fuel pressure NISSAN 300ZX 1984 Z31 Engine Fuel And Emission Control System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 79, PDF Size: 2.15 MB

Page 1 of 79

ENGINE FUEL &

- EMISSION - CONTROL SYSTEM

SECTION EFaEC

CONTENTS

PRECAUTIONS ..

COMPONENT PARTS LOCATION

ECCS DIAGRAM

. . .

ECCS CHART ..

ECC.S WIRING DIAGRAM . . ..

FUEL FLOW SYSTEM DESCRIPTION .

AIR FLOW SYSTEM DESCRIPTION ....

E C C S. DESCRIPTION . . . . ...

DIAGNOSTIC PROCEDURE . ..

SE LF-D I AGNOSIS ..

..

.. ..

..

..

..

...

ELECTRONfC CONTROL SYSTEM INSPECTION

MIXTURE RATIO FEEDBACK SYSTEM INSPECTION

. ,

FUEL SYSTEM INSPECTION

TURBOCHARGER

. ... ..

INJECTOR COOLING FAN (VG30ET) .

PRESSURE REGULATOR CONTROL

CRANKCASE EMISSION CONTROL SYSTEM

. . . .

EXHAUST EMISSION CONTROL SYSTEM . . ...

EVAPORATIVE EMISSION CONTROL SYSTEM . . .

SERVICE DATA AND SPECIFICATIONS (S DS). . . . . . .

. . EF&EC- 2

. EF&EC- 3

EF & EC- 4

EF&EC- 6

EF&EC- 8

.. EF & EC-10

EF

& EC-11

, EF&EC-13

EF

& EC-28

EF

& EC-35

EF

& EC43

EF & EC-60

EF

& EC-63

EF

& EC-66

EF

& EC-69

EF

& EC-72

. . EF & EC-74

EF

& EC-75

, EF&EC-76

EF & EC-79

Page 2 of 79

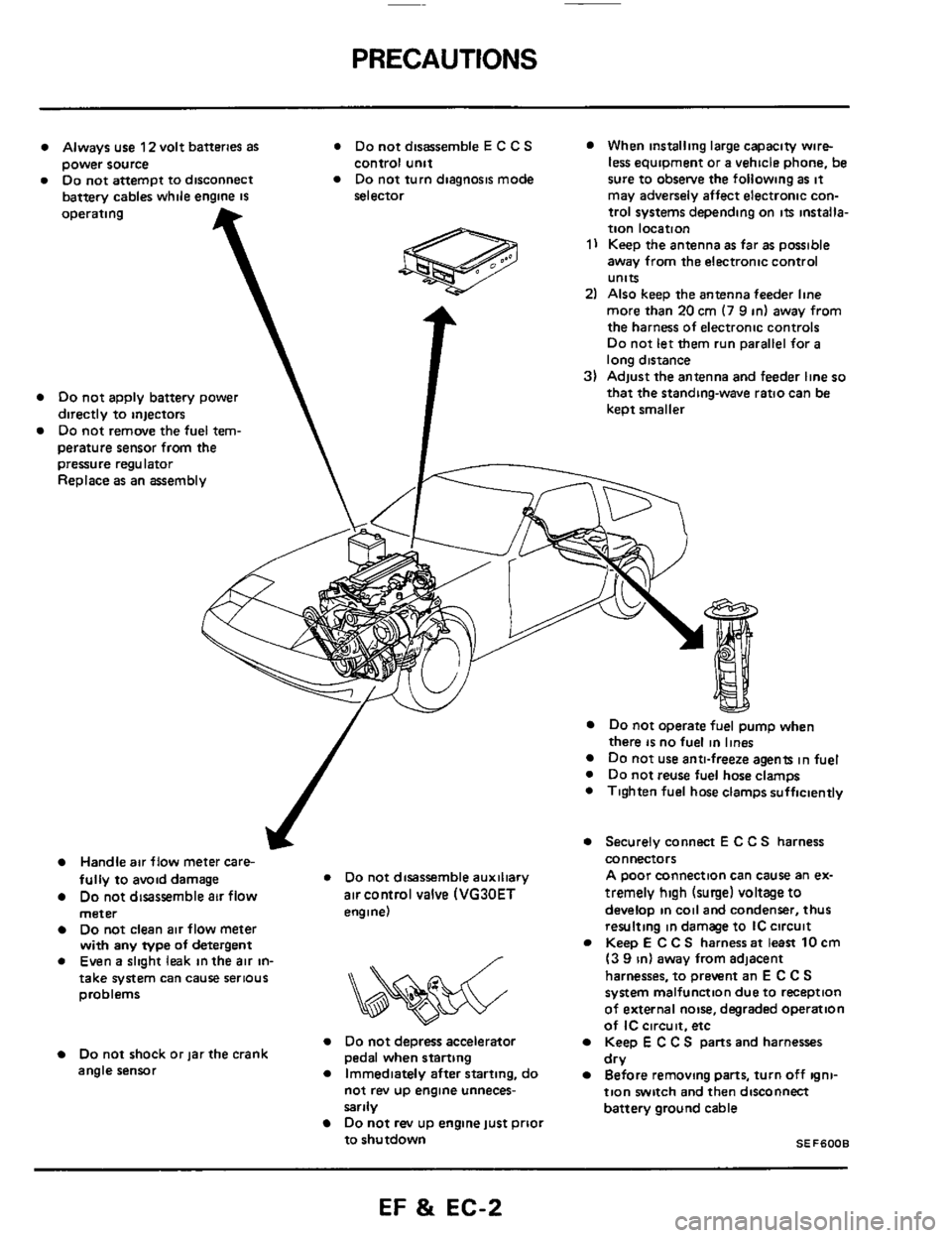

PRECAUTIONS

Always use 12 volt batteries as * Do not disassemble E C C S When installing large capacity wire-

