NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2241 of 2898

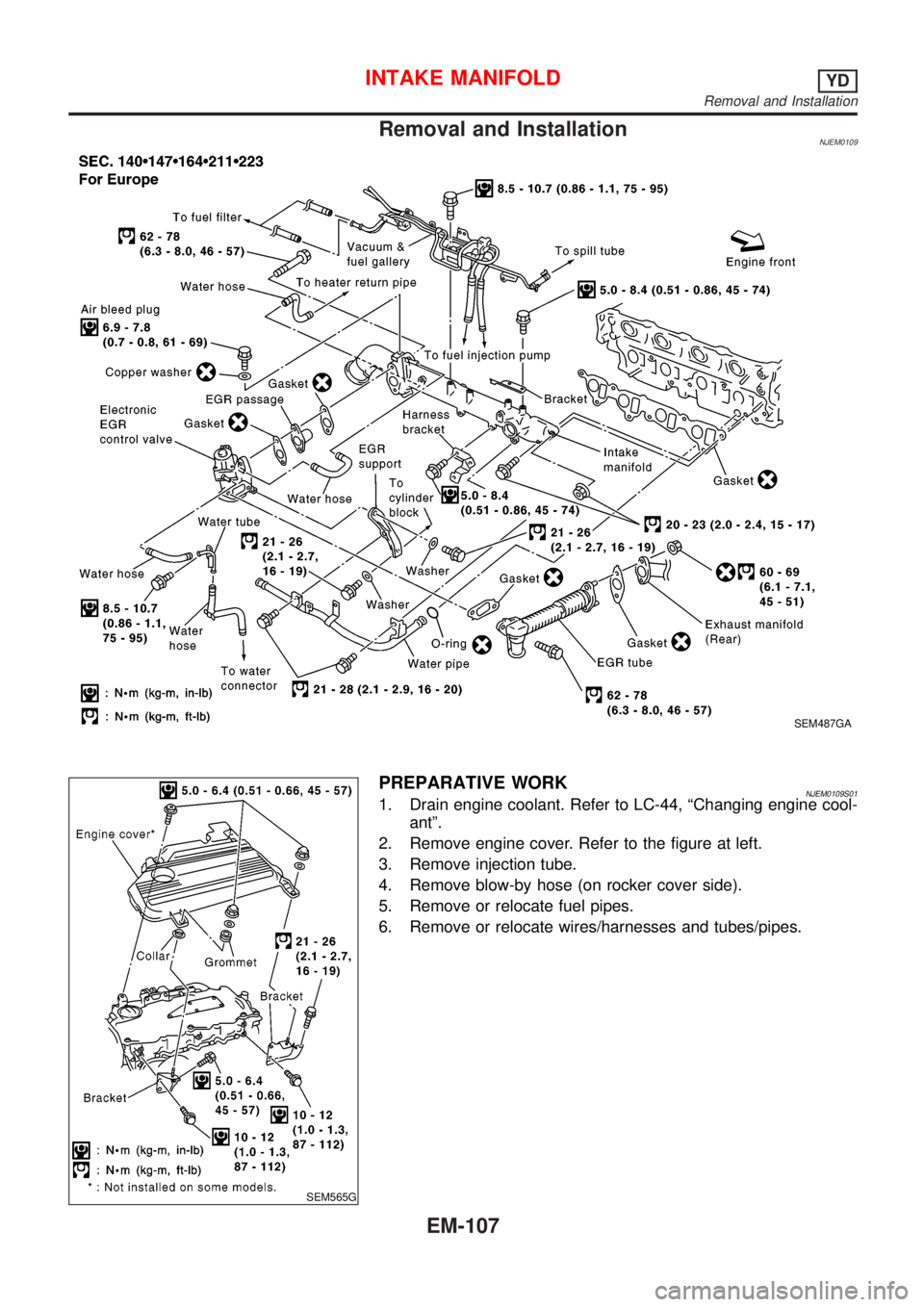

Removal and InstallationNJEM0109

SEM487GA

SEM565G

PREPARATIVE WORKNJEM0109S011. Drain engine coolant. Refer to LC-44, ªChanging engine cool-

antº.

2. Remove engine cover. Refer to the figure at left.

3. Remove injection tube.

4. Remove blow-by hose (on rocker cover side).

5. Remove or relocate fuel pipes.

6. Remove or relocate wires/harnesses and tubes/pipes.

INTAKE MANIFOLDYD

Removal and Installation

EM-107

Page 2242 of 2898

JEM238G

FUEL PIPINGNJEM0109S02RemovalNJEM0109S0201+To prevent fuel from flowing out, plug the opening of the hose

with a blind plug after disconnection.

+Be careful not to spill fuel in the engine compartment.

InstallationNJEM0109S0202+After repairing, bleed air in pipes by shifting priming pump up

and down until the touch is heavy.

+For further air bleeding, idle at least 1 minute or more.

