ESP NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2312 of 2898

JFE608A

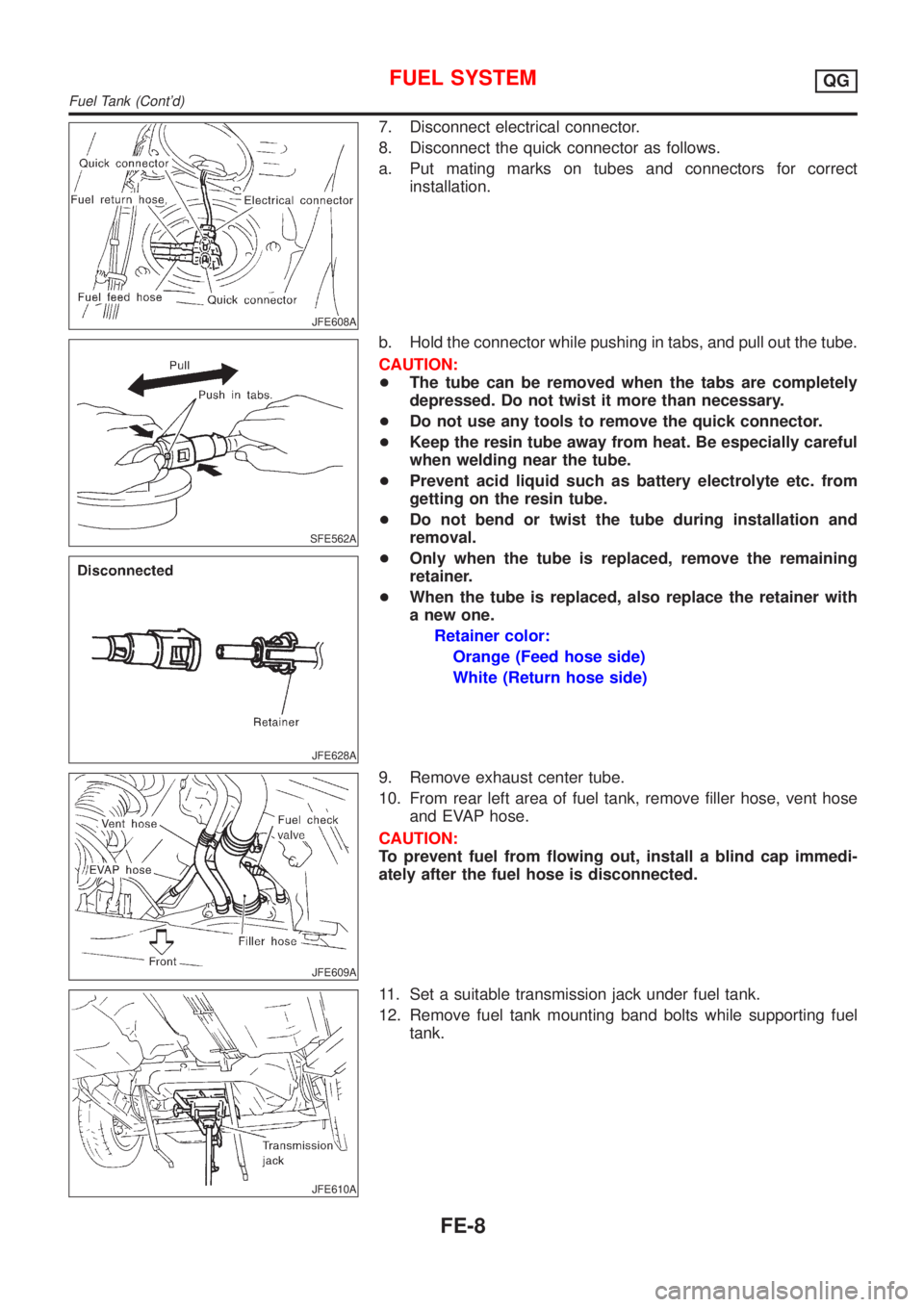

7. Disconnect electrical connector.

8. Disconnect the quick connector as follows.

a. Put mating marks on tubes and connectors for correct

installation.

SFE562A

JFE628A

b. Hold the connector while pushing in tabs, and pull out the tube.

CAUTION:

+The tube can be removed when the tabs are completely

depressed. Do not twist it more than necessary.

+Do not use any tools to remove the quick connector.

+Keep the resin tube away from heat. Be especially careful

when welding near the tube.

+Prevent acid liquid such as battery electrolyte etc. from

getting on the resin tube.

+Do not bend or twist the tube during installation and

removal.

+Only when the tube is replaced, remove the remaining

retainer.

+When the tube is replaced, also replace the retainer with

a new one.

Retainer color:

Orange (Feed hose side)

White (Return hose side)

JFE609A

9. Remove exhaust center tube.

10. From rear left area of fuel tank, remove filler hose, vent hose

and EVAP hose.

CAUTION:

To prevent fuel from flowing out, install a blind cap immedi-

ately after the fuel hose is disconnected.

JFE610A

11. Set a suitable transmission jack under fuel tank.

12. Remove fuel tank mounting band bolts while supporting fuel

tank.

FUEL SYSTEMQG

Fuel Tank (Cont'd)