Do not attempt to disconnect Do not turn diagnosis mode sure to obsetve the following as it power source

battery cables while engine

IS

control unit

selector less equipment or a vehicle phone, be

may adversely affect electronic con-

operating

Do not apply battery power

directly to injectors

Do not remove the fuel tem-

perature sensor from

the T

pressure regulator

Replace as an assembly

trol systems depending on its installa-

tion location

1) Keep the antenna as far as possible

away from the electronic control

units

2) Also keep the antenna feeder line

more than

20 cm (7 9 in) away from

the harness of electronic controls

Do not let them run parallel for a

long distance

3) Adjust the antenna and feeder line so

that the standing-wave ratio can be

keot smaller

J

Handle air flow meter care-

fully to avoid damage * Do not disassemble auxiliary

Do not disassemble air flow air control valve (VG30ET

meter engine)

Do not clean air flow meter

with any type of detergent

0 Even a slight leak in the air in- /

&&%$$?&

take system can cause serious

problems

Do not depress accelerator Do not shock or jar the crank

angle sensor

Immediately after starting, do

pedal when starting

not rev

up engine unneces-

sarily

Do not rev up engine just prioi

to shutdown

Do not operate fuel pump when

there is no fuel in lines Do not use anti-freeze agents in fuel

0 Do not reuse fuel hose clamps

0 Tighten fuel hose clamps sufficiently

Securely connect E C C S harness

connectors

A poor connection can cause an ex-

tremely

high (surge) voltage to

develop in coil and condenser, thus

resulting in damage to IC circuit

Keep

