battery NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2778 of 2898

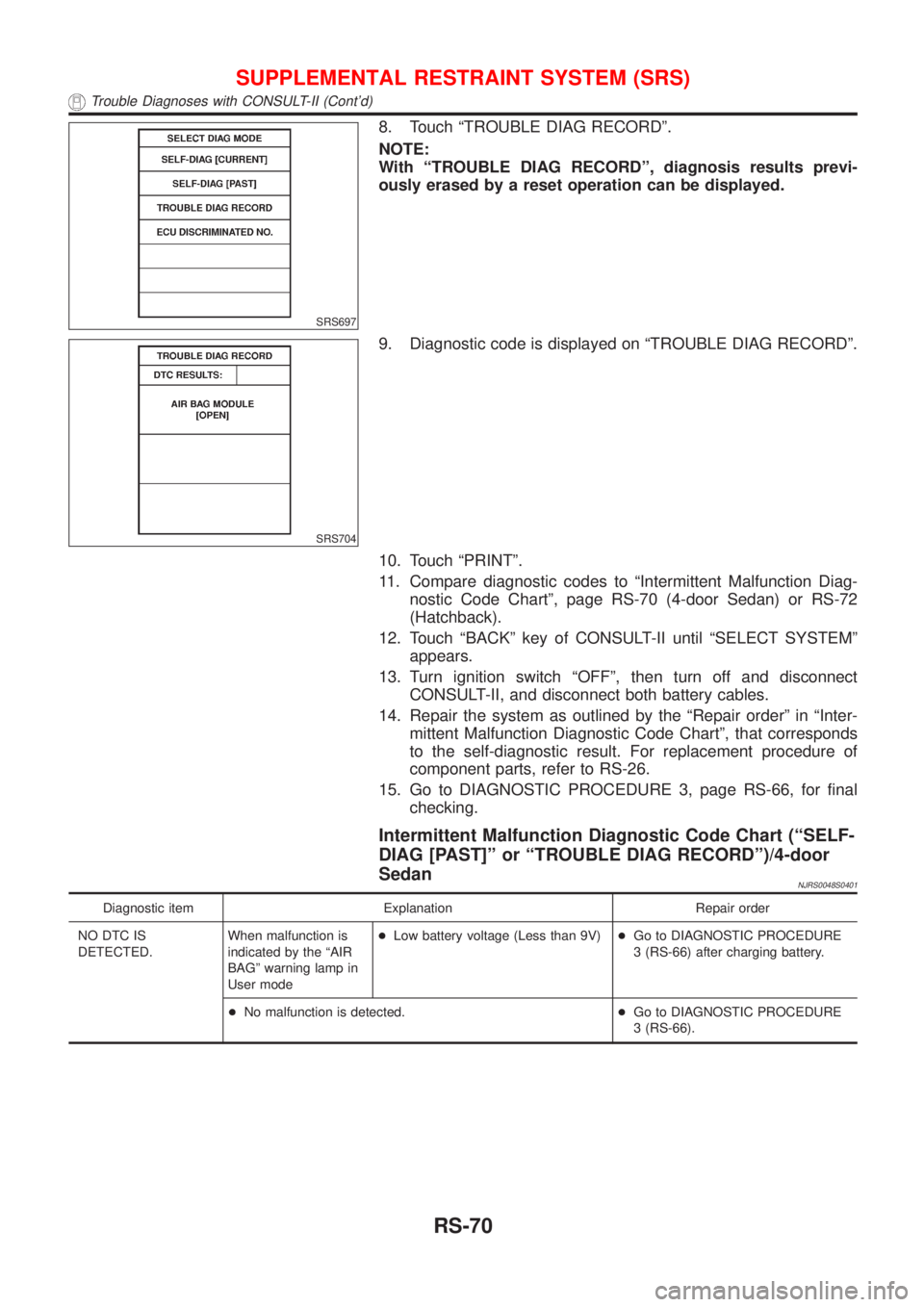

SRS697

8. Touch ªTROUBLE DIAG RECORDº.

NOTE:

With ªTROUBLE DIAG RECORDº, diagnosis results previ-

ously erased by a reset operation can be displayed.

SRS704

9. Diagnostic code is displayed on ªTROUBLE DIAG RECORDº.

10. Touch ªPRINTº.

11. Compare diagnostic codes to ªIntermittent Malfunction Diag-

nostic Code Chartº, page RS-70 (4-door Sedan) or RS-72

(Hatchback).

12. Touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears.

13. Turn ignition switch ªOFFº, then turn off and disconnect

CONSULT-II, and disconnect both battery cables.

14. Repair the system as outlined by the ªRepair orderº in ªInter-

mittent Malfunction Diagnostic Code Chartº, that corresponds

to the self-diagnostic result. For replacement procedure of

component parts, refer to RS-26.

15. Go to DIAGNOSTIC PROCEDURE 3, page RS-66, for final

checking.

Intermittent Malfunction Diagnostic Code Chart (ªSELF-

DIAG [PAST]º or ªTROUBLE DIAG RECORDº)/4-door

Sedan

NJRS0048S0401

Diagnostic item Explanation Repair order

NO DTC IS

DETECTED.When malfunction is

indicated by the ªAIR

BAGº warning lamp in

User mode+Low battery voltage (Less than 9V)+Go to DIAGNOSTIC PROCEDURE

3 (RS-66) after charging battery.

