brake NISSAN ALMERA 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 350 of 2898

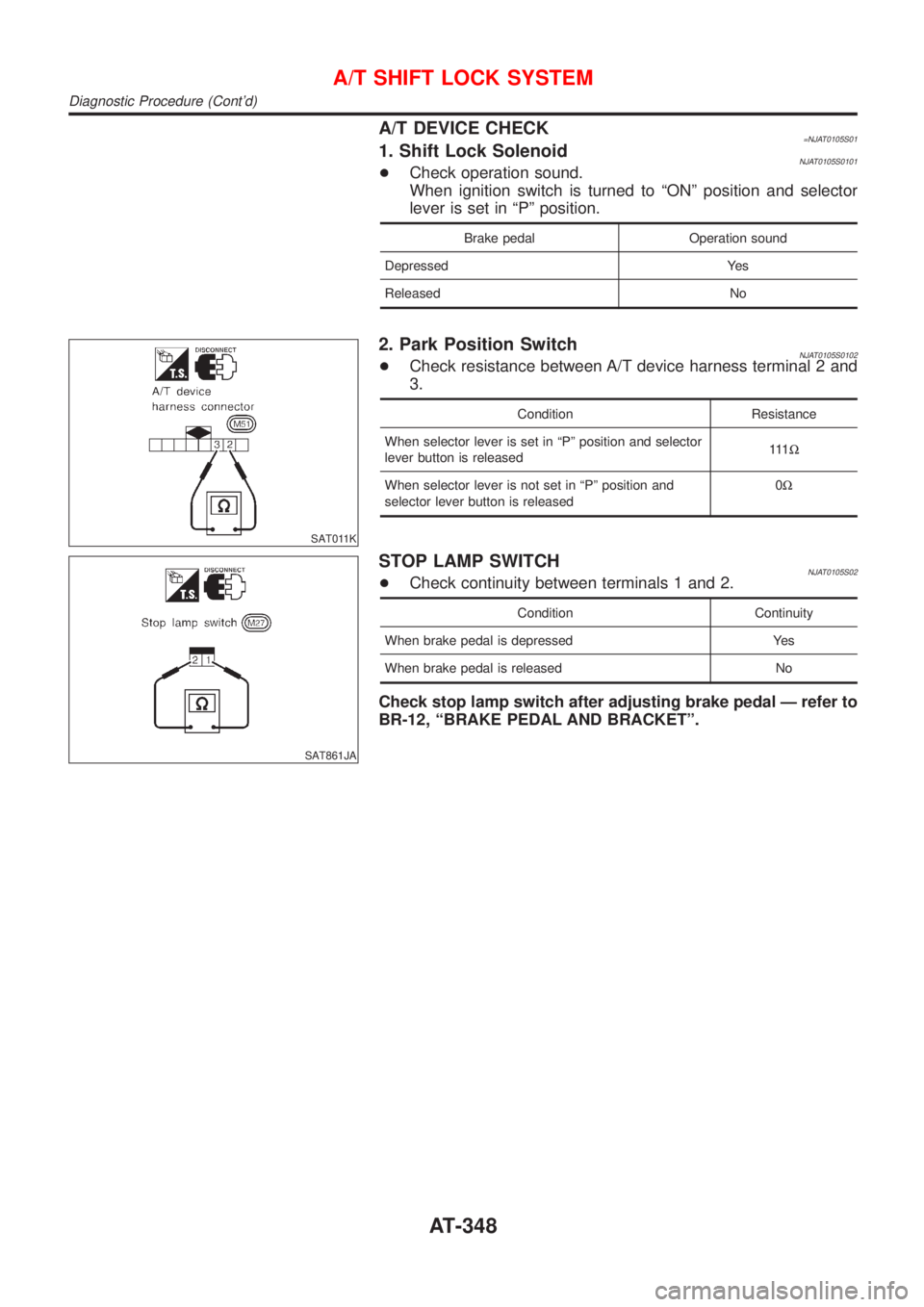

A/T DEVICE CHECK=NJAT0105S011. Shift Lock SolenoidNJAT0105S0101+Check operation sound.

When ignition switch is turned to ªONº position and selector

lever is set in ªPº position.

Brake pedal Operation sound

Depressed Yes

Released No

SAT011K

2. Park Position SwitchNJAT0105S0102+Check resistance between A/T device harness terminal 2 and

3.

Condition Resistance

When selector lever is set in ªPº position and selector

lever button is released111W

When selector lever is not set in ªPº position and

selector lever button is released0W

SAT861JA

STOP LAMP SWITCHNJAT0105S02+Check continuity between terminals 1 and 2.

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

Check stop lamp switch after adjusting brake pedal Ð refer to

BR-12, ªBRAKE PEDAL AND BRACKETº.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-348

Page 358 of 2898

SAT058K

*1: With gusset to A/T

*2: With gusset to cylinder block

SAT638A

5. Reinstall any part removed.

6. Adjust control cable. Refer to AT-352.

7. Check continuity of PNP switch. Refer to AT-334.

8. Refill transaxle with ATF and check fluid level.

9. Move selector lever through all positions to be sure that tran-

saxle operates correctly. With parking brake applied, idle

engine. Move selector lever through ªNº to ªDº, to ª2º, to ª1º and

ªRº positions. A slight shock should be felt through the hand

gripping the selector each time the transaxle is shifted.

