NISSAN 300ZX 1984 Z31 Engine Fuel And Emission Control System Owner's Manual

Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 79, PDF Size: 2.15 MB

Page 21 of 79

E. C. C. S. DESCRIPTION

Deceleration from @

Deceleration from @

Deceleration from 0 or @

Fuel Injection

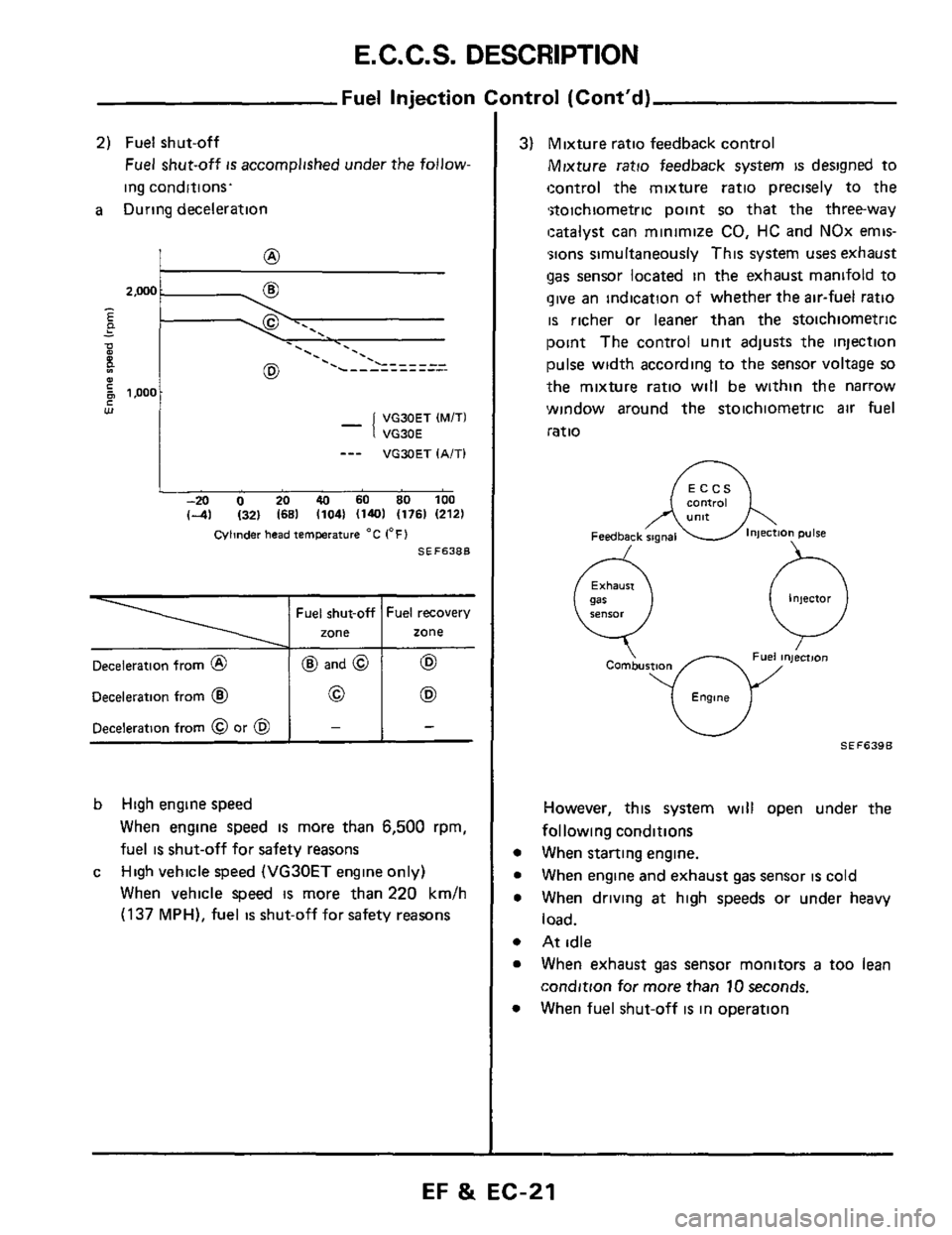

2) Fuel shut-off

Fuel shut-off is accomplished under the follow-

ing conditions.

a During deceleration

@ and @ 62

0 (E9

- -

- -.. . . . ._ '. .

VG30ET (MITI

VG30E

_-- VGXIET IA/Tl

-20 0 20 40 60 SO 100

(-41 1321 (681 11041 (1401 (1761 12121

Cvlinder head IemPerature "C 1°F)

SEF638B

b High engine speed

When engine speed is more than 6,500 rpm,

fuel

is shut-off for safety reasons

High vehicle speed

(VG30ET engine only)

When vehicle speed

is more than 220 km/h

(137 MPH), fuel is shut-off for safety reasons

c

mtrol (Cont'd)

3) Mixture ratio feedback control

Mixture ratio feedback system is designed to

control the mixture ratio precisely to the

*stoichiometric point

so that the three-way

!catalyst can minimize

CO, HC and NOx emis-

';ions simultaneously This system

uses exhaust

gas senwr located in the exhaust manifold to

give an indication of whether the air-fuel ratio

is richer or leaner than the stoichiometric

point The control unit adjusts the injection

pulse width according to the sensor voltage so

the mixture ratio will be within the narrow

window around the stoichiometric

air fuel

ratio

eontroi

Injector

0

Combustm

Engme

However, this system will open under the

following conditions

When starting engine.

