ECO mode NISSAN ALMERA 2001 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 249 of 2898

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0303S03CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine.

3) Drive vehicle in D position and allow the transmission to shift

ª1º®ª2º (ªGEARº).

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0750 SHIFT SOLENOID VALVE AEURO-OBD

Description (Cont'd)

AT-247

Page 255 of 2898

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0307S03CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine.

3) Drive vehicle in D position and allow the transmission to shift

1®2®3 (ªGEARº).

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0755 SHIFT SOLENOID VALVE BEURO-OBD

Description (Cont'd)

AT-253

Page 261 of 2898

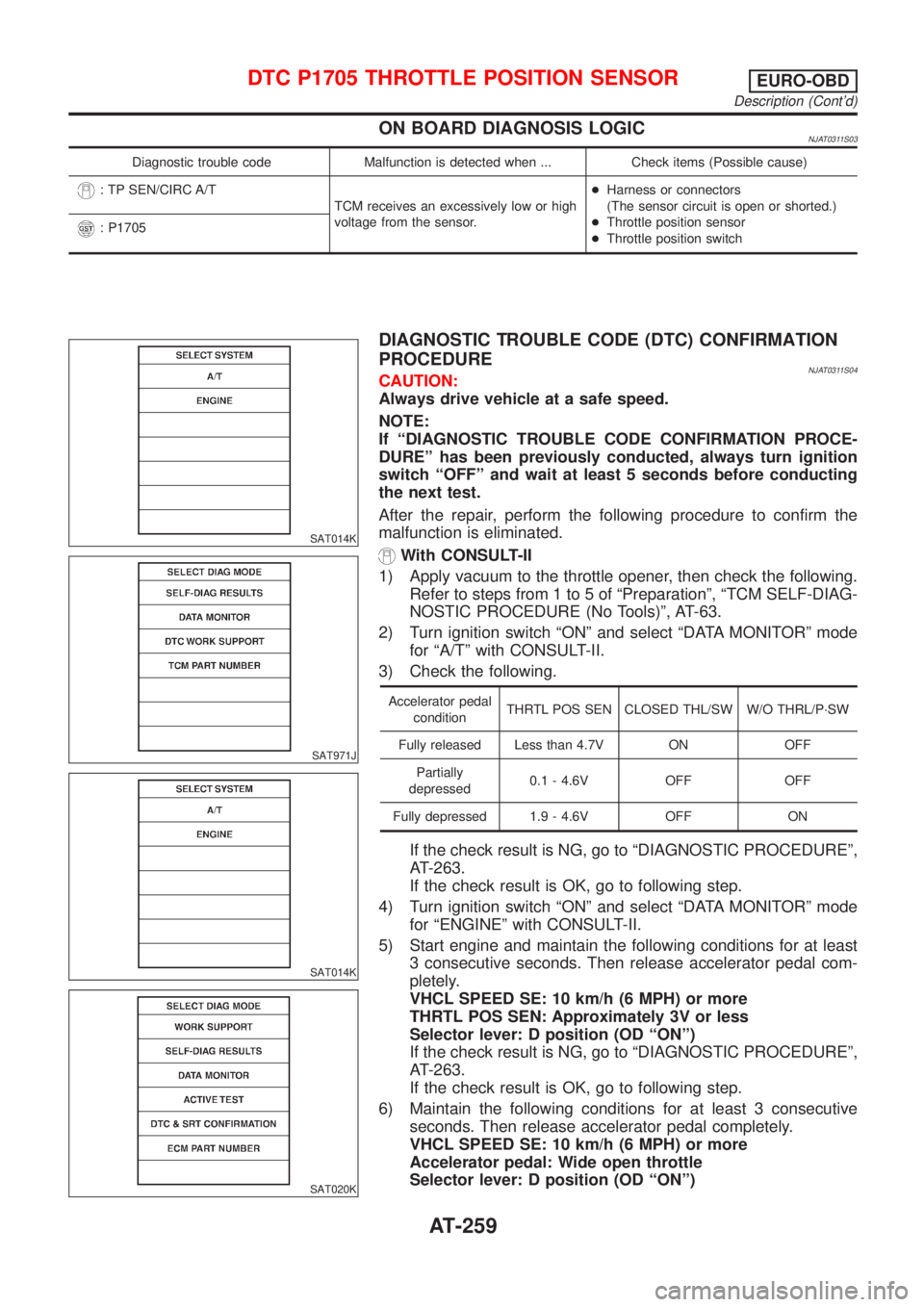

ON BOARD DIAGNOSIS LOGICNJAT0311S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: TP SEN/CIRC A/T

TCM receives an excessively low or high

voltage from the sensor.+Harness or connectors

(The sensor circuit is open or shorted.)

