ESP NISSAN ALMERA 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1007 of 2898

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

DTC P0139 HEATED OXYGEN SENSOR 2 (REAR)

(RESPONSE MONITORING)

QG

Component Inspection (Cont'd)

EC-283

Page 1015 of 2898

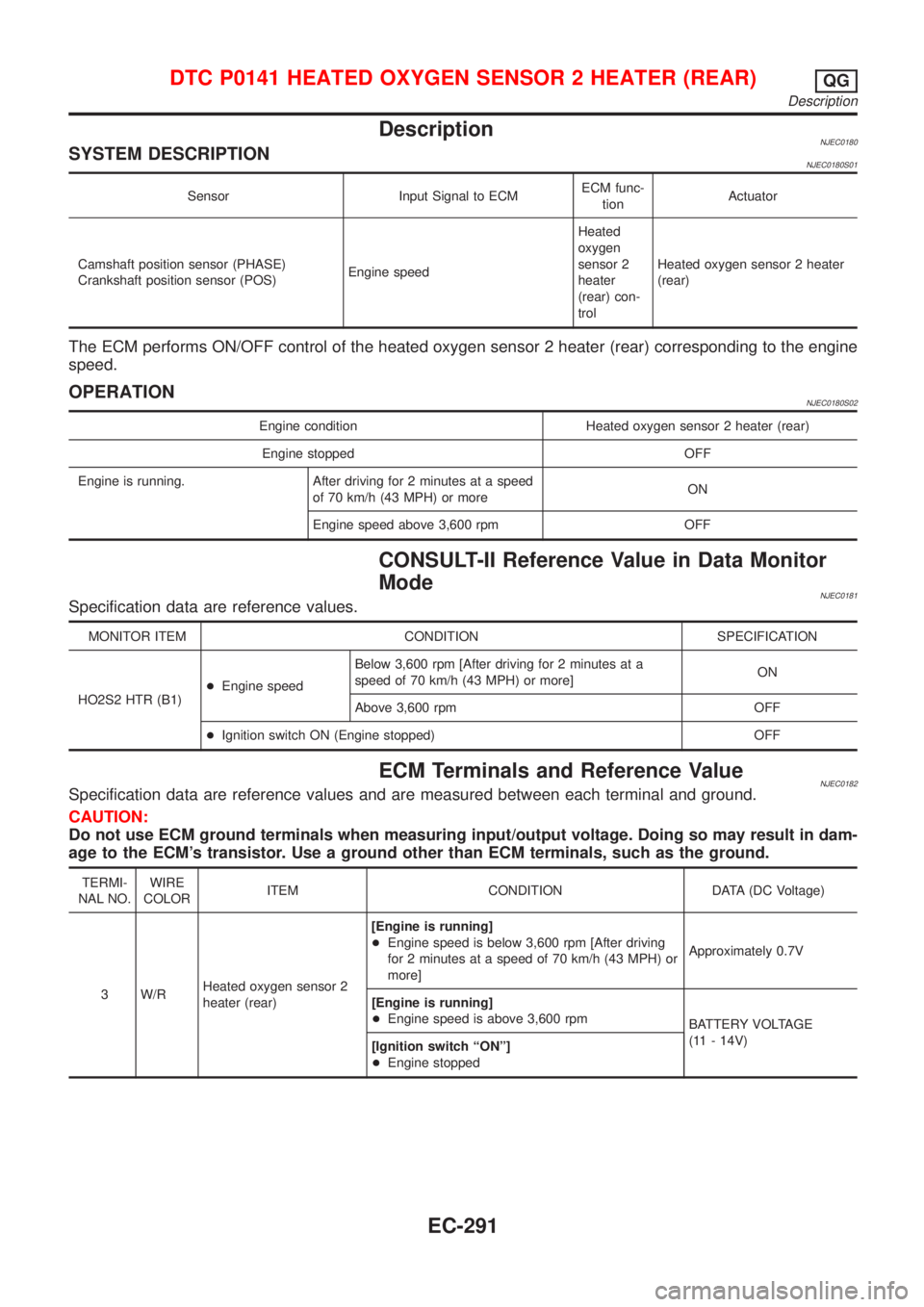

DescriptionNJEC0180SYSTEM DESCRIPTIONNJEC0180S01

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor (PHASE)

Crankshaft position sensor (POS)Engine speedHeated

oxygen

sensor 2

heater

(rear) con-

trolHeated oxygen sensor 2 heater

(rear)

The ECM performs ON/OFF control of the heated oxygen sensor 2 heater (rear) corresponding to the engine

speed.