10. Perform road test. Refer to AT-85.

REMOVAL AND INSTALLATION

Installation (Cont'd)

AT-356

Page 374 of 2898

SAT037DA

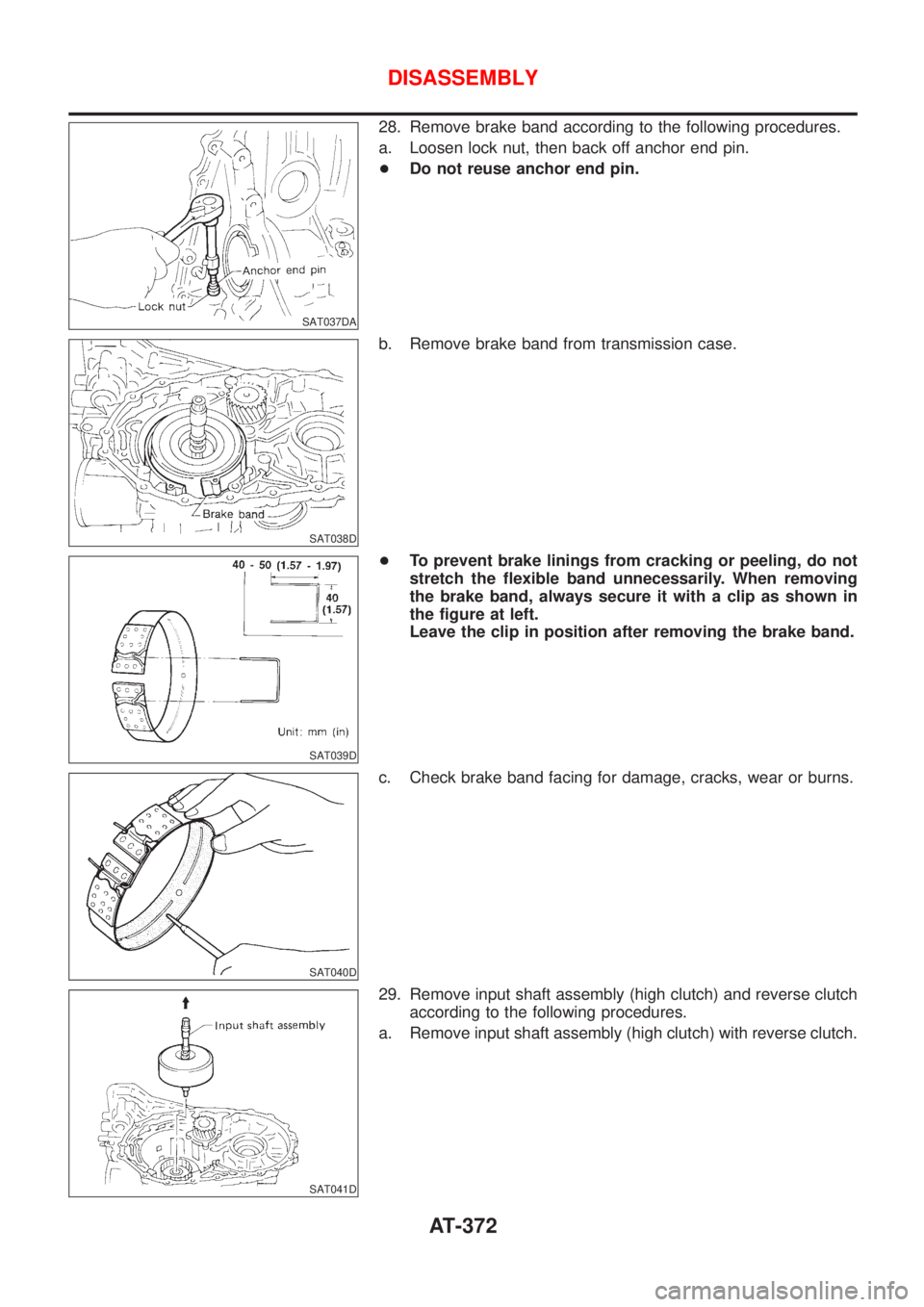

28. Remove brake band according to the following procedures.

a. Loosen lock nut, then back off anchor end pin.

+Do not reuse anchor end pin.

SAT038D

b. Remove brake band from transmission case.

SAT039D

+To prevent brake linings from cracking or peeling, do not

stretch the flexible band unnecessarily. When removing

the brake band, always secure it with a clip as shown in

the figure at left.

Leave the clip in position after removing the brake band.

SAT040D

c. Check brake band facing for damage, cracks, wear or burns.

SAT041D

29. Remove input shaft assembly (high clutch) and reverse clutch

according to the following procedures.

a. Remove input shaft assembly (high clutch) with reverse clutch.

