suspension NISSAN 300ZX 1984 Z31 Front Suspension Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 24, PDF Size: 0.68 MB

Page 1 of 24

FRONT AXLE &

FRONT SUSPENSION

SECTION FA

CONTENTS

FRONT AXLE AND FRONT SUSPENSION .. . ..

FRONT AXLE - Wheel Hub . . . . ..

FRONT SUSPENSION . . . .. .

FRONT SUSPENSION -Spring and Strut Assembly

TENSION ROD AND STABILIZER BAR

TRANSVERSE LINK AND LOWER BALL JOINT

. .

SUSPENSION CROSSMEMBER .. .

ADJUSTABLE SHOCK ABSORBER .. . . .. .

SERVICE DATA AND SPECIFICATIONS (S D S )

SPECIAL SERVICE TOOLS . .

.

..

. FA- 2

FA- 3

FA- 6

FA- 7

FA-1 1

. FA-12

FA-14

. . . FA-15

. . FA-22

. FA-24

RL

Page 2 of 24

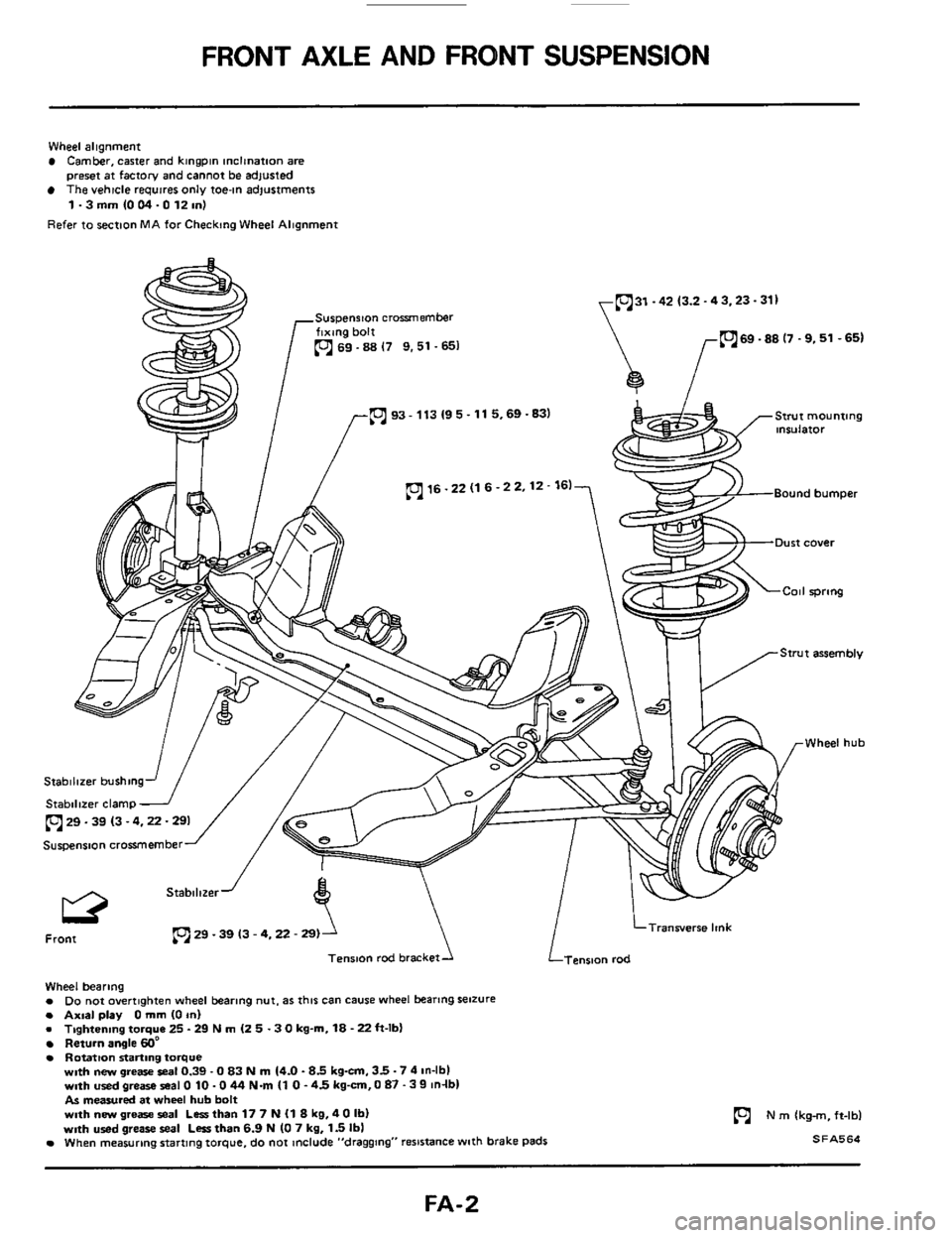

FRONT AXLE AND FRONT SUSPENSION

Wheel alignment Camber, caster and kingpin inclination are preset at factory and cannot be adjusted The vehicle requires only toe-in adjustments