+Throttle position sensor

+Throttle position switch

: P1705

SAT014K

SAT971J

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0311S04CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Apply vacuum to the throttle opener, then check the following.

Refer to steps from 1 to 5 of ªPreparationº, ªTCM SELF-DIAG-

NOSTIC PROCEDURE (No Tools)º, AT-63.

2) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªA/Tº with CONSULT-II.

3) Check the following.

Accelerator pedal

conditionTHRTL POS SEN CLOSED THL/SW W/O THRL/P´SW

Fully released Less than 4.7V ON OFF

Partially

depressed0.1 - 4.6V OFF OFF

Fully depressed 1.9 - 4.6V OFF ON

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-263.

If the check result is OK, go to following step.

4) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

5) Start engine and maintain the following conditions for at least

3 consecutive seconds. Then release accelerator pedal com-

pletely.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: Approximately 3V or less

Selector lever: D position (OD ªONº)

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-263.

If the check result is OK, go to following step.

6) Maintain the following conditions for at least 3 consecutive

seconds. Then release accelerator pedal completely.

VHCL SPEED SE: 10 km/h (6 MPH) or more

Accelerator pedal: Wide open throttle

Selector lever: D position (OD ªONº)

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Description (Cont'd)

AT-259

Page 270 of 2898

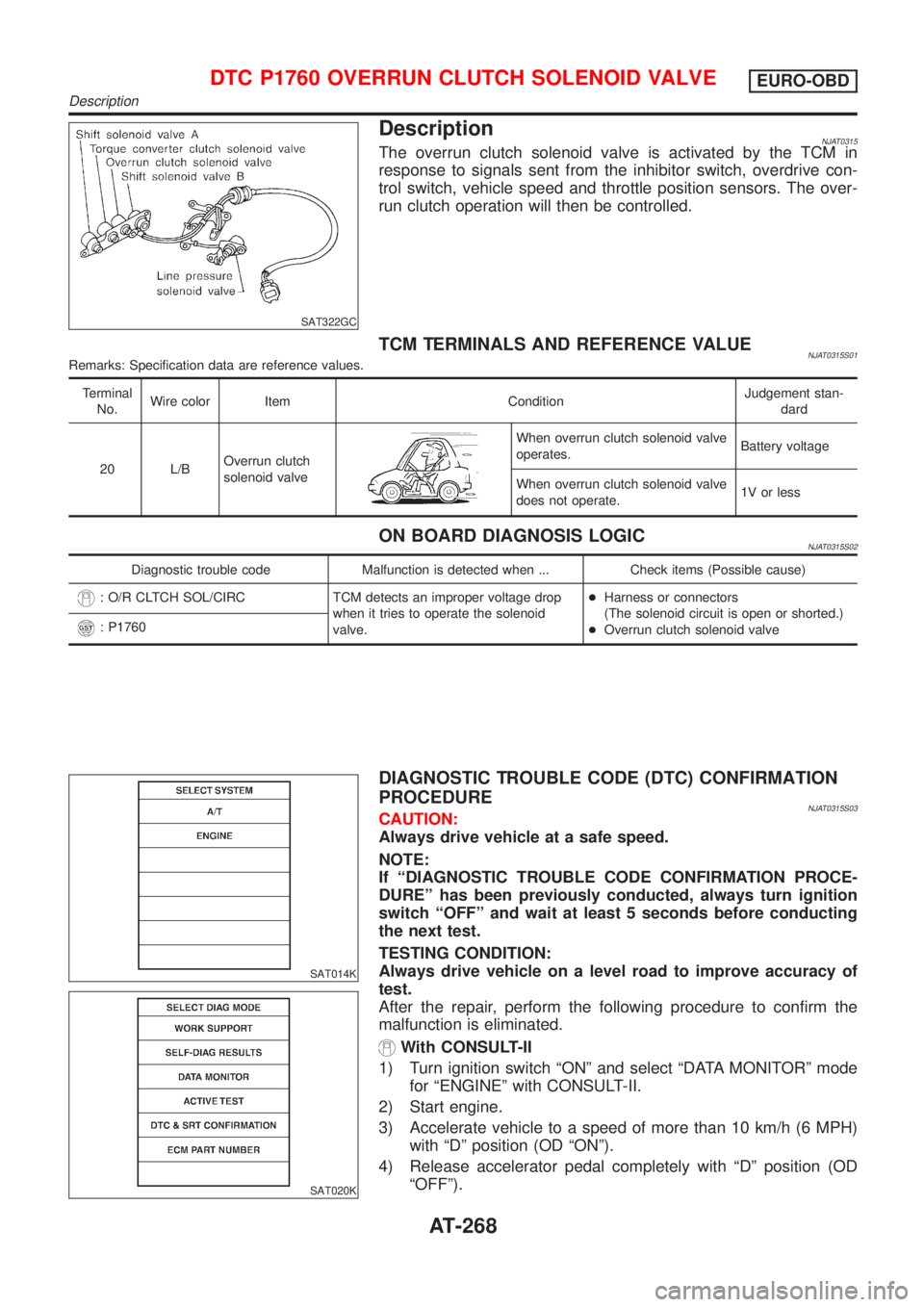

SAT322GC

DescriptionNJAT0315The overrun clutch solenoid valve is activated by the TCM in

response to signals sent from the inhibitor switch, overdrive con-

trol switch, vehicle speed and throttle position sensors. The over-

run clutch operation will then be controlled.

TCM TERMINALS AND REFERENCE VALUENJAT0315S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

20 L/BOverrun clutch

solenoid valve

When overrun clutch solenoid valve

operates.Battery voltage

When overrun clutch solenoid valve

does not operate.1V or less

ON BOARD DIAGNOSIS LOGICNJAT0315S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: O/R CLTCH SOL/CIRC TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or shorted.)

+Overrun clutch solenoid valve

: P1760

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0315S03CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITION:

Always drive vehicle on a level road to improve accuracy of

test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine.

3) Accelerate vehicle to a speed of more than 10 km/h (6 MPH)

with ªDº position (OD ªONº).

4) Release accelerator pedal completely with ªDº position (OD

ªOFFº).

