ESP NISSAN ALMERA 2001 Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1454 of 2898

DescriptionNJEC0660SYSTEM DESCRIPTIONNJEC0660S01

Sensor Input signal to ECM ECM function Actuator

Vehicle speed sensor Vehicle speed

Cooling fan

controlCooling fan relay Engine coolant temperature sensor Engine coolant temperature

Air conditioner switch Air conditioner ªONº signal

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, air condi-

tioner ON signal. The control system has 3-step control [HIGH/LOW/OFF].

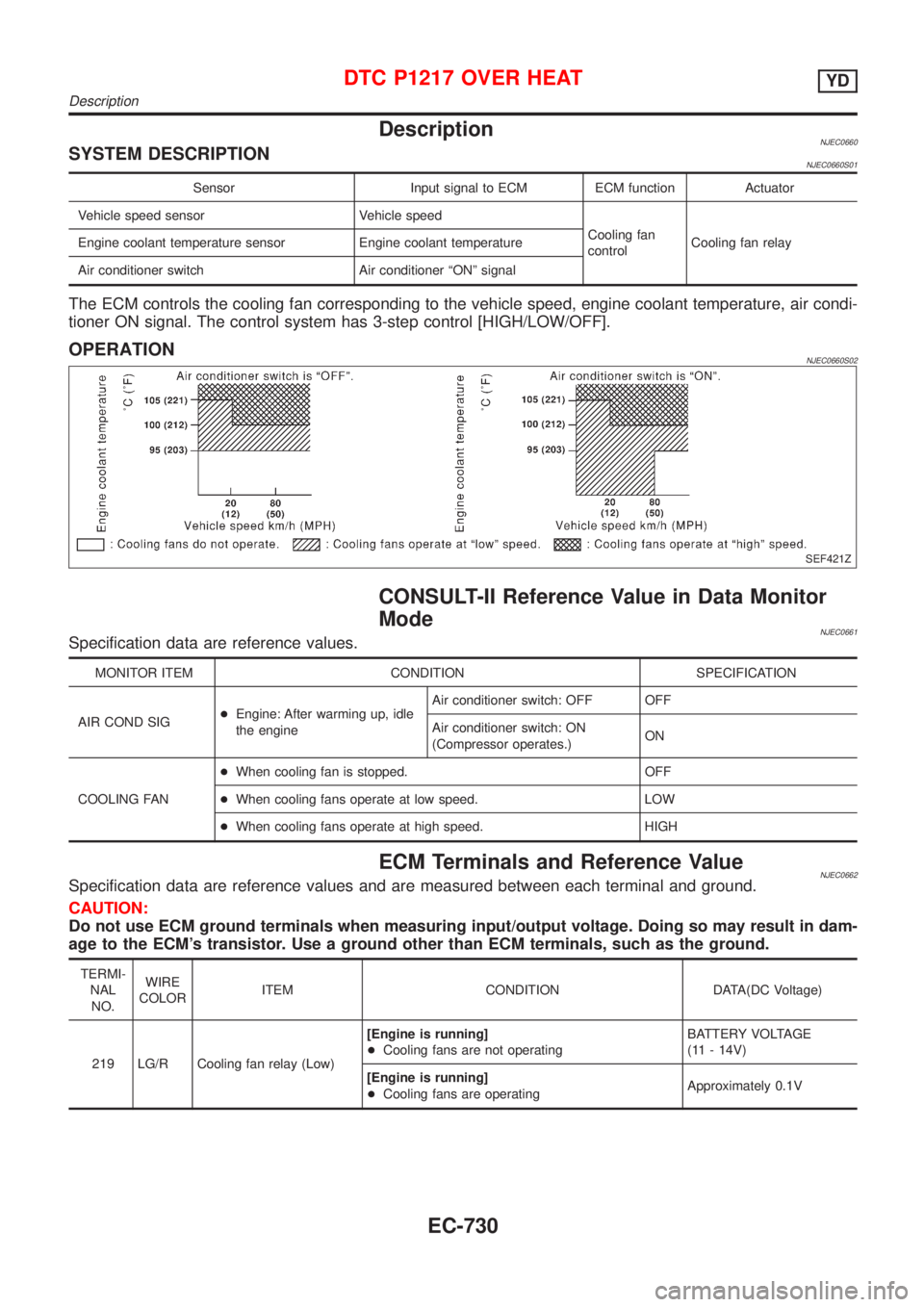

OPERATIONNJEC0660S02

SEF421Z

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0661Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

AIR COND SIG+Engine: After warming up, idle

the engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

COOLING FAN+When cooling fan is stopped. OFF

+When cooling fans operate at low speed. LOW

+When cooling fans operate at high speed. HIGH

ECM Terminals and Reference ValueNJEC0662Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA(DC Voltage)

219 LG/R Cooling fan relay (Low)[Engine is running]

+Cooling fans are not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Cooling fans are operatingApproximately 0.1V

DTC P1217 OVER HEATYD

Description

EC-730

Page 1530 of 2898

DescriptionNJEC0760SYSTEM DESCRIPTIONNJEC0760S01

Sensor Input Signal to ECMECM

Func-

tionActuator

Crankshaft position sensor

(TDC)Engine speed

Glow

controlGlow lamp,

Glow relay

¯

Glow plugs Engine coolant tempera-

ture sensorEngine coolant tem-

perature

When engine coolant temperature is more than approximately

75ÉC (167ÉF), the glow relay turns off.

