battery NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1996 of 2898

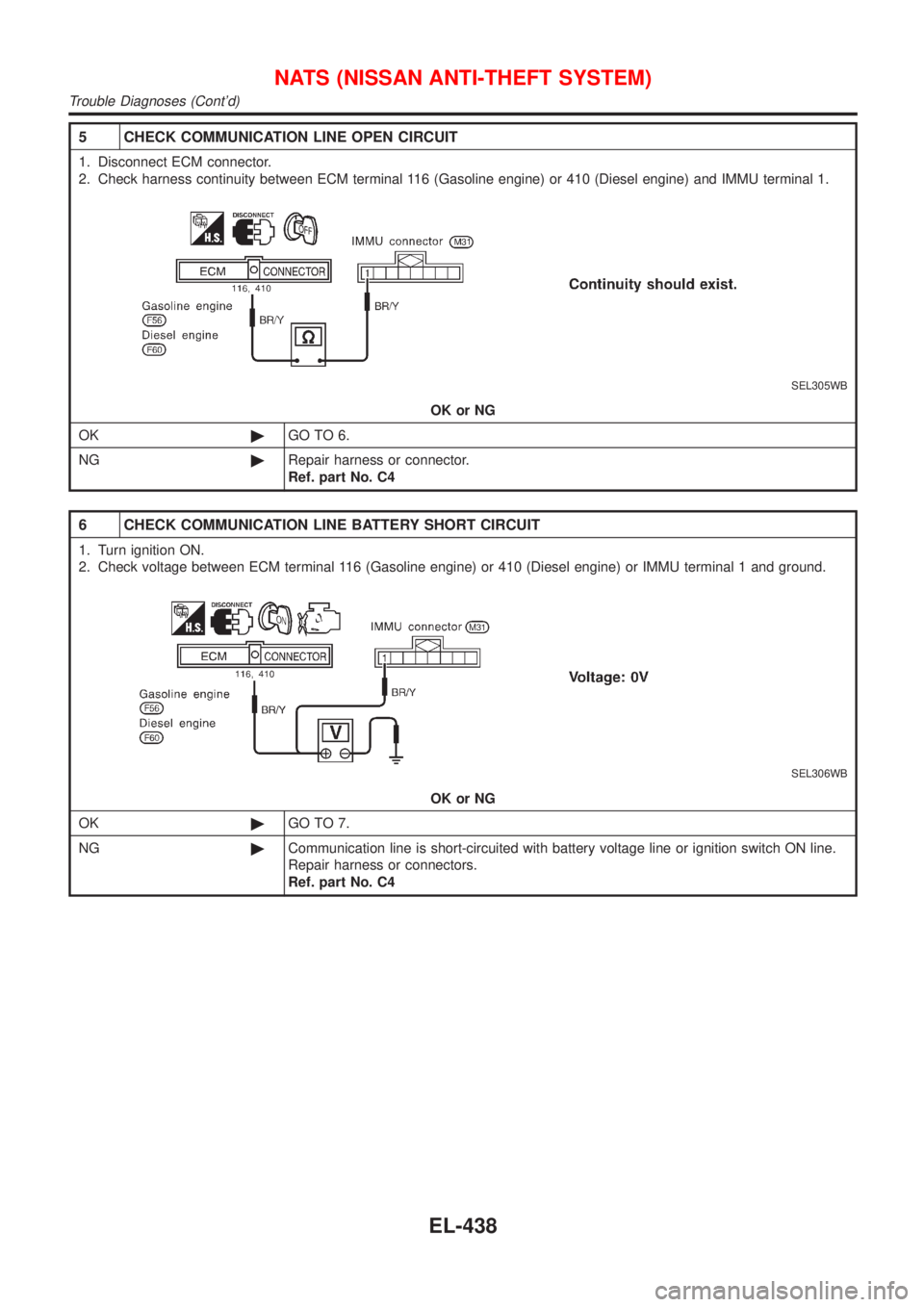

5 CHECK COMMUNICATION LINE OPEN CIRCUIT

1. Disconnect ECM connector.

2. Check harness continuity between ECM terminal 116 (Gasoline engine) or 410 (Diesel engine) and IMMU terminal 1.

SEL305WB

OK or NG

OK©GO TO 6.

NG©Repair harness or connector.

Ref. part No. C4

6 CHECK COMMUNICATION LINE BATTERY SHORT CIRCUIT

1. Turn ignition ON.

2. Check voltage between ECM terminal 116 (Gasoline engine) or 410 (Diesel engine) or IMMU terminal 1 and ground.

SEL306WB

OK or NG

OK©GO TO 7.

NG©Communication line is short-circuited with battery voltage line or ignition switch ON line.

Repair harness or connectors.

Ref. part No. C4

NATS (NISSAN ANTI-THEFT SYSTEM)

Trouble Diagnoses (Cont'd)

EL-438

Page 2008 of 2898

PrecautionsNJEL0514WARNING:

Do not attempt to disassemble the monitor. Parts of the monitor have high voltages that can result in

severe and dangerous electric shock.

CAUTION:

+Do not reverse battery connections.

+Do not attach unauthorized parts.

+Protect the unit from severe impact.