When engine and exhaust

gas sensor is cold

When driving

at high speeds or under heavy

load.

At idle

When exhaust

gas sensor monitors a too lean

condition for more than

10 seconds.

When fuel shut-off

is in omration

EF & EC-21

Page 22 of 79

E.C.C.S. DESCRIPTION

-Fuel injection Control (Cont'd)-

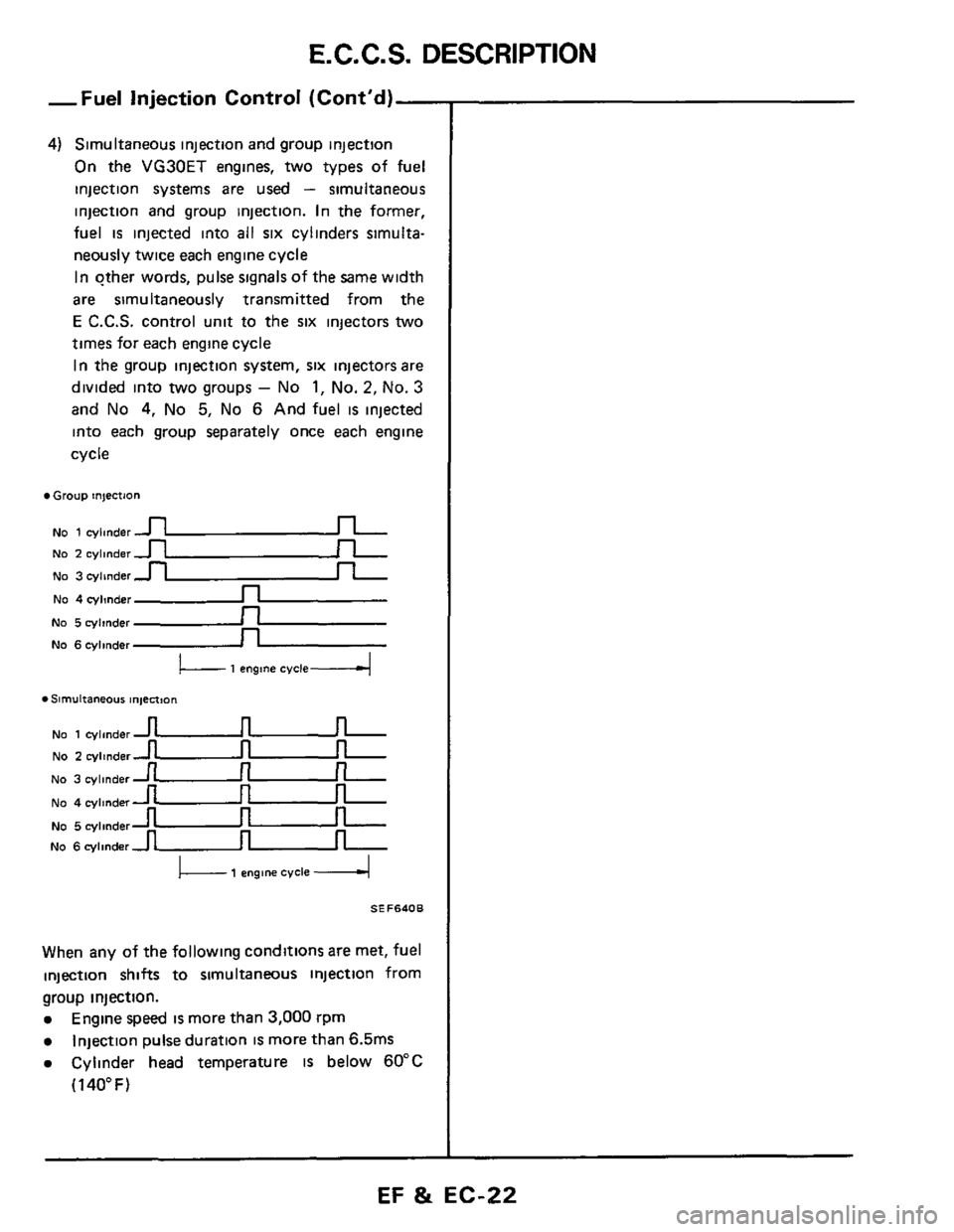

4) Simultaneous injection and group injection

On the VG30ET engines, two types of fuel

injection systems

are used - simultaneous

injection and group injection. In the former,

fuel is injected into all six cylinders simulta-

neously twice each engine cycle

In other words, pulse signals

of the same width

are simultaneously transmitted from the

E C.C.S. control unit to the six injectors two

times for each engine cycle

In the group injection system, six injectors are

divided into

two groups - No 1, No. 2, No. 3

and No 4, No 5, No 6 And fuel is injected

into each group separately once each engine

cycle

Group injection

NO 1 cylmder u

No 5 cylinder n

No 6cylinder _n

No 1 cylinder u

NO 2 cylinder -

u

u

u

u

NO 2 cylinder-

No 3 cylinder -

No 4 cylmdern

L- 1 engine cvcle4

. Slrnultaneous ln,ect,On

No 3 cylinder

No 4 cylinder

No 5 cylinder

No 6 cylinder

I 1 engm cycle I

SEF640B

When any of the following conditions are met, fuel

injection shifts to simultaneous injection from

group injection.

