NISSAN 300ZX 1984 Z31 Engine Fuel And Emission Control System Manual PDF

Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 79, PDF Size: 2.15 MB

Page 71 of 79

INJECTOR COOLING FAN (VG30ET)

lnspectio

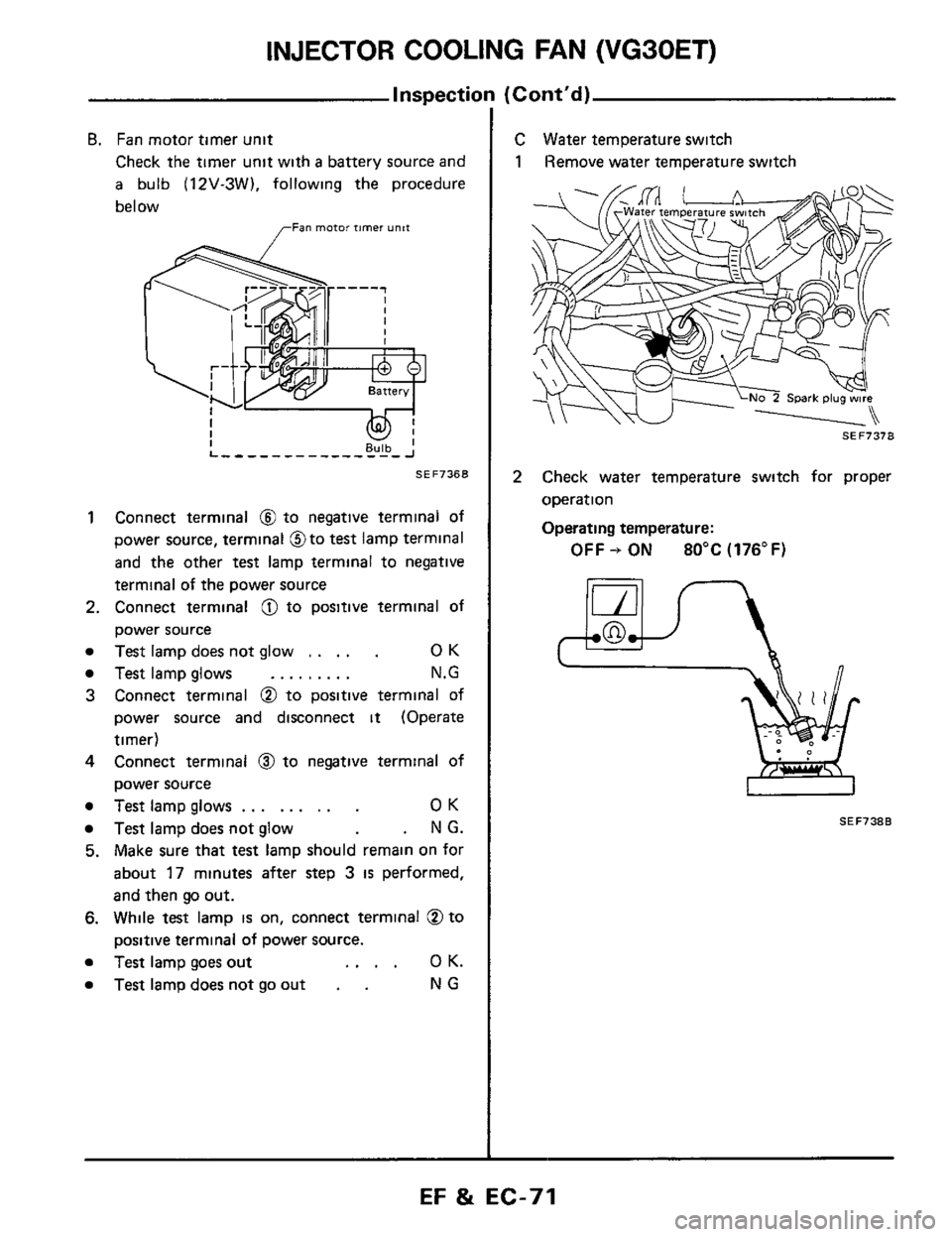

B. Fan motor timer unit

Check the timer unit with a battery source and

a bulb (12V-3W). following the procedure

below

,,-Fan motor timer unit

1 Connect terminal @ to negative terminal of

power source, terminal @to

test lamp terminal

and the other

test lamp terminal to negative

terminal of the power source

2. Connect terminal @ to positive terminal of

power source

Test lamp does not glow ..... OK

Test lamp glows ......... N.G

3 Connect terminal @ to positive terminal of

power source and disconnect it (Operate

timer)

4 Connect terminal @ to negative terminal of

power source

Test lamp glows ......... OK

Test lamp does not glow . N G.

5. Make sure that test lamp should remain on for

about 17 minutes after step 3 is performed,

and then go out.

6. While test lamp is on, connect terminal @to

positive terminal of power source.

Test lamp goes out .... OK.