NOTE:

Before beginning repair, determine whether or not the unit is defective. Refer to ªThis Condition Is Not

Abnormalº (EL-507).

NAVIGATION SYSTEM

Precautions

EL-450

Page 2059 of 2898

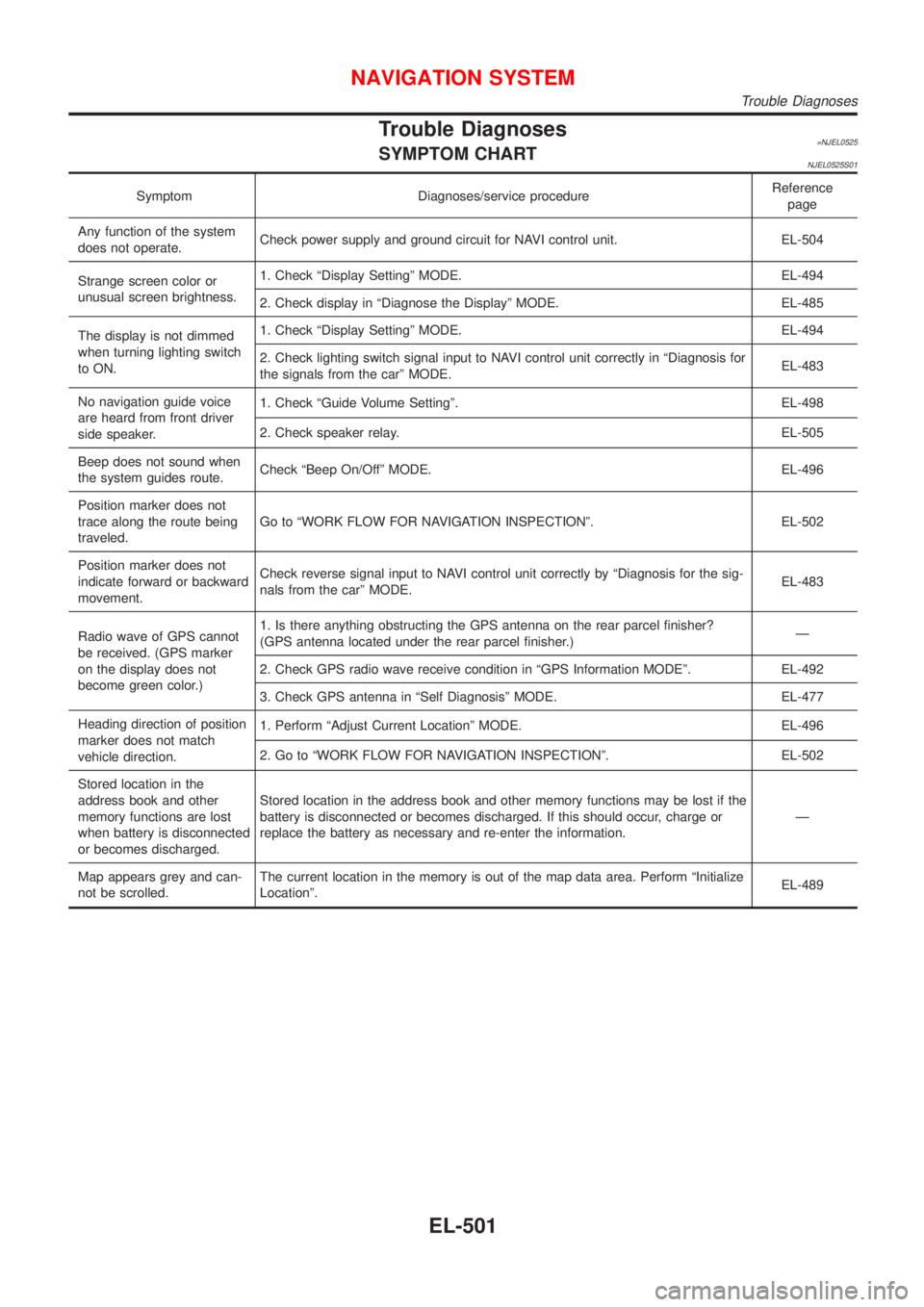

Trouble Diagnoses=NJEL0525SYMPTOM CHARTNJEL0525S01

Symptom Diagnoses/service procedureReference

page

Any function of the system

does not operate.Check power supply and ground circuit for NAVI control unit. EL-504

Strange screen color or

unusual screen brightness.1. Check ªDisplay Settingº MODE. EL-494

2. Check display in ªDiagnose the Displayº MODE. EL-485

The display is not dimmed

when turning lighting switch

to ON.1. Check ªDisplay Settingº MODE. EL-494

2. Check lighting switch signal input to NAVI control unit correctly in ªDiagnosis for

the signals from the carº MODE.EL-483

No navigation guide voice

are heard from front driver

side speaker.1. Check ªGuide Volume Settingº. EL-498

2. Check speaker relay. EL-505

Beep does not sound when

the system guides route.Check ªBeep On/Offº MODE. EL-496

Position marker does not

trace along the route being

traveled.Go to ªWORK FLOW FOR NAVIGATION INSPECTIONº. EL-502

Position marker does not

indicate forward or backward

movement.Check reverse signal input to NAVI control unit correctly by ªDiagnosis for the sig-

nals from the carº MODE.EL-483

Radio wave of GPS cannot

be received. (GPS marker

on the display does not

become green color.)1. Is there anything obstructing the GPS antenna on the rear parcel finisher?