When coolant temperature is lower than approximately 75ÉC

(167ÉF):

+Ignition switch ON

After ignition switch has turned to ON, the glow relay turns ON

for a certain period of time in relation to engine coolant

temperature, allowing current to flow through glow plug.

+Cranking

The glow relay turns ON, allowing current to flow through glow

plug.

+Starting

After engine has started, current continues to flow through

glow plug (after-glow mode) for a certain period in relation to

engine coolant temperature.

The glow indicator lamp turns ON for a certain period of time in

relation to engine cooalnt temperature at the time glow relay is

turned ON.

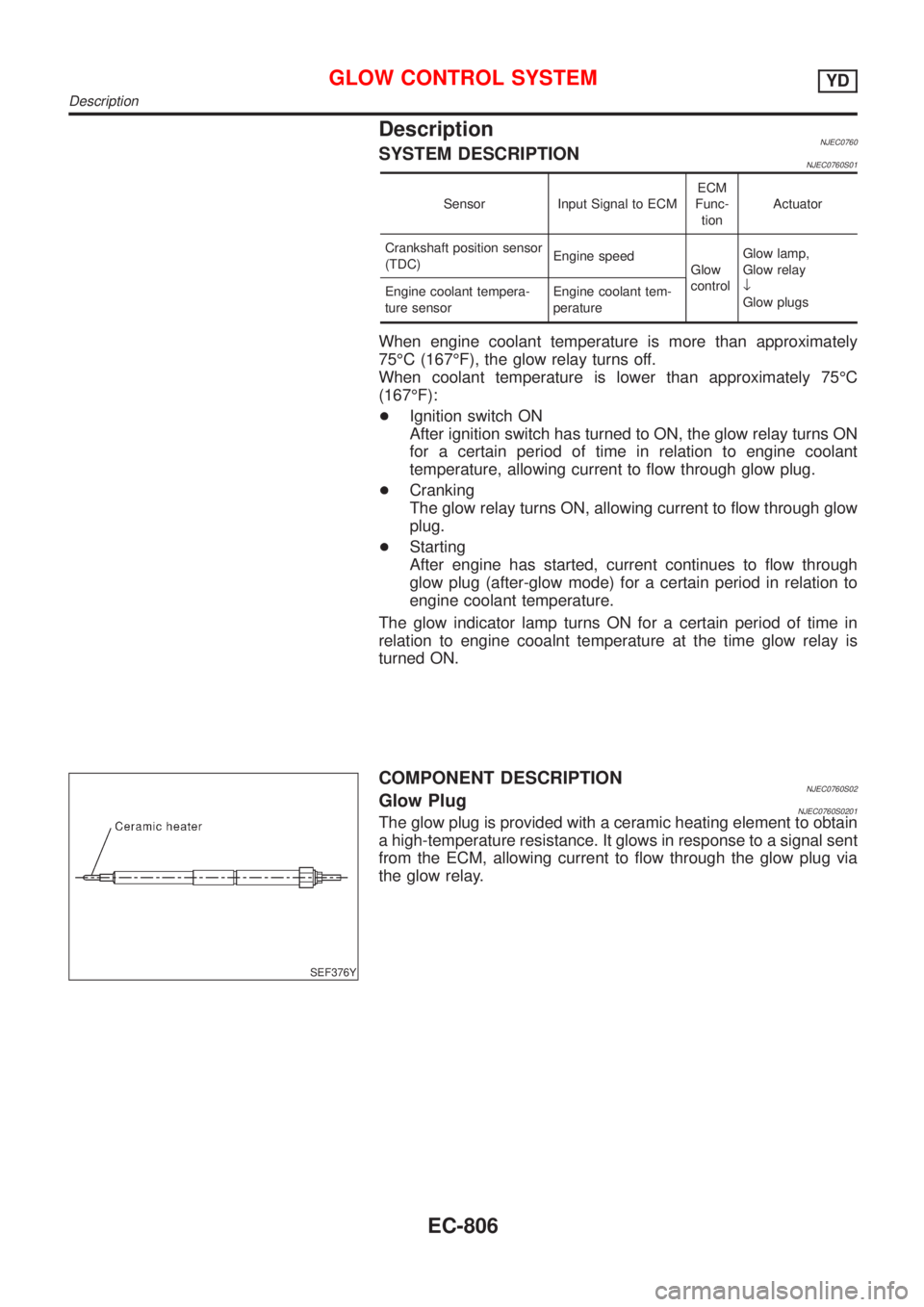

SEF376Y

COMPONENT DESCRIPTIONNJEC0760S02Glow PlugNJEC0760S0201The glow plug is provided with a ceramic heating element to obtain

a high-temperature resistance. It glows in response to a signal sent

from the ECM, allowing current to flow through the glow plug via

the glow relay.

GLOW CONTROL SYSTEMYD

Description

EC-806

Page 1539 of 2898

DescriptionNJEC0764SYSTEM DESCRIPTIONNJEC0764S01

Sensor Input Signal to ECM ECM Function Actuator

Electronic controlled fuel injection pump Fuel injection signal

EGR volume con-

trolEGR volume control

valve Crankshaft position sensor (TDC) Engine speed

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Accelerator position sensor Accelerator position

Mass air flow sensor Amount of intake air

Air conditioner switch Air conditioner operation

Electrical load Electrical load signal

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions.

The EGR volume control valve remains close under the following

conditions.

