wheel NISSAN ALMERA 2001 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 523 of 2898

NJBR0005

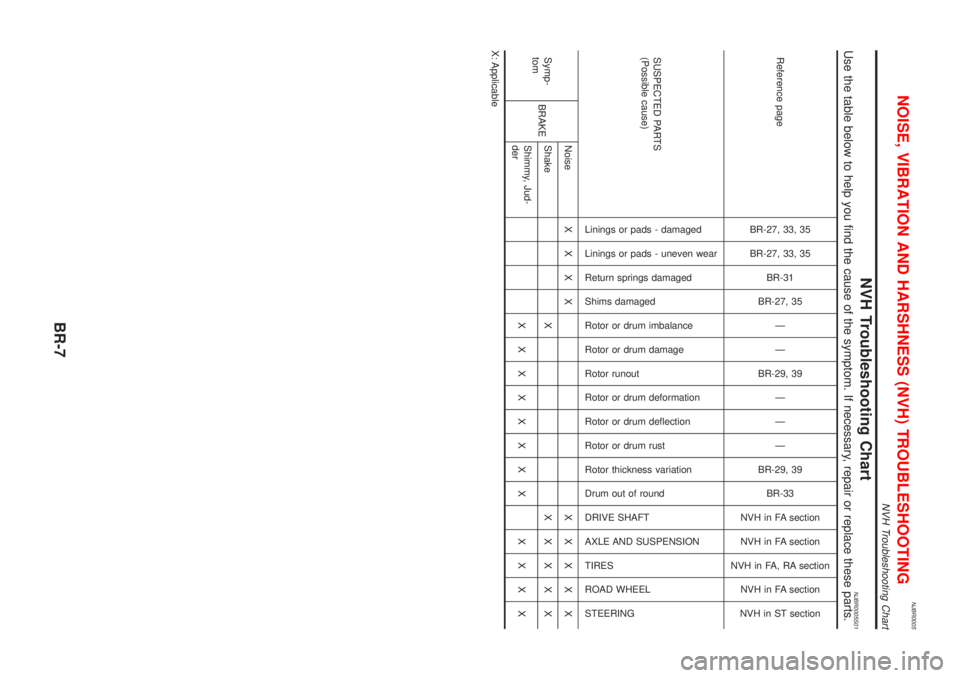

NVH Troubleshooting ChartNJBR0005S01Use the table below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference page

BR-27, 33, 35

BR-27, 33, 35

BR-31

BR-27, 35

Ð

Ð

BR-29, 39

Ð

Ð

Ð

BR-29, 39

BR-33

NVH in FA section

NVH in FA section

NVH in FA, RA section

NVH in FA section

NVH in ST section

SUSPECTED PARTS

(Possible cause)