+No malfunction is detected.+Go to DIAGNOSTIC PROCEDURE

3 (RS-66).

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-70

Page 2782 of 2898

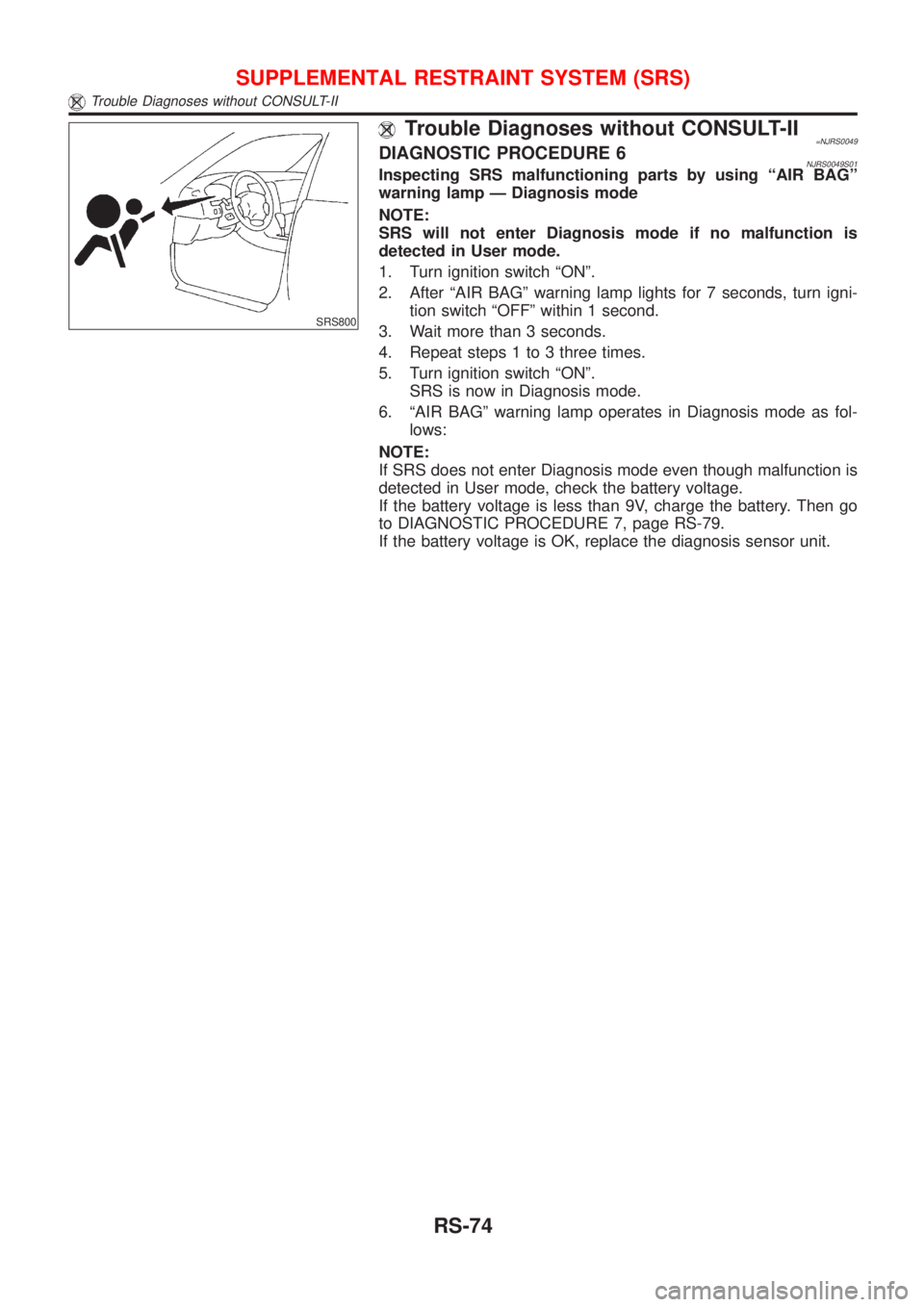

SRS800

Trouble Diagnoses without CONSULT-II=NJRS0049DIAGNOSTIC PROCEDURE 6NJRS0049S01Inspecting SRS malfunctioning parts by using ªAIR BAGº

warning lamp Ð Diagnosis mode

NOTE:

SRS will not enter Diagnosis mode if no malfunction is

detected in User mode.

1. Turn ignition switch ªONº.

2. After ªAIR BAGº warning lamp lights for 7 seconds, turn igni-

tion switch ªOFFº within 1 second.

3. Wait more than 3 seconds.

4. Repeat steps 1 to 3 three times.

5. Turn ignition switch ªONº.

SRS is now in Diagnosis mode.

6. ªAIR BAGº warning lamp operates in Diagnosis mode as fol-

lows:

NOTE:

If SRS does not enter Diagnosis mode even though malfunction is

detected in User mode, check the battery voltage.

If the battery voltage is less than 9V, charge the battery. Then go

to DIAGNOSTIC PROCEDURE 7, page RS-79.

