wheel NISSAN ALMERA 2001 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 608 of 2898

5. Pedal Vibration and Noise=NJBR0108

1 INSPECTION START

Pedal vibration and noise inspection

SAT797A

©GO TO 2.

2 CHECK SYMPTOM

1. Apply brake.

2. Start engine.

Does the symptom appear only when engine is started?

Ye s©Carry out self-diagnosis. Refer to BR-63, BR-65.

No©GO TO 3.

3 RECHECK SYMPTOM

Does the symptom appear when electrical equipment switches (such as headlamp) are operated?

Ye s©GO TO 4.

No©Go to ª3. CHECK WARNING LAMP INDICATIONº in ª2. Unexpected Pedal Actionº,

BR-89.

4 CHECK WHEEL SENSOR

Check wheel sensor shield ground. For location of shield ground, refer to wiring diagram and ªHARNESS LAYOUTº in EL

section.

Is wheel sensor shield grounded properly?

Ye s©Check ABS actuator and electric unit pin terminals for damage or the connection of ABS

actuator and electric unit harness connector. Reconnect ABS actuator and electric unit

harness connector. Then retest.

No©Repair.

NOTE:

ABS may operate and cause vibration under any of the following

conditions.

+Applying brake gradually when shifting or operating clutch.

+Low friction (slippery) road.

+High speed cornering.

+Driving over bumps and pot holes.

+Engine speed is over 5,000 rpm with vehicle stopped.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

