ECO mode NISSAN ALMERA 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 852 of 2898

36 ERASE UNNECESSARY DTC

After this inspection, unnecessary DTC No. might be displayed.

Erase the stored memory in ECM and TCM (Transmission control module).

Refer to ªHow to Erase Emission-Related Diagnostic Informationº, EC-70 and AT-52, ªHOW TO ERASE DTCº.

©INSPECTION END

Basic Inspection/HatchbackNJEC1785MODELS WITH THROTTLE POSITION SWITCHNJEC1785S01Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

+Headlamp switch is OFF,

On vehicle equipped with daytime light systems, set lighting

switch to the 1st position to light only small lamps.

+Air conditioner switch is OFF,

+Rear window defogger switch is OFF,

+Steering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem, or a current need for scheduled

maintenance.

2. Open engine hood and check the following:

+Harness connectors for improper connections

+Vacuum hoses for splits, kinks and improper connections

+Wiring for improper connections, pinches and cuts

+Air cleaner clogging

+Hoses and ducts for leaks

SEF983U

©GO TO 2.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Sedan (Cont'd)

EC-128

Page 860 of 2898

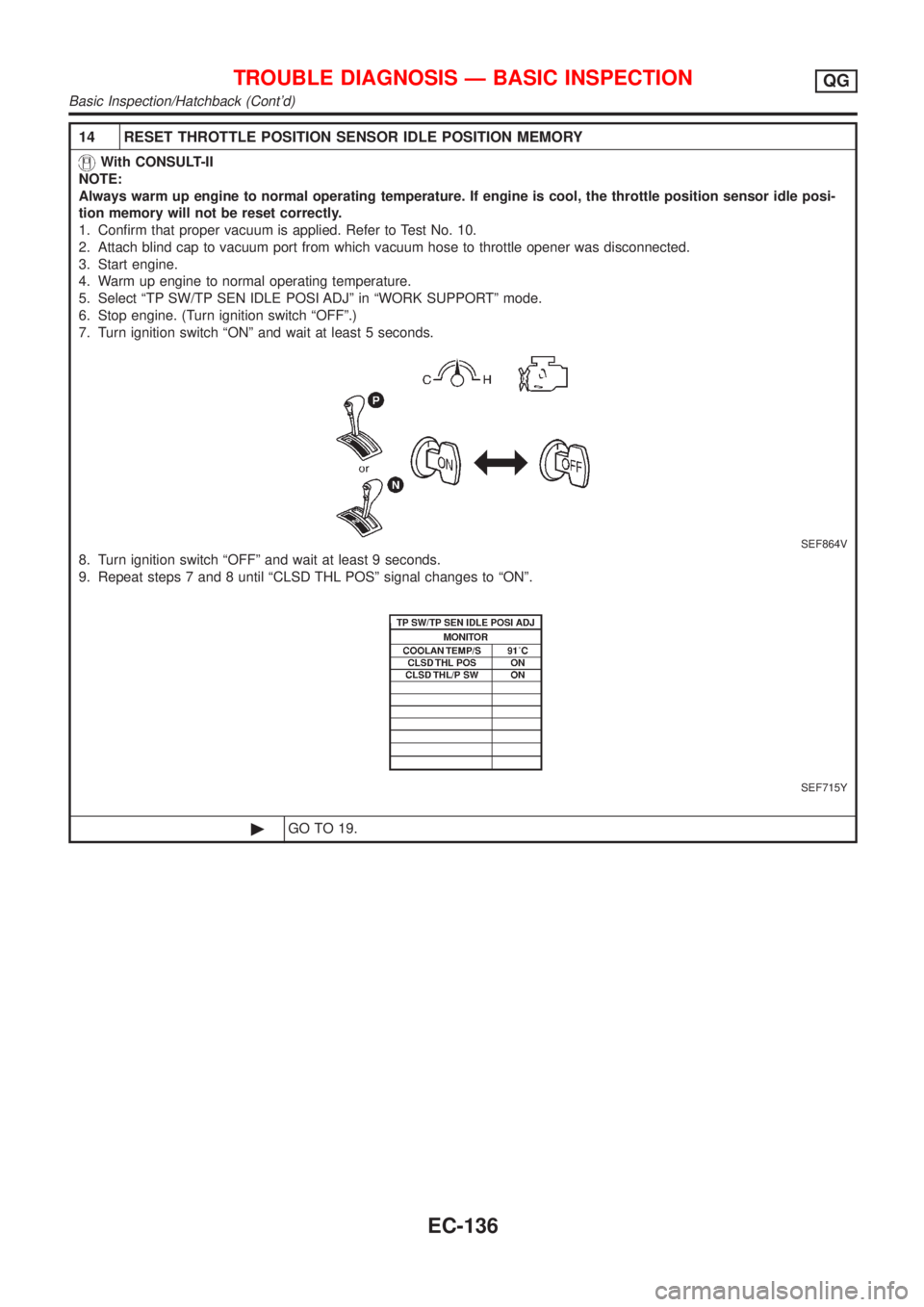

14 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Confirm that proper vacuum is applied. Refer to Test No. 10.

2. Attach blind cap to vacuum port from which vacuum hose to throttle opener was disconnected.

3. Start engine.

4. Warm up engine to normal operating temperature.

5. Select ªTP SW/TP SEN IDLE POSI ADJº in ªWORK SUPPORTº mode.

6. Stop engine. (Turn ignition switch ªOFFº.)

7. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

8. Turn ignition switch ªOFFº and wait at least 9 seconds.

9. Repeat steps 7 and 8 until ªCLSD THL POSº signal changes to ªONº.

SEF715Y

©GO TO 19.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Hatchback (Cont'd)

EC-136

Page 868 of 2898

35 CHECK IGNITION TIMING AGAIN

Check ignition timing again. Refer to Test No. 31.

OK or NG

OK©GO TO 37.

NG©GO TO 36.

36 CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-28, ªInstallationº.

OK or NG

OK©GO TO 34.

NG©1. Repair the timing chain installation.

2. GO TO 32.

37 ERASE UNNECESSARY DTC

After this inspection, unnecessary DTC No. might be displayed.

Erase the stored memory in ECM and TCM (Transmission control module).

Refer to ªHow to Erase Emission-Related Diagnostic Informationº, EC-70 or EC-77 and AT-52, ªHOW TO ERASE DTCº.

OK or NG

©INSPECTION END

MODELS WITHOUT THROTTLE POSITION SWITCHNJEC1785S02Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

+Headlamp switch is OFF,

On vehicle equipped with daytime light system, set lighting

switch to the 1st position to light only small lamps.

+Air conditioner switch is OFF,

+Rear window defogger switch is OFF,

+Steering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem, or a current need for scheduled

maintenance.

2. Open engine hood and check the following:

+Harness connectors for improper connections

+Vacuum hoses for splits, kinks and improper connections

+Wiring for improper connections, pinches and cuts

+Air cleaner clogging

+Hoses and ducts for leaks

SEF983U

©GO TO 2.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Hatchback (Cont'd)