OPERATIONNJEC0180S02

Engine condition Heated oxygen sensor 2 heater (rear)

Engine stopped OFF

Engine is running. After driving for 2 minutes at a speed

of 70 km/h (43 MPH) or moreON

Engine speed above 3,600 rpm OFF

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0181Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 HTR (B1)+Engine speedBelow 3,600 rpm [After driving for 2 minutes at a

speed of 70 km/h (43 MPH) or more]ON

Above 3,600 rpm OFF

+Ignition switch ON (Engine stopped) OFF

ECM Terminals and Reference ValueNJEC0182Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

3 W/RHeated oxygen sensor 2

heater (rear)[Engine is running]

+Engine speed is below 3,600 rpm [After driving

for 2 minutes at a speed of 70 km/h (43 MPH) or

more]Approximately 0.7V

[Engine is running]

+Engine speed is above 3,600 rpm

BATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

+Engine stopped

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)QG

Description

EC-291

Page 1067 of 2898

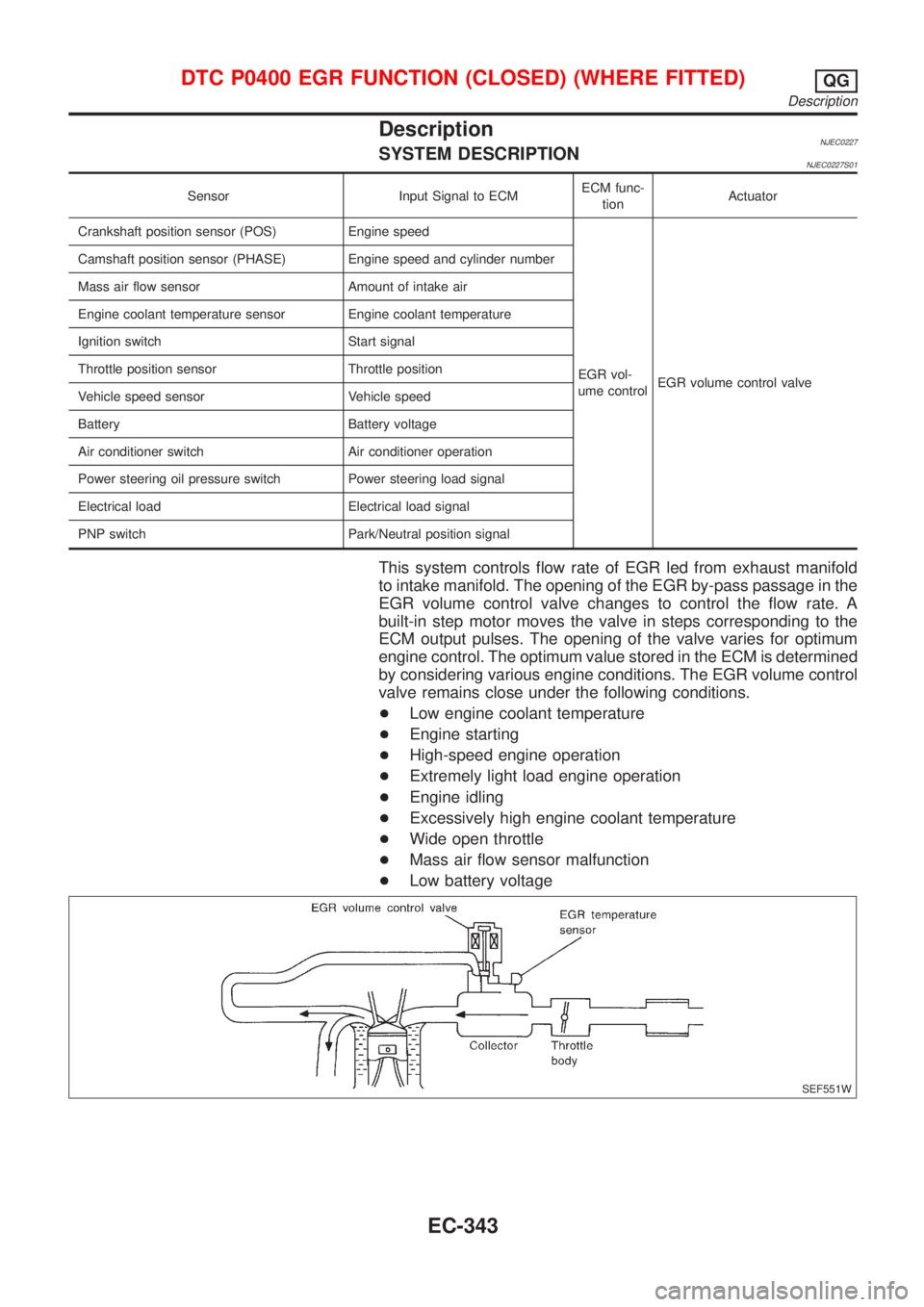

DescriptionNJEC0227SYSTEM DESCRIPTIONNJEC0227S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

EGR vol-

ume controlEGR volume control valve Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Vehicle speed sensor Vehicle speed

Battery Battery voltage

Air conditioner switch Air conditioner operation

Power steering oil pressure switch Power steering load signal

Electrical load Electrical load signal

PNP switch Park/Neutral position signal

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions. The EGR volume control

valve remains close under the following conditions.