DTC P1760 OVERRUN CLUTCH SOLENOID VALVEEURO-OBD

Description

AT-268

Page 284 of 2898

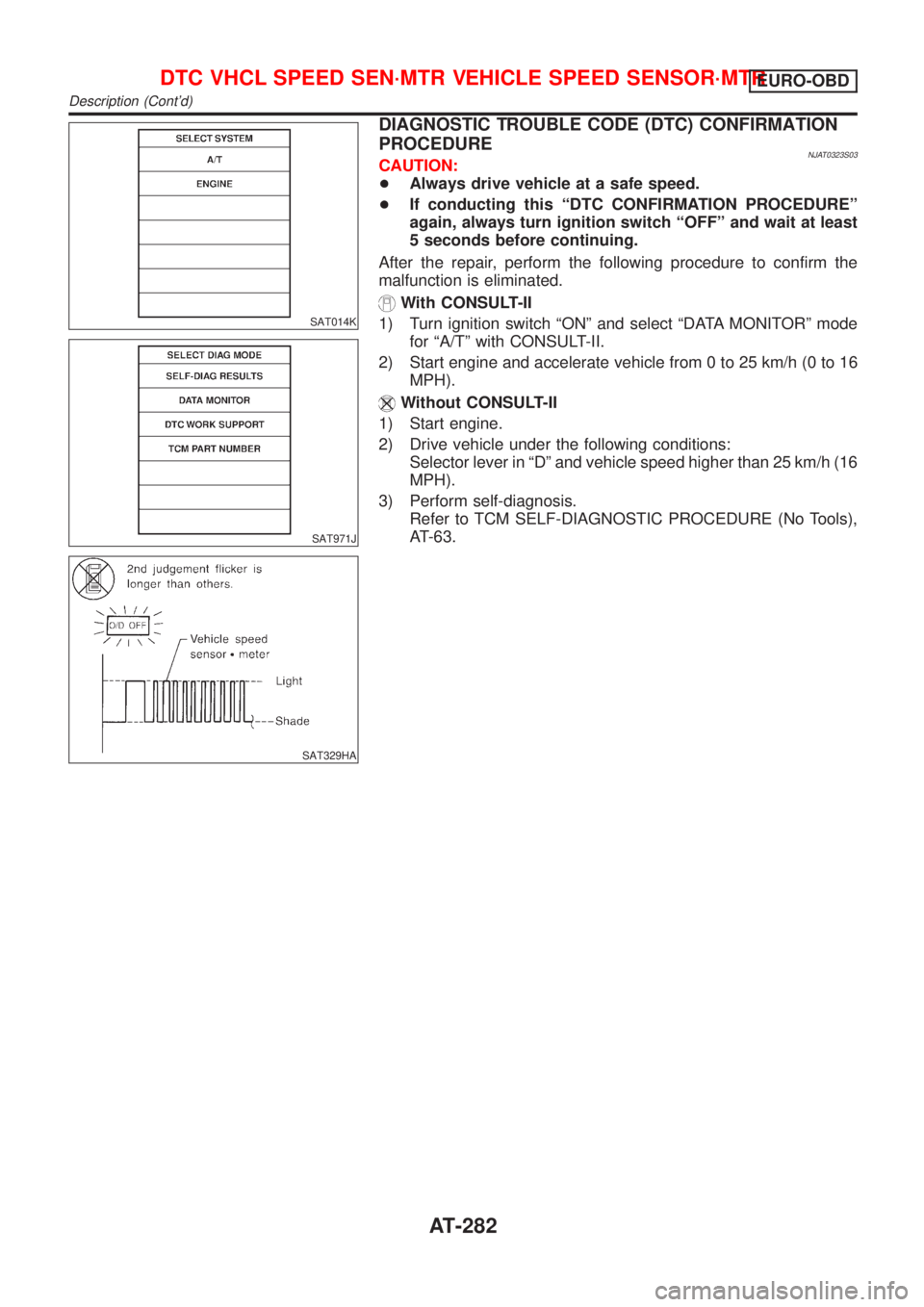

SAT014K

SAT971J

SAT329HA

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0323S03CAUTION:

+Always drive vehicle at a safe speed.

+If conducting this ªDTC CONFIRMATION PROCEDUREº

again, always turn ignition switch ªOFFº and wait at least

5 seconds before continuing.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªA/Tº with CONSULT-II.

2) Start engine and accelerate vehicle from 0 to 25 km/h (0 to 16

MPH).

Without CONSULT-II

1) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº and vehicle speed higher than 25 km/h (16

MPH).

3) Perform self-diagnosis.

Refer to TCM SELF-DIAGNOSTIC PROCEDURE (No Tools),

AT-63.

DTC VHCL SPEED SEN´MTR VEHICLE SPEED SENSOR´MTREURO-OBD

Description (Cont'd)