Engine speed is more than 3,000 rpm

Injection pulse duration is more than 6.5ms

Cylinder head temperature IS below 60°C

(1 40" F)

EF & EC-22

Page 23 of 79

E. C. C. S. DESCRIPTION

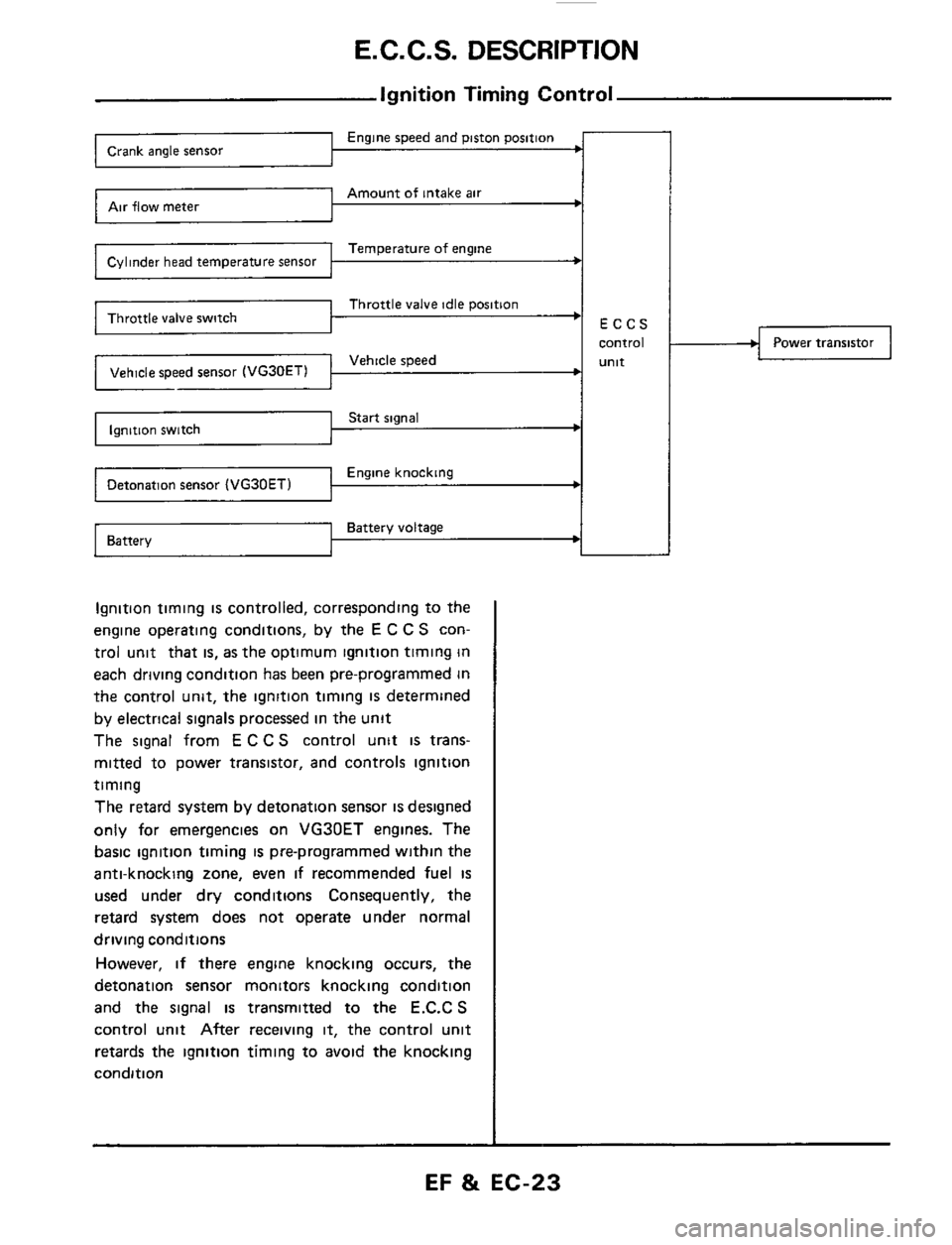

Ignition Timing Control

Engine speed and piston position Crank angle sensor

Amount of intake air Air flow meter

Temperature of engine Cylinder head temperature sensor

Throttle valve idle position

Vehicle speed Vehicle speed sensor (VG30ETl 1 I I

Start signal Ignition switch

Engine knocking Detonation sensor

Battery voltage Battery ~

Ignition

timing is controlled, corresponding to the

engine operating conditions, by the

E C C S con-

trol unit that

is, as the optimum ignition timing in

each driving condition has been pre-programmed in

the control unit, the ignition timing

IS determined

by electrical signals processed in the unit

The signal from

E C C S control unit is trans-

mitted to power transistor, and controls ignition

timing

The retard system by detonation sensor

is designed

only for emergencies on VG30ET engines. The