1-3 mm (0 04 -0 12 m)

Refer to section MA for Cheekmg Wheel Alignment

Wheel bearing Do not overtighten wheel bearing nut. as this can cause wheel bearing seizure Axial play 0 mm (0 on) . Tbghtenmg torque 25 - 29 N m (2 5 .3 0 kg-m. 18 - 22 ft-lb)

Return angle 60' Rotation narting torque with new grease seal 0.39.0 83 N m (4.0 - 8.5 kg-cm, 3.5.7 4 dbl wth used grease sal 0 10.0 44 N.m (1 0 - 4.5 kvm, 0 87.3 9 #nib) As measured at wheel hub bolt with new grease seal Lerr than 17 7 N (1 8 kg, 4 0 Ib) with used grease seal Lerr than 6.9 N 10 7 kg, 1.5 Ibl When measuring starting torque. do not include "dragging" resistance with brake pads

N m (kg-m, ft-lbl

SFA564

FA-2

Page 6 of 24

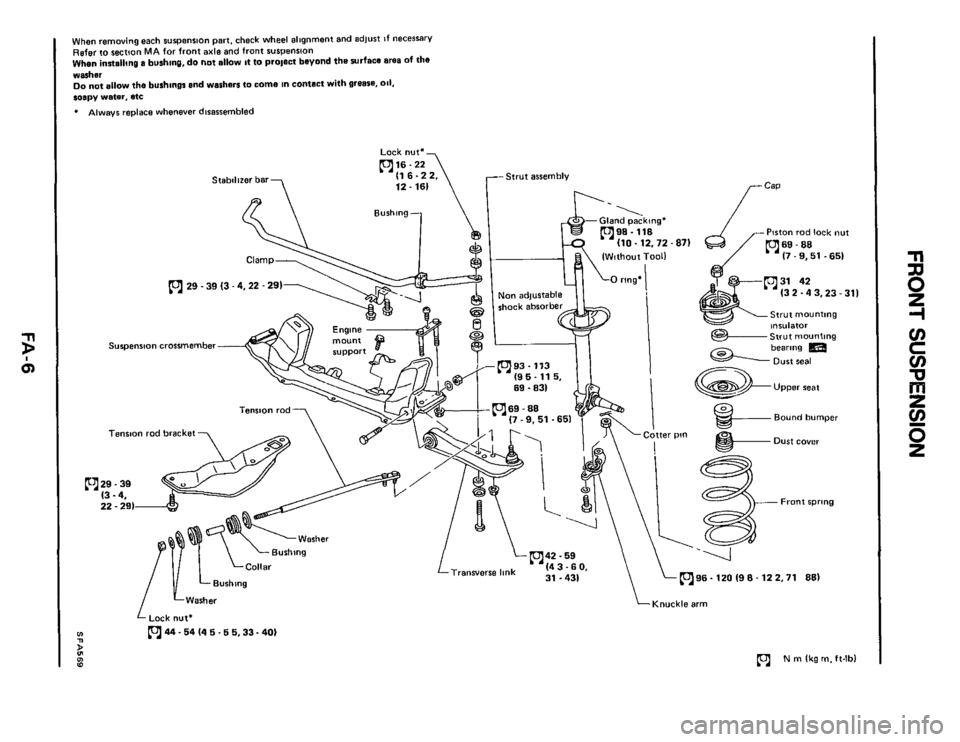

When removing each s~~pension part, check wheel allgnrnent and adlust If necessary

Refer to section MA for front axle and front suspension When innalling a bushing, do not allow It to prolect beyond the surface ares of the

warhsr

Do not allow the bushings and washers to come in conlact with grease. 011. soapy water. etc

* Always replace whenever disassembled

Strut assembly

Piston rad lock nut

(3 2.4 3,23 - 311

Strut mounting

Suspension crossmember

Tension rod bracket

m29-39

(3 - 4. 22.291

m96.120 19 8.12 2.71 881 Transverse link

LWasher

Lock nut*

m44- 54 (4 5.6 5,33- 40) m n

Knuckle arm

(c1 N m (kg m. ft-lbl g 0 10

n

8

z

-I

v)

c

v)