FE-8

Page 2313 of 2898

JFE611A

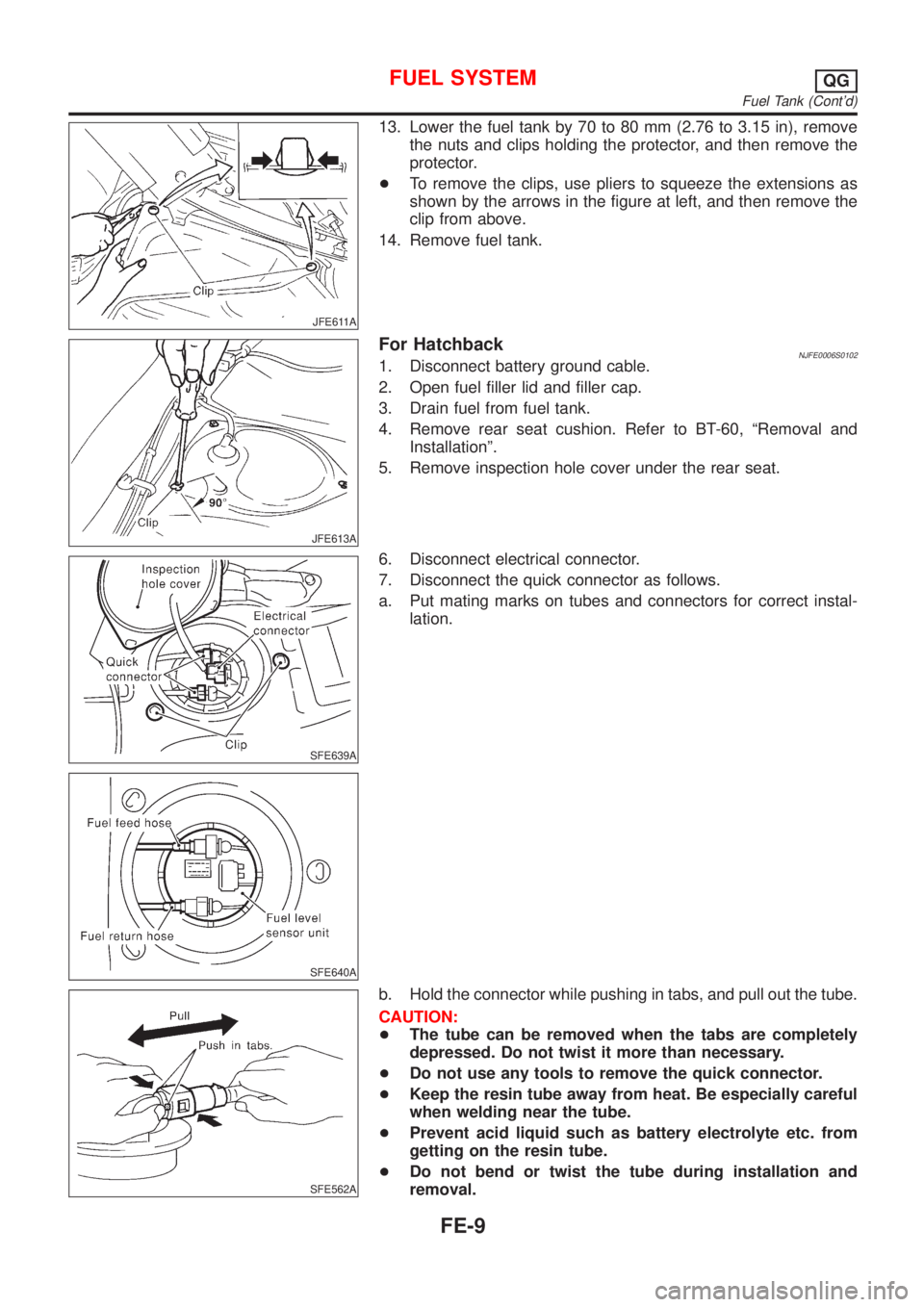

13. Lower the fuel tank by 70 to 80 mm (2.76 to 3.15 in), remove

the nuts and clips holding the protector, and then remove the

protector.

+To remove the clips, use pliers to squeeze the extensions as

shown by the arrows in the figure at left, and then remove the

clip from above.

14. Remove fuel tank.

JFE613A

For HatchbackNJFE0006S01021. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Drain fuel from fuel tank.

4. Remove rear seat cushion. Refer to BT-60, ªRemoval and

Installationº.

5. Remove inspection hole cover under the rear seat.

SFE639A

SFE640A

6. Disconnect electrical connector.

7. Disconnect the quick connector as follows.

a. Put mating marks on tubes and connectors for correct instal-

lation.

SFE562A

b. Hold the connector while pushing in tabs, and pull out the tube.

CAUTION:

+The tube can be removed when the tabs are completely

depressed. Do not twist it more than necessary.

+Do not use any tools to remove the quick connector.

+Keep the resin tube away from heat. Be especially careful

when welding near the tube.

+Prevent acid liquid such as battery electrolyte etc. from

getting on the resin tube.

+Do not bend or twist the tube during installation and

removal.

FUEL SYSTEMQG

Fuel Tank (Cont'd)