(GPS antenna located under the rear parcel finisher.)Ð

2. Check GPS radio wave receive condition in ªGPS Information MODEº. EL-492

3. Check GPS antenna in ªSelf Diagnosisº MODE. EL-477

Heading direction of position

marker does not match

vehicle direction.1. Perform ªAdjust Current Locationº MODE. EL-496

2. Go to ªWORK FLOW FOR NAVIGATION INSPECTIONº. EL-502

Stored location in the

address book and other

memory functions are lost

when battery is disconnected

or becomes discharged.Stored location in the address book and other memory functions may be lost if the

battery is disconnected or becomes discharged. If this should occur, charge or

replace the battery as necessary and re-enter the information.Ð

Map appears grey and can-

not be scrolled.The current location in the memory is out of the map data area. Perform ªInitialize

Locationº.EL-489

NAVIGATION SYSTEM

Trouble Diagnoses

EL-501

Page 2062 of 2898

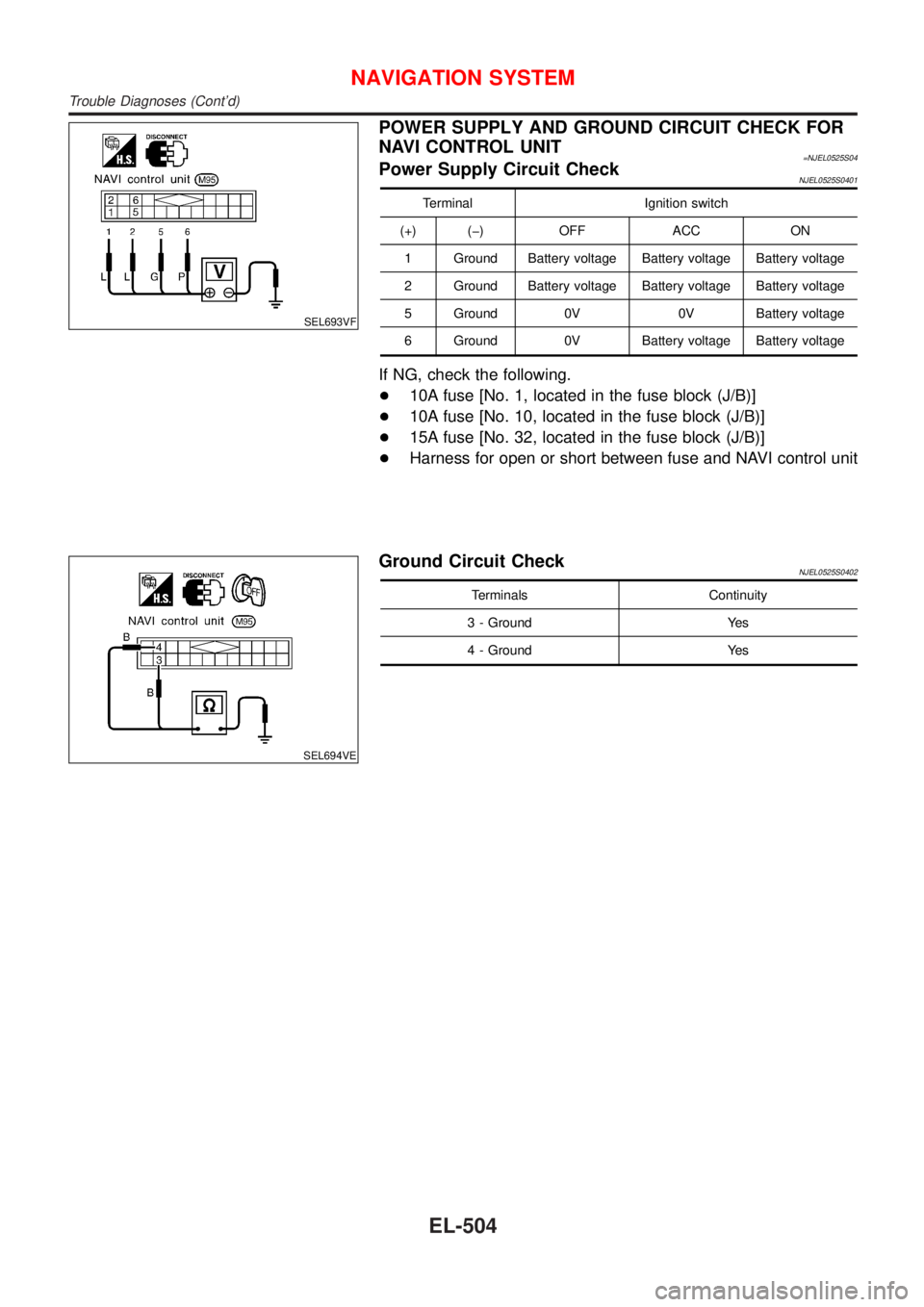

SEL693VF

POWER SUPPLY AND GROUND CIRCUIT CHECK FOR

NAVI CONTROL UNIT

=NJEL0525S04Power Supply Circuit CheckNJEL0525S0401

Terminal Ignition switch

(+) (þ) OFF ACC ON

1 Ground Battery voltage Battery voltage Battery voltage

2 Ground Battery voltage Battery voltage Battery voltage

5 Ground 0V 0V Battery voltage

6 Ground 0V Battery voltage Battery voltage

If NG, check the following.

