brake NISSAN ALMERA 2001 Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 476 of 2898

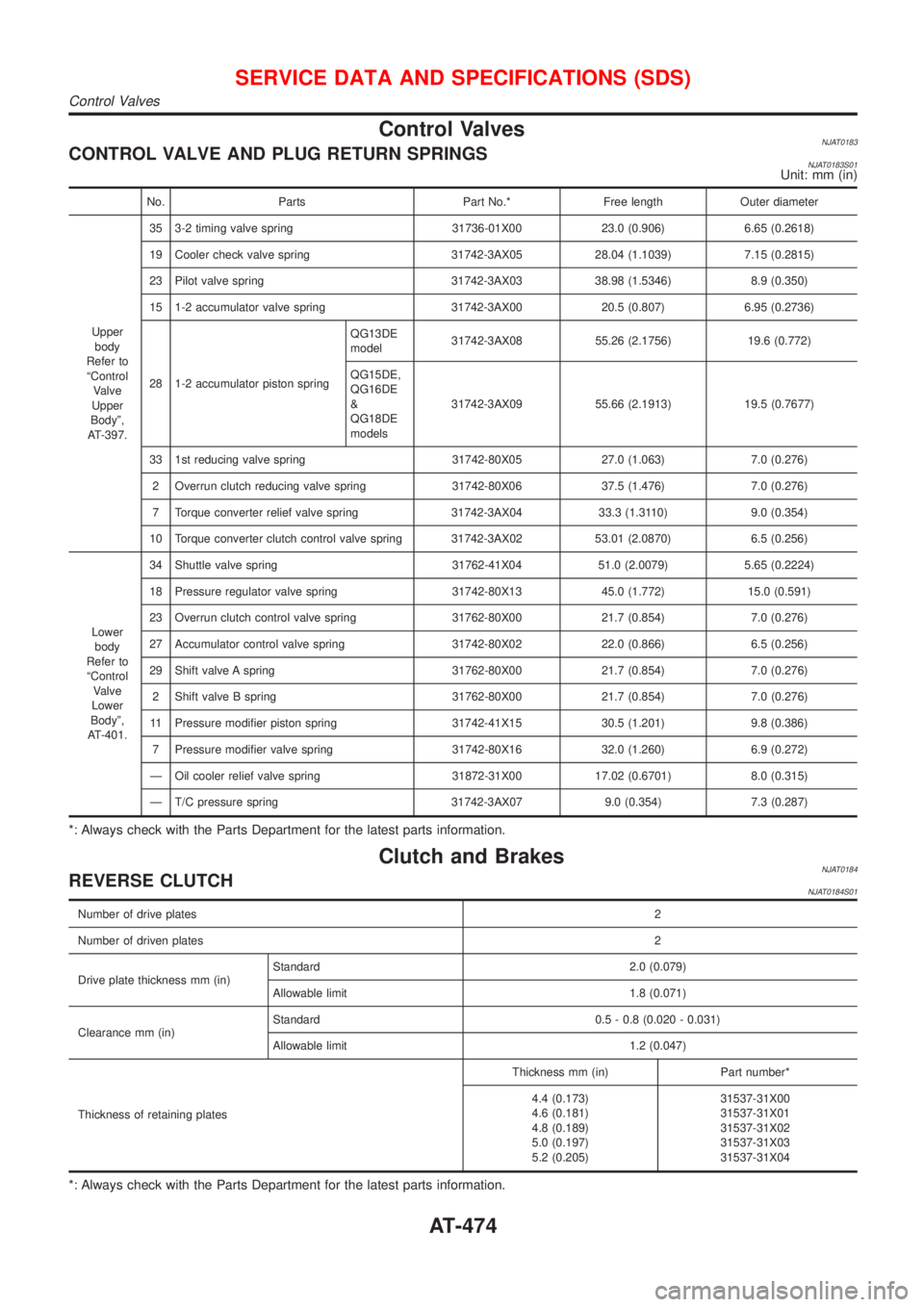

Control ValvesNJAT0183CONTROL VALVE AND PLUG RETURN SPRINGSNJAT0183S01Unit: mm (in)

No. Parts Part No.* Free length Outer diameter

Upper

body

Refer to

ªControl

Valve

Upper

Bodyº,

AT-397.35 3-2 timing valve spring 31736-01X00 23.0 (0.906) 6.65 (0.2618)

19 Cooler check valve spring 31742-3AX05 28.04 (1.1039) 7.15 (0.2815)

23 Pilot valve spring 31742-3AX03 38.98 (1.5346) 8.9 (0.350)

15 1-2 accumulator valve spring 31742-3AX00 20.5 (0.807) 6.95 (0.2736)

28 1-2 accumulator piston springQG13DE

model31742-3AX08 55.26 (2.1756) 19.6 (0.772)

QG15DE,

QG16DE

&

QG18DE

models31742-3AX09 55.66 (2.1913) 19.5 (0.7677)

33 1st reducing valve spring 31742-80X05 27.0 (1.063) 7.0 (0.276)

2 Overrun clutch reducing valve spring 31742-80X06 37.5 (1.476) 7.0 (0.276)

7 Torque converter relief valve spring 31742-3AX04 33.3 (1.3110) 9.0 (0.354)

10 Torque converter clutch control valve spring 31742-3AX02 53.01 (2.0870) 6.5 (0.256)

Lower

body

Refer to

ªControl

Valve

Lower

Bodyº,

AT-401.34 Shuttle valve spring 31762-41X04 51.0 (2.0079) 5.65 (0.2224)

18 Pressure regulator valve spring 31742-80X13 45.0 (1.772) 15.0 (0.591)

23 Overrun clutch control valve spring 31762-80X00 21.7 (0.854) 7.0 (0.276)

27 Accumulator control valve spring 31742-80X02 22.0 (0.866) 6.5 (0.256)

29 Shift valve A spring 31762-80X00 21.7 (0.854) 7.0 (0.276)

2 Shift valve B spring 31762-80X00 21.7 (0.854) 7.0 (0.276)

11 Pressure modifier piston spring 31742-41X15 30.5 (1.201) 9.8 (0.386)

7 Pressure modifier valve spring 31742-80X16 32.0 (1.260) 6.9 (0.272)

Ð Oil cooler relief valve spring 31872-31X00 17.02 (0.6701) 8.0 (0.315)

Ð T/C pressure spring 31742-3AX07 9.0 (0.354) 7.3 (0.287)

*: Always check with the Parts Department for the latest parts information.