FE-9

Page 2319 of 2898

SMA211A

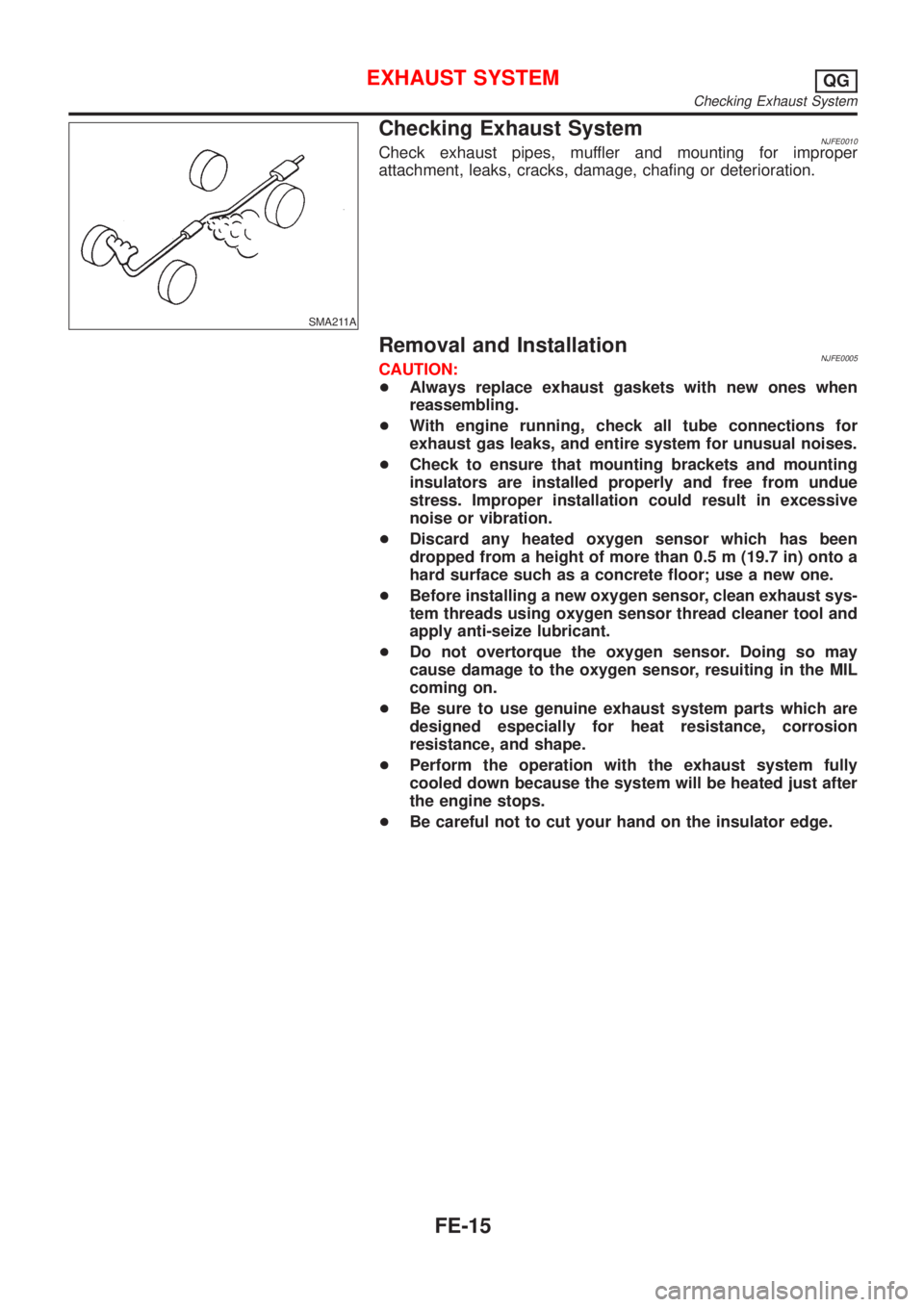

Checking Exhaust SystemNJFE0010Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, chafing or deterioration.

Removal and InstallationNJFE0005CAUTION:

+Always replace exhaust gaskets with new ones when

reassembling.

+With engine running, check all tube connections for

exhaust gas leaks, and entire system for unusual noises.

+Check to ensure that mounting brackets and mounting

insulators are installed properly and free from undue

stress. Improper installation could result in excessive

noise or vibration.

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing a new oxygen sensor, clean exhaust sys-

tem threads using oxygen sensor thread cleaner tool and

apply anti-seize lubricant.

+Do not overtorque the oxygen sensor. Doing so may

cause damage to the oxygen sensor, resuiting in the MIL

coming on.

+Be sure to use genuine exhaust system parts which are

designed especially for heat resistance, corrosion

resistance, and shape.

+Perform the operation with the exhaust system fully

cooled down because the system will be heated just after

the engine stops.

+Be careful not to cut your hand on the insulator edge.

EXHAUST SYSTEMQG

Checking Exhaust System

FE-15

Page 2324 of 2898

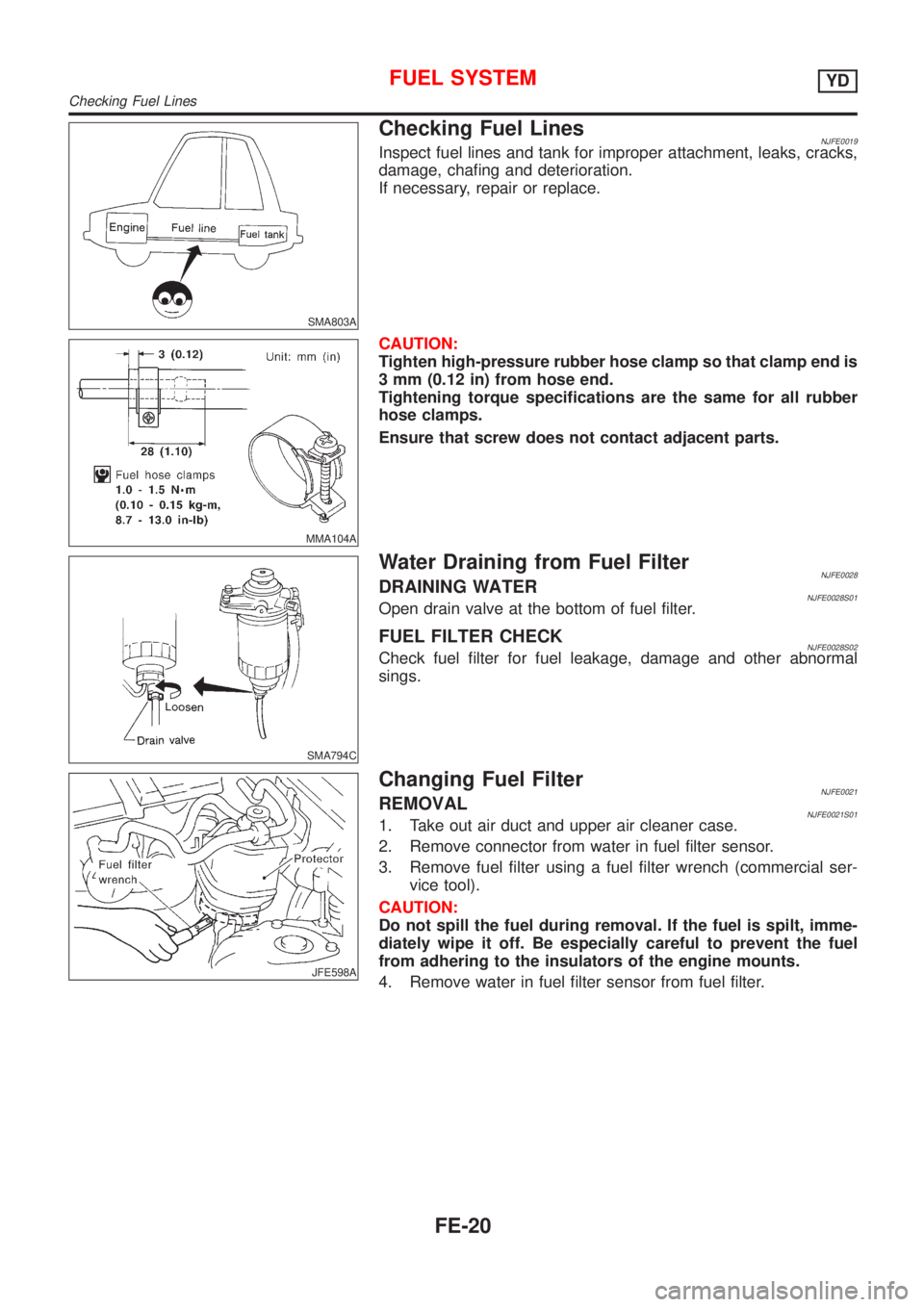

SMA803A

Checking Fuel LinesNJFE0019Inspect fuel lines and tank for improper attachment, leaks, cracks,

damage, chafing and deterioration.

If necessary, repair or replace.

MMA104A

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is

3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber

hose clamps.