'cl

v)

z

e

5

Page 7 of 24

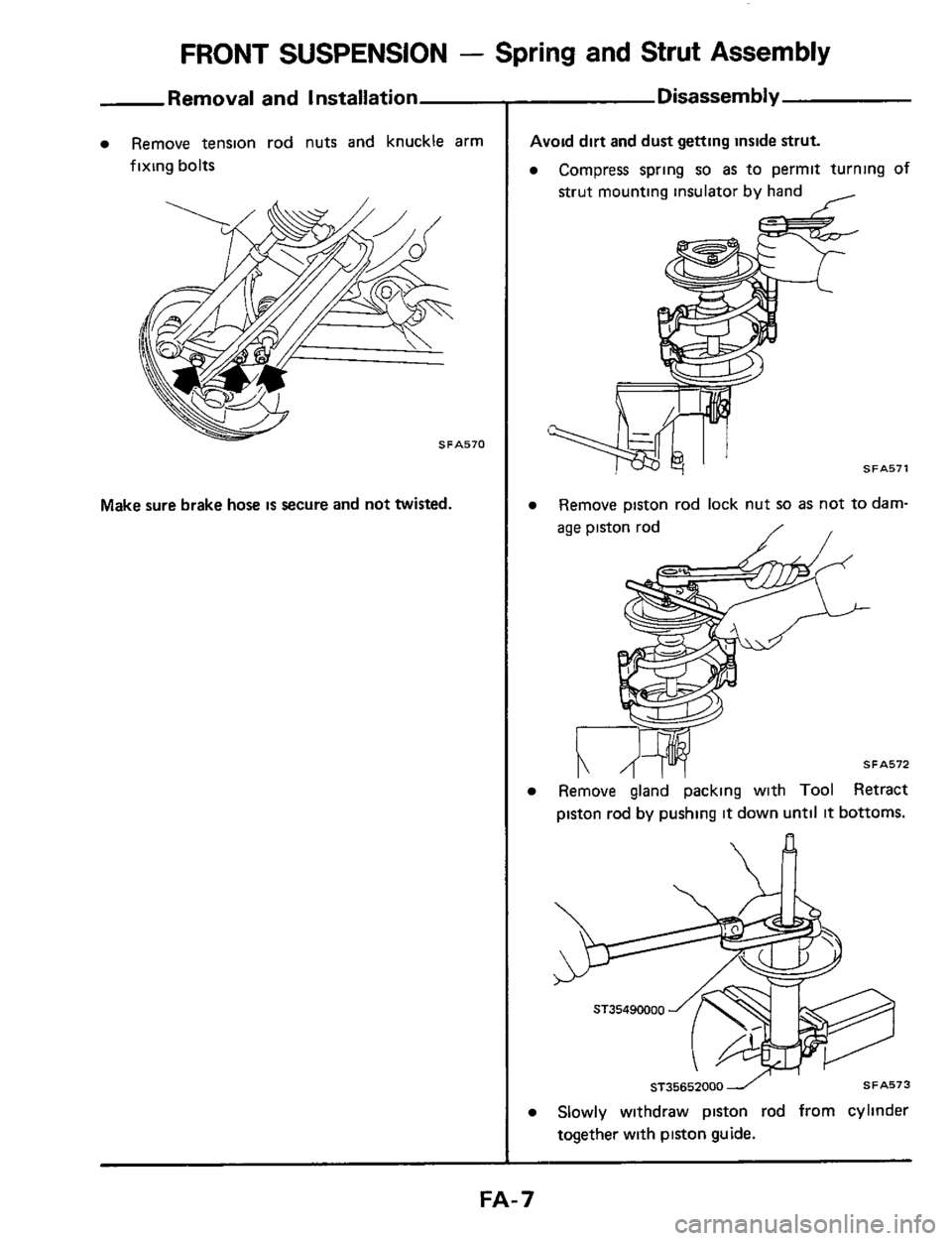

FRONT SUSPENSION - Spring and Strut Assembly

Removal and Installation

Remove tension rod nuts and knuckle arm

fixing bolts

Make sure brake hose is secure and not twisted.

Disassembly

Avoid dirt and dust getting inside strut.

Compress spring so as to permit turning of

strut mounting insulator by hand I

SFA571

Remove piston rod lock nut so as not to darn-

age piston rod / /

Remove gland packing with Tool Retract

piston rod

by pushing it down until it bottoms.

n

ST35652000 1 SFA573

Slowly withdraw piston rod from cylinder

together with piston guide.

FA- 7

Page 8 of 24

FRONT SUSPENSION - Spring and Strut Assembly

I nspl

Wash all parts, except for nonmetallic parts,

clean with suitable solvent and dry with com-

pressed air.

a Blow dirt and dust off of nonmetallic parts

using compressed air

a. Oil oozing out around gland packing does not

call for strut replacement.

If oil leakage

is evident on spring seat, check

piston rod and gland packing to correct

the

cause of problem.

If oil leakage occurs on welded portion of

outer strut

casing, replace strut assembly.

b. If shock absorber itself is malfunctioning,

replace

as shock absorber kit (including piston

rod, cylinder, bottom

valve and guide bushing).