If the battery voltage is OK, replace the diagnosis sensor unit.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II

RS-74

Page 2783 of 2898

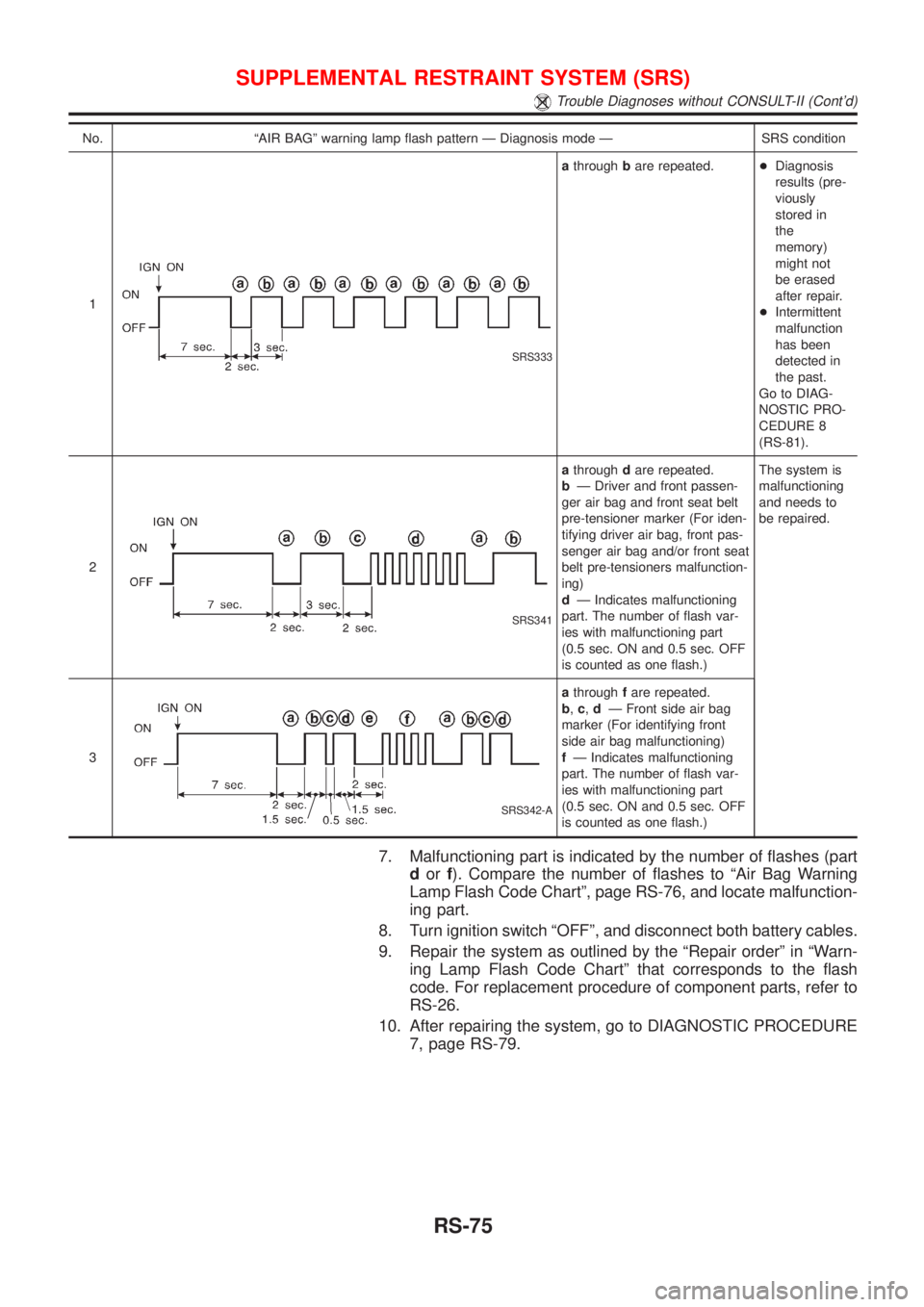

No. ªAIR BAGº warning lamp flash pattern Ð Diagnosis mode Ð SRS condition

1

SRS333

athroughbare repeated.+Diagnosis

results (pre-

viously

stored in

the

memory)

might not

be erased

after repair.

+Intermittent

malfunction

has been

detected in

the past.

Go to DIAG-

NOSTIC PRO-

CEDURE 8

(RS-81).

2

SRS341

athroughdare repeated.

bÐ Driver and front passen-

ger air bag and front seat belt

pre-tensioner marker (For iden-

tifying driver air bag, front pas-

senger air bag and/or front seat

belt pre-tensioners malfunction-

ing)

dÐ Indicates malfunctioning

part. The number of flash var-

ies with malfunctioning part

(0.5 sec. ON and 0.5 sec. OFF

is counted as one flash.)The system is

malfunctioning

and needs to

be repaired.

3

SRS342-A

athroughfare repeated.

b,c,dÐ Front side air bag

marker (For identifying front

side air bag malfunctioning)

fÐ Indicates malfunctioning

part. The number of flash var-

ies with malfunctioning part

(0.5 sec. ON and 0.5 sec. OFF

is counted as one flash.)

7. Malfunctioning part is indicated by the number of flashes (part

dorf). Compare the number of flashes to ªAir Bag Warning

Lamp Flash Code Chartº, page RS-76, and locate malfunction-

ing part.

8. Turn ignition switch ªOFFº, and disconnect both battery cables.

9. Repair the system as outlined by the ªRepair orderº in ªWarn-

ing Lamp Flash Code Chartº that corresponds to the flash

code. For replacement procedure of component parts, refer to

RS-26.