+10A fuse [No. 1, located in the fuse block (J/B)]

+10A fuse [No. 10, located in the fuse block (J/B)]

+15A fuse [No. 32, located in the fuse block (J/B)]

+Harness for open or short between fuse and NAVI control unit

SEL694VE

Ground Circuit CheckNJEL0525S0402

Terminals Continuity

3 - Ground Yes

4 - Ground Yes

NAVIGATION SYSTEM

Trouble Diagnoses (Cont'd)

EL-504

Page 2149 of 2898

NJEM0007

1. Warm up engine.

2. Turn ignition switch OFF.

3. Release fuel pressure.

Refer to EC-40, ªReleasing Fuel Pressureº.

4. Remove ignition coils.

5. Remove spark plugs.

+Clean area around plug with compressed air before removing

the spark plug.

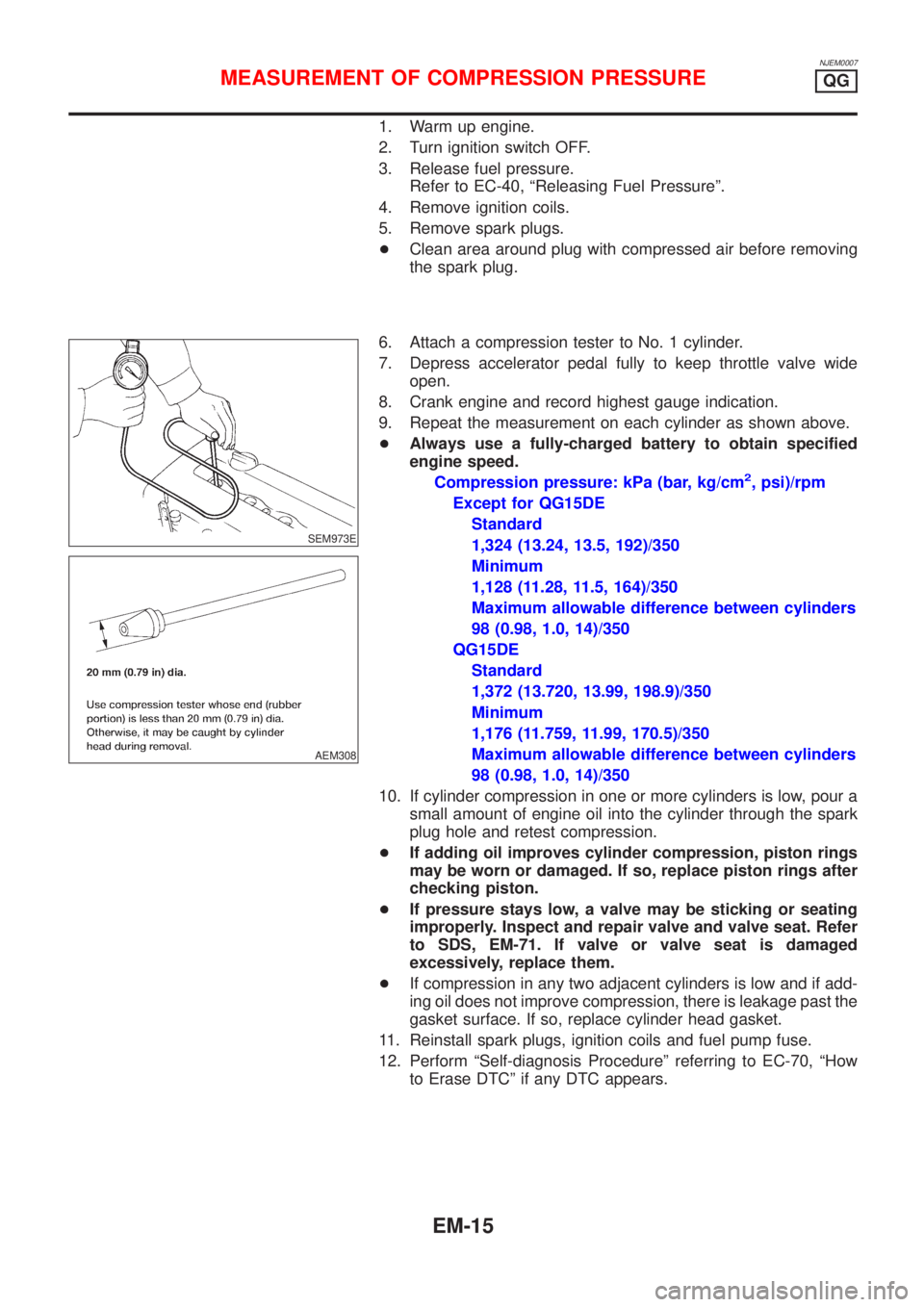

SEM973E

AEM308

6. Attach a compression tester to No. 1 cylinder.

7. Depress accelerator pedal fully to keep throttle valve wide

open.