+Low engine coolant temperature

+Engine starting

+High-speed engine operation

+Extremely light load engine operation

+Engine idling

+Excessively high engine coolant temperature

+Wide open throttle

+Mass air flow sensor malfunction

+Low battery voltage

SEF551W

DTC P0400 EGR FUNCTION (CLOSED) (WHERE FITTED)QG

Description

EC-343

Page 1076 of 2898

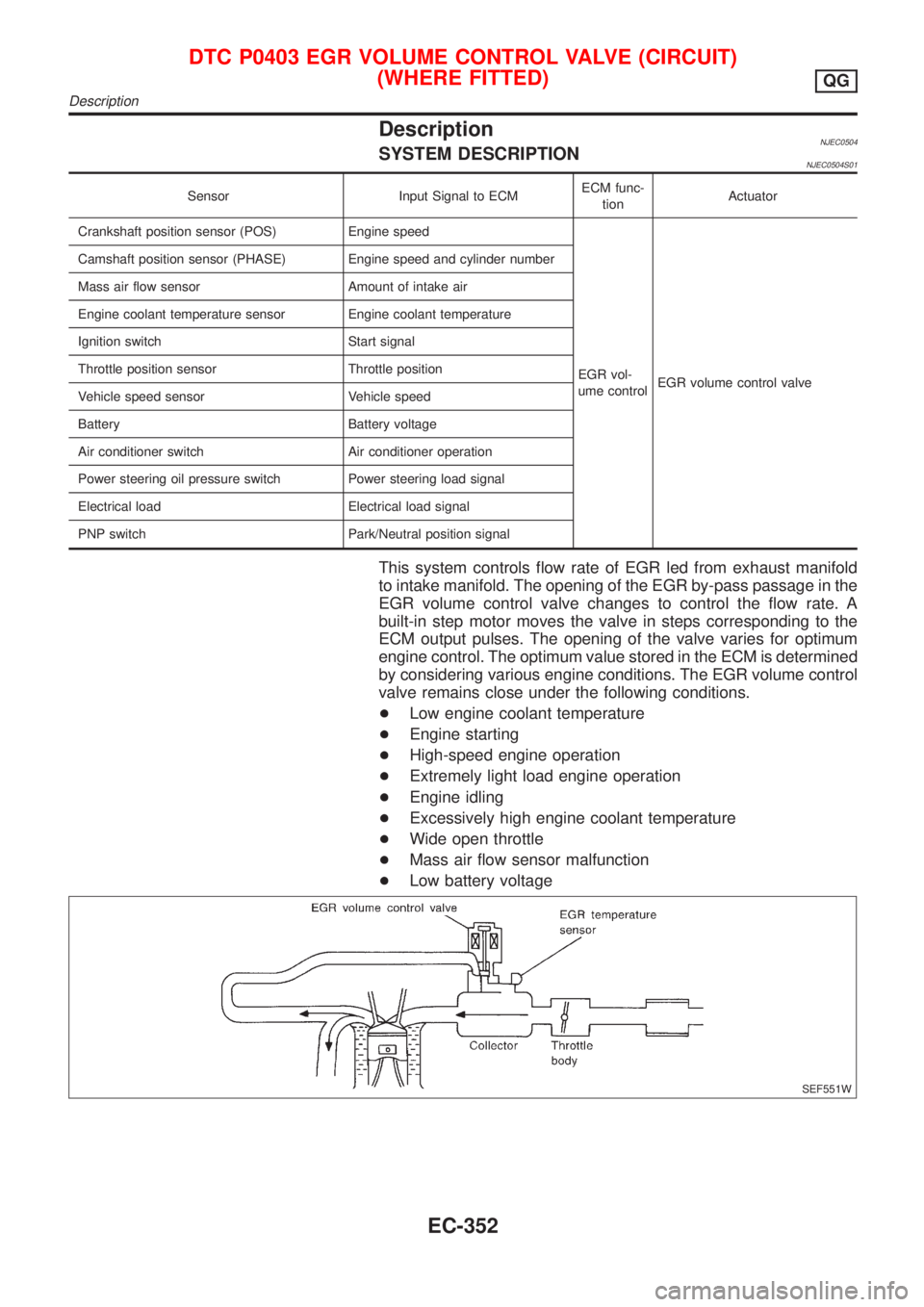

DescriptionNJEC0504SYSTEM DESCRIPTIONNJEC0504S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

EGR vol-

ume controlEGR volume control valve Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Vehicle speed sensor Vehicle speed

Battery Battery voltage

Air conditioner switch Air conditioner operation

Power steering oil pressure switch Power steering load signal

Electrical load Electrical load signal

PNP switch Park/Neutral position signal

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions. The EGR volume control

valve remains close under the following conditions.

+Low engine coolant temperature

+Engine starting

+High-speed engine operation

+Extremely light load engine operation

+Engine idling

+Excessively high engine coolant temperature

+Wide open throttle

+Mass air flow sensor malfunction

+Low battery voltage

SEF551W

DTC P0403 EGR VOLUME CONTROL VALVE (CIRCUIT)

(WHERE FITTED)

QG

Description

EC-352

Page 1100 of 2898

DescriptionNJEC0279SYSTEM DESCRIPTIONNJEC0279S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Idle air

controlIACV-AAC valve Camshaft position sensor (PHASE) Engine speed and cylinder number

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

PNP switch Park/Neutral position

Air conditioner switch Air conditioner operation

Power steering oil pressure switch Power steering load signal

Battery Battery voltage

Vehicle speed sensor Vehicle speed

Cooling fan Cooling fan operation

Electrical load Electrical load signal

This system automatically controls engine idle speed to a specified

level. Idle speed is controlled through fine adjustment of the

amount of air which by-passes the throttle valve via IACV-AAC

valve. The IACV-AAC valve changes the opening of the air by-pass

passage to control the amount of auxiliary air. This valve is actu-

ated by a step motor built into the valve, which moves the valve in

the axial direction in steps corresponding to the ECM output sig-

nals. One step of IACV-AAC valve movement causes the respec-

tive opening of the air by-pass passage. (i.e. when the step

advances, the opening is enlarged.) The opening of the valve is

varied to allow for optimum control of the engine idling speed. The

crankshaft position sensor (POS) detects the actual engine speed

and sends a signal to the ECM. The ECM then controls the step

position of the IACV-AAC valve so that engine speed coincides with

the target value memorized in ECM. The target engine speed is the

lowest speed at which the engine can operate steadily. The opti-

mum value stored in the ECM is determined by taking into consid-

eration various engine conditions, such as during warm up,

deceleration, and engine load (air conditioner, power steering, cool-

ing fan operation and electrical load).