DISASSEMBLY

AT-372

Page 421 of 2898

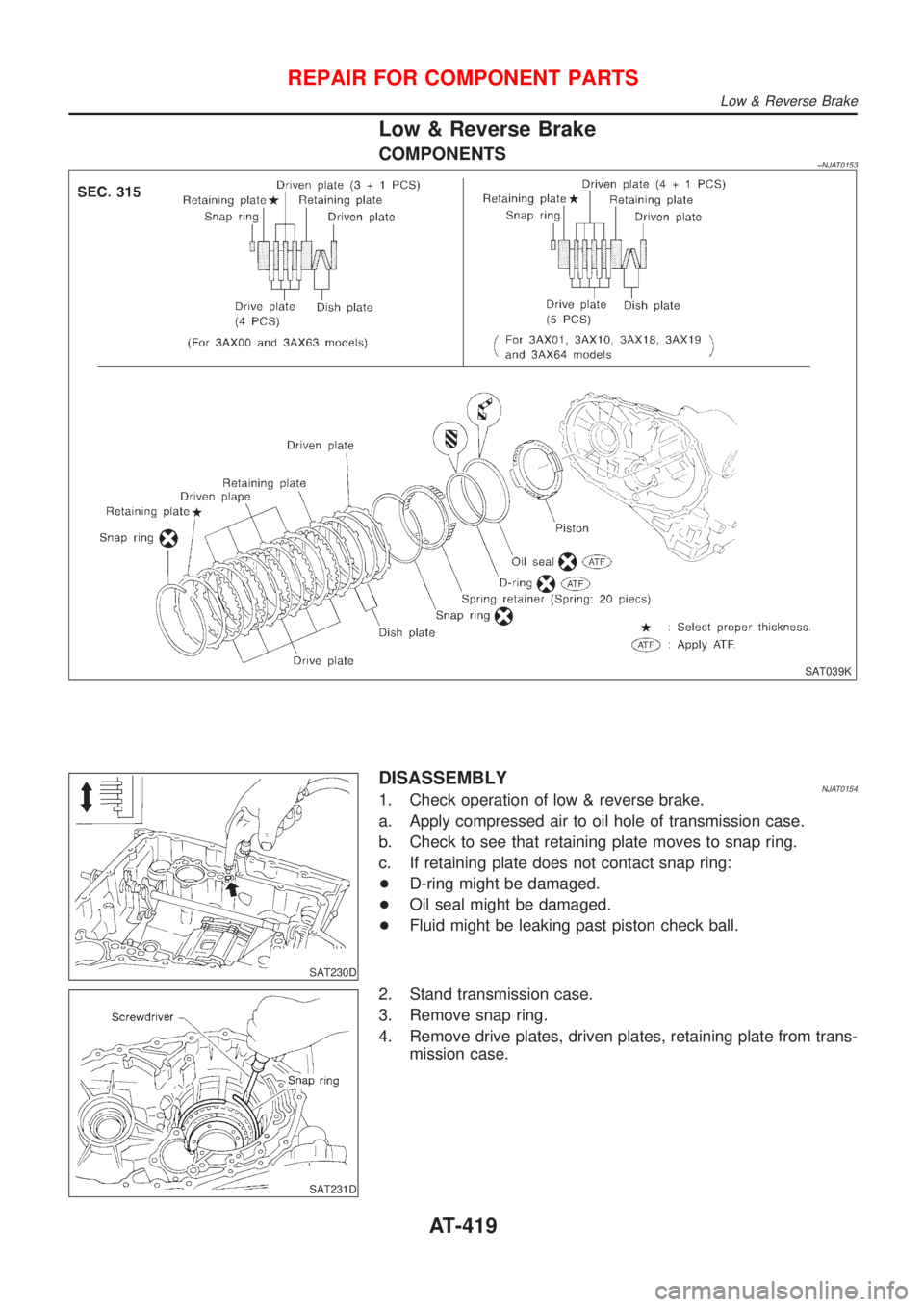

Low & Reverse Brake

COMPONENTS=NJAT0153

SAT039K

SAT230D

DISASSEMBLYNJAT01541. Check operation of low & reverse brake.

a. Apply compressed air to oil hole of transmission case.

b. Check to see that retaining plate moves to snap ring.

c. If retaining plate does not contact snap ring:

+D-ring might be damaged.

+Oil seal might be damaged.

+Fluid might be leaking past piston check ball.

SAT231D

2. Stand transmission case.

3. Remove snap ring.

4. Remove drive plates, driven plates, retaining plate from trans-

mission case.