Ensure that screw does not contact adjacent parts.

SMA794C

Water Draining from Fuel FilterNJFE0028DRAINING WATERNJFE0028S01Open drain valve at the bottom of fuel filter.

FUEL FILTER CHECKNJFE0028S02Check fuel filter for fuel leakage, damage and other abnormal

sings.

JFE598A

Changing Fuel FilterNJFE0021REMOVALNJFE0021S011. Take out air duct and upper air cleaner case.

2. Remove connector from water in fuel filter sensor.

3. Remove fuel filter using a fuel filter wrench (commercial ser-

vice tool).

CAUTION:

Do not spill the fuel during removal. If the fuel is spilt, imme-

diately wipe it off. Be especially careful to prevent the fuel

from adhering to the insulators of the engine mounts.

4. Remove water in fuel filter sensor from fuel filter.

FUEL SYSTEMYD

Checking Fuel Lines

FE-20

Page 2329 of 2898

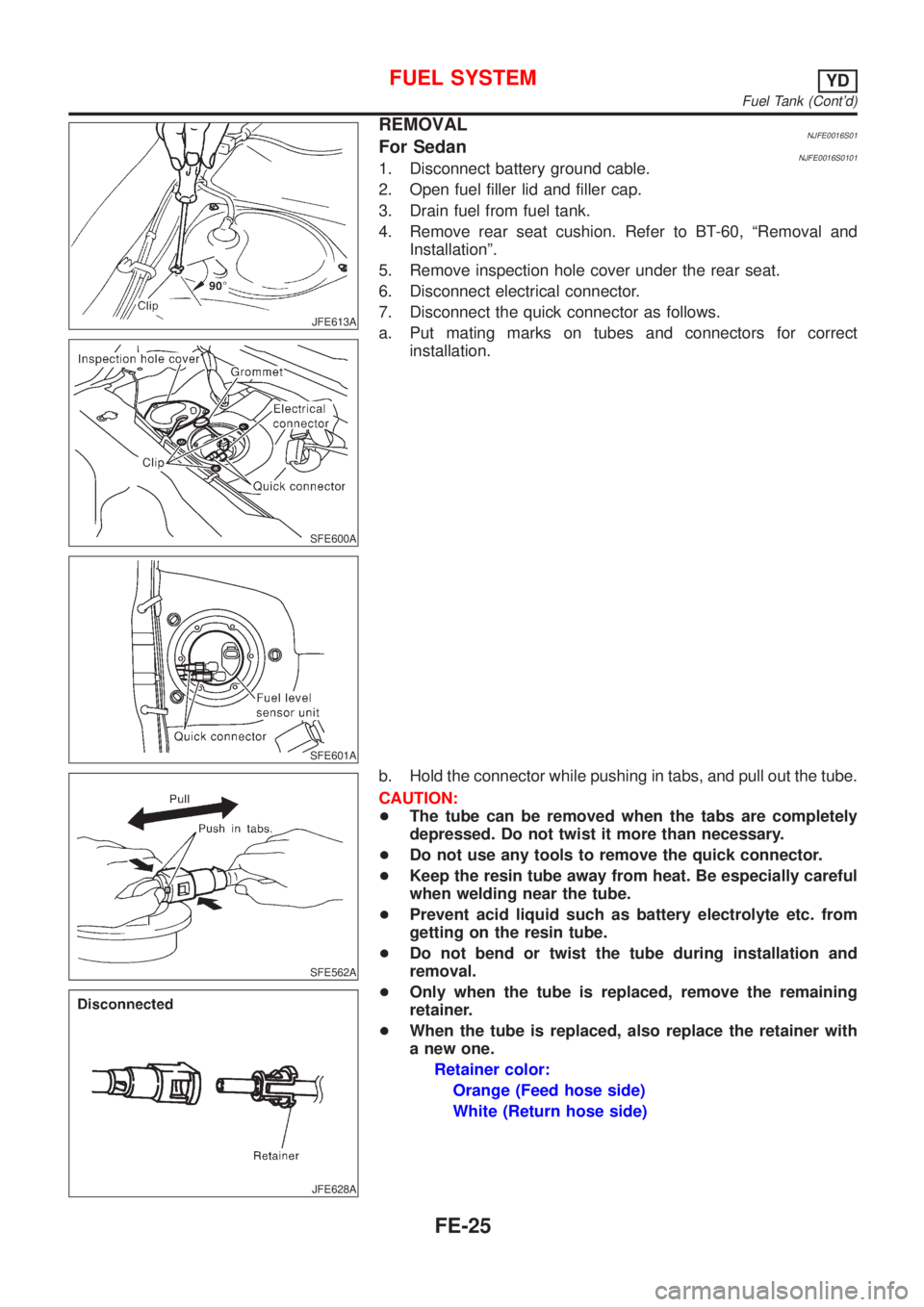

JFE613A

SFE600A

SFE601A

REMOVALNJFE0016S01For SedanNJFE0016S01011. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Drain fuel from fuel tank.

4. Remove rear seat cushion. Refer to BT-60, ªRemoval and

Installationº.

5. Remove inspection hole cover under the rear seat.

6. Disconnect electrical connector.

7. Disconnect the quick connector as follows.

a. Put mating marks on tubes and connectors for correct

installation.

SFE562A

JFE628A

b. Hold the connector while pushing in tabs, and pull out the tube.

CAUTION:

+The tube can be removed when the tabs are completely

depressed. Do not twist it more than necessary.

+Do not use any tools to remove the quick connector.

+Keep the resin tube away from heat. Be especially careful

when welding near the tube.

+Prevent acid liquid such as battery electrolyte etc. from

getting on the resin tube.

+Do not bend or twist the tube during installation and

removal.

+Only when the tube is replaced, remove the remaining

retainer.

+When the tube is replaced, also replace the retainer with

a new one.