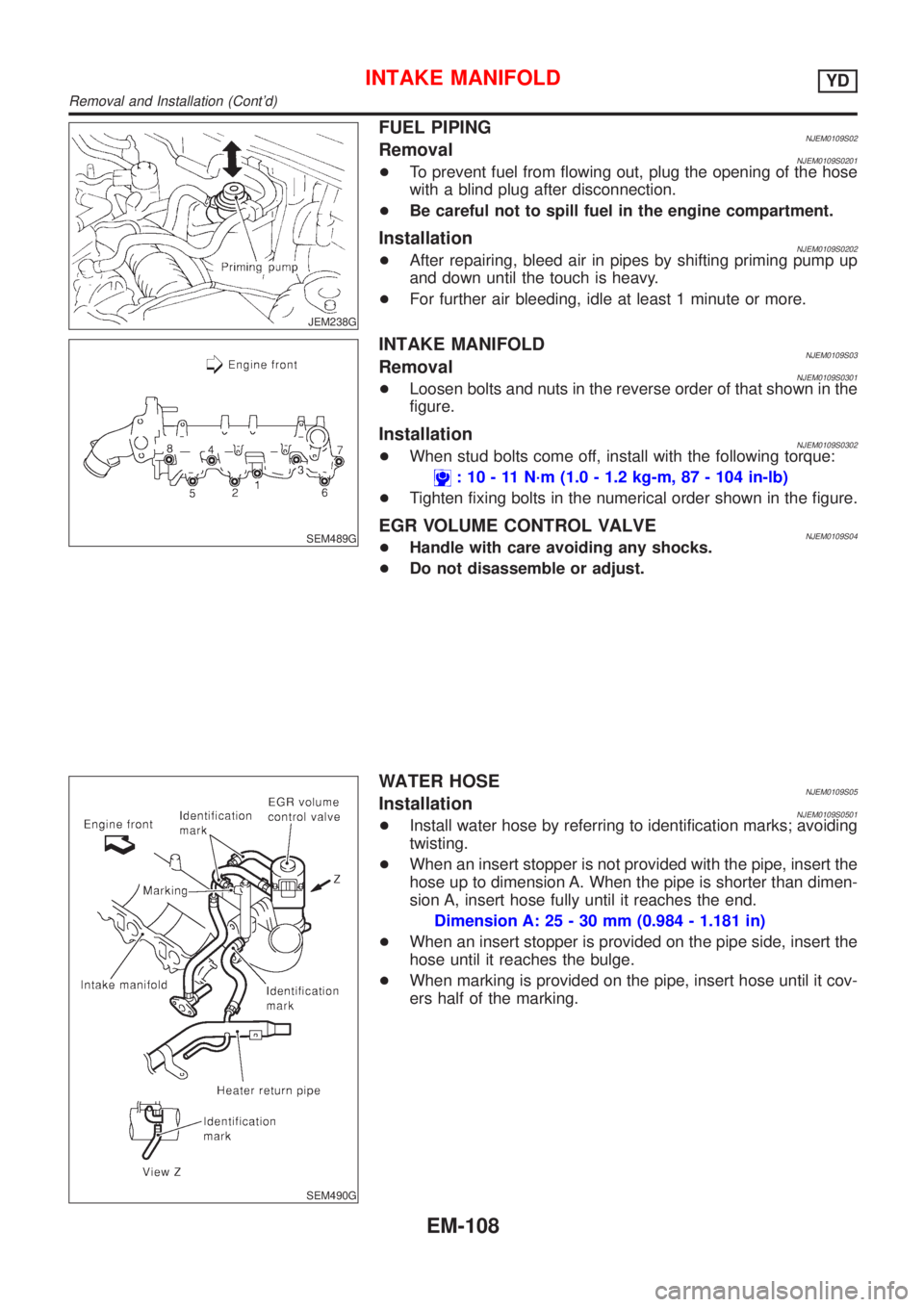

SEM489G

INTAKE MANIFOLDNJEM0109S03RemovalNJEM0109S0301+Loosen bolts and nuts in the reverse order of that shown in the

figure.

InstallationNJEM0109S0302+When stud bolts come off, install with the following torque:

: 10 - 11 N´m (1.0 - 1.2 kg-m, 87 - 104 in-lb)

+Tighten fixing bolts in the numerical order shown in the figure.

EGR VOLUME CONTROL VALVENJEM0109S04+Handle with care avoiding any shocks.

+Do not disassemble or adjust.

SEM490G

WATER HOSENJEM0109S05InstallationNJEM0109S0501+Install water hose by referring to identification marks; avoiding

twisting.

+When an insert stopper is not provided with the pipe, insert the

hose up to dimension A. When the pipe is shorter than dimen-

sion A, insert hose fully until it reaches the end.

Dimension A: 25 - 30 mm (0.984 - 1.181 in)

+When an insert stopper is provided on the pipe side, insert the

hose until it reaches the bulge.

+When marking is provided on the pipe, insert hose until it cov-

ers half of the marking.

INTAKE MANIFOLDYD

Removal and Installation (Cont'd)

