oil NISSAN 300ZX 1984 Z31 Engine Fuel And Emission Control System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 79, PDF Size: 2.15 MB

Page 2 of 79

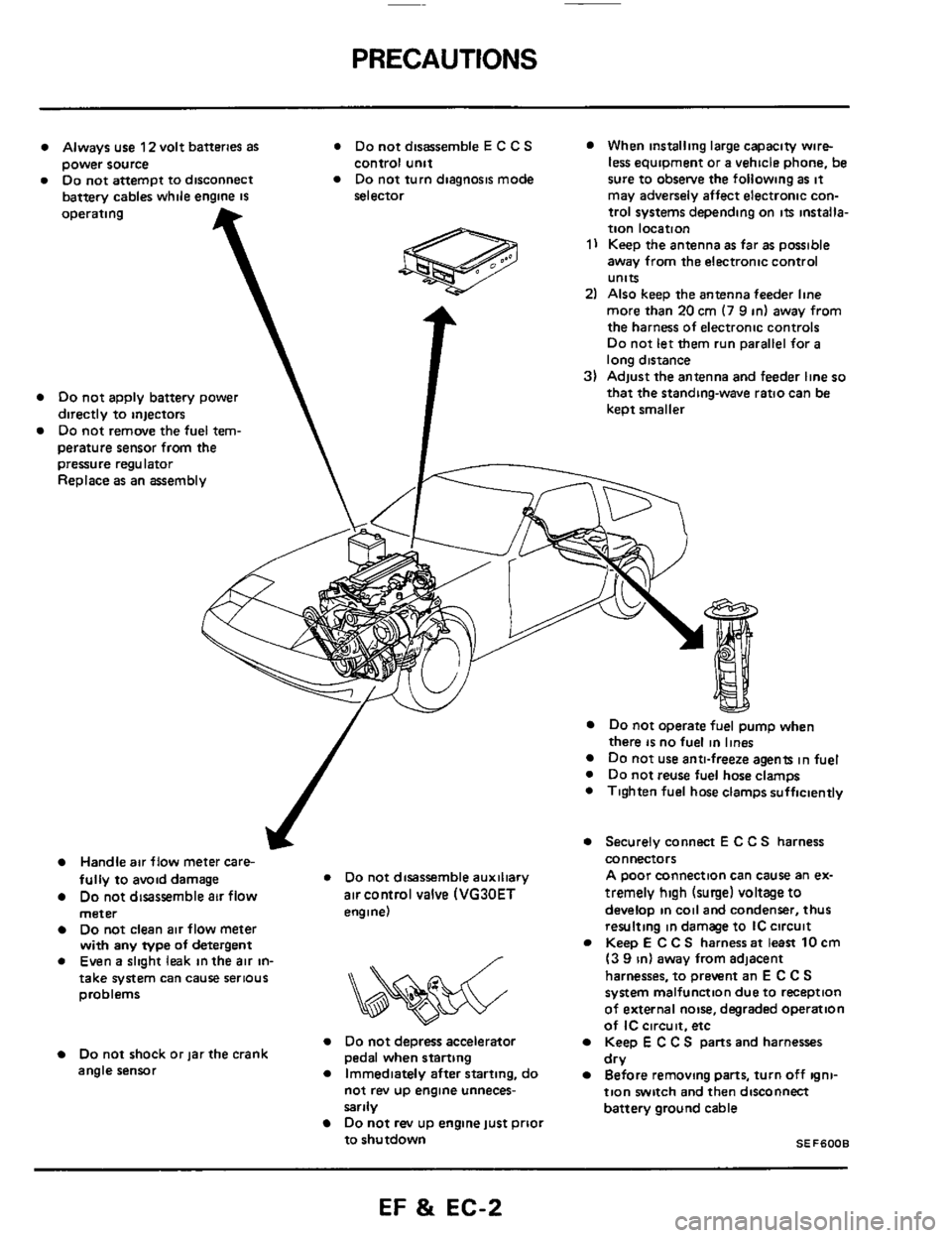

PRECAUTIONS

Always use 12 volt batteries as * Do not disassemble E C C S When installing large capacity wire-

Do not attempt to disconnect Do not turn diagnosis mode sure to obsetve the following as it power source

battery cables while engine

IS

control unit

selector less equipment or a vehicle phone, be

may adversely affect electronic con-

operating

Do not apply battery power

directly to injectors

Do not remove the fuel tem-

perature sensor from

the T

pressure regulator

Replace as an assembly

trol systems depending on its installa-

tion location

1) Keep the antenna as far as possible

away from the electronic control

units

2) Also keep the antenna feeder line

more than

20 cm (7 9 in) away from

the harness of electronic controls

Do not let them run parallel for a

long distance

3) Adjust the antenna and feeder line so

that the standing-wave ratio can be

keot smaller

J

Handle air flow meter care-

fully to avoid damage * Do not disassemble auxiliary

Do not disassemble air flow air control valve (VG30ET

meter engine)