Retainer color:

Orange (Feed hose side)

White (Return hose side)

FUEL SYSTEMYD

Fuel Tank (Cont'd)

FE-25

Page 2331 of 2898

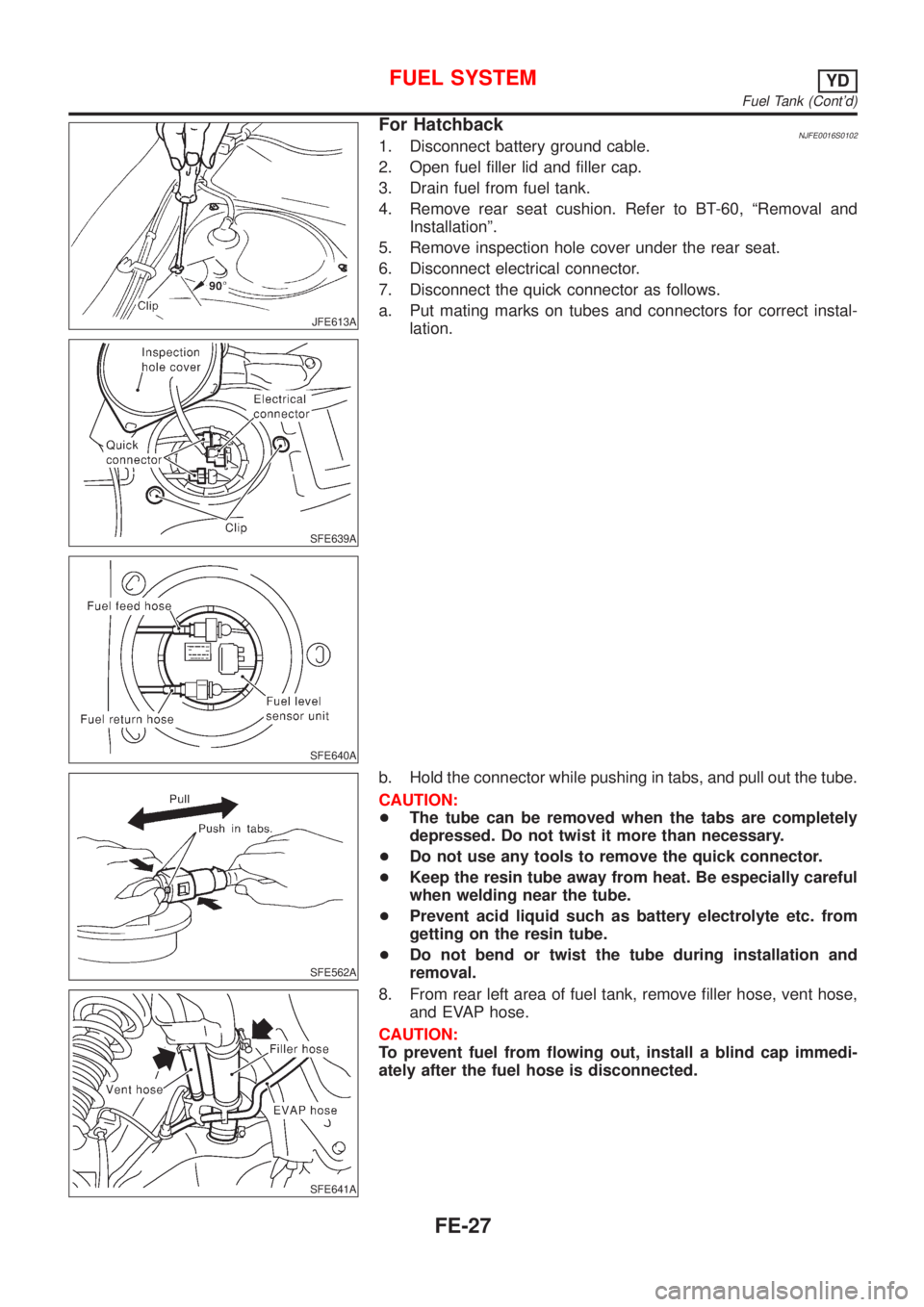

JFE613A

SFE639A

SFE640A

For HatchbackNJFE0016S01021. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Drain fuel from fuel tank.

4. Remove rear seat cushion. Refer to BT-60, ªRemoval and

Installationº.

5. Remove inspection hole cover under the rear seat.

6. Disconnect electrical connector.

7. Disconnect the quick connector as follows.

a. Put mating marks on tubes and connectors for correct instal-

lation.

SFE562A

b. Hold the connector while pushing in tabs, and pull out the tube.

CAUTION:

+The tube can be removed when the tabs are completely

depressed. Do not twist it more than necessary.

+Do not use any tools to remove the quick connector.

+Keep the resin tube away from heat. Be especially careful

when welding near the tube.

+Prevent acid liquid such as battery electrolyte etc. from

getting on the resin tube.

+Do not bend or twist the tube during installation and

removal.

SFE641A

8. From rear left area of fuel tank, remove filler hose, vent hose,

and EVAP hose.

CAUTION:

To prevent fuel from flowing out, install a blind cap immedi-

ately after the fuel hose is disconnected.

FUEL SYSTEMYD

Fuel Tank (Cont'd)