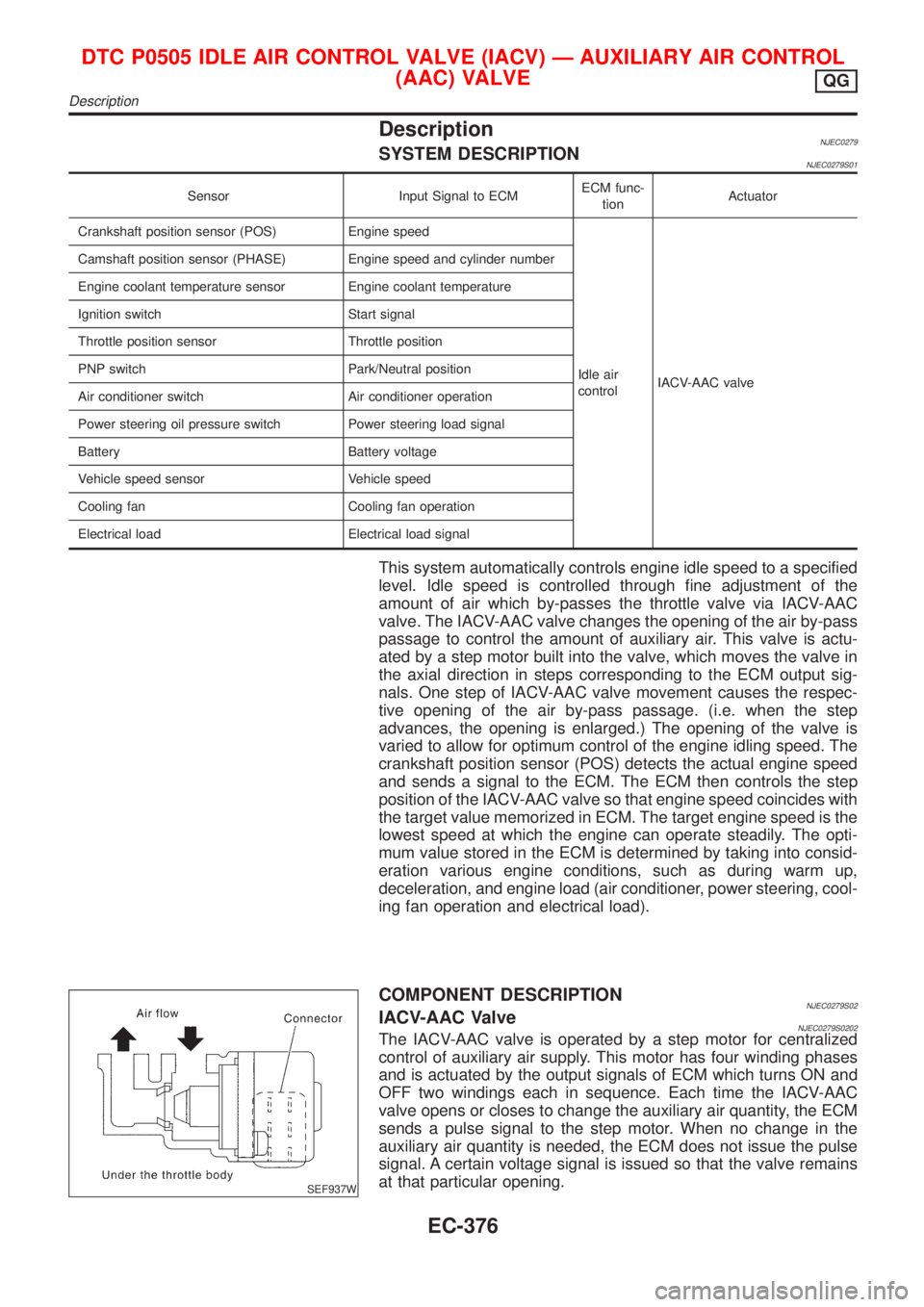

SEF937W

COMPONENT DESCRIPTIONNJEC0279S02IACV-AAC ValveNJEC0279S0202The IACV-AAC valve is operated by a step motor for centralized

control of auxiliary air supply. This motor has four winding phases

and is actuated by the output signals of ECM which turns ON and

OFF two windings each in sequence. Each time the IACV-AAC

valve opens or closes to change the auxiliary air quantity, the ECM

sends a pulse signal to the step motor. When no change in the

auxiliary air quantity is needed, the ECM does not issue the pulse

signal. A certain voltage signal is issued so that the valve remains

at that particular opening.

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

QG

Description

EC-376

Page 1124 of 2898

ECM Terminals and Reference Value=NJEC0524Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

104 SBSwirl control valve control

solenoid valve[Engine is running]

+Engine coolant temperature is between 15ÉC

(59ÉF) to 40ÉC (104ÉF).