EC-144

Page 870 of 2898

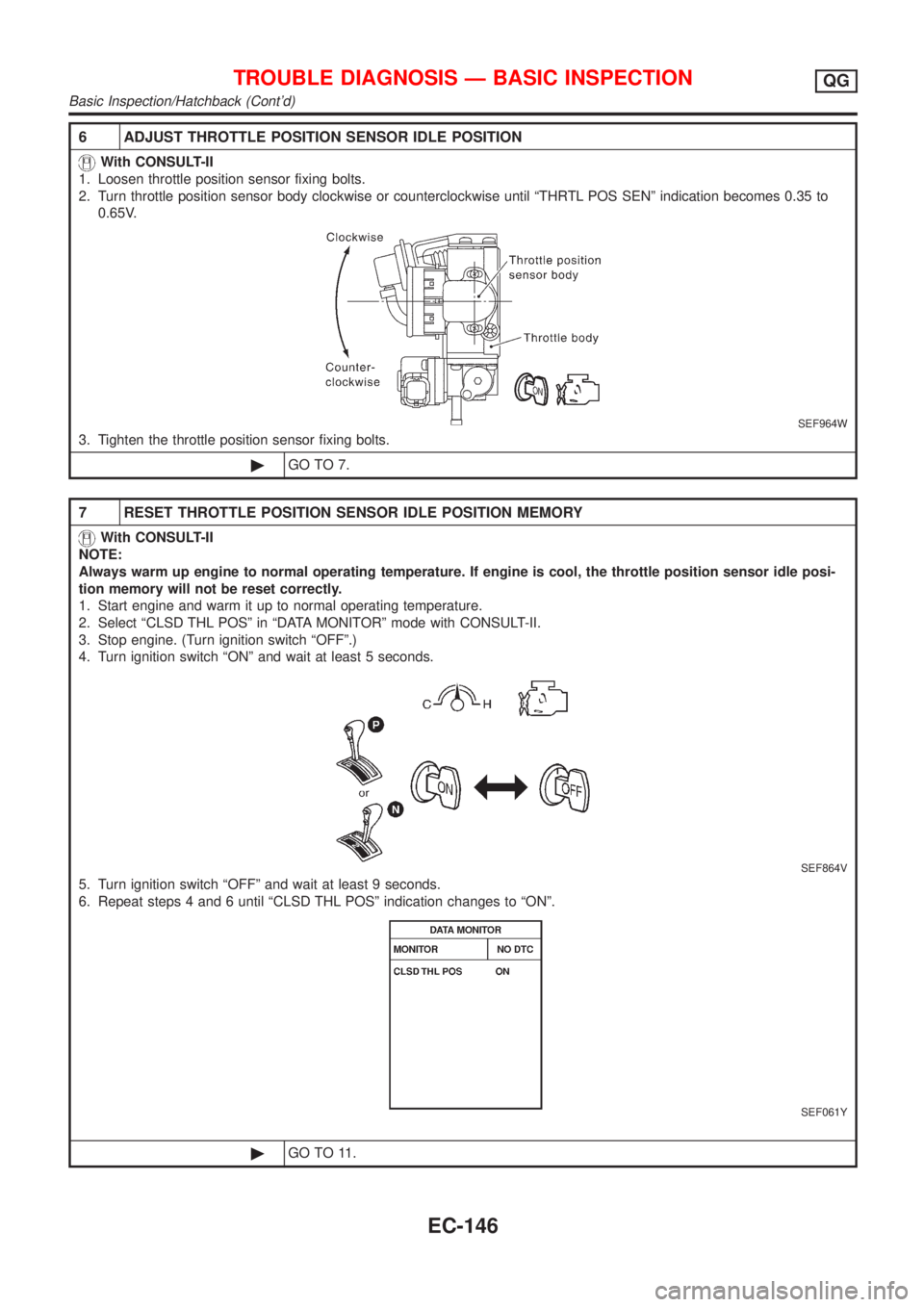

6 ADJUST THROTTLE POSITION SENSOR IDLE POSITION

With CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until ªTHRTL POS SENº indication becomes 0.35 to

0.65V.

SEF964W

3. Tighten the throttle position sensor fixing bolts.

©GO TO 7.

7 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Start engine and warm it up to normal operating temperature.

2. Select ªCLSD THL POSº in ªDATA MONITORº mode with CONSULT-II.

3. Stop engine. (Turn ignition switch ªOFFº.)

4. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

5. Turn ignition switch ªOFFº and wait at least 9 seconds.

6. Repeat steps 4 and 6 until ªCLSD THL POSº indication changes to ªONº.

SEF061Y

©GO TO 11.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Hatchback (Cont'd)

