ESP NISSAN ALMERA 2001 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2048 of 2898

SETTING

SEL618X

5. Push ªSETTINGº switch.

6. Select ªSystem Settingº.

SEL559X

7. Select ªGPS Informationº.

SEL146W

8. More than one GPS satellite icon turns green. (It may take 1

to 15 minutes.)

NOTE:

Drive the vehicle for a while* in order to change the receiving

condition of the radio wave from the GPS satellite if the GPS

icon does not turn green.

* The driving distance which is necessary depends on the

receiving condition of the radio wave from the GPS satellite.

9. Push ªMAPº switch and check the following.

+Confirm that the GPS icon on the map turns green.

+Then the position marker should show the current location.

+Position marker rotates corresponding to the movement of the

vehicle.

10. Initialization is completed.

NAVIGATION SYSTEM

Confirmation/Adjustment Mode (Cont'd)

EL-490

Page 2049 of 2898

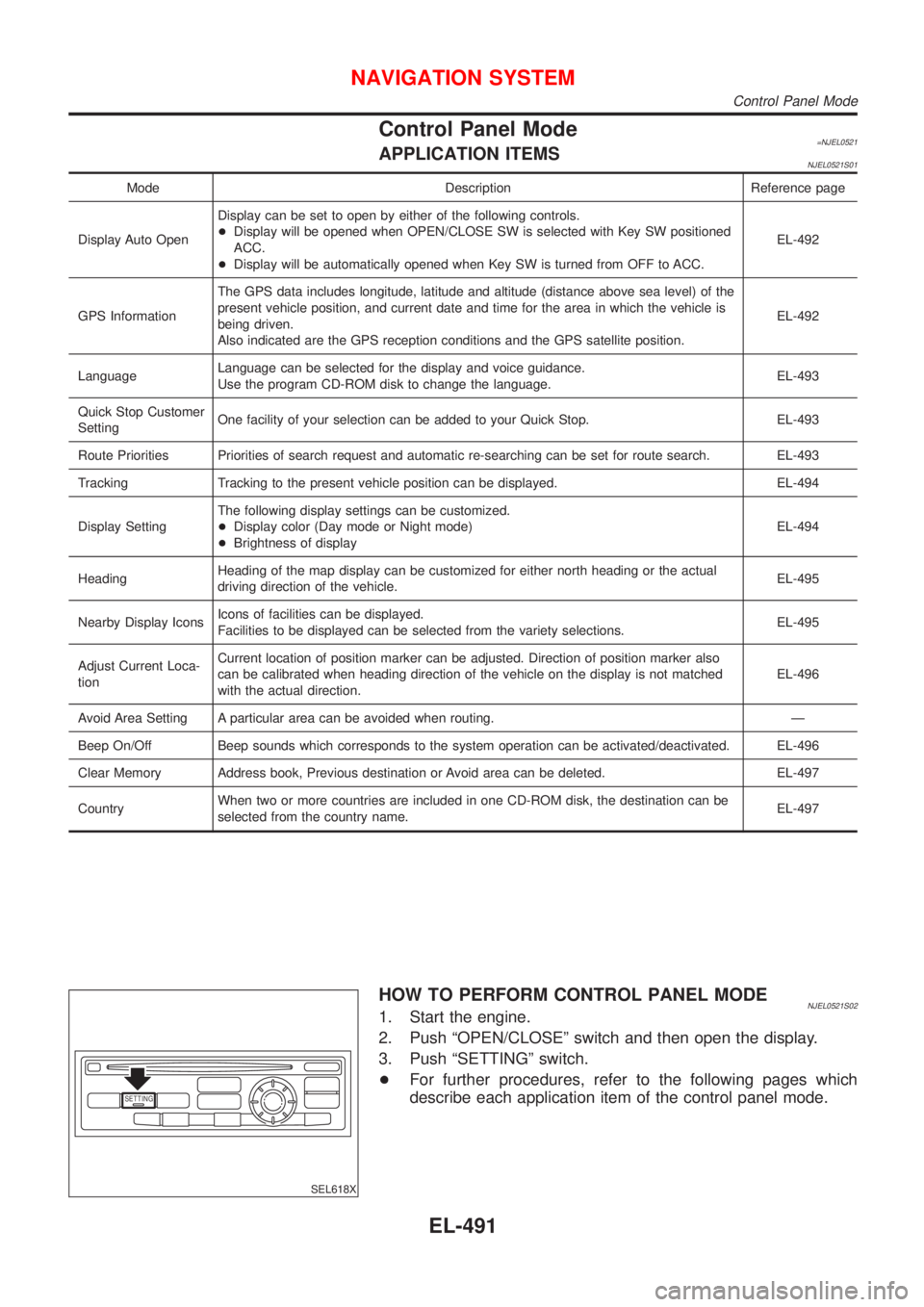

Control Panel Mode=NJEL0521APPLICATION ITEMSNJEL0521S01

Mode Description Reference page

Display Auto OpenDisplay can be set to open by either of the following controls.

+Display will be opened when OPEN/CLOSE SW is selected with Key SW positioned

ACC.

+Display will be automatically opened when Key SW is turned from OFF to ACC.EL-492

GPS InformationThe GPS data includes longitude, latitude and altitude (distance above sea level) of the

present vehicle position, and current date and time for the area in which the vehicle is

being driven.

Also indicated are the GPS reception conditions and the GPS satellite position.EL-492

LanguageLanguage can be selected for the display and voice guidance.

Use the program CD-ROM disk to change the language.EL-493

Quick Stop Customer

SettingOne facility of your selection can be added to your Quick Stop. EL-493

Route Priorities Priorities of search request and automatic re-searching can be set for route search. EL-493

Tracking Tracking to the present vehicle position can be displayed. EL-494

Display SettingThe following display settings can be customized.