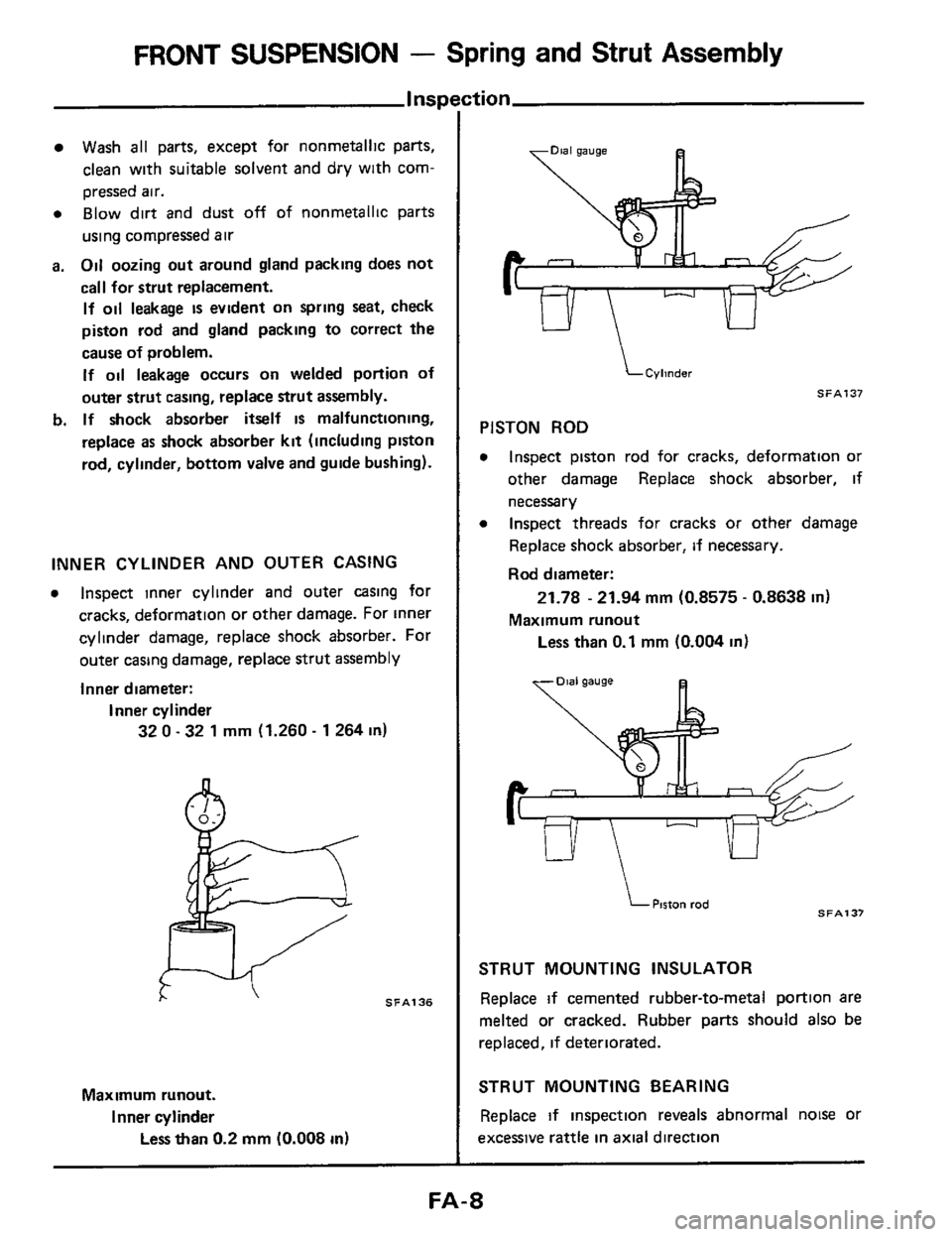

INNER CYLINDER AND OUTER CASING

a Inspect inner cylinder and outer casing for

cracks, deformation or other damage. For inner

cylinder damage, replace shock absorber. For

outer casing damage, replace strut assembly

Inner diameter:

Inner cylinder

32 0.32 1 mm (1.260 - 1 264 in)

n

SFA136

Maximum runout.

Inner cylinder

Less than 0.2 mm (0.008 in)

LCylinder

SFA137

PISTON ROD

a Inspect piston rod for cracks, deformation or

other damage Replace shock absorber, if

necessary Inspect threads for cracks or other damage

Replace shock absorber, if necessary.