+Engine stopped

+Engine starting

+Low engine coolant temperature

+Excessively high engine coolant temperature

+High engine speed

+Wide open throttle

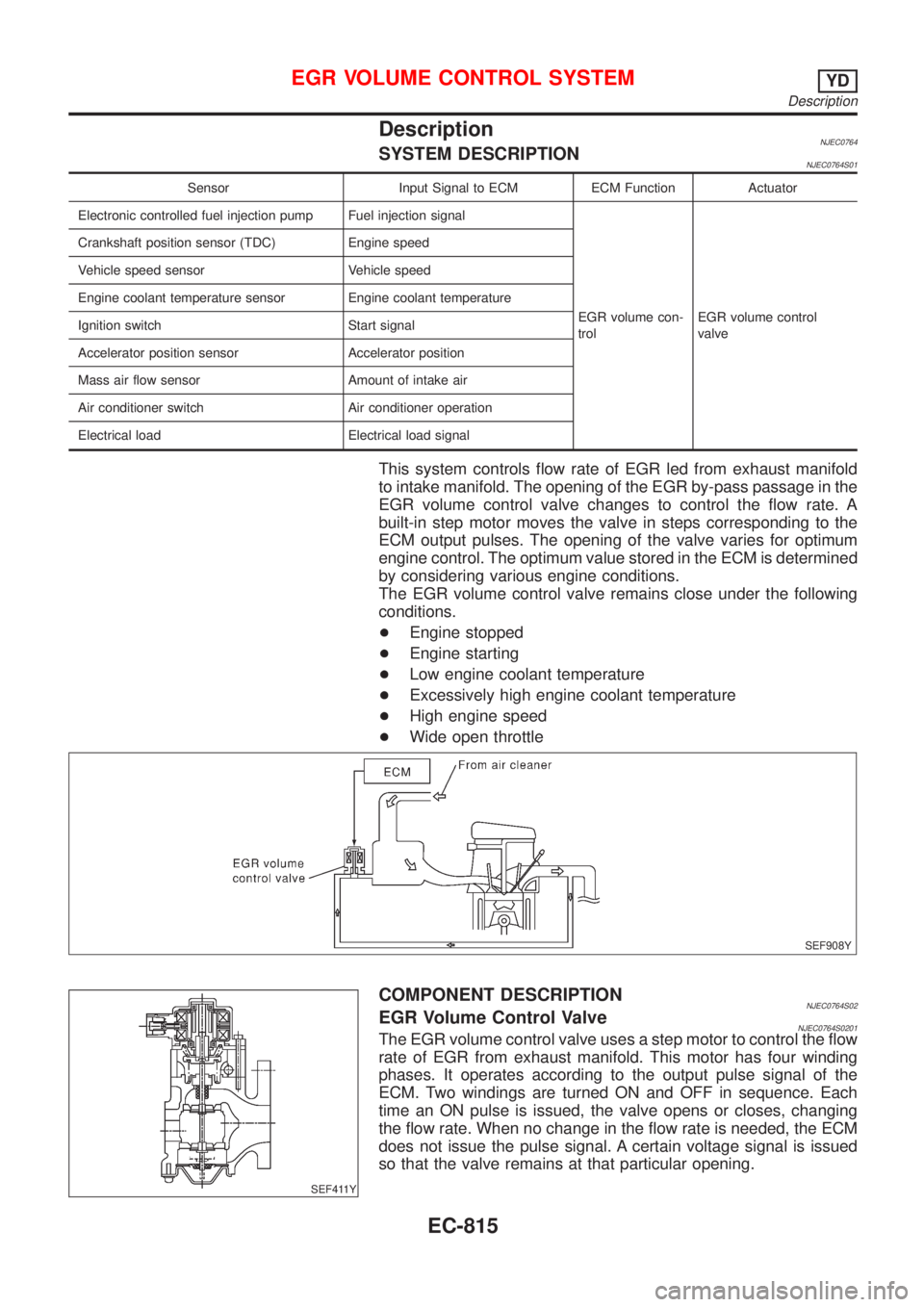

SEF908Y

SEF411Y

COMPONENT DESCRIPTIONNJEC0764S02EGR Volume Control ValveNJEC0764S0201The EGR volume control valve uses a step motor to control the flow

rate of EGR from exhaust manifold. This motor has four winding

phases. It operates according to the output pulse signal of the

ECM. Two windings are turned ON and OFF in sequence. Each

time an ON pulse is issued, the valve opens or closes, changing

the flow rate. When no change in the flow rate is needed, the ECM

does not issue the pulse signal. A certain voltage signal is issued

so that the valve remains at that particular opening.