+Display color (Day mode or Night mode)

+Brightness of displayEL-494

HeadingHeading of the map display can be customized for either north heading or the actual

driving direction of the vehicle.EL-495

Nearby Display IconsIcons of facilities can be displayed.

Facilities to be displayed can be selected from the variety selections.EL-495

Adjust Current Loca-

tionCurrent location of position marker can be adjusted. Direction of position marker also

can be calibrated when heading direction of the vehicle on the display is not matched

with the actual direction.EL-496

Avoid Area Setting A particular area can be avoided when routing. Ð

Beep On/Off Beep sounds which corresponds to the system operation can be activated/deactivated. EL-496

Clear Memory Address book, Previous destination or Avoid area can be deleted. EL-497

CountryWhen two or more countries are included in one CD-ROM disk, the destination can be

selected from the country name.EL-497

SETTING

SEL618X

HOW TO PERFORM CONTROL PANEL MODENJEL0521S021. Start the engine.

2. Push ªOPEN/CLOSEº switch and then open the display.

3. Push ªSETTINGº switch.

+For further procedures, refer to the following pages which

describe each application item of the control panel mode.

NAVIGATION SYSTEM

Control Panel Mode

EL-491

Page 2054 of 2898

SEL552X

6. Select and touch an item on the list.

7. Push ªMAPº switch, then the display will go back to the current

location map.

SEL553X

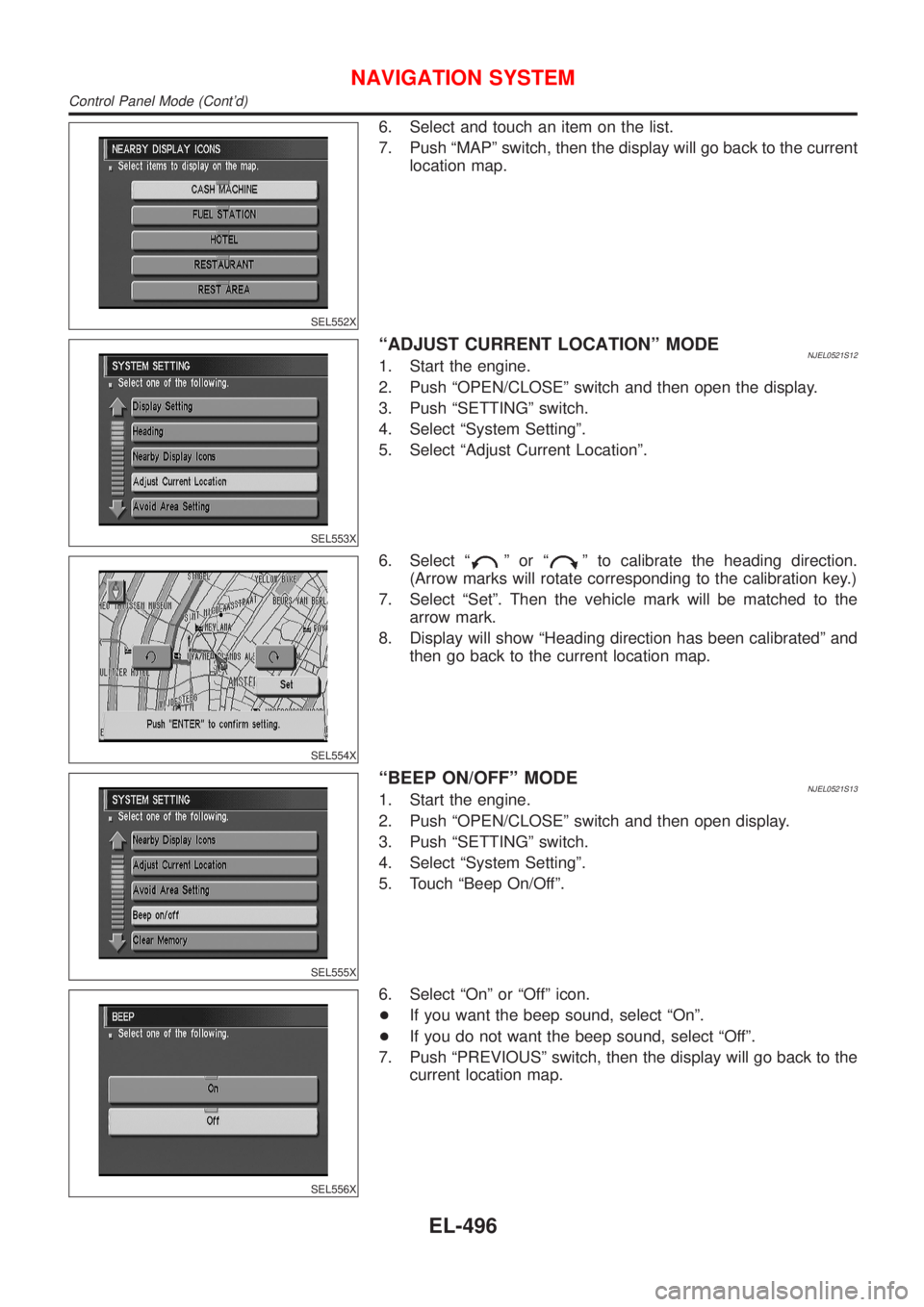

ªADJUST CURRENT LOCATIONº MODENJEL0521S121. Start the engine.

2. Push ªOPEN/CLOSEº switch and then open the display.

3. Push ªSETTINGº switch.

4. Select ªSystem Settingº.

5. Select ªAdjust Current Locationº.

SEL554X

6. Select ªºorªº to calibrate the heading direction.

(Arrow marks will rotate corresponding to the calibration key.)

7. Select ªSetº. Then the vehicle mark will be matched to the

arrow mark.

8. Display will show ªHeading direction has been calibratedº and

then go back to the current location map.