Rod diameter:

Maximum runout

a

21.78 - 21.94 mm (0.8575 - 0.8638 in)

Less than 0.1 mm (0.004 in)

To'ai gauge R

SFA137 Piston rod

STRUT MOUNTING INSULATOR

Replace if cemented rubber-to-metal portion are

melted or cracked. Rubber parts should also be

replaced, if deteriorated.

STRUT MOUNTING BEARING

Replace if inspection reveals abnormal noise or

excessive rattle in axial direction

FA-8

Page 9 of 24

FRONT SUSPENSION - Spring and Strut Assembly

c _. _.

e 78i8.581 .

: +

0

59 16,431

Assc

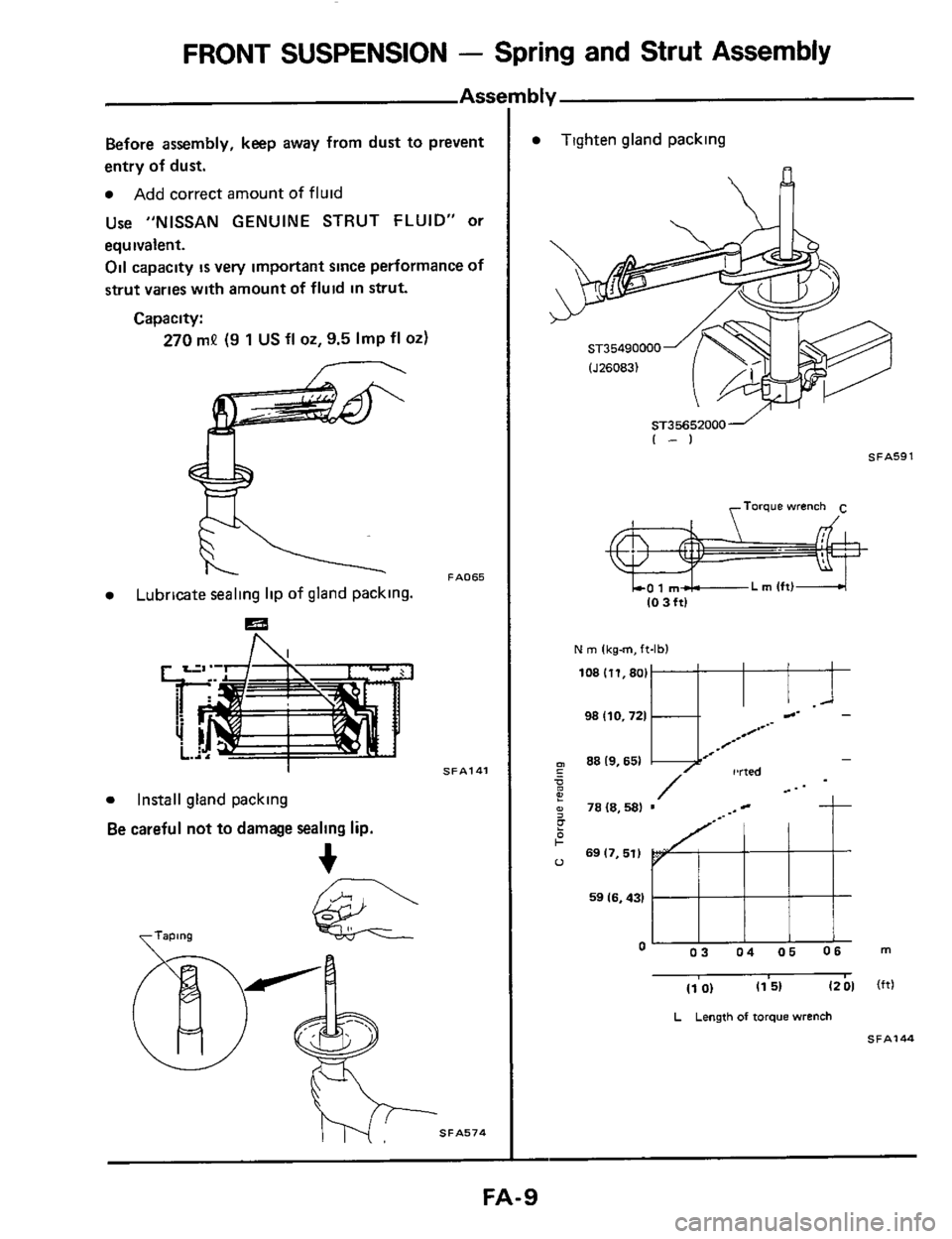

Before assembly, keep away from dust to prevent

entry of dust.

Use "NISSAN GENUINE STRUT FLUID" or

equivalent.

Oil capacity

is very important since performance of

strut varies with amount of fluid in strut.

Add correct amount of fluid

Capacity:

270 me (9 1 US fl oz,9.5 Imp fl 02)

__

Lubricate sealing lip of gland packing.