EM-108

Page 2243 of 2898

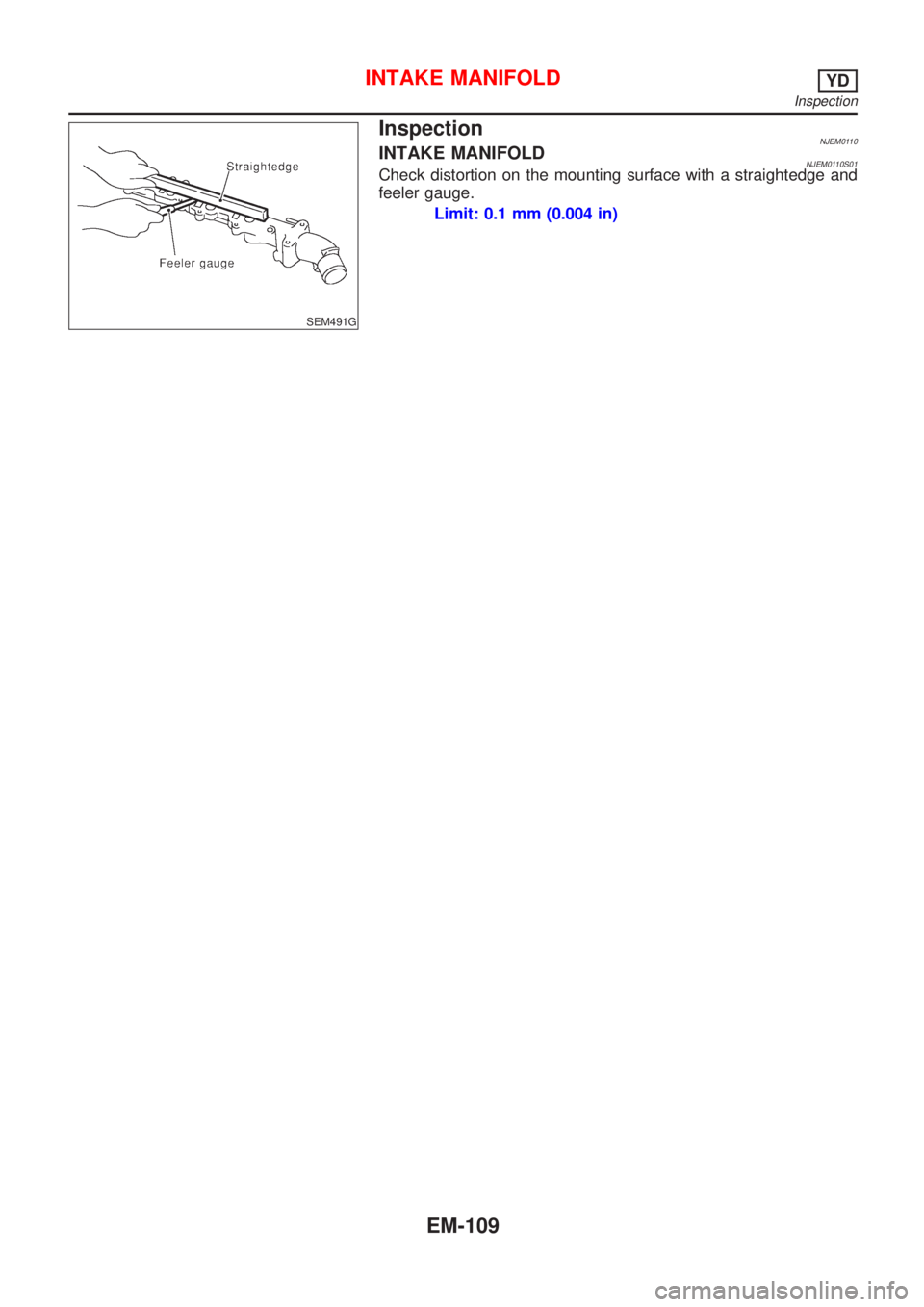

SEM491G

InspectionNJEM0110INTAKE MANIFOLDNJEM0110S01Check distortion on the mounting surface with a straightedge and

feeler gauge.

Limit: 0.1 mm (0.004 in)