basic ignition timing

is pre-programmed within the

anti-knocking zone, even

if recommended fuel is

used under dry conditions Consequently, the

retard system does not operate under normal

driving conditions

However,

if there engine knocking occurs, the

detonation sensor monitors knocking condition

and the signal is transmitted to the E.C.C S

control unit After receiving it, the control unit

retards the ignition timing to avoid the knocking

condition

Power transistor

EF & EC-23

Page 24 of 79

E.C.C.S. DESCRIPTION

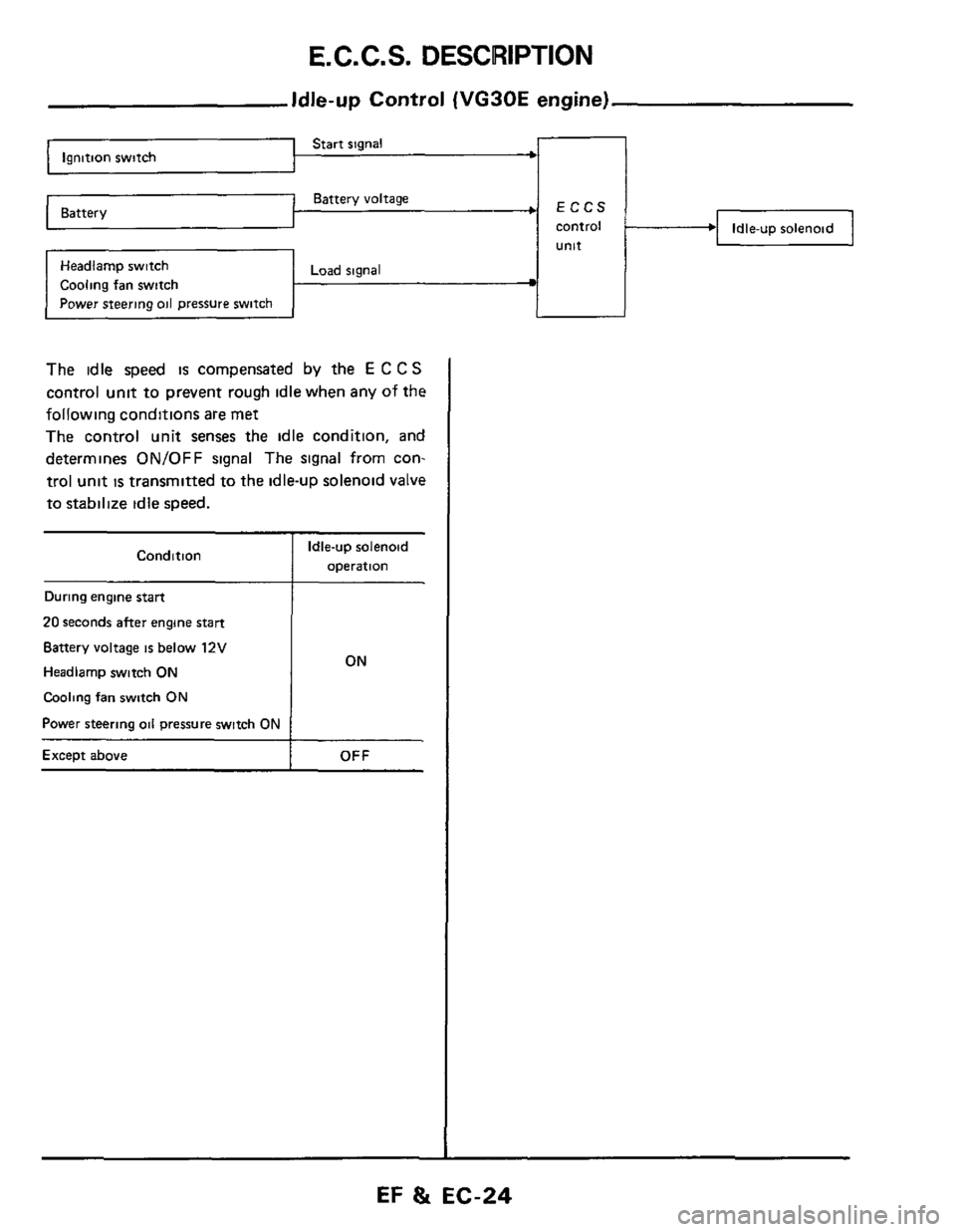

Battery voltage Battery

~-

Headlarnp switch Load signal

Cooling fan switch

Power steering oil pressure switch

Idle-up Control (VG30E engine)

Start signal Ignition switch

ECCS

control

unit

The idle speed is compensated by the E C C S

control unit to prevent rough idle when any of the

following conditions

are met

The control unit senses the idle condition, and

determines

ON/OFF signal The signal from con-

trol unit

is transmitted to the idle-uD solenoid valve

to stabilize idle speed.