Do not clean air flow meter

with any type of detergent

0 Even a slight leak in the air in- /

&&%$$?&

take system can cause serious

problems

Do not depress accelerator Do not shock or jar the crank

angle sensor

Immediately after starting, do

pedal when starting

not rev

up engine unneces-

sarily

Do not rev up engine just prioi

to shutdown

Do not operate fuel pump when

there is no fuel in lines Do not use anti-freeze agents in fuel

0 Do not reuse fuel hose clamps

0 Tighten fuel hose clamps sufficiently

Securely connect E C C S harness

connectors

A poor connection can cause an ex-

tremely

high (surge) voltage to

develop in coil and condenser, thus

resulting in damage to IC circuit

Keep

E C C S harness at least 10 cm

(3 9 in) away from adjacent

harnesses, to prevent an

E C C S

system malfunction due to reception

of external noise, degraded operation

of

IC circuit. etc

Keep E C C S parts and harnesses

Before removing parts, turn off igni-

tion switch and then disconnect

battery ground cable dry

SEF6008

EF & EC-2

Page 17 of 79

E. C. C. S. DESCRIPTION

E.C.C.S. Corn

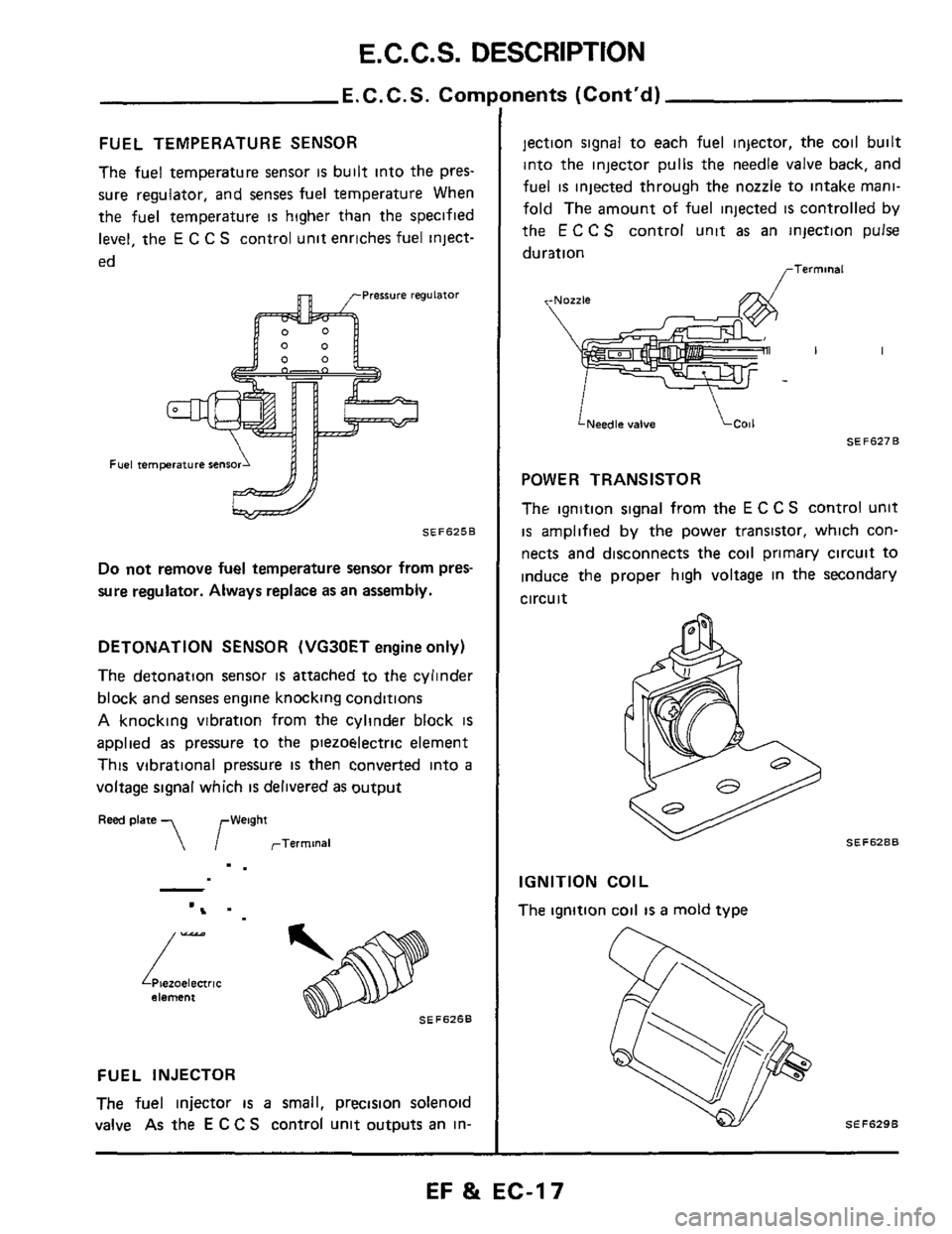

FUEL TEMPERATURE SENSOR

The fuel temperature sensor is built into the pres-

sure regulator, and senses fuel temperature When

the fuel temperature

IS higher than the specified

level, the

E C C S control unit enriches fuel inject-

ed

Pressure regulator

Fuel temprature $ens

SEF625B

Do not remove fuel temperature sensor from pres-

sure regulator. Always replace as

an assembly.

DETONATION SENSOR (VG30ET engine only)

The detonation sensor

is attached to the cylinder

block and senses engine knocking conditions

A knocking vibration from the cylinder block is

applied as pressure to the piezoelectric element

This vibrational pressure

IS then converted into a

voltage signal which is delivered as output

Reed plate ,, ,-Weight

rTerminal

-.