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake

AT-419

Page 422 of 2898

SAT242D

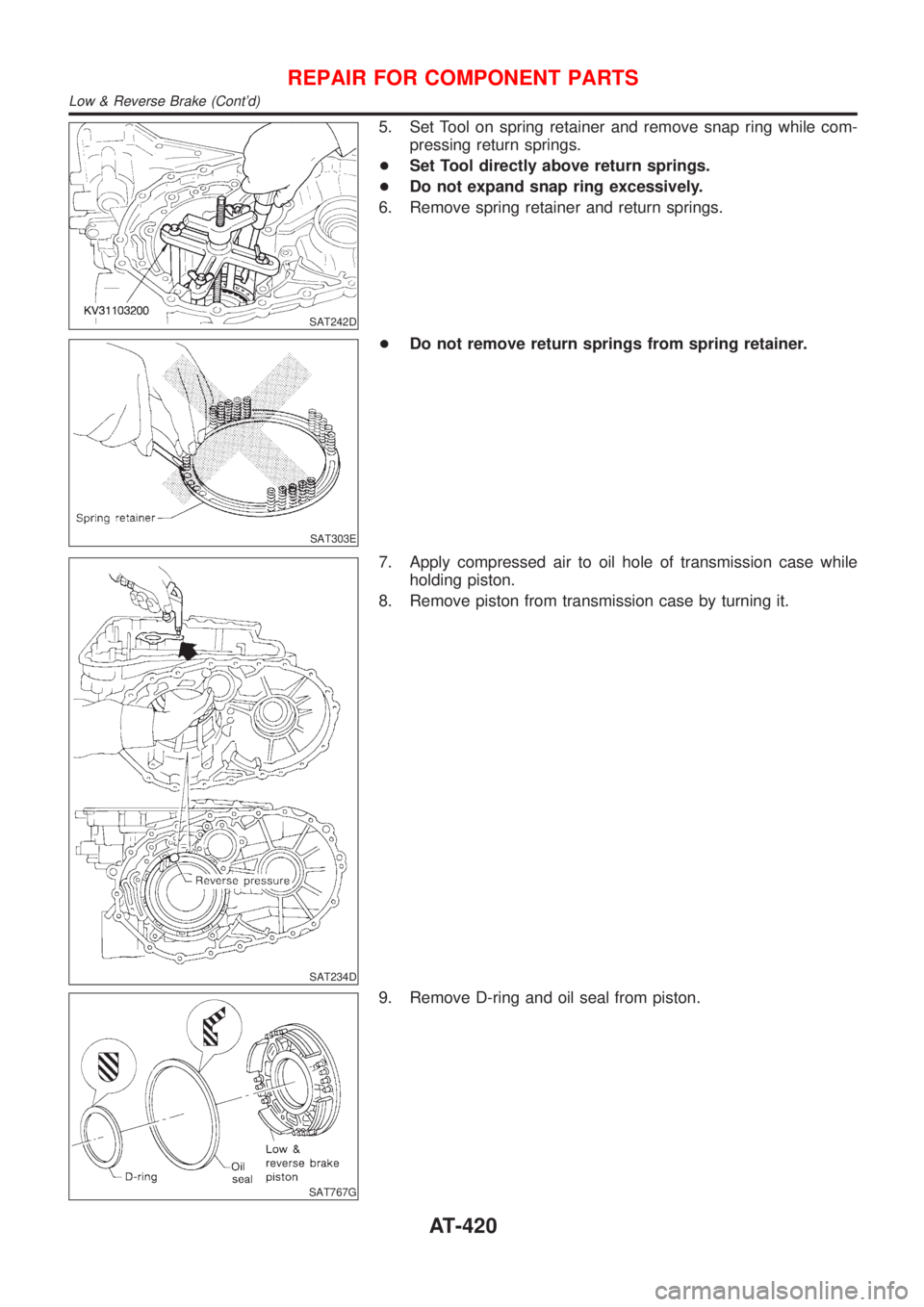

5. Set Tool on spring retainer and remove snap ring while com-

pressing return springs.

+Set Tool directly above return springs.

+Do not expand snap ring excessively.

6. Remove spring retainer and return springs.

SAT303E

+Do not remove return springs from spring retainer.

SAT234D

7. Apply compressed air to oil hole of transmission case while

holding piston.