Linings or pads - damaged

Linings or pads - uneven wear

Return springs damaged

Shims damaged

Rotor or drum imbalance

Rotor or drum damage

Rotor runout

Rotor or drum deformation

Rotor or drum deflection

Rotor or drum rust

Rotor thickness variation

Drum out of round

DRIVE SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

STEERING

Symp-

tomBRAKENoiseXXXX XXXXX

Shake XXXXXX

Shimmy, Jud-

derXXXXXXXX XXXX

X: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

BR-7

Page 529 of 2898

SBR229E

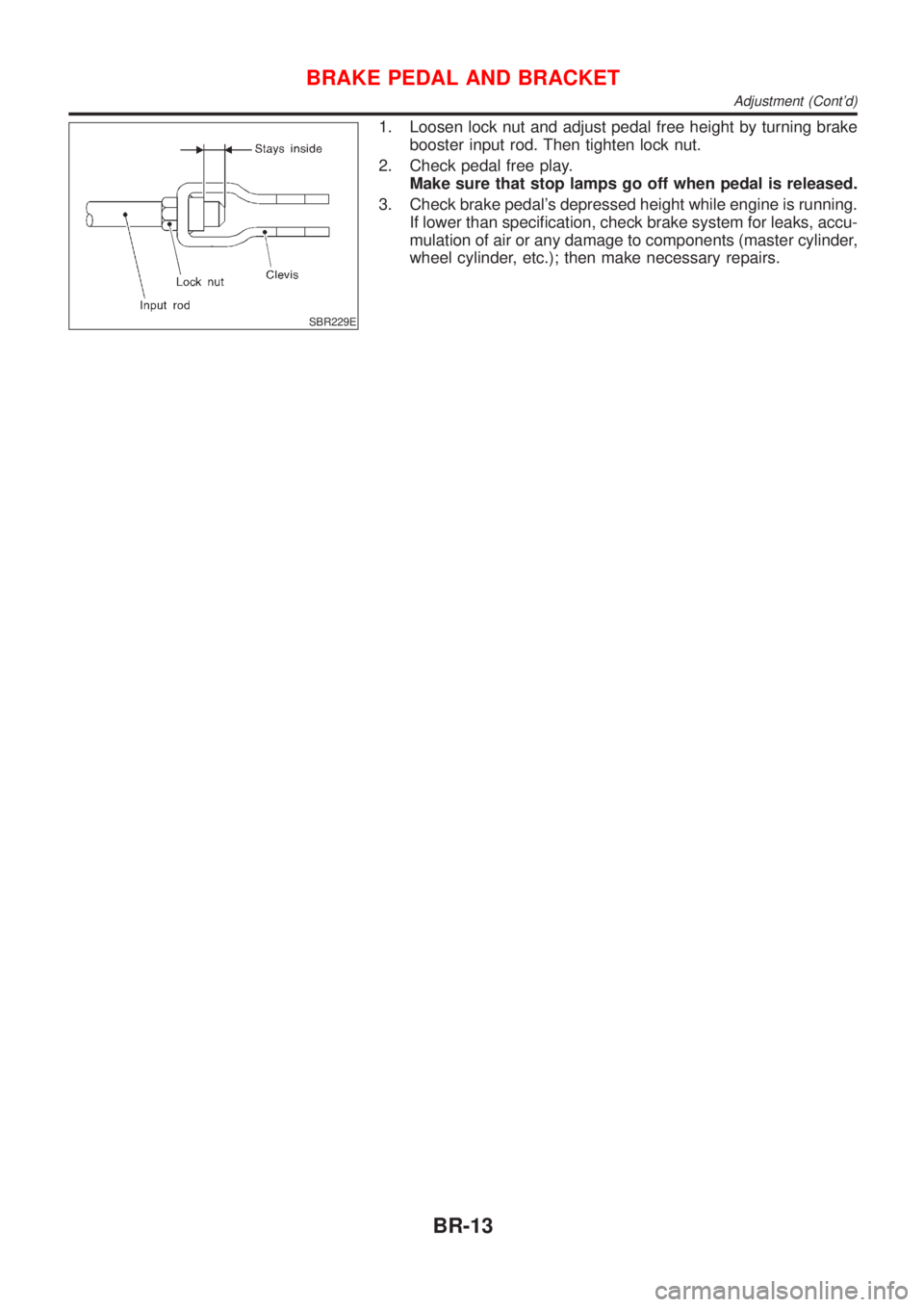

1. Loosen lock nut and adjust pedal free height by turning brake

booster input rod. Then tighten lock nut.

2. Check pedal free play.

Make sure that stop lamps go off when pedal is released.

3. Check brake pedal's depressed height while engine is running.

If lower than specification, check brake system for leaks, accu-

mulation of air or any damage to components (master cylinder,

wheel cylinder, etc.); then make necessary repairs.

BRAKE PEDAL AND BRACKET

Adjustment (Cont'd)

BR-13

Page 545 of 2898

PistonNJBR0033S0102CAUTION:

Piston sliding surface is plated. Do not polish with emery

paper even if rust or foreign materials are stuck to sliding

surface.

Check piston for score, rust, wear, damage or presence of foreign

materials. Replace if any of the above conditions are observed.

Slide Pin, Pin Bolt and Pin BootNJBR0033S0103Check for wear, cracks or other damage. Replace if any of the

above conditions are observed.

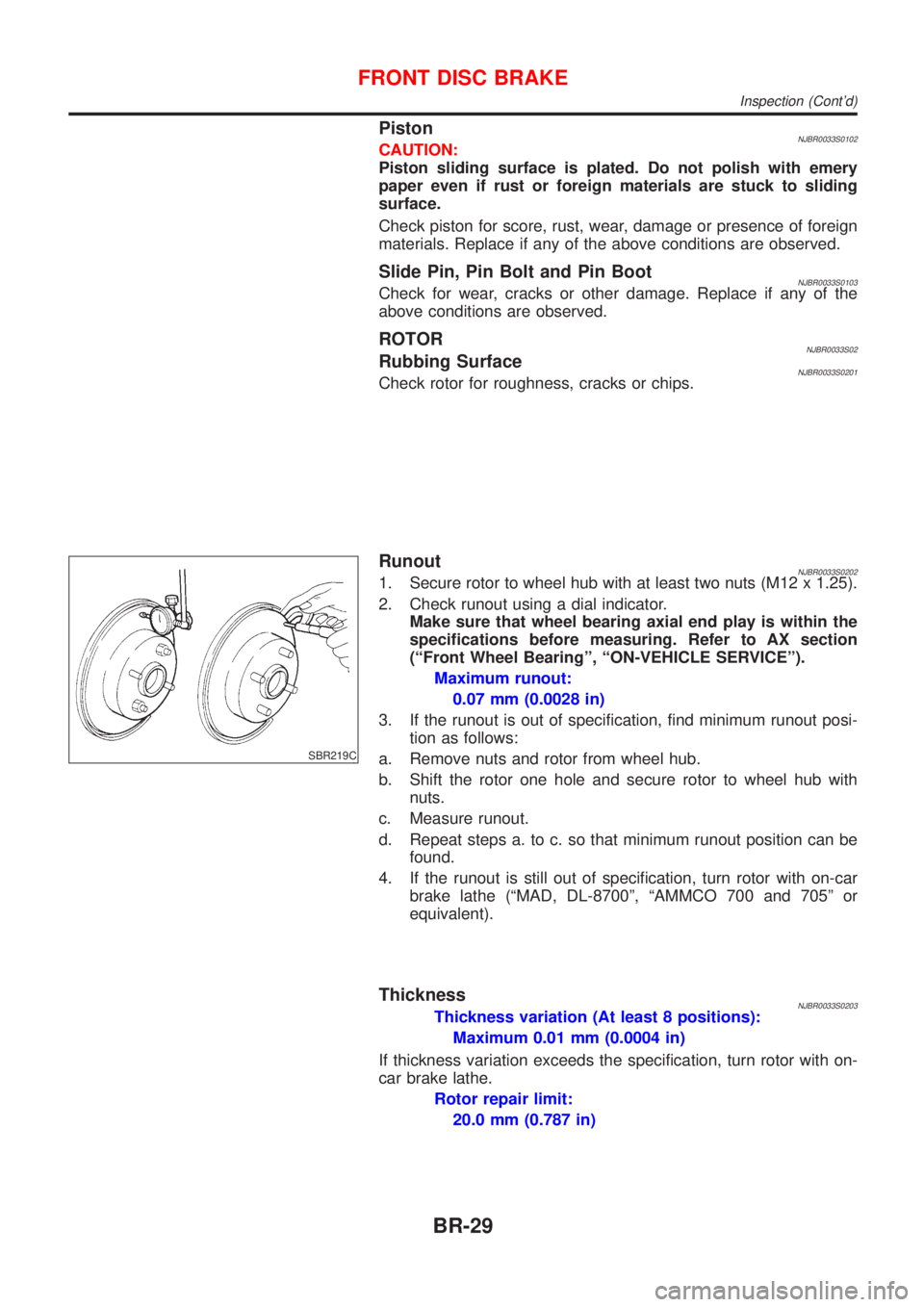

ROTORNJBR0033S02Rubbing SurfaceNJBR0033S0201Check rotor for roughness, cracks or chips.