+Idle speed0-1V

[Engine is running]

+Engine coolant temperature is above 40ÉC

(104ÉF).

+Idle speedBATTERY VOLTAGE

(11 - 14V)

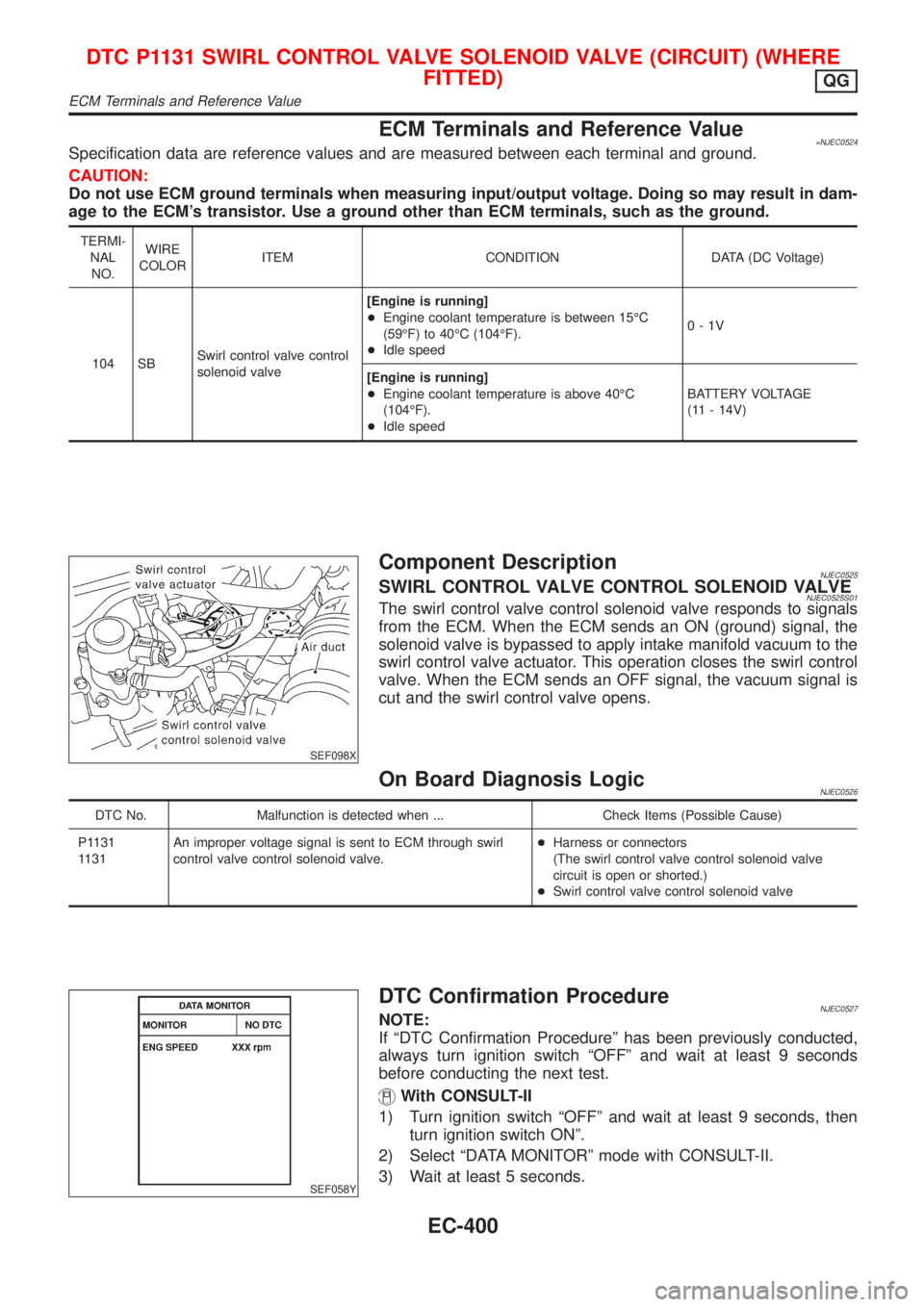

SEF098X

Component DescriptionNJEC0525SWIRL CONTROL VALVE CONTROL SOLENOID VALVENJEC0525S01The swirl control valve control solenoid valve responds to signals

from the ECM. When the ECM sends an ON (ground) signal, the

solenoid valve is bypassed to apply intake manifold vacuum to the

swirl control valve actuator. This operation closes the swirl control

valve. When the ECM sends an OFF signal, the vacuum signal is

cut and the swirl control valve opens.

On Board Diagnosis LogicNJEC0526

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1131

1131An improper voltage signal is sent to ECM through swirl

control valve control solenoid valve.+Harness or connectors

(The swirl control valve control solenoid valve

circuit is open or shorted.)

+Swirl control valve control solenoid valve

SEF058Y

DTC Confirmation ProcedureNJEC0527NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªOFFº and wait at least 9 seconds, then

turn ignition switch ONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

DTC P1131 SWIRL CONTROL VALVE SOLENOID VALVE (CIRCUIT) (WHERE

FITTED)

QG

ECM Terminals and Reference Value

EC-400

Page 1130 of 2898

System DescriptionNJEC0433COOLING FAN CONTROLNJEC0433S01

Sensor Input Signal to ECMECM func-

tionActuator

Vehicle speed sensor Vehicle speed

Cooling fan

controlCooling fan relay(s) Engine coolant temperature sensor Engine coolant temperature

Air conditioner switch Air conditioner ªONº signal

Ignition switch Start signal

Refrigerant pressure sensor Refrigerant pressure

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refriger-

ant pressure, and air conditioner ON signal. The control system has ON-OFF control.