SEL555X

ªBEEP ON/OFFº MODENJEL0521S131. Start the engine.

2. Push ªOPEN/CLOSEº switch and then open display.

3. Push ªSETTINGº switch.

4. Select ªSystem Settingº.

5. Touch ªBeep On/Offº.

SEL556X

6. Select ªOnº or ªOffº icon.

+If you want the beep sound, select ªOnº.

+If you do not want the beep sound, select ªOffº.

7. Push ªPREVIOUSº switch, then the display will go back to the

current location map.

NAVIGATION SYSTEM

Control Panel Mode (Cont'd)

EL-496

Page 2068 of 2898

Possible cause Drive condition Service procedure

Opera-

tionDriving immediately after starting engine.The gyro (angular velocity sensor)

needs about 15 seconds after the

engine is started to precisely sense

the angular velocity.

Directional sensing errors will occur

if the vehicle is moved immediately

after starting the engine. The posi-

tion marker may indicate inaccurate

position.Wait a few moments

between starting the engine

and actually driving the

vehicle.

Continuous driving for long distances (non-stop)When the vehicle is driven continu-

ously without stopping over a long

distance, errors in directional sens-

ing may occur. The position marker

may indicate inaccurate position.Stop the vehicle. Perform

ªSpeed Calibrationº (EL-488).

Rough or violent drivingWheel spinning (peeling out) or simi-

lar rough driving techniques can

adversely affect sensing accuracy.

The position marker may indicate

inaccurate position.If the position marker does

not move to the correct posi-

tion even after the vehicle

has been driven approxi-

mately 10 km (6 miles), per-

form ªAdjust Current Loca-

tionº MODE (EL-496).

Posi-

tional

calibra-

tion

proce-

duresPositional calibration precision

SEL701V

If current vehicle location is roughly

set, the system may be unable to

locate the road that the vehicle is

traveling on. (This is especially true

in an area where there are many

roads.)Perform ªAdjust Current

Locationº MODE (EL-496)

within a precision standard of

1 mm (0.04 in) on the dis-

play.

NOTE:

During calibration, use the

most detailed map possible.

Position calibration direction

SEL702V

When calibrating the position, check

the vehicle direction. If the vehicle

direction is not correct, subsequent

precision of current location will be

affected.Perform ªAdjust Current

Locationº MODE, refer to

EL-496.

NAVIGATION SYSTEM

This Condition Is Not Abnormal (Cont'd)

EL-510

Page 2194 of 2898

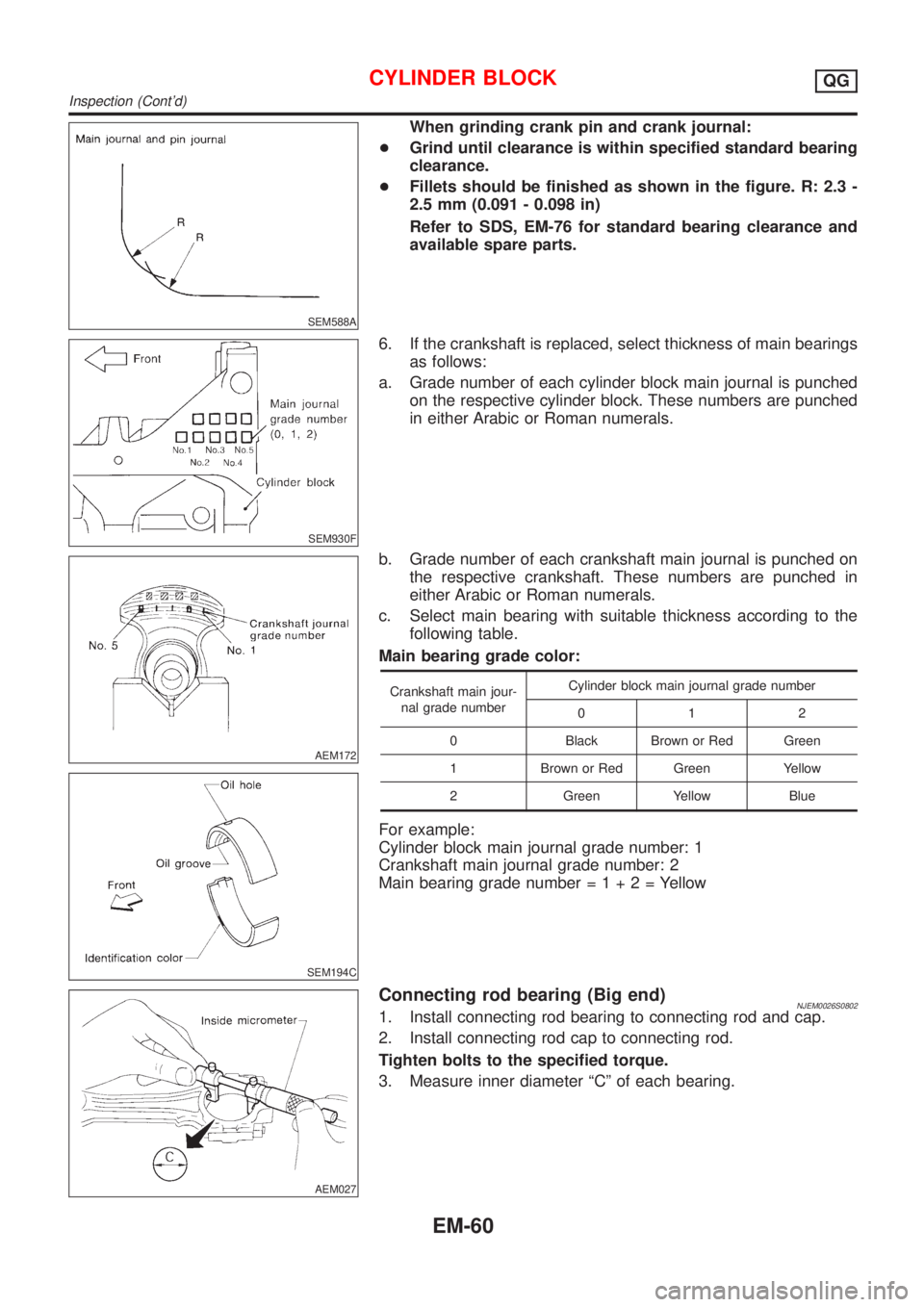

SEM588A

When grinding crank pin and crank journal:

+Grind until clearance is within specified standard bearing

clearance.