SBR219C

RunoutNJBR0033S02021. Secure rotor to wheel hub with at least two nuts (M12 x 1.25).

2. Check runout using a dial indicator.

Make sure that wheel bearing axial end play is within the

specifications before measuring. Refer to AX section

(ªFront Wheel Bearingº, ªON-VEHICLE SERVICEº).

Maximum runout:

0.07 mm (0.0028 in)

3. If the runout is out of specification, find minimum runout posi-

tion as follows:

a. Remove nuts and rotor from wheel hub.

b. Shift the rotor one hole and secure rotor to wheel hub with

nuts.

c. Measure runout.

d. Repeat steps a. to c. so that minimum runout position can be

found.

4. If the runout is still out of specification, turn rotor with on-car

brake lathe (ªMAD, DL-8700º, ªAMMCO 700 and 705º or

equivalent).

ThicknessNJBR0033S0203Thickness variation (At least 8 positions):

Maximum 0.01 mm (0.0004 in)

If thickness variation exceeds the specification, turn rotor with on-

car brake lathe.

Rotor repair limit:

20.0 mm (0.787 in)

FRONT DISC BRAKE

Inspection (Cont'd)

BR-29

Page 547 of 2898

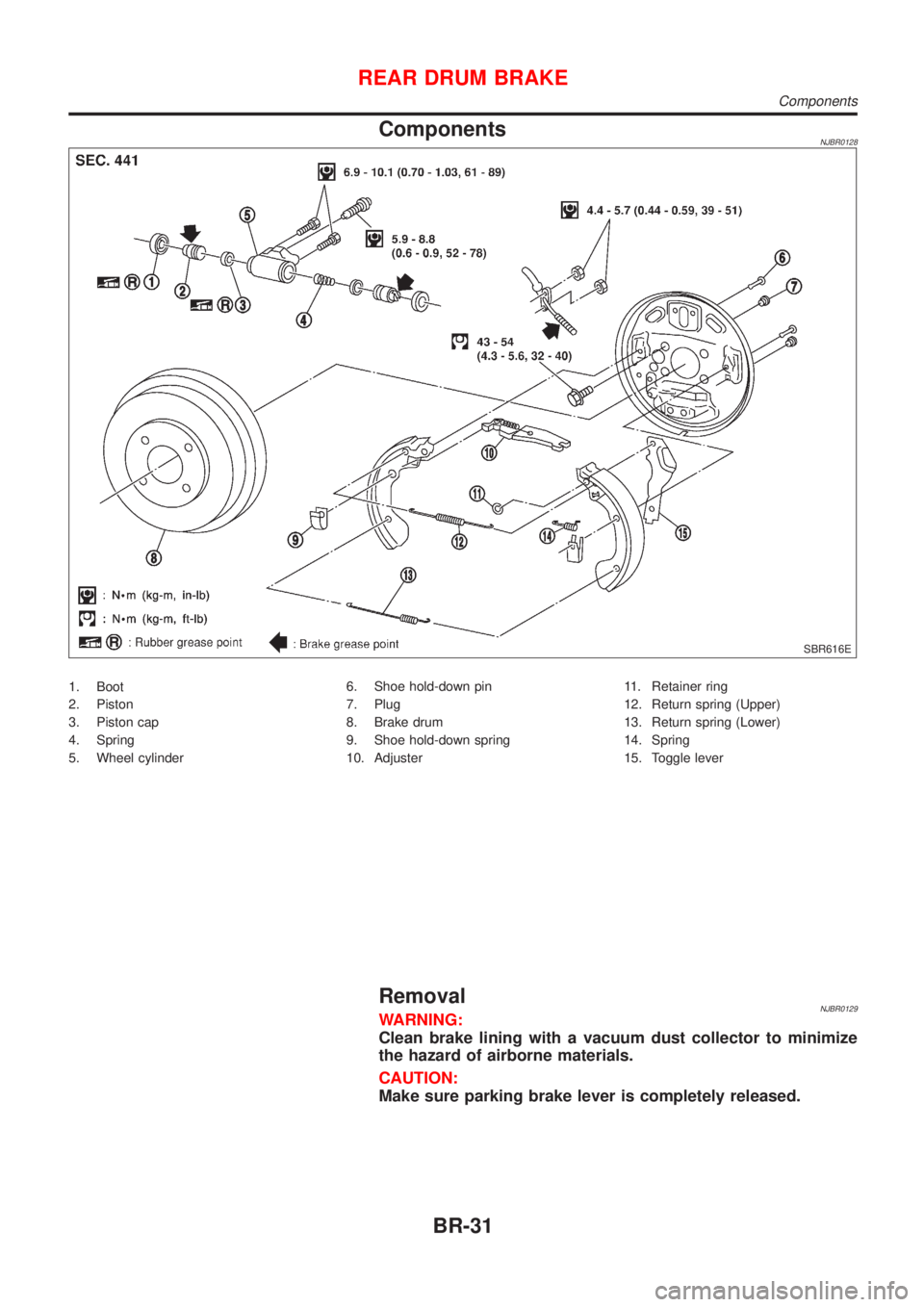

ComponentsNJBR0128

SBR616E

1. Boot

2. Piston

3. Piston cap

4. Spring

5. Wheel cylinder6. Shoe hold-down pin

7. Plug

8. Brake drum

9. Shoe hold-down spring

10. Adjuster11. Retainer ring

12. Return spring (Upper)

13. Return spring (Lower)

14. Spring

15. Toggle lever

RemovalNJBR0129WARNING:

Clean brake lining with a vacuum dust collector to minimize

the hazard of airborne materials.

CAUTION:

Make sure parking brake lever is completely released.