OPERATIONNJEC0433S02Engine coolant temperatures at which the cooling fan turns ªONº are indicated in the Table below.

Vehicle speed km/h (MPH)

Air conditioner switchHigh pressure of

refrigerant

kPa (bar, kg/cm

2, psi)Less than 50 (30) 50 - 80 (30 - 50) More than 80 (50)

ONMore than 1,680

(16.8, 17.14, 244)Always Always More than 95ÉC (203ÉF)

Less than 1,680

(16.8, 17.14, 244)Always More than 95ÉC (203ÉF) More than 95ÉC (203ÉF)

OFFMore than 100ÉC

(212ÉF)More than 95ÉC (203ÉF) More than 95ÉC (203ÉF)

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0486Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

AIR COND SIG+Engine: After warming up, idle

the engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates)ON

COOLING FAN+After warming up engine, idle

the engine.

+Air conditioner switch: OFFEngine coolant temperature is less

than 100ÉC (212ÉF)OFF

Engine coolant temperature is

100ÉC (212ÉF) or moreON

DTC P1217 OVERHEAT (COOLING SYSTEM)QG

System Description

EC-406

Page 1149 of 2898

DescriptionNJEC0349SYSTEM DESCRIPTIONNJEC0349S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

EGR vol-

ume controlEGR volume control valve Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Vehicle speed sensor Vehicle speed

Battery Battery voltage

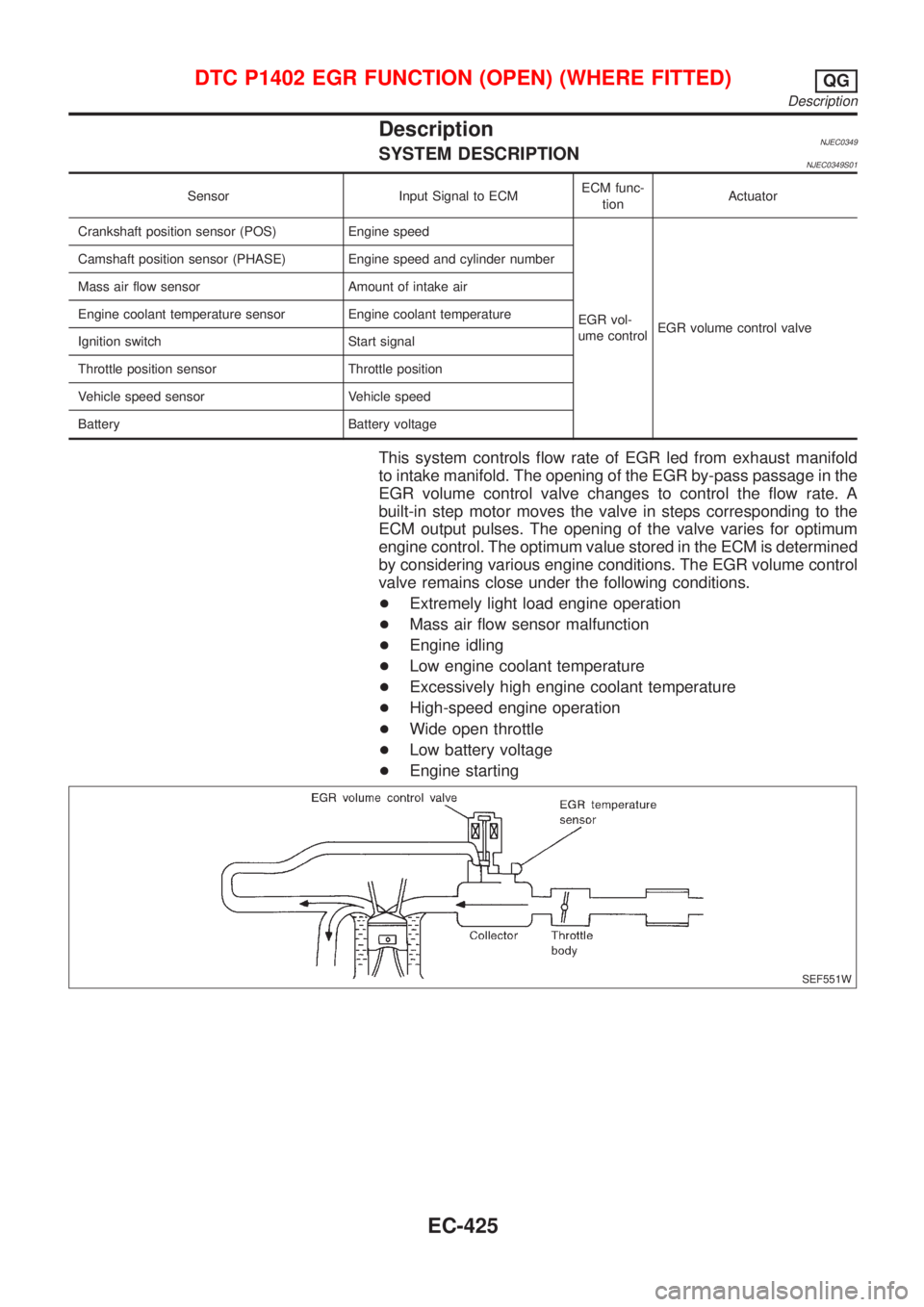

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions. The EGR volume control

valve remains close under the following conditions.