Piezoelectric element

SEFSZSB

/-

FUEL INJECTOR

The

fuel injector is a small, precision solenoid

valve As the

E C C S control unit outputs an in-

lnents (Cont’d)

jection signal to each fuel injector, the coil built

into the injector pulls the needle valve back, and

fuel

is injected through the nozzle to intake mani-

fold The amount of fuel injected

is controlled by

the

E C C S control unit as an injection pulse

duration

<-Nozzle

LNeedle valve

SEF627B

POWER TRANSISTOR

The ignition signal from the

E C C S control unit

is amplified by the power transistor, which con-

nects and disconnects the coil primary circuit to

induce the proper high voltage in the secondary

circuit

SEFSZBB

IGNITION COIL

The ignition coil

IS a mold type

EF & EC-17

Page 18 of 79

E. C. C. S. DESCRIPTION

E.C.C.S. Corn1

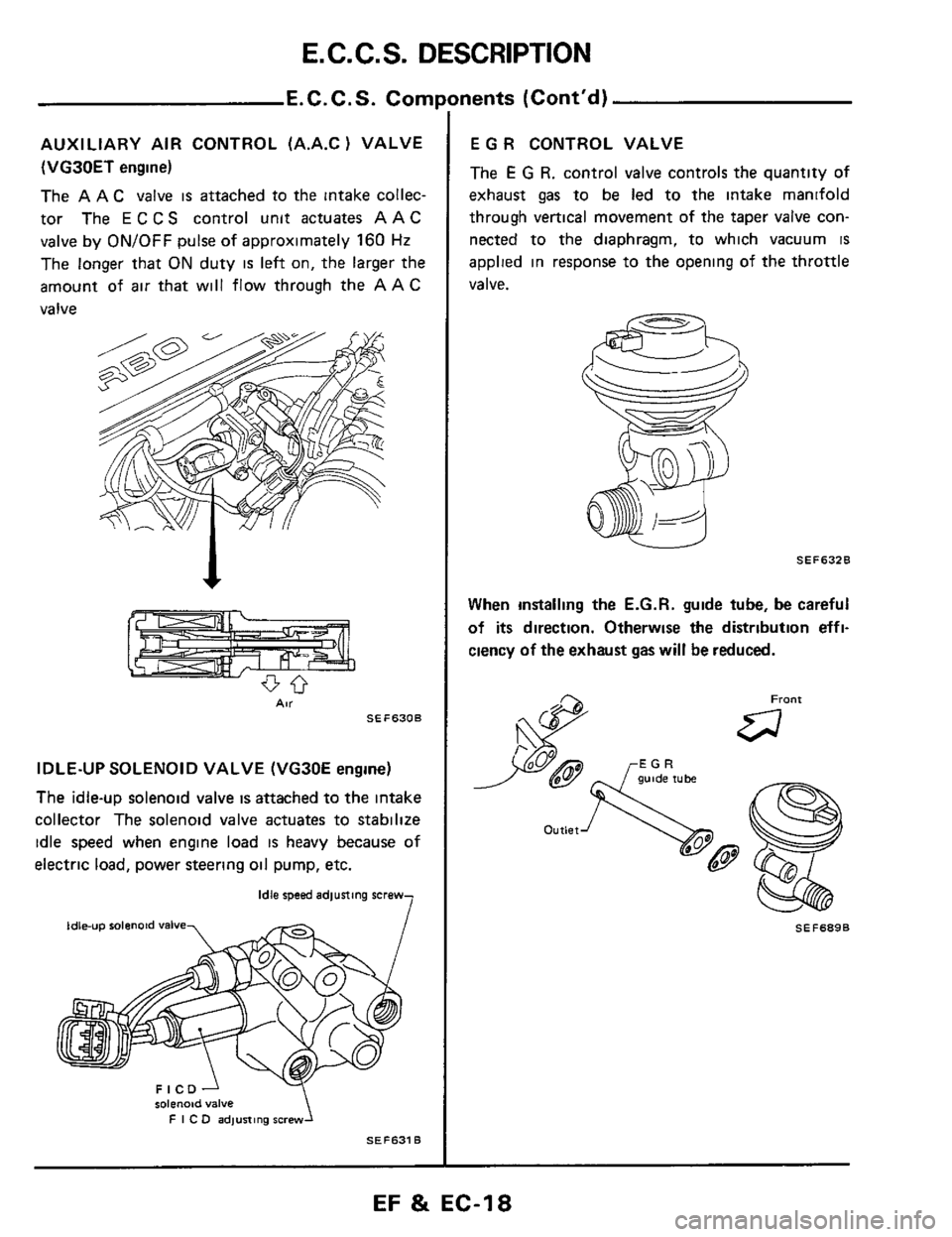

AUXILIARY AIR CONTROL (A.A.C 1 VALVE

(VG30ET

engine)

The

A A C valve is attached to the intake collec-

tor The E C CS control unit actuates AAC

valve by ON/OFF pulse of approximately 160 Hz

The longer that ON duty is left on, the larger the

amount of

air that will flow through the A A C

valve

1

AV SEF630B

IDLE-UP SOLENOID VALVE (VG30E engine)

The idle-up solenoid valve is attached to the intake

collector The solenoid valve actuates to stabilize

idle speed when engine load

is heavy because of

electric load, power steering oil pump, etc.

7

idle speed adiuning screw

ldleup solenoid valve

SEF631 B

FICDJ solenoid valve

F I C D adjusling screw

nents (Cont'd)

E G R CONTROL VALVE

The E G R. control valve controls the quantity of

exhaust

gas to be led to the intake manifold

through vertical movement of the taper valve con-

nected to the diaphragm, to which vacuum

IS

applied in response to the opening of the throttle

valve.

SEF632B

When installing the E.G.R. guide tube, be careful

of its direction. Otherwise the distribution effi-

ciency of the exhaust gas will be reduced.