EC-146

Page 872 of 2898

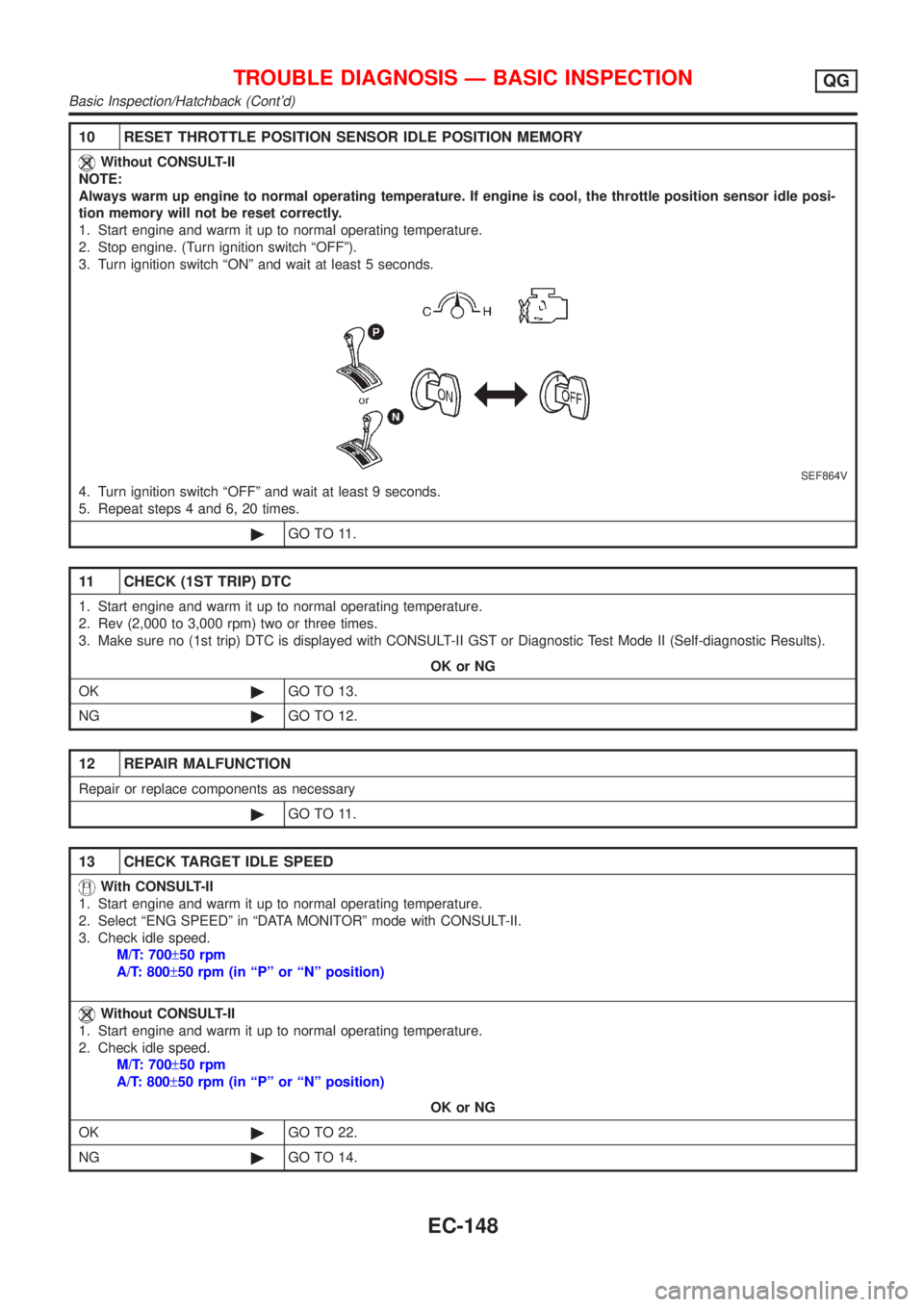

10 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Start engine and warm it up to normal operating temperature.

2. Stop engine. (Turn ignition switch ªOFFº).

3. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

4. Turn ignition switch ªOFFº and wait at least 9 seconds.

5. Repeat steps 4 and 6, 20 times.

©GO TO 11.

11 CHECK (1ST TRIP) DTC

1. Start engine and warm it up to normal operating temperature.

2. Rev (2,000 to 3,000 rpm) two or three times.

3. Make sure no (1st trip) DTC is displayed with CONSULT-II GST or Diagnostic Test Mode II (Self-diagnostic Results).

OK or NG

OK©GO TO 13.

NG©GO TO 12.

12 REPAIR MALFUNCTION

Repair or replace components as necessary

©GO TO 11.

13 CHECK TARGET IDLE SPEED

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

M/T: 700±50 rpm

A/T: 800±50 rpm (in ªPº or ªNº position)

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

M/T: 700±50 rpm

A/T: 800±50 rpm (in ªPº or ªNº position)

OK or NG

OK©GO TO 22.

NG©GO TO 14.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Hatchback (Cont'd)

