brake NISSAN ALMERA 2001 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 307 of 2898

6. Vehicle Does Not Creep Backward In ªRº

Position

=NJAT0336SYMPTOM:

Vehicle does not creep backward when selecting ªRº position.

1 CHECK A/T FLUID LEVEL

Check A/T fluid level again.

SAT638A

OK or NG

OK©GO TO 2.

NG©Refill ATF.

2 CHECK STALL TEST

Check stall revolution with selector lever in ª1º and ªRº positions.

Refer to ªSTALL TESTº, AT-80.

SAT493G

OK or NG

OK©GO TO 3.

OK in ª1º position, NG in

ªRº position©1. Remove control valve assembly. Refer to ªON-VEHICLE SERVICEº, AT-351.

2. Check the following items:

+Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot

valve and pilot filter)

+Line pressure solenoid valve (AT-176: General and except for Euro-OBD/AT-239:

Euro-OBD)

3. Disassemble A/T.

4. Check the following items:

+Oil pump assembly

+Torque converter

+Reverse clutch assembly

+High clutch assembly

+Low & reverse brake assembly

+Low one-way clutch

NG in both ª1º and ªRº

positions©GO TO 6.

TROUBLE DIAGNOSES FOR SYMPTOMS

6. Vehicle Does Not Creep Backward In ªRº Position

AT-305

Page 309 of 2898

6 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to ªON-VEHICLE SERVICEº, AT-351.

2. Check the following items:

+Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot filter)

+Line pressure solenoid valve (AT-176: General and except for Euro-OBD/AT-239: Euro-OBD)

3. Disassemble A/T.

4. Check the following items:

+Oil pump assembly

+Torque converter

+Reverse clutch assembly

+High clutch assembly

+Low & reverse brake assembly

+Low one-way clutch

OK or NG

OK©GO TO 5.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

6. Vehicle Does Not Creep Backward In ªRº Position (Cont'd)

AT-307

Page 312 of 2898

6 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-351.

2. Check the following items:

+Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot filter)

+Line pressure solenoid valve (AT-176: General and except for Euro-OBD/AT-239: Euro-OBD)

3. Disassemble A/T.

4. Check the following items:

+Oil pump assembly

+Forward clutch assembly

+Forward one-way clutch

+Low one-way clutch

+Low & reverse brake assembly

+Torque converter

OK or NG

OK©GO TO 5.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position (Cont'd)

AT-310

Page 318 of 2898

7 CHECK SYMPTOM

Check again.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

8 DETECT MALFUNCTIONING ITEM

1. Remove control valve. Refer to AT-351.

2. Check the following items:

+Shift valve A

+Shift solenoid valve A (AT-142: General and except for Euro-OBD/AT-246: Euro-OBD)

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following items:

+Servo piston assembly

+Brake band

+Oil pump assembly

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

9. A/T Does Not Shift: D1®D2Or Does Not Kickdown: D4®D2(Cont'd)

AT-316

Page 324 of 2898

6 CHECK SYMPTOM

Check again.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

7 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-351.

2. Check the following items:

+Shift valve B

+Overrun clutch control valve

+Shift solenoid valve B

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following items:

+Servo piston assembly

+Brake band

+Torque converter

+Oil pump assembly

OK or NG

OK©GO TO 6.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

11. A/T Does Not Shift: D3®D4(Cont'd)

AT-322

Page 330 of 2898

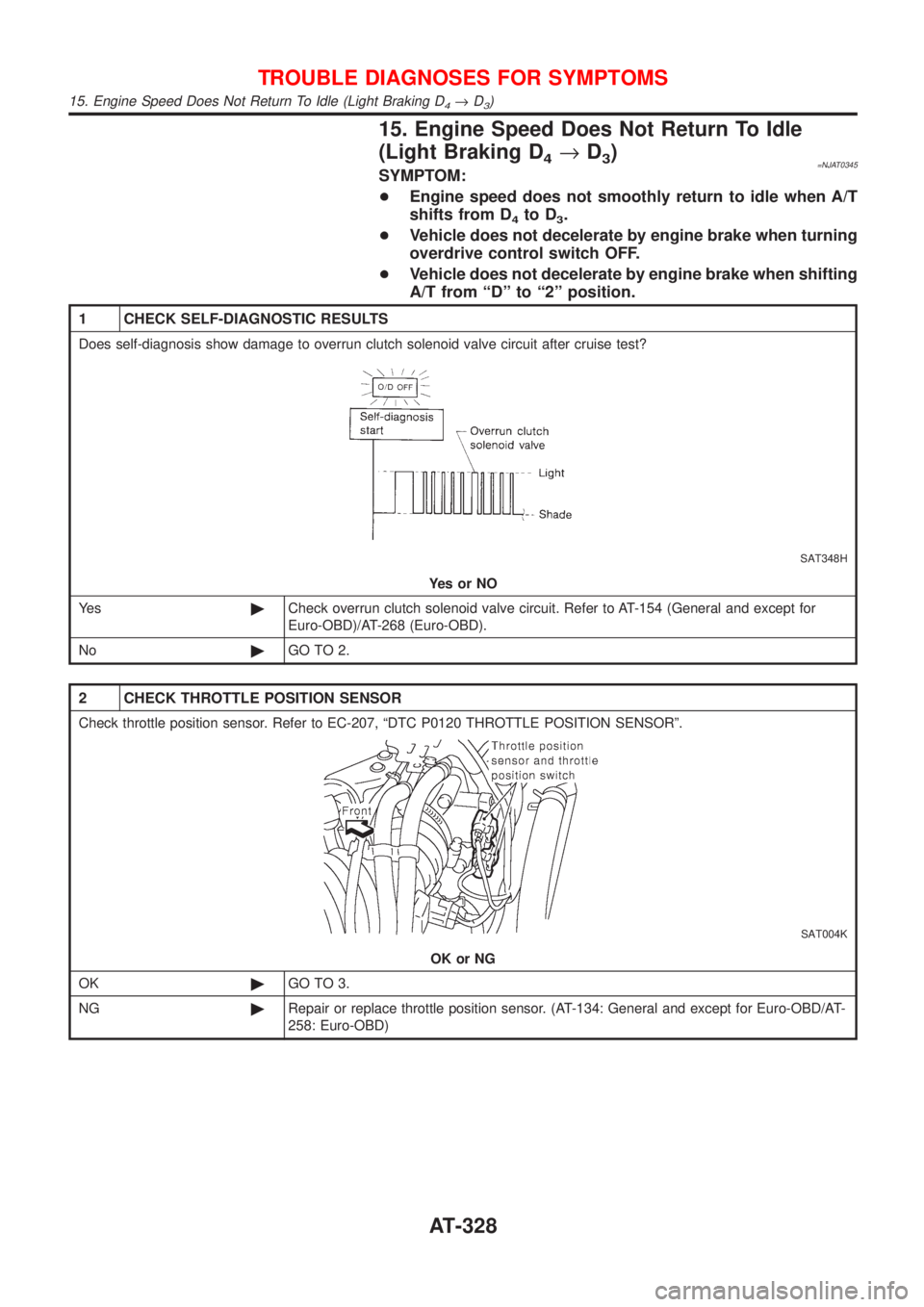

15. Engine Speed Does Not Return To Idle

(Light Braking D

4®D3)=NJAT0345SYMPTOM:

+Engine speed does not smoothly return to idle when A/T

shifts from D

4to D3.

+Vehicle does not decelerate by engine brake when turning

overdrive control switch OFF.

+Vehicle does not decelerate by engine brake when shifting

A/T from ªDº to ª2º position.

1 CHECK SELF-DIAGNOSTIC RESULTS

Does self-diagnosis show damage to overrun clutch solenoid valve circuit after cruise test?

SAT348H

YesorNO

Ye s©Check overrun clutch solenoid valve circuit. Refer to AT-154 (General and except for

Euro-OBD)/AT-268 (Euro-OBD).

No©GO TO 2.