Clutch and BrakesNJAT0184REVERSE CLUTCHNJAT0184S01

Number of drive plates2

Number of driven plates2

Drive plate thickness mm (in)Standard 2.0 (0.079)

Allowable limit 1.8 (0.071)

Clearance mm (in)Standard 0.5 - 0.8 (0.020 - 0.031)

Allowable limit 1.2 (0.047)

Thickness of retaining platesThickness mm (in) Part number*

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)31537-31X00

31537-31X01

31537-31X02

31537-31X03

31537-31X04

*: Always check with the Parts Department for the latest parts information.

SERVICE DATA AND SPECIFICATIONS (SDS)

Control Valves

AT-474

Page 477 of 2898

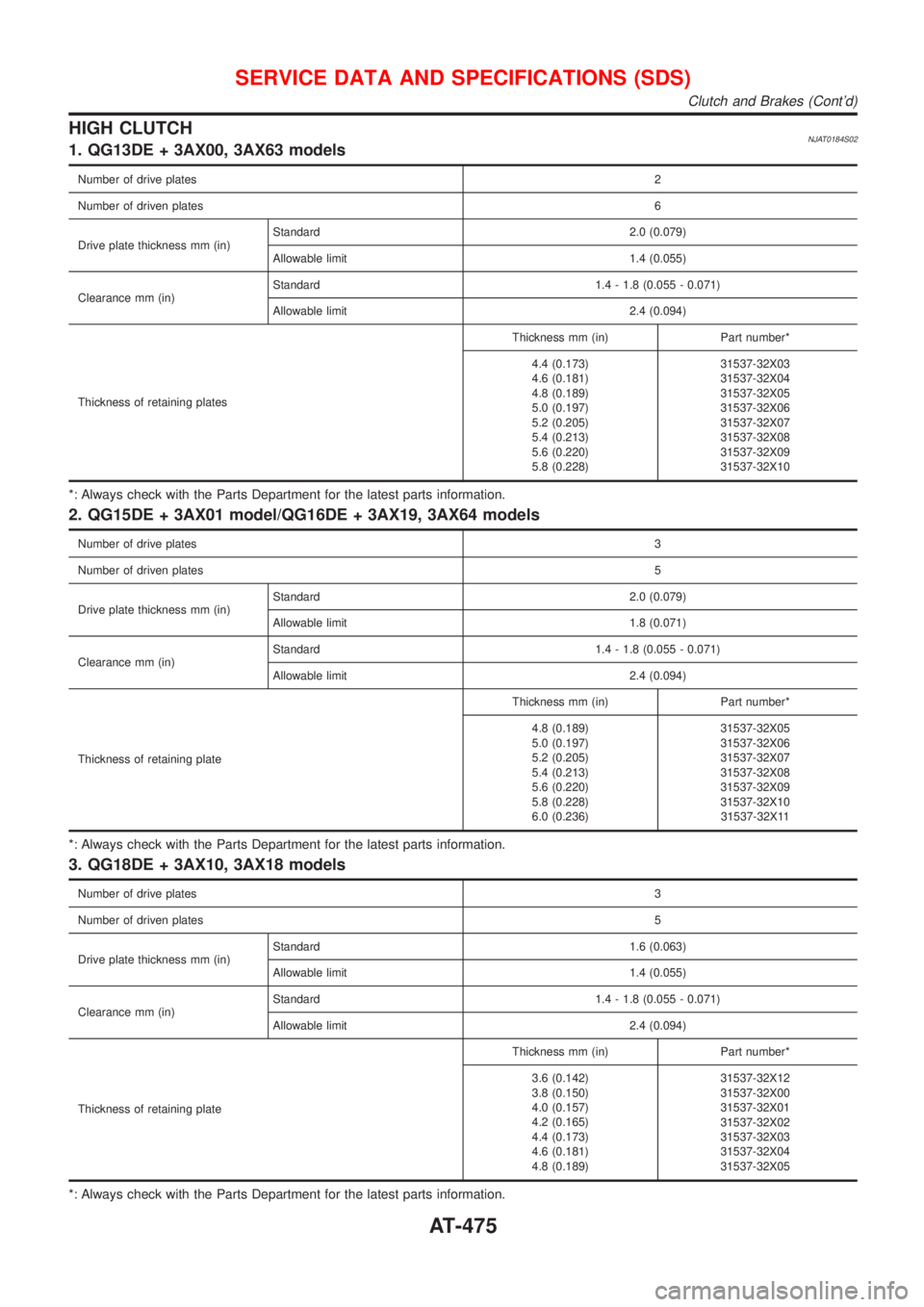

HIGH CLUTCHNJAT0184S021. QG13DE + 3AX00, 3AX63 models

Number of drive plates2

Number of driven plates6

Drive plate thickness mm (in)Standard 2.0 (0.079)

Allowable limit 1.4 (0.055)

Clearance mm (in)Standard 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.4 (0.094)

Thickness of retaining platesThickness mm (in) Part number*

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)

5.4 (0.213)

5.6 (0.220)

5.8 (0.228)31537-32X03

31537-32X04

31537-32X05

31537-32X06

31537-32X07

31537-32X08

31537-32X09

31537-32X10

*: Always check with the Parts Department for the latest parts information.

2. QG15DE + 3AX01 model/QG16DE + 3AX19, 3AX64 models

Number of drive plates3

Number of driven plates5

Drive plate thickness mm (in)Standard 2.0 (0.079)

Allowable limit 1.8 (0.071)

Clearance mm (in)Standard 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.4 (0.094)

Thickness of retaining plateThickness mm (in) Part number*

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)

5.4 (0.213)

5.6 (0.220)

5.8 (0.228)

6.0 (0.236)31537-32X05

31537-32X06

31537-32X07

31537-32X08

31537-32X09

31537-32X10

31537-32X11

*: Always check with the Parts Department for the latest parts information.