Condition

During engine start

20 seconds after engine start

Battery voltage is below 12V

Headlarnp switch ON

Cooling fan switch ON

Power steering oil pressure switch ON

Except above

Idle-up solenoid

operation

ON

OFF

EF 8t EC-24

Page 25 of 79

E. C. C. S. DESCRIPTION

Start signal ’ Ignition switch

Throttle valve idle position

Neutral position t

Battery voltage Battery

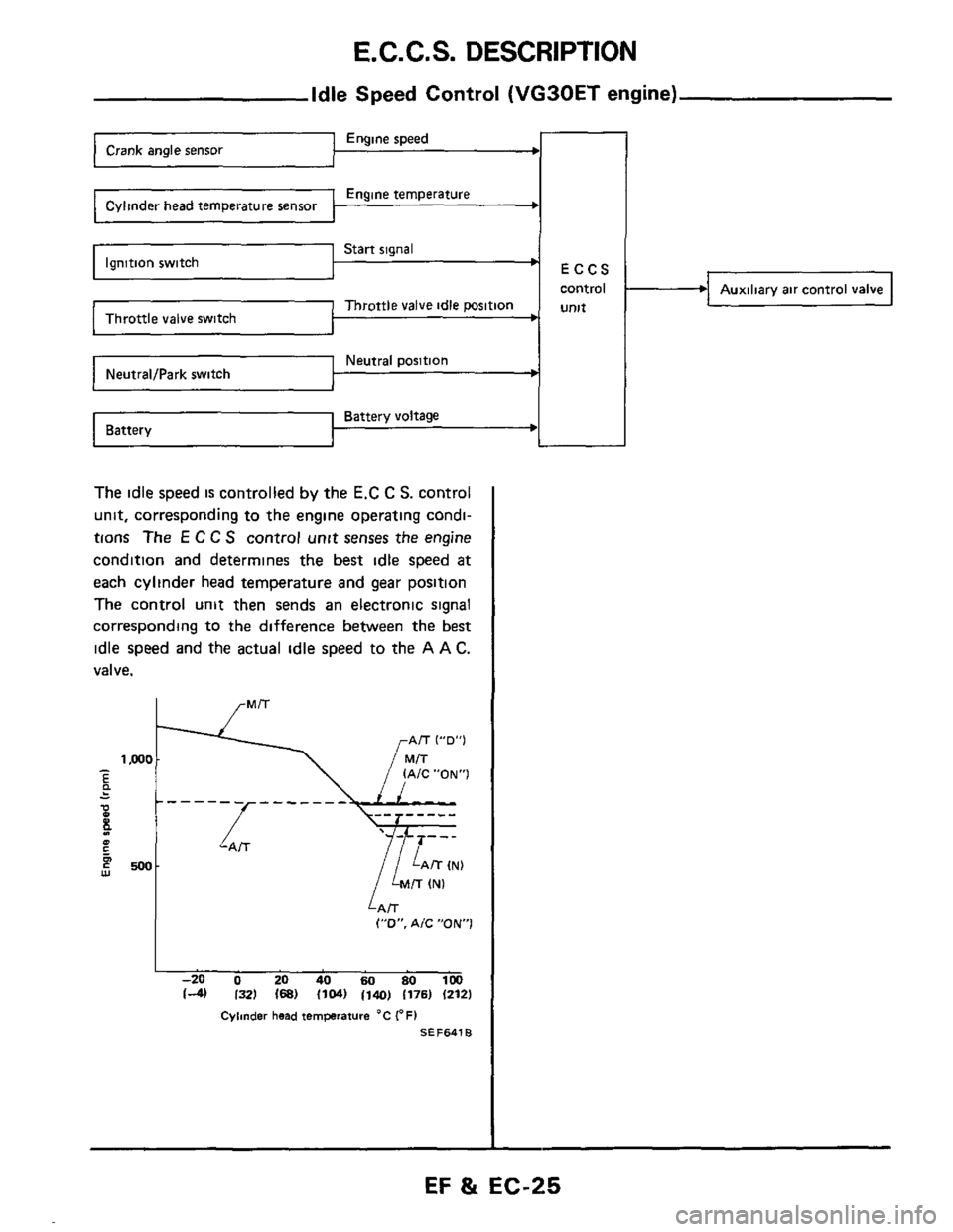

Idle Speed Control (VG30ET engine)

Engine speed

Engine temperature

ECCS

control

Unlt

-

The idle speed is controlled by the E.C C S. control

unit, corresponding to the engine operating condi-

tions

The E C C S control unit senses the engine

condition and determines the best idle speed

at

each cylinder head temperature and gear position

The control unit then sends an electronic signal

corresponding

to the difference between the best

idle speed and the actual idle speed to the A A C.

valve.

I

,/ lAiC”ON”1 -‘I E .. -

P - 0 E 4 1 - - - -L- - - - - - lZN)

500 w

LAiT (”0”. A/C ”ON1

I -20 0 20 40 60 80 1M) 14) I321 168) 11041 1140) 1176) (212)

Cylinder head ternprature “C (OF1

SEF641B

Auxiliary air control valve

EF & EC-25

Page 26 of 79

E.C.C.S. DESCRIPTION

Engine speed Crank angle sensor c

Engine temperature ’