8. Crank engine and record highest gauge indication.

9. Repeat the measurement on each cylinder as shown above.

+Always use a fully-charged battery to obtain specified

engine speed.

Compression pressure: kPa (bar, kg/cm

2, psi)/rpm

Except for QG15DE

Standard

1,324 (13.24, 13.5, 192)/350

Minimum

1,128 (11.28, 11.5, 164)/350

Maximum allowable difference between cylinders

98 (0.98, 1.0, 14)/350

QG15DE

Standard

1,372 (13.720, 13.99, 198.9)/350

Minimum

1,176 (11.759, 11.99, 170.5)/350

Maximum allowable difference between cylinders

98 (0.98, 1.0, 14)/350

10. If cylinder compression in one or more cylinders is low, pour a

small amount of engine oil into the cylinder through the spark

plug hole and retest compression.

+If adding oil improves cylinder compression, piston rings

may be worn or damaged. If so, replace piston rings after

checking piston.

+If pressure stays low, a valve may be sticking or seating

improperly. Inspect and repair valve and valve seat. Refer

to SDS, EM-71. If valve or valve seat is damaged

excessively, replace them.

+If compression in any two adjacent cylinders is low and if add-

ing oil does not improve compression, there is leakage past the

gasket surface. If so, replace cylinder head gasket.

11. Reinstall spark plugs, ignition coils and fuel pump fuse.

12. Perform ªSelf-diagnosis Procedureº referring to EC-70, ªHow

to Erase DTCº if any DTC appears.

MEASUREMENT OF COMPRESSION PRESSUREQG

EM-15

Page 2186 of 2898

WARNING:

+Position vehicle on a flat and solid surface.

+Place chocks at front and back of rear wheels.

+Do not remove engine until exhaust system has com-

pletely cooled off, otherwise, you may burn yourself

and/or fire may break out in fuel line.

+Before disconnecting fuel hose, release pressure.

Refer to EC-40, ªFuel Pressure Releaseº.

+Be sure to lift engine and transaxle in a safe manner.

+For engines not equipped with engine slingers, attach

proper slingers and bolts described in PARTS CATALOG.

CAUTION:

+When lifting engine, be sure to clear surrounding parts.

Use special care near accelerator wire casing, brake lines

and brake master cylinder.

+When lifting the engine, always use engine slingers in a

safe manner.

+When removing drive shaft, be careful not to damage

grease seal of transaxle.

+Before separating engine and transaxle, remove crank-

shaft position sensor (POS) from the cylinder block

assembly.

+Always be extra careful not to damage edge of crankshaft

position sensor (POS), or signal plate teeth.

Engine cannot be removed separately from transaxle. Remove

engine with transaxle as an assembly.

REMOVALNJEM0022S011. Drain coolant from radiator and cylinder block. Refer to LC-18,

ªChanging Engine Coolantº.

2. Remove coolant reservoir tank and bracket.

3. Drain engine oil.

4. Remove battery and battery tray.

5. Remove air cleaner and air duct.

6. Remove drive belts.

7. Remove alternator and air conditioner compressor from

engine.

8. Remove power steering oil pump from engine and position

aside.

Power steering oil pump does not need to be disconnected

from power steering tubes.

ENGINE ASSEMBLYQG

Removal and Installation (Cont'd)