EGR VOLUME CONTROL SYSTEMYD

Description

EC-815

Page 1565 of 2898

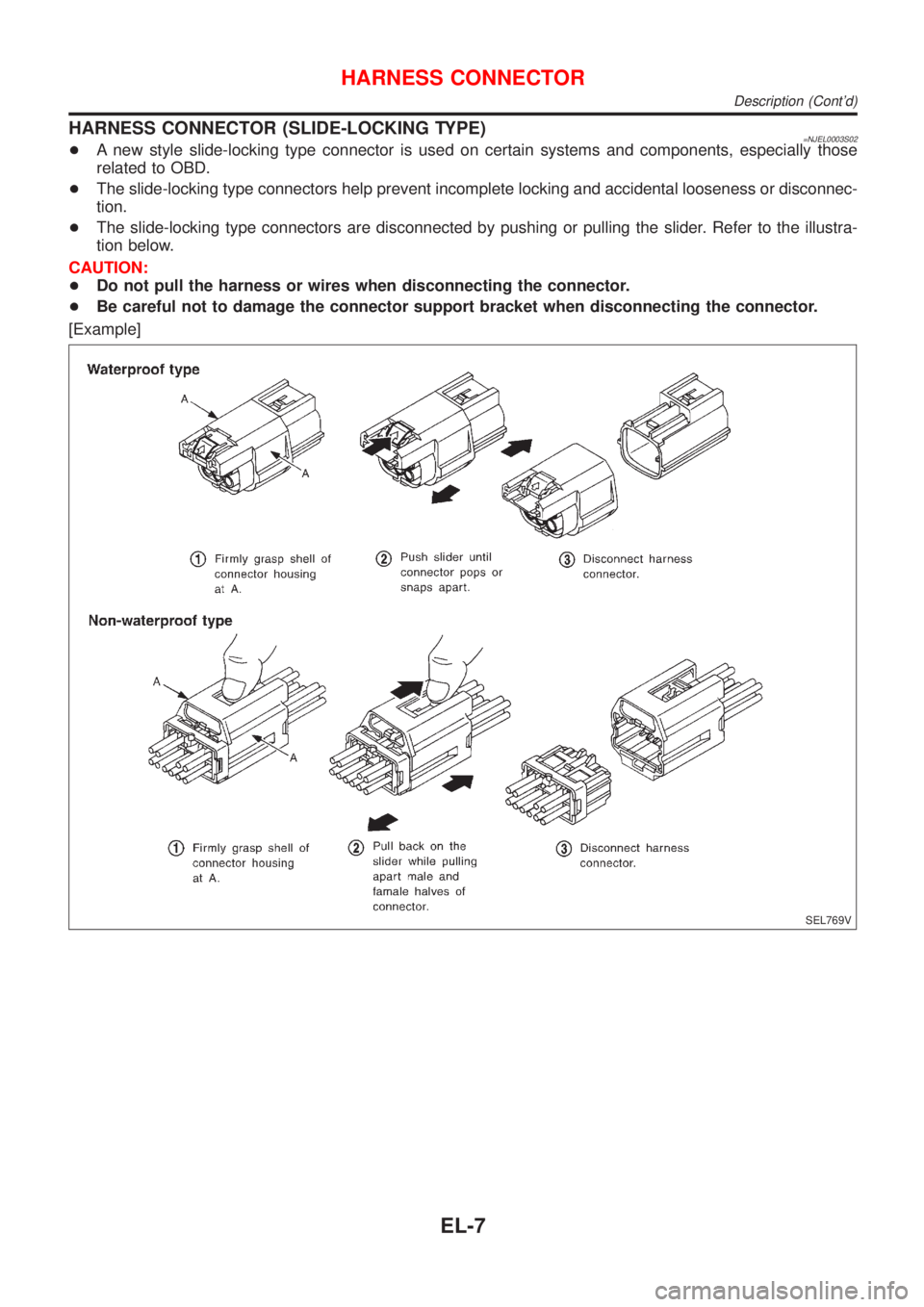

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)=NJEL0003S02+A new style slide-locking type connector is used on certain systems and components, especially those

related to OBD.

+The slide-locking type connectors help prevent incomplete locking and accidental looseness or disconnec-

tion.

+The slide-locking type connectors are disconnected by pushing or pulling the slider. Refer to the illustra-

tion below.

CAUTION:

+Do not pull the harness or wires when disconnecting the connector.

+Be careful not to damage the connector support bracket when disconnecting the connector.

[Example]

SEL769V

HARNESS CONNECTOR

Description (Cont'd)