+Fillets should be finished as shown in the figure. R: 2.3 -

2.5 mm (0.091 - 0.098 in)

Refer to SDS, EM-76 for standard bearing clearance and

available spare parts.

SEM930F

6. If the crankshaft is replaced, select thickness of main bearings

as follows:

a. Grade number of each cylinder block main journal is punched

on the respective cylinder block. These numbers are punched

in either Arabic or Roman numerals.

AEM172

SEM194C

b. Grade number of each crankshaft main journal is punched on

the respective crankshaft. These numbers are punched in

either Arabic or Roman numerals.

c. Select main bearing with suitable thickness according to the

following table.

Main bearing grade color:

Crankshaft main jour-

nal grade numberCylinder block main journal grade number

012

0 Black Brown or Red Green

1 Brown or Red Green Yellow

2 Green Yellow Blue

For example:

Cylinder block main journal grade number: 1

Crankshaft main journal grade number: 2

Main bearing grade number=1+2=Yellow

AEM027

Connecting rod bearing (Big end)NJEM0026S08021. Install connecting rod bearing to connecting rod and cap.

2. Install connecting rod cap to connecting rod.

Tighten bolts to the specified torque.

3. Measure inner diameter ªCº of each bearing.

CYLINDER BLOCKQG

Inspection (Cont'd)

EM-60

Page 2196 of 2898

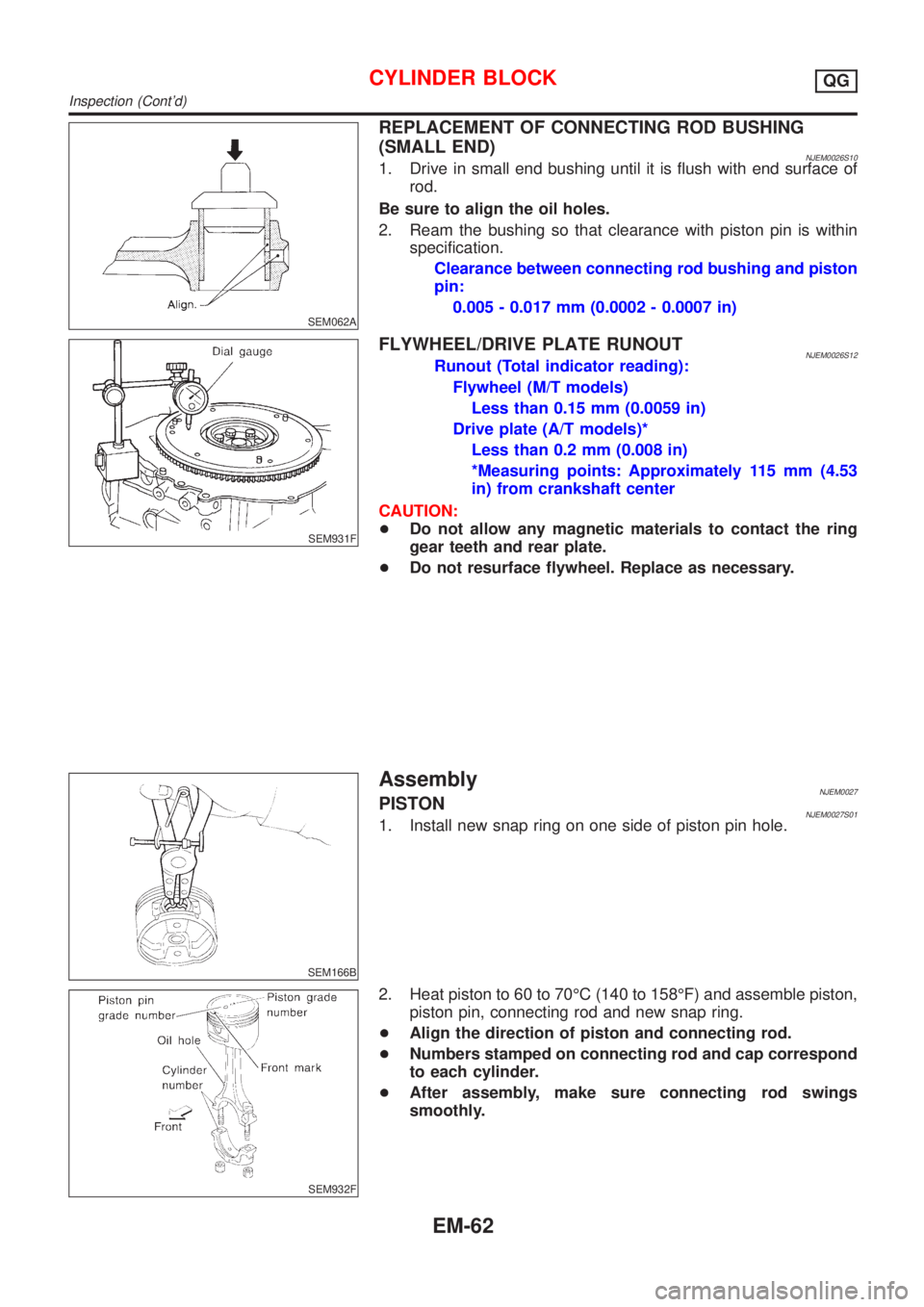

SEM062A

REPLACEMENT OF CONNECTING ROD BUSHING

(SMALL END)

NJEM0026S101. Drive in small end bushing until it is flush with end surface of

rod.