AT-282

Page 288 of 2898

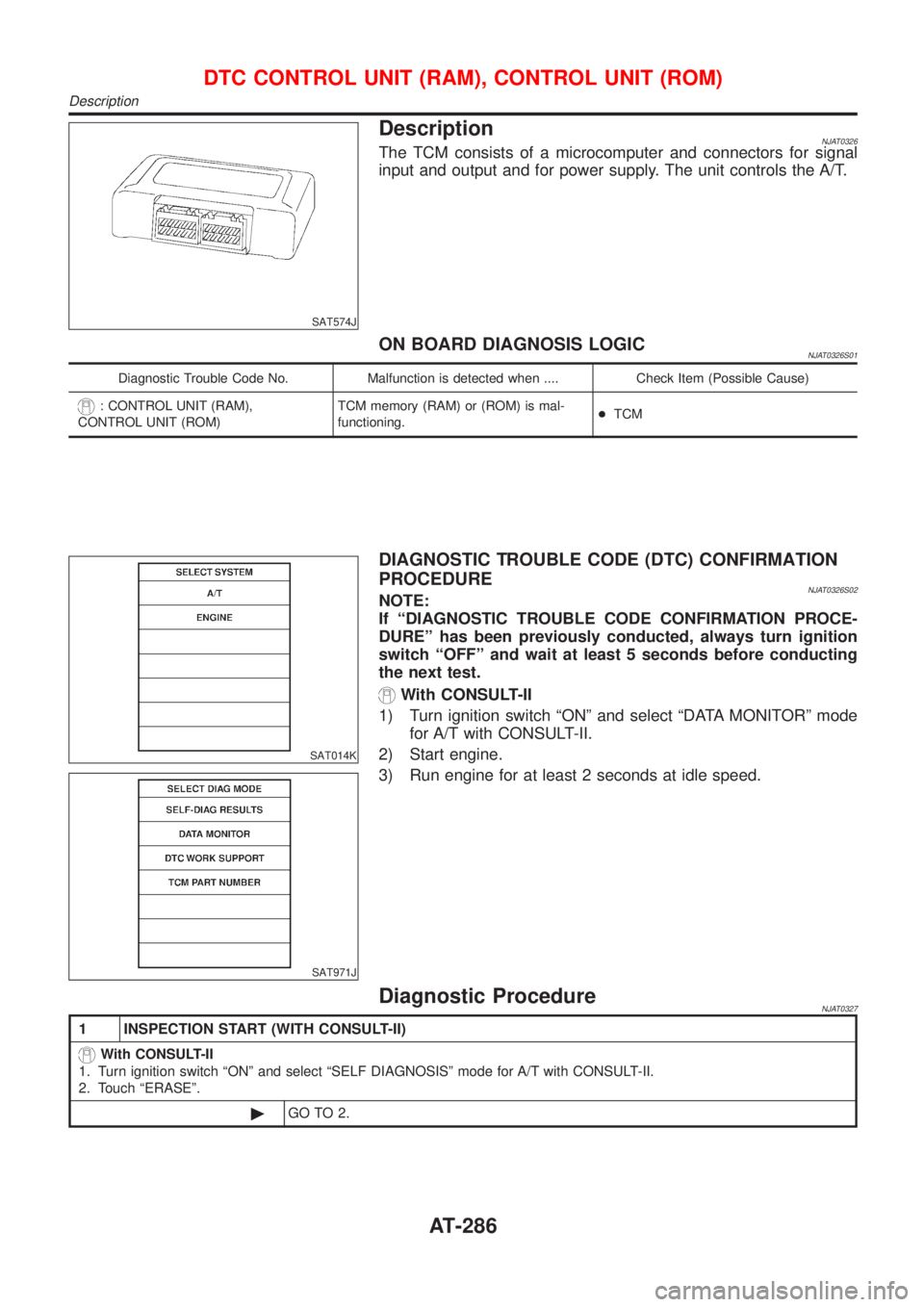

SAT574J

DescriptionNJAT0326The TCM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the A/T.

ON BOARD DIAGNOSIS LOGICNJAT0326S01

Diagnostic Trouble Code No. Malfunction is detected when .... Check Item (Possible Cause)

: CONTROL UNIT (RAM),

CONTROL UNIT (ROM)TCM memory (RAM) or (ROM) is mal-

functioning.+TCM

SAT014K

SAT971J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0326S02NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for A/T with CONSULT-II.

2) Start engine.

3) Run engine for at least 2 seconds at idle speed.

Diagnostic ProcedureNJAT0327

1 INSPECTION START (WITH CONSULT-II)

With CONSULT-II

1. Turn ignition switch ªONº and select ªSELF DIAGNOSISº mode for A/T with CONSULT-II.

2. Touch ªERASEº.

©GO TO 2.

DTC CONTROL UNIT (RAM), CONTROL UNIT (ROM)