5. Pedal Vibration and Noise

BR-92

Page 613 of 2898

NJBR0111

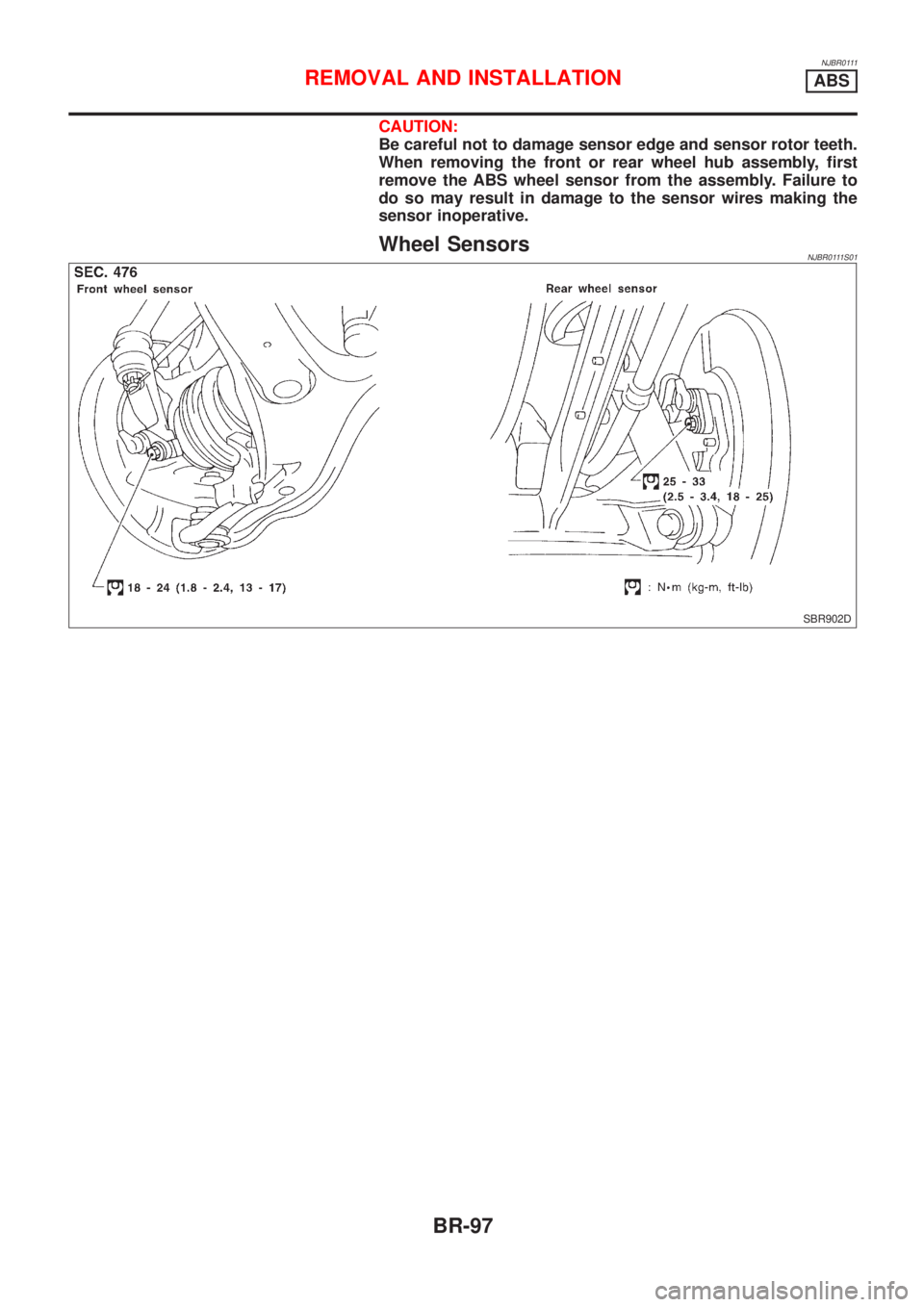

CAUTION:

Be careful not to damage sensor edge and sensor rotor teeth.

When removing the front or rear wheel hub assembly, first

remove the ABS wheel sensor from the assembly. Failure to

do so may result in damage to the sensor wires making the

sensor inoperative.