REAR DRUM BRAKE

Components

BR-31

Page 548 of 2898

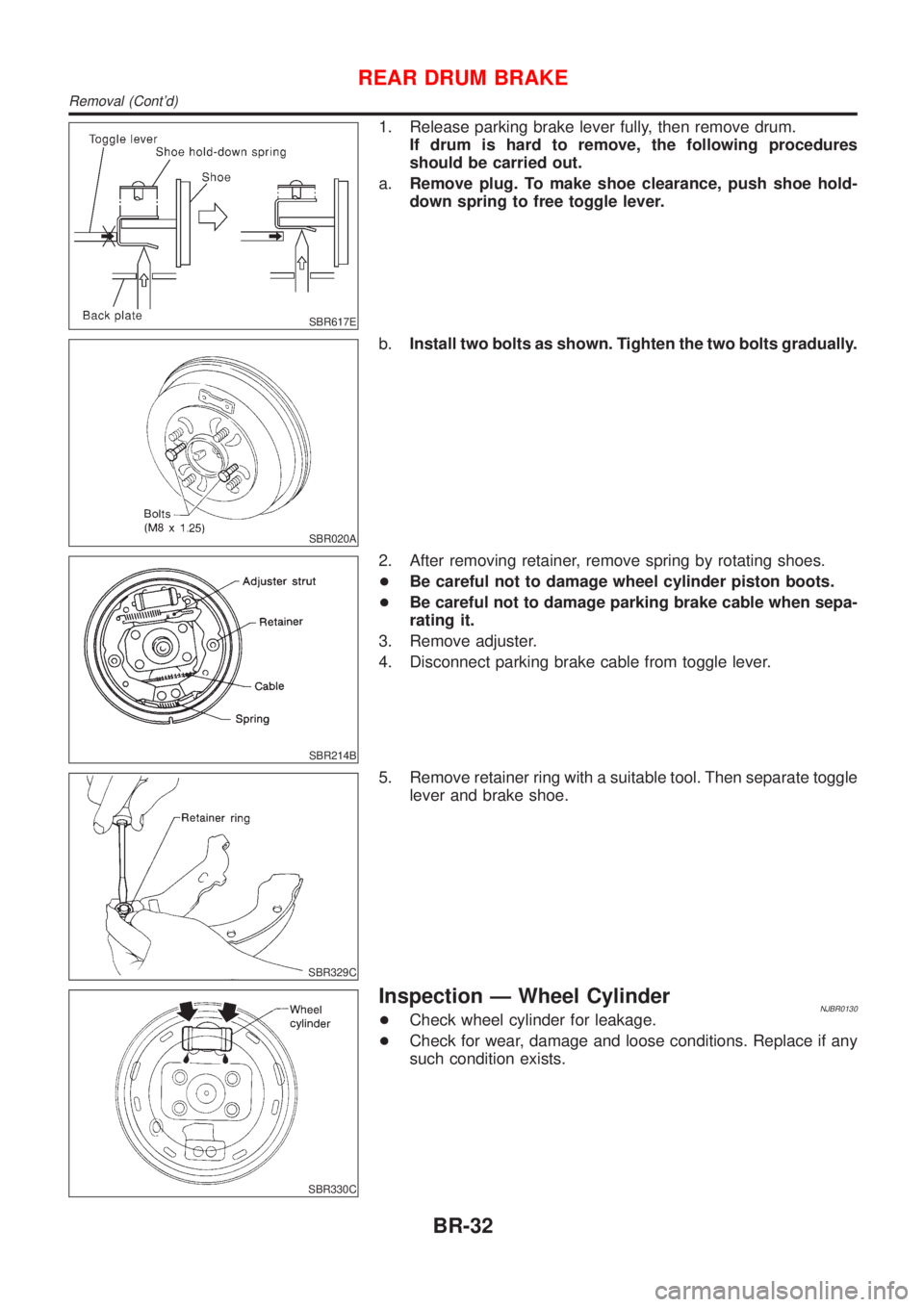

SBR617E

1. Release parking brake lever fully, then remove drum.

If drum is hard to remove, the following procedures

should be carried out.

a.Remove plug. To make shoe clearance, push shoe hold-

down spring to free toggle lever.

SBR020A

b.Install two bolts as shown. Tighten the two bolts gradually.

SBR214B

2. After removing retainer, remove spring by rotating shoes.

+Be careful not to damage wheel cylinder piston boots.

+Be careful not to damage parking brake cable when sepa-

rating it.

3. Remove adjuster.

4. Disconnect parking brake cable from toggle lever.

SBR329C

5. Remove retainer ring with a suitable tool. Then separate toggle

lever and brake shoe.

SBR330C

Inspection Ð Wheel CylinderNJBR0130+Check wheel cylinder for leakage.

+Check for wear, damage and loose conditions. Replace if any

such condition exists.

REAR DRUM BRAKE

Removal (Cont'd)