3. QG18DE + 3AX10, 3AX18 models

Number of drive plates3

Number of driven plates5

Drive plate thickness mm (in)Standard 1.6 (0.063)

Allowable limit 1.4 (0.055)

Clearance mm (in)Standard 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.4 (0.094)

Thickness of retaining plateThickness mm (in) Part number*

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)31537-32X12

31537-32X00

31537-32X01

31537-32X02

31537-32X03

31537-32X04

31537-32X05

*: Always check with the Parts Department for the latest parts information.

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutch and Brakes (Cont'd)

AT-475

Page 478 of 2898

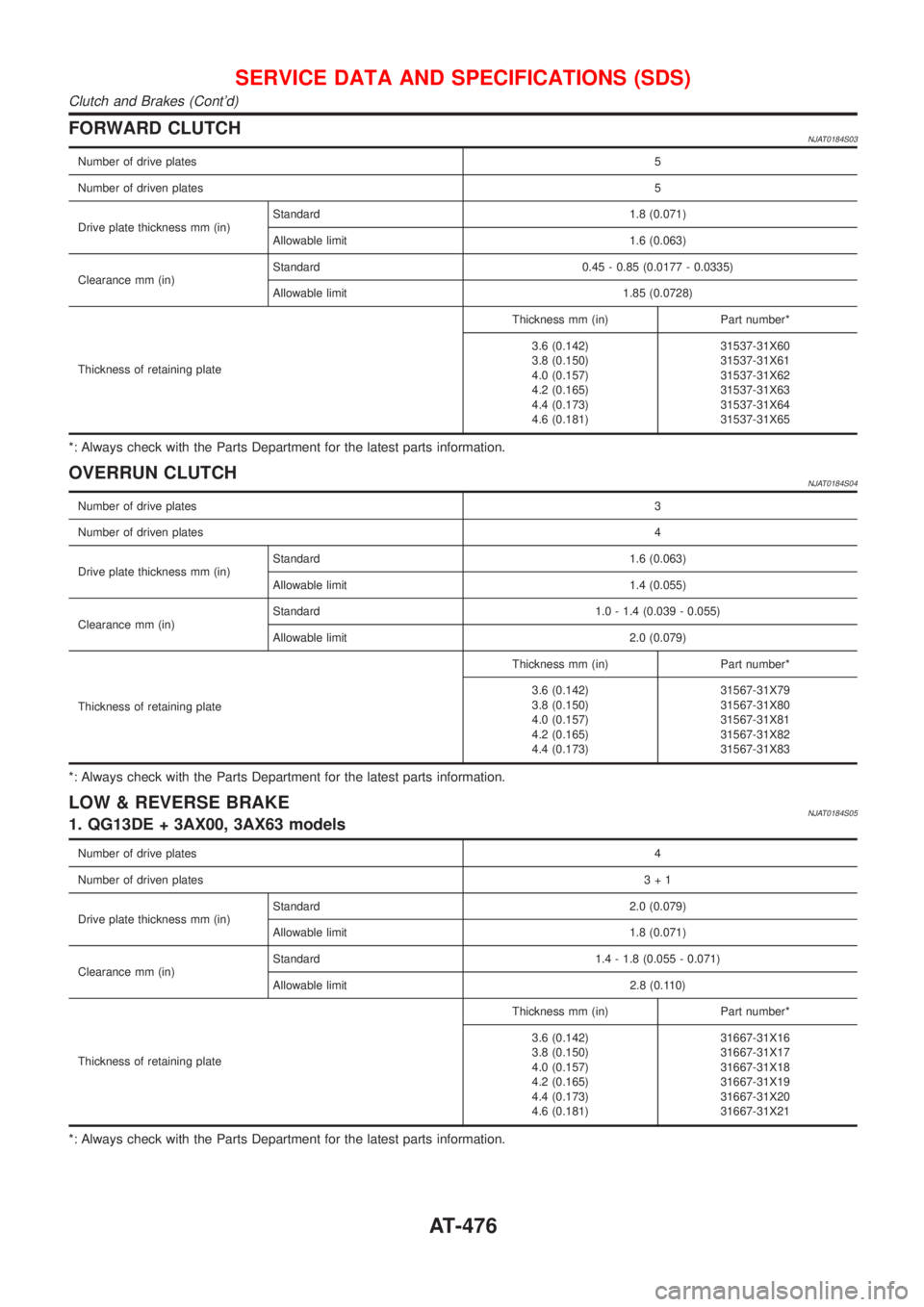

FORWARD CLUTCHNJAT0184S03

Number of drive plates5

Number of driven plates5

Drive plate thickness mm (in)Standard 1.8 (0.071)

Allowable limit 1.6 (0.063)

Clearance mm (in)Standard 0.45 - 0.85 (0.0177 - 0.0335)

Allowable limit 1.85 (0.0728)

Thickness of retaining plateThickness mm (in) Part number*

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)31537-31X60

31537-31X61

31537-31X62

31537-31X63

31537-31X64

31537-31X65

*: Always check with the Parts Department for the latest parts information.

OVERRUN CLUTCHNJAT0184S04

Number of drive plates3

Number of driven plates4

Drive plate thickness mm (in)Standard 1.6 (0.063)

Allowable limit 1.4 (0.055)

Clearance mm (in)Standard 1.0 - 1.4 (0.039 - 0.055)

Allowable limit 2.0 (0.079)

Thickness of retaining plateThickness mm (in) Part number*

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)31567-31X79

31567-31X80

31567-31X81

31567-31X82

31567-31X83

*: Always check with the Parts Department for the latest parts information.

LOW & REVERSE BRAKENJAT0184S051. QG13DE + 3AX00, 3AX63 models

Number of drive plates4

Number of driven plates3+1

Drive plate thickness mm (in)Standard 2.0 (0.079)

Allowable limit 1.8 (0.071)

Clearance mm (in)Standard 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.8 (0.110)

Thickness of retaining plateThickness mm (in) Part number*

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)31667-31X16

31667-31X17

31667-31X18

31667-31X19

31667-31X20

31667-31X21

*: Always check with the Parts Department for the latest parts information.

