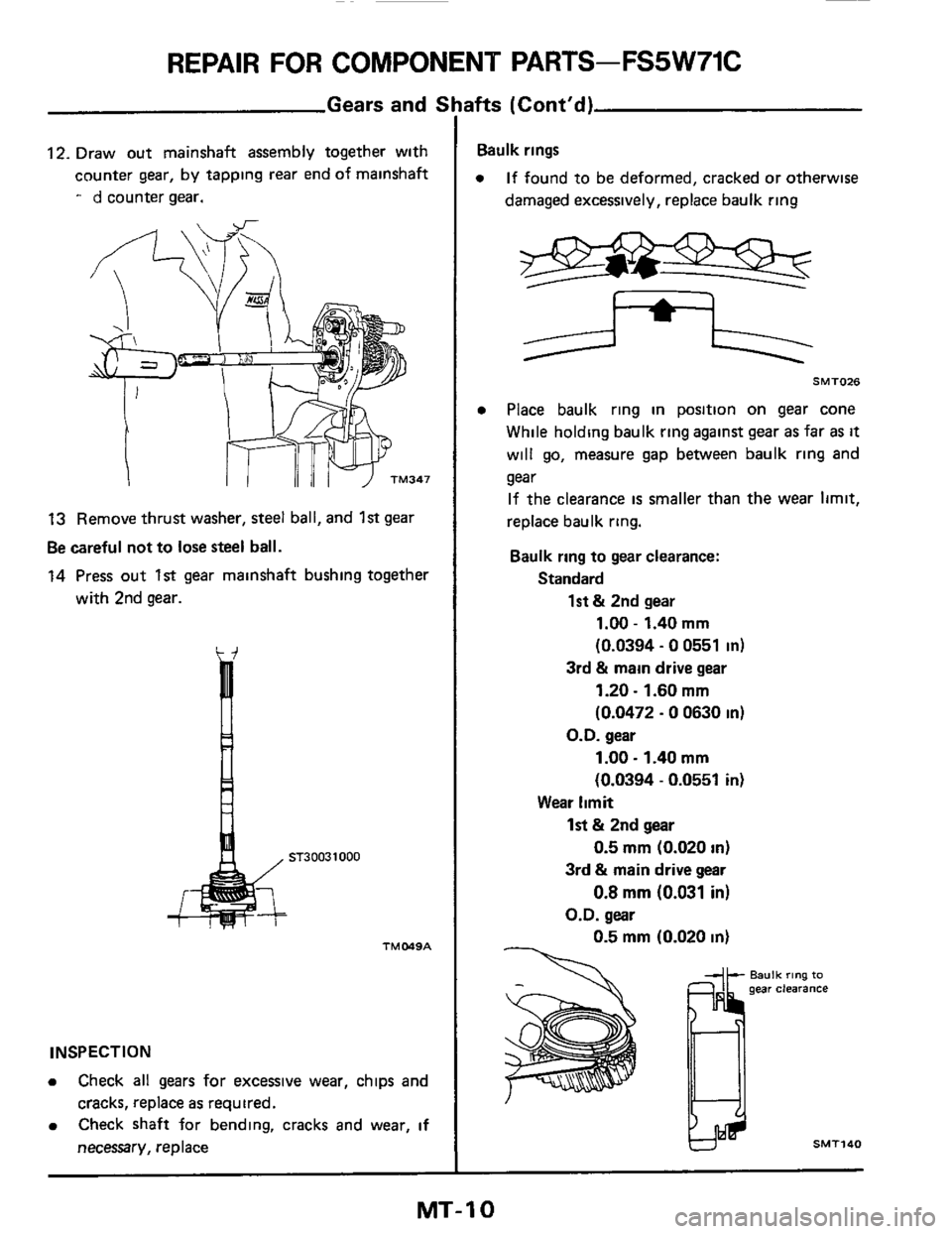

3 Remove snap ring and draw out counter drive

gear with main drive gear

SMT023

4 Remove snap ring and draw out 3rd & 4th

synchronizer and 3rd

gear

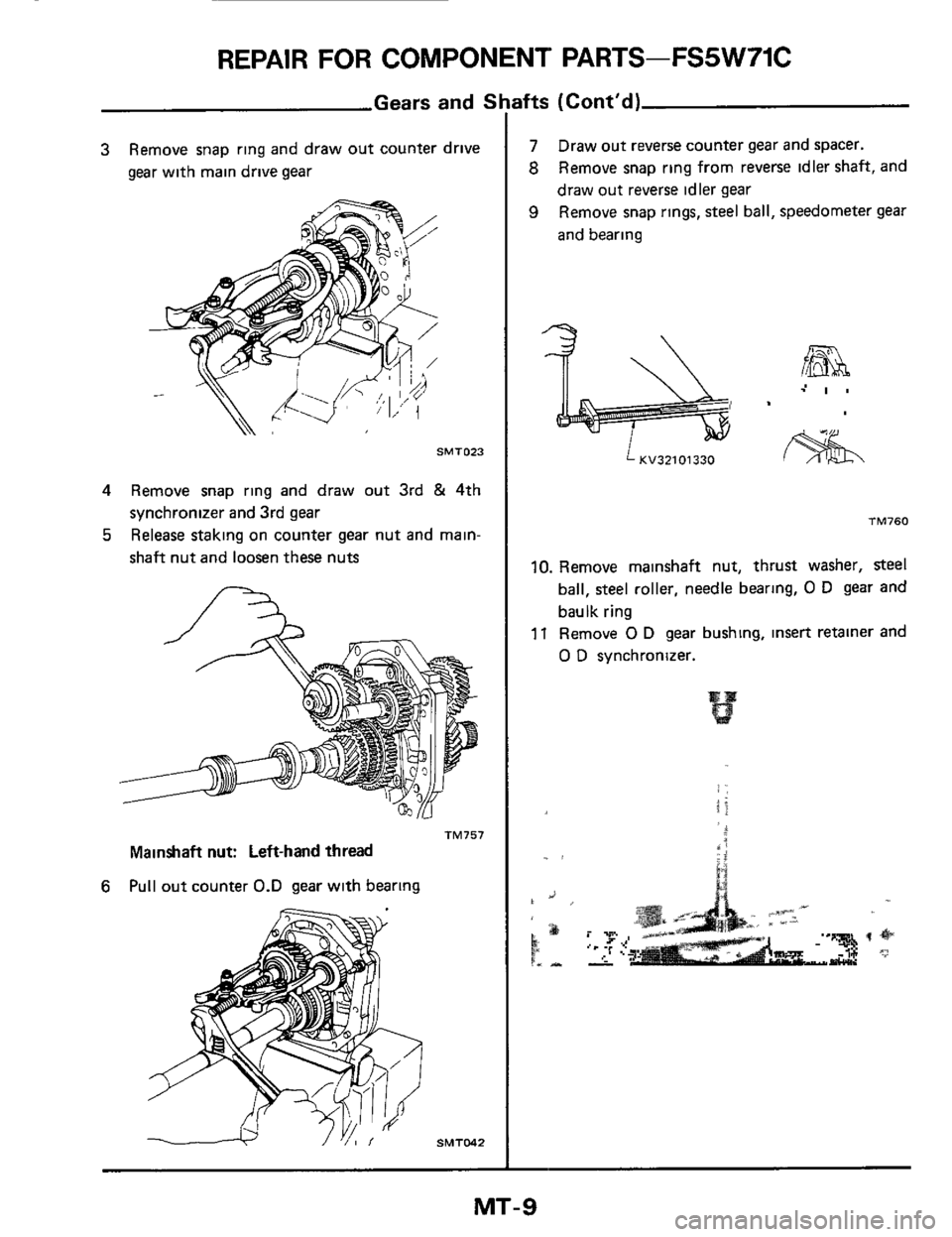

5 Release staking on counter gear nut and main-

shaft nut and loosen these nuts

TM757

Mainshaft nut: Left-hand thread

Pull out counter 0.D gear with bearing 6

ifts (Cont'd)

7

8

9

Draw out reverse counter gear and spacer.