8. Remove piston from transmission case by turning it.

SAT767G

9. Remove D-ring and oil seal from piston.

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-420

Page 423 of 2898

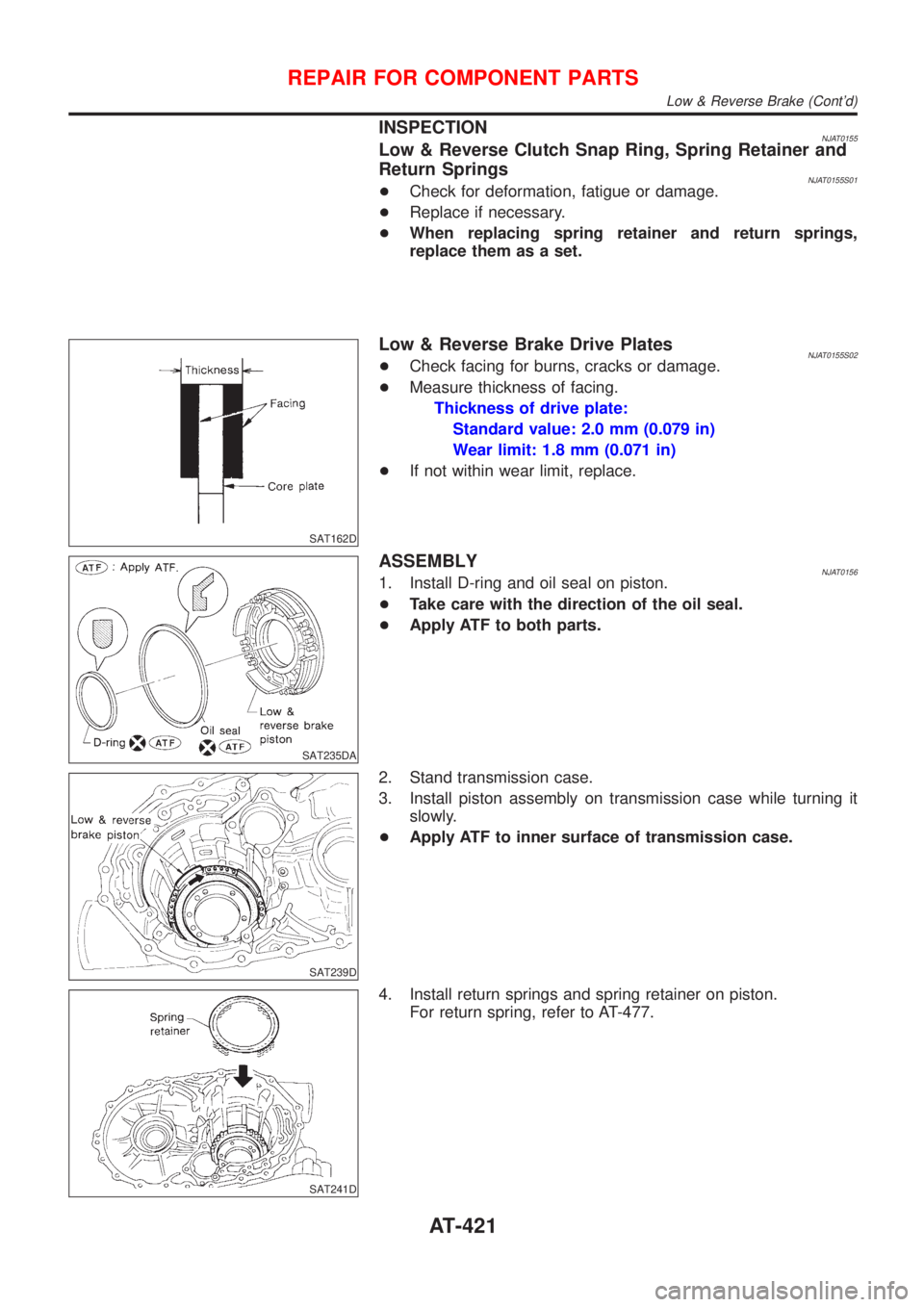

INSPECTIONNJAT0155Low & Reverse Clutch Snap Ring, Spring Retainer and

Return Springs

NJAT0155S01+Check for deformation, fatigue or damage.

+Replace if necessary.

+When replacing spring retainer and return springs,

replace them as a set.

SAT162D

Low & Reverse Brake Drive PlatesNJAT0155S02+Check facing for burns, cracks or damage.

+Measure thickness of facing.

Thickness of drive plate:

Standard value: 2.0 mm (0.079 in)

Wear limit: 1.8 mm (0.071 in)

+If not within wear limit, replace.

SAT235DA

ASSEMBLYNJAT01561. Install D-ring and oil seal on piston.

+Take care with the direction of the oil seal.

+Apply ATF to both parts.

SAT239D

2. Stand transmission case.

3. Install piston assembly on transmission case while turning it

slowly.

+Apply ATF to inner surface of transmission case.

SAT241D

4. Install return springs and spring retainer on piston.

For return spring, refer to AT-477.