Wheel SensorsNJBR0111S01

SBR902D

REMOVAL AND INSTALLATIONABS

BR-97

Page 615 of 2898

SBR984C

SBR873CA

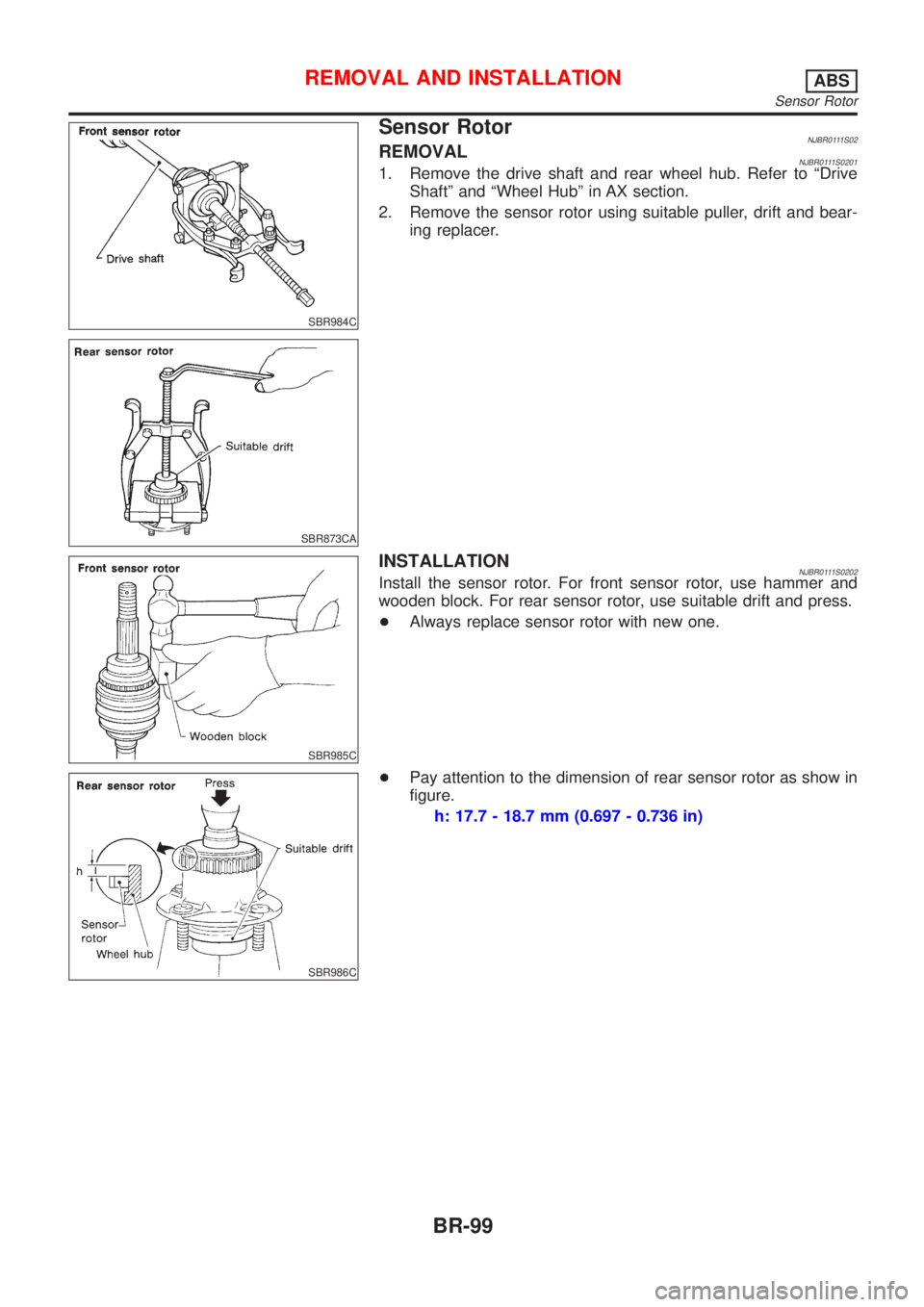

Sensor RotorNJBR0111S02REMOVALNJBR0111S02011. Remove the drive shaft and rear wheel hub. Refer to ªDrive

Shaftº and ªWheel Hubº in AX section.

2. Remove the sensor rotor using suitable puller, drift and bear-

ing replacer.

SBR985C

INSTALLATIONNJBR0111S0202Install the sensor rotor. For front sensor rotor, use hammer and

wooden block. For rear sensor rotor, use suitable drift and press.

+Always replace sensor rotor with new one.

SBR986C

+Pay attention to the dimension of rear sensor rotor as show in

figure.

h: 17.7 - 18.7 mm (0.697 - 0.736 in)

REMOVAL AND INSTALLATIONABS

Sensor Rotor

BR-99

Page 621 of 2898

Service NoticeNJBT0001+When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

+Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to oil

or damage them.

+Apply sealing compound where necessary when installing parts.

+When applying sealing compound, be careful that the sealing compound does not protrude from parts.

+When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJBT0002The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

PRECAUTIONS

Service Notice

BT-3

Page 624 of 2898

Checking Body CorrosionNJBT0033Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Trunk lid opening, sunroof opening, fender wheelarch flange, fuel filler lid flange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE (FOR EUROPE)