Description

AT-286

Page 290 of 2898

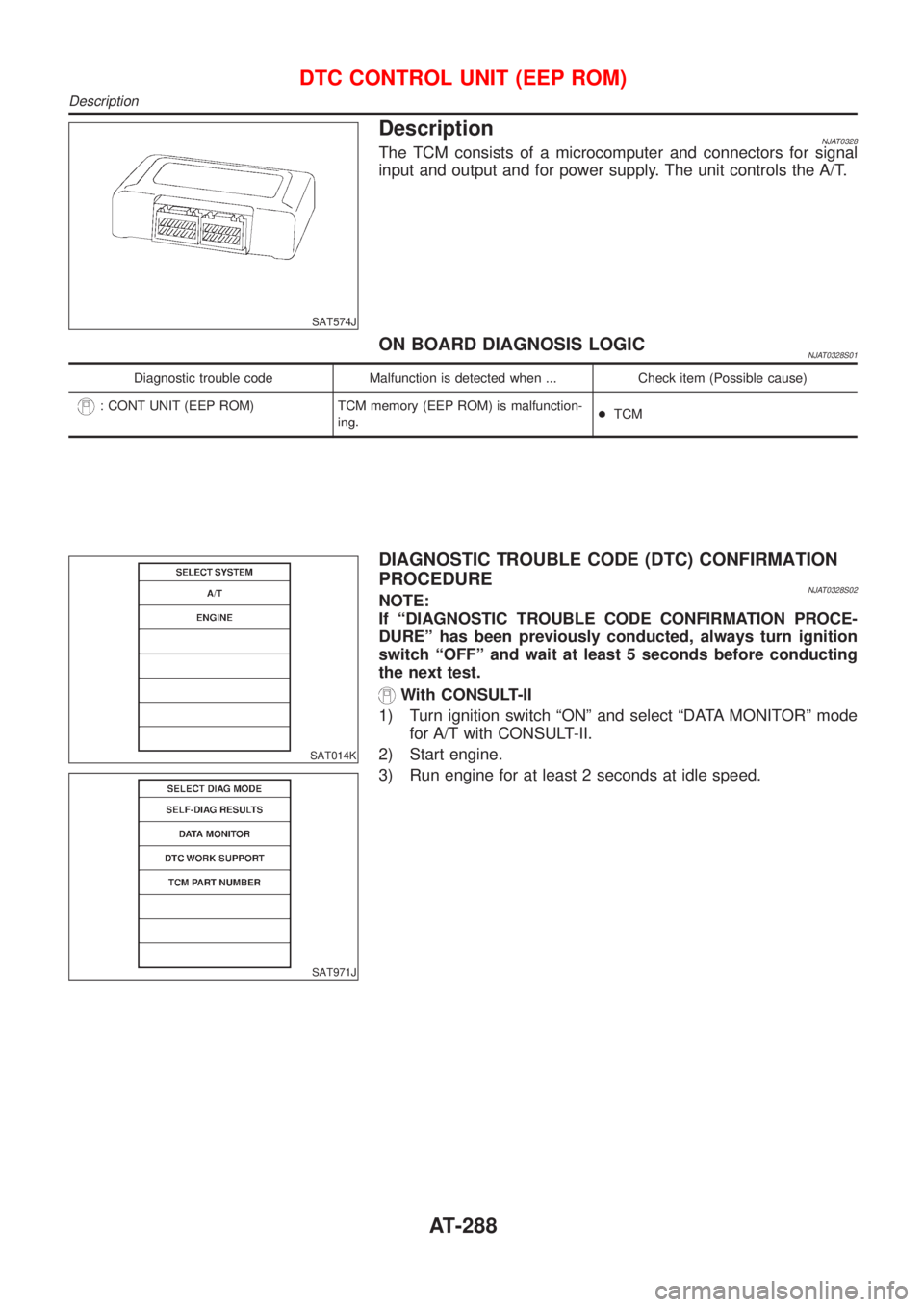

SAT574J

DescriptionNJAT0328The TCM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the A/T.

ON BOARD DIAGNOSIS LOGICNJAT0328S01

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: CONT UNIT (EEP ROM) TCM memory (EEP ROM) is malfunction-

ing.+TCM

SAT014K

SAT971J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0328S02NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for A/T with CONSULT-II.

2) Start engine.

3) Run engine for at least 2 seconds at idle speed.

DTC CONTROL UNIT (EEP ROM)