Throttle valve idle position Throttle valve switch

Start signal

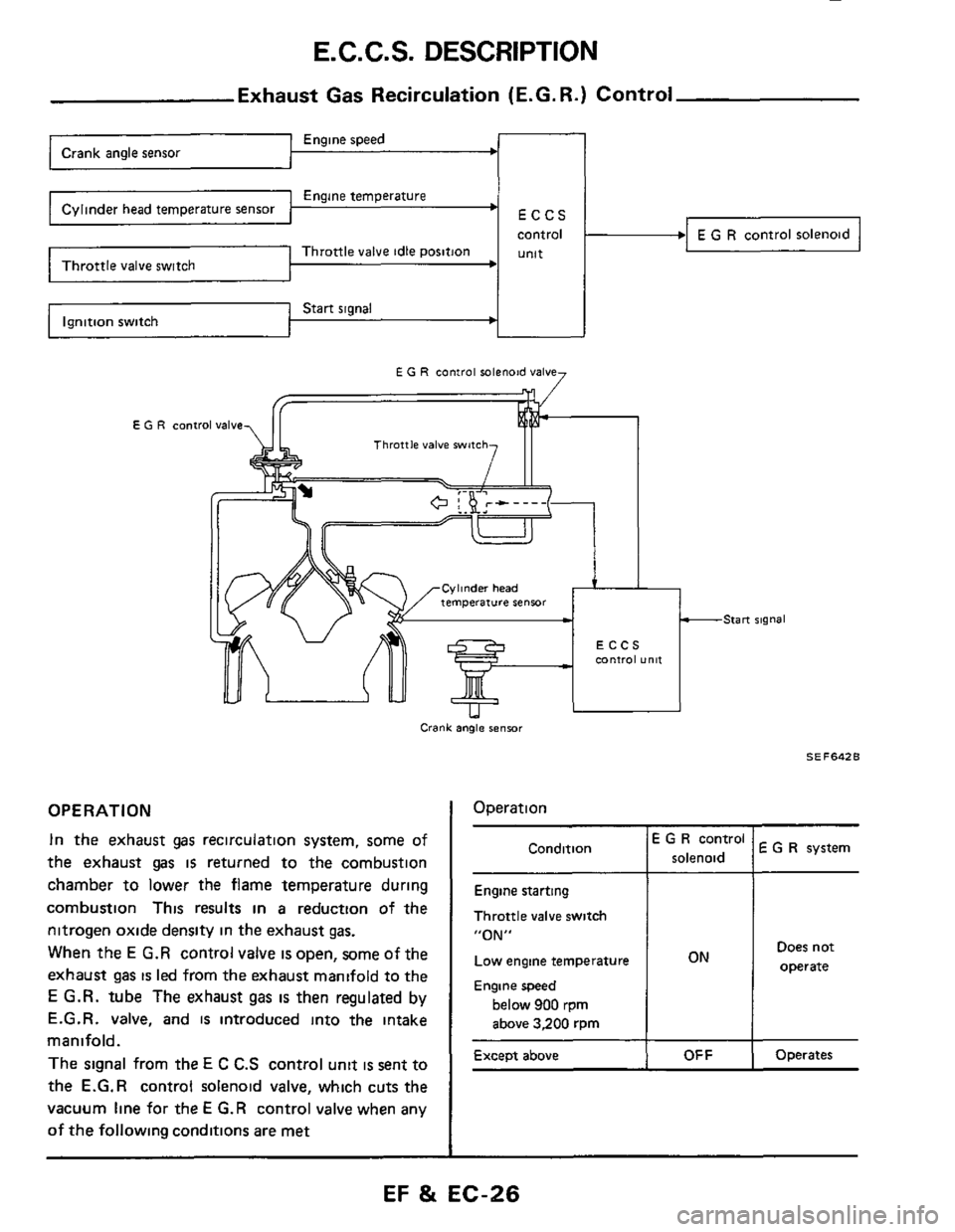

Exhaust Gas Recirculation (E.G. R.) Control

ECCS

control

unit

EGR

E G R control sclenoid valv

Throttle valve witch

C lhnder head era1“re semor

Crank angle sensor

OPERATION

In the exhaust gas recirculation system, some of

the exhaust

gas is returned to the combustion

chamber to lower

the flame temperature during

combustion This results

in a reduction of the

nitrogen oxide density in the exhaust

gas.

When the E G.R control valve is open, some of the

exhaust

gas is led from the exhaust manifold to the

E G.R. tube The exhaust gas is then regulated by

E.G.R. valve, and

is introduced into the intake

manifold.

The signal from the E C C.S control unit is sent to

the

E.G.R control solenoid valve, which cuts the

vacuum line for the E G.R control valve when any

of the following conditions are met

-Start signal

SE F642 B

I Operation

E G R system I

Condition E G R control

solenoid

Engine starting

Throttle valve switch

“ON”