BR-32

Page 549 of 2898

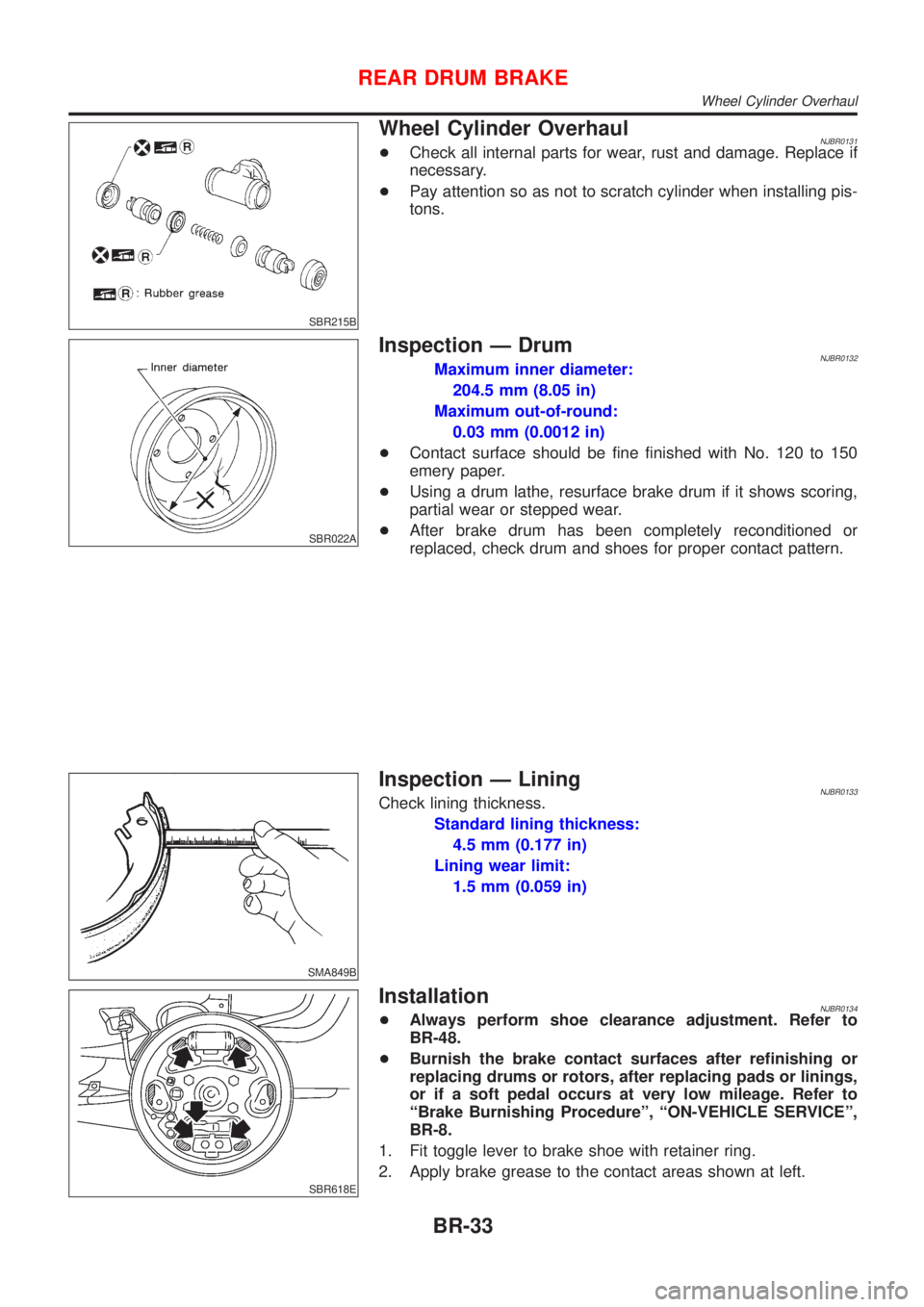

SBR215B

Wheel Cylinder OverhaulNJBR0131+Check all internal parts for wear, rust and damage. Replace if

necessary.

+Pay attention so as not to scratch cylinder when installing pis-

tons.

SBR022A

Inspection Ð DrumNJBR0132Maximum inner diameter:

204.5 mm (8.05 in)

Maximum out-of-round:

0.03 mm (0.0012 in)

+Contact surface should be fine finished with No. 120 to 150

emery paper.

+Using a drum lathe, resurface brake drum if it shows scoring,

partial wear or stepped wear.

+After brake drum has been completely reconditioned or

replaced, check drum and shoes for proper contact pattern.

SMA849B

Inspection Ð LiningNJBR0133Check lining thickness.

Standard lining thickness:

4.5 mm (0.177 in)

Lining wear limit:

1.5 mm (0.059 in)

SBR618E

InstallationNJBR0134+Always perform shoe clearance adjustment. Refer to

BR-48.

+Burnish the brake contact surfaces after refinishing or

replacing drums or rotors, after replacing pads or linings,

or if a soft pedal occurs at very low mileage. Refer to

ªBrake Burnishing Procedureº, ªON-VEHICLE SERVICEº,

BR-8.