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutch and Brakes (Cont'd)

AT-476

Page 479 of 2898

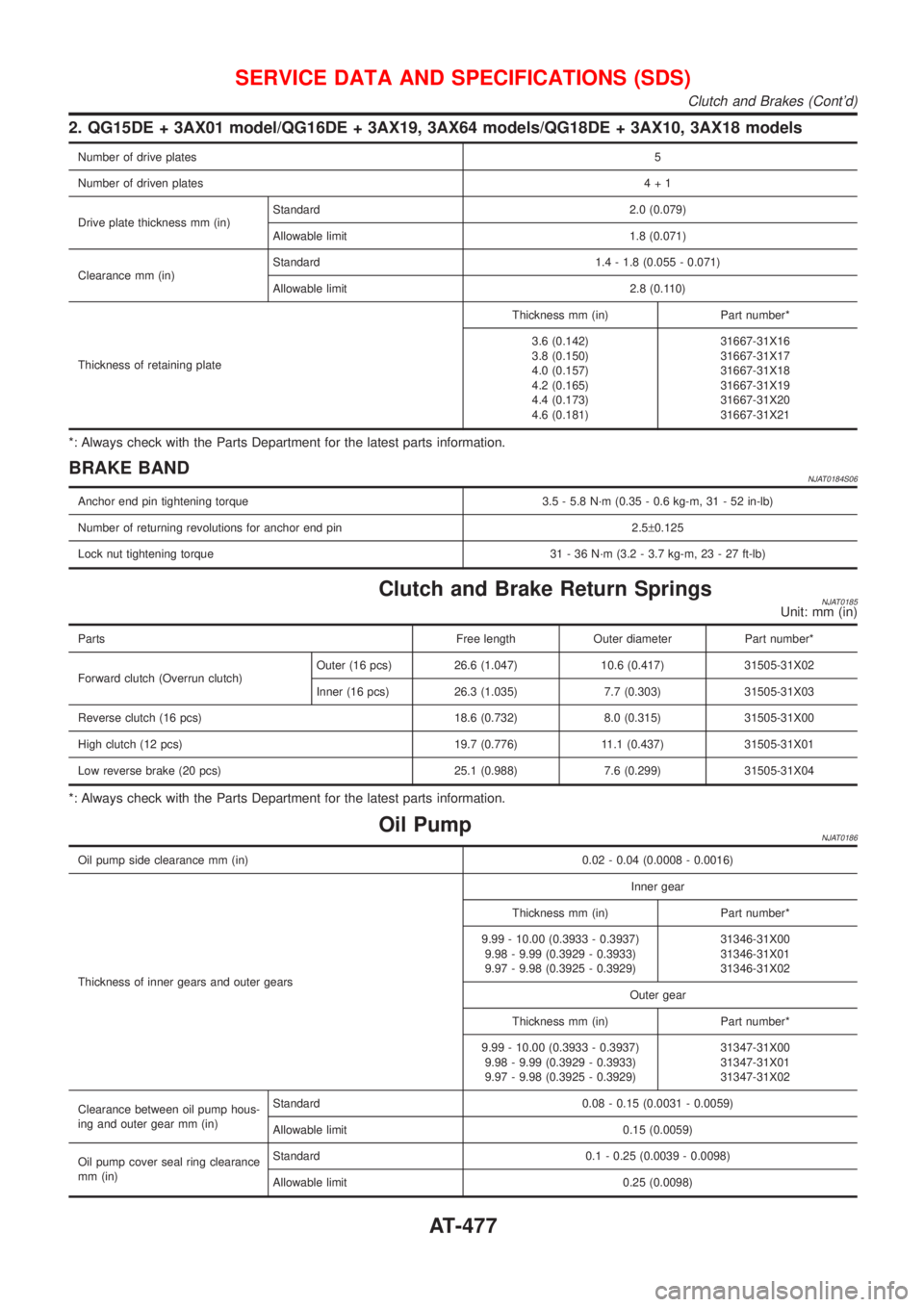

2. QG15DE + 3AX01 model/QG16DE + 3AX19, 3AX64 models/QG18DE + 3AX10, 3AX18 models

Number of drive plates5

Number of driven plates4+1

Drive plate thickness mm (in)Standard 2.0 (0.079)

Allowable limit 1.8 (0.071)

Clearance mm (in)Standard 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.8 (0.110)

Thickness of retaining plateThickness mm (in) Part number*

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)31667-31X16

31667-31X17

31667-31X18

31667-31X19

31667-31X20

31667-31X21

*: Always check with the Parts Department for the latest parts information.

BRAKE BANDNJAT0184S06

Anchor end pin tightening torque 3.5 - 5.8 N´m (0.35 - 0.6 kg-m, 31 - 52 in-lb)

Number of returning revolutions for anchor end pin 2.5±0.125

Lock nut tightening torque 31 - 36 N´m (3.2 - 3.7 kg-m, 23 - 27 ft-lb)

Clutch and Brake Return SpringsNJAT0185Unit: mm (in)

Parts Free length Outer diameter Part number*

Forward clutch (Overrun clutch)Outer (16 pcs) 26.6 (1.047) 10.6 (0.417) 31505-31X02

Inner (16 pcs) 26.3 (1.035) 7.7 (0.303) 31505-31X03

Reverse clutch (16 pcs) 18.6 (0.732) 8.0 (0.315) 31505-31X00

High clutch (12 pcs) 19.7 (0.776) 11.1 (0.437) 31505-31X01

Low reverse brake (20 pcs) 25.1 (0.988) 7.6 (0.299) 31505-31X04

*: Always check with the Parts Department for the latest parts information.

Oil PumpNJAT0186

Oil pump side clearance mm (in) 0.02 - 0.04 (0.0008 - 0.0016)

Thickness of inner gears and outer gearsInner gear

Thickness mm (in) Part number*

9.99 - 10.00 (0.3933 - 0.3937)

9.98 - 9.99 (0.3929 - 0.3933)

9.97 - 9.98 (0.3925 - 0.3929)31346-31X00

31346-31X01

31346-31X02

Outer gear

Thickness mm (in) Part number*

9.99 - 10.00 (0.3933 - 0.3937)

9.98 - 9.99 (0.3929 - 0.3933)

9.97 - 9.98 (0.3925 - 0.3929)31347-31X00

31347-31X01

31347-31X02

Clearance between oil pump hous-

ing and outer gear mm (in)Standard 0.08 - 0.15 (0.0031 - 0.0059)

Allowable limit 0.15 (0.0059)

Oil pump cover seal ring clearance

mm (in)Standard 0.1 - 0.25 (0.0039 - 0.0098)

Allowable limit 0.25 (0.0098)

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutch and Brakes (Cont'd)

AT-477

Page 490 of 2898

SBR686C

Precautions

PRECAUTIONSNJAX0001+When installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+After installing removed suspension parts, check wheel

alignment and adjust if necessary.