Ea

Install gland packing

Be careful not to damage sealing lip.

FA065

SFA141

Tighten gland packing

ST35652000l 1-1

rTnrque wrench c

lo^, m-I-L m iftJd 10 3ftl

N m Ikg-m,ft-lbl

SFAS91

rn

I I1 01 I1 51 1201 (ftl

L Length of torque wrench

SFA144

FA-9

Page 10 of 24

FRONT SUSPENSION - Spring and Strut Assembly

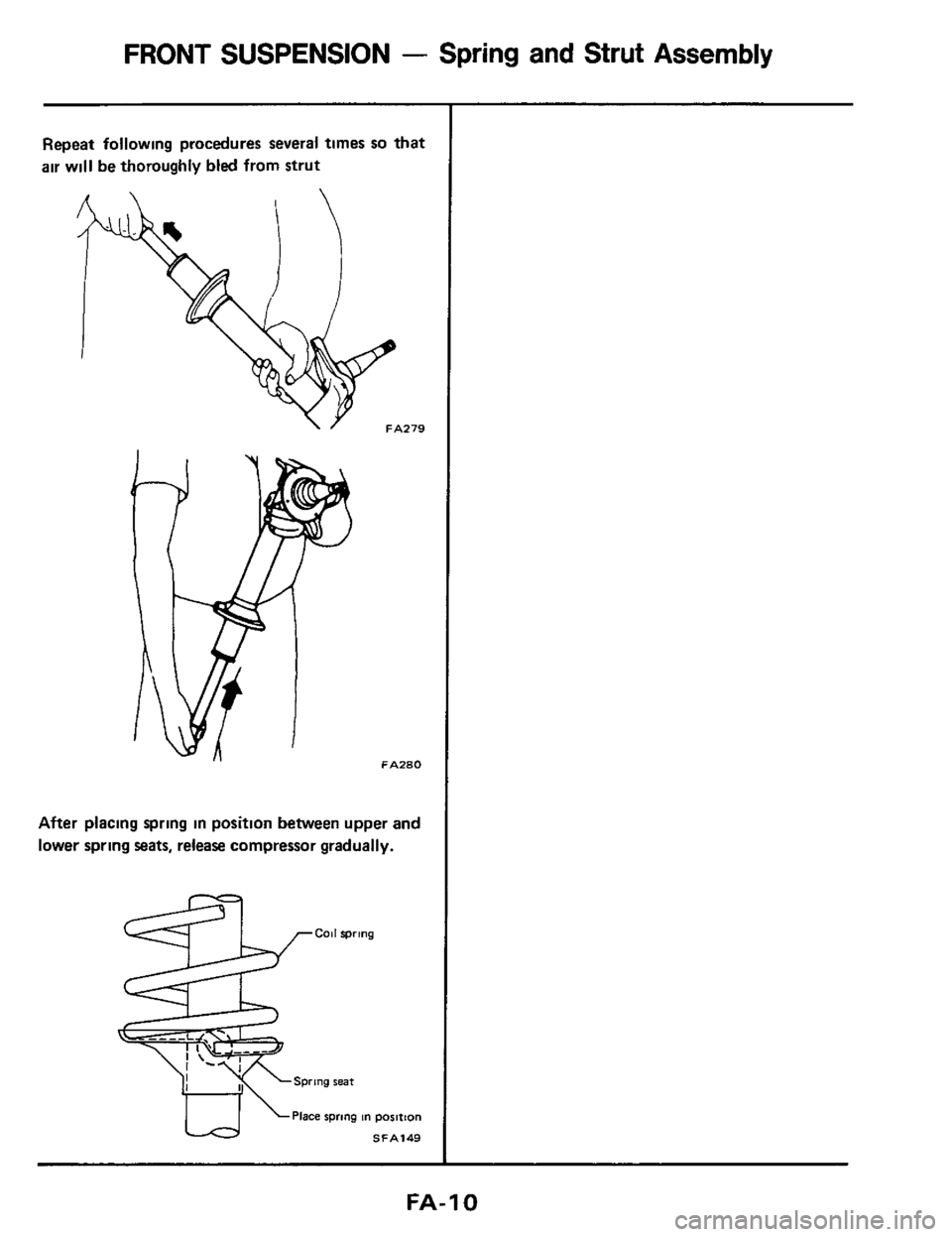

Repeat following procedures several times so that

air will be thoroughly bled from strut

FA279

FA280

After placing spring in position between upper and

lower spring seats, release compressor gradually.