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-421

Page 424 of 2898

SAT242D

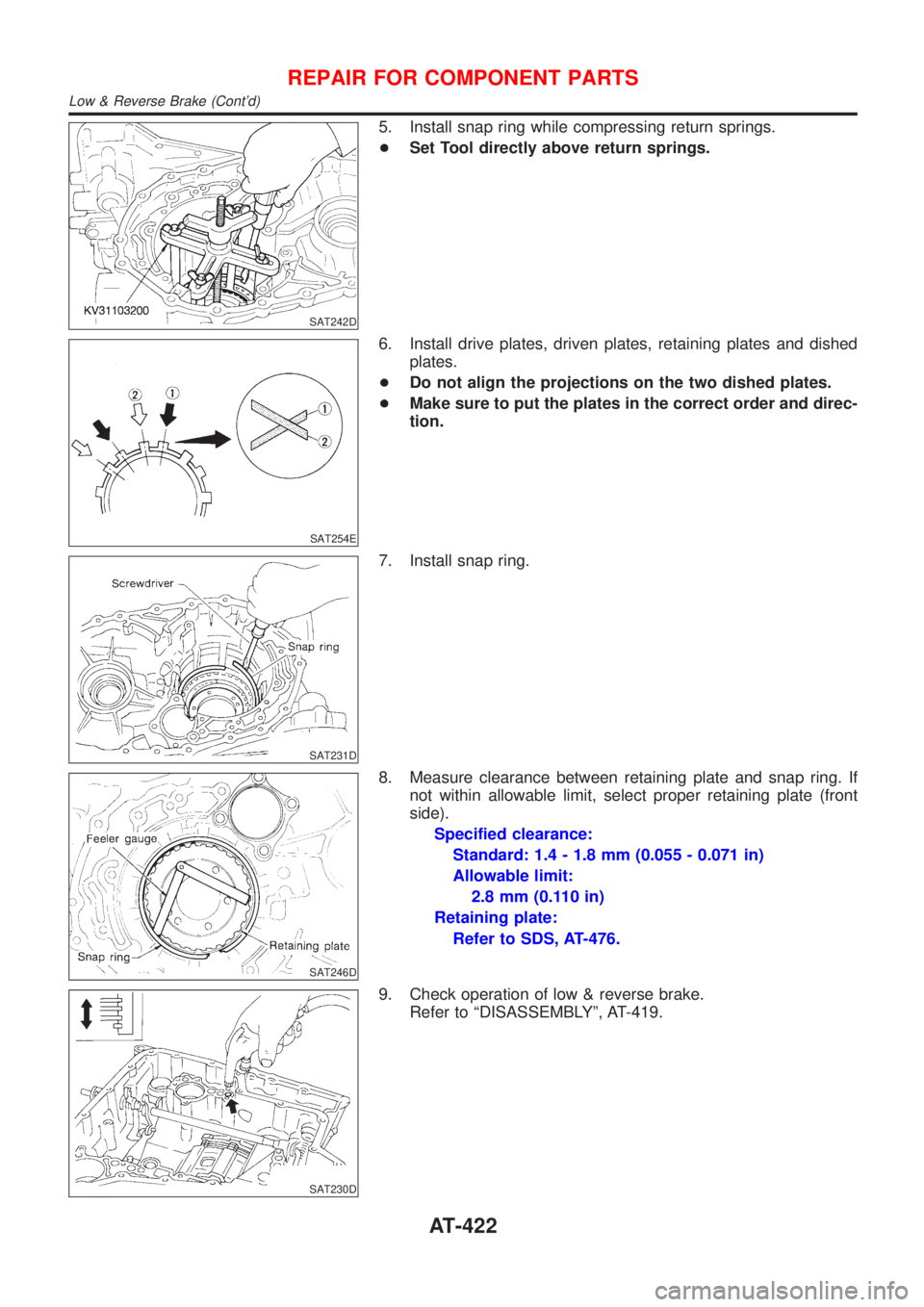

5. Install snap ring while compressing return springs.

+Set Tool directly above return springs.

SAT254E

6. Install drive plates, driven plates, retaining plates and dished

plates.

+Do not align the projections on the two dished plates.

+Make sure to put the plates in the correct order and direc-

tion.

SAT231D

7. Install snap ring.

SAT246D

8. Measure clearance between retaining plate and snap ring. If

not within allowable limit, select proper retaining plate (front

side).

Specified clearance:

Standard: 1.4 - 1.8 mm (0.055 - 0.071 in)

Allowable limit:

2.8 mm (0.110 in)

Retaining plate:

Refer to SDS, AT-476.

SAT230D

9. Check operation of low & reverse brake.

Refer to ªDISASSEMBLYº, AT-419.

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-422

Page 457 of 2898

SAT124E

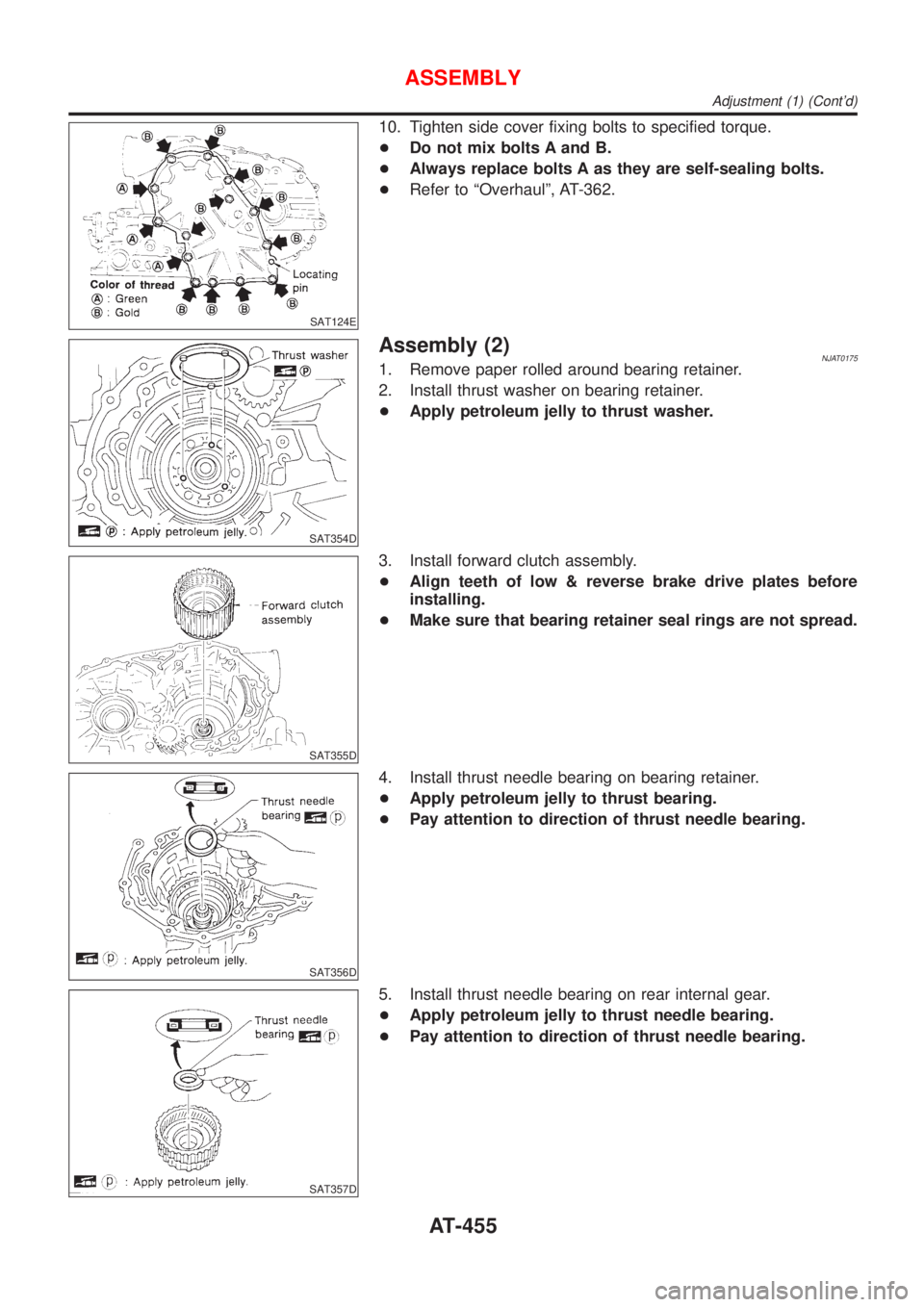

10. Tighten side cover fixing bolts to specified torque.

+Do not mix bolts A and B.