EC-148

Page 883 of 2898

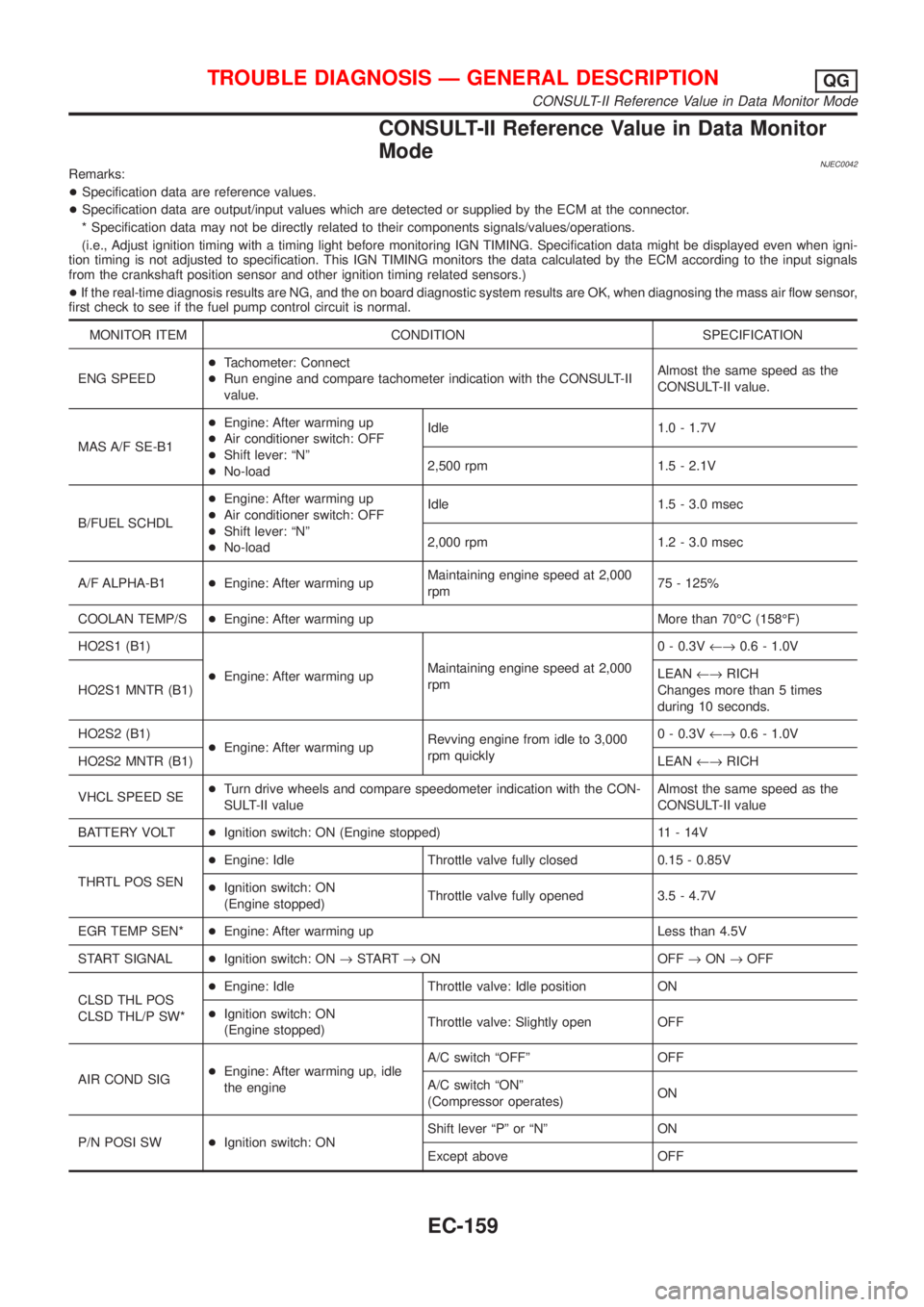

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0042Remarks:

+Specification data are reference values.

+Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

(i.e., Adjust ignition timing with a timing light before monitoring IGN TIMING. Specification data might be displayed even when igni-

tion timing is not adjusted to specification. This IGN TIMING monitors the data calculated by the ECM according to the input signals

from the crankshaft position sensor and other ignition timing related sensors.)

+If the real-time diagnosis results are NG, and the on board diagnostic system results are OK, when diagnosing the mass air flow sensor,

first check to see if the fuel pump control circuit is normal.

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value.

MAS A/F SE-B1+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ªNº

+No-loadIdle 1.0 - 1.7V

2,500 rpm 1.5 - 2.1V

B/FUEL SCHDL+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ªNº

+No-loadIdle 1.5 - 3.0 msec

2,000 rpm 1.2 - 3.0 msec

A/F ALPHA-B1+Engine: After warming upMaintaining engine speed at 2,000

rpm75 - 125%

COOLAN TEMP/S+Engine: After warming up More than 70ÉC (158ÉF)

HO2S1 (B1)

+Engine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V¨0.6 - 1.0V

HO2S1 MNTR (B1)LEAN¨RICH

Changes more than 5 times

during 10 seconds.