SEF689B

EF 8i EC-18

Page 19 of 79

E. C. C. S. DESCRIPTION

E.C.C.S. Components (Cont’d)

E.G.R. CONTROL SOLENOID VALVE

E G R control solenoid valve cuts intake manifold

vacuum signal for

E G.R control The solenoid

valve actuates in response to the ON/OFF signal

from

the E C.C S control unit. When the solenoid

is off, vacuum signal from intake manifold is fed

into the

E G R control valve As the control

unit outputs an ON signal, the coil pulls the

plunger downward, and cuts the vacuum signal

9 Atmosphere

ToEGR control valve

From intake

SEF6336 0 manifold

FUEL PUMP

The fuel pump, which is located in the fuel tank, IS

a wet type pump where the vane rollers are directly

coupled to

a motor which is filled with fuel

1 Outlet A

AIR REGULATOR

Air regulator gives an air by-pass when the engine is

cold for the purpose of a fast idle during warm-up

SE F635 B

A bimetal, heater and rotary shutter are built into

the air regulator When the bimetal temperature

IS

low,

the air by-pass port is open As the engine

starts and electric current flows through a heater,

the bimetal begins to rotate the shutter

to close off

the by-pass port The air passage remalns closed

until the engine

is stopped and the bimetal tem-

perature drops

SEF636B

EF & EC-19

Page 24 of 79

E.C.C.S. DESCRIPTION

Battery voltage Battery

~-

Headlarnp switch Load signal

Cooling fan switch

Power steering oil pressure switch

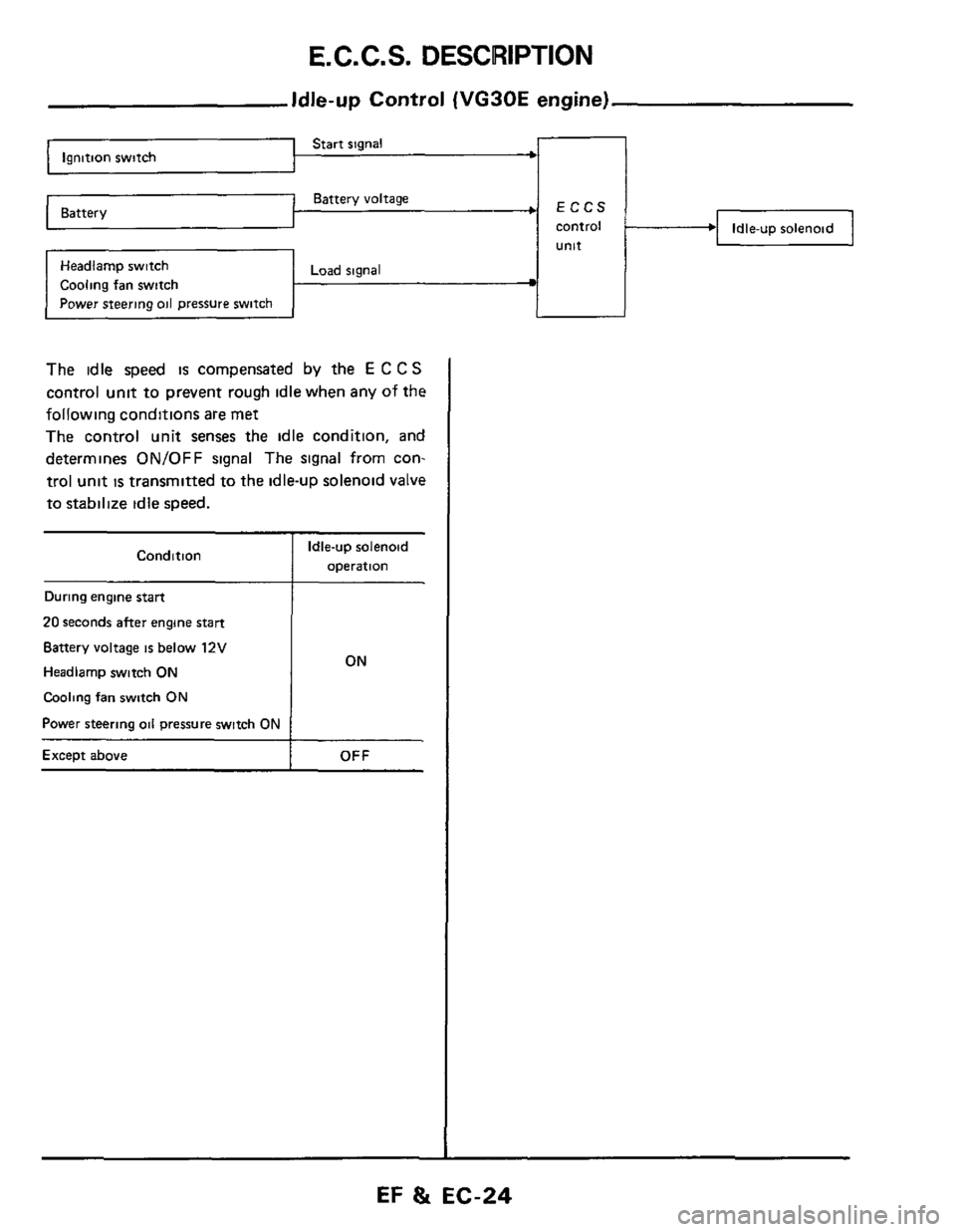

Idle-up Control (VG30E engine)

Start signal Ignition switch

ECCS

control

unit

The idle speed is compensated by the E C C S

control unit to prevent rough idle when any of the

following conditions

are met

The control unit senses the idle condition, and

determines

ON/OFF signal The signal from con-

trol unit

is transmitted to the idle-uD solenoid valve

to stabilize idle speed.