EL-7

Page 1596 of 2898

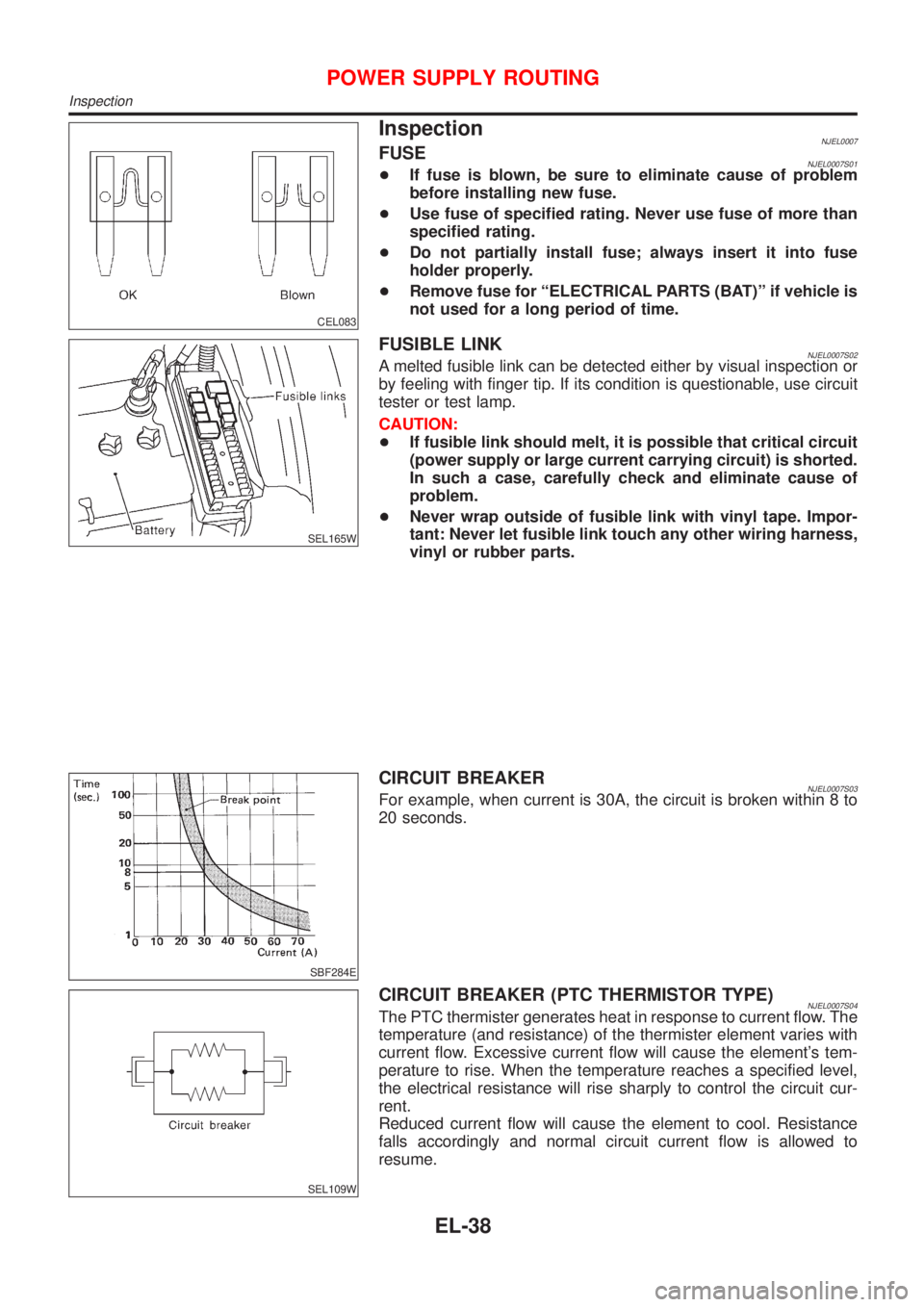

CEL083

InspectionNJEL0007FUSENJEL0007S01+If fuse is blown, be sure to eliminate cause of problem

before installing new fuse.

+Use fuse of specified rating. Never use fuse of more than

specified rating.

+Do not partially install fuse; always insert it into fuse

holder properly.

+Remove fuse for ªELECTRICAL PARTS (BAT)º if vehicle is

not used for a long period of time.

SEL165W

FUSIBLE LINKNJEL0007S02A melted fusible link can be detected either by visual inspection or

by feeling with finger tip. If its condition is questionable, use circuit

tester or test lamp.

CAUTION:

+If fusible link should melt, it is possible that critical circuit

(power supply or large current carrying circuit) is shorted.

In such a case, carefully check and eliminate cause of

problem.

+Never wrap outside of fusible link with vinyl tape. Impor-

tant: Never let fusible link touch any other wiring harness,

vinyl or rubber parts.

SBF284E

CIRCUIT BREAKERNJEL0007S03For example, when current is 30A, the circuit is broken within 8 to

20 seconds.

SEL109W

CIRCUIT BREAKER (PTC THERMISTOR TYPE)NJEL0007S04The PTC thermister generates heat in response to current flow. The

temperature (and resistance) of the thermister element varies with

current flow. Excessive current flow will cause the element's tem-

perature to rise. When the temperature reaches a specified level,

the electrical resistance will rise sharply to control the circuit cur-

rent.

Reduced current flow will cause the element to cool. Resistance

falls accordingly and normal circuit current flow is allowed to

resume.

POWER SUPPLY ROUTING

Inspection

EL-38

Page 1856 of 2898

System Description/Sedan=NJEL0391Power is supplied at all times

+from 30A fusible link (letterE, located in the fuse and fusible link box)

+to circuit breaker terminal 1

+through circuit breaker terminal 2

+to power window relay terminal 5.

With ignition switch in ON or START position, power is supplied

+through 10A fuse [No. 10, located in the fuse block (J/B)]

+to power window relay terminal 1.

Ground is supplied to power window relay terminal 2

+through body grounds M28 and M67.

The power window relay is energized and power is supplied

+through power window relay terminal 3

+to power window main switch terminal 1,

+to front power window sub-switch terminal 5,

+to rear power window sub-switch LH and RH terminals 5 (models with rear power window).

MANUAL OPERATIONNJEL0391S01Front Door (Driver Side)NJEL0391S0101Ground is supplied

+to power window main switch terminal 3

+through body grounds M28 and M67.

WINDOW UP

When the driver's window switch in the power window main switch is pressed in the up position, power is

supplied

+through power window main switch terminal 9

+to driver side power window regulator terminal 2.

Ground is supplied

+through power window main switch terminal 8

+to driver side power window regulator terminal 1.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the driver's window switch in the power window main switch is pressed in the down position, power is

supplied

+through power window main switch terminal 8

+to driver side power window regulator terminal 1.

Ground is supplied

+to driver side power window regulator terminal 2

+through power window main switch terminal 9.

Then, the motor lowers the window until the switch is released.

Front Door (Passenger Side)NJEL0391S0102Ground is supplied

+to power window main switch terminal 3

+through body grounds M28 and M67.

NOTE:

Numbers in parentheses are terminal numbers, when power window switch is pressed in the UP and DOWN

positions respectively.

POWER WINDOW MAIN SWITCH OPERATION

Power is supplied

+through power window main switch (5, 6)

+to front power window sub-switch (3, 4).