FE-27

Page 2336 of 2898

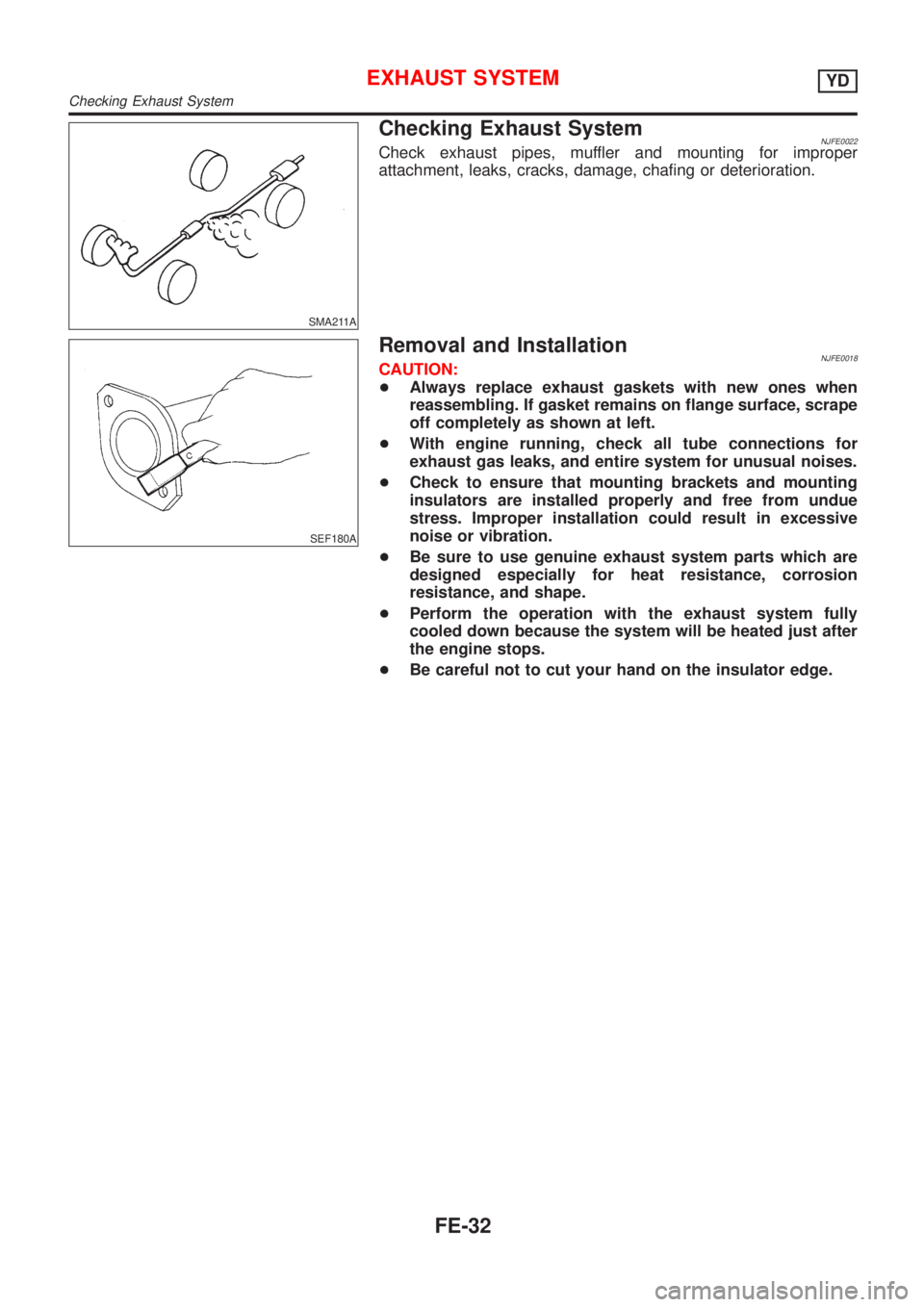

SMA211A

Checking Exhaust SystemNJFE0022Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, chafing or deterioration.

SEF180A

Removal and InstallationNJFE0018CAUTION:

+Always replace exhaust gaskets with new ones when

reassembling. If gasket remains on flange surface, scrape

off completely as shown at left.

+With engine running, check all tube connections for

exhaust gas leaks, and entire system for unusual noises.

+Check to ensure that mounting brackets and mounting

insulators are installed properly and free from undue

stress. Improper installation could result in excessive

noise or vibration.

+Be sure to use genuine exhaust system parts which are

designed especially for heat resistance, corrosion

resistance, and shape.

+Perform the operation with the exhaust system fully

cooled down because the system will be heated just after

the engine stops.

+Be careful not to cut your hand on the insulator edge.

EXHAUST SYSTEMYD

Checking Exhaust System

FE-32

Page 2350 of 2898

combination meter. The indicator blinks when the ignition switch is

in ªOFFº or ªACCº position. Therefore, NATS warns outsiders that

the vehicle is equipped with the anti-theft system.

+When NATS detects trouble, the security indicator lamp lights

up while ignition switch is in ªONº position.

This lighting up indicates that the anti-theft is not functioning,

so prompt service is required.

+When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs),

CONSULT-II hardware and CONSULT-II NATS software is

necessary.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Therefore, CONSULT-II NATS software (program card and

operation manual) must be kept strictly confidential to main-

tain the integrity of the anti-theft function.

+When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs), it

may be necessary to re-register original key identification.

Therefore, be sure to receive all keys from vehicle owner. A

maximum of five key IDs can be registered into NATS.

+When failing to start the engine first time using the key of

NATS, start as follows.

a) Leave the ignition key in ªONº position for approximately 5

seconds.

b) Turn ignition key to ªOFFº or ªLOCKº position and wait approxi-

mately 5 seconds.

c) Repeat step 1 and 2 again.

d) Restart the engine while keeping the key separate from any

others on key-chain.