2 CHECK THROTTLE POSITION SENSOR

Check throttle position sensor. Refer to EC-207, ªDTC P0120 THROTTLE POSITION SENSORº.

SAT004K

OK or NG

OK©GO TO 3.

NG©Repair or replace throttle position sensor. (AT-134: General and except for Euro-OBD/AT-

258: Euro-OBD)

TROUBLE DIAGNOSES FOR SYMPTOMS

15. Engine Speed Does Not Return To Idle (Light Braking D4®D3)

AT-328

Page 336 of 2898

20. Vehicle Does Not Decelerate By Engine

Brake

=NJAT0350SYMPTOM:

Vehicle does not decelerate by engine brake when shifting

from 2

2(12)to11.

1 CHECK SYMPTOM

Is 6. Vehicle Does Not Creep Backward In ªRº Position OK?

YesorNo

Ye s©Go to 15. Engine Speed Does Not Return To Idle (Light Braking D

4®D3), AT-328.

No©Go to 6. Vehicle Does Not Creep Backward In ªRº Position, AT-305.

SAT088JA

SAT360H

SAT004K

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position

Switches Circuit Checks)

NJAT0351SYMPTOM:

O/D OFF indicator lamp does not come on in TCM self-diag-

nostic procedure even if the lamp circuit is good.

DESCRIPTIONNJAT0351S01+PNP switch

The PNP switch assembly includes a transmission range

switch. The transmission range switch detects the selector

lever position and sends a signal to the TCM.

+Overdrive control switch

Detects the overdrive control switch position (ON or OFF) and

sends a signal to the TCM.

+Throttle position switch

Consists of a wide open throttle position switch and a closed

throttle position switch.

The wide open throttle position switch sends a signal to the

TCM when the throttle valve is open at least 1/2 of the full

throttle position. The closed throttle position switch sends a

signal to the TCM when the throttle valve is fully closed.