Description

AT-288

Page 291 of 2898

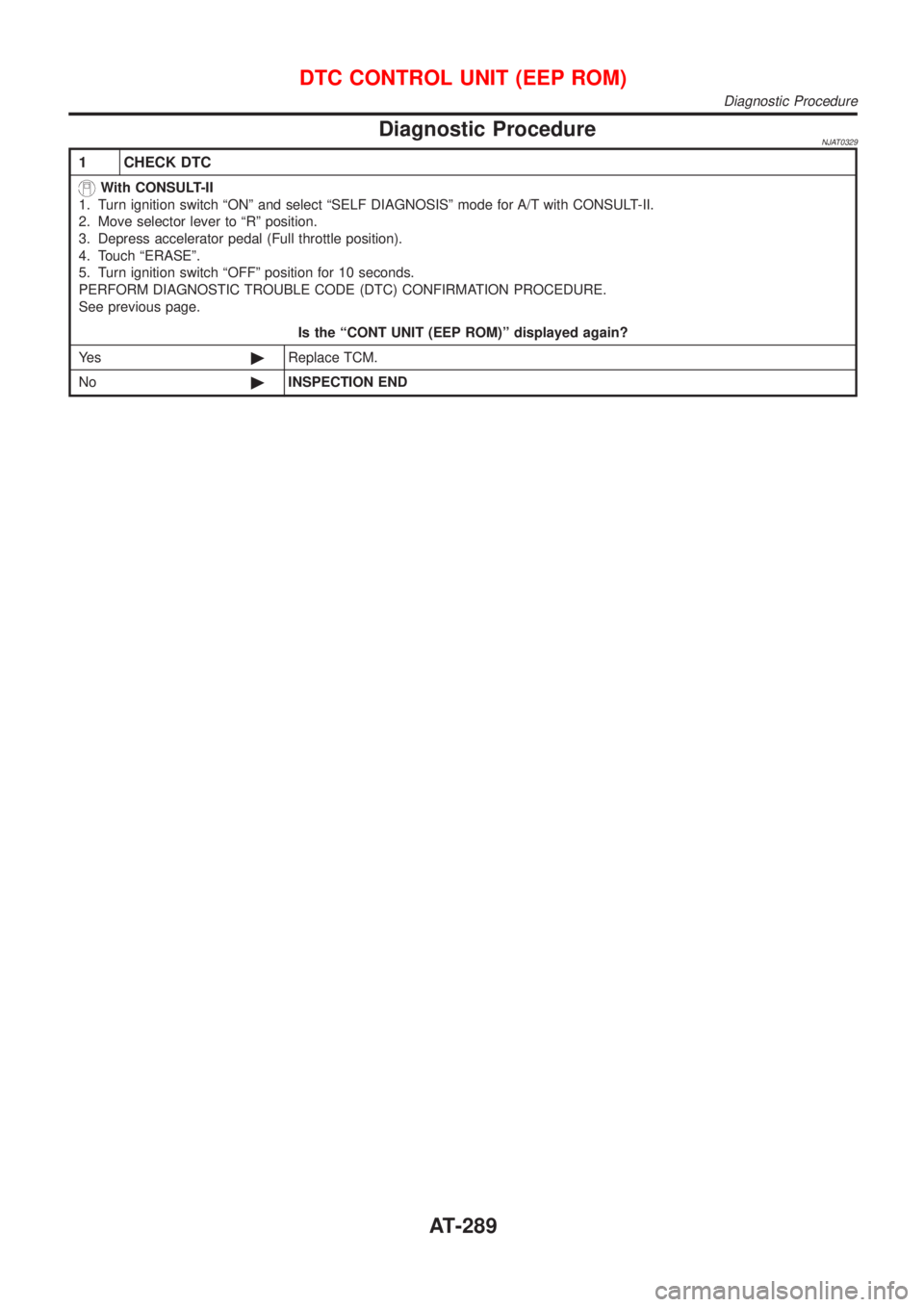

Diagnostic ProcedureNJAT0329

1 CHECK DTC

With CONSULT-II

1. Turn ignition switch ªONº and select ªSELF DIAGNOSISº mode for A/T with CONSULT-II.

2. Move selector lever to ªRº position.

3. Depress accelerator pedal (Full throttle position).

4. Touch ªERASEº.

5. Turn ignition switch ªOFFº position for 10 seconds.

PERFORM DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE.

See previous page.

Is the ªCONT UNIT (EEP ROM)º displayed again?

Ye s©Replace TCM.

No©INSPECTION END

DTC CONTROL UNIT (EEP ROM)