Test lampdoesnotgoout . . NG

(Corrt'd)

C \Mater temperature switch

1 IRemove water temperature switch

SEF737B

2 Check water temperature switch for proper

operation

Operating temperature:

OFF + ON 80°C (176°F)

SEF738B

EF & EC-71

Page 72 of 79

ZL-33 % A3

NO SI iaieaq iosuas se6 isneqx3

10tl

I

i

3snj

BSELJ3S

Page 73 of 79

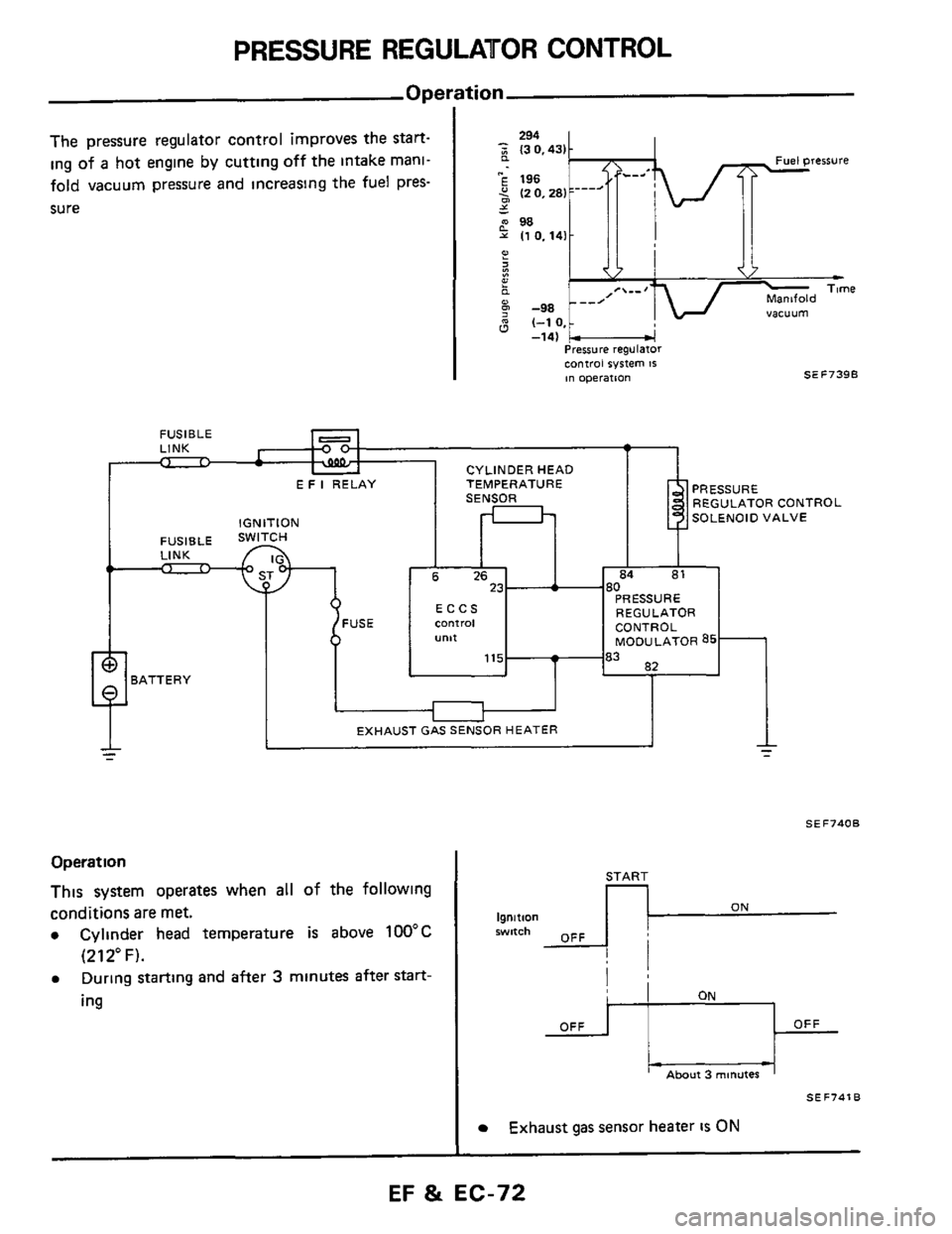

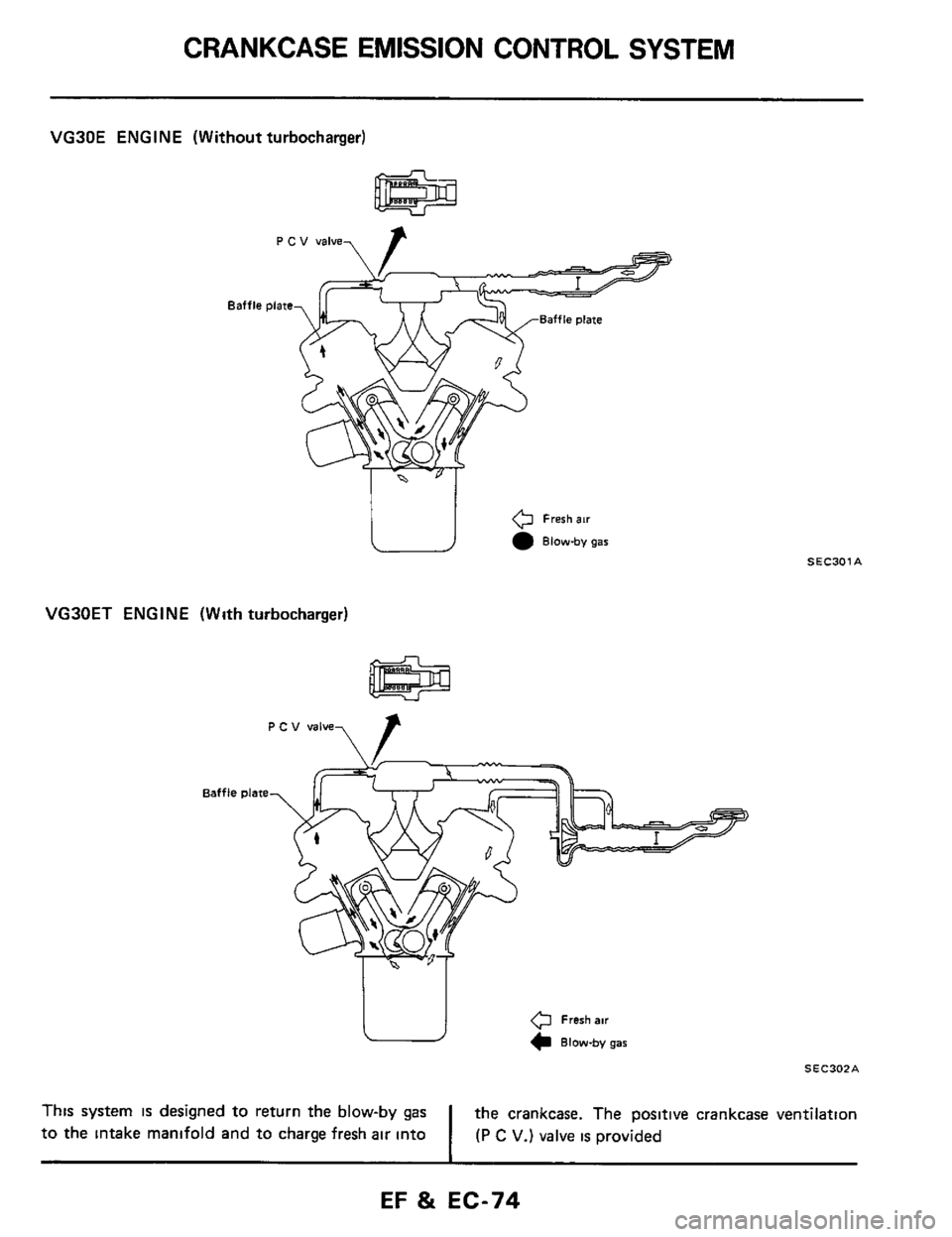

PRESSURE REGULATOR CONTROL

I nspi

1 Disconnect cylinder head temperature sensor

harness connector and connect terminals of

harness connector with

a lead wire

2 Disconnect a vacuum hose between pressure

regulator and solenoid valve

3 Start engine and make sure that the vacuum

does not exist for three minutes

SEF743B

4 If vacuum exists, disconnect pressure regulator

control modulator harness connector for the

modulator located under the battery and check

solenoid valve and circuit

a Ignition switch OFF

SEF744B OR

b Ignition switch ON

a,@, @ Battery voltage

@ Between OV and battery voltage

SEF745B

c. lgnitlon switch START

13isconnect starter motor "S" terminal

I

Battery voltage

4

SEF7468

d Check continuity between terminals of sole-

noid valve

Continuity should emst

SE F 6988

5 If solenoid valve and circuit are 0.K , replace

pressure regulator control modulator.