1. Fit toggle lever to brake shoe with retainer ring.

2. Apply brake grease to the contact areas shown at left.

REAR DRUM BRAKE

Wheel Cylinder Overhaul

BR-33

Page 550 of 2898

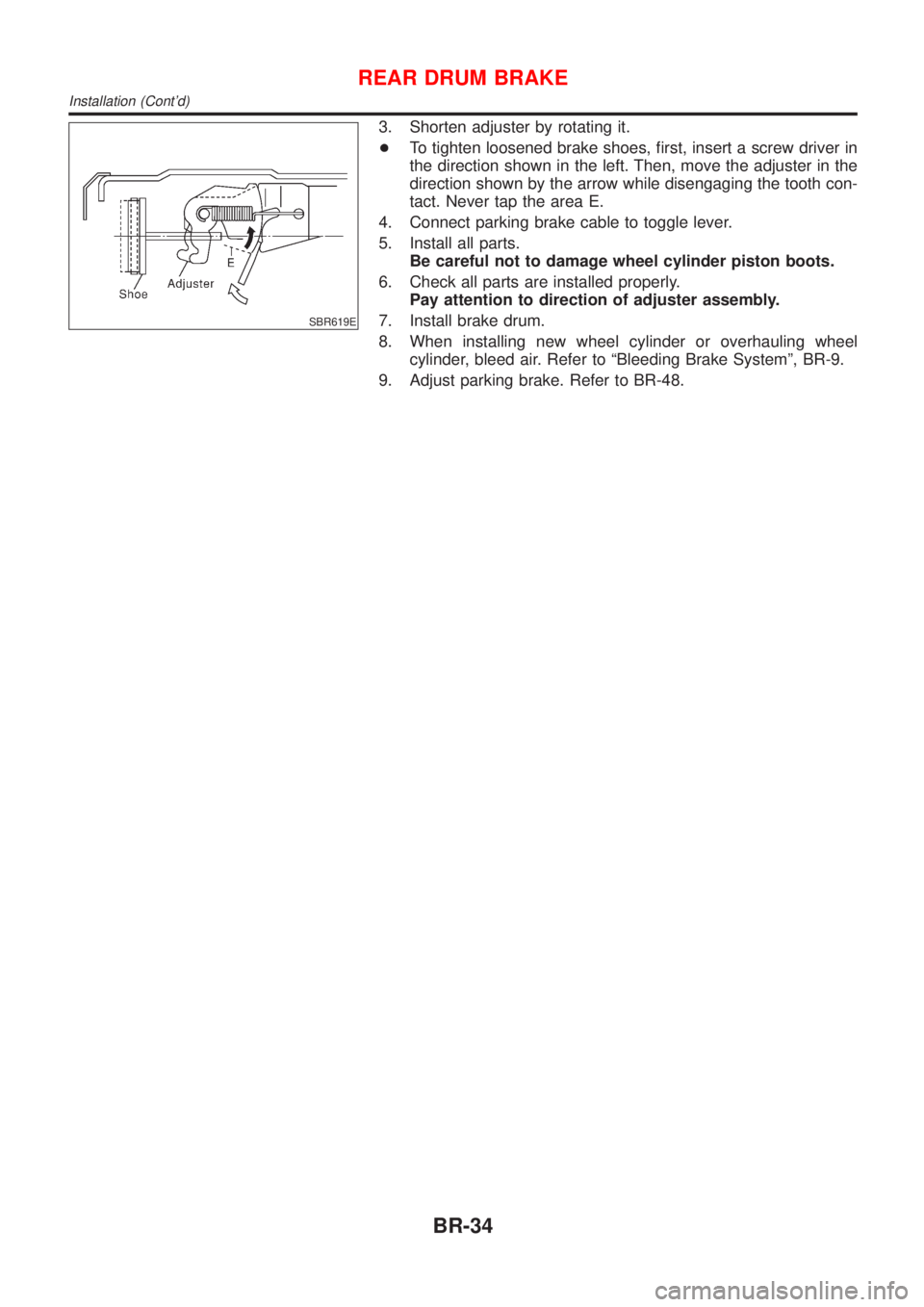

SBR619E

3. Shorten adjuster by rotating it.

+To tighten loosened brake shoes, first, insert a screw driver in

the direction shown in the left. Then, move the adjuster in the

direction shown by the arrow while disengaging the tooth con-

tact. Never tap the area E.

4. Connect parking brake cable to toggle lever.

5. Install all parts.

Be careful not to damage wheel cylinder piston boots.

6. Check all parts are installed properly.

Pay attention to direction of adjuster assembly.

7. Install brake drum.

8. When installing new wheel cylinder or overhauling wheel

cylinder, bleed air. Refer to ªBleeding Brake Systemº, BR-9.

9. Adjust parking brake. Refer to BR-48.

REAR DRUM BRAKE

Installation (Cont'd)

BR-34

Page 555 of 2898

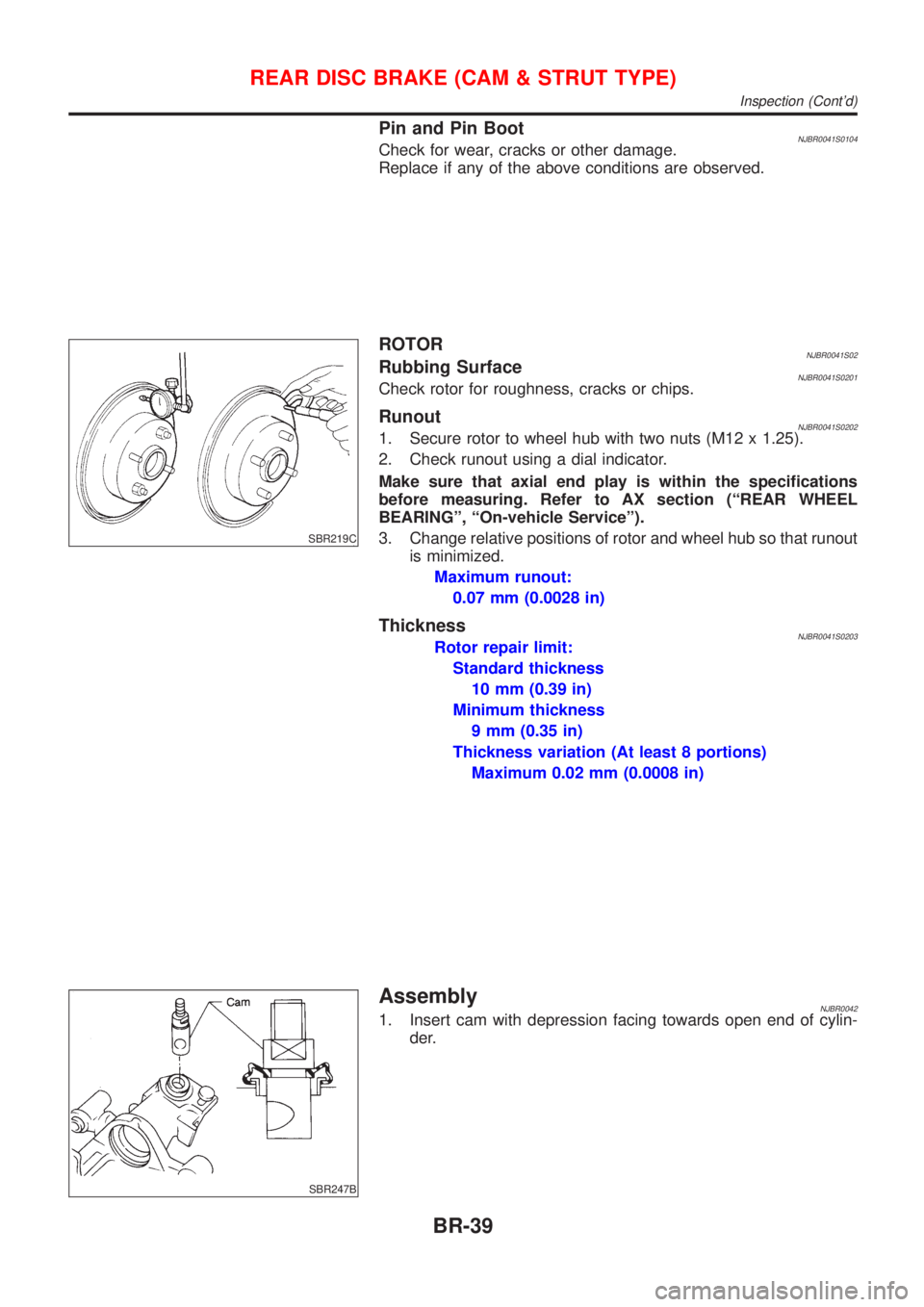

Pin and Pin BootNJBR0041S0104Check for wear, cracks or other damage.