Condition

During engine start

20 seconds after engine start

Battery voltage is below 12V

Headlarnp switch ON

Cooling fan switch ON

Power steering oil pressure switch ON

Except above

Idle-up solenoid

operation

ON

OFF

EF 8t EC-24

Page 35 of 79

SELF-DIAGNOSIS

Self-diagni

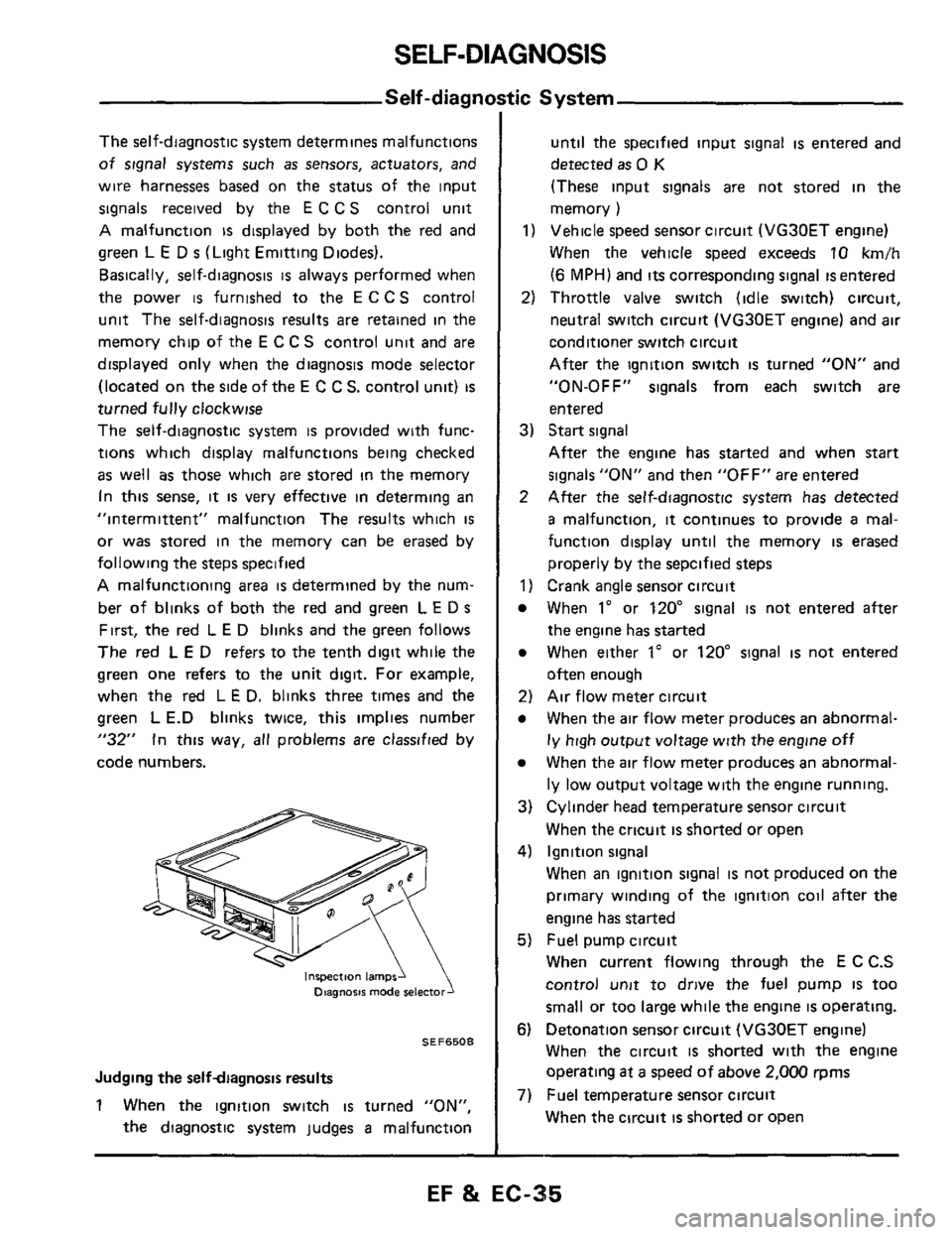

The self-diagnostic system determines malfunctions

of signal systems such as sensors, actuators, and

wire harnesses based on the status of the input

signals received by the

E C C S control unit

A malfunction is displayed by both the red and

green

L E D s (Light Emitting Diodes).