TROUBLE DIAGNOSES FOR SYMPTOMS

20. Vehicle Does Not Decelerate By Engine Brake

AT-334

Page 345 of 2898

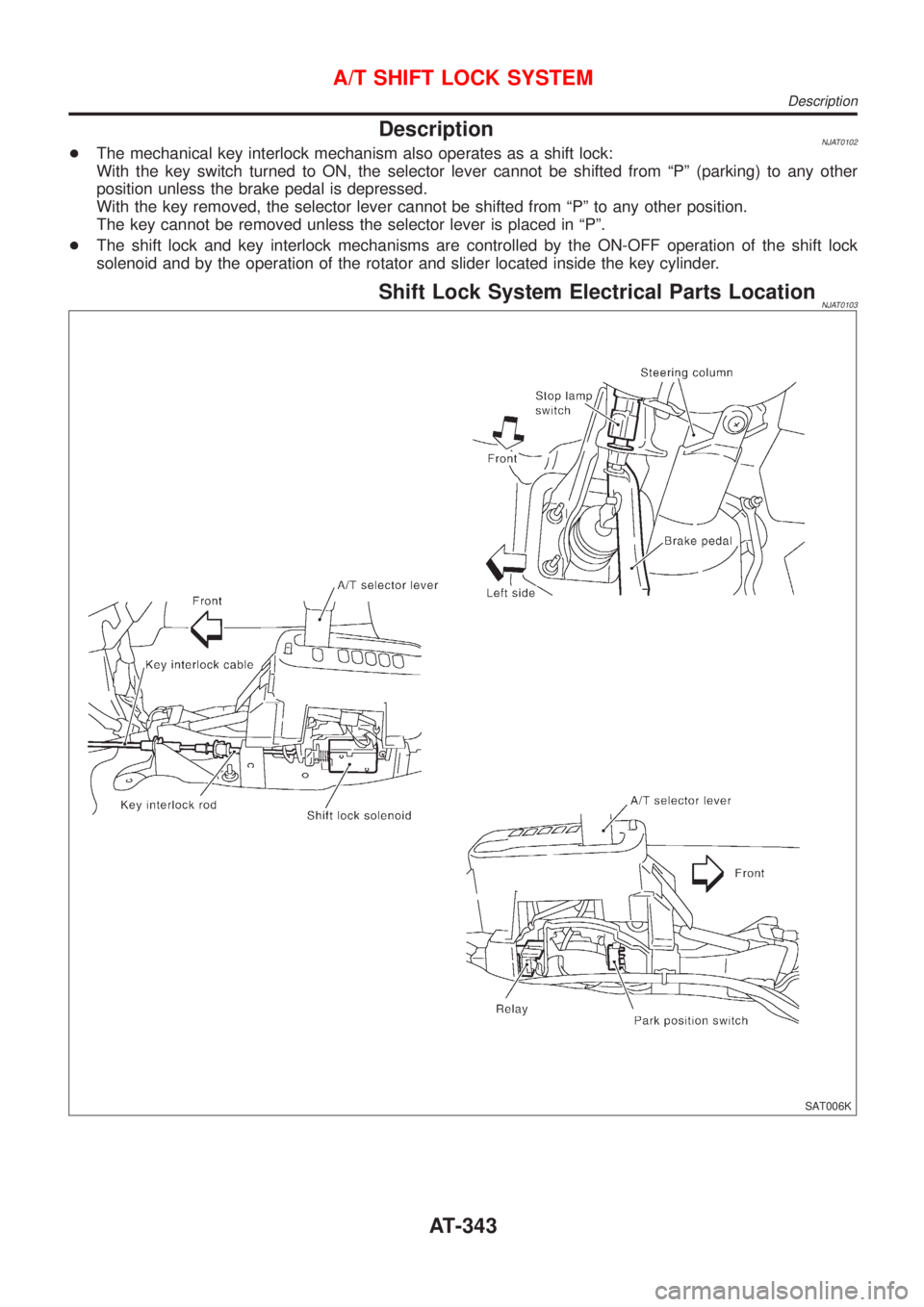

DescriptionNJAT0102+The mechanical key interlock mechanism also operates as a shift lock:

With the key switch turned to ON, the selector lever cannot be shifted from ªPº (parking) to any other

position unless the brake pedal is depressed.

With the key removed, the selector lever cannot be shifted from ªPº to any other position.

The key cannot be removed unless the selector lever is placed in ªPº.

+The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock

solenoid and by the operation of the rotator and slider located inside the key cylinder.

Shift Lock System Electrical Parts LocationNJAT0103

SAT006K

A/T SHIFT LOCK SYSTEM

Description

AT-343

Page 347 of 2898

Diagnostic ProcedureNJAT0105SYMPTOM 1:

+Selector lever cannot be moved from ªPº position with key

in ON position and brake pedal applied.

+Selector lever can be moved from ªPº position with key in

ON position and brake pedal released.

+Selector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

1 CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK©GO TO 2.

NG©Repair key interlock cable. Refer to AT-349.

2 CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK©GO TO 3.

NG©Check selector lever. Refer to ªON-VEHICLE SERVICE Ð PNP Switch and Control

Cable Adjustmentº, AT-352.