Be sure to align the oil holes.

2. Ream the bushing so that clearance with piston pin is within

specification.

Clearance between connecting rod bushing and piston

pin:

0.005 - 0.017 mm (0.0002 - 0.0007 in)

SEM931F

FLYWHEEL/DRIVE PLATE RUNOUTNJEM0026S12Runout (Total indicator reading):

Flywheel (M/T models)

Less than 0.15 mm (0.0059 in)

Drive plate (A/T models)*

Less than 0.2 mm (0.008 in)

*Measuring points: Approximately 115 mm (4.53

in) from crankshaft center

CAUTION:

+Do not allow any magnetic materials to contact the ring

gear teeth and rear plate.

+Do not resurface flywheel. Replace as necessary.

SEM166B

AssemblyNJEM0027PISTONNJEM0027S011. Install new snap ring on one side of piston pin hole.

SEM932F

2. Heat piston to 60 to 70ÉC (140 to 158ÉF) and assemble piston,

piston pin, connecting rod and new snap ring.

+Align the direction of piston and connecting rod.

+Numbers stamped on connecting rod and cap correspond

to each cylinder.

+After assembly, make sure connecting rod swings

smoothly.

CYLINDER BLOCKQG

Inspection (Cont'd)

EM-62

Page 2198 of 2898

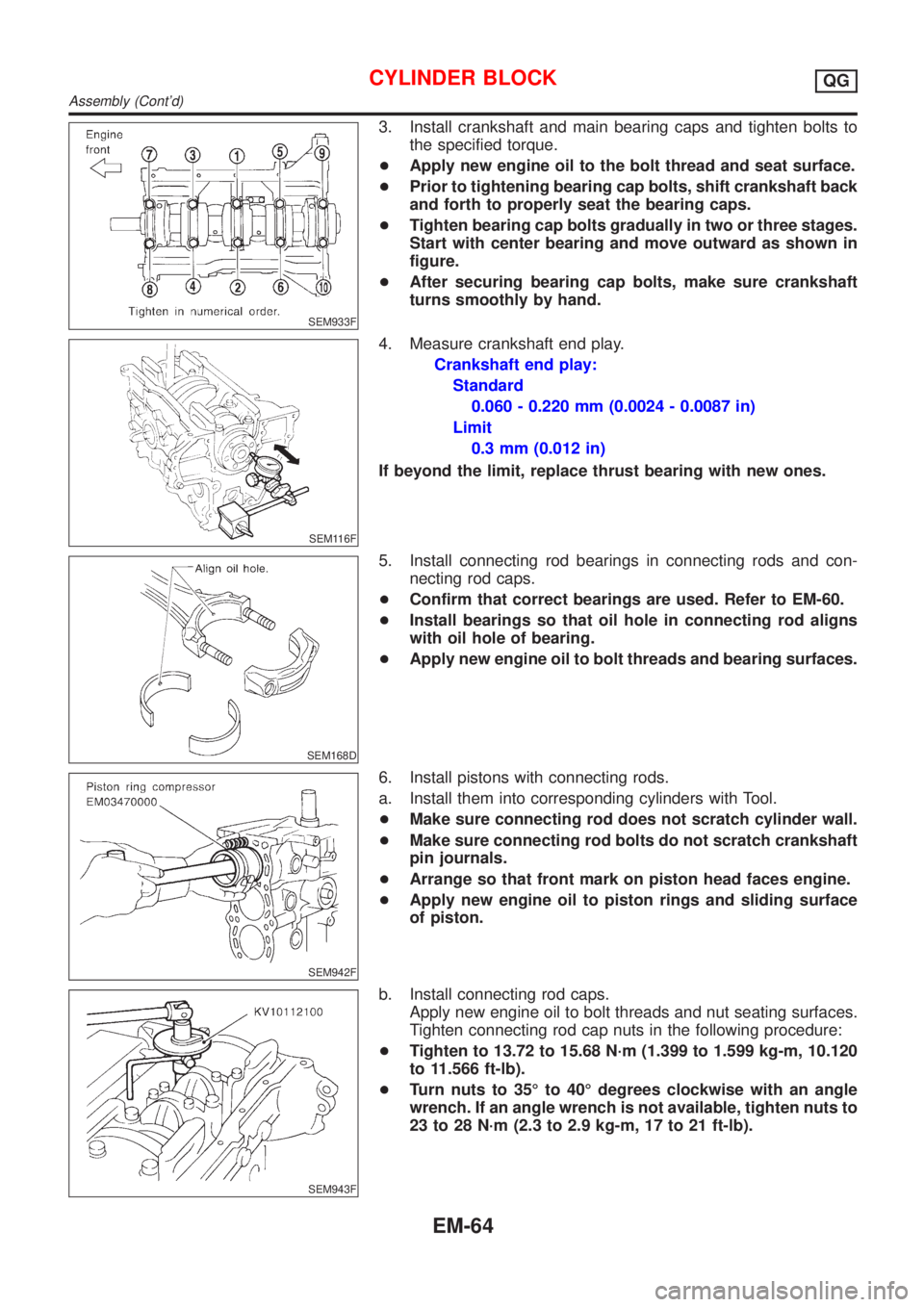

SEM933F

3. Install crankshaft and main bearing caps and tighten bolts to

the specified torque.

+Apply new engine oil to the bolt thread and seat surface.

+Prior to tightening bearing cap bolts, shift crankshaft back

and forth to properly seat the bearing caps.

+Tighten bearing cap bolts gradually in two or three stages.

Start with center bearing and move outward as shown in

figure.