+Extremely light load engine operation

+Mass air flow sensor malfunction

+Engine idling

+Low engine coolant temperature

+Excessively high engine coolant temperature

+High-speed engine operation

+Wide open throttle

+Low battery voltage

+Engine starting

SEF551W

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG

Description

EC-425

Page 1166 of 2898

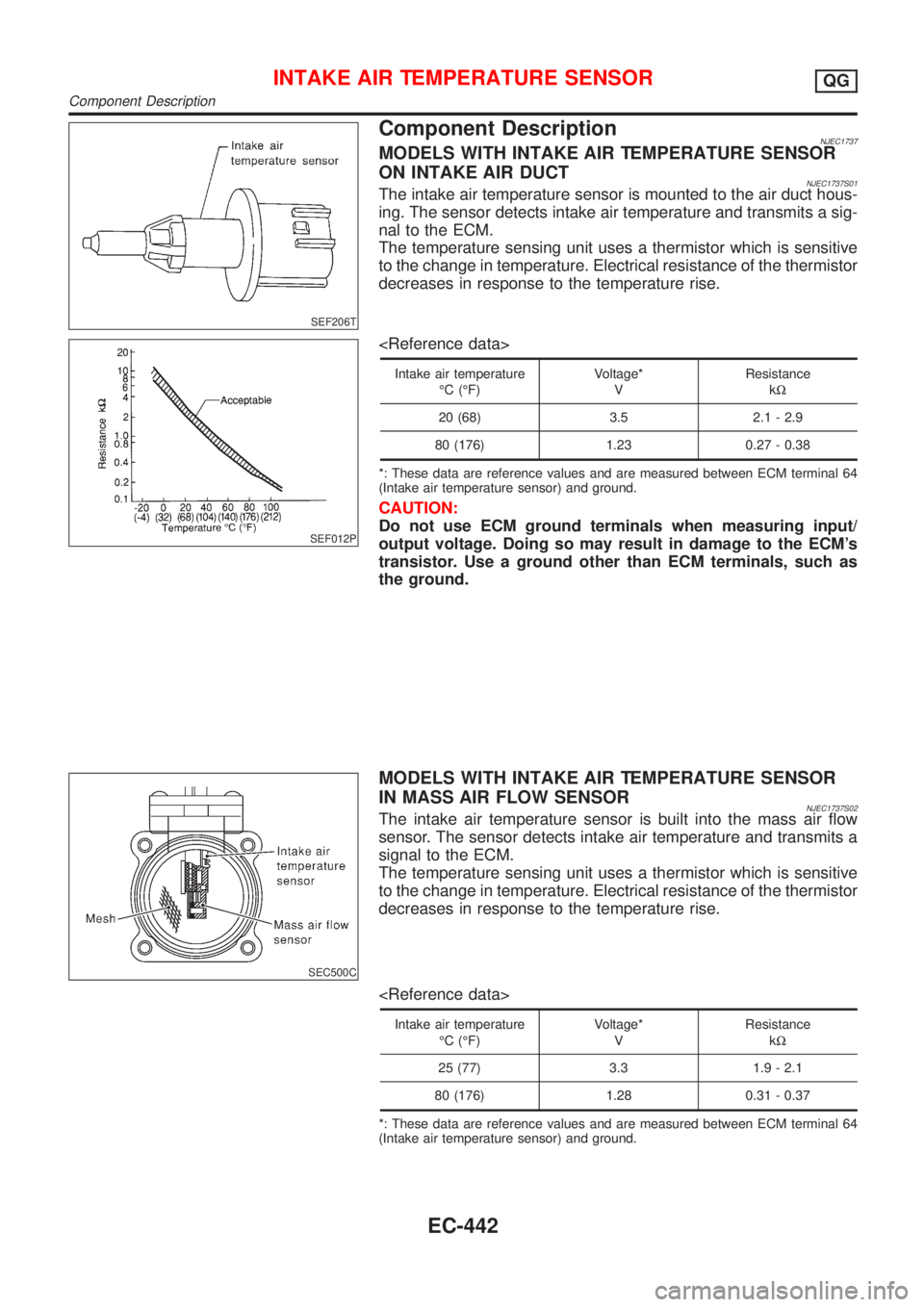

SEF206T

Component DescriptionNJEC1737MODELS WITH INTAKE AIR TEMPERATURE SENSOR

ON INTAKE AIR DUCT

NJEC1737S01The intake air temperature sensor is mounted to the air duct hous-

ing. The sensor detects intake air temperature and transmits a sig-

nal to the ECM.

The temperature sensing unit uses a thermistor which is sensitive

to the change in temperature. Electrical resistance of the thermistor

decreases in response to the temperature rise.

SEF012P

Intake air temperature

ÉC (ÉF)Voltage*

VResistance

kW

20 (68) 3.5 2.1 - 2.9

80 (176) 1.23 0.27 - 0.38

*: These data are reference values and are measured between ECM terminal 64

(Intake air temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

SEC500C

MODELS WITH INTAKE AIR TEMPERATURE SENSOR

IN MASS AIR FLOW SENSOR

NJEC1737S02The intake air temperature sensor is built into the mass air flow

sensor. The sensor detects intake air temperature and transmits a

signal to the ECM.