Replace if any of the above conditions are observed.

SBR219C

ROTORNJBR0041S02Rubbing SurfaceNJBR0041S0201Check rotor for roughness, cracks or chips.

RunoutNJBR0041S02021. Secure rotor to wheel hub with two nuts (M12 x 1.25).

2. Check runout using a dial indicator.

Make sure that axial end play is within the specifications

before measuring. Refer to AX section (ªREAR WHEEL

BEARINGº, ªOn-vehicle Serviceº).

3. Change relative positions of rotor and wheel hub so that runout

is minimized.

Maximum runout:

0.07 mm (0.0028 in)

ThicknessNJBR0041S0203Rotor repair limit:

Standard thickness

10 mm (0.39 in)

Minimum thickness

9 mm (0.35 in)

Thickness variation (At least 8 portions)

Maximum 0.02 mm (0.0008 in)

SBR247B

AssemblyNJBR00421. Insert cam with depression facing towards open end of cylin-

der.

REAR DISC BRAKE (CAM & STRUT TYPE)

Inspection (Cont'd)

BR-39

Page 562 of 2898

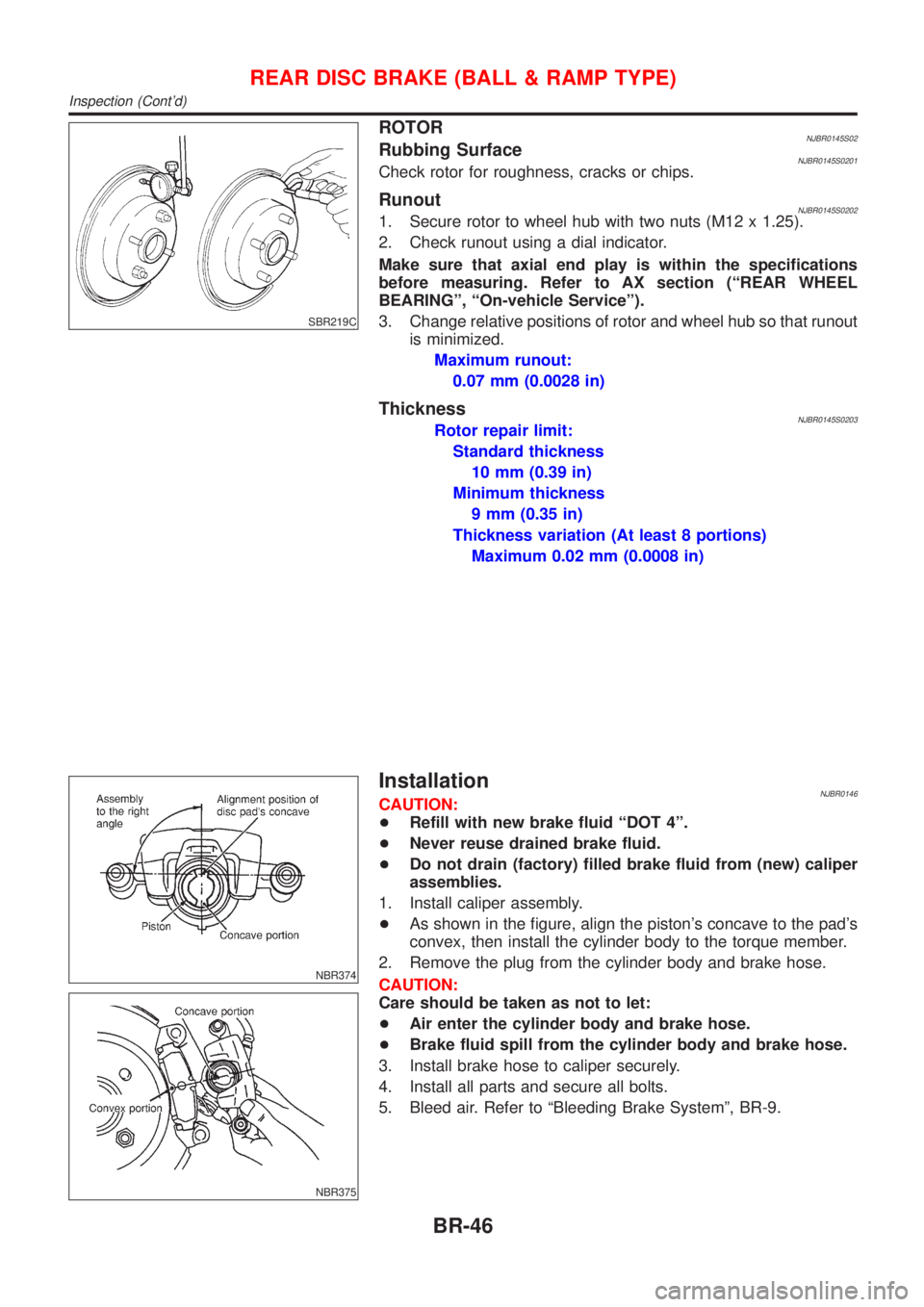

SBR219C

ROTORNJBR0145S02Rubbing SurfaceNJBR0145S0201Check rotor for roughness, cracks or chips.

RunoutNJBR0145S02021. Secure rotor to wheel hub with two nuts (M12 x 1.25).

2. Check runout using a dial indicator.

Make sure that axial end play is within the specifications

before measuring. Refer to AX section (ªREAR WHEEL

BEARINGº, ªOn-vehicle Serviceº).

3. Change relative positions of rotor and wheel hub so that runout

is minimized.

Maximum runout:

0.07 mm (0.0028 in)

ThicknessNJBR0145S0203Rotor repair limit:

Standard thickness

10 mm (0.39 in)

Minimum thickness

9 mm (0.35 in)

Thickness variation (At least 8 portions)

Maximum 0.02 mm (0.0008 in)

NBR374

NBR375

InstallationNJBR0146CAUTION:

+Refill with new brake fluid ªDOT 4º.

