NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 701 of 2898

CLUTCH

SECTION

CL

CONTENTS

PRECAUTIONS...............................................................2

Precautions ..................................................................2

PREPARATION...............................................................3

Special Service Tools ..................................................3

Commercial Service Tools ...........................................3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................4

NVH Troubleshooting Chart.........................................4

CLUTCH...................................................................4

CLUTCH SYSTEM...........................................................5

Components - RHD Model with QG Engine - .............5

Components - LHD Model with QG Engine -..............6

Components - RHD Model with YD Engine -..............7

Components - LHD Model with YD Engine - ..............8

Inspection and Adjustment ..........................................9

CLUTCH PEDAL INSPECTION...................................9

CLUTCH PEDAL ADJUSTMENT...............................10

AIR BLEEDING PROCEDURE..................................10

CLUTCH MASTER CYLINDER..................................... 11

Components............................................................... 11

Removal .....................................................................12

Installation ..................................................................12

Disassembly...............................................................12

Inspection...................................................................12

Assembly ...................................................................13

OPERATING CYLINDER...............................................14

Components...............................................................14

Removal .....................................................................14

Disassembly...............................................................14

Inspection...................................................................14

Assembly ...................................................................15

Installation ..................................................................15

PIPING...........................................................................16

Removal .....................................................................16Installation ..................................................................16

RS5F30A, RS5F70A

CLUTCH RELEASE MECHANISM...............................17

Components...............................................................17

Removal .....................................................................17

Inspection...................................................................17

Installation ..................................................................17

RS5F50A

CLUTCH RELEASE MECHANISM...............................20

Components...............................................................20

Removal .....................................................................20

Inspection...................................................................20

Installation ..................................................................20

CLUTCH DISC, CLUTCH COVER AND

FLYWHEEL....................................................................22

Components...............................................................22

Inspection and Adjustment ........................................22

CLUTCH DISC.........................................................22

CLUTCH COVER.....................................................23

FLYWHEEL.............................................................23

Installation ..................................................................23

SERVICE DATA AND SPECIFICATIONS (SDS).........24

Clutch Control System ...............................................24

Clutch Master Cylinder ..............................................24

Clutch Operating Cylinder .........................................24

Clutch Disc.................................................................24

Clutch Cover ..............................................................24

Clutch Pedal ..............................................................24

Page 702 of 2898

SBR820BA

PrecautionsNJCL0001+Recommended fluid is brake fluid ªDOT 4º. Refer to

MA-16, ªFluid and Lubricantsº.

+Never reuse drained brake fluid.

+Be careful not to splash brake fluid on painted areas.

+When removing and installing clutch piping, use Tool.

+Use new brake fluid to clean or wash all parts of master

cylinder and operating cylinder.

+Never use mineral oils such as gasoline or kerosene. It will

ruin the rubber parts of the hydraulic system.

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Do not

use compressed air.