+Use flare nut wrench when removing or installing brake

tubes.

+Always torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNJAX0002

Tool number

Tool nameDescription

HT72520000

Ball joint remover

NT146

Removing tie-rod outer end and lower ball joint

KV38106800

Differential side oil seal

protector

NT147

Installing drive shaft

KV38106800

COMMERCIAL SERVICE TOOLSNJAX0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

FRONT AXLE

Precautions

AX-2

Page 491 of 2898

Noise, Vibration and Harshness (NVH)

Troubleshooting

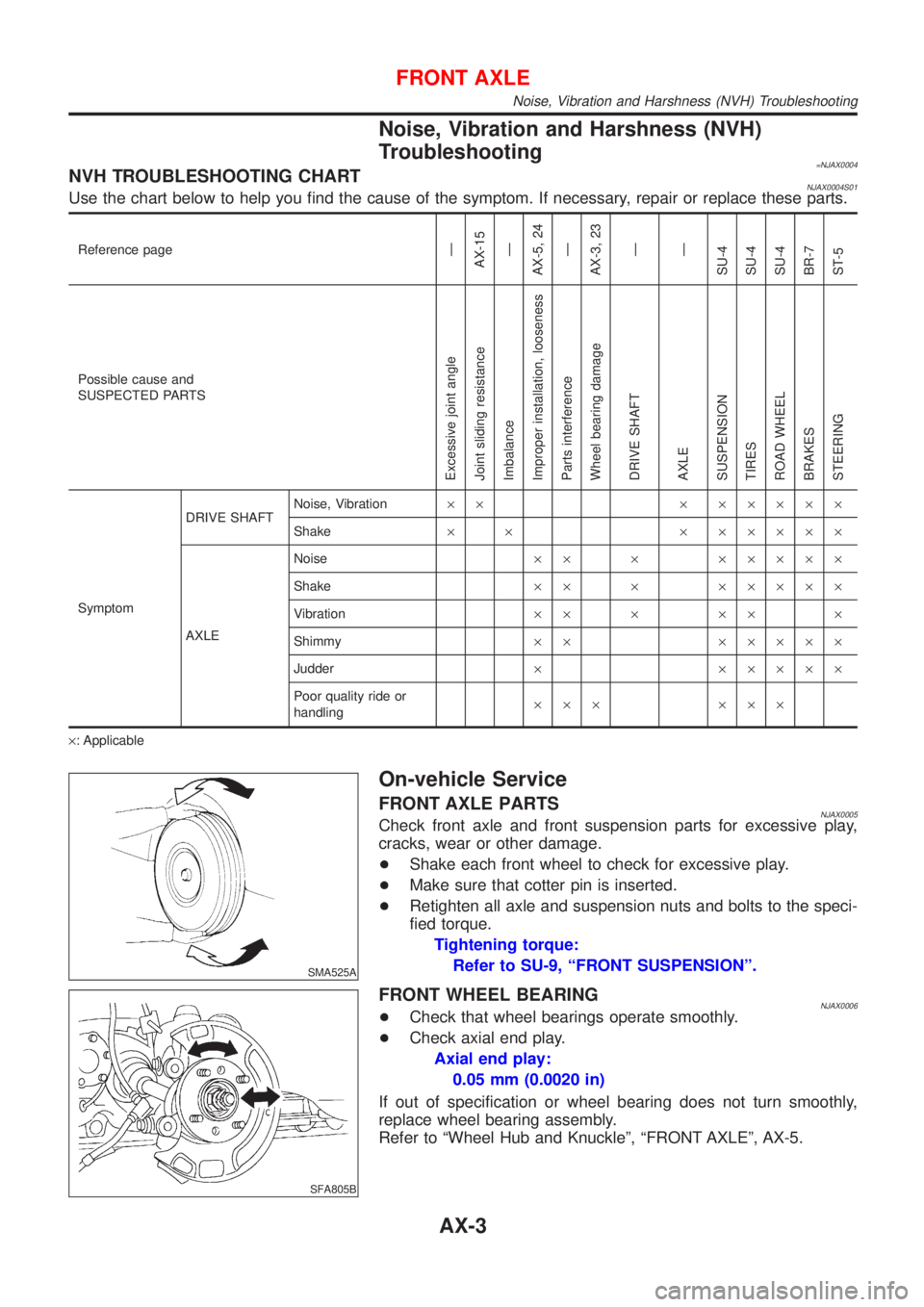

=NJAX0004NVH TROUBLESHOOTING CHARTNJAX0004S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

AX-15

Ð

AX-5, 24

Ð

AX-3, 23

Ð

Ð

SU-4

SU-4

SU-4

BR-7

ST-5

Possible cause and

SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomDRIVE SHAFTNoise, Vibration´´ ´ ´´´´´

Shake´ ´ ´ ´´´´´

AXLENoise´´ ´ ´´´´´

Shake´´ ´ ´´´´´

Vibration´´ ´ ´´ ´

Shimmy´´ ´´´´´

Judder´ ´´´´´

Poor quality ride or

handling´´´ ´´´

´: Applicable

SMA525A

On-vehicle Service

FRONT AXLE PARTSNJAX0005Check front axle and front suspension parts for excessive play,

cracks, wear or other damage.

+Shake each front wheel to check for excessive play.

+Make sure that cotter pin is inserted.

+Retighten all axle and suspension nuts and bolts to the speci-

fied torque.

Tightening torque:

Refer to SU-9, ªFRONT SUSPENSIONº.

SFA805B

FRONT WHEEL BEARINGNJAX0006+Check that wheel bearings operate smoothly.

+Check axial end play.

Axial end play:

0.05 mm (0.0020 in)

If out of specification or wheel bearing does not turn smoothly,

replace wheel bearing assembly.

Refer to ªWheel Hub and Knuckleº, ªFRONT AXLEº, AX-5.