HO2S2 (B1)

+Engine: After warming upRevving engine from idle to 3,000

rpm quickly0 - 0.3V¨0.6 - 1.0V

HO2S2 MNTR (B1)LEAN¨RICH

VHCL SPEED SE+Turn drive wheels and compare speedometer indication with the CON-

SULT-II valueAlmost the same speed as the

CONSULT-II value

BATTERY VOLT+Ignition switch: ON (Engine stopped) 11 - 14V

THRTL POS SEN+Engine: Idle Throttle valve fully closed 0.15 - 0.85V

+Ignition switch: ON

(Engine stopped)Throttle valve fully opened 3.5 - 4.7V

EGR TEMP SEN*+Engine: After warming up Less than 4.5V

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

CLSD THL POS

CLSD THL/P SW*+Engine: Idle Throttle valve: Idle position ON

+Ignition switch: ON

(Engine stopped)Throttle valve: Slightly open OFF

AIR COND SIG+Engine: After warming up, idle

the engineA/C switch ªOFFº OFF

A/C switch ªONº

(Compressor operates)ON

P/N POSI SW+Ignition switch: ONShift lever ªPº or ªNº ON

Except above OFF

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

CONSULT-II Reference Value in Data Monitor Mode

EC-159

Page 885 of 2898

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLY+Ignition switch is turned to ON (Operates for 1 second)

+Engine running and cranking

+When engine is stopped (stops in 1.5 seconds)ON

+Except as shown above OFF

COOLING FAN+After warming up engine, idle

the engine.

+Air conditioner switch: OFFEngine coolant temperature is 99ÉC

(210ÉF) or lessOFF

Engine coolant temperature is 100ÉC

(212ÉF) or moreON

HO2S1 HTR (B1)+Engine speed: Below 3,200 rpm ON

+Engine speed: Above 3,200 rpm OFF

HO2S2 HTR (B1)+Engine speedBelow 3,600 rpm [After driving for 2

minutes at a speed of 70 km/h (43

MPH) or more]ON

Above 3,600 rpm OFF

+Ignition switch ON (Engine stopped) OFF

TRVL AFTER MI+Ignition switch: ONVehicle has traveled after MI has

turned ON.0 - 65,535 km

(0 - 40,723 mile)