EM-52

Page 2217 of 2898

NJEM0053

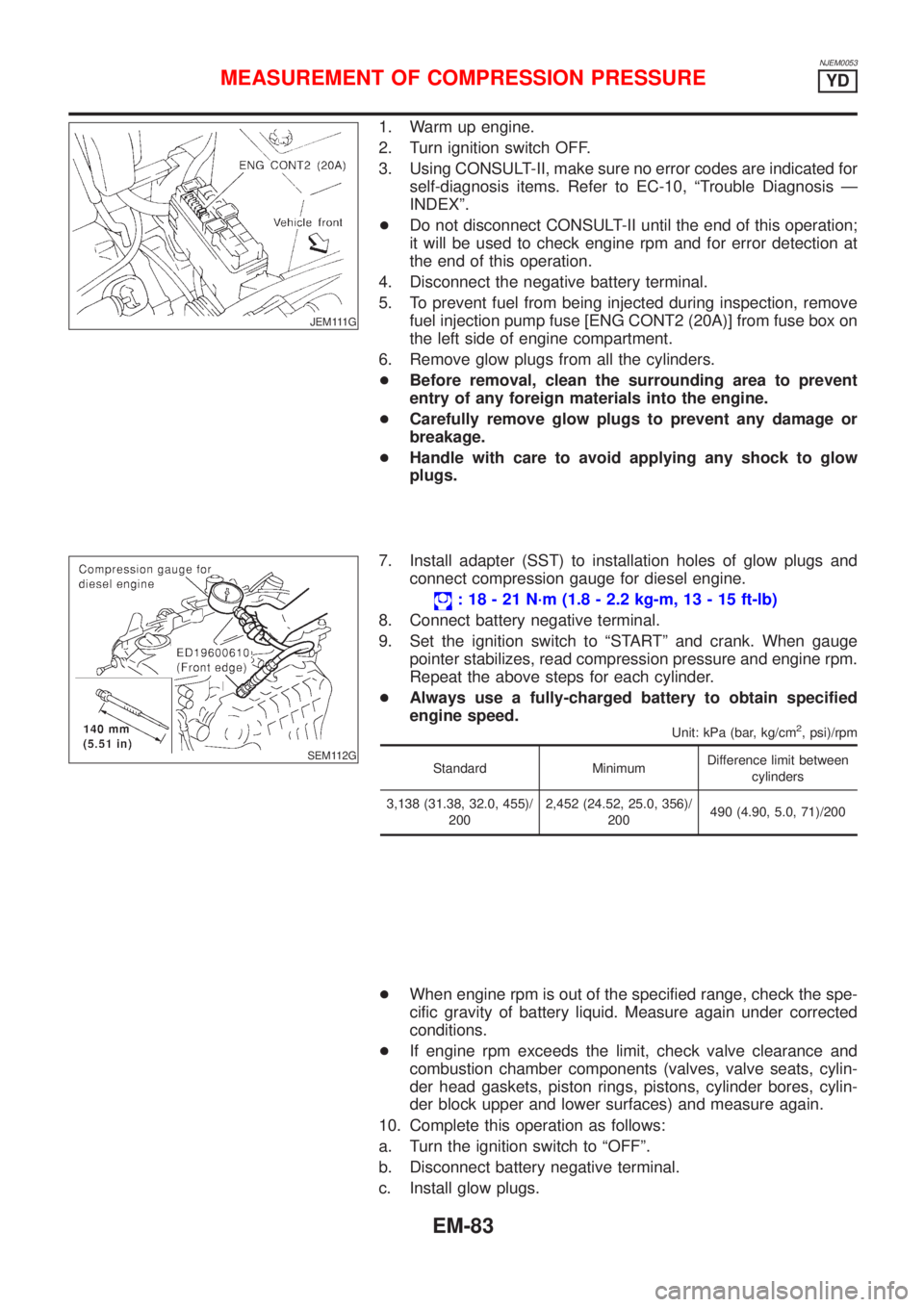

JEM111G

1. Warm up engine.

2. Turn ignition switch OFF.

3. Using CONSULT-II, make sure no error codes are indicated for

self-diagnosis items. Refer to EC-10, ªTrouble Diagnosis Ð

INDEXº.

+Do not disconnect CONSULT-II until the end of this operation;

it will be used to check engine rpm and for error detection at

the end of this operation.

4. Disconnect the negative battery terminal.

5. To prevent fuel from being injected during inspection, remove

fuel injection pump fuse [ENG CONT2 (20A)] from fuse box on

the left side of engine compartment.

6. Remove glow plugs from all the cylinders.

+Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

+Carefully remove glow plugs to prevent any damage or

breakage.

+Handle with care to avoid applying any shock to glow

plugs.

SEM112G

7. Install adapter (SST) to installation holes of glow plugs and

connect compression gauge for diesel engine.

: 18 - 21 N´m (1.8 - 2.2 kg-m, 13 - 15 ft-lb)

8. Connect battery negative terminal.

9. Set the ignition switch to ªSTARTº and crank. When gauge

pointer stabilizes, read compression pressure and engine rpm.

Repeat the above steps for each cylinder.

+Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

3,138 (31.38, 32.0, 455)/

2002,452 (24.52, 25.0, 356)/

200490 (4.90, 5.0, 71)/200

+When engine rpm is out of the specified range, check the spe-

cific gravity of battery liquid. Measure again under corrected

conditions.

+If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cylin-

der head gaskets, piston rings, pistons, cylinder bores, cylin-

der block upper and lower surfaces) and measure again.

10. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Install glow plugs.

MEASUREMENT OF COMPRESSION PRESSUREYD

EM-83

Page 2218 of 2898

![NISSAN ALMERA 2001 Service Manual d. Install fuel injection pump fuse [ENG CONT2 (20A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for

items of self- diagnosis. Refer to EC-10, ªTr NISSAN ALMERA 2001 Service Manual d. Install fuel injection pump fuse [ENG CONT2 (20A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for

items of self- diagnosis. Refer to EC-10, ªTr](/img/5/57348/w960_57348-2217.png)

d. Install fuel injection pump fuse [ENG CONT2 (20A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for

items of self- diagnosis. Refer to EC-10, ªTrouble Diagnosis Ð

INDEXº.