FRONT AXLE

Noise, Vibration and Harshness (NVH) Troubleshooting

AX-3

Page 493 of 2898

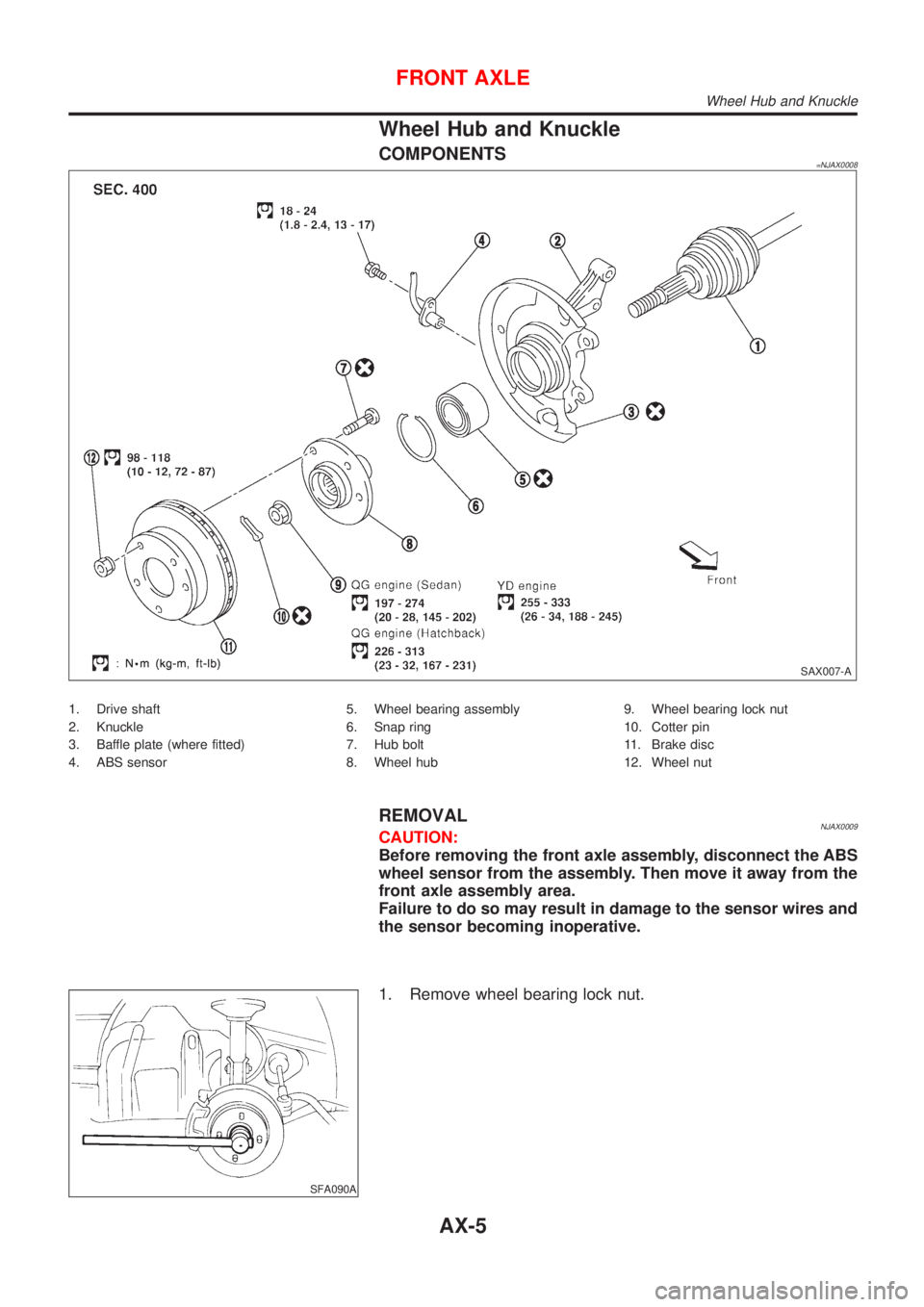

Wheel Hub and Knuckle

COMPONENTS=NJAX0008

SAX007-A

1. Drive shaft

2. Knuckle

3. Baffle plate (where fitted)

4. ABS sensor5. Wheel bearing assembly

6. Snap ring

7. Hub bolt

8. Wheel hub9. Wheel bearing lock nut

10. Cotter pin

11. Brake disc

12. Wheel nut

REMOVALNJAX0009CAUTION:

Before removing the front axle assembly, disconnect the ABS

wheel sensor from the assembly. Then move it away from the

front axle assembly area.

Failure to do so may result in damage to the sensor wires and

the sensor becoming inoperative.