10. After repairing the system, go to DIAGNOSTIC PROCEDURE

7, page RS-79.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II (Cont'd)

RS-75

Page 2787 of 2898

The LH side air bag (sat-

ellite) sensor is malfunc-

tioning.

(f: 4 flashes)Flash pattern

SRS339-A

athroughfare repeated.

fÐ Four flashes indi-

cate malfunctioning LH

side air bag (satellite)

sensor circuit.

Repair order (ªRecheck SRS at each replacement.º)

1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the LH side air bag (satellite) sensor.

4. Replace the diagnosis sensor unit.

5. Replace the related harness.

* Follow the procedures in numerical order when repairing malfunctioning parts. Confirm whether malfunction is eliminated

using the air bag warning lamp or CONSULT-II each time repair is finished. If malfunction is still observed, proceed to the next

step. When malfunction is eliminated, further repair work is not required.

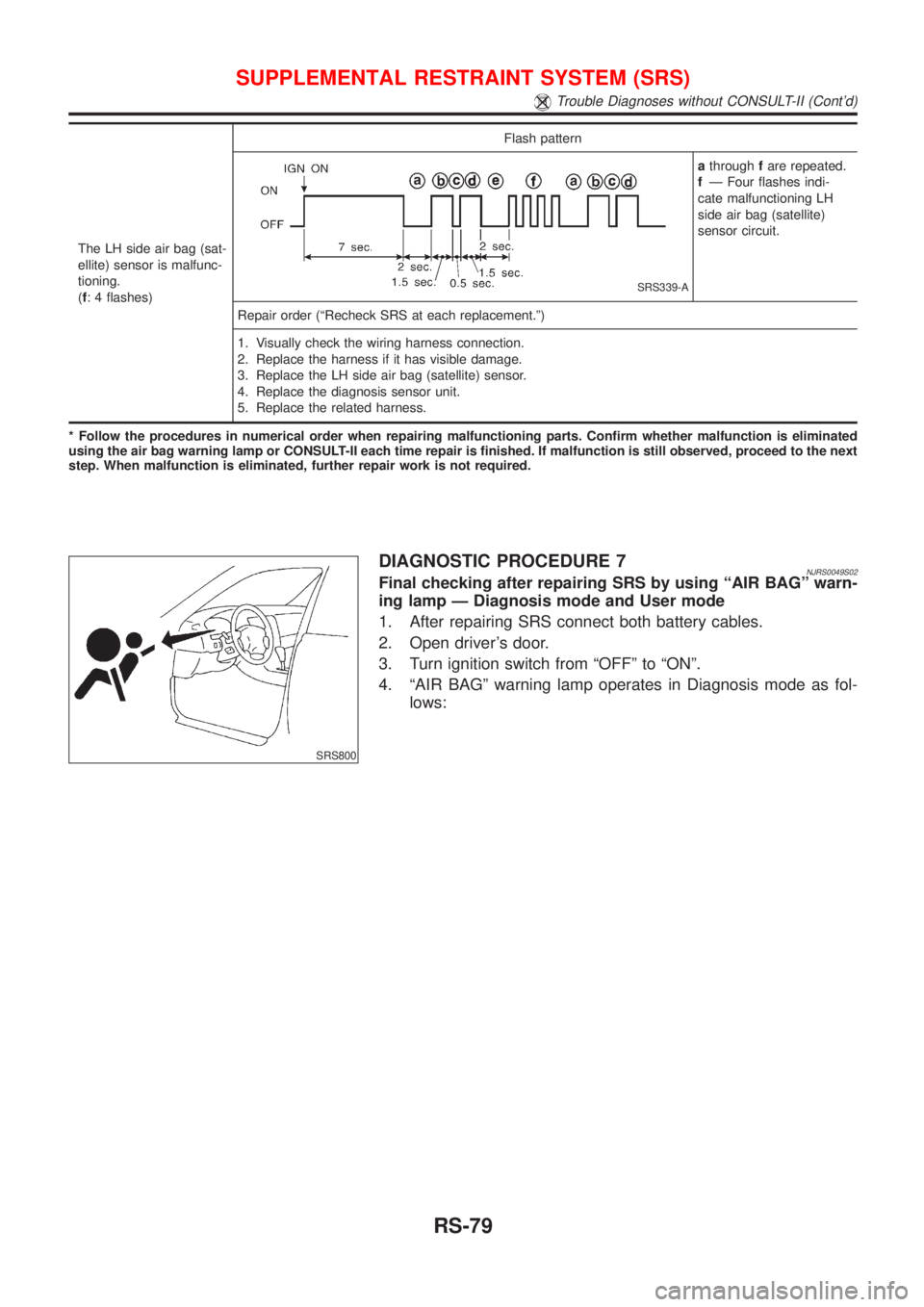

SRS800

DIAGNOSTIC PROCEDURE 7NJRS0049S02Final checking after repairing SRS by using ªAIR BAGº warn-

ing lamp Ð Diagnosis mode and User mode

1. After repairing SRS connect both battery cables.

2. Open driver's door.

3. Turn ignition switch from ªOFFº to ªONº.

4. ªAIR BAGº warning lamp operates in Diagnosis mode as fol-

lows:

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II (Cont'd)

RS-79

Page 2797 of 2898

STARTING & CHARGING SYSTEMS

SECTION

SC

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Wiring Diagrams and Trouble Diagnoses....................2