INTAKE MANIFOLDYD

Inspection

EM-109

Page 2244 of 2898

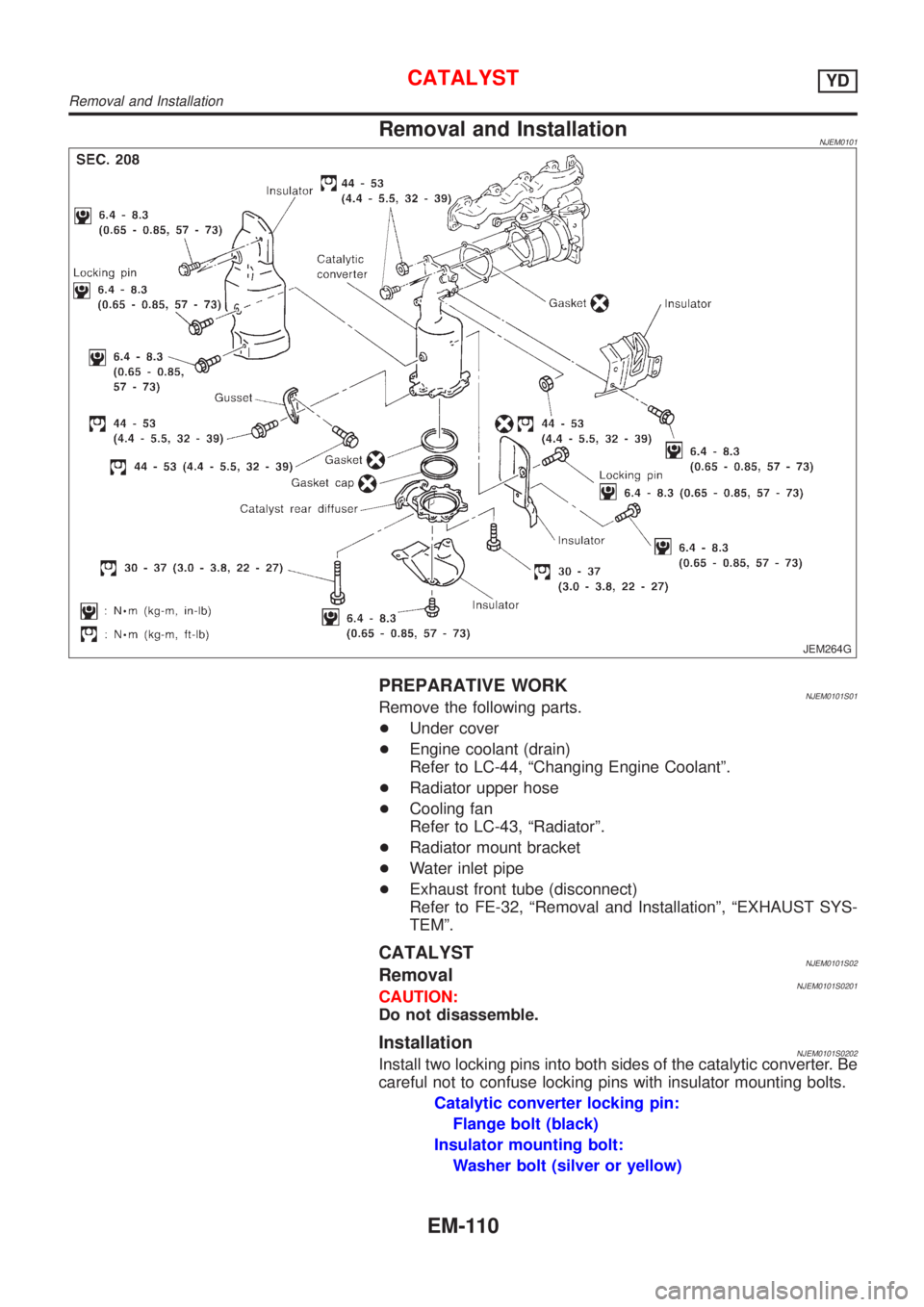

Removal and InstallationNJEM0101

JEM264G

PREPARATIVE WORKNJEM0101S01Remove the following parts.

+Under cover

+Engine coolant (drain)

Refer to LC-44, ªChanging Engine Coolantº.

+Radiator upper hose

+Cooling fan

Refer to LC-43, ªRadiatorº.

+Radiator mount bracket

+Water inlet pipe

+Exhaust front tube (disconnect)

Refer to FE-32, ªRemoval and Installationº, ªEXHAUST SYS-

TEMº.

CATALYSTNJEM0101S02RemovalNJEM0101S0201CAUTION:

Do not disassemble.

InstallationNJEM0101S0202Install two locking pins into both sides of the catalytic converter. Be

careful not to confuse locking pins with insulator mounting bolts.

Catalytic converter locking pin:

Flange bolt (black)

Insulator mounting bolt:

Washer bolt (silver or yellow)

CATALYSTYD

Removal and Installation

EM-110

Page 2245 of 2898

GUSSETNJEM0101S03InstallationNJEM0101S0301Pushing gussets against the oil pan and the catalytic converter,

temporarily tighten the mounting bolt. And then tighten it to the

specified torque.

CATALYSTYD

Removal and Installation (Cont'd)

EM-111

Page 2246 of 2898

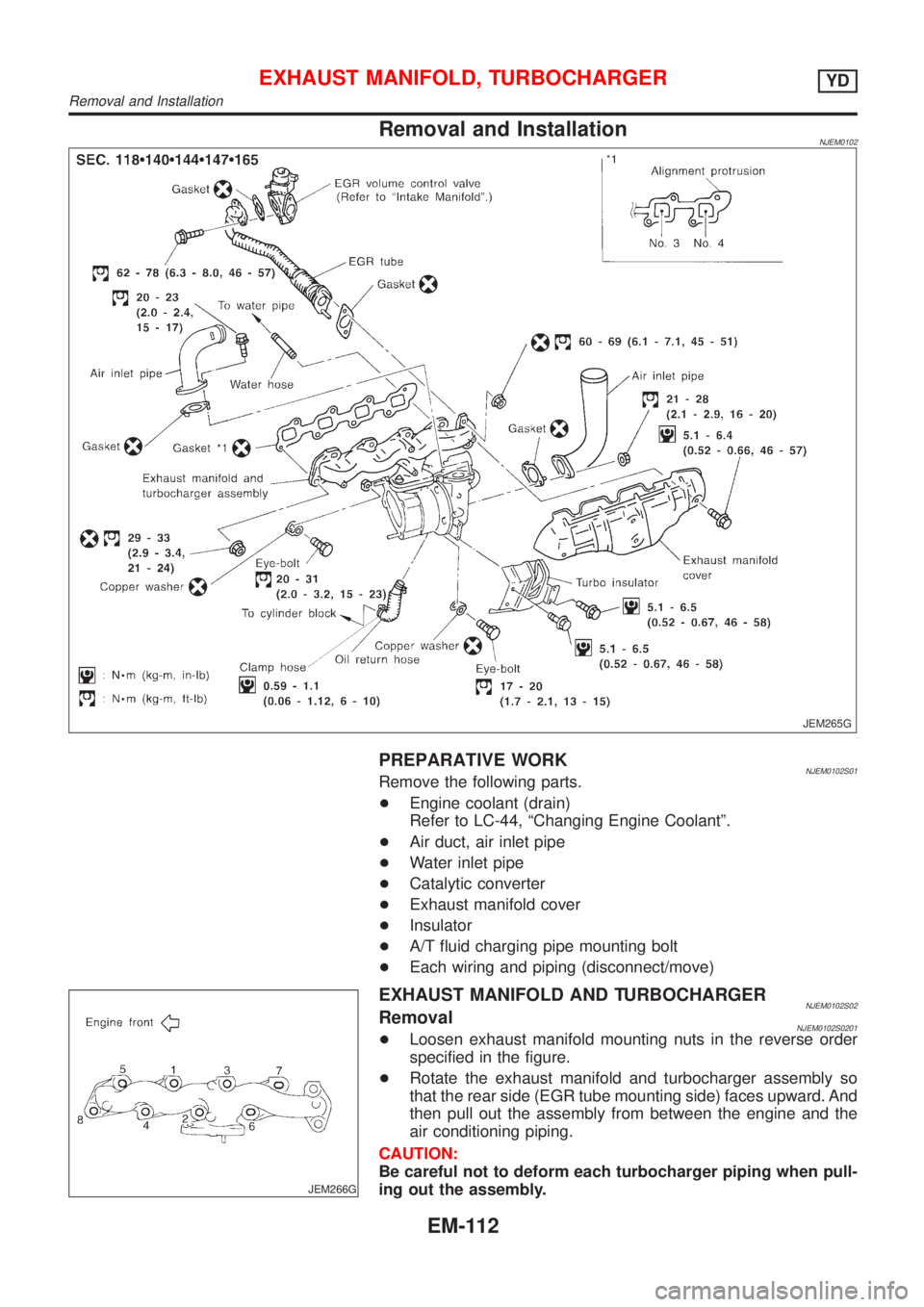

Removal and InstallationNJEM0102

JEM265G

PREPARATIVE WORKNJEM0102S01Remove the following parts.