Checking Body Corrosion

BT-6

Page 625 of 2898

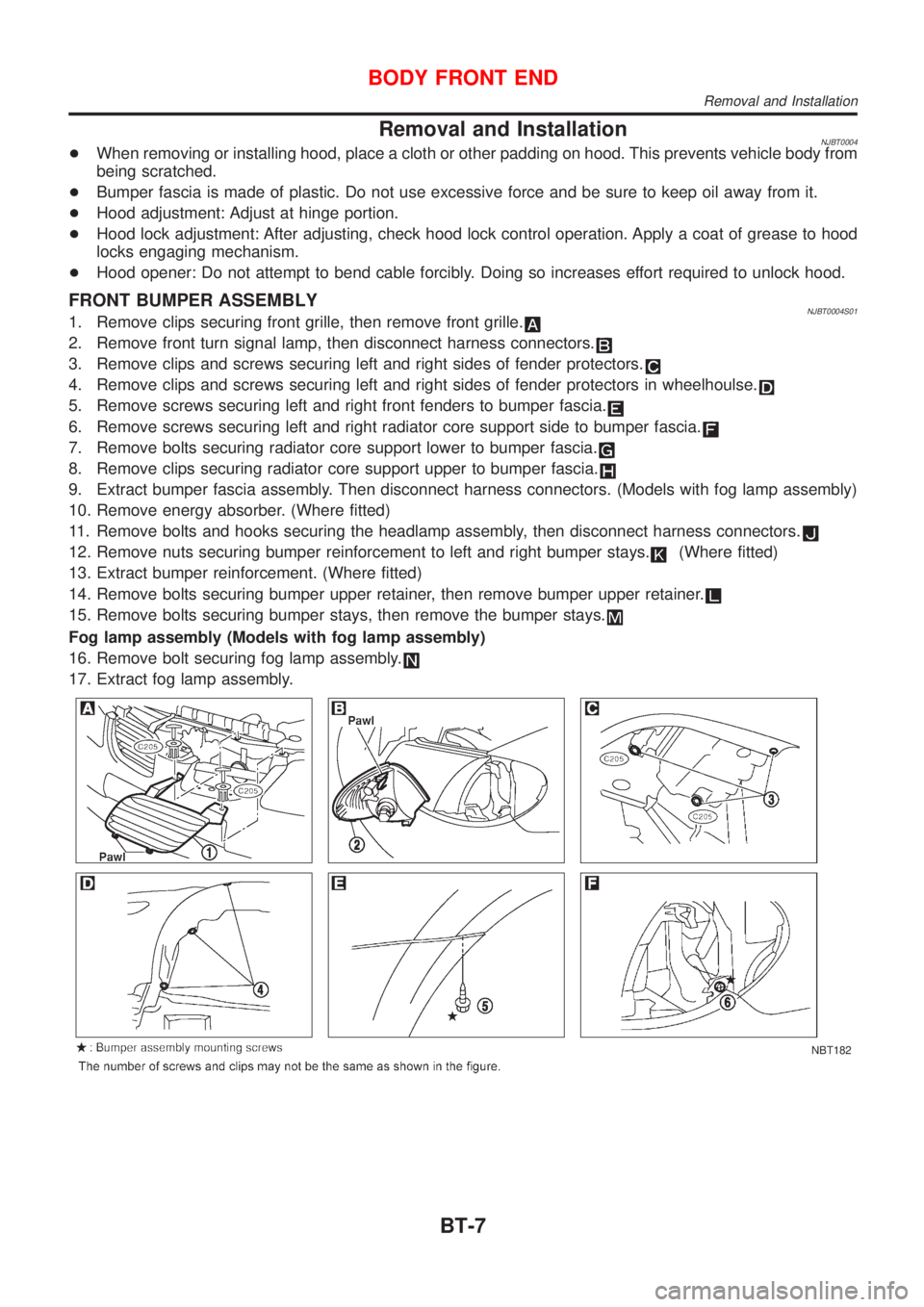

Removal and InstallationNJBT0004+When removing or installing hood, place a cloth or other padding on hood. This prevents vehicle body from

being scratched.

+Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

+Hood adjustment: Adjust at hinge portion.

+Hood lock adjustment: After adjusting, check hood lock control operation. Apply a coat of grease to hood

locks engaging mechanism.

+Hood opener: Do not attempt to bend cable forcibly. Doing so increases effort required to unlock hood.

FRONT BUMPER ASSEMBLYNJBT0004S011. Remove clips securing front grille, then remove front grille.