E C C S harness at least 10 cm

(3 9 in) away from adjacent

harnesses, to prevent an

E C C S

system malfunction due to reception

of external noise, degraded operation

of

IC circuit. etc

Keep E C C S parts and harnesses

Before removing parts, turn off igni-

tion switch and then disconnect

battery ground cable dry

SEF6008

EF & EC-2

Page 10 of 79

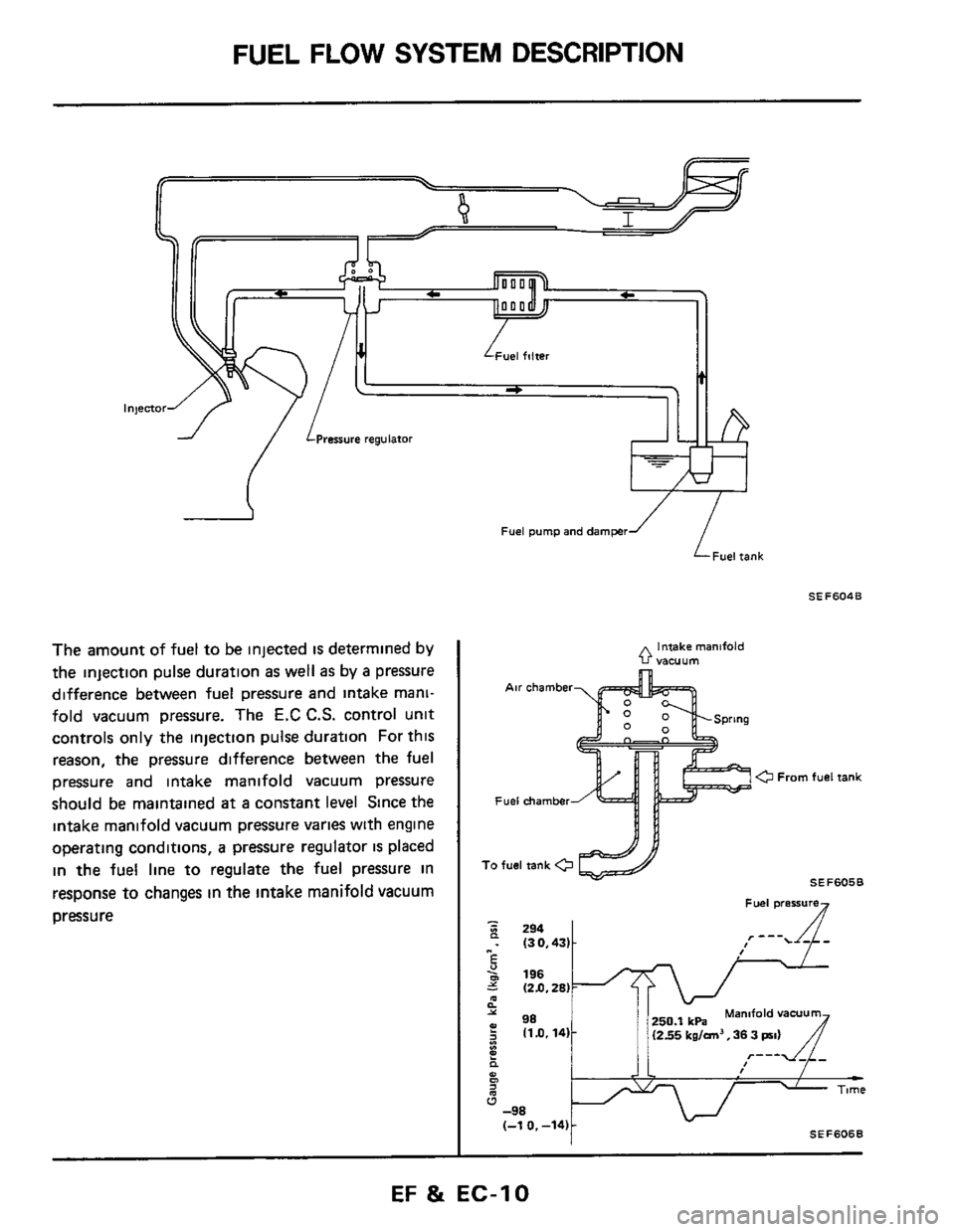

FUEL FLOW SYSTEM DESCRIPTION

The amount of fuel to be injected is determined by

the injection pulse duration

as well as by a pressure

difference between fuel pressure and intake mani-

fold vacuum pressure. The

E.C C.S. control unit

controls only the injection pulse duration For this

reason,

the pressure difference between the fuel

pressure and intake manifold vacuum pressure

should be maintained

at a constant level Since the

intake manifold vacuum pressure varies with engine

operating conditions,

a pressure regulator IS placed

in the fuel line to regulate the fuel pressure in

response to changes

in the intake manifold vacuum

pressure

Fuel pump and damper

’ iFueirank

SEF604B

intake manifold 0 vacuum

a From fuel tank

Fuel chamber

SEF605B

Fuel presswe

EF & EC-10

Page 17 of 79

E. C. C. S. DESCRIPTION

E.C.C.S. Corn

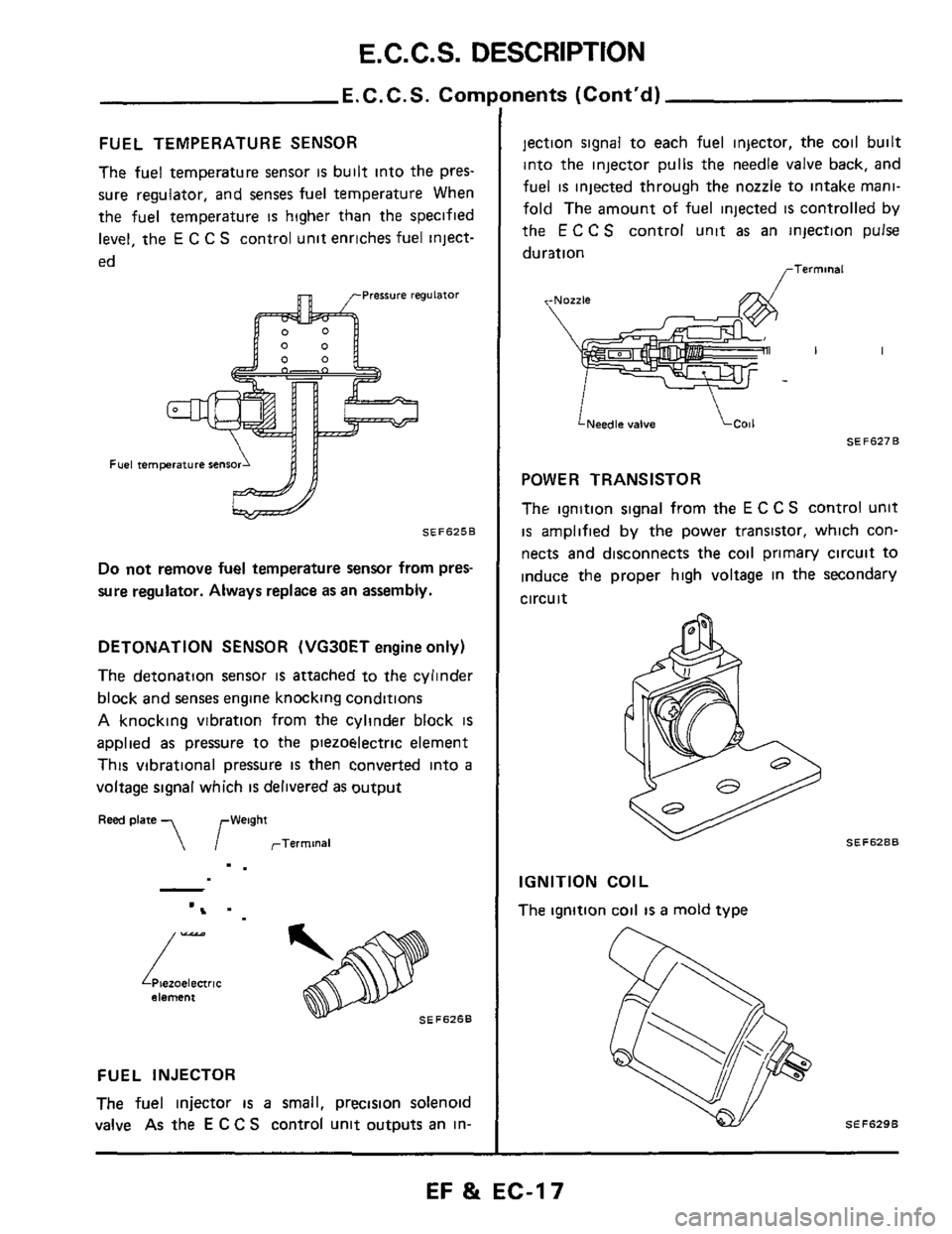

FUEL TEMPERATURE SENSOR

The fuel temperature sensor is built into the pres-

sure regulator, and senses fuel temperature When

the fuel temperature

IS higher than the specified

level, the

E C C S control unit enriches fuel inject-

ed

Pressure regulator

Fuel temprature $ens

SEF625B

Do not remove fuel temperature sensor from pres-

sure regulator. Always replace as

an assembly.