The temperature sensing unit uses a thermistor which is sensitive

to the change in temperature. Electrical resistance of the thermistor

decreases in response to the temperature rise.

Intake air temperature

ÉC (ÉF)Voltage*

VResistance

kW

25 (77) 3.3 1.9 - 2.1

80 (176) 1.28 0.31 - 0.37

*: These data are reference values and are measured between ECM terminal 64

(Intake air temperature sensor) and ground.

INTAKE AIR TEMPERATURE SENSORQG

Component Description

EC-442

Page 1178 of 2898

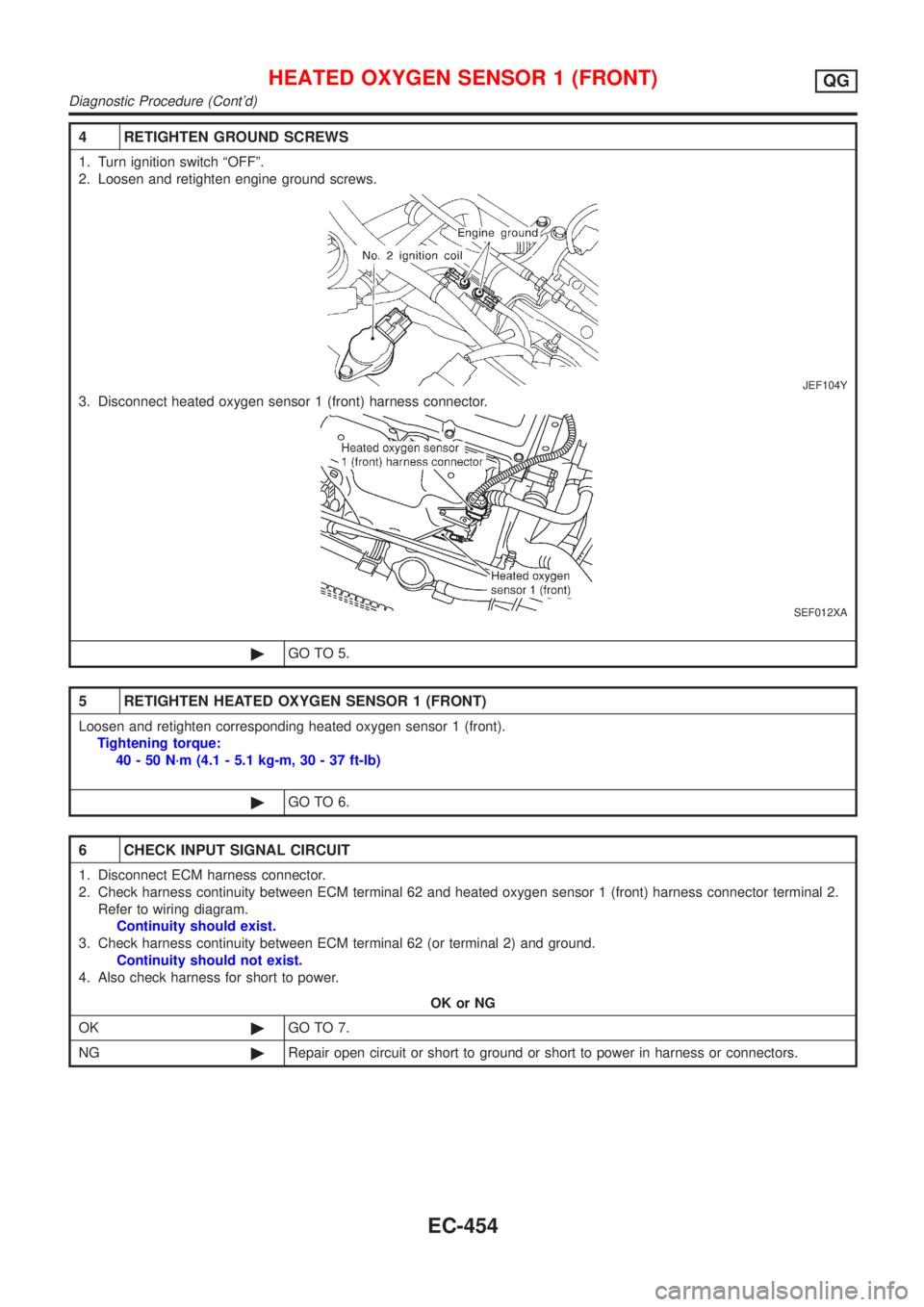

4 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

JEF104Y

3. Disconnect heated oxygen sensor 1 (front) harness connector.

SEF012XA

©GO TO 5.

5 RETIGHTEN HEATED OXYGEN SENSOR 1 (FRONT)

Loosen and retighten corresponding heated oxygen sensor 1 (front).

Tightening torque:

40 - 50 N´m (4.1 - 5.1 kg-m, 30 - 37 ft-lb)

©GO TO 6.

6 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Check harness continuity between ECM terminal 62 (or terminal 2) and ground.

Continuity should not exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 7.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

HEATED OXYGEN SENSOR 1 (FRONT)QG

Diagnostic Procedure (Cont'd)

EC-454