+Engine coolant (drain)

Refer to LC-44, ªChanging Engine Coolantº.

+Air duct, air inlet pipe

+Water inlet pipe

+Catalytic converter

+Exhaust manifold cover

+Insulator

+A/T fluid charging pipe mounting bolt

+Each wiring and piping (disconnect/move)

JEM266G

EXHAUST MANIFOLD AND TURBOCHARGERNJEM0102S02RemovalNJEM0102S0201+Loosen exhaust manifold mounting nuts in the reverse order

specified in the figure.

+Rotate the exhaust manifold and turbocharger assembly so

that the rear side (EGR tube mounting side) faces upward. And

then pull out the assembly from between the engine and the

air conditioning piping.

CAUTION:

Be careful not to deform each turbocharger piping when pull-

ing out the assembly.

EXHAUST MANIFOLD, TURBOCHARGERYD

Removal and Installation

EM-112

Page 2247 of 2898

InstallationNJEM0102S0202+When a stud bolt is pulled out, tighten it to the following torque:

: 18 - 21 N´m (1.8 - 2.2 kg-m, 13 - 15 ft-lb)

+Tighten the exhaust manifold mounting nuts in the following

procedure:

a) Tighten the nuts in the order specified in the figure.

b) Re-tighten the nuts 1 to 4.

EXHAUST MANIFOLD GASKETNJEM0102S03InstallationNJEM0102S0301Install the gasket so that the alignment protrusion faces the No. 4

port.

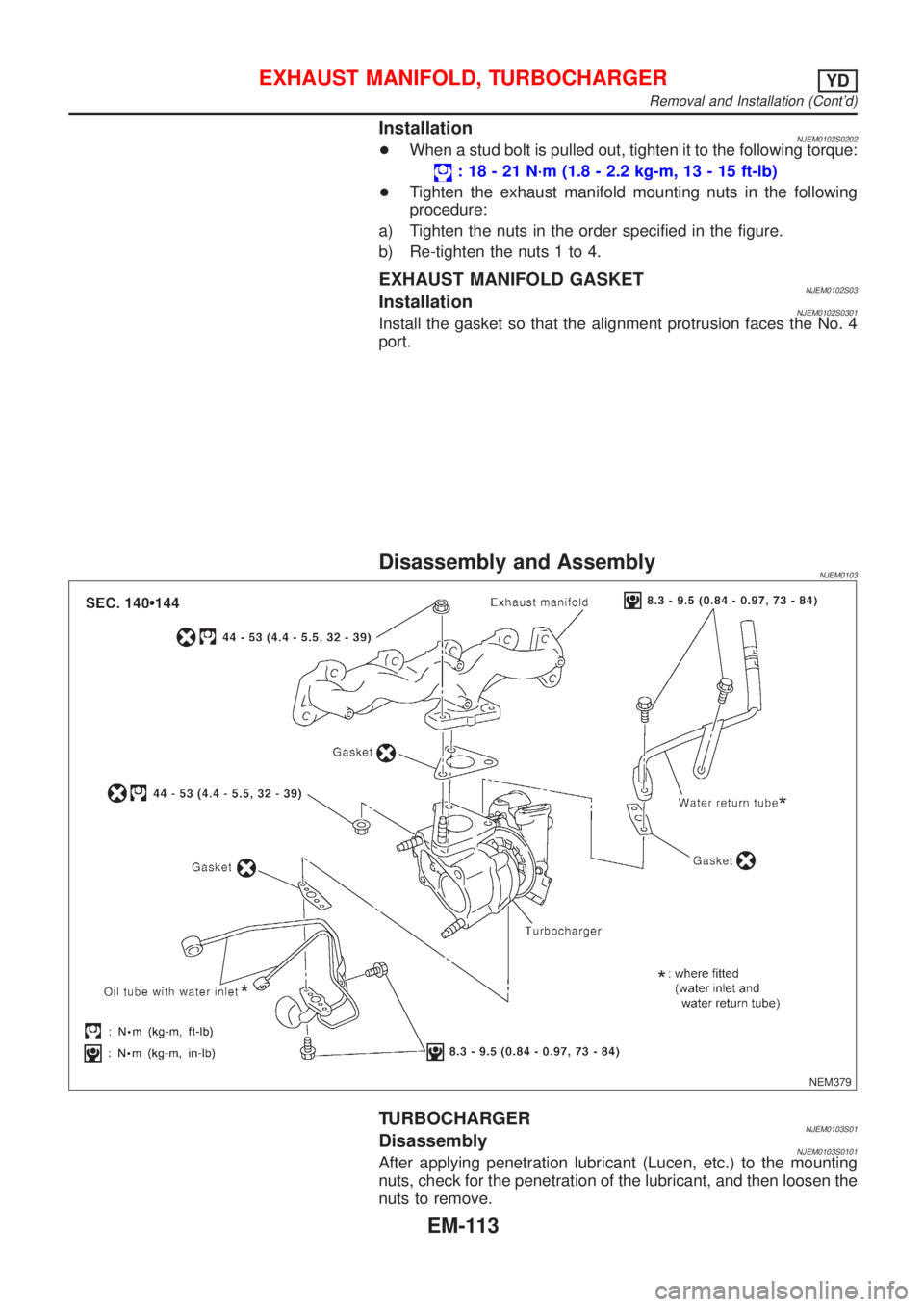

Disassembly and AssemblyNJEM0103

NEM379

TURBOCHARGERNJEM0103S01DisassemblyNJEM0103S0101After applying penetration lubricant (Lucen, etc.) to the mounting

nuts, check for the penetration of the lubricant, and then loosen the

nuts to remove.