DETONATION SENSOR (VG30ET engine only)

The detonation sensor

is attached to the cylinder

block and senses engine knocking conditions

A knocking vibration from the cylinder block is

applied as pressure to the piezoelectric element

This vibrational pressure

IS then converted into a

voltage signal which is delivered as output

Reed plate ,, ,-Weight

rTerminal

-.

Piezoelectric element

SEFSZSB

/-

FUEL INJECTOR

The

fuel injector is a small, precision solenoid

valve As the

E C C S control unit outputs an in-

lnents (Cont’d)

jection signal to each fuel injector, the coil built

into the injector pulls the needle valve back, and

fuel

is injected through the nozzle to intake mani-

fold The amount of fuel injected

is controlled by

the

E C C S control unit as an injection pulse

duration

<-Nozzle

LNeedle valve

SEF627B

POWER TRANSISTOR

The ignition signal from the

E C C S control unit

is amplified by the power transistor, which con-

nects and disconnects the coil primary circuit to

induce the proper high voltage in the secondary

circuit

SEFSZBB

IGNITION COIL

The ignition coil

IS a mold type

EF & EC-17

Page 63 of 79

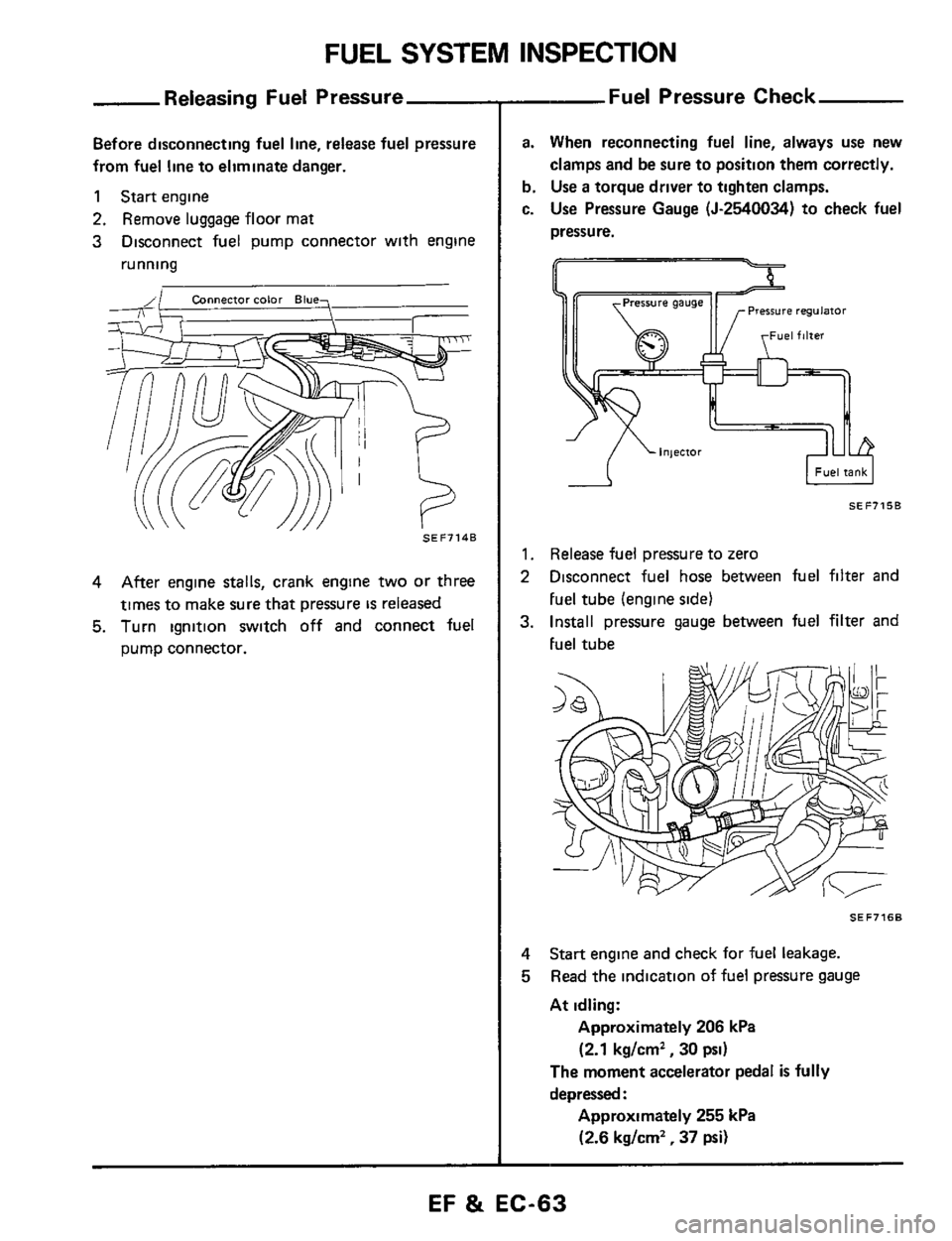

FUEL SYSTEM INSPECTION

Releasing Fuel Pressure

Before disconnecting fuel line, release fuel pressure

from fuel line to eliminate danger.

1 Start engine

2. Remove luggage floor mat

3 Disconnect fuel pump connector with engine

running

SEF7148

4 After engine stalls, crank engine two or three

times to make sure that pressure

IS released

5. Turn ignition switch off and connect fuel

pump connector.

--Fuel Pressure Check

a. When reconnecting fuel line, always use new

clamps and be sure to position them correctly.

b. Use a torque driver to tighten clamps.

c.

Use Pressure Gauge (5-2540034) to check fuel

pressure.