BATTERY.........................................................................3

How to Handle Battery ................................................3

METHODS OF PREVENTING OVER-DISCHARGE......3

CHECKING ELECTROLYTE LEVEL............................3

SPECIFIC GRAVITY CHECK......................................4

Battery Test and Charging Chart .................................6

CHART I...................................................................6

CHART II..................................................................7

A: SLOW CHARGE....................................................8

B: STANDARD CHARGE..........................................10

C: QUICK CHARGE................................................. 11

STARTING SYSTEM.....................................................13

System Description ....................................................13

M/T MODELS..........................................................13

A/T MODELS...........................................................13

Wiring Diagram - START -/Sedan .............................14

M/T MODELS..........................................................14

A/T MODELS...........................................................15

Wiring Diagram - START -/Hatchback.......................16

Trouble Diagnoses.....................................................17

Construction ...............................................................18

Removal and Installation ...........................................21

REMOVAL...............................................................21

INSTALLATION........................................................21

Inspection...................................................................21

MAGNETIC SWITCH CHECK...................................21

PINION/CLUTCH CHECK.........................................21

BRUSH CHECK.......................................................22

YOKE CHECK.........................................................23

ARMATURE CHECK................................................23

Assembly ...................................................................24

PINION PROTRUSION LENGTH ADJUSTMENT........24

CHARGING SYSTEM....................................................26

System Description ....................................................26

SEDAN...................................................................26

HATCHBACK...........................................................26

Wiring Diagram - CHARGE -/Sedan .........................27

GASOLINE ENGINE MODELS..................................27

DIESEL ENGINE MODELS.......................................28

Wiring Diagram - CHARGE -/Hatchback...................29

Trouble Diagnoses.....................................................30

WITH IC REGULATOR.............................................30

MALFUNCTION INDICATOR....................................30

Construction ...............................................................31

Removal and Installation ...........................................34

REMOVAL (QG ENGINE).........................................34

REMOVAL (YD ENGINE)..........................................34

INSTALLATION........................................................35

Disassembly...............................................................35

REAR COVER.........................................................35

REAR BEARING......................................................35

Inspection...................................................................35

ROTOR CHECK......................................................35

BRUSH CHECK.......................................................36

STATOR CHECK.....................................................36

Assembly ...................................................................36

RING FITTING IN REAR BEARING...........................36

REAR COVER INSTALLATION.................................37

SERVICE DATA AND SPECIFICATIONS (SDS).........38

Battery........................................................................38

Starter ........................................................................38

Alternator ...................................................................39

Page 2799 of 2898

How to Handle BatteryNJSC0003CAUTION:

If it becomes necessary to start the engine with a booster

battery and jumper cables,

1) Use a 12-volt booster battery.

2) After connecting battery cables, ensure that they are

tightly clamped to battery terminals for good contact.

MEL040F

METHODS OF PREVENTING OVER-DISCHARGENJSC0003S01The following precautions must be taken to prevent over-discharg-

ing a battery.

+The battery surface (particularly its top) should always be kept

clean and dry.

+The terminal connections should be clean and tight.

+At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as ªlow maintenanceº

and ªmaintenance-freeº.

MEL041F

+When the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal.

MEL042F

+Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep

a close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVELNJSC0003S02WARNING:

Do not allow battery fluid to come in contact with skin, eyes,

fabrics, or painted surfaces. After touching a battery, do not

touch or rub your eyes until you have thoroughly washed your

hands. If acid contacts eyes, skin or clothing, immediately

flush with water for 15 minutes and seek medical attention.