POWER WINDOW

System Description/Sedan

EL-298

Page 1864 of 2898

System Description/Hatchback=NJEL0498Power is supplied at all times

+from 30A fusible link (letterE, located in the fuse and fusible link box)

+to circuit breaker terminal 1

+through circuit breaker terminal 2

+to power window relay terminal 5

With ignition switch in ON or START position, power is supplied

+through 10A fuse [No. 10, located in the fuse block (J/B)]

+to power window relay terminal 1

Ground is supplied to power window relay terminal 2

+through body grounds M28 and M67.

The power window relay is energized and power is supplied

+through power window relay terminal 3

+to power window main switch terminal 1,

+to front power window sub-switch terminal 5,

+to rear power window sub-switch LH and RH terminals 5 (models with rear power window).

MANUAL OPERATIONNJEL0498S01Front Door (Driver Side)NJEL0498S0101Ground is supplied

+to power window main switch terminal 3

+through body grounds M28 and M67.

WINDOW UP

When the driver's window switch in the power window main switch is pressed in the up position, power is

supplied

+through power window main switch terminal 9

+to driver side power window regulator terminal 1.

Ground is supplied

+through power window main switch terminal 2

+to driver side power window regulator terminal 8.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the driver's window switch in the power window main switch is pressed in the down position, power is

supplied

+through power window main switch terminal 8

+to driver side power window regulator terminal 2.

Ground is supplied

+to driver side power window regulator terminal 1

+through power window main switch terminal 9.

Then, the motor lowers the window until the switch is released.

Front Door (Passenger Side)NJEL0498S0102Ground is supplied

+to power window main switch terminal 3

+through body grounds M28 and M67.

NOTE:

Numbers in parentheses are terminal numbers, when power window switch is pressed in the UP and DOWN

positions respectively.

POWER WINDOW MAIN SWITCH OPERATION

Power is supplied

+through power window main switch (5, 6)

+to front power window sub-switch (3, 4).

POWER WINDOW

System Description/Hatchback

EL-306

Page 1916 of 2898

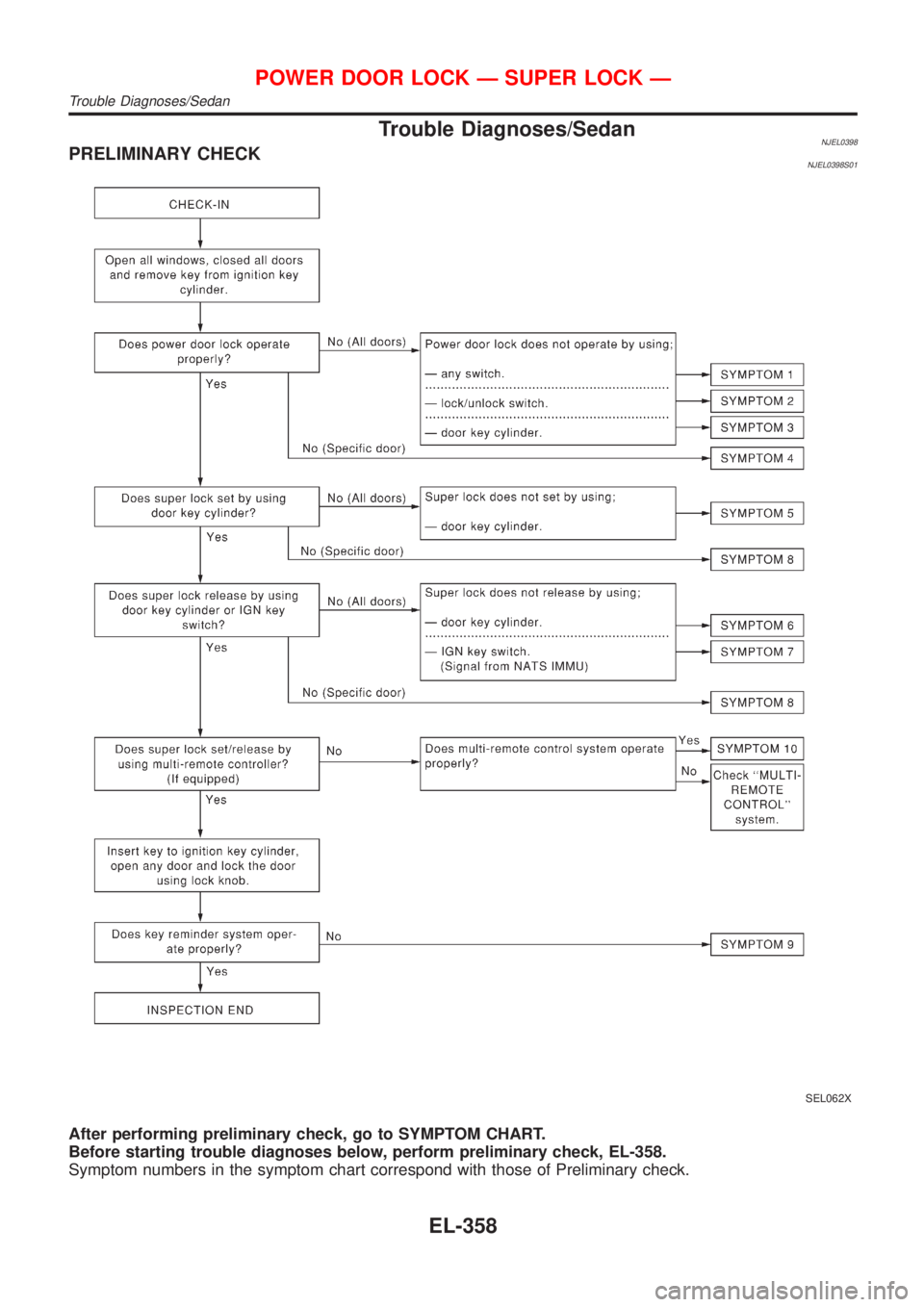

Trouble Diagnoses/SedanNJEL0398PRELIMINARY CHECKNJEL0398S01

SEL062X

After performing preliminary check, go to SYMPTOM CHART.