I Fuel tank I -A

SEF7158

1. Release fuel pressure to zero

2 Disconnect fuel hose between fuel filter and

Fuel tube (engine side1

3. Install pressure gauge between fuel filter and

Fuel tube

SEF7168

4

5

Start engine and check for fuel leakage.

Read the indication of fuel pressure gauge

At idling:

Approximately 206 kPa

(2.1 kg/cm2, 30 psi)

The moment accelerator pedal is fully

depressed

:

Approximately 255 kPa

(2.6 kg/cm2, 37 psi)

EF & EC-63

Page 64 of 79

FUEL SYSTEM INSPECTION

Fuel Pressure Check (Cont'd)

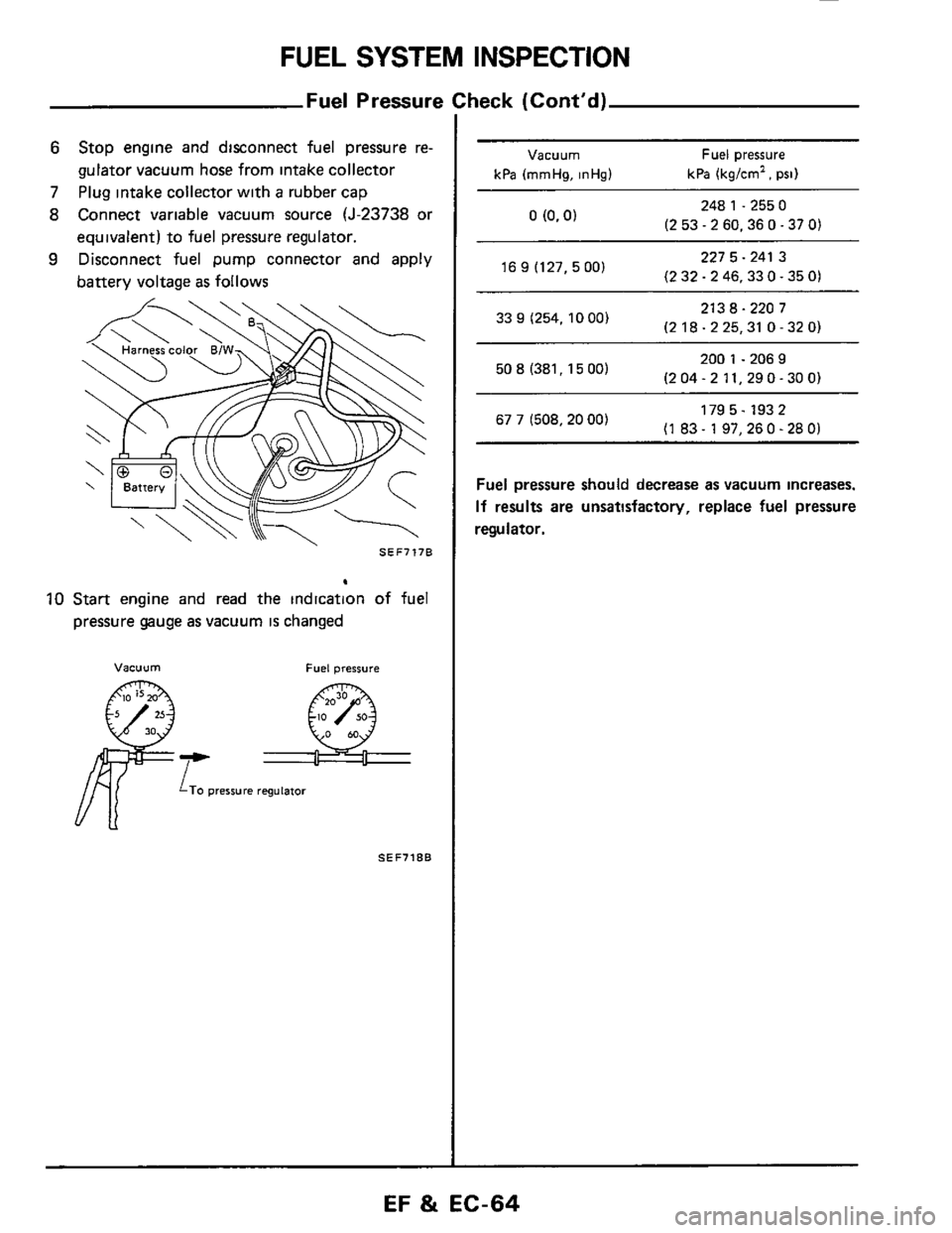

6 Stop engine and disconnect fuel pressure re-

gulator vacuum hose from intake collector

7

Plug intake collector with a rubber cap

8 Connect variable vacuum source (J-23738 or

equivalent) to fuel pressure regulator.

9 Disconnect fuel pump connector and apply

battery voltage

as follows

SEF717B

10 Start engine and read the indication of fuel

pressure gauge as vacuum is changed

Vacuum Fuel prerrure

SEF718B

Vacuum Fuel pressure

kPa (mmHg, inHg) kPa (kg/cm2, psi1

0 (0.01 248 1 .255 0

(2 53

- 2 60.36 0.37 01

227 5.241 3

(2 32.2 46,330.35

01 16 9 (127, 5 00)

213 8.220 7

(2 18.2 25,31 0 - 32 01 33 9 (254. 10 001

200 1 - 206 9

(2 04

- 2 11.29 0- 30 01 50 8 (381,15 00)

179 5. 193 2

(1 83-197.260-280) 67 7 (508.20 00)

Fuel pressure should decrease as vacuum increases.

If results are unsatisfactory, replace fuel pressure

regulator.