+After securing bearing cap bolts, make sure crankshaft

turns smoothly by hand.

SEM116F

4. Measure crankshaft end play.

Crankshaft end play:

Standard

0.060 - 0.220 mm (0.0024 - 0.0087 in)

Limit

0.3 mm (0.012 in)

If beyond the limit, replace thrust bearing with new ones.

SEM168D

5. Install connecting rod bearings in connecting rods and con-

necting rod caps.

+Confirm that correct bearings are used. Refer to EM-60.

+Install bearings so that oil hole in connecting rod aligns

with oil hole of bearing.

+Apply new engine oil to bolt threads and bearing surfaces.

SEM942F

6. Install pistons with connecting rods.

a. Install them into corresponding cylinders with Tool.

+Make sure connecting rod does not scratch cylinder wall.

+Make sure connecting rod bolts do not scratch crankshaft

pin journals.

+Arrange so that front mark on piston head faces engine.

+Apply new engine oil to piston rings and sliding surface

of piston.

SEM943F

b. Install connecting rod caps.

Apply new engine oil to bolt threads and nut seating surfaces.

Tighten connecting rod cap nuts in the following procedure:

+Tighten to 13.72 to 15.68 N´m (1.399 to 1.599 kg-m, 10.120

to 11.566 ft-lb).

+Turn nuts to 35É to 40É degrees clockwise with an angle

wrench. If an angle wrench is not available, tighten nuts to

23 to 28 N´m (2.3 to 2.9 kg-m, 17 to 21 ft-lb).

CYLINDER BLOCKQG

Assembly (Cont'd)

EM-64

Page 2271 of 2898

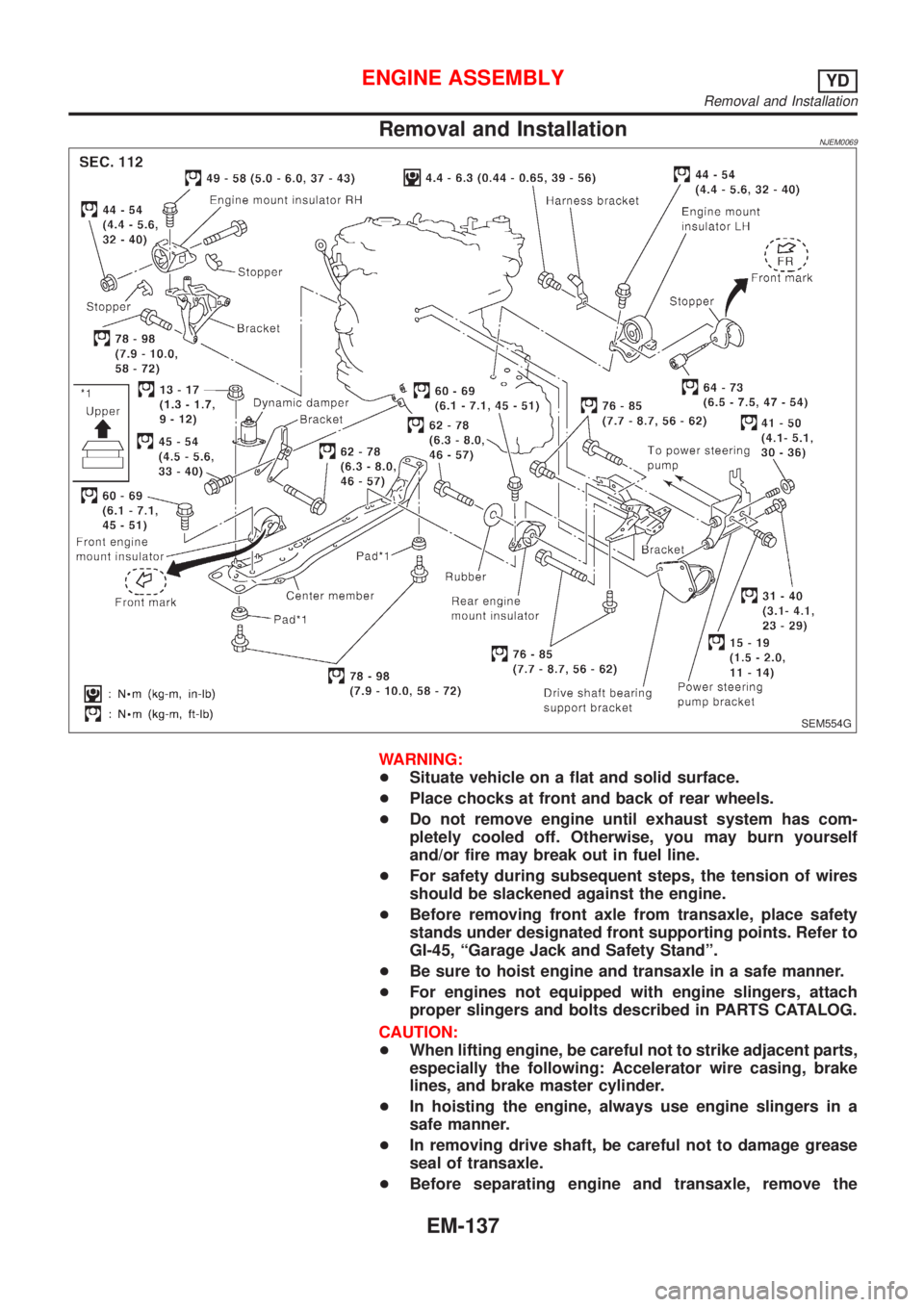

Removal and InstallationNJEM0069

SEM554G

WARNING:

+Situate vehicle on a flat and solid surface.

+Place chocks at front and back of rear wheels.

+Do not remove engine until exhaust system has com-

pletely cooled off. Otherwise, you may burn yourself

and/or fire may break out in fuel line.

+For safety during subsequent steps, the tension of wires

should be slackened against the engine.