2. Remove front turn signal lamp, then disconnect harness connectors.

3. Remove clips and screws securing left and right sides of fender protectors.

4. Remove clips and screws securing left and right sides of fender protectors in wheelhoulse.

5. Remove screws securing left and right front fenders to bumper fascia.

6. Remove screws securing left and right radiator core support side to bumper fascia.

7. Remove bolts securing radiator core support lower to bumper fascia.

8. Remove clips securing radiator core support upper to bumper fascia.

9. Extract bumper fascia assembly. Then disconnect harness connectors. (Models with fog lamp assembly)

10. Remove energy absorber. (Where fitted)

11. Remove bolts and hooks securing the headlamp assembly, then disconnect harness connectors.

12. Remove nuts securing bumper reinforcement to left and right bumper stays.(Where fitted)

13. Extract bumper reinforcement. (Where fitted)

14. Remove bolts securing bumper upper retainer, then remove bumper upper retainer.

15. Remove bolts securing bumper stays, then remove the bumper stays.

Fog lamp assembly (Models with fog lamp assembly)

16. Remove bolt securing fog lamp assembly.

17. Extract fog lamp assembly.

NBT182

BODY FRONT END

Removal and Installation

BT-7

Page 652 of 2898

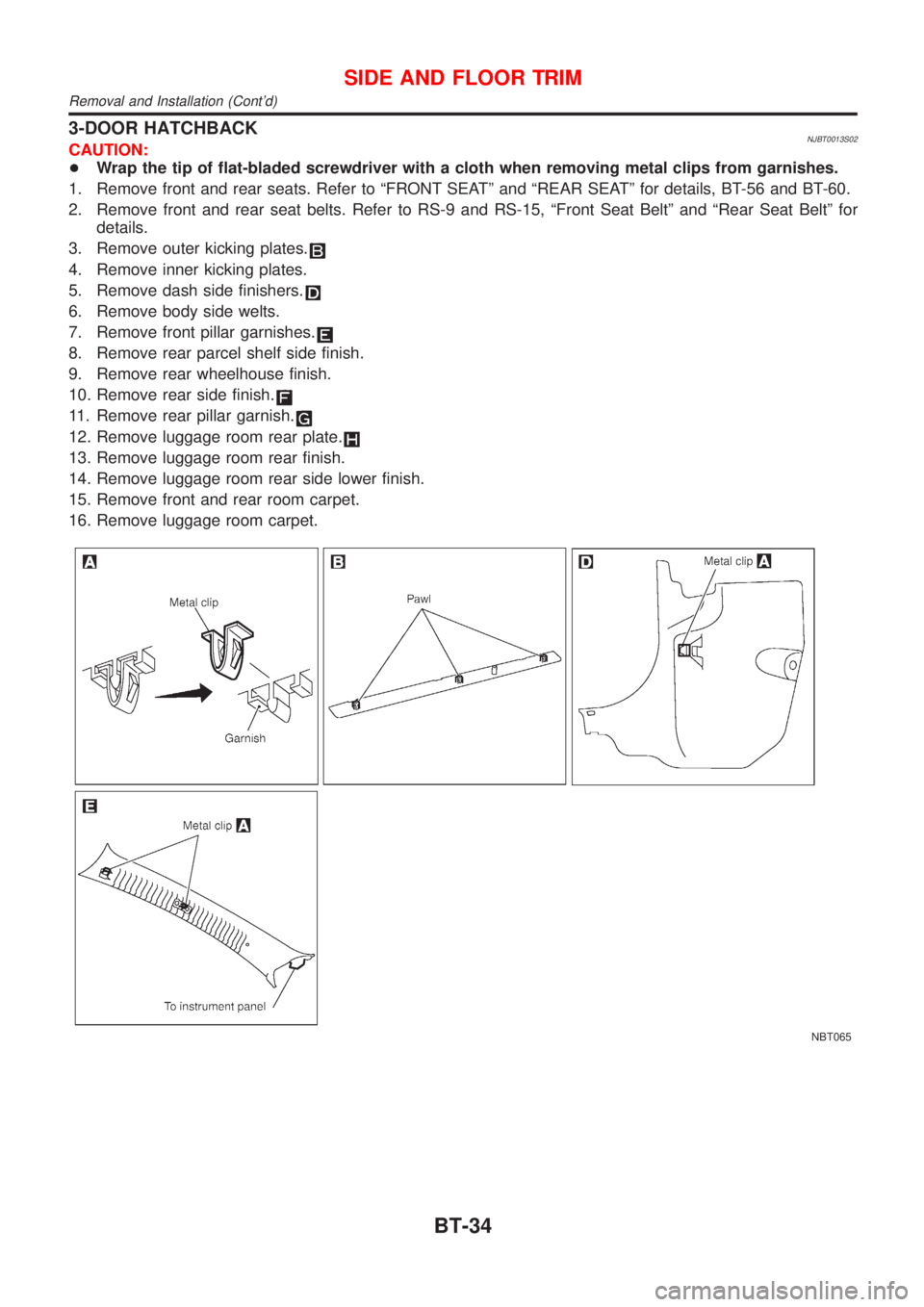

3-DOOR HATCHBACKNJBT0013S02CAUTION:

+Wrap the tip of flat-bladed screwdriver with a cloth when removing metal clips from garnishes.

1. Remove front and rear seats. Refer to ªFRONT SEATº and ªREAR SEATº for details, BT-56 and BT-60.

2. Remove front and rear seat belts. Refer to RS-9 and RS-15, ªFront Seat Beltº and ªRear Seat Beltº for

details.

3. Remove outer kicking plates.

4. Remove inner kicking plates.

5. Remove dash side finishers.

6. Remove body side welts.

7. Remove front pillar garnishes.

8. Remove rear parcel shelf side finish.

9. Remove rear wheelhouse finish.

10. Remove rear side finish.

11. Remove rear pillar garnish.

12. Remove luggage room rear plate.

13. Remove luggage room rear finish.

14. Remove luggage room rear side lower finish.

15. Remove front and rear room carpet.

16. Remove luggage room carpet.

NBT065

SIDE AND FLOOR TRIM

Removal and Installation (Cont'd)

BT-34

Page 654 of 2898

5-DOOR HATCHBACKNJBT0013S03CAUTION:

+Wrap the tip of flat-bladed screwdriver with a cloth when removing metal clips from garnishes.

1. Remove front and rear seats. Refer to ªFRONT SEATº and ªREAR SEATº for details, BT-56 and BT-60.

2. Remove front and rear seat belts. Refer to RS-7 and RS-15, ªFront Seat Beltº and ªRear Seat Beltº for

details.

3. Remove front and rear outer kicking plates.

4. Remove front and rear inner kicking plates.

5. Remove dash side finishers.

6. Remove front and rear body side welts.