EXHAUST MANIFOLD, TURBOCHARGERYD

Removal and Installation (Cont'd)

EM-113

Page 2248 of 2898

CAUTION:

Do not disassemble or adjust the turbocharger body.

AssemblyNJEM0103S0102When a stud bolt is pulled out, tighten it to the following torque:

: 24 - 27 N´m (2.4 - 2.8 kg-m, 18 - 20 ft-lb)

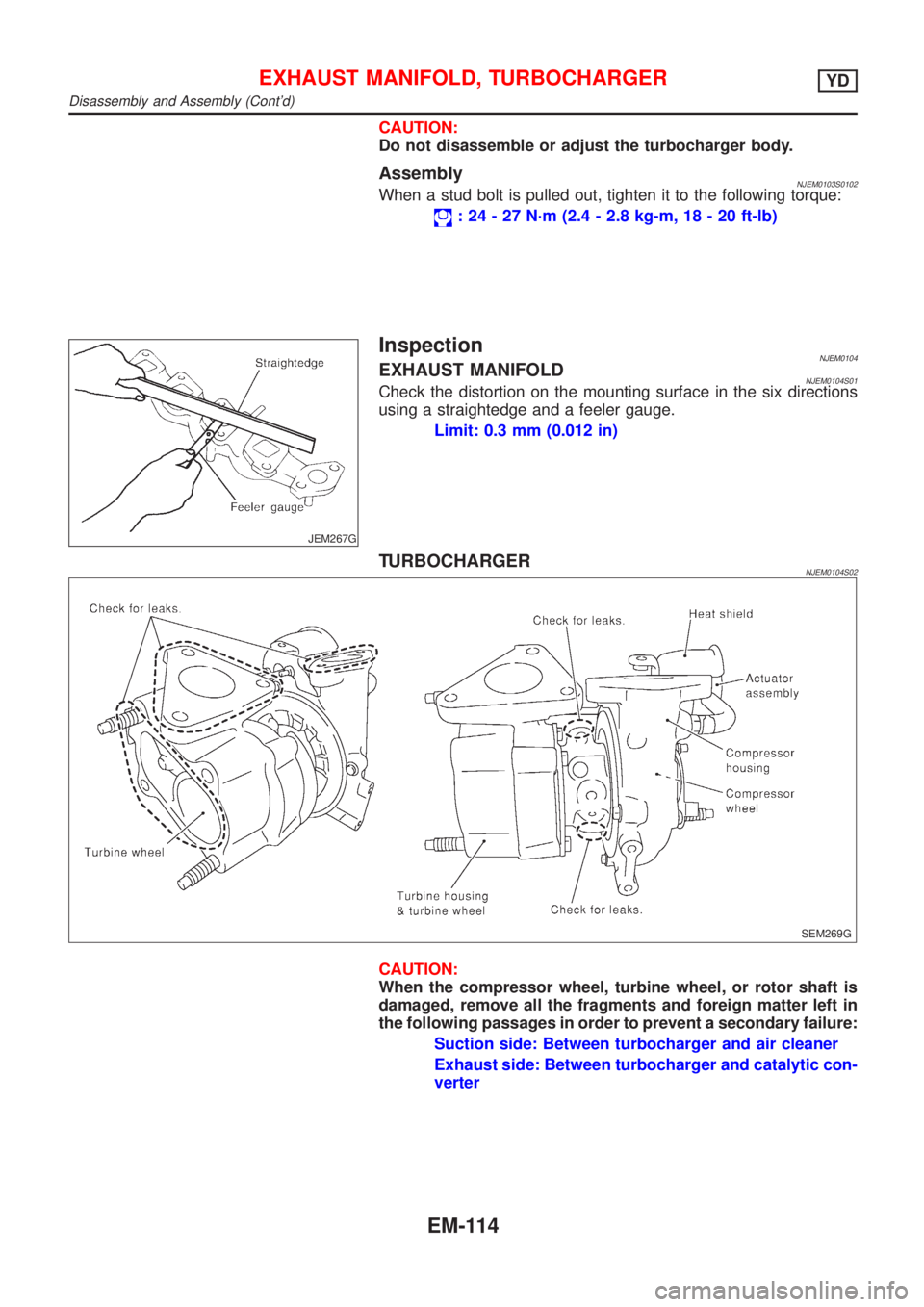

JEM267G

InspectionNJEM0104EXHAUST MANIFOLDNJEM0104S01Check the distortion on the mounting surface in the six directions

using a straightedge and a feeler gauge.