EF 8t EC-64

Page 65 of 79

FUEL SYSTEM INSPECTION

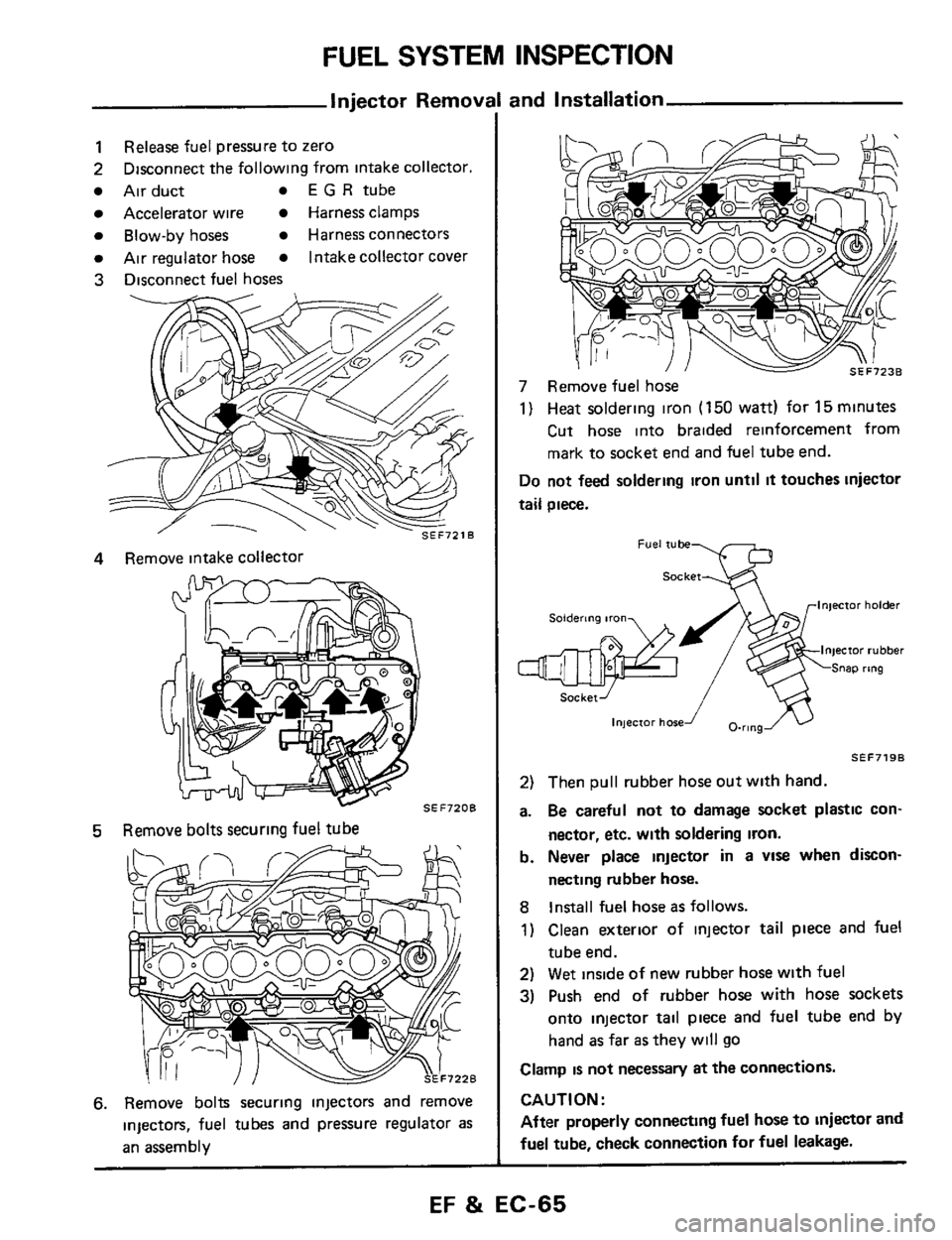

Injector Removi

1

2

Air duct E G R tube

Accelerator wire Harness clamps

Blow-by hoses Harness connectors

Air regulator hose Intakecollector cover

3 Disconnect fuel hoses

Release fuel pressure to zero

Disconnect the following from intake collector.

4 Remove intake collector

5 Remove bolts securing fuel tube

6. Remove bolts securing injectors and remove

injecton, fuel tubes and pressure regulator

as

an assembly

and installation

7 Remove fuel hose

1) Heat soldering iron (150 watt) for 15minutes

Cut hose into braided reinforcement from

mark to socket end and

fuel tube end.

Do not feed soldermg iron until it touches injector

tail piece.

Socket

Fuel tube

Injector holder Soldering iron

InjeCtor rubber

Snap rtng

injector hosef O-ring

SEF719B

2) Then pull rubber hose out with hand.

a.

Be careful not to damage socket plastic con-

nector, etc. with soldering

iron.

b. Never place injector in a VIS when dixon-

necting rubber hose.

8

Install fuel hose as follows.

1) Clean exterior of injector

tail piece and fuel

tube end.

2) Wet inside of new rubber hose with fuel

3) Push end of rubber hose with hose sockets

onto injector tail piece and fuel tube end by

hand

as far as they will go

Clamp is not necessary at the connections.

CAUTION:

After properly connecting fuel hose

to injector and

fuel tube, check connection

for fuel leakage.