Diagnostic Procedure

AT-289

Page 472 of 2898

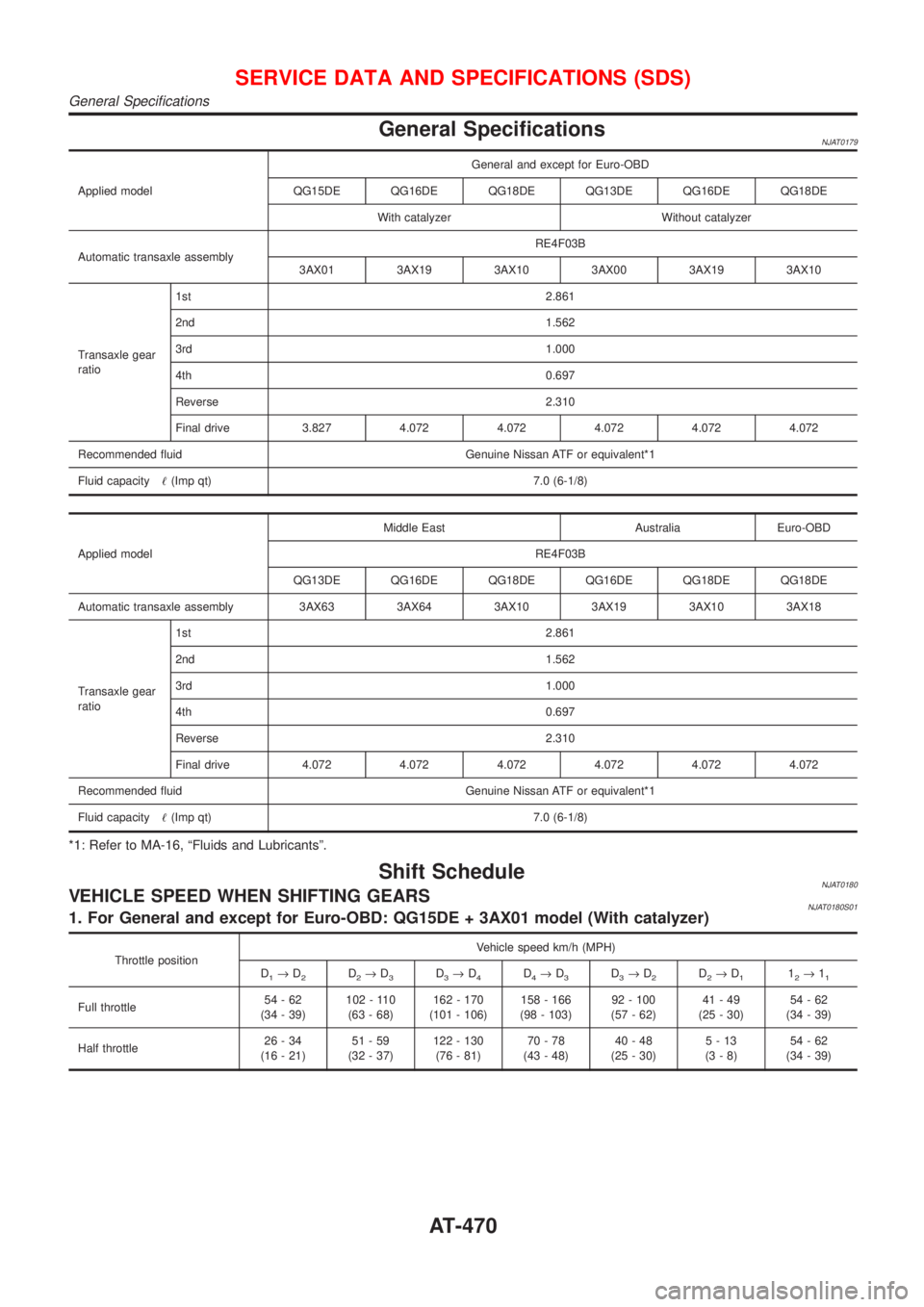

General SpecificationsNJAT0179

Applied modelGeneral and except for Euro-OBD

QG15DE QG16DE QG18DE QG13DE QG16DE QG18DE

With catalyzer Without catalyzer

Automatic transaxle assemblyRE4F03B

3AX01 3AX19 3AX10 3AX00 3AX19 3AX10

Transaxle gear

ratio1st 2.861

2nd 1.562

3rd 1.000

4th 0.697

Reverse 2.310

Final drive 3.827 4.072 4.072 4.072 4.072 4.072

Recommended fluid Genuine Nissan ATF or equivalent*1

Fluid capacity!(Imp qt) 7.0 (6-1/8)

Applied modelMiddle East Australia Euro-OBD

RE4F03B

QG13DE QG16DE QG18DE QG16DE QG18DE QG18DE

Automatic transaxle assembly 3AX63 3AX64 3AX10 3AX19 3AX10 3AX18

Transaxle gear

ratio1st 2.861

2nd 1.562

3rd 1.000

4th 0.697

Reverse 2.310

Final drive 4.072 4.072 4.072 4.072 4.072 4.072

Recommended fluid Genuine Nissan ATF or equivalent*1

Fluid capacity!(Imp qt) 7.0 (6-1/8)

*1: Refer to MA-16, ªFluids and Lubricantsº.

Shift ScheduleNJAT0180VEHICLE SPEED WHEN SHIFTING GEARSNJAT0180S011. For General and except for Euro-OBD: QG15DE + 3AX01 model (With catalyzer)

Throttle positionVehicle speed km/h (MPH)

D

1®D2D2®D3D3®D4D4®D3D3®D2D2®D112®11

Full throttle54-62

(34 - 39)102 - 110

(63 - 68)162 - 170

(101 - 106)158 - 166

(98 - 103)92 - 100

(57 - 62)41-49

(25 - 30)54-62

(34 - 39)

Half throttle26-34

(16 - 21)51-59

(32 - 37)122 - 130

(76 - 81)70-78

(43 - 48)40-48

(25 - 30)5-13

(3-8)54-62

(34 - 39)

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

AT-470

Page 520 of 2898

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJBR0139The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

SBR686C

Precautions for Brake SystemNJBR0002+Recommended fluid is brake fluid ªDOT 4º.

+Never reuse drained brake fluid.

+Be careful not to splash brake fluid on painted areas.

+To clean or wash all parts of master cylinder, disc brake

caliper and wheel cylinder, use clean brake fluid.

+Never use mineral oils such as gasoline or kerosene. They

will ruin rubber parts of the hydraulic system.

+Use flare nut wrench when removing and installing brake

tube.

+Always torque brake lines when installing.

+Burnish the brake contact surfaces after refinishing or

replacing drums or rotors, after replacing pads or linings,

or if a soft pedal occurs at very low mileage.

Refer to ªBrake Burnishing Procedureº, ªON-VEHICLE

SERVICEº, BR-8.

WARNING:

+Clean brake pads and shoes with a waste cloth, then wipe

with a dust collector.

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

BR-4