Limit: 0.3 mm (0.012 in)

TURBOCHARGERNJEM0104S02

SEM269G

CAUTION:

When the compressor wheel, turbine wheel, or rotor shaft is

damaged, remove all the fragments and foreign matter left in

the following passages in order to prevent a secondary failure:

Suction side: Between turbocharger and air cleaner

Exhaust side: Between turbocharger and catalytic con-

verter

EXHAUST MANIFOLD, TURBOCHARGERYD

Disassembly and Assembly (Cont'd)

EM-114

Page 2249 of 2898

SEM270G

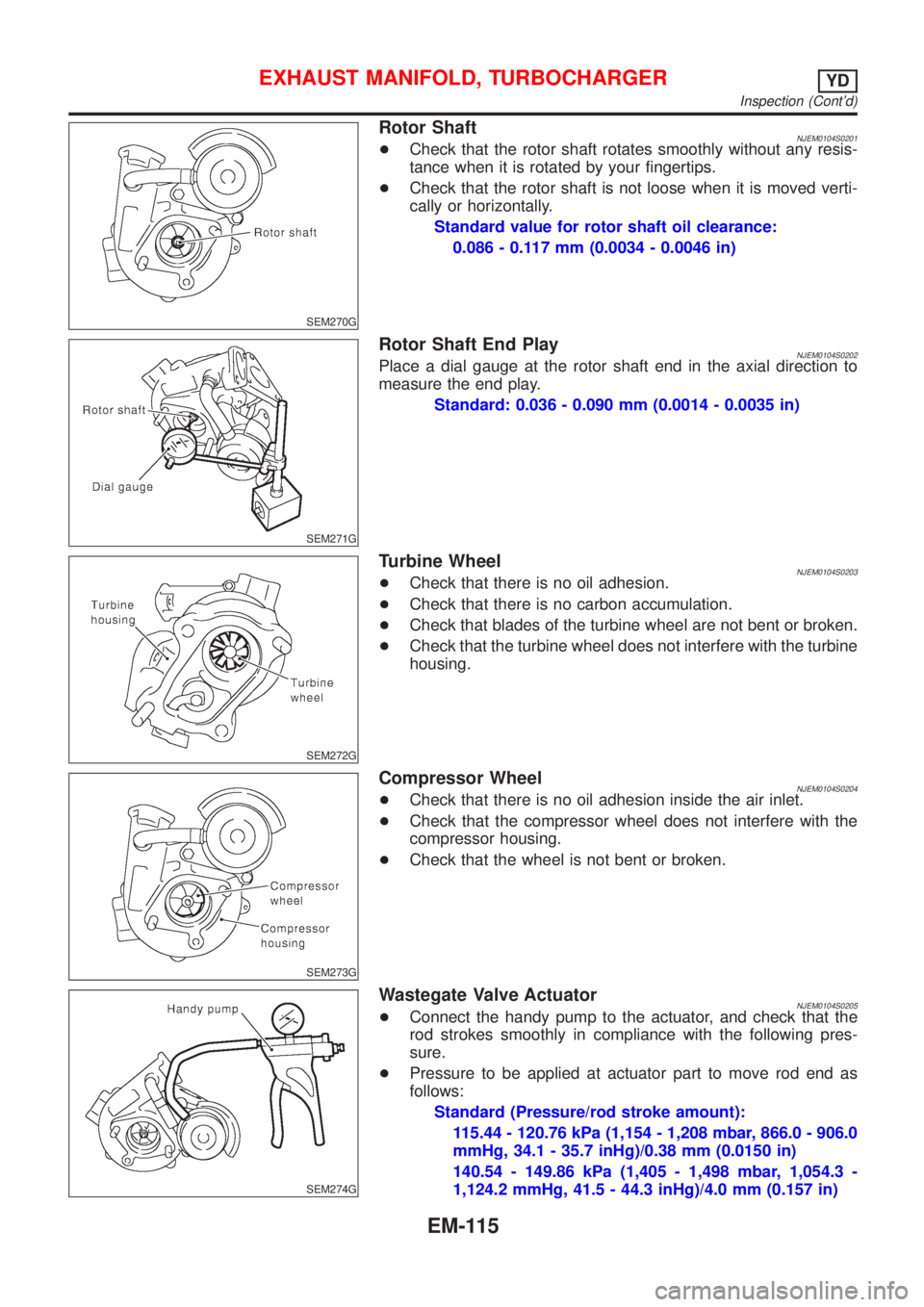

Rotor ShaftNJEM0104S0201+Check that the rotor shaft rotates smoothly without any resis-

tance when it is rotated by your fingertips.

+Check that the rotor shaft is not loose when it is moved verti-

cally or horizontally.

Standard value for rotor shaft oil clearance:

0.086 - 0.117 mm (0.0034 - 0.0046 in)

SEM271G

Rotor Shaft End PlayNJEM0104S0202Place a dial gauge at the rotor shaft end in the axial direction to

measure the end play.

Standard: 0.036 - 0.090 mm (0.0014 - 0.0035 in)

SEM272G

Turbine WheelNJEM0104S0203+Check that there is no oil adhesion.

+Check that there is no carbon accumulation.

+Check that blades of the turbine wheel are not bent or broken.

+Check that the turbine wheel does not interfere with the turbine

housing.

SEM273G

Compressor WheelNJEM0104S0204+Check that there is no oil adhesion inside the air inlet.

+Check that the compressor wheel does not interfere with the

compressor housing.

+Check that the wheel is not bent or broken.

SEM274G

Wastegate Valve ActuatorNJEM0104S0205+Connect the handy pump to the actuator, and check that the

rod strokes smoothly in compliance with the following pres-

sure.