-

EF & EC-73

Page 74 of 79

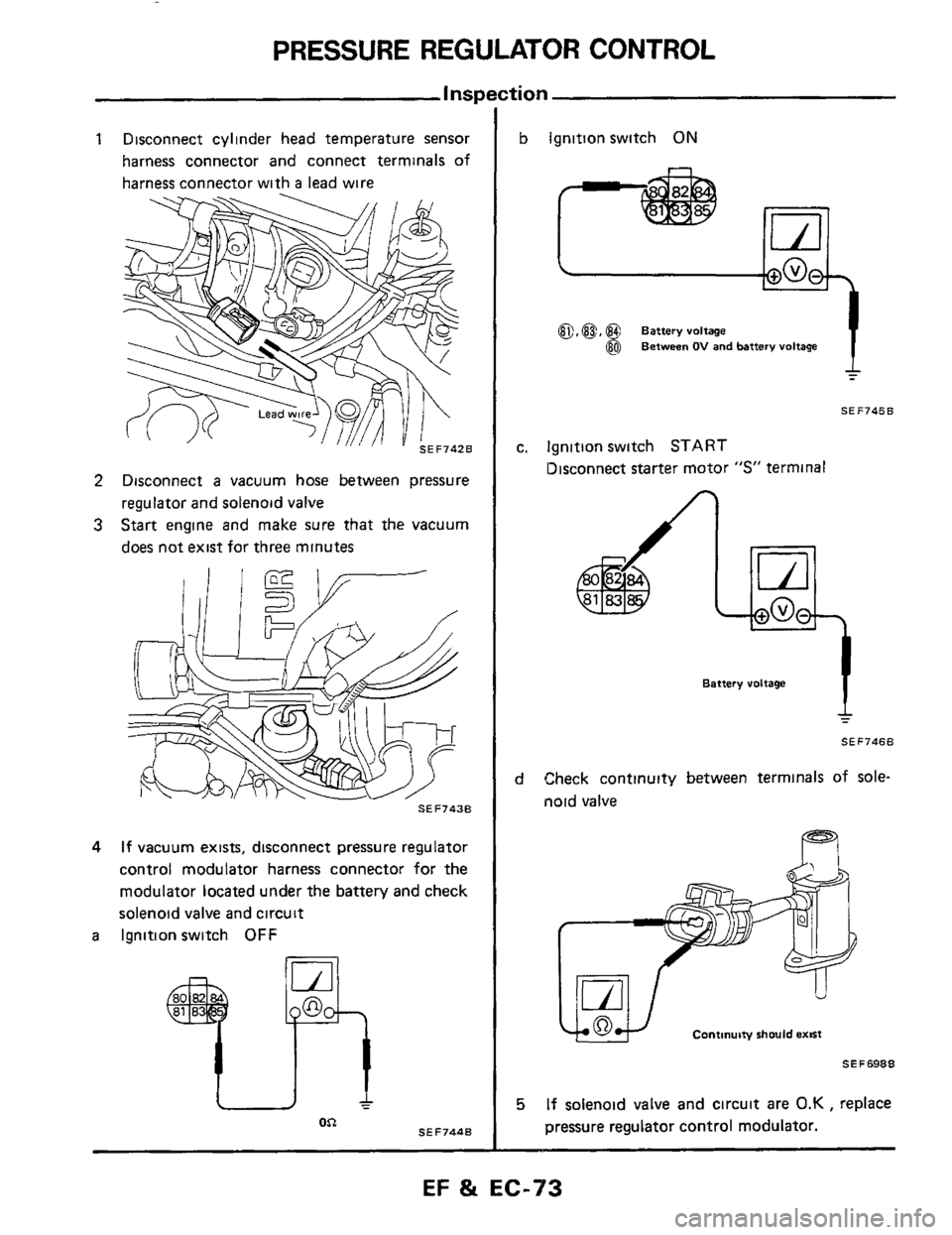

CRANKCASE EMISSION CONTROL SYSTEM

VG30E ENGINE (Without turbocharger)

I "I

e Fresh air

Blow-by gar

VG30ET ENGINE (With turbocharger)

0 Fresh air

Blow-by gar

SEC301A

SEC302A

the crankcase. The positive crankcase ventilation

I (P C V.) valve is provided

This system is designed to return the blow-by gas

to the intake manifold and to charge fresh air into

EF & EC-74

Page 75 of 79

EXHAUST EMISSION CONTROL SYSTEM

-Intake Manifold Vacuum Control-

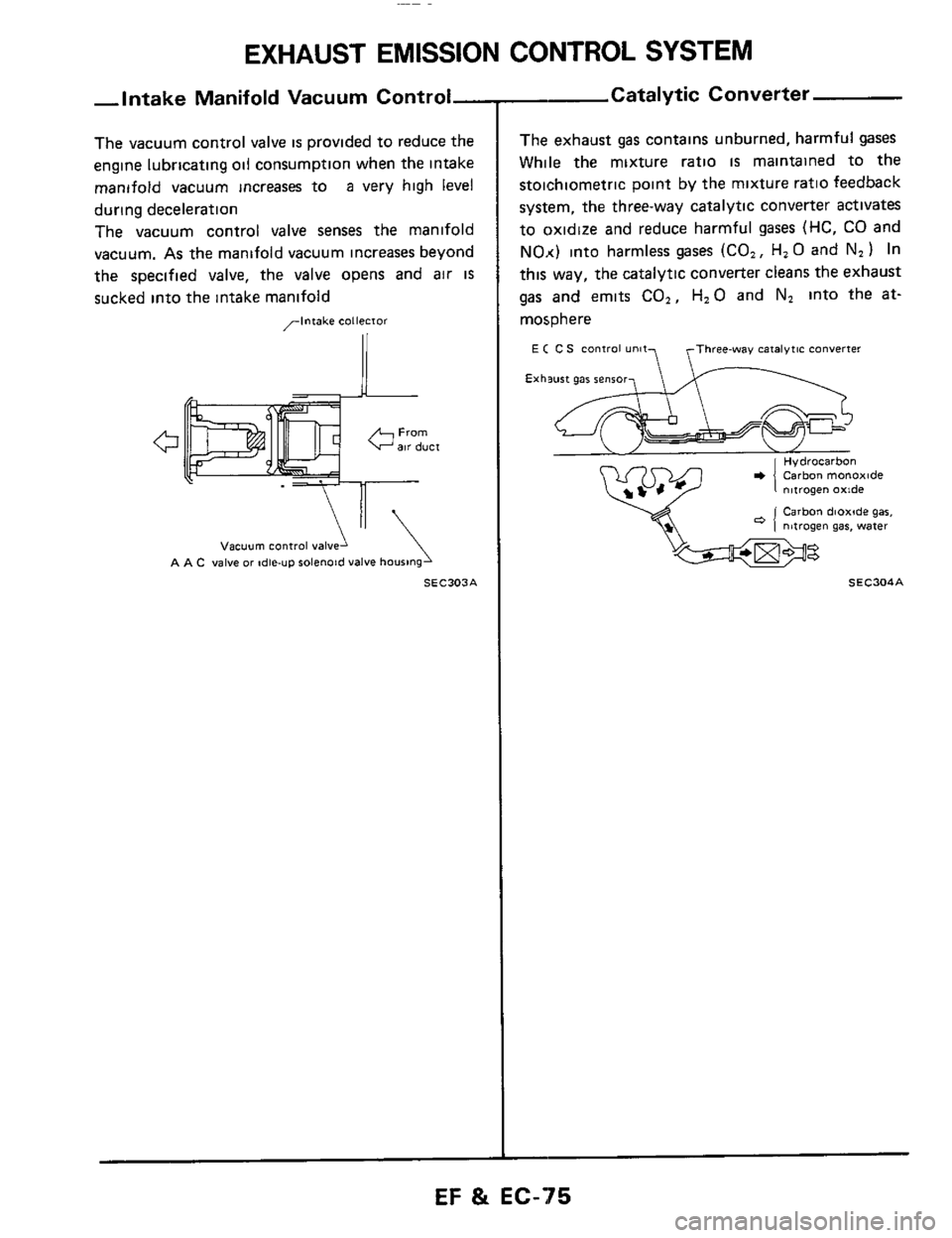

The vacuum control valve is provided to reduce the

engine lubricating oil consumption when the intake

manifold vacuum increases to

a very high level

during deceleration

The vacuum control valve senses

the manifold

vacuum.