Basically, self-diagnosis

is always performed when

the power

is furnished to the E C C S control

unit The self-diagnosis results

are retained in the

memory chip of the

E C C S control unit and are

displayed only when the diagnosis mode selector

(located on

the side of the E C C S. control unit) is

turned fully clockwise

The self-diagnostic system

is provided with func-

tions which display malfunctions being checked

as well as those which are stored in the memory

In

this sense, it is very effective in determing an

"intermittent" malfunction The results which

is

or was stored in the memory can be erased by

following the steps specified

A malfunctioning area is determined by the num-

ber of blinks of both the

red and green L E D s

First, the red L E D blinks and the green follows

The red L E D refers to the tenth digit while the

green

one refers to the unit digit. For example,

when the red L

E D. blinks three times and the

green

L E.D blinks twice, this implies number

"32" In this way, all problems are classified by

code numbers.

inspection lamps1 Diagnosis mode

SEF6508

Judging the selfdiagnosis results

1 When the ignition switch is turned "ON",

the diagnostic system judges

a malfunction

tic System

until the specified input signal is entered and

detected

as 0 K

(These input signals are not stored in the

memory

)

1) Vehicle speed sensor circuit (VG30ET engine)

When the vehicle speed exceeds

10 km/h

(6 MPH) and its corresponding signal is entered

2) Throttle valve switch (idle switch) circuit,

neutral switch circuit (VG30ET engine) and

air

conditioner switch circuit

After the ignition switch

is turned "ON" and

"ON-OFF"

signals from each switch are

entered

3) Start signal

After the engine has started and when start

signals "ON" and then "OFF" are entered

2 After the self-diagnostic system has detected

a malfunction, it continues to provide a mal-

function display until the memory

is erased

properly by the sepcified steps

1) Crank angle sensor circuit

When 1" or 120" signal is not entered after

the engine has started

When either 1" or 120" signal is not entered

often enough

2) Air flow meter circuit

When the air flow meter produces an abnormal-

ly high output voltage with the engine off

When the air flow meter produces an abnormal-

ly low output voltage with the engine running.

3) Cylinder head temperature sensor circuit

When the cricuit

is shorted or open

4) Ignition signal

When an ignition signal

is not produced on the

primary winding of the ignition coil after

the

engine has started

5) Fuel pump circuit

When current flowing through the E

C C.S

control

unit to drive the fuel pump IS too

small or too large while the engine

is operating.

6) Detonation sensor circuit (VG30ET engine)

When the circuit

is shorted with the engine

operating

at a speed of above 2,000 rpms

When the circuit is shorted or open

7) Fuel temperature sensor circuit

EF & EC-35

Page 67 of 79

TURBOCHARGER

Worn journal or bearing

Inspection (Cont’d)

Replace turbocharger assembly

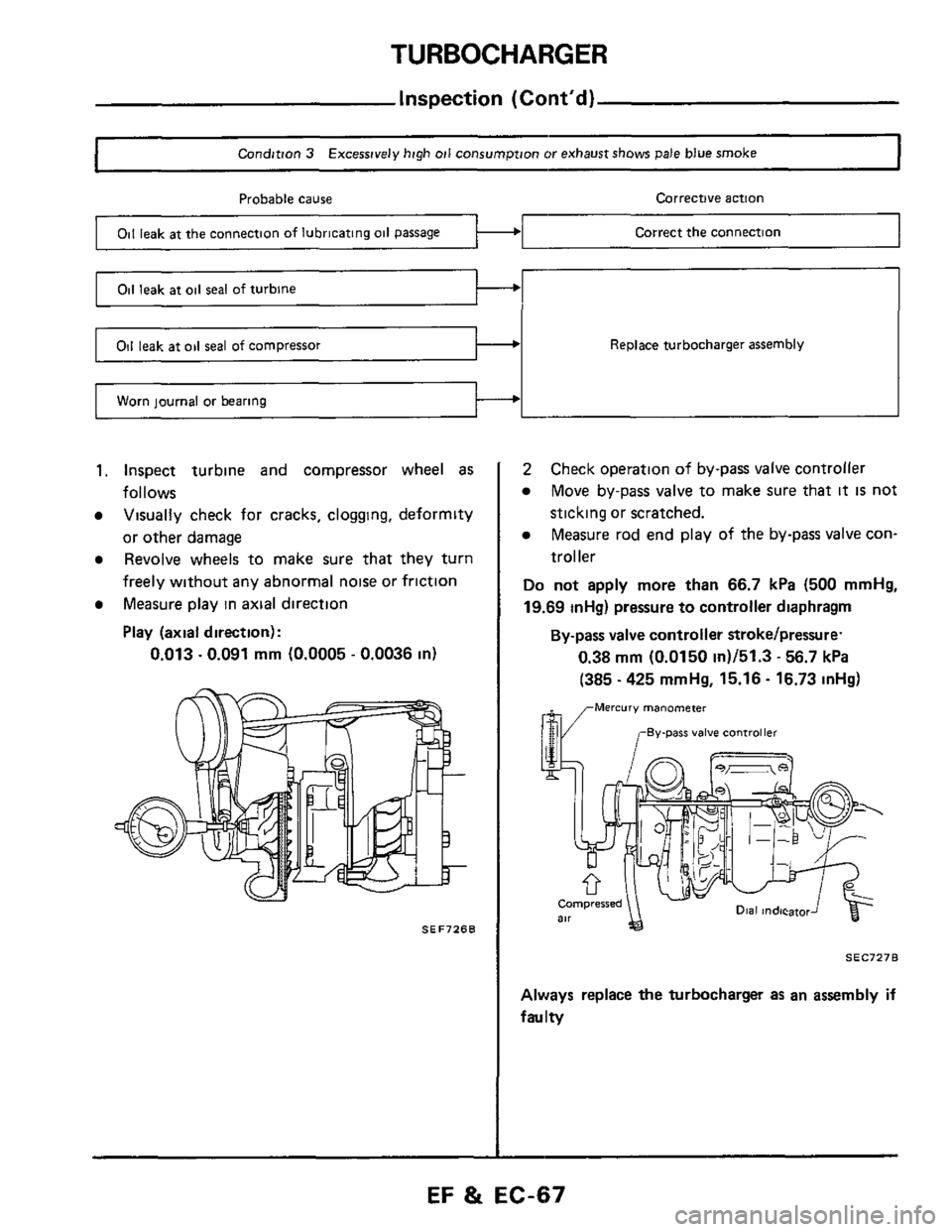

I Condition 3 Excessively high oil consumption or exhaust shows pale blue smoke I

Probable cause Corrective action

Oil leak at the connection of lubricating oil passage Correct the connection

1. Inspect turbine and compressor wheel as

follows

Visually check for cracks, clogging, deformity

or other damage

Revolve wheels to make sure that they turn

freely without any abnormal noise or friction

Measure play in axial direction

Play (axial direction):

0.013.0.091 mm (0.0005 - 0.0036 in)

SEF726B

2 Check operation of by-pass valve controller

Move by-pass valve to make sure that

it is not

sticking or scratched.