SFA090A

1. Remove wheel bearing lock nut.

FRONT AXLE

Wheel Hub and Knuckle

AX-5

Page 494 of 2898

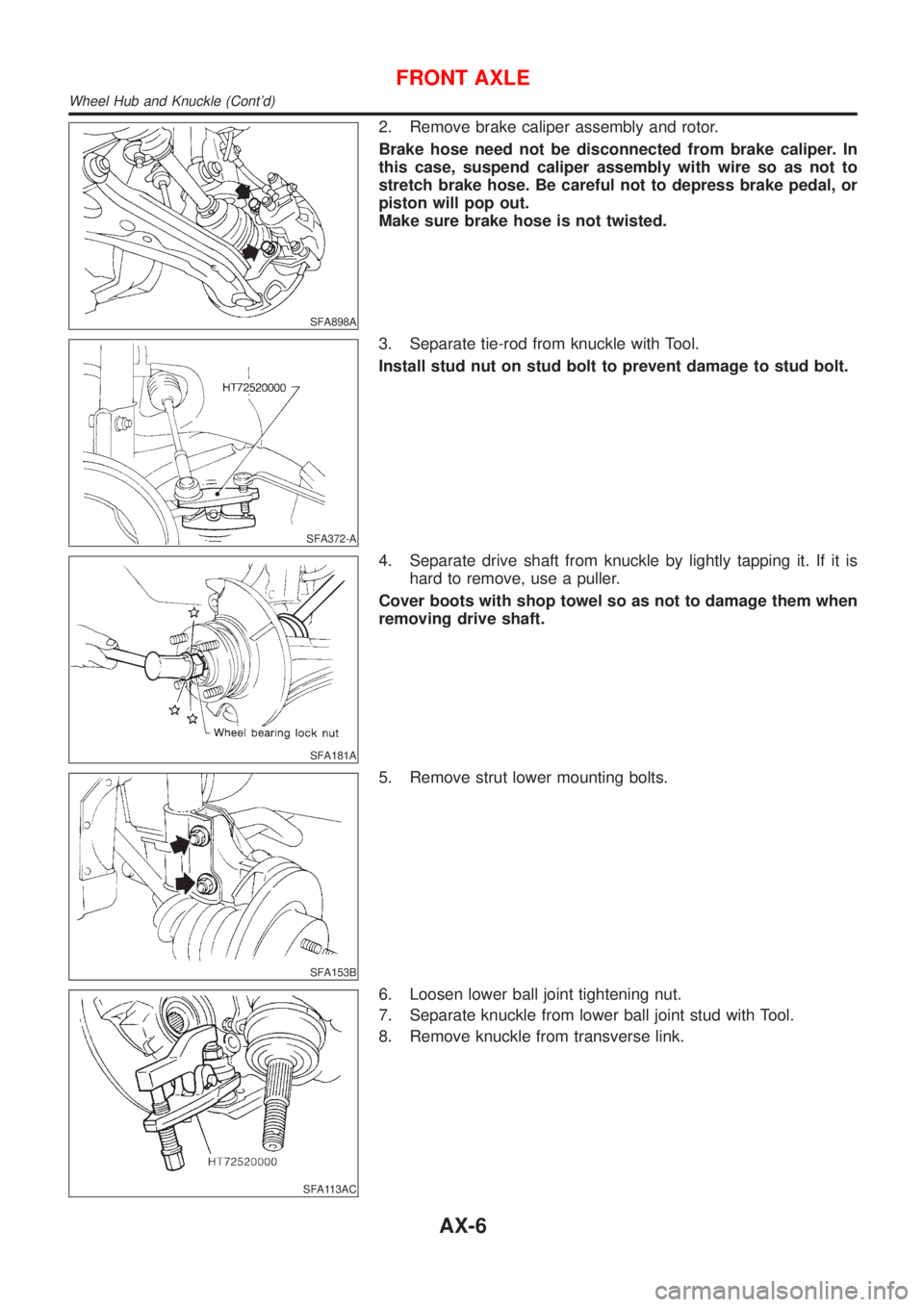

SFA898A

2. Remove brake caliper assembly and rotor.

Brake hose need not be disconnected from brake caliper. In

this case, suspend caliper assembly with wire so as not to

stretch brake hose. Be careful not to depress brake pedal, or

piston will pop out.

Make sure brake hose is not twisted.

SFA372-A

3. Separate tie-rod from knuckle with Tool.

Install stud nut on stud bolt to prevent damage to stud bolt.

SFA181A

4. Separate drive shaft from knuckle by lightly tapping it. If it is

hard to remove, use a puller.

Cover boots with shop towel so as not to damage them when

removing drive shaft.

SFA153B

5. Remove strut lower mounting bolts.

SFA113AC

6. Loosen lower ball joint tightening nut.

7. Separate knuckle from lower ball joint stud with Tool.

8. Remove knuckle from transverse link.

FRONT AXLE

Wheel Hub and Knuckle (Cont'd)

AX-6

Page 499 of 2898

SFA090A

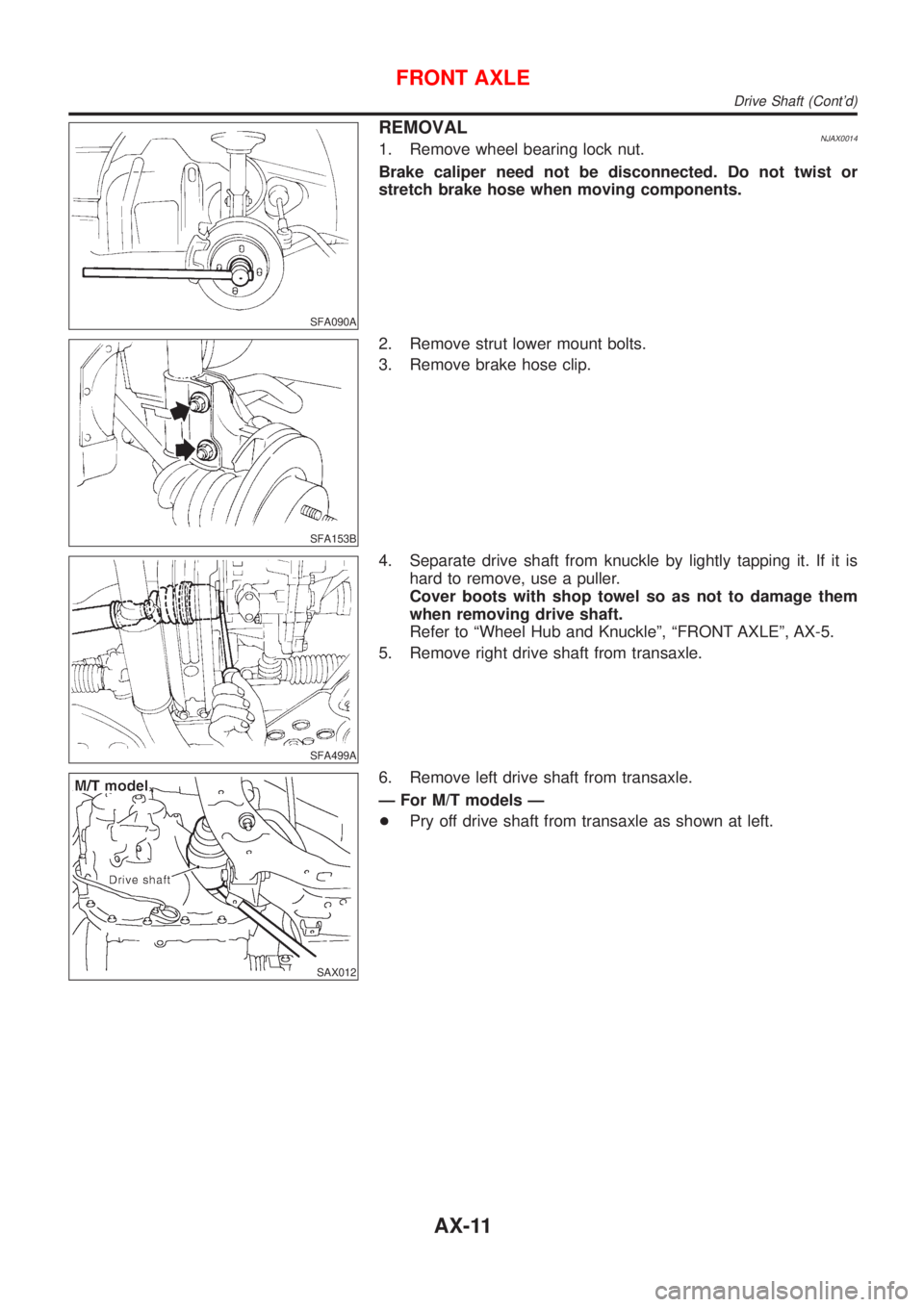

REMOVALNJAX00141. Remove wheel bearing lock nut.