Remove snap ring from reverse idler shaft, and

draw out reverse idler gear

Remove snap rings,

steel ball, speedometer gear

and bearing

-37 \ II \ .' I . .-

KV32101330

TM760

10. Remove mainshaft nut, thrust washer, steel

ball, steel roller, needle bearing, 0 D gear and

baulk ring

11 Remove 0 D gear bushing, insert retainer and

0 D synchronizer.

MT-9

Page 10 of 34

REPAIR FOR COMPONENT PARTS-FS5W71C

Gears and S

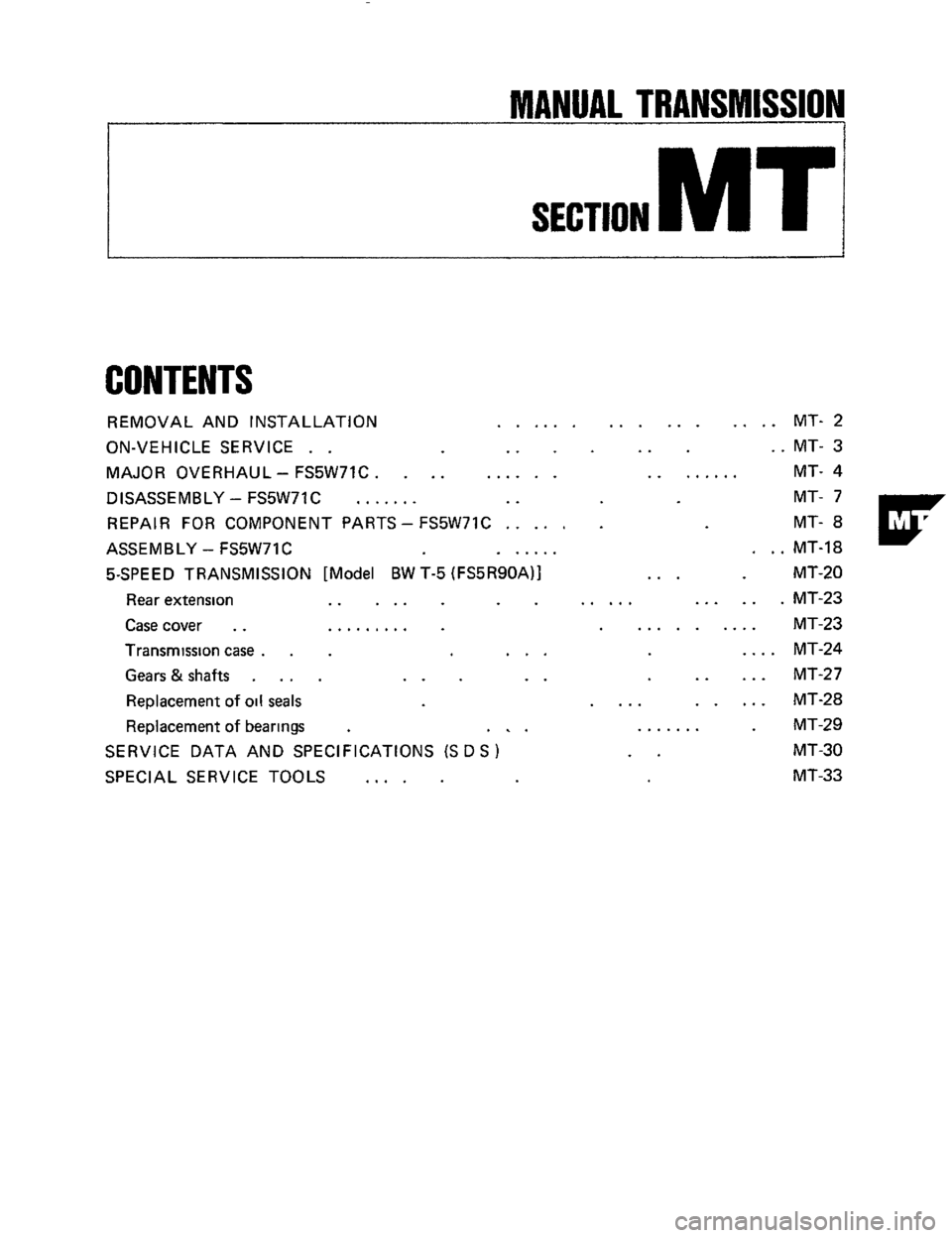

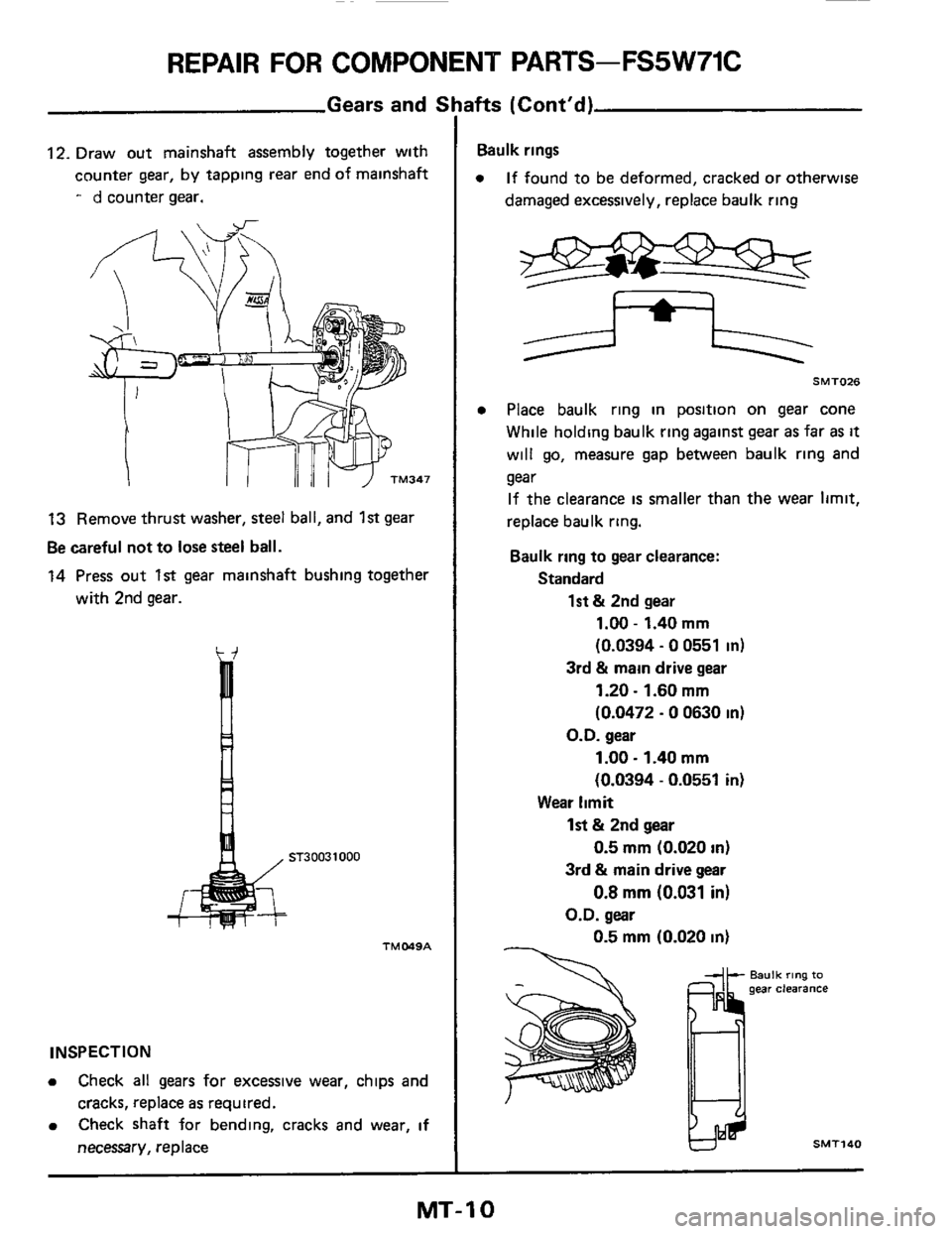

12. Draw out mainshaft assembly together with

counter gear, by tapping rear end of mainshaft

- d counter gear.

13 Remove thrust washer, steel ball, and 1st gear

Be careful not to lose steel ball.

14 Press out 1st gear mainshaft bushing together

with 2nd gear.

d H

TMMSA

INSPECTION

0 Check all gears for excessive wear, chips and

cracks, replace

as required.