‘-piace spring m positton

SFA149

FA-I 0

Page 12 of 24

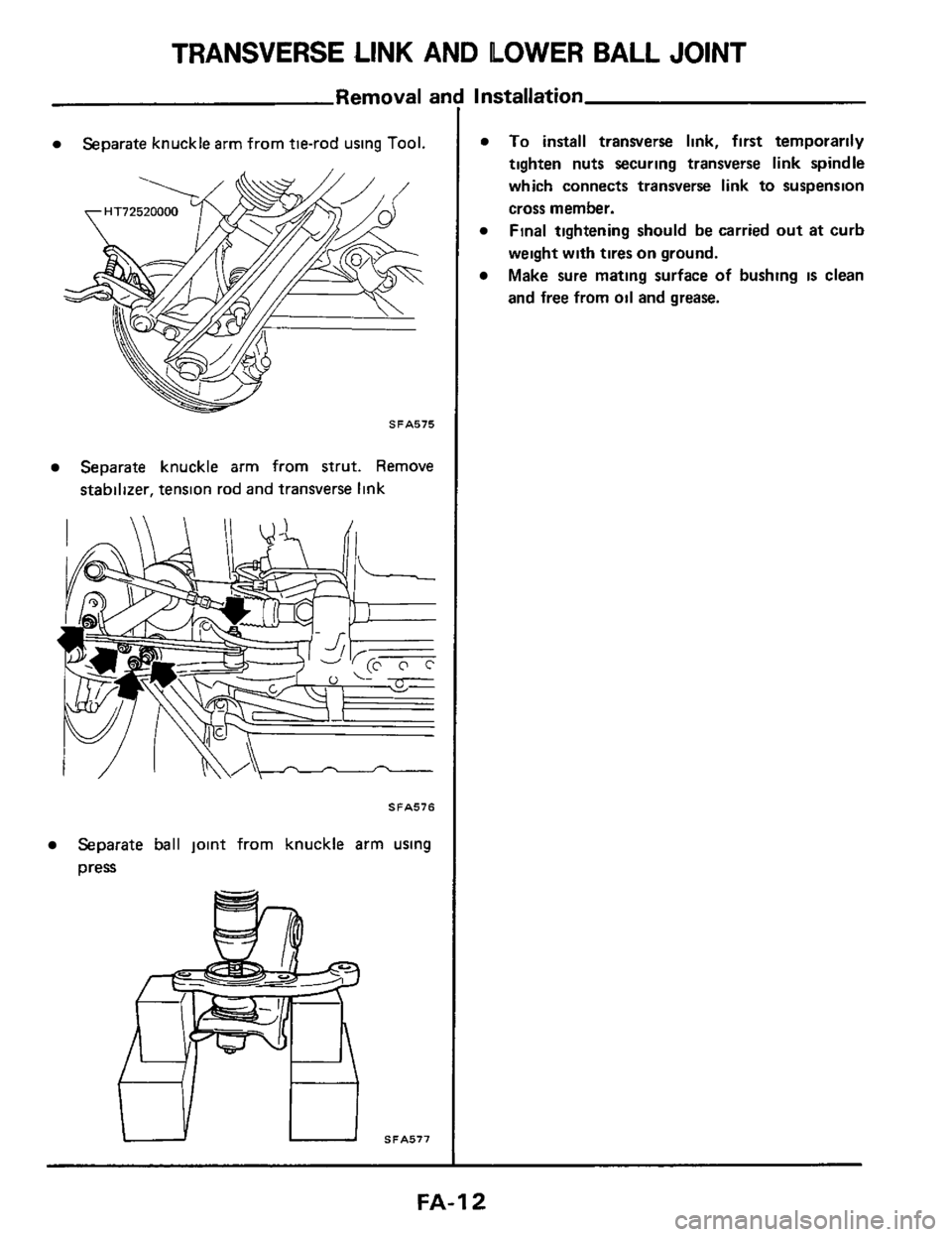

TRANSVERSE LINK AND LOWER BALL JOINT

Removal ar

Separate knuckle arm from tie-rod using Tool.

SFA575

Separate knuckle arm from strut. Remove

stabilizer, tension rod and transverse link

SFA576

Separate ball joint from knuckle arm using

press

SFA577

Installation

To install transverse link, first temporarily

tighten nuts securing transverse

link spindle

which connects transverse

link to suspension

cross member.

Final tightening should be carried out at curb

weight with tires

on ground.

Make sure mating surface of bushing

is clean

and free from oil and grease.

FA-I 2

Page 14 of 24

SUSPENSION CROSSMEMBER

Removal and Installation

Precaution

Support engine weight to remove

load from engine

mounting.

Inspection

Check suspension crossmember for deformation or

cracking. Replace

if necessary.