As the manifold vacuum increases beyond

the specified valve, the valve opens and

air IS

sucked into the intake manifold

,-intake collecior

\'I

vacuum COntiOl vaivel

A A C valve or de-up rolenoid valve housing

SEC303A

- Catalytic Converter

The exhaust gas contains unburned, harmful gases

While the mixture ratio

is maintained to the

stoichiometric point by the mixture ratio feedback

system, the three-way catalytic converter activates

to oxidize and reduce harmful

gases (HC, CO and

NO.<) into harmless gases (CO,, H, 0 and N2 1 In

this way, the catalytic converter cleans the exhaust

gas and emits CO,, H,O and N, into the at-

mosphere

E ( C S Control unit? yThree-way catalytic Converter

'h

Exhsurt gar renror,

Hydrocarbon Carbon monoxide nltrogen oxide

Carbon dioxide gar. nitrogen gas, water

SEC304A

EF & EC-75

Page 76 of 79

EVAPORATIVE EMISSION CONTROL SYSTEM

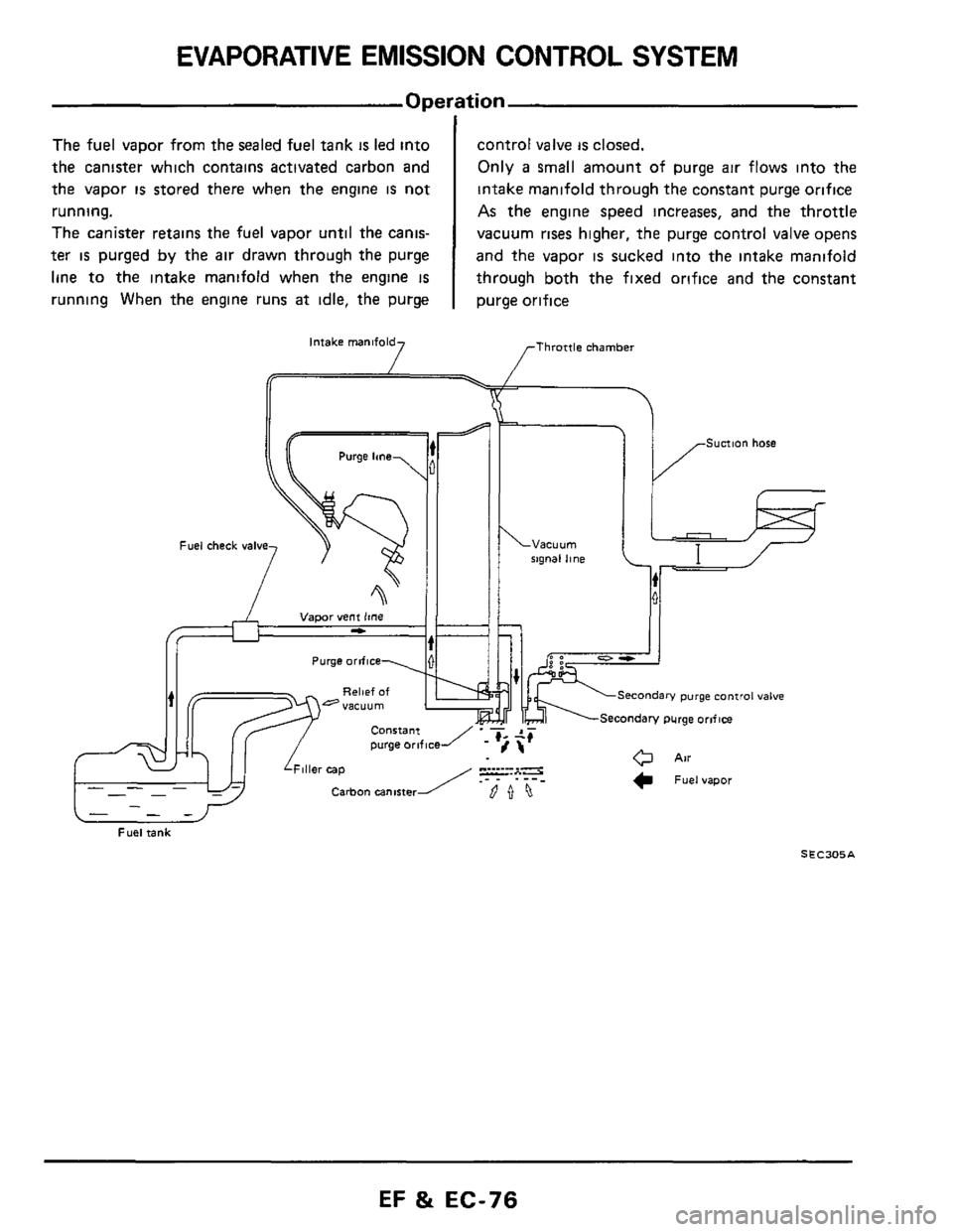

The fuel vapor from the sealed fuel tank is led into

the canister which contains activated carbon and

the vapor

is stored there when the engine is not

running.

The canister retains the fuel vapor until the canis-

ter is purged by the air drawn through the purge

line to the intake manifold when the engine

IS

running When the engine runs at idle, the purge

control valve is closed.