PRECAUTIONS

Precautions

CL-2

Page 703 of 2898

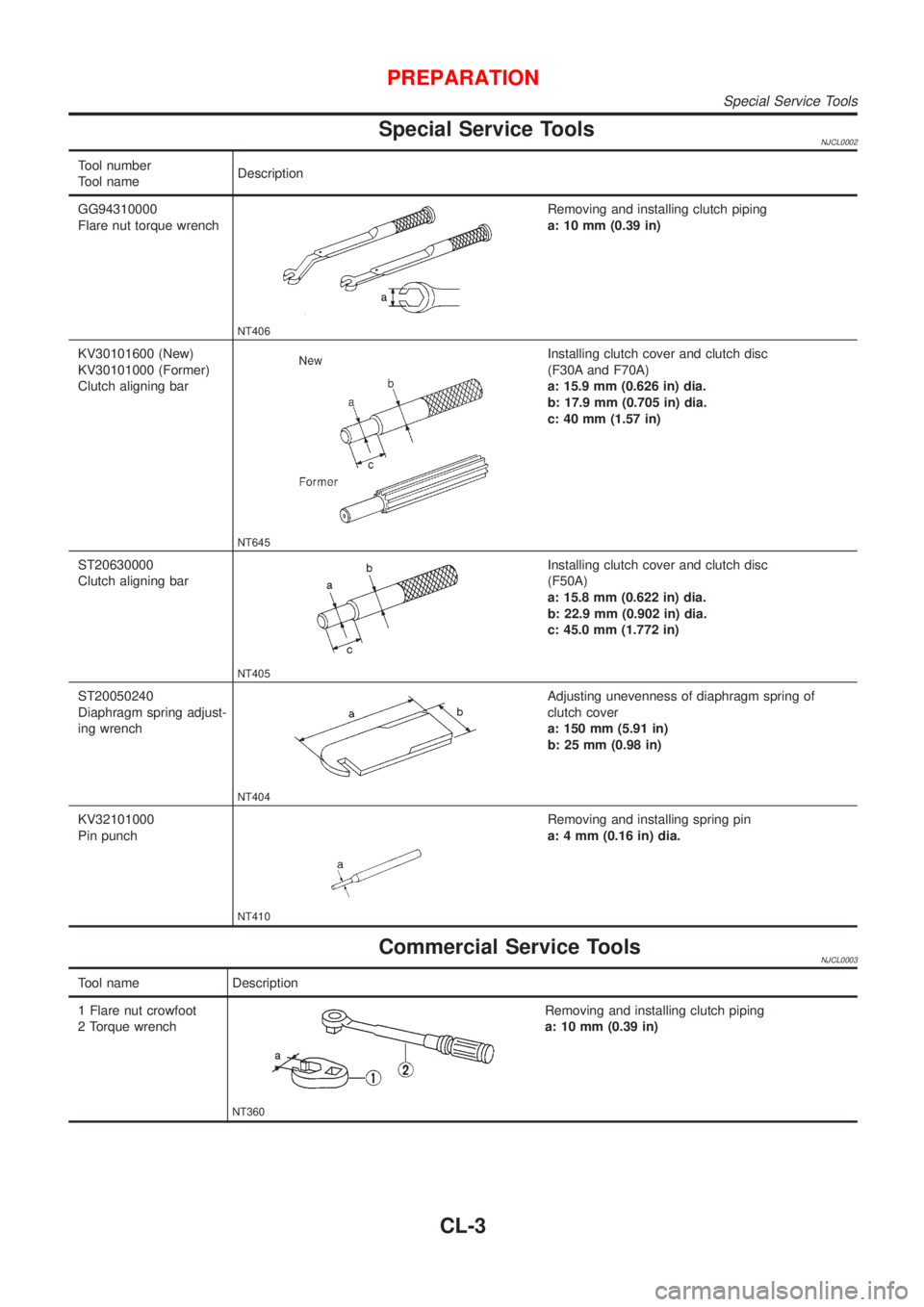

Special Service ToolsNJCL0002

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

NT406

Removing and installing clutch piping

a: 10 mm (0.39 in)

KV30101600 (New)

KV30101000 (Former)

Clutch aligning bar

NT645

Installing clutch cover and clutch disc

(F30A and F70A)

a: 15.9 mm (0.626 in) dia.

b: 17.9 mm (0.705 in) dia.

c: 40 mm (1.57 in)

ST20630000

Clutch aligning bar

NT405

Installing clutch cover and clutch disc

(F50A)

a: 15.8 mm (0.622 in) dia.

b: 22.9 mm (0.902 in) dia.

c: 45.0 mm (1.772 in)

ST20050240

Diaphragm spring adjust-

ing wrench

NT404

Adjusting unevenness of diaphragm spring of

clutch cover

a: 150 mm (5.91 in)

b: 25 mm (0.98 in)

KV32101000

Pin punch

NT410

Removing and installing spring pin

a: 4 mm (0.16 in) dia.