Check shaft for bending, cracks and wear, if

necessary, replace

0

ifts (Cont'd)

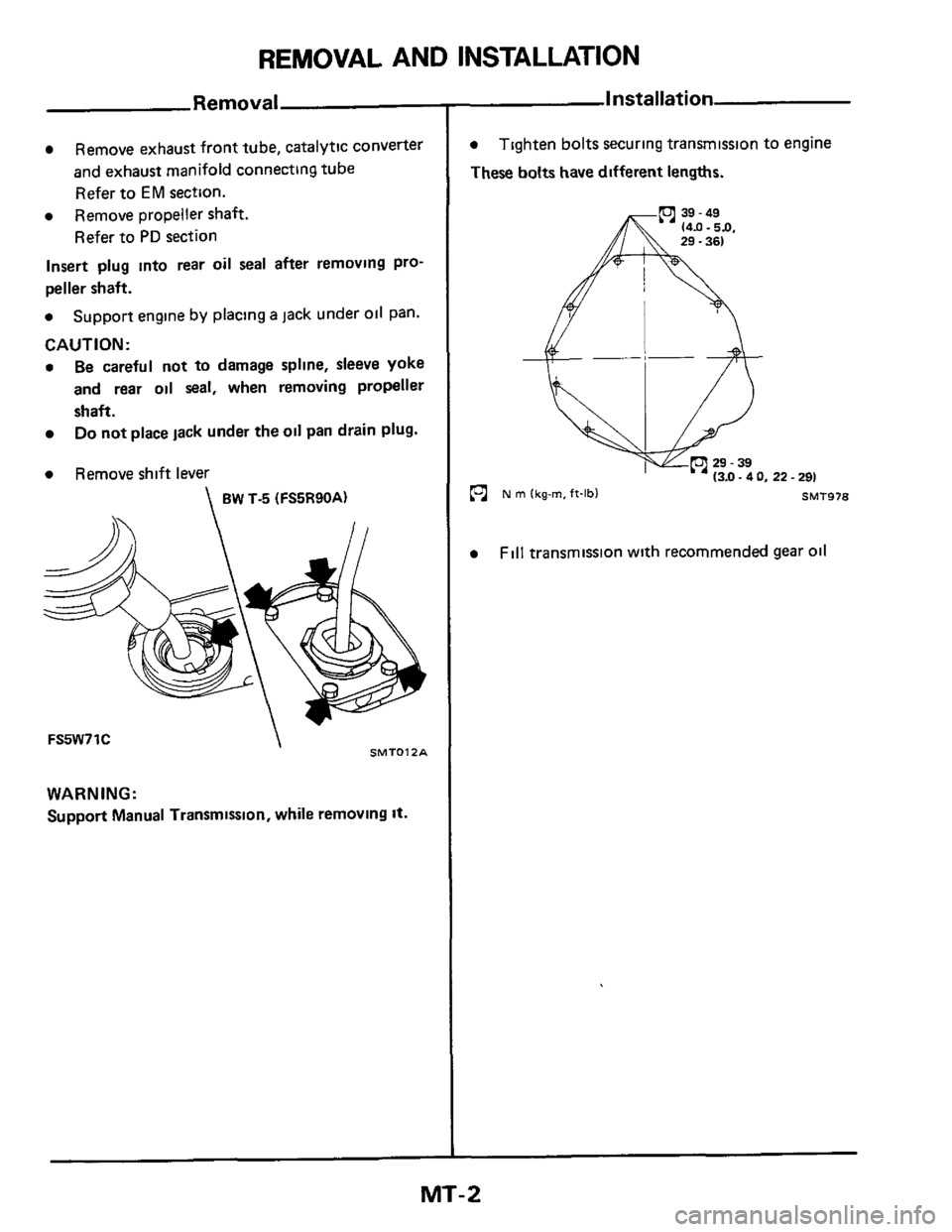

bulk rings

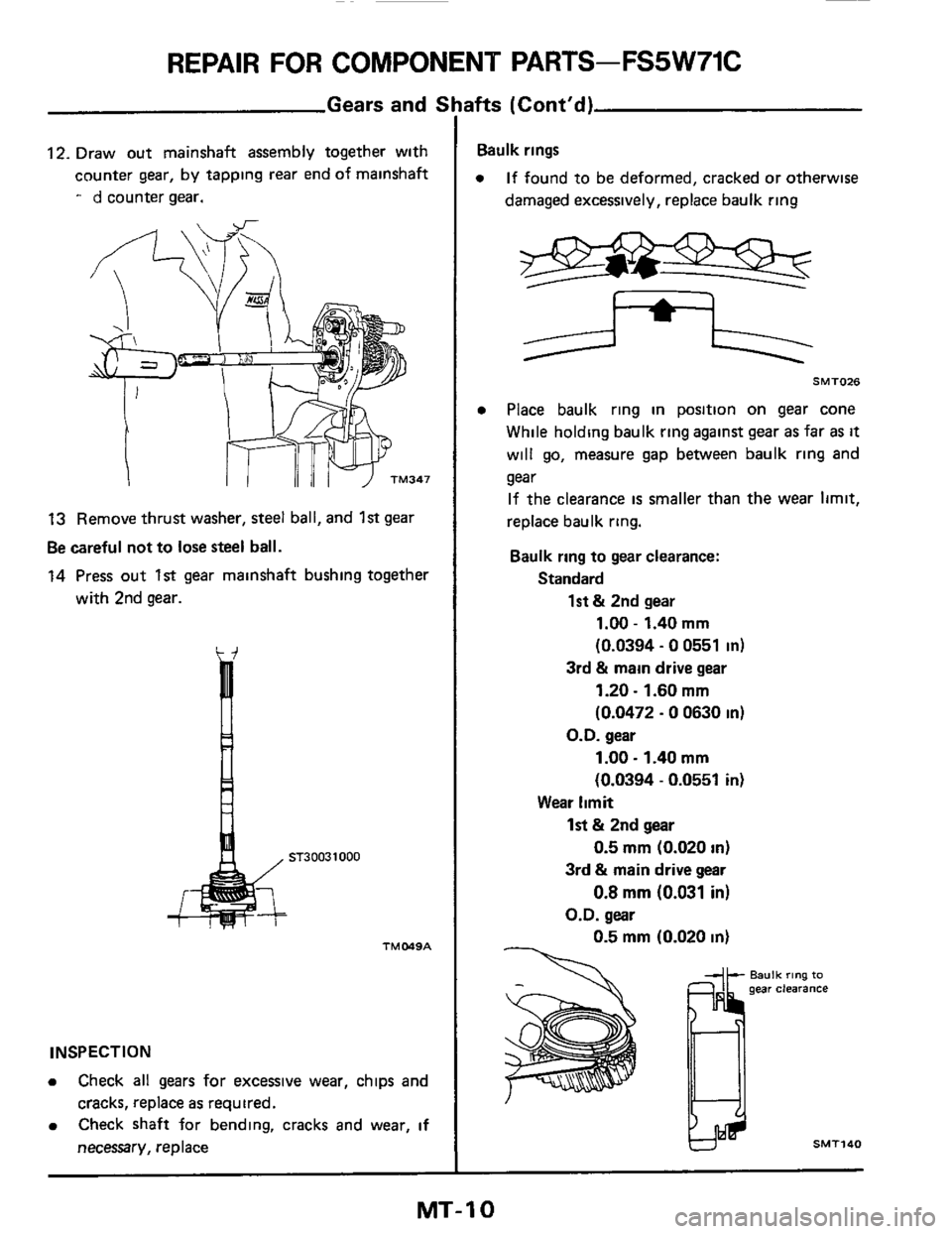

0 If found to be deformed, cracked or otherwise

damaged excessively, replace baulk ring

SMT026

0 Place baulk ring in position on gear cone

While holding baulk ring against gear

as far as it

will go, measure gap between baulk ring and

gear If the clearance

is smaller than the wear limit,

replace baulk ring.

Baulk ring to gear clearance:

Standard

1st & 2nd gear

1.00 - 1.40 mm

(0.0394 - 0 0551 in)

3rd & main drive gear

1.20 - 1.60 mm

(0.0472 - 0 0630 in)

1 .OO - 1.40 mm

(0.0394 - 0.0551 in)

O.D. gear

Wear limit

1st & 2nd gear

0.5 mm (0.020 in)

3rd

& main drive gear

0.8 mm (0.031 in)

O.D. gear

0.5

mm (0.020 in)

hulk ring to gear clearance

w SMT140

MT-10

Trending: ECU, lock, light, drain bolt, clutch, tow, Gear shifter