EF & EC-65

Page 77 of 79

EVAPORATIVE EMISSION CONTROL SYSTEM

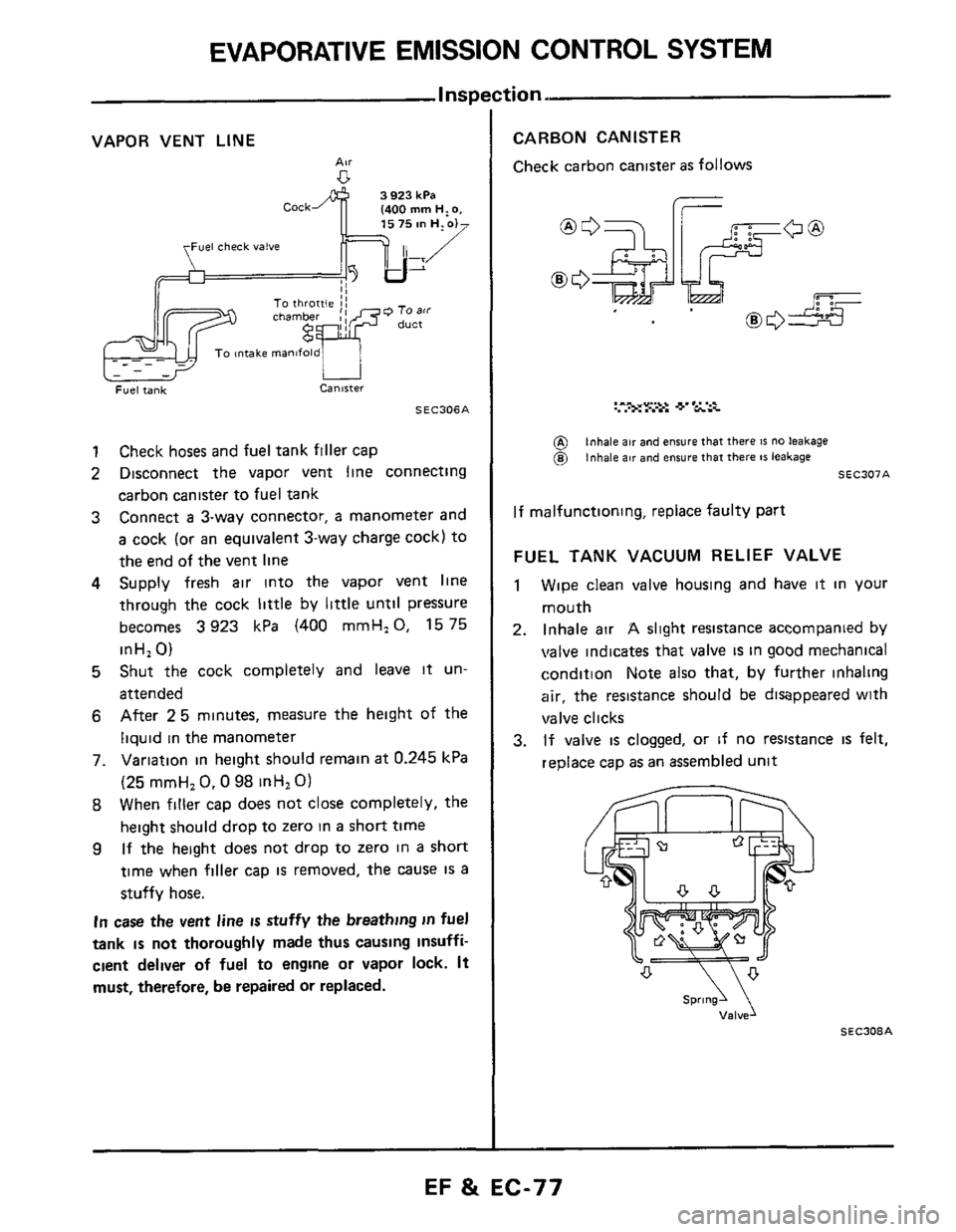

VAPOR VENT LINE

AN

Fuel check valve

SEC306A

1 Check hoses and fuel tank filler cap

2 Disconnect the vapor vent line connecting

carbon canister to fuel tank

3 Connect a 3-way connector, a manometer and

a cock (or an equivalent 3-way charge cock) to

the end of the vent line

4 Supply fresh air into the vapor vent line

through the cock

little by little untll pressure

becomes

3923 kPa (400 mmH,O, 1575

inH,

0)

5 Shut the cock completely and leave it un-

attended

6 After 25 minutes, measure the height of the

liquid

in the manometer

7. Variation in height should remain

at 0.245 kPa

(25 mmH,

0.0 98 inHl 0)

8 When filler cap does not close completely, the

height should drop to zero in

a short time

9 If the height does not drop to zero in a short

time when filler cap is removed, the cause IS a

stuffy hose.

In case the vent line is stuffy the breathing in fuel

tank

is not thoroughly made thus causing insuffi-

cient deliver of fuel to engine or vapor lock. It

must, therefore, be repaired or replaced.

tion.

CARBON CANISTER

Check carbon canister as follows

I-

UL

@ @)

inhale air and ensure that there IS no leakage inhale air and ensure that there 81 leakage