Commercial Service ToolsNJCL0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing clutch piping

a: 10 mm (0.39 in)

PREPARATION

Special Service Tools

CL-3

Page 704 of 2898

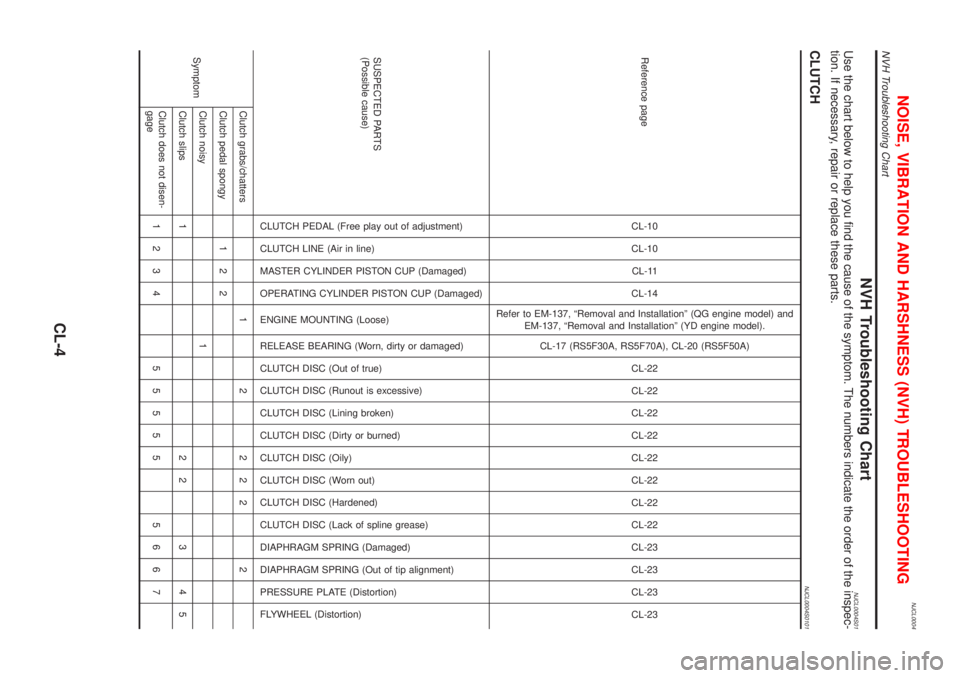

NJCL0004

NVH Troubleshooting ChartNJCL0004S01Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

CLUTCHNJCL0004S0101

Reference pageCL-10

CL-10

CL-11

CL-14

Refer to EM-137, ªRemoval and Installationº (QG engine model) and

EM-137, ªRemoval and Installationº (YD engine model).

CL-17 (RS5F30A, RS5F70A), CL-20 (RS5F50A)

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-23

CL-23

CL-23

CL-23

SUSPECTED PARTS

(Possible cause)

CLUTCH PEDAL (Free play out of adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disen-