BATTERY

How to Handle Battery

SC-3

Page 2800 of 2898

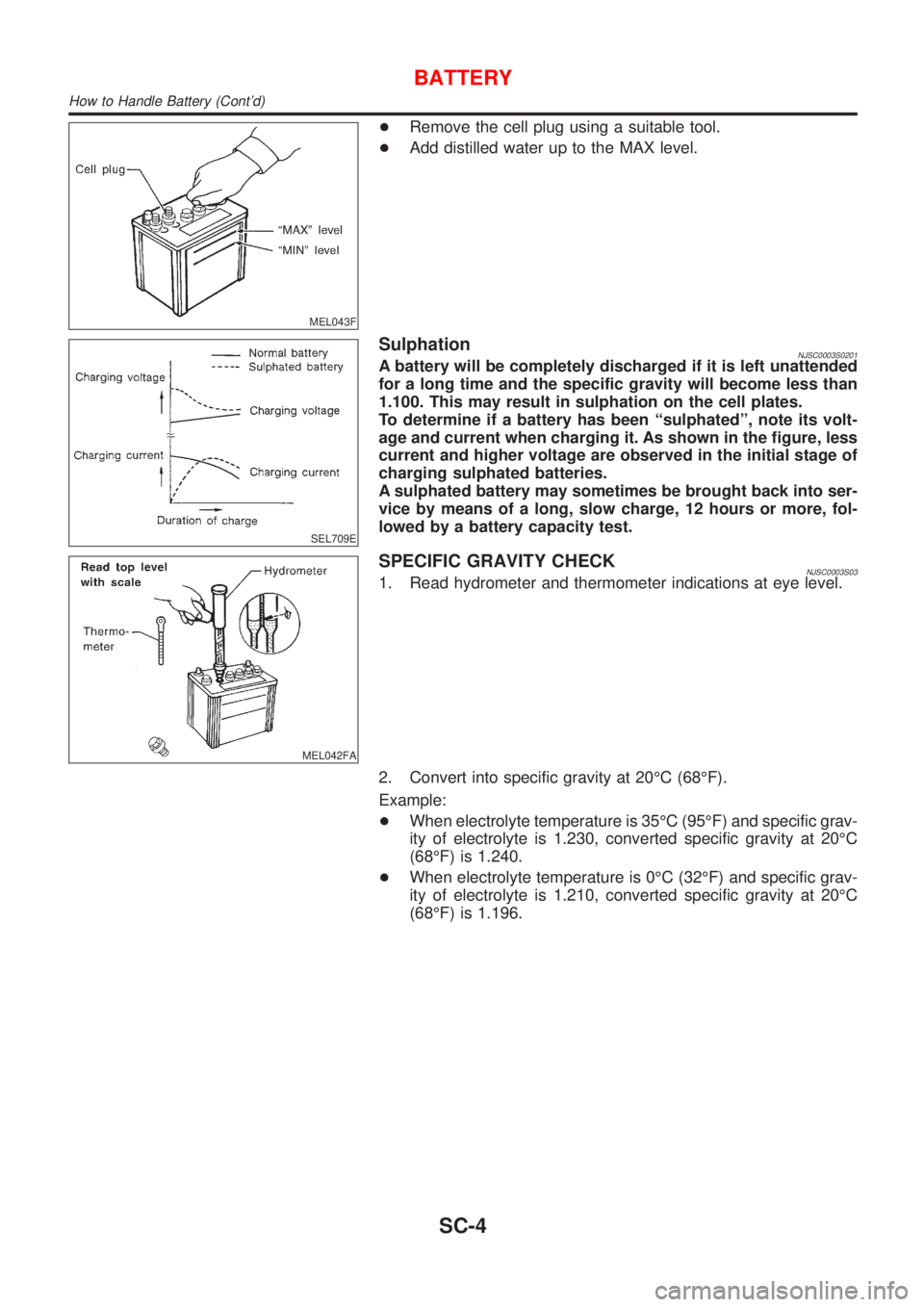

MEL043F

+Remove the cell plug using a suitable tool.

+Add distilled water up to the MAX level.

SEL709E

SulphationNJSC0003S0201A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates.

To determine if a battery has been ªsulphatedº, note its volt-

age and current when charging it. As shown in the figure, less

current and higher voltage are observed in the initial stage of

charging sulphated batteries.

A sulphated battery may sometimes be brought back into ser-

vice by means of a long, slow charge, 12 hours or more, fol-

lowed by a battery capacity test.

MEL042FA

SPECIFIC GRAVITY CHECKNJSC0003S031. Read hydrometer and thermometer indications at eye level.