MEASUREMENT OF COMPRESSION PRESSUREYD

EM-84

Page 2272 of 2898

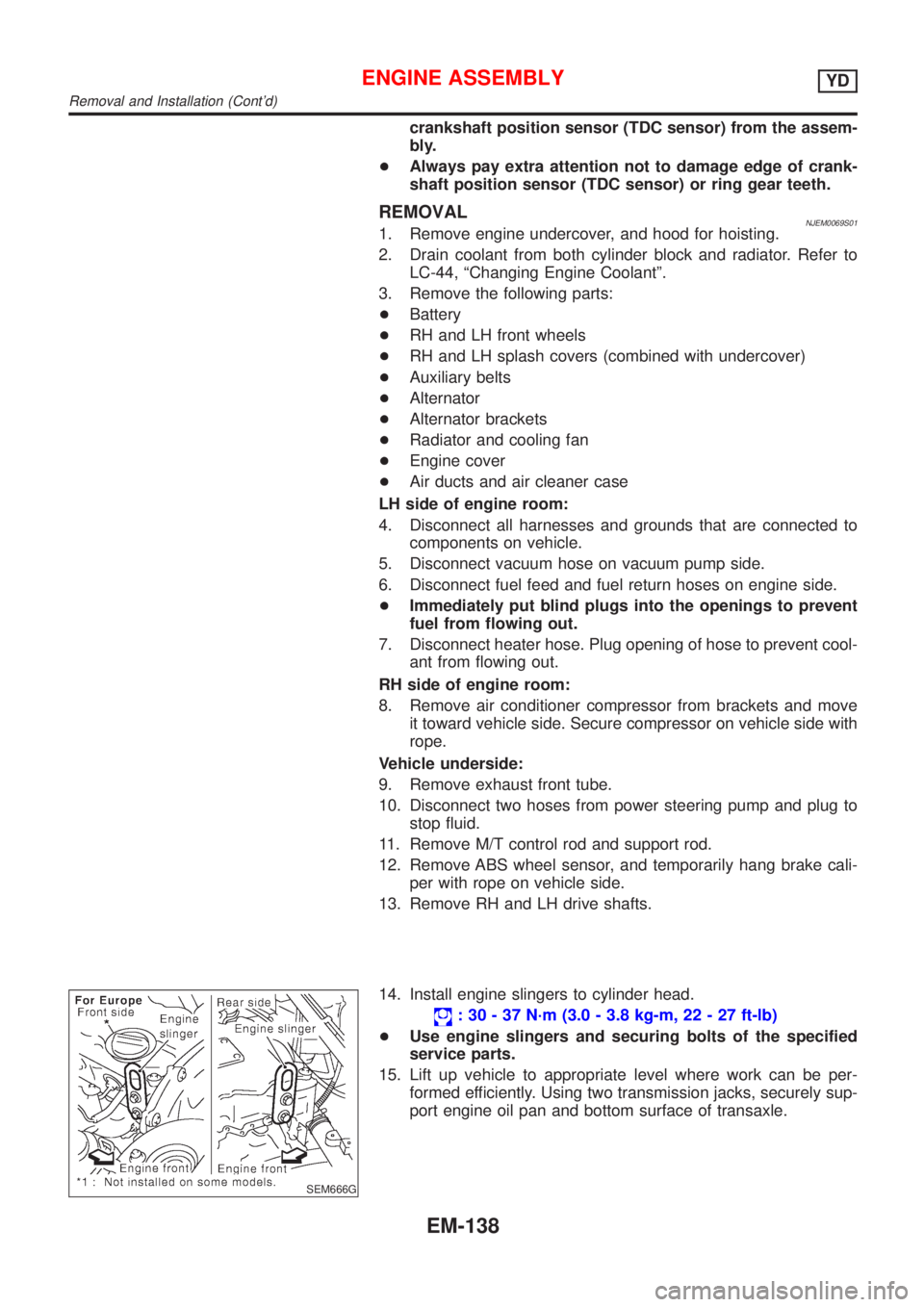

crankshaft position sensor (TDC sensor) from the assem-

bly.

+Always pay extra attention not to damage edge of crank-

shaft position sensor (TDC sensor) or ring gear teeth.

REMOVALNJEM0069S011. Remove engine undercover, and hood for hoisting.

2. Drain coolant from both cylinder block and radiator. Refer to

LC-44, ªChanging Engine Coolantº.

3. Remove the following parts:

+Battery

+RH and LH front wheels

+RH and LH splash covers (combined with undercover)

+Auxiliary belts

+Alternator

+Alternator brackets

+Radiator and cooling fan

+Engine cover

+Air ducts and air cleaner case

LH side of engine room:

4. Disconnect all harnesses and grounds that are connected to

components on vehicle.

5. Disconnect vacuum hose on vacuum pump side.

6. Disconnect fuel feed and fuel return hoses on engine side.

+Immediately put blind plugs into the openings to prevent

fuel from flowing out.

7. Disconnect heater hose. Plug opening of hose to prevent cool-

ant from flowing out.

RH side of engine room:

8. Remove air conditioner compressor from brackets and move

it toward vehicle side. Secure compressor on vehicle side with

rope.

Vehicle underside:

9. Remove exhaust front tube.

10. Disconnect two hoses from power steering pump and plug to

stop fluid.

11. Remove M/T control rod and support rod.

12. Remove ABS wheel sensor, and temporarily hang brake cali-

per with rope on vehicle side.

13. Remove RH and LH drive shafts.

SEM666G

14. Install engine slingers to cylinder head.

: 30 - 37 N´m (3.0 - 3.8 kg-m, 22 - 27 ft-lb)

+Use engine slingers and securing bolts of the specified

service parts.

15. Lift up vehicle to appropriate level where work can be per-

formed efficiently. Using two transmission jacks, securely sup-

port engine oil pan and bottom surface of transaxle.