Only

a small amount of purge air flows into the

intake manifold through the constant purge orifice

As the engine speed increases, and the throttle

vacuum

rises higher, the purge control valve opens

and the vapor

is sucked into the intake manifold

through both the fixed orifice and the constant

purge orifice

Intake manifold [Throttle chamber 7 I /F

Sunion hose Purge lane

rxgnal line Fuel check valve

I /F

Sunion hose Purge lane

. ___ -. . . rxgnal line

Purge orifice

i, II

hi II

bl+;fr'

Secondary purge control valve

\Secondary purge orlflce

- -- -

Fuel tank

S E C305 A

EF & EC-76

Page 77 of 79

EVAPORATIVE EMISSION CONTROL SYSTEM

VAPOR VENT LINE

AN

Fuel check valve

SEC306A

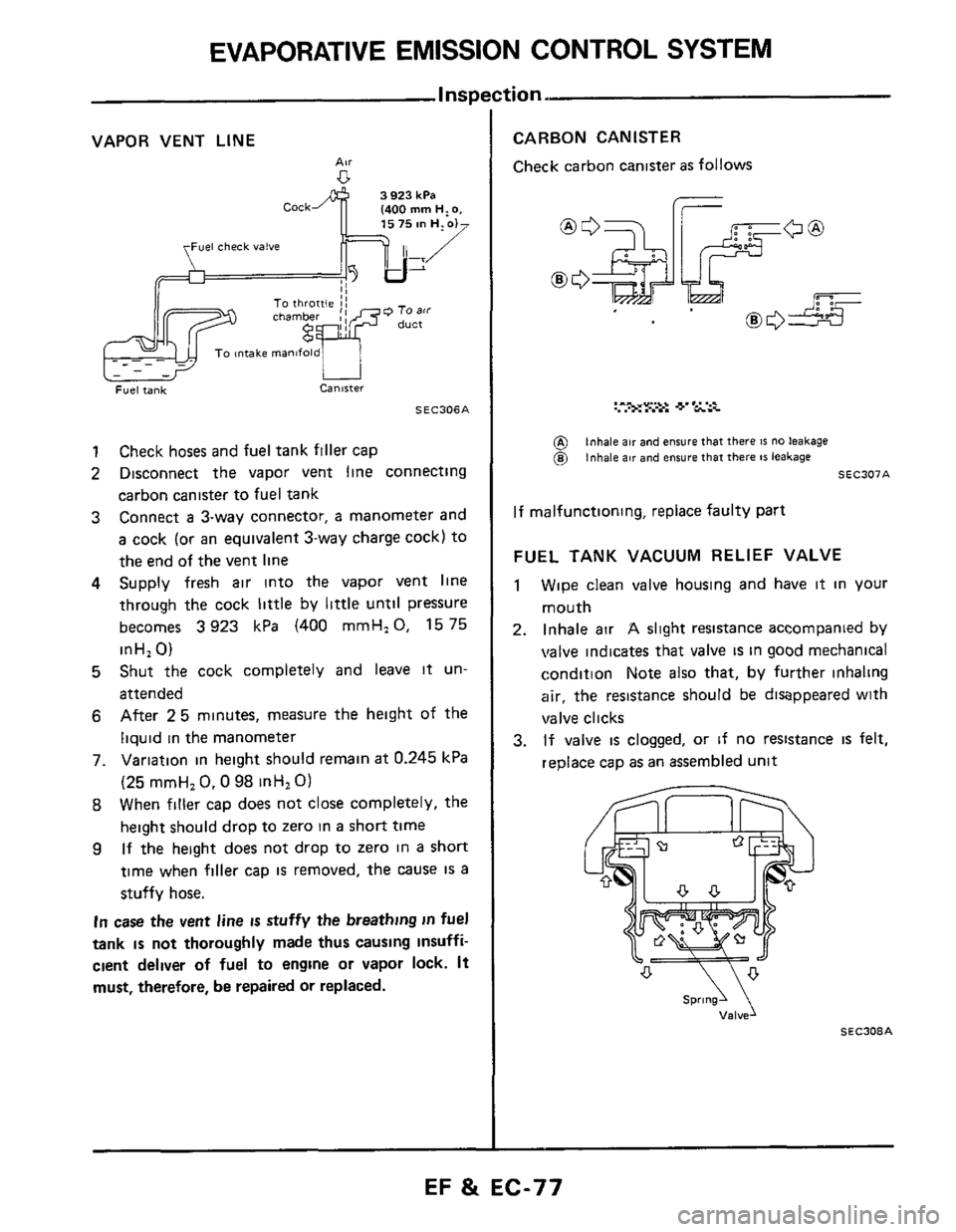

1 Check hoses and fuel tank filler cap

2 Disconnect the vapor vent line connecting

carbon canister to fuel tank

3 Connect a 3-way connector, a manometer and

a cock (or an equivalent 3-way charge cock) to

the end of the vent line

4 Supply fresh air into the vapor vent line

through the cock

little by little untll pressure

becomes

3923 kPa (400 mmH,O, 1575

inH,

0)

5 Shut the cock completely and leave it un-

attended

6 After 25 minutes, measure the height of the

liquid

in the manometer

7. Variation in height should remain

at 0.245 kPa

(25 mmH,

0.0 98 inHl 0)

8 When filler cap does not close completely, the

height should drop to zero in

a short time

9 If the height does not drop to zero in a short

time when filler cap is removed, the cause IS a

stuffy hose.