*: If so equipped

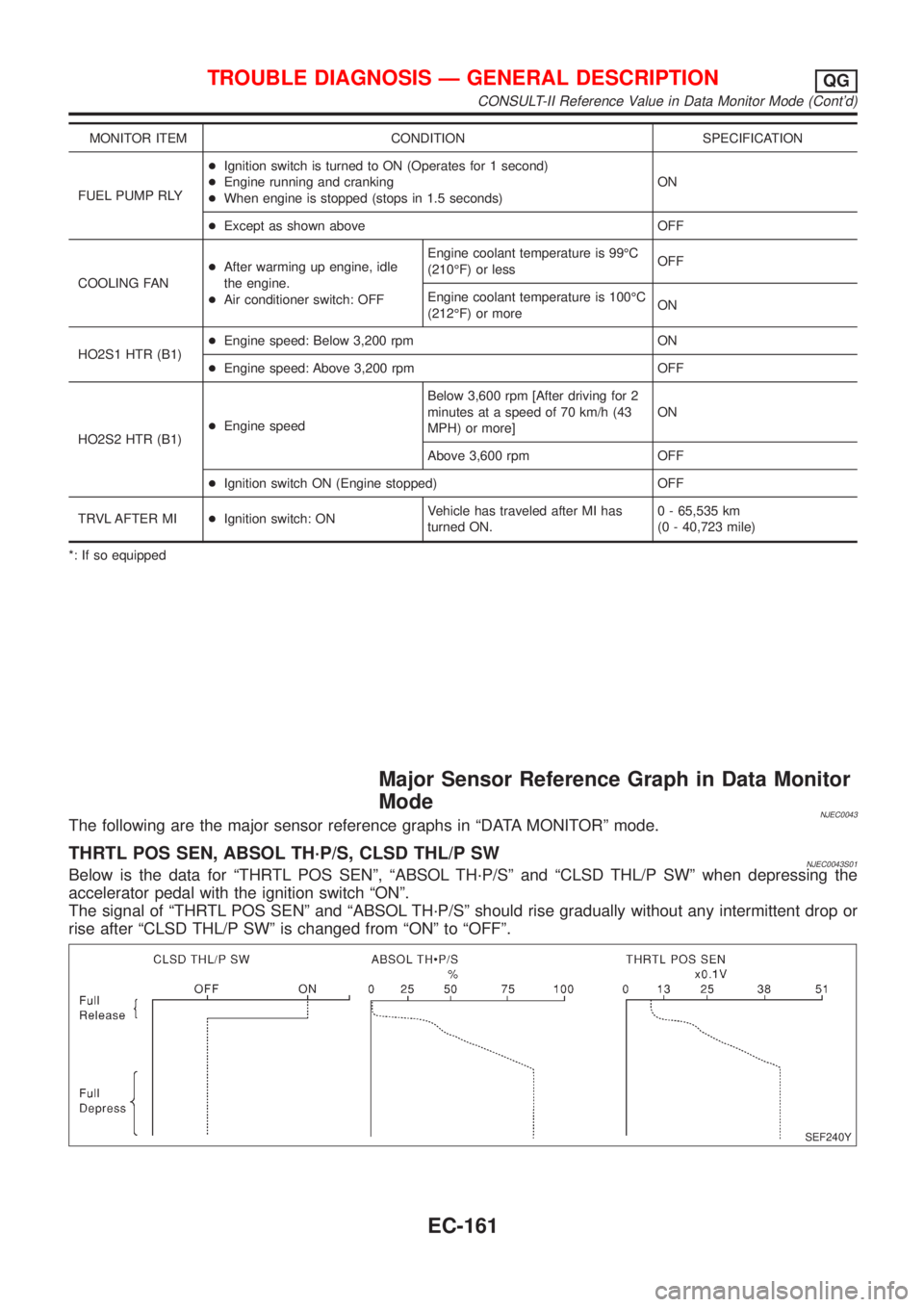

Major Sensor Reference Graph in Data Monitor

Mode

NJEC0043The following are the major sensor reference graphs in ªDATA MONITORº mode.

THRTL POS SEN, ABSOL TH´P/S, CLSD THL/P SWNJEC0043S01Below is the data for ªTHRTL POS SENº, ªABSOL TH´P/Sº and ªCLSD THL/P SWº when depressing the

accelerator pedal with the ignition switch ªONº.

The signal of ªTHRTL POS SENº and ªABSOL TH´P/Sº should rise gradually without any intermittent drop or

rise after ªCLSD THL/P SWº is changed from ªONº to ªOFFº.

SEF240Y

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-161

Page 912 of 2898

Fail-safe ModeNJEC0589

Detected items Engine operating condition in fail-safe mode

Mass air flow sensor circuitEngine speed will not rise more than 2,400 rpm due to the fuel

cut.

DTC Confirmation ProcedureNJEC0054CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

SEF058Y

PROCEDURE FOR MALFUNCTION ANJEC0054S01With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 2 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-191.

With GST

Follow the procedure ªWith CONSULT-IIº above.

SEF058Y

PROCEDURE FOR MALFUNCTION BNJEC0054S02With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait 2 seconds at most.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-191.

With GST

Follow the procedure ªWith CONSULT-IIº above.

DTC P0100 MASS AIR FLOW SENSOR (MAFS)QG

Fail-safe Mode

EC-188

Page 919 of 2898

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

On Board Diagnosis LogicNJEC0067

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0110

0110An excessively low or high voltage from the sensor is sent

to ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Intake air temperature sensor

DTC Confirmation ProcedureNJEC0068NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

SEF058Y

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-198.

With GST

Follow the procedure ªWith CONSULT-IIº above.

DTC P0110 INTAKE AIR TEMPERATURE SENSORQG

Component Description (Cont'd)

EC-195

Page 926 of 2898

Fail-safe ModeNJEC0566

Detected items Engine operating condition in fail-safe mode

Engine coolant tempera-

ture sensor circuitEngine coolant temperature will be determined by ECM based on the time after turning ignition switch

ªONº or ªSTARTº.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided (CONSULT-II

display)

Just as ignition switch is turned ON or Start 40ÉC (104ÉF)

More than approx. 4 minutes after ignition ON or

Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling fan operates

while the engine is running.

SEF013Y

DTC Confirmation ProcedureNJEC0075NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-205 .

With GST

Follow the procedure ªWith CONSULT-IIº above.

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)

QG

Fail-safe Mode

EC-202