Measure rod end play of the bypass valve con-

troller

Do not apply more than 66.7 kPa (500 mmHg,

19.69 mHg) pressure to controller diaphragm

0.38 mm (0.0150 in)/51.3 - 56.7 kPa

(385 - 425 mmHg, 15.16 - 16.73 inHg)

By-pass valve controller strokelpressure.

,vMercury manometer

,-By-parr valve controller

SEC7278

Always replace the turbocharger as an assembly if

faultv

EF & EC-67

Page 68 of 79

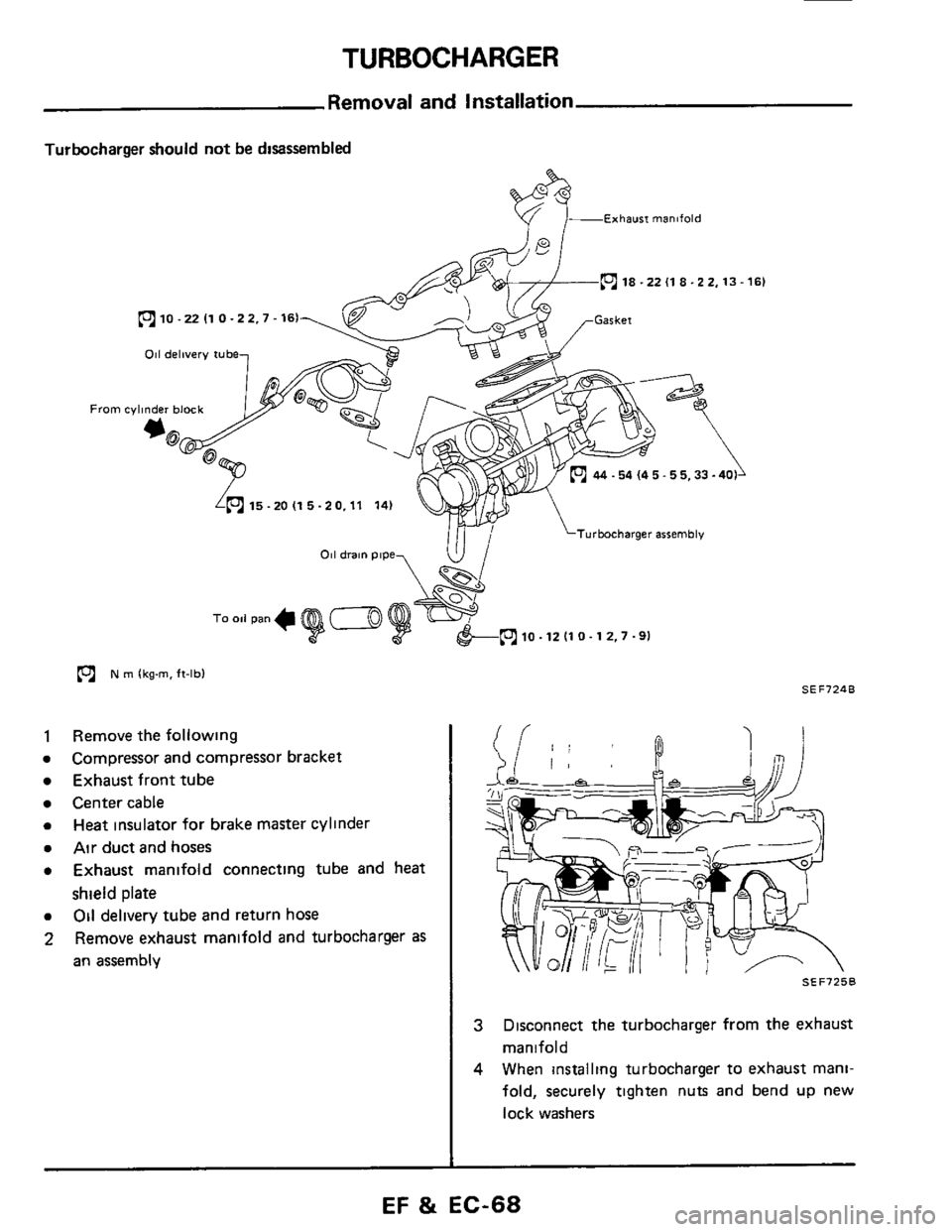

TURBOCHARGER

Removal and Installation

Turbocharger should not be disassembled

&- Exhaw manifold

(c1 18 -22 (1 8-22.13-161

10 -22 I1 0 -22.7.161

011 delivery tube

From cylinder block

*@

15-2OI15-20.11 14)