SEC307A

If malfunctioning, replace faulty part

FUEL TANK VACUUM RELIEF VALVE

1 Wipe clean valve housing and have it in your

mouth

2. Inhale air A slight resistance accompanied by

valve indicates that valve is in good mechanical

condition Note also that, by further inhaling

air, the resistance should be disappeared with

valve clicks

3. If valve is clogged, or if no resistance is felt,

replace cap

as an assembled unit

SEC308A

EF & EC-77

Page 79 of 79

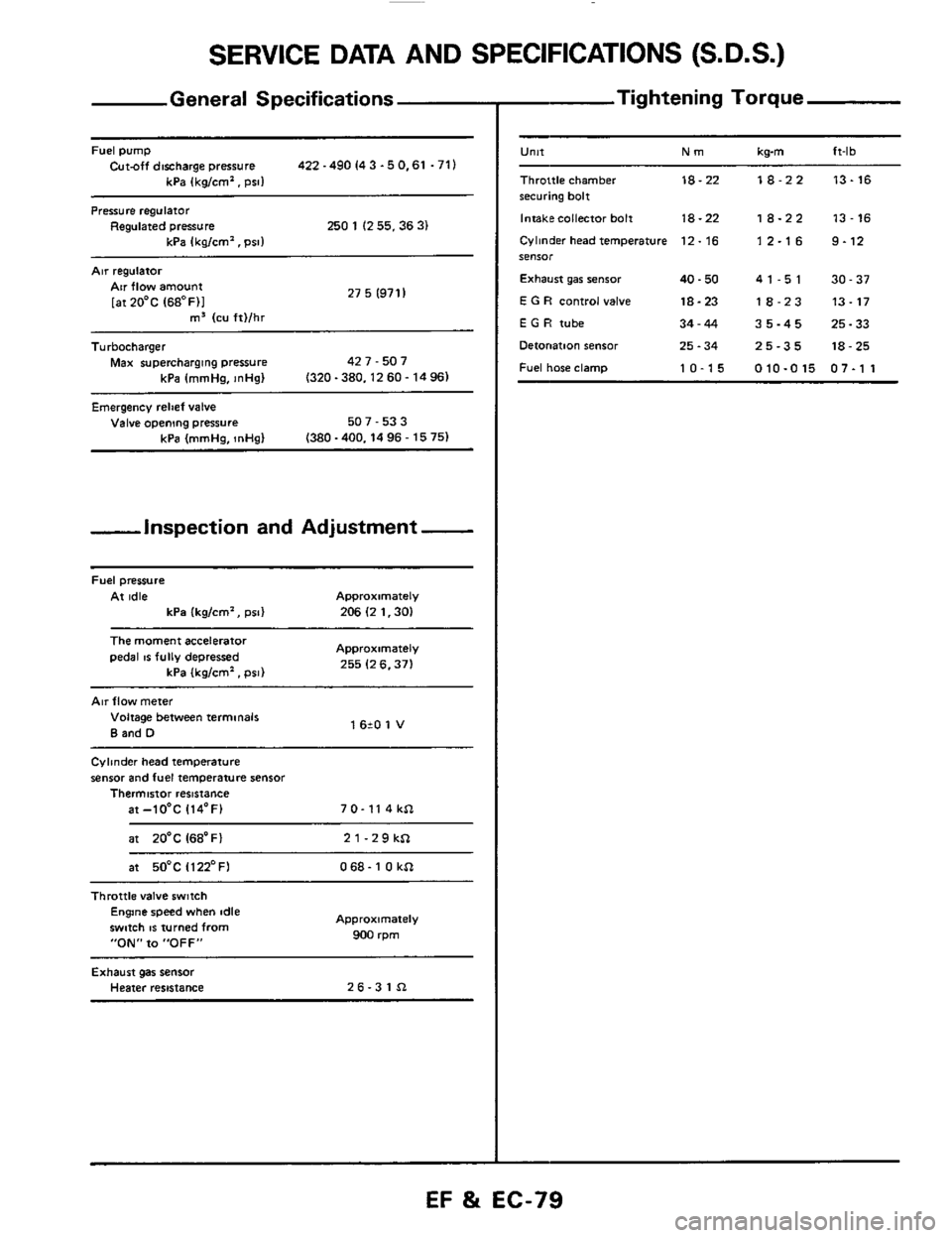

SERVICE DATA AND SPECIFICATIONS (S.D.S.)

General Specifications

Fuel pump Cut-off discharge pressure 422 -490 I4 3 -5 0.61 .71)

kPa (kg/cm'. psi1

Pressure regulator Regulated pressure 250 1 (2 55.36 3) kPa Ikalcm'. Dsll

Air regulatoi

27 5 (971 I Air flow amount

[atZO'C (68OF)I m3 (cu ft)/hr ~~

Turbocharger

Max supercharging pressure 42 7 - 507

kPa (mmHa.

InHal (320-380.1260-1496)

Emergency relief valve Valve opening pressure 507 - 53 3

(380 -400.14 96 - 15 75) kPa (mmHg, InHg)

-inspection and Adjustment -

Fuel pressure

At idle Approximately

kPa (kg/cm', psi) 206 (2 1.30)

The moment accelerator

pedal IS fully depressed Approximately

255 (2 6.371 kPa (kglcm'. psi)

Air flow meter

Voltage between terminals

B and D 1 620 1 V

Cylinder head temperature

sensor and fuel temperature sensor Thermistor resistance

at-lO'C 114'F) 7 0- 11 4 kSl

at 20'C I68'Fl 21-29kSl

at 50°C Il22'FI 068- 1 0 kSl ~~~~

Throttle

valve switch Engine speed when idle

swmh

IS turned from

"ON" to "OFF"

Approximately

900 rpm

Exhaust gas sensor Heater resistance 26-31Sl

- Tightening Torque

-

U"lt Nm kwn ft-lb

Throttle chamber 18-22 18-22 13-16 securing bolt

Intakecollector bolt

18-22 18-22 13-16

Cylinder head temperature 12. 16 1 2.1 6 9.12 SeIlSOr

Exhaust gar senior 40.50 41-51 30-37

E G R control valve 18-23 18-23 13-17

E G H tube 34-44 35-45 25-33

Detonation sensor 25.34 25-35 18-25

Fuel hose clamp 10-15 010-015 07-1 1

EF %i EC-79