+Before removing front axle from transaxle, place safety

stands under designated front supporting points. Refer to

GI-45, ªGarage Jack and Safety Standº.

+Be sure to hoist engine and transaxle in a safe manner.

+For engines not equipped with engine slingers, attach

proper slingers and bolts described in PARTS CATALOG.

CAUTION:

+When lifting engine, be careful not to strike adjacent parts,

especially the following: Accelerator wire casing, brake

lines, and brake master cylinder.

+In hoisting the engine, always use engine slingers in a

safe manner.

+In removing drive shaft, be careful not to damage grease

seal of transaxle.

+Before separating engine and transaxle, remove the

ENGINE ASSEMBLYYD

Removal and Installation

EM-137

Page 2275 of 2898

Removal and InstallationNJEM0071CAUTION:

+When installing bearings, pistons, or other sliding parts,

lubricate contacting surfaces with new engine oil.

+Place removed parts such as bearings and bearing caps

in their proper order and direction.

+When installing connecting rod nuts, and main bearing

cap bolts, apply new engine oil to threads and seating

surfaces.

+Do not allow any magnetic materials to contact the signal

plate of flywheel.

+Do not remove the signal plate at back.

+Do not place the signal plate side facing under.

+Handle with care so as not to damage the signal plate

[especially four places on protrusions for signal of crank

position sensor (TDC sensor)].

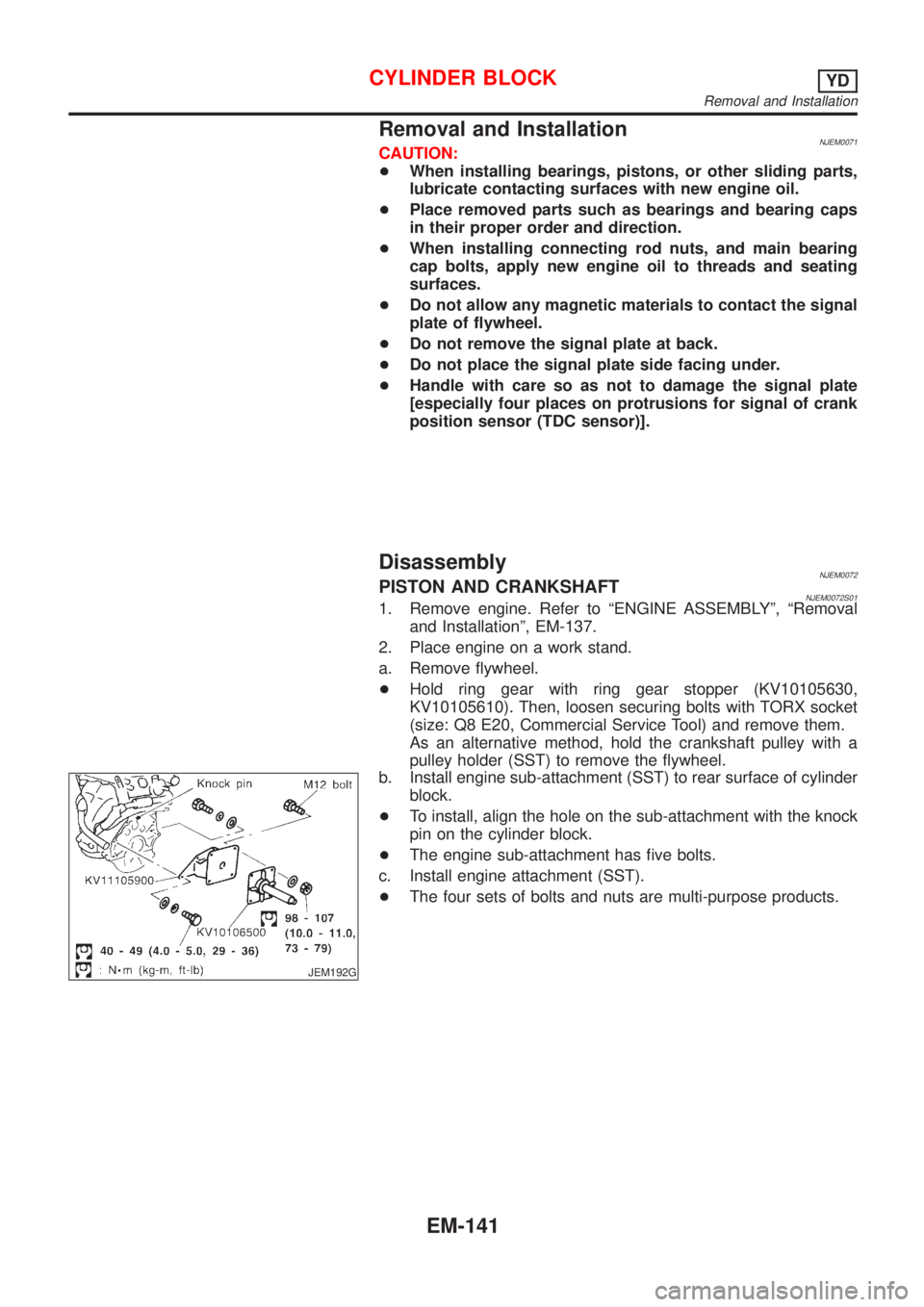

DisassemblyNJEM0072PISTON AND CRANKSHAFTNJEM0072S011. Remove engine. Refer to ªENGINE ASSEMBLYº, ªRemoval

and Installationº, EM-137.

2. Place engine on a work stand.

a. Remove flywheel.

+Hold ring gear with ring gear stopper (KV10105630,

KV10105610). Then, loosen securing bolts with TORX socket

(size: Q8 E20, Commercial Service Tool) and remove them.

As an alternative method, hold the crankshaft pulley with a

pulley holder (SST) to remove the flywheel.