7. Remove front pillar garnishes.

8. Remove center pillar lower garnishes.

9. Remove center pillar upper garnishes.

10. Remove rear parcel shelf side finish.

11. Remove rear pillar garnish.

12. Remove rear wheelhouse finish.

13. Remove luggage room rear plate.

14. Remove luggage room rear finish.

15. Remove luggage room rear side lower finish.

16. Remove front and rear room carpet.

17. Remove luggage room carpet.

SIDE AND FLOOR TRIM

Removal and Installation (Cont'd)

BT-36

Page 701 of 2898

CLUTCH

SECTION

CL

CONTENTS

PRECAUTIONS...............................................................2

Precautions ..................................................................2

PREPARATION...............................................................3

Special Service Tools ..................................................3

Commercial Service Tools ...........................................3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................4

NVH Troubleshooting Chart.........................................4

CLUTCH...................................................................4

CLUTCH SYSTEM...........................................................5

Components - RHD Model with QG Engine - .............5

Components - LHD Model with QG Engine -..............6

Components - RHD Model with YD Engine -..............7

Components - LHD Model with YD Engine - ..............8

Inspection and Adjustment ..........................................9

CLUTCH PEDAL INSPECTION...................................9

CLUTCH PEDAL ADJUSTMENT...............................10

AIR BLEEDING PROCEDURE..................................10

CLUTCH MASTER CYLINDER..................................... 11

Components............................................................... 11

Removal .....................................................................12

Installation ..................................................................12

Disassembly...............................................................12

Inspection...................................................................12

Assembly ...................................................................13

OPERATING CYLINDER...............................................14

Components...............................................................14

Removal .....................................................................14

Disassembly...............................................................14

Inspection...................................................................14

Assembly ...................................................................15

Installation ..................................................................15