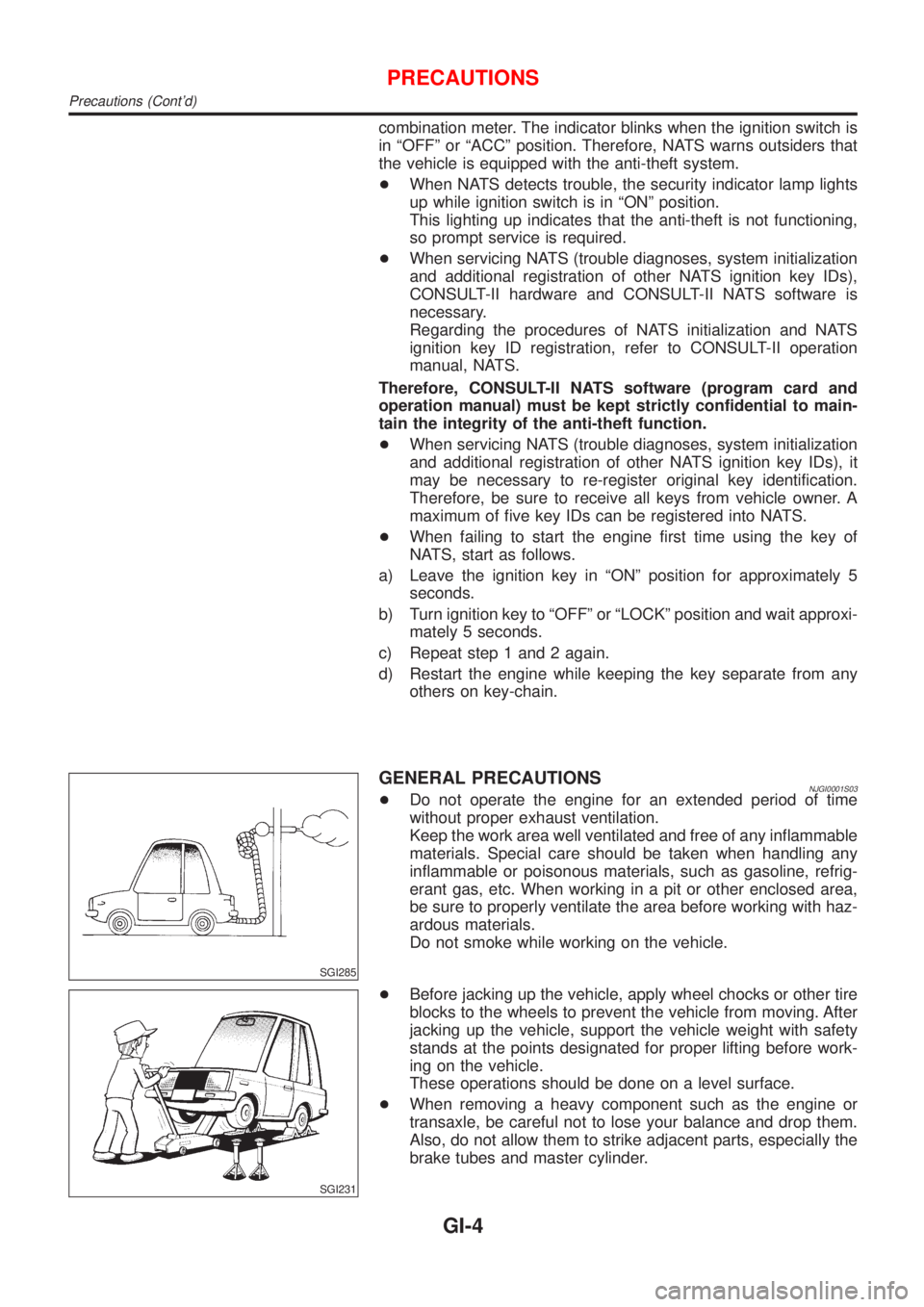

SGI285

GENERAL PRECAUTIONSNJGI0001S03+Do not operate the engine for an extended period of time

without proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refrig-

erant gas, etc. When working in a pit or other enclosed area,

be sure to properly ventilate the area before working with haz-

ardous materials.

Do not smoke while working on the vehicle.

SGI231

+Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before work-

ing on the vehicle.

These operations should be done on a level surface.

+When removing a heavy component such as the engine or

transaxle, be careful not to lose your balance and drop them.

Also, do not allow them to strike adjacent parts, especially the

brake tubes and master cylinder.

PRECAUTIONS

Precautions (Cont'd)

GI-4

Page 2359 of 2898

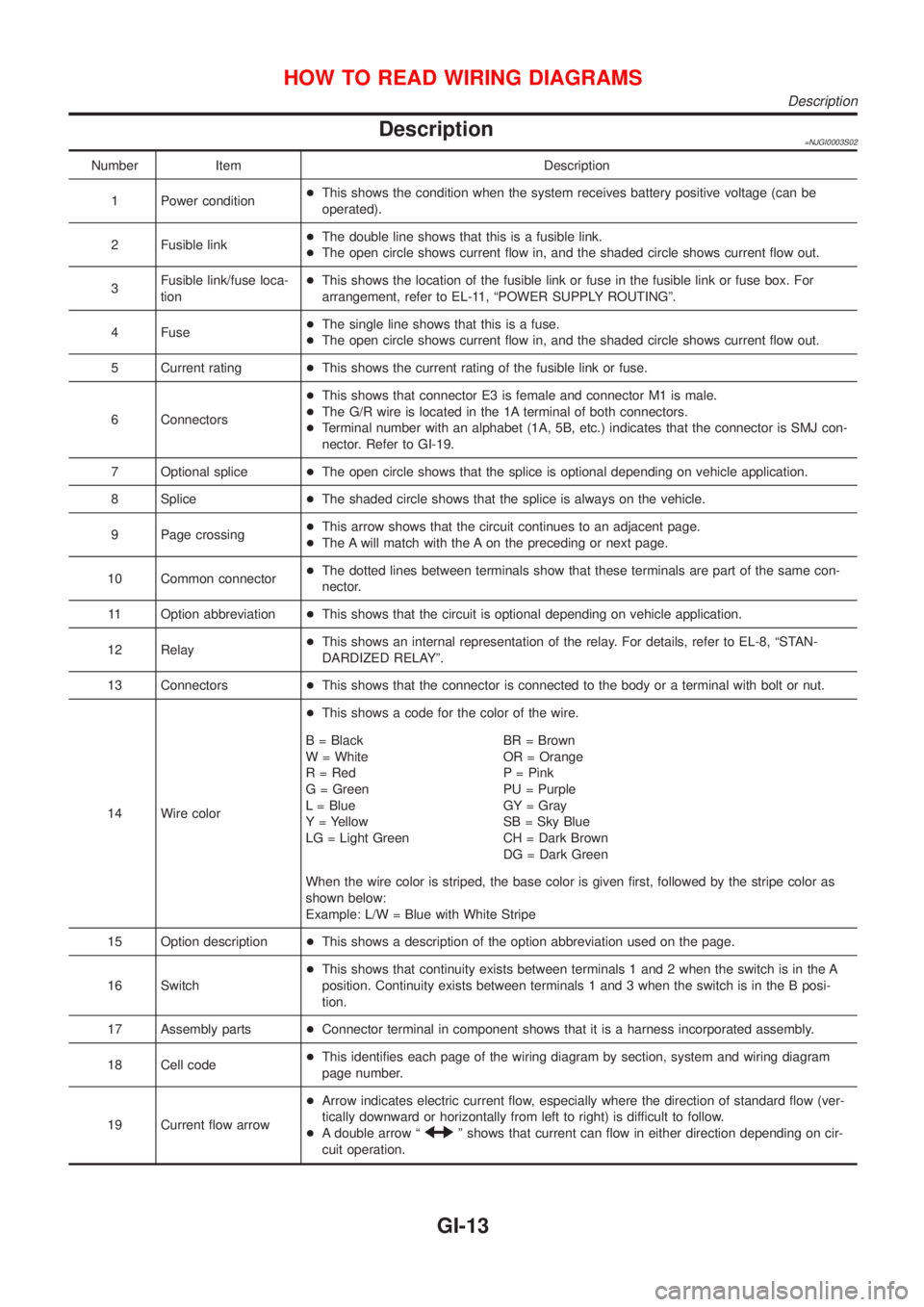

Description=NJGI0003S02

Number Item Description

1 Power condition+This shows the condition when the system receives battery positive voltage (can be

operated).

2 Fusible link+The double line shows that this is a fusible link.

+The open circle shows current flow in, and the shaded circle shows current flow out.

3Fusible link/fuse loca-

tion+This shows the location of the fusible link or fuse in the fusible link or fuse box. For

arrangement, refer to EL-11, ªPOWER SUPPLY ROUTINGº.

4 Fuse+The single line shows that this is a fuse.

+The open circle shows current flow in, and the shaded circle shows current flow out.