Low engine temperature Does not

Engine speed

below 900 rpm

above 3,200 rpm

Operates Except above

EF & EC-26

Page 27 of 79

E.C.C.S. DESCRIPTION

FUELPUMP ~

FUEL PUMP RELAY

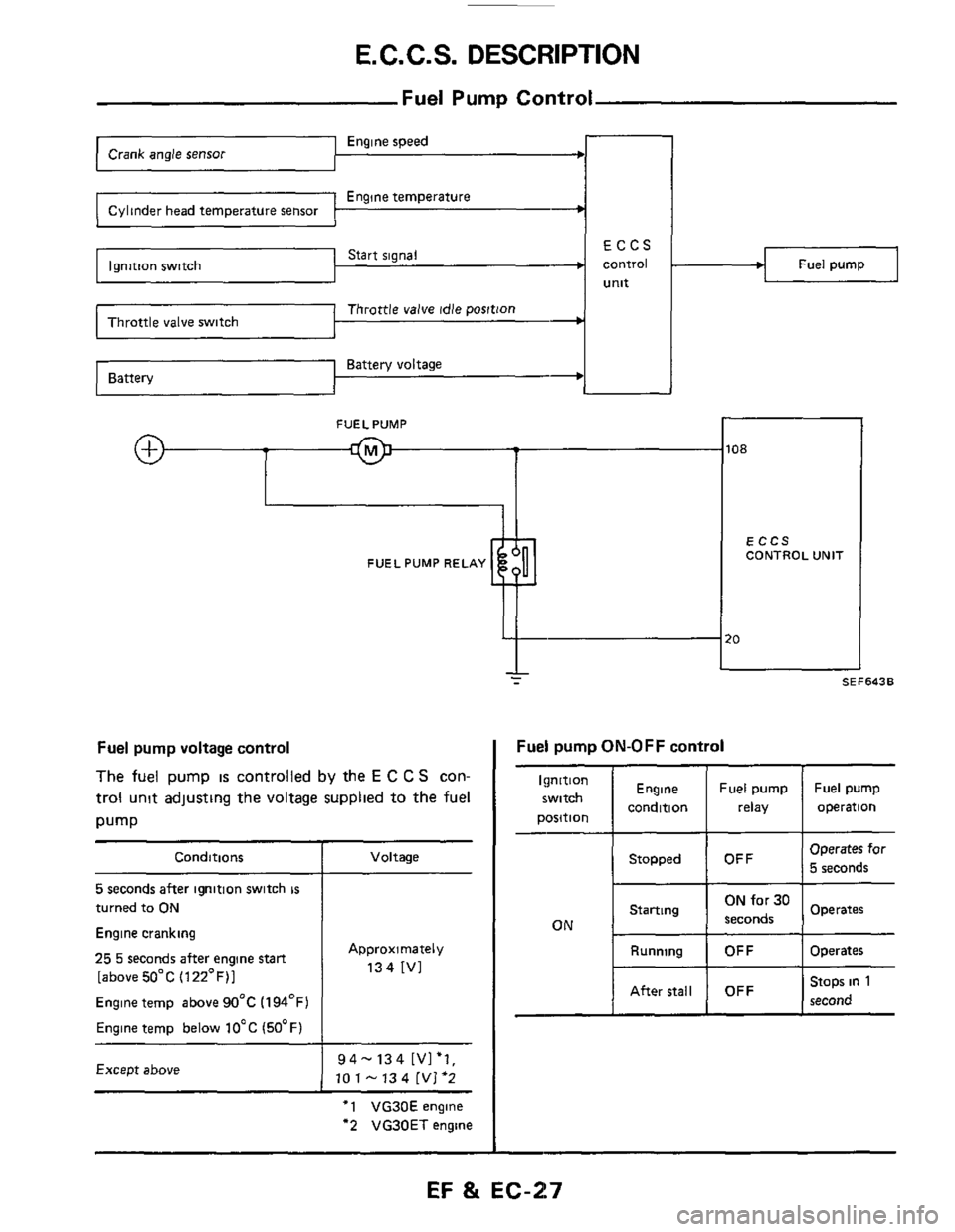

Fuel Pump Control

108

ECCS

CONTROL UNIT

Engine speed --r

Engine temperature

control Fuel pump Start signal

Ignition

switch

position Engine

condition

Throttle valve idle position

Fuel pump Fuel pump

relay operation

Battery voltage Battery

Starting ON

ON for 30 Operates

seconds

Fuel pump voltage control

The fuel pump is controlled by the E C C S con-

trol unit adjusting the voltage supplied to the fuel

pump

Conditions

5 seconds after ignition switch is

turned to ON

Engine cranking

25 5 seconds after engine stan

[above 50°C (122°F)1

Engine temp above 90°C (194OF)

Engine temp below 10°C (50°F)

Except above

Voltage

Approximately

134 [VI

94-134 [Vl'l,

10 1 - 13 4 [VI '2

'1 VG30E engine

"2 VG30ET engine

I SEF643B

Operates for

I OFF I 5 seconds Stopped

I Running I OFF I Operates

Stops in 1

I I I second After stall OFF

EF %t EC-217

Page 28 of 79

DIAGNOSTIC PROCEDURE

Caution

a. Before connecting or disconnecting E C C S

b

C

d

e

harness connector to or from any E C.C S.

unit, be sure to turn the ignition switch to the

"OFF" position and disconnect the negative

battery terminal

Otherwise, there may

be damage to control

unit

Do not attempt to disassemble any E C C S

component parts. To conduct electrical checks

on these component parts, closely follow the

steps outlined under "ELECTRONIC CON-

TROL SYSTEM INSPECTI0N"on pages EF

&

EC-43 through EF & EC-59.

When conducting self-diagnosing, follow the

steps outlined under "SELF-DIAGNOSIS" on

pages EF

& EC-35 through EF & EC-42 in

order to obtain accurate diagnosing results

After selfdiagnosing has been completed, erase

the memory properly

Always turn the diagnosis mode selector care-

fully using

a screwdriver If it is turned forci-

bly,

it may be damaged, resulting in the inabili-

ty to perform the self-diagnosing or to monitor

the mixture ratio

Before troubleshooting, ensure that

all harness

connectors are secure.