+Always replace bolts A as they are self-sealing bolts.

+Refer to ªOverhaulº, AT-362.

SAT354D

Assembly (2)NJAT01751. Remove paper rolled around bearing retainer.

2. Install thrust washer on bearing retainer.

+Apply petroleum jelly to thrust washer.

SAT355D

3. Install forward clutch assembly.

+Align teeth of low & reverse brake drive plates before

installing.

+Make sure that bearing retainer seal rings are not spread.

SAT356D

4. Install thrust needle bearing on bearing retainer.

+Apply petroleum jelly to thrust bearing.

+Pay attention to direction of thrust needle bearing.

SAT357D

5. Install thrust needle bearing on rear internal gear.

+Apply petroleum jelly to thrust needle bearing.

+Pay attention to direction of thrust needle bearing.

ASSEMBLY

Adjustment (1) (Cont'd)

AT-455

Page 465 of 2898

SAT038D

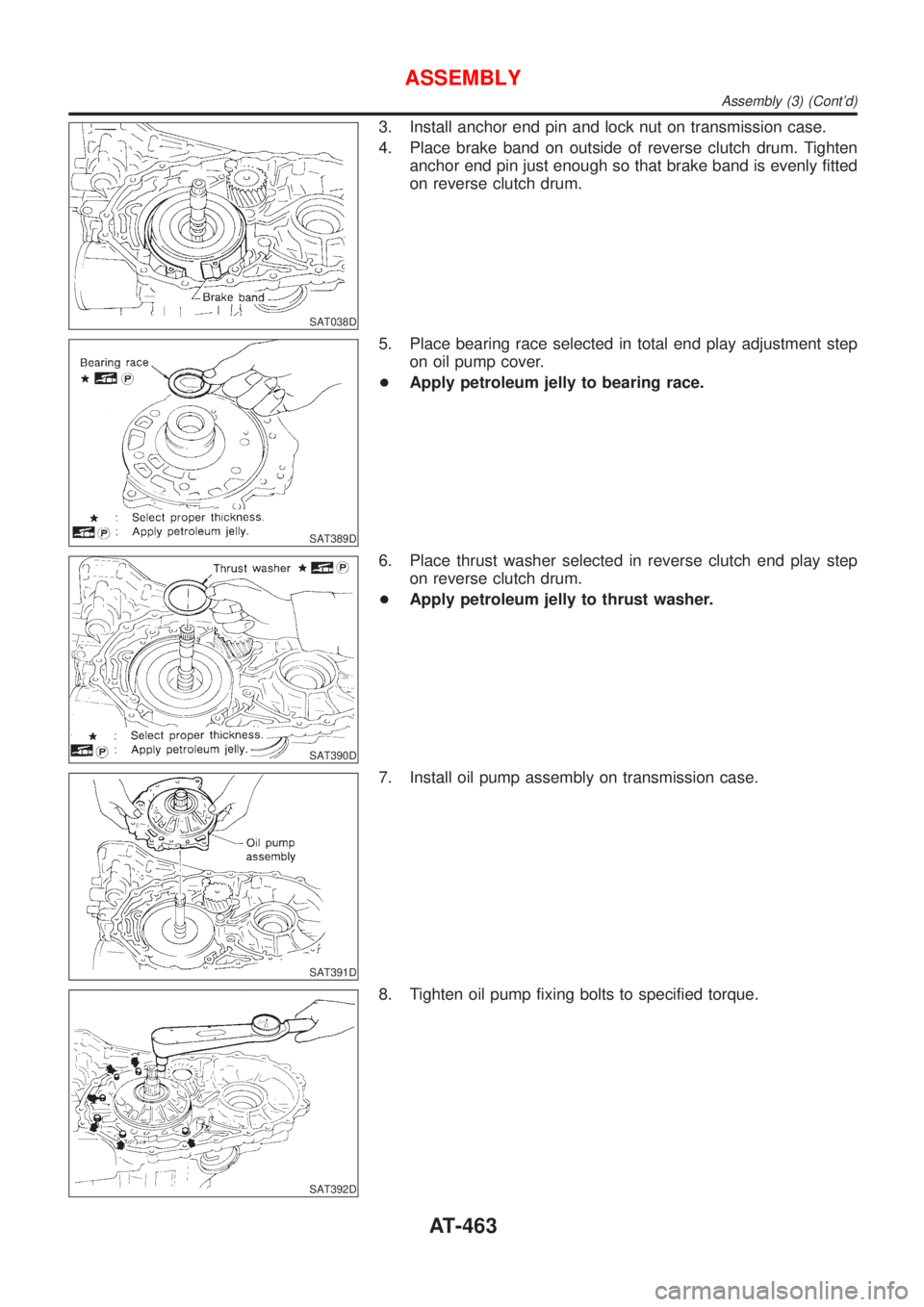

3. Install anchor end pin and lock nut on transmission case.

4. Place brake band on outside of reverse clutch drum. Tighten

anchor end pin just enough so that brake band is evenly fitted

on reverse clutch drum.