5 Current rating+This shows the current rating of the fusible link or fuse.

6 Connectors+This shows that connector E3 is female and connector M1 is male.

+The G/R wire is located in the 1A terminal of both connectors.

+Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is SMJ con-

nector. Refer to GI-19.

7 Optional splice+The open circle shows that the splice is optional depending on vehicle application.

8 Splice+The shaded circle shows that the splice is always on the vehicle.

9 Page crossing+This arrow shows that the circuit continues to an adjacent page.

+The A will match with the A on the preceding or next page.

10 Common connector+The dotted lines between terminals show that these terminals are part of the same con-

nector.

11 Option abbreviation+This shows that the circuit is optional depending on vehicle application.

12 Relay+This shows an internal representation of the relay. For details, refer to EL-8, ªSTAN-

DARDIZED RELAYº.

13 Connectors+This shows that the connector is connected to the body or a terminal with bolt or nut.

14 Wire color+This shows a code for the color of the wire.

B = Black

W = White

R = Red

G = Green

L = Blue

Y = Yellow

LG = Light GreenBR = Brown

OR = Orange

P = Pink

PU = Purple

GY = Gray

SB = Sky Blue

CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given first, followed by the stripe color as

shown below:

Example: L/W = Blue with White Stripe

15 Option description+This shows a description of the option abbreviation used on the page.

16 Switch+This shows that continuity exists between terminals 1 and 2 when the switch is in the A

position. Continuity exists between terminals 1 and 3 when the switch is in the B posi-

tion.

17 Assembly parts+Connector terminal in component shows that it is a harness incorporated assembly.

18 Cell code+This identifies each page of the wiring diagram by section, system and wiring diagram

page number.

19 Current flow arrow+Arrow indicates electric current flow, especially where the direction of standard flow (ver-

tically downward or horizontally from left to right) is difficult to follow.

+A double arrow ª

º shows that current can flow in either direction depending on cir-

cuit operation.

HOW TO READ WIRING DIAGRAMS

Description

GI-13

Page 2361 of 2898

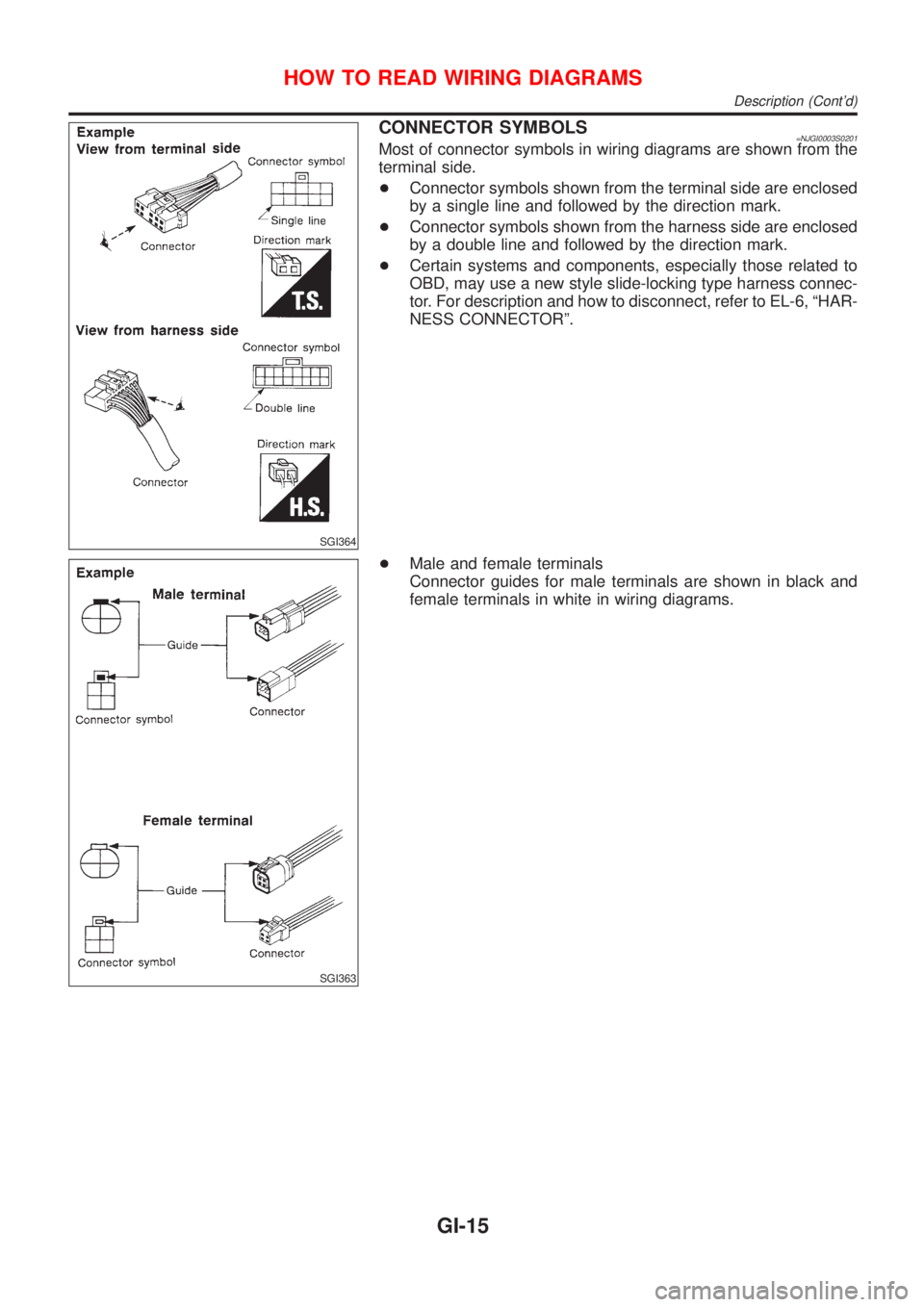

SGI364

CONNECTOR SYMBOLS=NJGI0003S0201Most of connector symbols in wiring diagrams are shown from the

terminal side.

+Connector symbols shown from the terminal side are enclosed

by a single line and followed by the direction mark.

+Connector symbols shown from the harness side are enclosed

by a double line and followed by the direction mark.

+Certain systems and components, especially those related to

OBD, may use a new style slide-locking type harness connec-

tor. For description and how to disconnect, refer to EL-6, ªHAR-

NESS CONNECTORº.

SGI363

+Male and female terminals

Connector guides for male terminals are shown in black and

female terminals in white in wiring diagrams.

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)

GI-15