Turbocharger assembly

p? N m lkg-m. ft-lbl SEF724B

Remove the following

Compressor and compressor bracket

Exhaust front tube

Center cable

Heat insulator for brake master cylini

Air duct and hoses

Exhaust manifold connecting tube and heat

shield plate

Oil delivery tube and return hose

Remove exhaust manlfold and turbocharger

as

an assembly

SEF725B

3

4

Disconnect the turbocharger from the exhaust

manifold

When installing turbocharger

to exhaust mani-

fold, securely tighten nuts and bend

up new

lock washers

EF 8i EC-68

Page 75 of 79

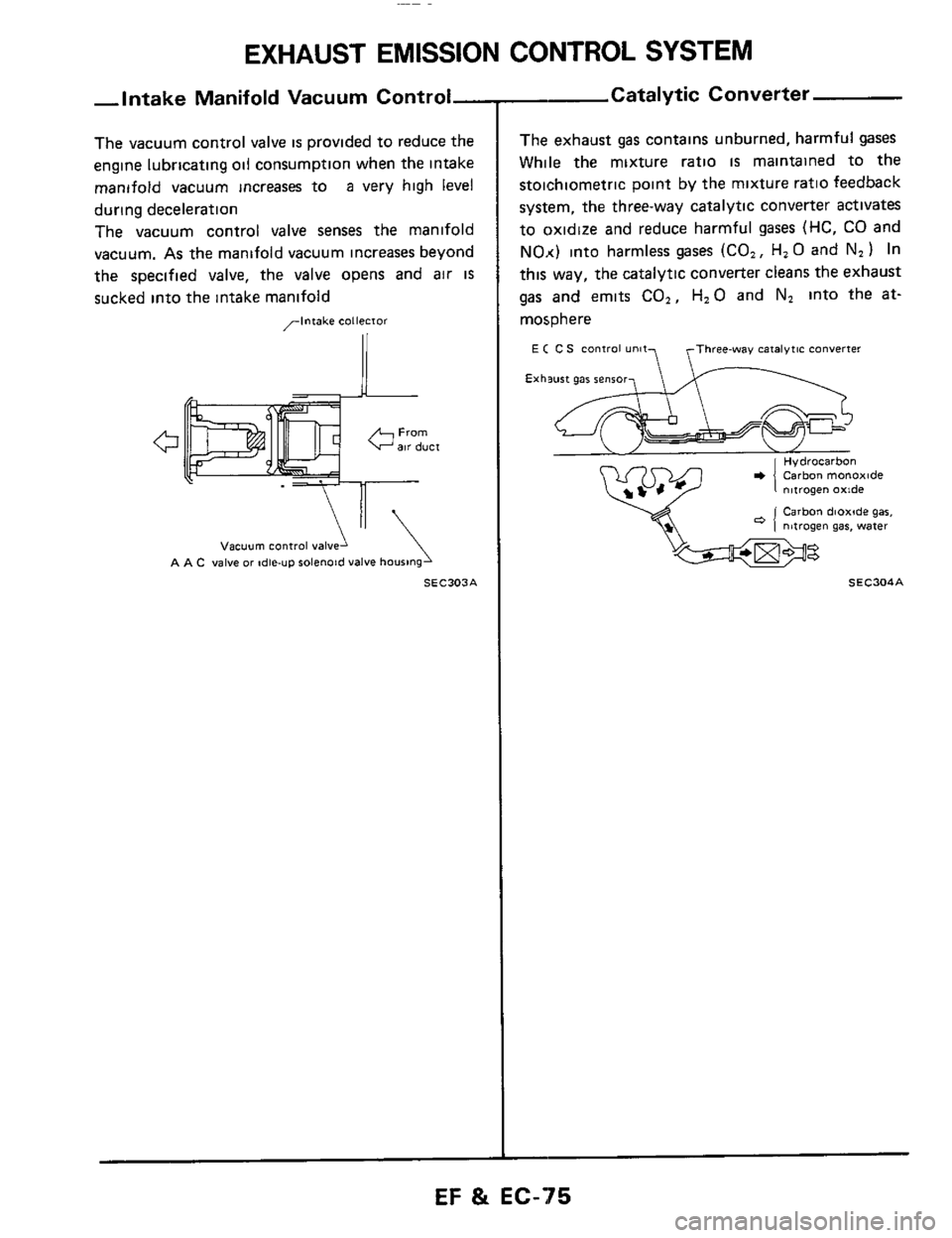

EXHAUST EMISSION CONTROL SYSTEM

-Intake Manifold Vacuum Control-

The vacuum control valve is provided to reduce the

engine lubricating oil consumption when the intake

manifold vacuum increases to

a very high level

during deceleration

The vacuum control valve senses

the manifold

vacuum.

As the manifold vacuum increases beyond

the specified valve, the valve opens and

air IS

sucked into the intake manifold

,-intake collecior

\'I

vacuum COntiOl vaivel

A A C valve or de-up rolenoid valve housing

SEC303A

- Catalytic Converter

The exhaust gas contains unburned, harmful gases

While the mixture ratio

is maintained to the

stoichiometric point by the mixture ratio feedback

system, the three-way catalytic converter activates

to oxidize and reduce harmful

gases (HC, CO and

NO.<) into harmless gases (CO,, H, 0 and N2 1 In

this way, the catalytic converter cleans the exhaust

gas and emits CO,, H,O and N, into the at-

mosphere

E ( C S Control unit? yThree-way catalytic Converter

'h

Exhsurt gar renror,

Hydrocarbon Carbon monoxide nltrogen oxide

Carbon dioxide gar. nitrogen gas, water

SEC304A

EF & EC-75