+Never reuse drained brake fluid.

+Do not drain (factory) filled brake fluid from (new) caliper

assemblies.

1. Install caliper assembly.

+As shown in the figure, align the piston's concave to the pad's

convex, then install the cylinder body to the torque member.

2. Remove the plug from the cylinder body and brake hose.

CAUTION:

Care should be taken as not to let:

+Air enter the cylinder body and brake hose.

+Brake fluid spill from the cylinder body and brake hose.

3. Install brake hose to caliper securely.

4. Install all parts and secure all bolts.

5. Bleed air. Refer to ªBleeding Brake Systemº, BR-9.

REAR DISC BRAKE (BALL & RAMP TYPE)

Inspection (Cont'd)

BR-46

Page 565 of 2898

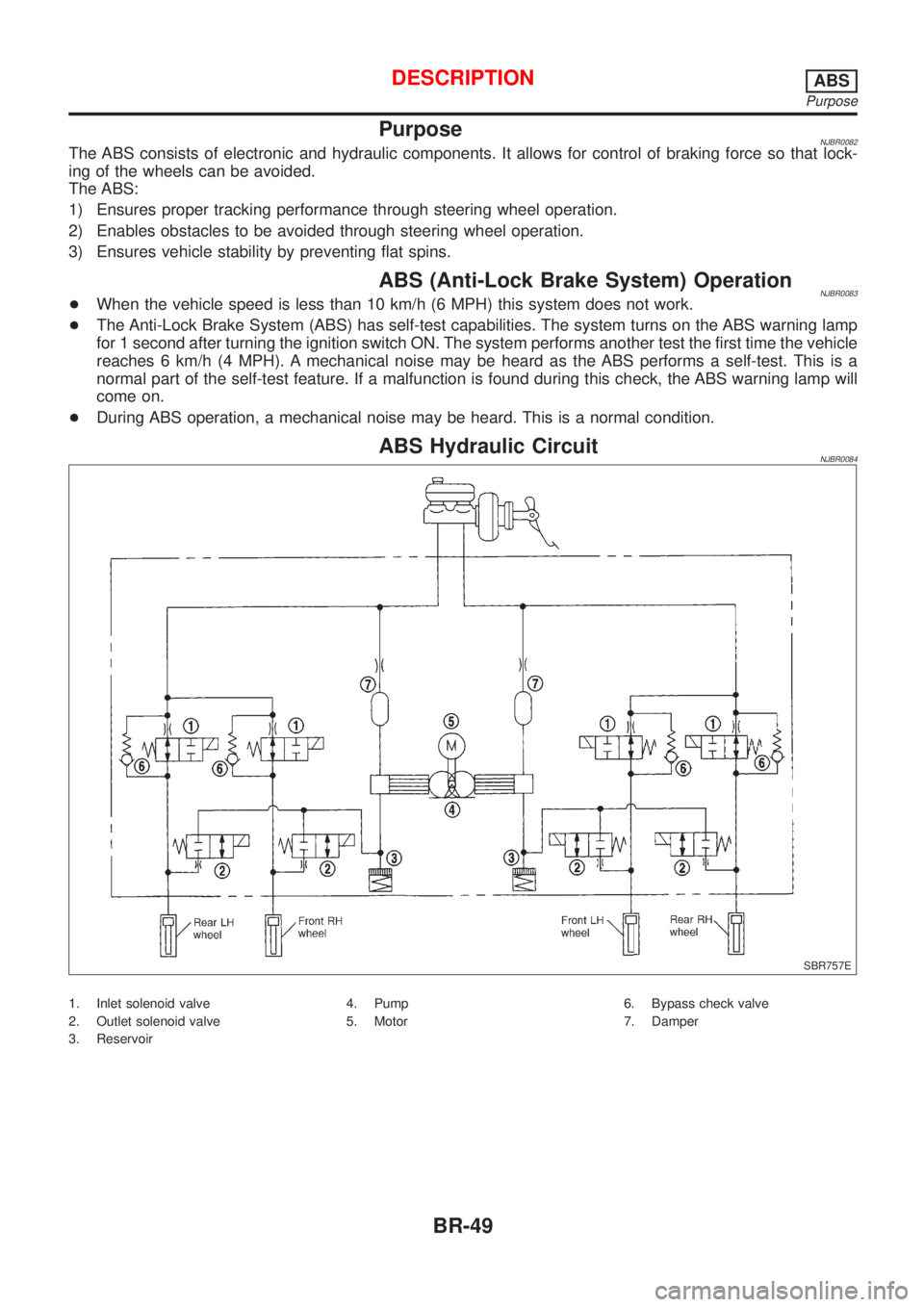

PurposeNJBR0082The ABS consists of electronic and hydraulic components. It allows for control of braking force so that lock-

ing of the wheels can be avoided.

The ABS:

1) Ensures proper tracking performance through steering wheel operation.

2) Enables obstacles to be avoided through steering wheel operation.

3) Ensures vehicle stability by preventing flat spins.

ABS (Anti-Lock Brake System) OperationNJBR0083+When the vehicle speed is less than 10 km/h (6 MPH) this system does not work.

+The Anti-Lock Brake System (ABS) has self-test capabilities. The system turns on the ABS warning lamp

for 1 second after turning the ignition switch ON. The system performs another test the first time the vehicle

reaches 6 km/h (4 MPH). A mechanical noise may be heard as the ABS performs a self-test. This is a

normal part of the self-test feature. If a malfunction is found during this check, the ABS warning lamp will

come on.

+During ABS operation, a mechanical noise may be heard. This is a normal condition.

ABS Hydraulic CircuitNJBR0084

SBR757E

1. Inlet solenoid valve

2. Outlet solenoid valve

3. Reservoir4. Pump

5. Motor6. Bypass check valve

7. Damper

DESCRIPTIONABS

Purpose

BR-49