gage1234 55555 5667

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

CL-4

Page 705 of 2898

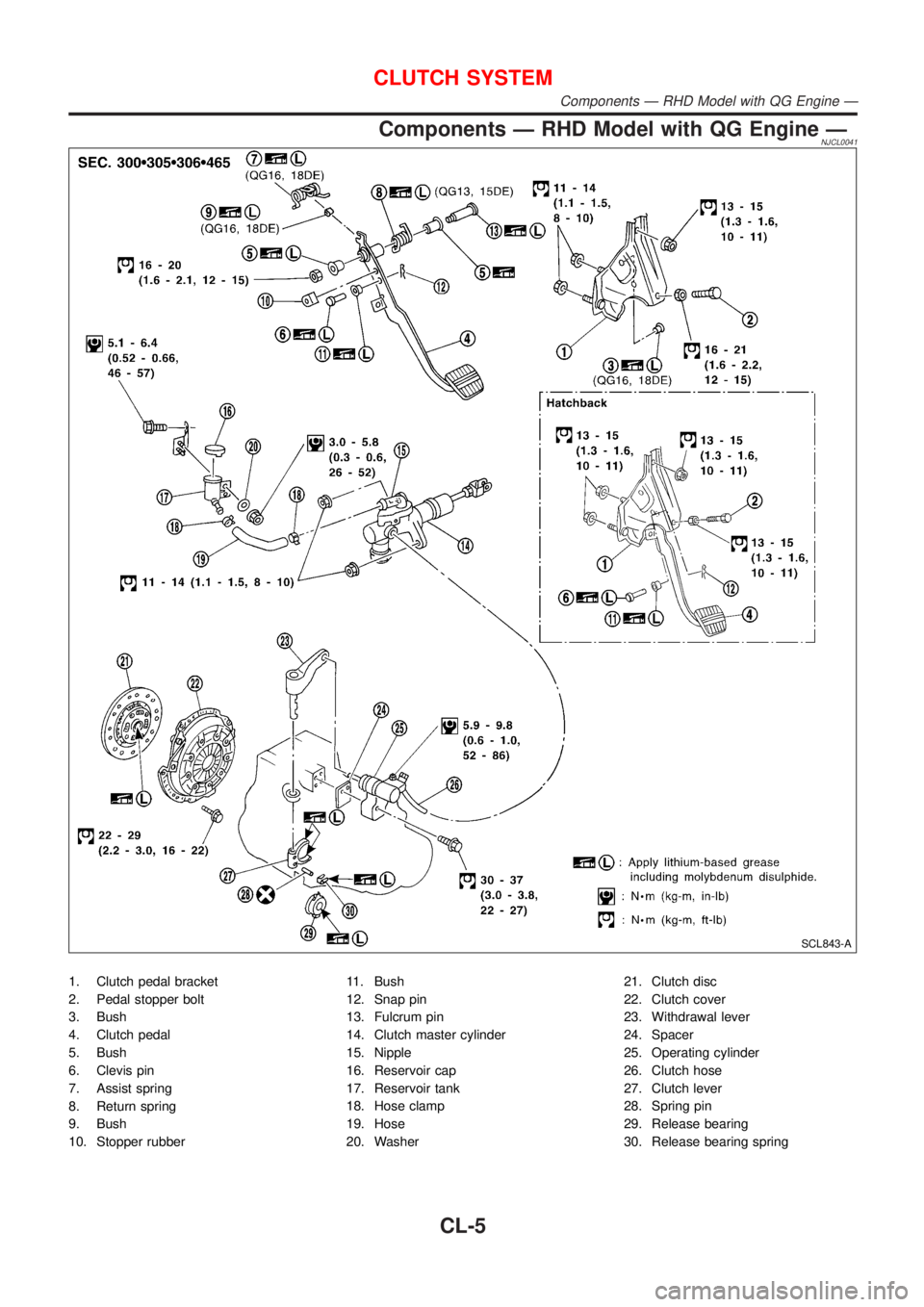

Components Ð RHD Model with QG Engine ÐNJCL0041

SCL843-A

1. Clutch pedal bracket

2. Pedal stopper bolt

3. Bush

4. Clutch pedal

5. Bush

6. Clevis pin

7. Assist spring

8. Return spring

9. Bush

10. Stopper rubber11. Bush

12. Snap pin

13. Fulcrum pin

14. Clutch master cylinder

15. Nipple

16. Reservoir cap

17. Reservoir tank

18. Hose clamp

19. Hose

20. Washer21. Clutch disc

22. Clutch cover

23. Withdrawal lever

24. Spacer

25. Operating cylinder

26. Clutch hose

27. Clutch lever

28. Spring pin

29. Release bearing