PIPING...........................................................................16

Removal .....................................................................16Installation ..................................................................16

RS5F30A, RS5F70A

CLUTCH RELEASE MECHANISM...............................17

Components...............................................................17

Removal .....................................................................17

Inspection...................................................................17

Installation ..................................................................17

RS5F50A

CLUTCH RELEASE MECHANISM...............................20

Components...............................................................20

Removal .....................................................................20

Inspection...................................................................20

Installation ..................................................................20

CLUTCH DISC, CLUTCH COVER AND

FLYWHEEL....................................................................22

Components...............................................................22

Inspection and Adjustment ........................................22

CLUTCH DISC.........................................................22

CLUTCH COVER.....................................................23

FLYWHEEL.............................................................23

Installation ..................................................................23

SERVICE DATA AND SPECIFICATIONS (SDS).........24

Clutch Control System ...............................................24

Clutch Master Cylinder ..............................................24

Clutch Operating Cylinder .........................................24

Clutch Disc.................................................................24

Clutch Cover ..............................................................24

Clutch Pedal ..............................................................24

Page 704 of 2898

NJCL0004

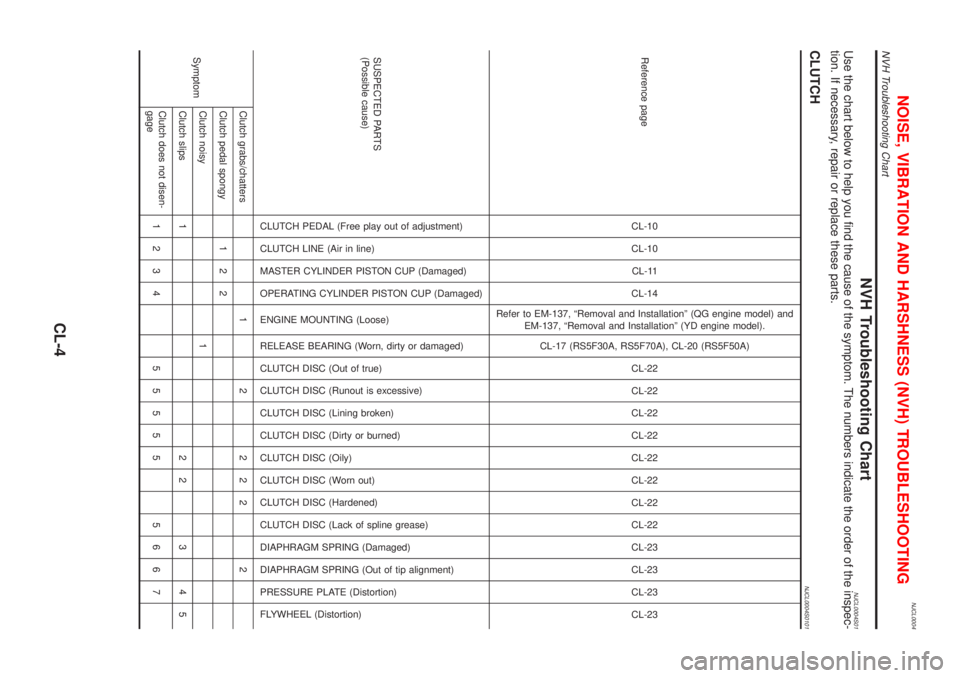

NVH Troubleshooting ChartNJCL0004S01Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

CLUTCHNJCL0004S0101

Reference pageCL-10

CL-10

CL-11

CL-14

Refer to EM-137, ªRemoval and Installationº (QG engine model) and

EM-137, ªRemoval and Installationº (YD engine model).

CL-17 (RS5F30A, RS5F70A), CL-20 (RS5F50A)

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-23

CL-23

CL-23

CL-23

SUSPECTED PARTS

(Possible cause)

CLUTCH PEDAL (Free play out of adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disen-

gage1234 55555 5667

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

CL-4