In case the vent line is stuffy the breathing in fuel

tank

is not thoroughly made thus causing insuffi-

cient deliver of fuel to engine or vapor lock. It

must, therefore, be repaired or replaced.

tion.

CARBON CANISTER

Check carbon canister as follows

I-

UL

@ @)

inhale air and ensure that there IS no leakage inhale air and ensure that there 81 leakage

SEC307A

If malfunctioning, replace faulty part

FUEL TANK VACUUM RELIEF VALVE

1 Wipe clean valve housing and have it in your

mouth

2. Inhale air A slight resistance accompanied by

valve indicates that valve is in good mechanical

condition Note also that, by further inhaling

air, the resistance should be disappeared with

valve clicks

3. If valve is clogged, or if no resistance is felt,

replace cap

as an assembled unit

SEC308A

EF & EC-77

Page 78 of 79

EVAPORATIVE EMISSION CONTROL SYSTEM

I (Cont'd) Inspectic

FUEL CHECK VALVE

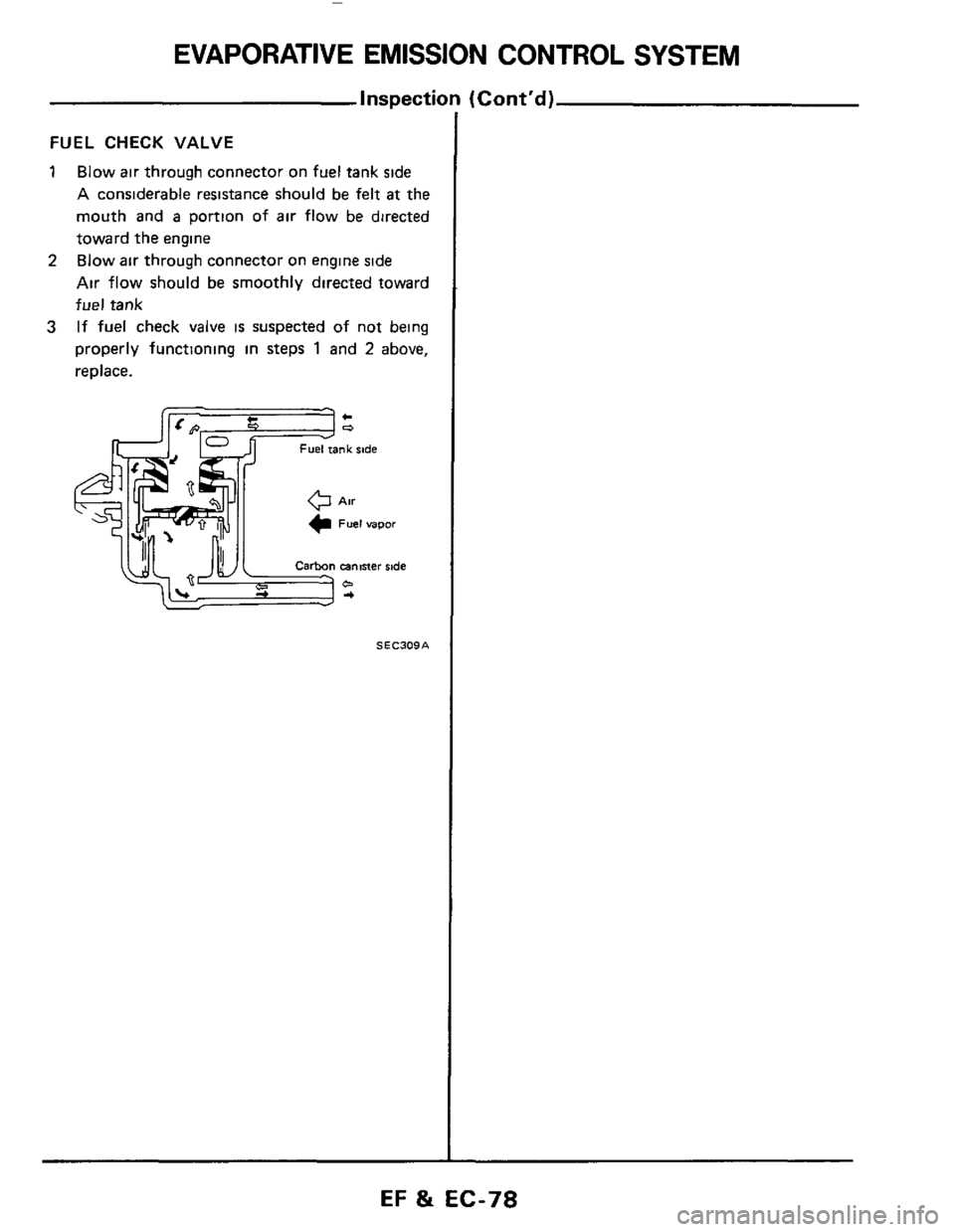

1 Blow air through connector on fuel tank side

A considerable resistance should be felt at the

mouth and

a portion of air flow be directed

toward the engine

Blow

air through connector on engine side

Air flow should be smoothly directed toward

fuel tank

If fuel check valve

is suspected of not being

properly functioning in steps

1 and 2 above,

replace.