30. Release bearing spring

CLUTCH SYSTEM

Components Ð RHD Model with QG Engine Ð

CL-5

Page 706 of 2898

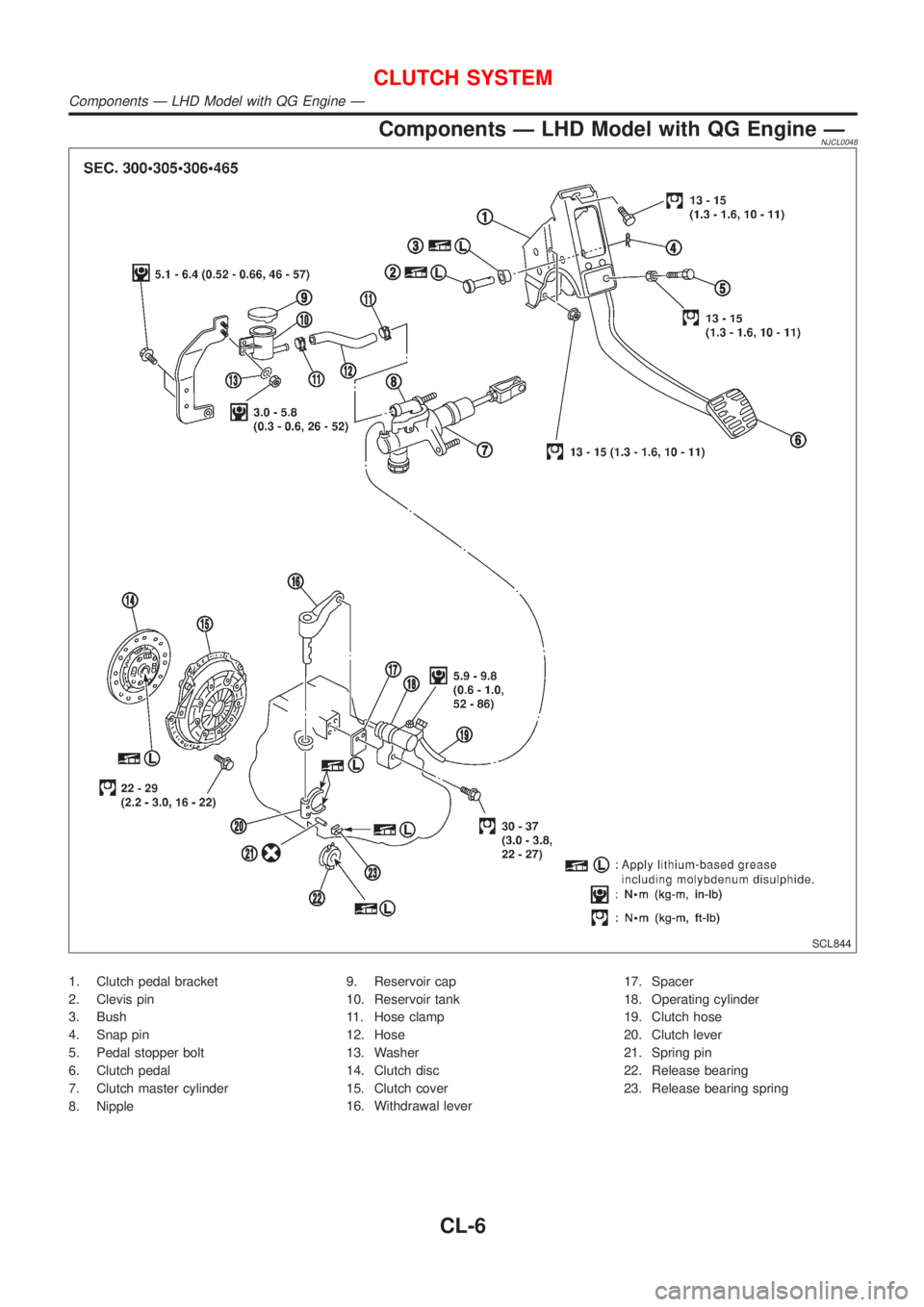

Components Ð LHD Model with QG Engine ÐNJCL0048

SCL844

1. Clutch pedal bracket

2. Clevis pin

3. Bush

4. Snap pin

5. Pedal stopper bolt

6. Clutch pedal

7. Clutch master cylinder

8. Nipple9. Reservoir cap

10. Reservoir tank

11. Hose clamp

12. Hose

13. Washer

14. Clutch disc

15. Clutch cover

16. Withdrawal lever17. Spacer

18. Operating cylinder

19. Clutch hose

20. Clutch lever

21. Spring pin

22. Release bearing

23. Release bearing spring

CLUTCH SYSTEM

Components Ð LHD Model with QG Engine Ð

CL-6