Before starting trouble diagnoses below, perform preliminary check, EL-358.

Symptom numbers in the symptom chart correspond with those of Preliminary check.

POWER DOOR LOCK Ð SUPER LOCK Ð

Trouble Diagnoses/Sedan

EL-358

Page 1937 of 2898

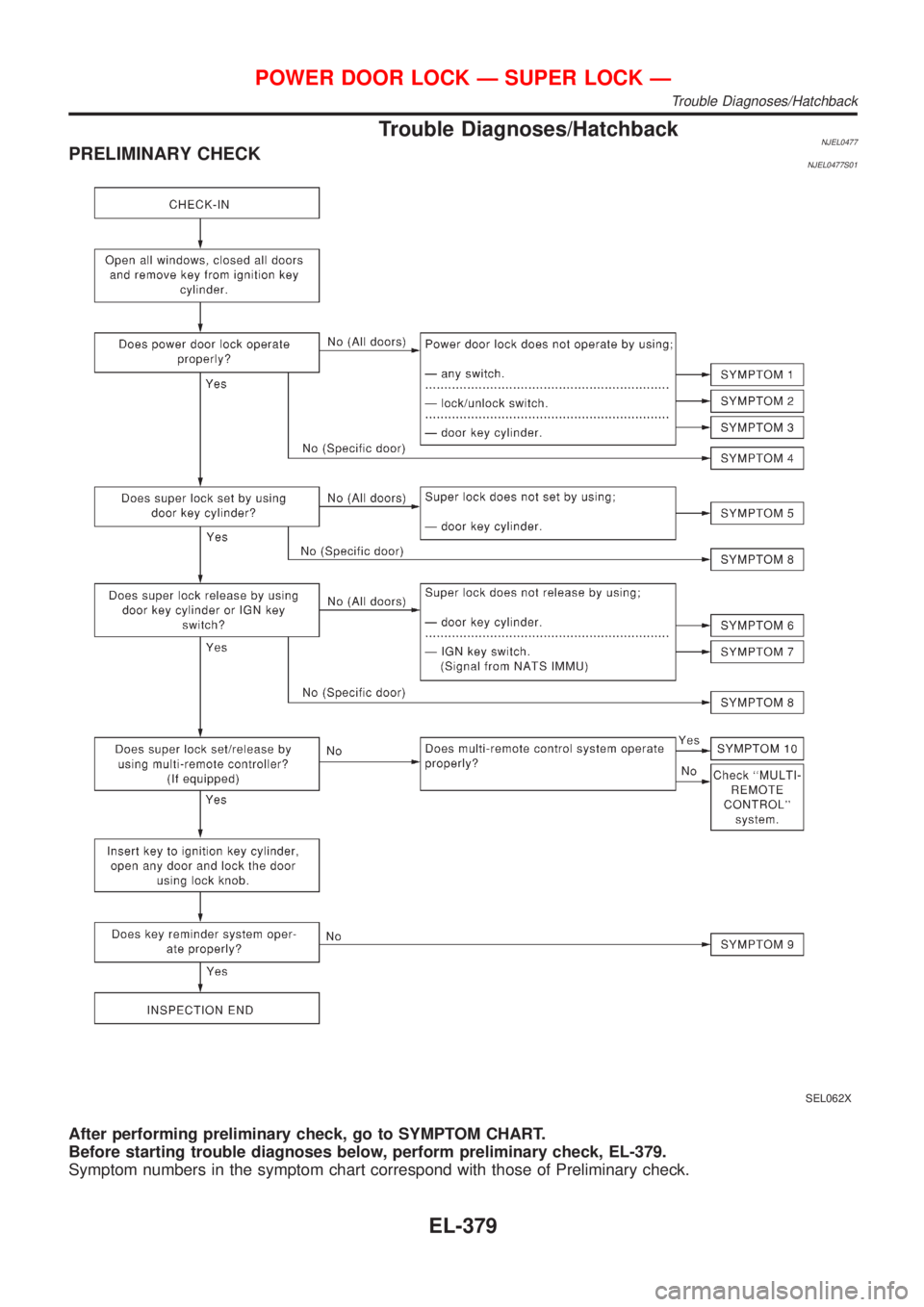

Trouble Diagnoses/HatchbackNJEL0477PRELIMINARY CHECKNJEL0477S01

SEL062X

After performing preliminary check, go to SYMPTOM CHART.

Before starting trouble diagnoses below, perform preliminary check, EL-379.

Symptom numbers in the symptom chart correspond with those of Preliminary check.

POWER DOOR LOCK Ð SUPER LOCK Ð

Trouble Diagnoses/Hatchback

EL-379

Page 2012 of 2898

for example, when the vehicle is in a tunnel, in a parking lot

inside building, under an elevated superhighway or near strong

power lines, the location may not be detected. Turbulent/

electric weather conditions may also affect positioning perfor-

mance. If something is placed on the antenna, the radio wave

from GPS satellites may not be received.