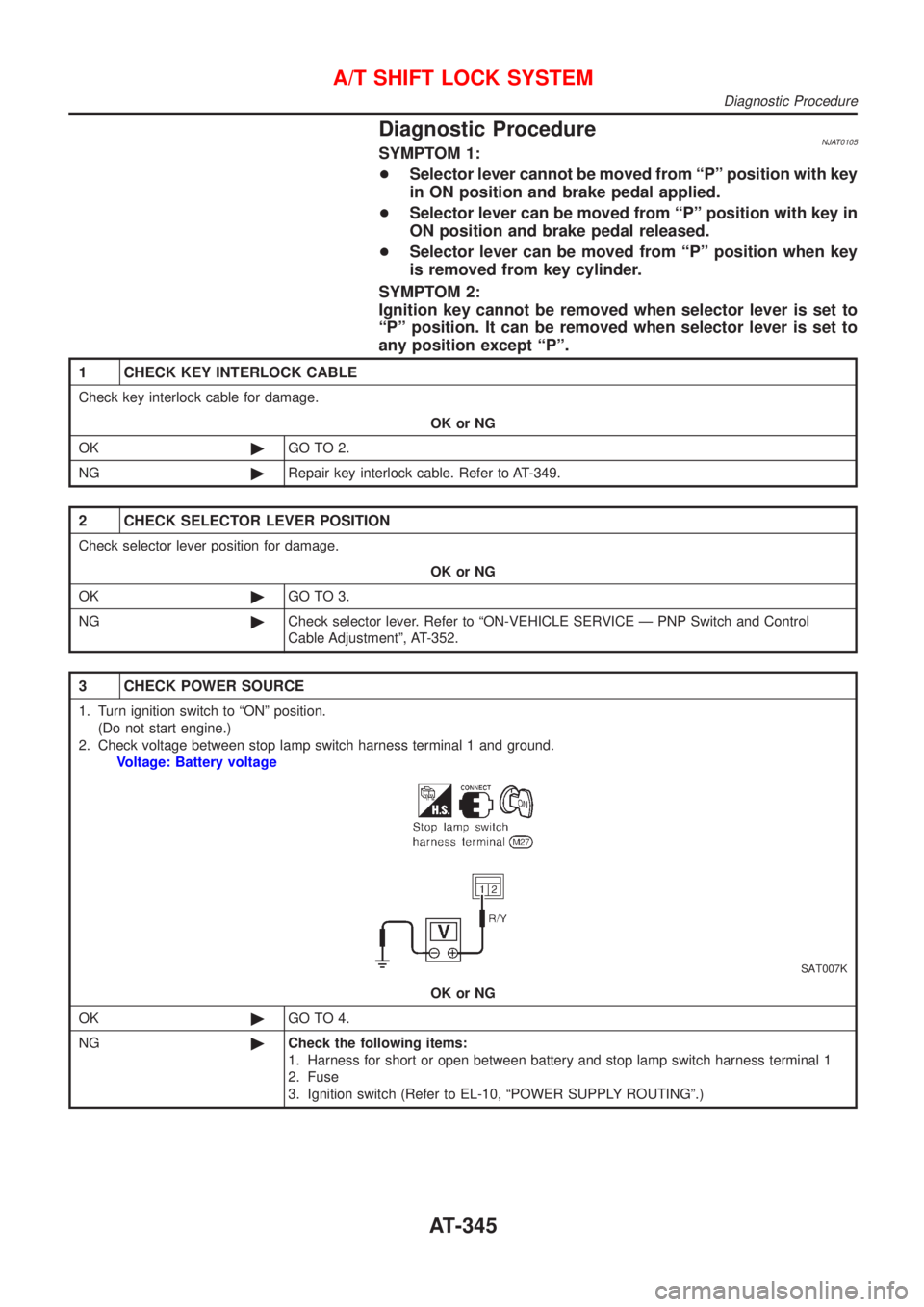

3 CHECK POWER SOURCE

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between stop lamp switch harness terminal 1 and ground.

Voltage: Battery voltage

SAT007K

OK or NG

OK©GO TO 4.

NG©Check the following items:

1. Harness for short or open between battery and stop lamp switch harness terminal 1

2. Fuse

3. Ignition switch (Refer to EL-10, ªPOWER SUPPLY ROUTINGº.)

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

AT-345

Page 348 of 2898

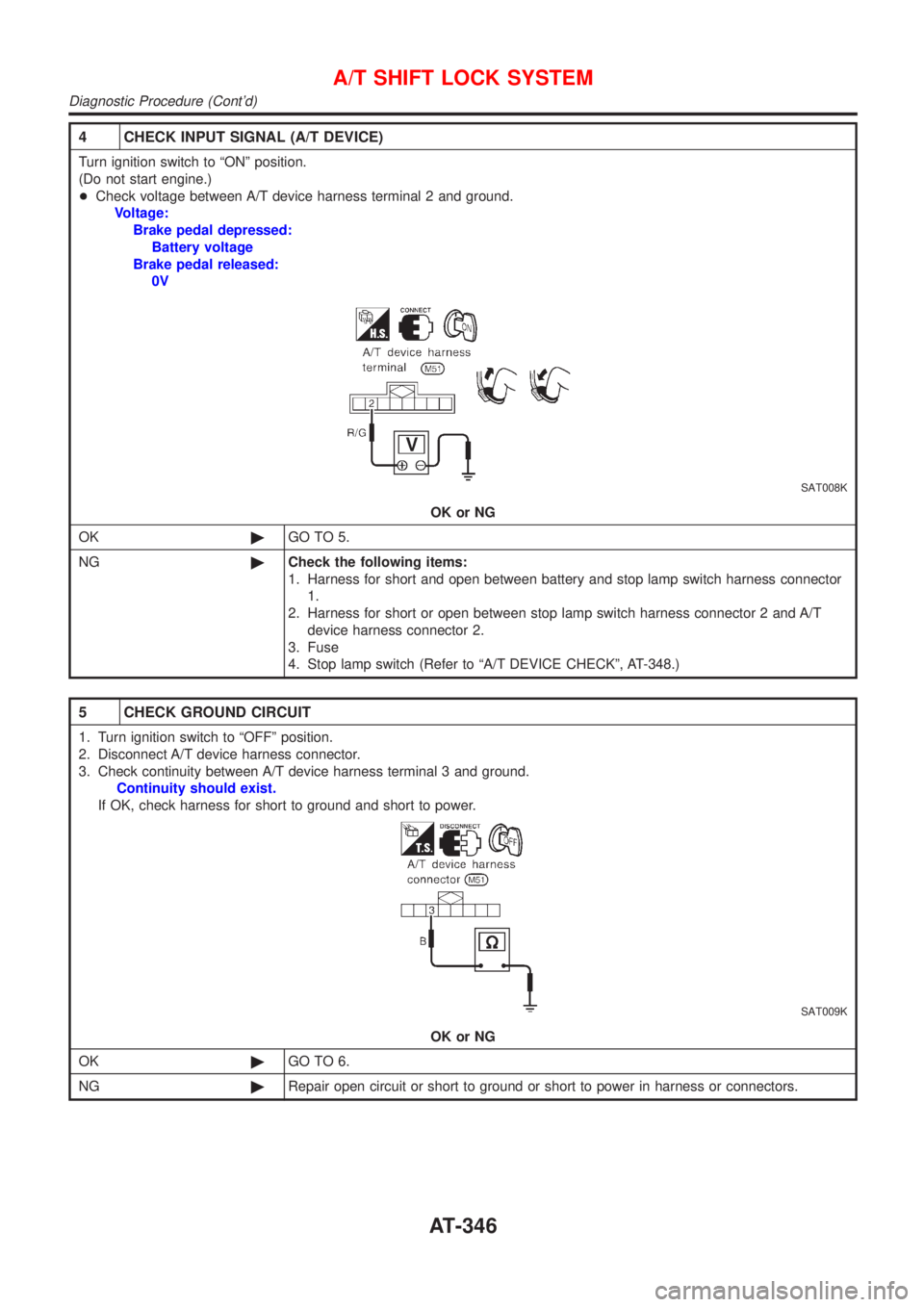

4 CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to ªONº position.

(Do not start engine.)

+Check voltage between A/T device harness terminal 2 and ground.

Voltage:

Brake pedal depressed:

Battery voltage

Brake pedal released:

0V

SAT008K

OK or NG

OK©GO TO 5.

NG©Check the following items:

1. Harness for short and open between battery and stop lamp switch harness connector

1.

2. Harness for short or open between stop lamp switch harness connector 2 and A/T

device harness connector 2.

3. Fuse

4. Stop lamp switch (Refer to ªA/T DEVICE CHECKº, AT-348.)

5 CHECK GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness terminal 3 and ground.

Continuity should exist.

If OK, check harness for short to ground and short to power.

SAT009K

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-346