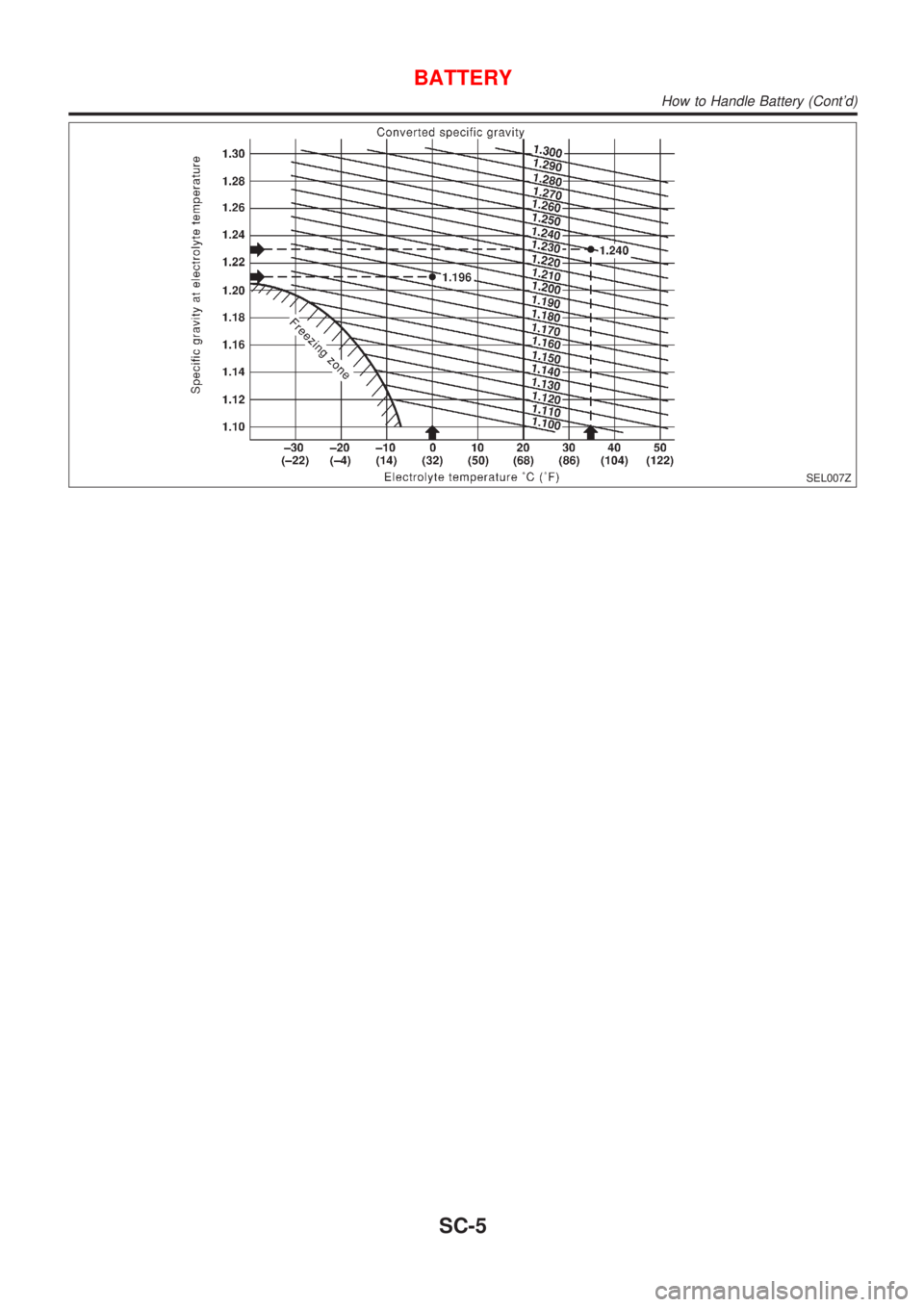

2. Convert into specific gravity at 20ÉC (68ÉF).

Example:

+When electrolyte temperature is 35ÉC (95ÉF) and specific grav-

ity of electrolyte is 1.230, converted specific gravity at 20ÉC

(68ÉF) is 1.240.

+When electrolyte temperature is 0ÉC (32ÉF) and specific grav-

ity of electrolyte is 1.210, converted specific gravity at 20ÉC

(68ÉF) is 1.196.

BATTERY

How to Handle Battery (Cont'd)

SC-4

Page 2801 of 2898

SEL007Z

BATTERY

How to Handle Battery (Cont'd)