ENGINE ASSEMBLYYD

Removal and Installation (Cont'd)

EM-138

Page 2309 of 2898

SMA803A

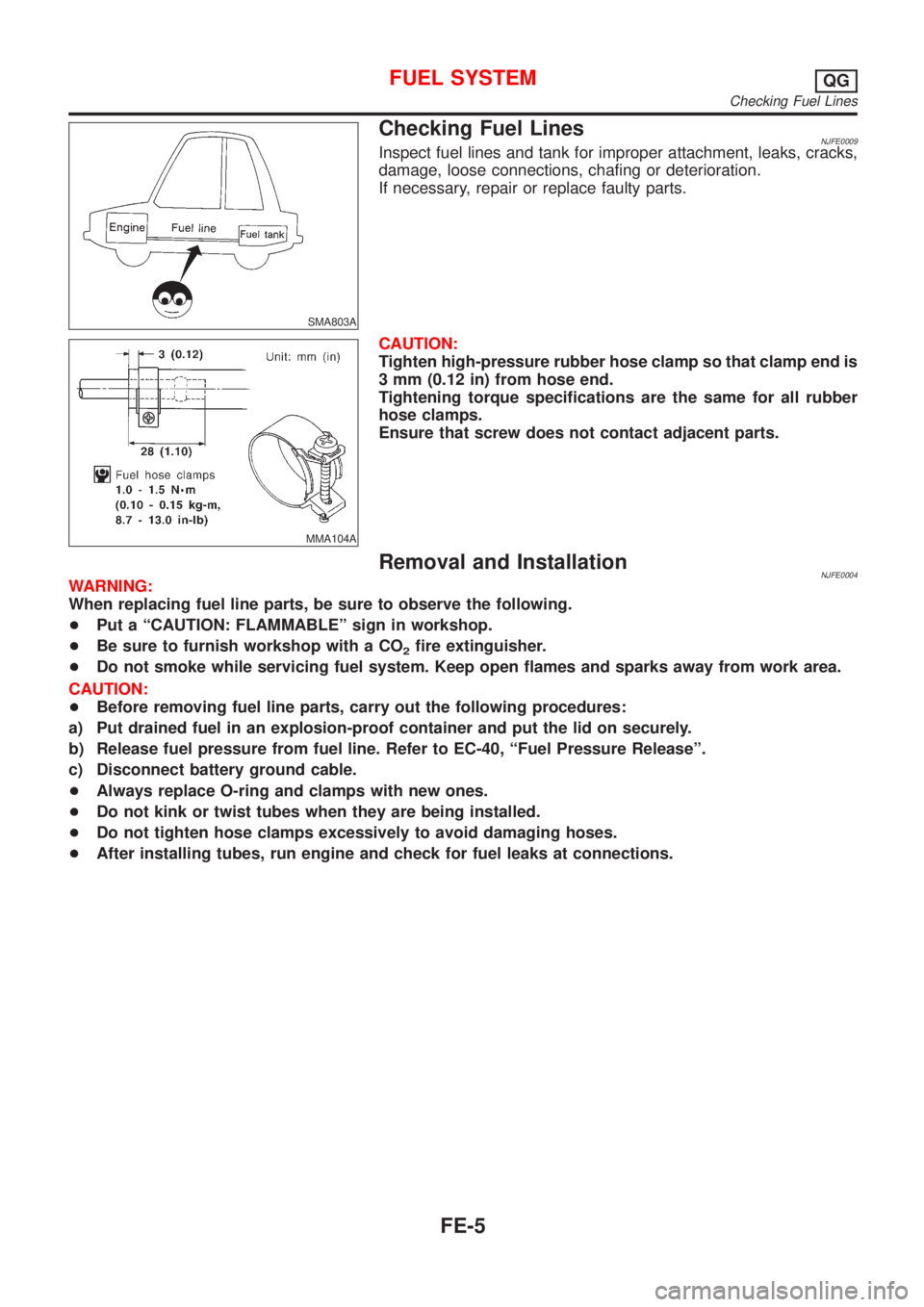

Checking Fuel LinesNJFE0009Inspect fuel lines and tank for improper attachment, leaks, cracks,

damage, loose connections, chafing or deterioration.

If necessary, repair or replace faulty parts.

MMA104A

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is

3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber

hose clamps.

Ensure that screw does not contact adjacent parts.

Removal and InstallationNJFE0004WARNING:

When replacing fuel line parts, be sure to observe the following.

+Put a ªCAUTION: FLAMMABLEº sign in workshop.

+Be sure to furnish workshop with a CO

2fire extinguisher.

+Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

CAUTION:

+Before removing fuel line parts, carry out the following procedures:

a) Put drained fuel in an explosion-proof container and put the lid on securely.

b) Release fuel pressure from fuel line. Refer to EC-40, ªFuel Pressure Releaseº.

c) Disconnect battery ground cable.

+Always replace O-ring and clamps with new ones.

+Do not kink or twist tubes when they are being installed.

+Do not tighten hose clamps excessively to avoid damaging hoses.

+After installing tubes, run engine and check for fuel leaks at connections.

FUEL SYSTEMQG

Checking Fuel Lines

FE-5