FA-I 4

Page 16 of 24

ADJUSTABLE SHOCK ABSORBER

-Removal and Installation (Cont'dL

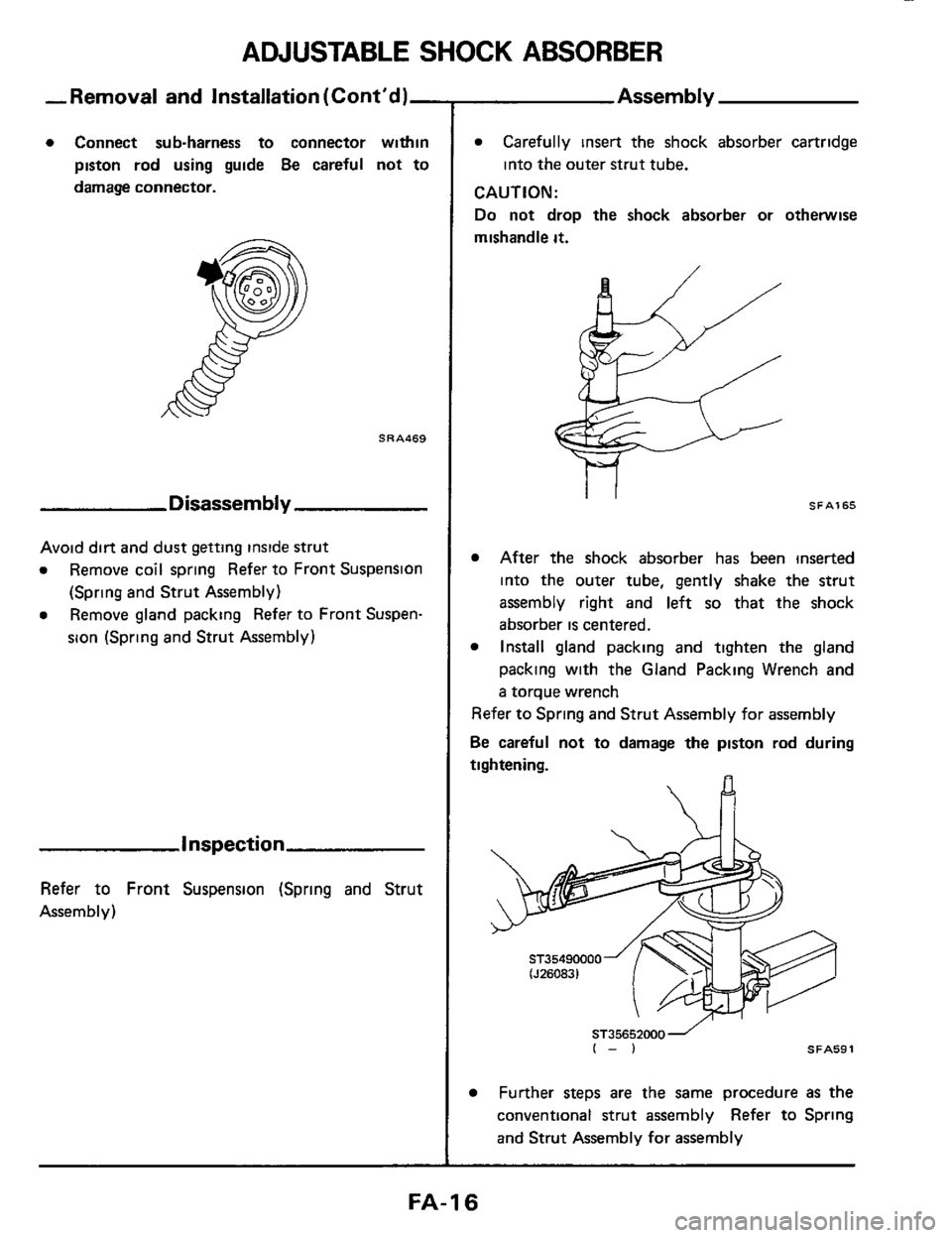

0 Connect sub-harness to connector within

piston rod using guide

Be careful not to

damage connector.

SRA469

Disassembly

Avoid dirt and dust getting inside strut

0 Remove coil spring Refer to Front Suspension

0 Remove gland packing Refer to Front Suspen-

(Spring and Strut Assembly)

sion (Spring and Strut Assembly)

Inspection

Refer to Front Suspension (Spring and Strut

Assembly)

0 Carefully insert the shock absorber cartridge

into the outer strut tube.

CAUTION:

Do not drop the shock absorber or otherwise

mishandle

it.

SFA165

After the shock absorber has been inserted

into the outer tube, gently shake the strut

assembly right and left

so that the shock

absorber

is centered.

Install gland packing and tighten the gland

packing with the Gland Packing Wrench and

a torque wrench

Refer to Spring and Strut Assembly for assembly

Be careful not to damage the piston rod during

tightening.

ST35652000- I-) SFA591

Further steps are the same procedure as the

conventional strut assembly Refer to Spring

and Strut Assembly for assembly

FA-I 6