JEM192G

b. Install engine sub-attachment (SST) to rear surface of cylinder

block.

+To install, align the hole on the sub-attachment with the knock

pin on the cylinder block.

+The engine sub-attachment has five bolts.

c. Install engine attachment (SST).

+The four sets of bolts and nuts are multi-purpose products.

CYLINDER BLOCKYD

Removal and Installation

EM-141

Page 2288 of 2898

JEM220G

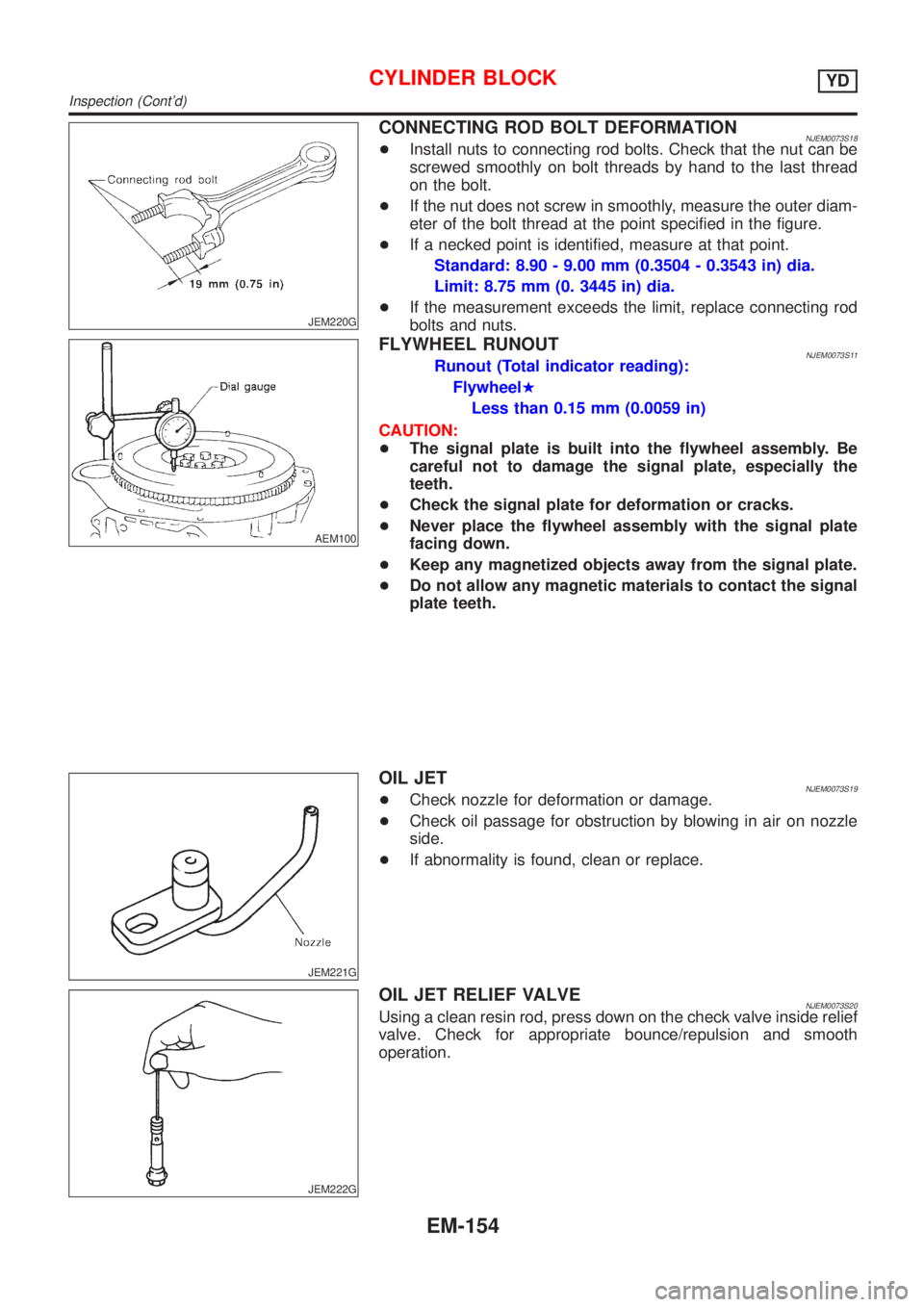

CONNECTING ROD BOLT DEFORMATIONNJEM0073S18+Install nuts to connecting rod bolts. Check that the nut can be

screwed smoothly on bolt threads by hand to the last thread

on the bolt.

+If the nut does not screw in smoothly, measure the outer diam-

eter of the bolt thread at the point specified in the figure.

+If a necked point is identified, measure at that point.

Standard: 8.90 - 9.00 mm (0.3504 - 0.3543 in) dia.

Limit: 8.75 mm (0. 3445 in) dia.

+If the measurement exceeds the limit, replace connecting rod

bolts and nuts.

AEM100

FLYWHEEL RUNOUTNJEM0073S11Runout (Total indicator reading):

FlywheelH

Less than 0.15 mm (0.0059 in)

CAUTION:

+The signal plate is built into the flywheel assembly. Be

careful not to damage the signal plate, especially the

teeth.

+Check the signal plate for deformation or cracks.

+Never place the flywheel assembly with the signal plate

facing down.

+Keep any magnetized objects away from the signal plate.

+Do not allow any magnetic materials to contact the signal

plate teeth.

JEM221G

OIL JETNJEM0073S19+Check nozzle for deformation or damage.

+Check oil passage for obstruction by blowing in air on nozzle

side.

+If abnormality is found, clean or replace.

JEM222G

OIL JET RELIEF VALVENJEM0073S20Using a clean resin rod, press down on the check valve inside relief

valve. Check for appropriate bounce/repulsion and smooth

operation.

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-154