SAT389D

5. Place bearing race selected in total end play adjustment step

on oil pump cover.

+Apply petroleum jelly to bearing race.

SAT390D

6. Place thrust washer selected in reverse clutch end play step

on reverse clutch drum.

+Apply petroleum jelly to thrust washer.

SAT391D

7. Install oil pump assembly on transmission case.

SAT392D

8. Tighten oil pump fixing bolts to specified torque.

ASSEMBLY

Assembly (3) (Cont'd)

AT-463

Page 466 of 2898

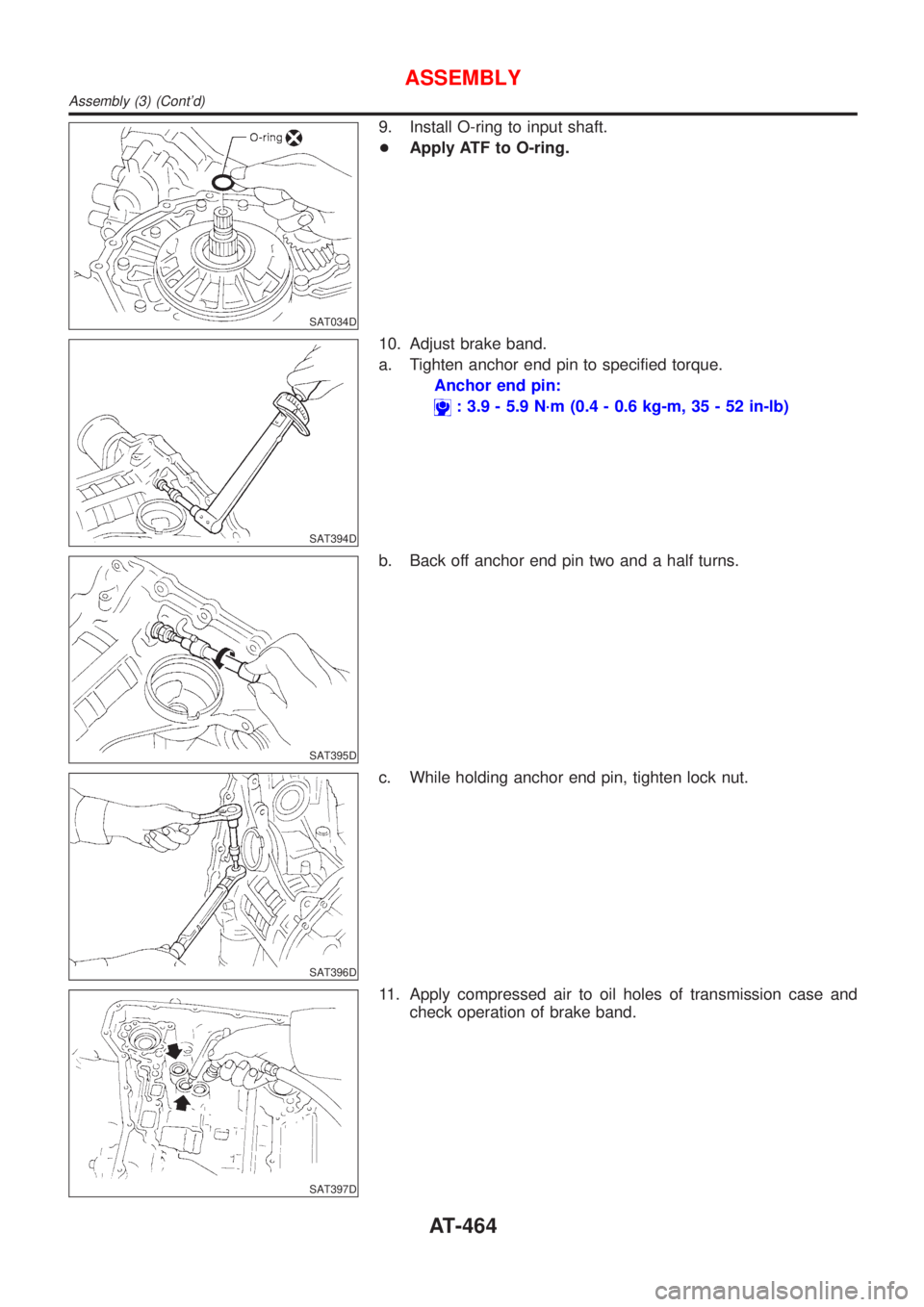

SAT034D

9. Install O-ring to input shaft.

+Apply ATF to O-ring.

SAT394D

10. Adjust brake band.

a. Tighten anchor end pin to specified torque.

Anchor end pin:

: 3.9 - 5.9 N´m (0.4 - 0.6 kg-m, 35 - 52 in-lb)

SAT395D

b. Back off anchor end pin two and a half turns.

SAT396D

c. While holding anchor end pin, tighten lock nut.

SAT397D

11. Apply compressed air to oil holes of transmission case and

check operation of brake band.

ASSEMBLY

Assembly (3) (Cont'd)

AT-464