Brake caliper need not be disconnected. Do not twist or

stretch brake hose when moving components.

SFA153B

2. Remove strut lower mount bolts.

3. Remove brake hose clip.

SFA499A

4. Separate drive shaft from knuckle by lightly tapping it. If it is

hard to remove, use a puller.

Cover boots with shop towel so as not to damage them

when removing drive shaft.

Refer to ªWheel Hub and Knuckleº, ªFRONT AXLEº, AX-5.

5. Remove right drive shaft from transaxle.

SAX012

6. Remove left drive shaft from transaxle.

Ð For M/T models Ð

+Pry off drive shaft from transaxle as shown at left.

FRONT AXLE

Drive Shaft (Cont'd)

AX-11

Page 510 of 2898

SBR686C

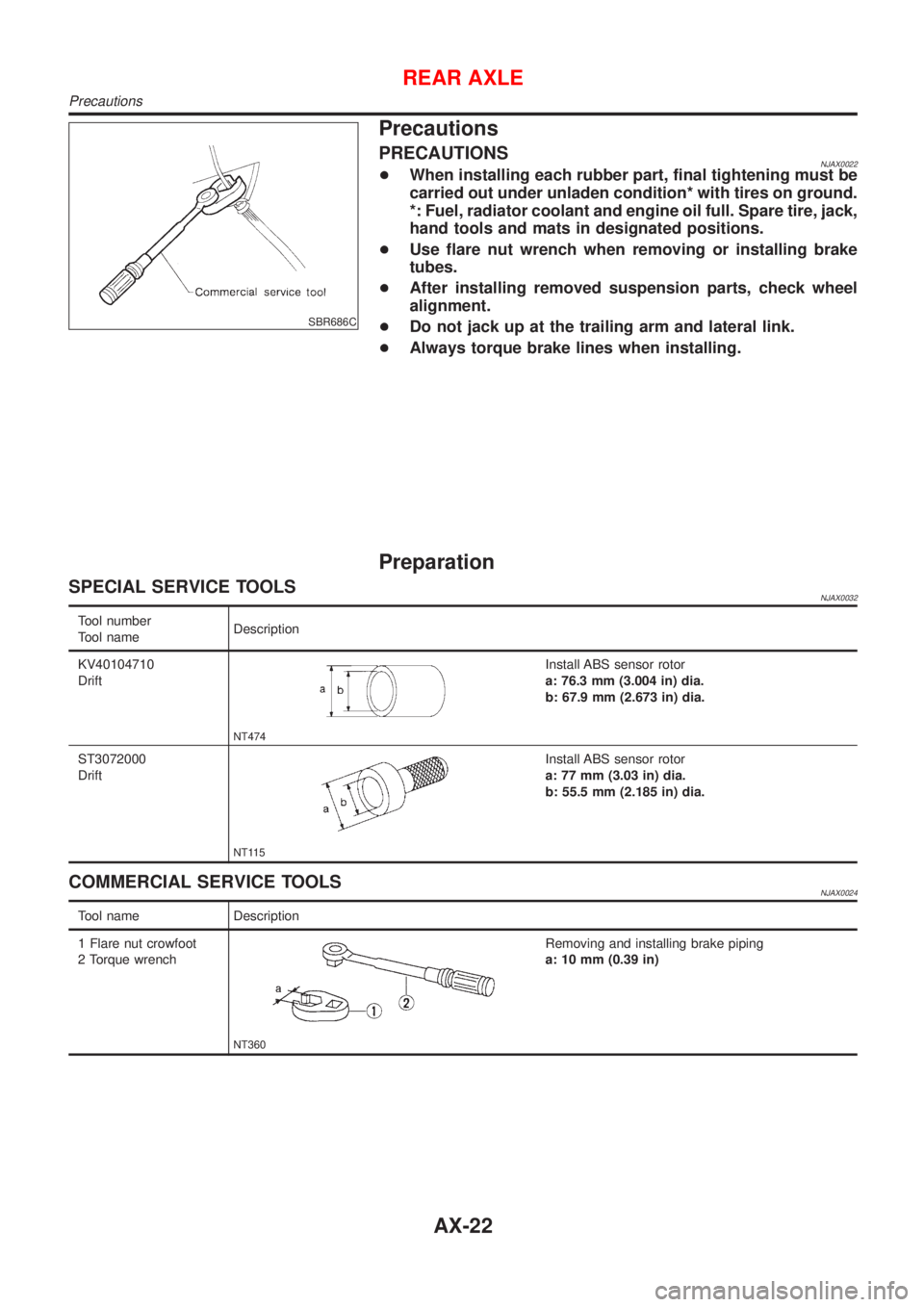

Precautions

PRECAUTIONSNJAX0022+When installing each rubber part, final tightening must be

carried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+Use flare nut wrench when removing or installing brake

tubes.

+After installing removed suspension parts, check wheel

alignment.

+Do not jack up at the trailing arm and lateral link.

+Always torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNJAX0032

Tool number

Tool nameDescription

KV40104710

Drift

NT474

Install ABS sensor rotor

a: 76.3 mm (3.004 in) dia.

b: 67.9 mm (2.673 in) dia.

ST3072000

Drift

NT115

Install ABS sensor rotor

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

COMMERCIAL SERVICE TOOLSNJAX0024

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing brake piping

a: 10 mm (0.39 in)

REAR AXLE

Precautions

AX-22