2

3

SEC309A

EF 8t EC-78

Page 79 of 79

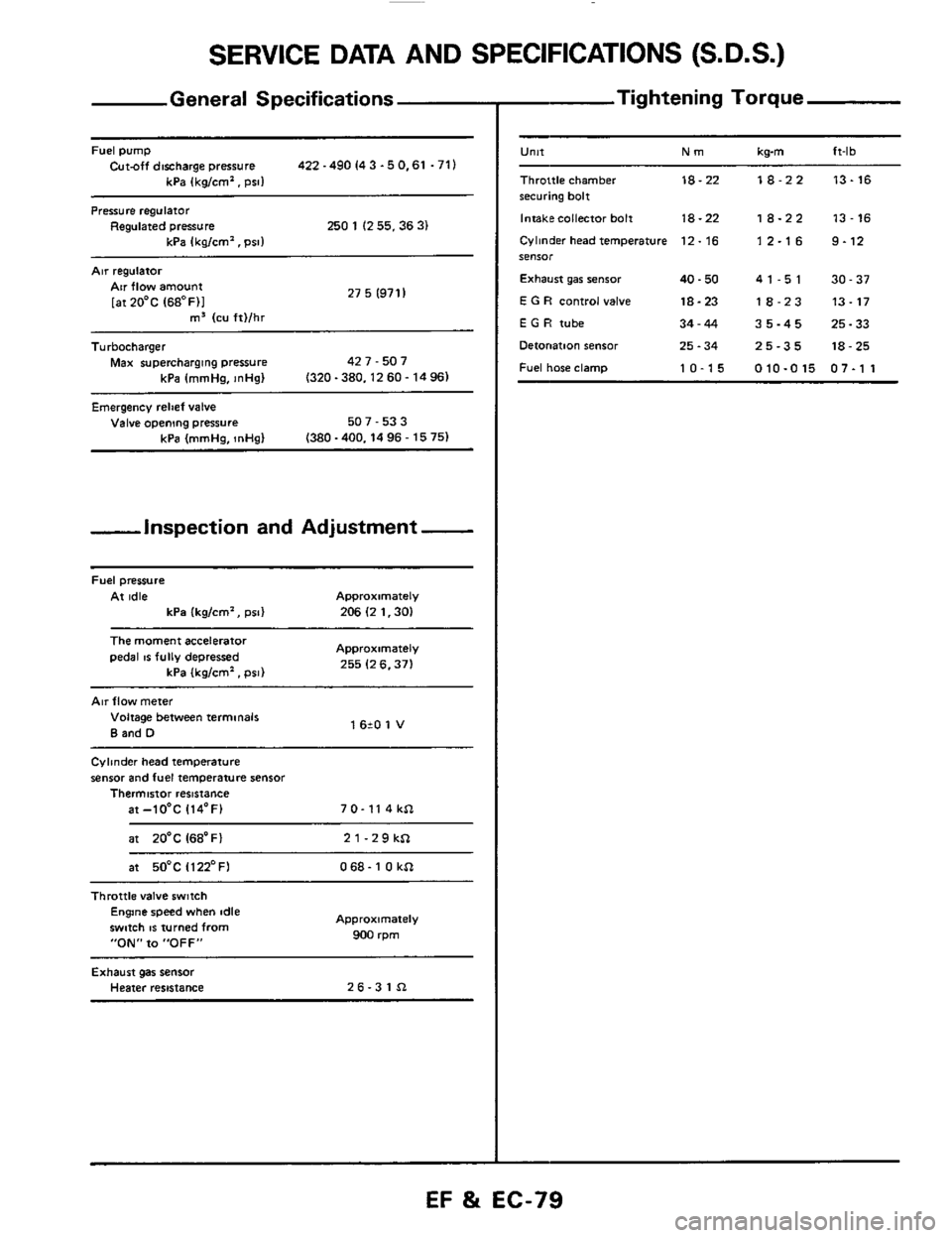

SERVICE DATA AND SPECIFICATIONS (S.D.S.)

General Specifications

Fuel pump Cut-off discharge pressure 422 -490 I4 3 -5 0.61 .71)

kPa (kg/cm'. psi1

Pressure regulator Regulated pressure 250 1 (2 55.36 3) kPa Ikalcm'. Dsll

Air regulatoi

27 5 (971 I Air flow amount

[atZO'C (68OF)I m3 (cu ft)/hr ~~

Turbocharger

Max supercharging pressure 42 7 - 507

kPa (mmHa.

InHal (320-380.1260-1496)

Emergency relief valve Valve opening pressure 507 - 53 3

(380 -400.14 96 - 15 75) kPa (mmHg, InHg)

-inspection and Adjustment -

Fuel pressure

At idle Approximately

kPa (kg/cm', psi) 206 (2 1.30)

The moment accelerator

pedal IS fully depressed Approximately

255 (2 6.371 kPa (kglcm'. psi)

Air flow meter

Voltage between terminals

B and D 1 620 1 V

Cylinder head temperature

sensor and fuel temperature sensor Thermistor resistance

at-lO'C 114'F) 7 0- 11 4 kSl

at 20'C I68'Fl 21-29kSl

at 50°C Il22'FI 068- 1 0 kSl ~~~~

Throttle

valve switch Engine speed when idle

swmh

IS turned from

"ON" to "OFF"

Approximately

900 rpm

Exhaust gas sensor Heater resistance 26-31Sl

- Tightening Torque

-

U"lt Nm kwn ft-lb

Throttle chamber 18-22 18-22 13-16 securing bolt

Intakecollector bolt

18-22 18-22 13-16

Cylinder head temperature 12. 16 1 2.1 6 9.12 SeIlSOr

Exhaust gar senior 40.50 41-51 30-37

E G R control valve 18-23 18-23 13-17

E G H tube 34-44 35-45 25-33

Detonation sensor 25.34 25-35 18-25

Fuel hose clamp 10-15 010-015 07-1 1

EF %i EC-79