EF & EC-28

Page 29 of 79

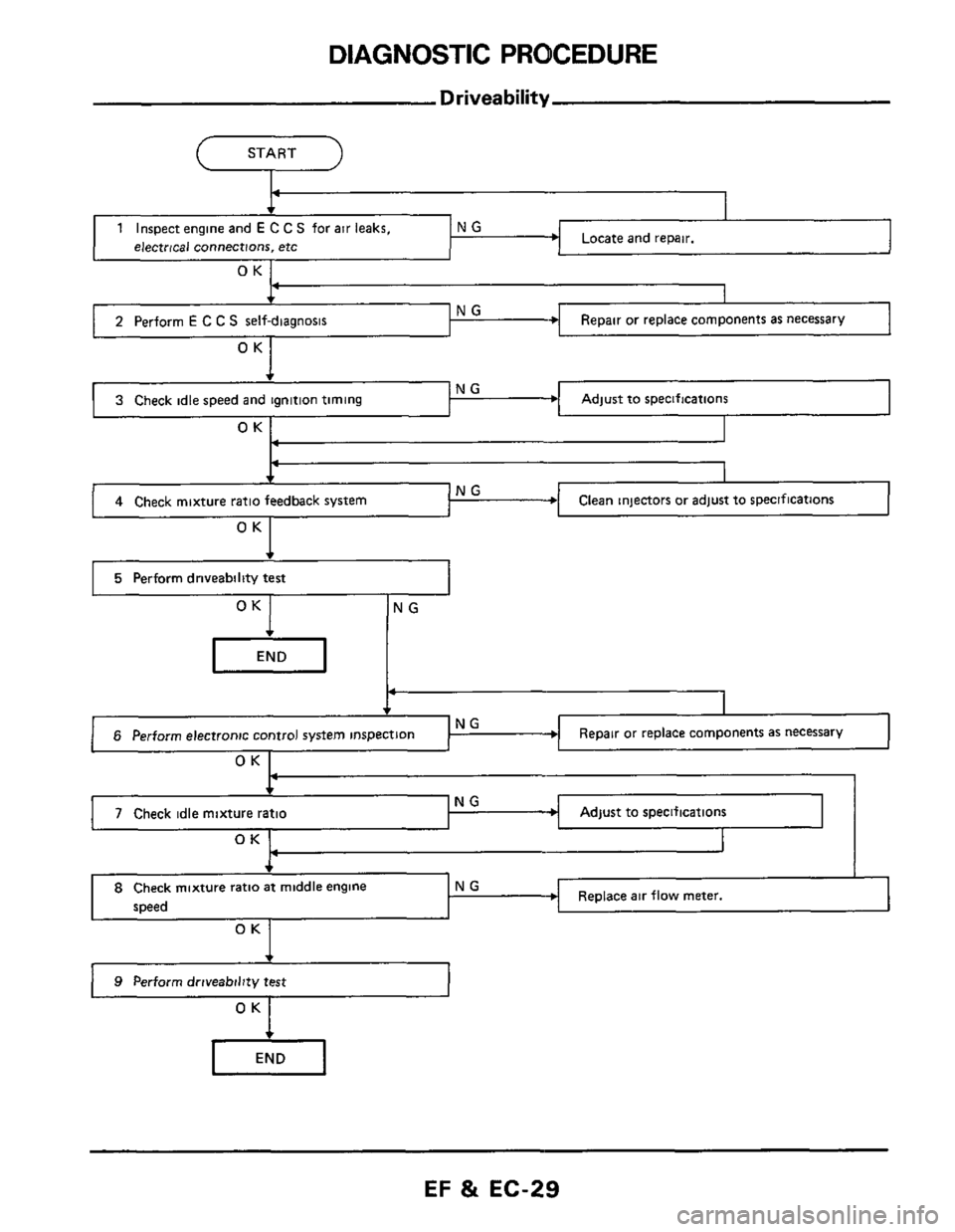

DIAGNOSTIC PROCEDURE

b NG 3 Check idle speed and ignition timing

Driveability

(--- START -l

Adjust to specifications

4 Check mixture ratio feedback system Clean injectors or adjust to specifications

I 5 Perform driveability test I

OK NG

Repair or replace components as necessary

P

6 Perform electronic control system inspection

OK I

Adjust to specifications

OK 1 I

NG 4-

7 Check idle mixture ratio

, I

I

Replace air flow meter. 8 Check mixture ratio at middle engine NG

speed

OK

) 9 Perform driveability test

EF & EC-29

Page 30 of 79

DIAGNOSTIC PROCEDURE

Driveabil

1. Inspect engine and E C C.S. for air leaks,

proper electrical connections, etc

1) Check all hoses and ducts for air leaks

2) Check air cleaner for clogging

3) Check harness connectors for proper connec-

tions

4) Check ignition wiring

5) Check gaskets for leaks at all air intake com-

ponents

6) Check E G.R valve operation

7) Check air regulator operation

2 Perform E C C S self-diagnosis

Follow the procedure in E CCS SELF-

DIAGNOSIS (Page EF & EC-35)

3 Check idle speed and ignition timing

a. Prepare the following conditions:

Headlampswitch' OFF

Heater blower: OFF

Air conditioner switch: OFF

Front wheel (Power steering model):

KEEP STRAIGHT AHEAD

b. Warm engine to operating temperature.

Check

and adjust as follows

[VG30E engine (Without turbocharger)]

1) Stop engine and disconnect idle-up solenoid

valve harness connector

Idle-up solenoid

2) Start engine and race engine two or three times

under no-load, then run engine

at idle speed

(Cont'd)

3) Check idle speed

M/T & A/T (in "D" position)

700250 rpm at sea level

650250 rpm at high altitude condition

If necessary, adjust to the specified

speed by

turning idle speed adjusting screw

I, SEF6456

4) Stop engine and connect idle-up solenoid valve

harness connector

5) Start engine and check ignition timing with

a

timing light

20ai2" B.T.D.C.

If necessary, adjust ignition

timing by turning

distributor

[VG30ET engine (With turbocharger)]

1) Race engine two or three times under no-load,

then run engine at idle speed

2) Check idle speed.

M/T: 70W50rpm

A/T: 650k50 rpm (in "D" position)

EF & EC-30