+Pressure to be applied at actuator part to move rod end as

follows:

Standard (Pressure/rod stroke amount):

115.44 - 120.76 kPa (1,154 - 1,208 mbar, 866.0 - 906.0

mmHg, 34.1 - 35.7 inHg)/0.38 mm (0.0150 in)

140.54 - 149.86 kPa (1,405 - 1,498 mbar, 1,054.3 -

1,124.2 mmHg, 41.5 - 44.3 inHg)/4.0 mm (0.157 in)

EXHAUST MANIFOLD, TURBOCHARGERYD

Inspection (Cont'd)

EM-115

Page 2250 of 2898

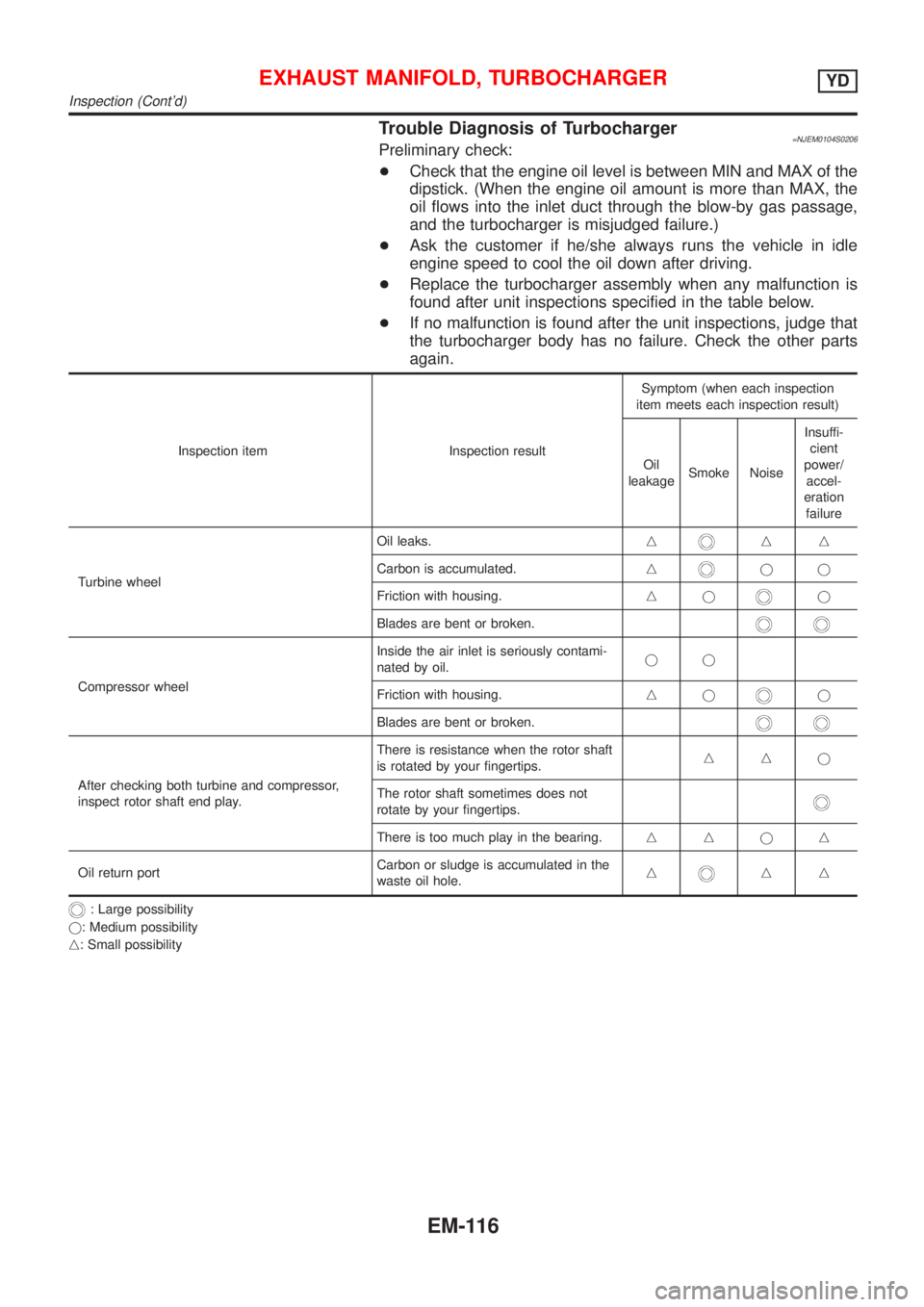

Trouble Diagnosis of Turbocharger=NJEM0104S0206Preliminary check:

+Check that the engine oil level is between MIN and MAX of the

dipstick. (When the engine oil amount is more than MAX, the

oil flows into the inlet duct through the blow-by gas passage,

and the turbocharger is misjudged failure.)

+Ask the customer if he/she always runs the vehicle in idle

engine speed to cool the oil down after driving.

+Replace the turbocharger assembly when any malfunction is

found after unit inspections specified in the table below.

+If no malfunction is found after the unit inspections, judge that

the turbocharger body has no failure. Check the other parts

again.

Inspection item Inspection resultSymptom (when each inspection

item meets each inspection result)

Oil

leakageSmoke NoiseInsuffi-

cient

power/

accel-

eration

failure

Turbine wheelOil leaks.n

nn

Carbon is accumulated.n

jj

Friction with housing.nj

j

Blades are bent or broken.

Compressor wheelInside the air inlet is seriously contami-

nated by oil.jj

Friction with housing.njj

Blades are bent or broken.

After checking both turbine and compressor,

inspect rotor shaft end play.There is resistance when the rotor shaft

is rotated by your fingertips.nnj

The rotor shaft sometimes does not

rotate by your fingertips.

There is too much play in the bearing.nnjn

Oil return portCarbon or sludge is accumulated in the

waste oil hole.n

nn

: Large possibility

j: Medium possibility

n: Small possibility

EXHAUST MANIFOLD, TURBOCHARGERYD

Inspection (Cont'd)

EM-116