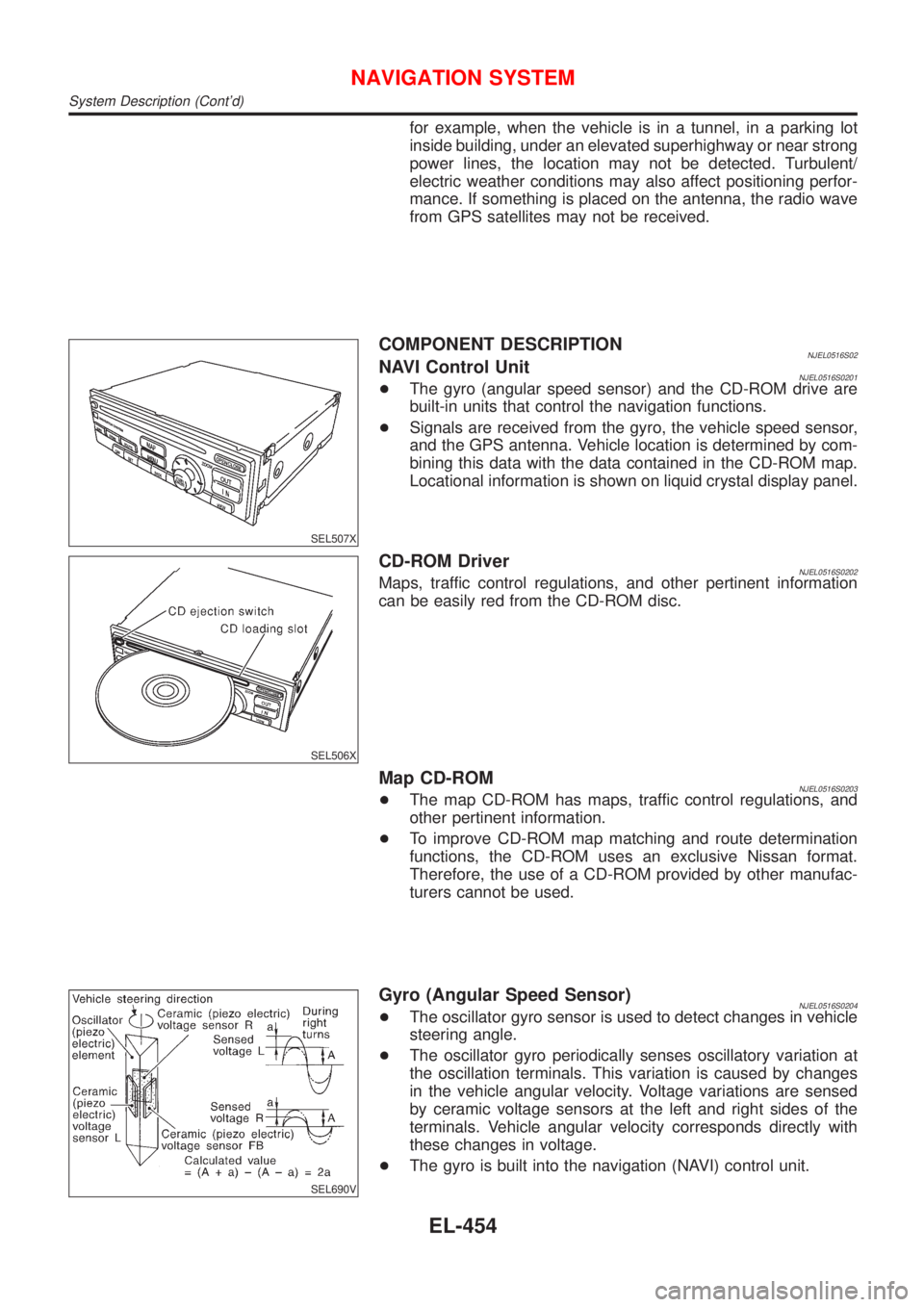

SEL507X

COMPONENT DESCRIPTIONNJEL0516S02NAVI Control UnitNJEL0516S0201+The gyro (angular speed sensor) and the CD-ROM drive are

built-in units that control the navigation functions.

+Signals are received from the gyro, the vehicle speed sensor,

and the GPS antenna. Vehicle location is determined by com-

bining this data with the data contained in the CD-ROM map.

Locational information is shown on liquid crystal display panel.

SEL506X

CD-ROM DriverNJEL0516S0202Maps, traffic control regulations, and other pertinent information

can be easily red from the CD-ROM disc.

Map CD-ROMNJEL0516S0203+The map CD-ROM has maps, traffic control regulations, and

other pertinent information.

+To improve CD-ROM map matching and route determination

functions, the CD-ROM uses an exclusive Nissan format.

Therefore, the use of a CD-ROM provided by other manufac-

turers cannot be used.

SEL690V

Gyro (Angular Speed Sensor)NJEL0516S0204+The oscillator gyro sensor is used to detect changes in vehicle

steering angle.

+The oscillator gyro periodically senses oscillatory variation at

the oscillation terminals. This variation is caused by changes

in the vehicle angular velocity. Voltage variations are sensed

by ceramic voltage sensors at the left and right sides of the

terminals. Vehicle angular velocity corresponds directly with

these changes in voltage.

+The gyro is built into the navigation (NAVI) control unit.

NAVIGATION SYSTEM

System Description (Cont'd)

EL-454