SC-5

Page 2802 of 2898

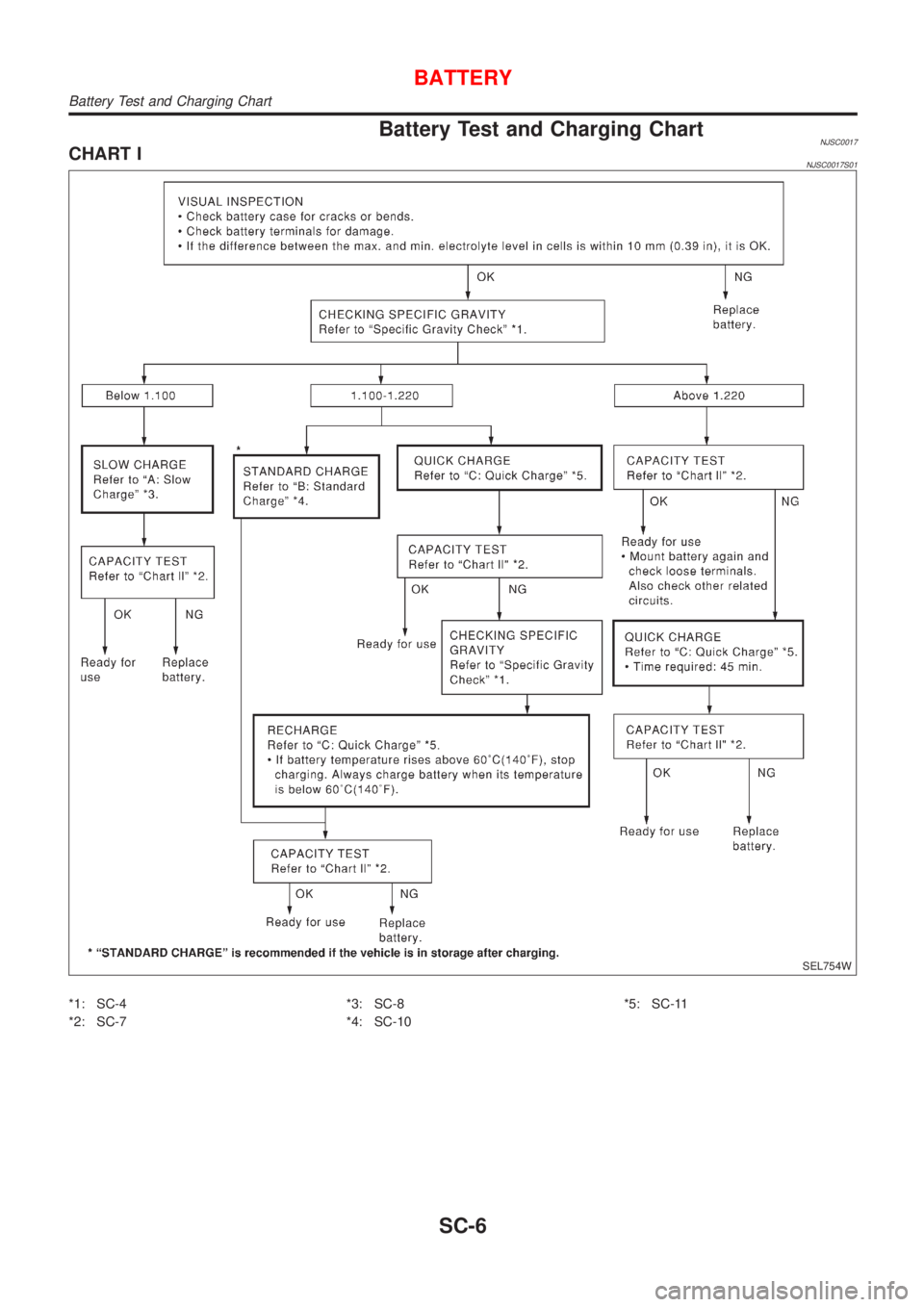

Battery Test and Charging ChartNJSC0017CHART INJSC0017S01

SEL754W

*1: SC-4

*2: SC-7*3: SC-8

*4: SC-10*5: SC-11

BATTERY

Battery Test and Charging Chart

SC-6

Page 2803 of 2898

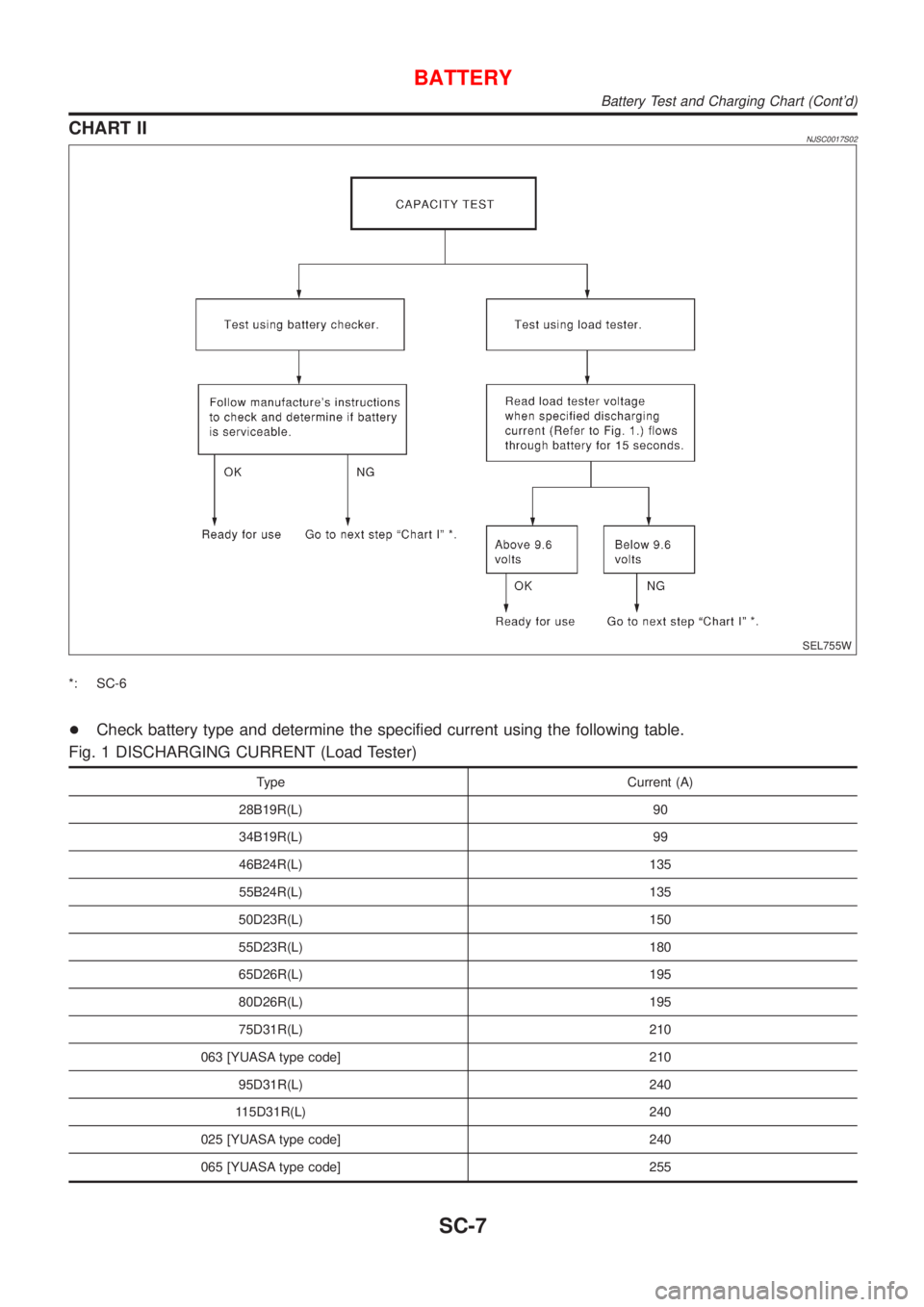

CHART IINJSC0017S02

SEL755W

*: SC-6

+Check battery type and determine the specified current using the following table.

Fig. 1 DISCHARGING CURRENT (Load Tester)

Type Current (A)

28B19R(L) 90

34B19R(L) 99

46B24R(L) 135

55B24R(L) 135

50D23R(L) 150

55D23R(L) 180

65D26R(L) 195

80D26R(L) 195

75D31R(L) 210

063 [YUASA type code] 210

95D31R(L) 240

115D31R(L) 240

025 [YUASA type code] 240

065 [YUASA type code] 255

BATTERY

Battery Test and Charging Chart (Cont'd)

SC-7