Page 707 of 2898

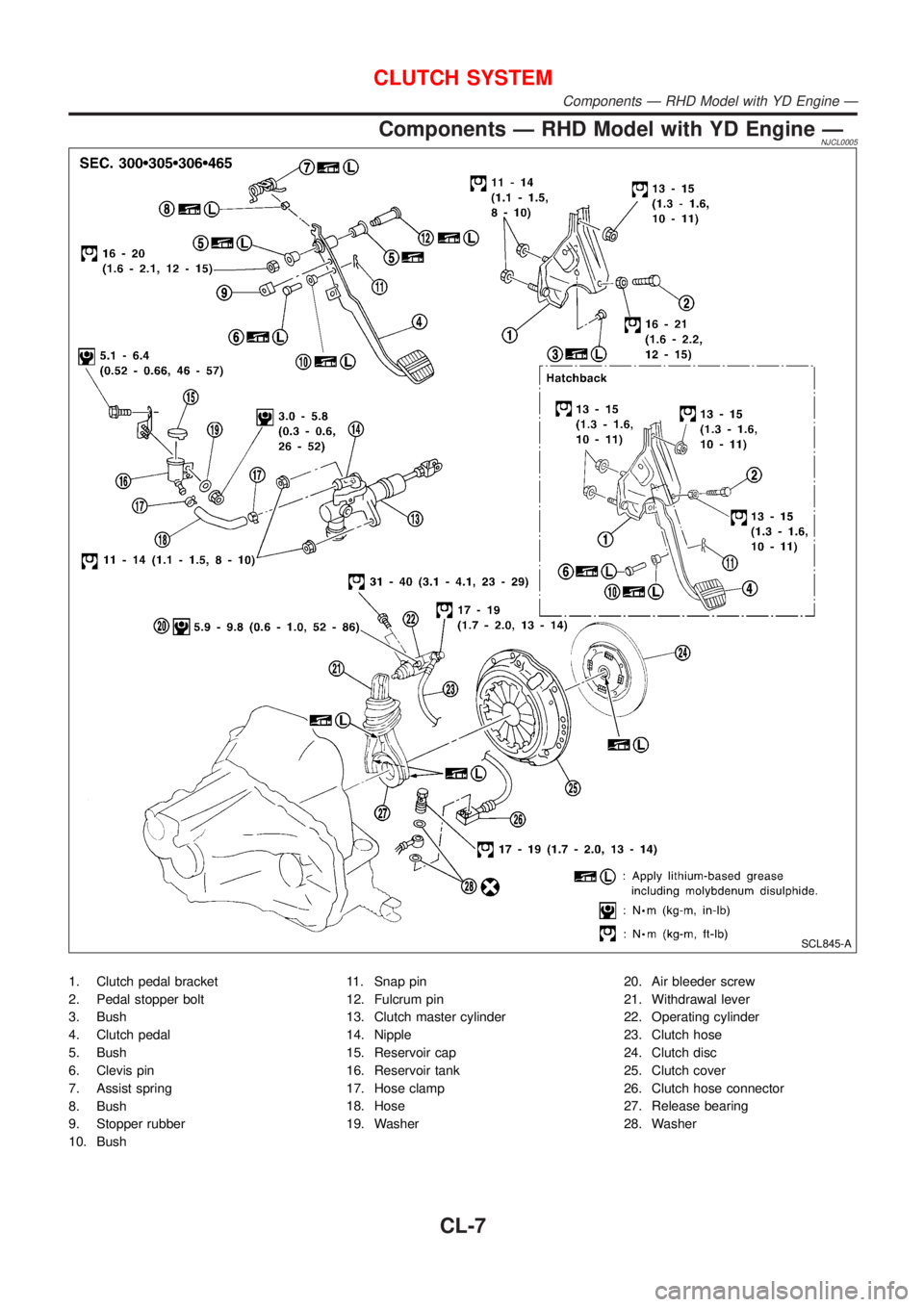

Components Ð RHD Model with YD Engine ÐNJCL0005

SCL845-A

1. Clutch pedal bracket

2. Pedal stopper bolt

3. Bush

4. Clutch pedal

5. Bush

6. Clevis pin

7. Assist spring

8. Bush

9. Stopper rubber

10. Bush11. Snap pin

12. Fulcrum pin

13. Clutch master cylinder

14. Nipple

15. Reservoir cap

16. Reservoir tank

17. Hose clamp

18. Hose

19. Washer20. Air bleeder screw

21. Withdrawal lever

22. Operating cylinder

23. Clutch hose

24. Clutch disc

25. Clutch cover

26. Clutch hose connector

27. Release bearing

28. Washer

CLUTCH SYSTEM

Components Ð RHD Model with YD Engine Ð

CL-7

Page 708 of 2898

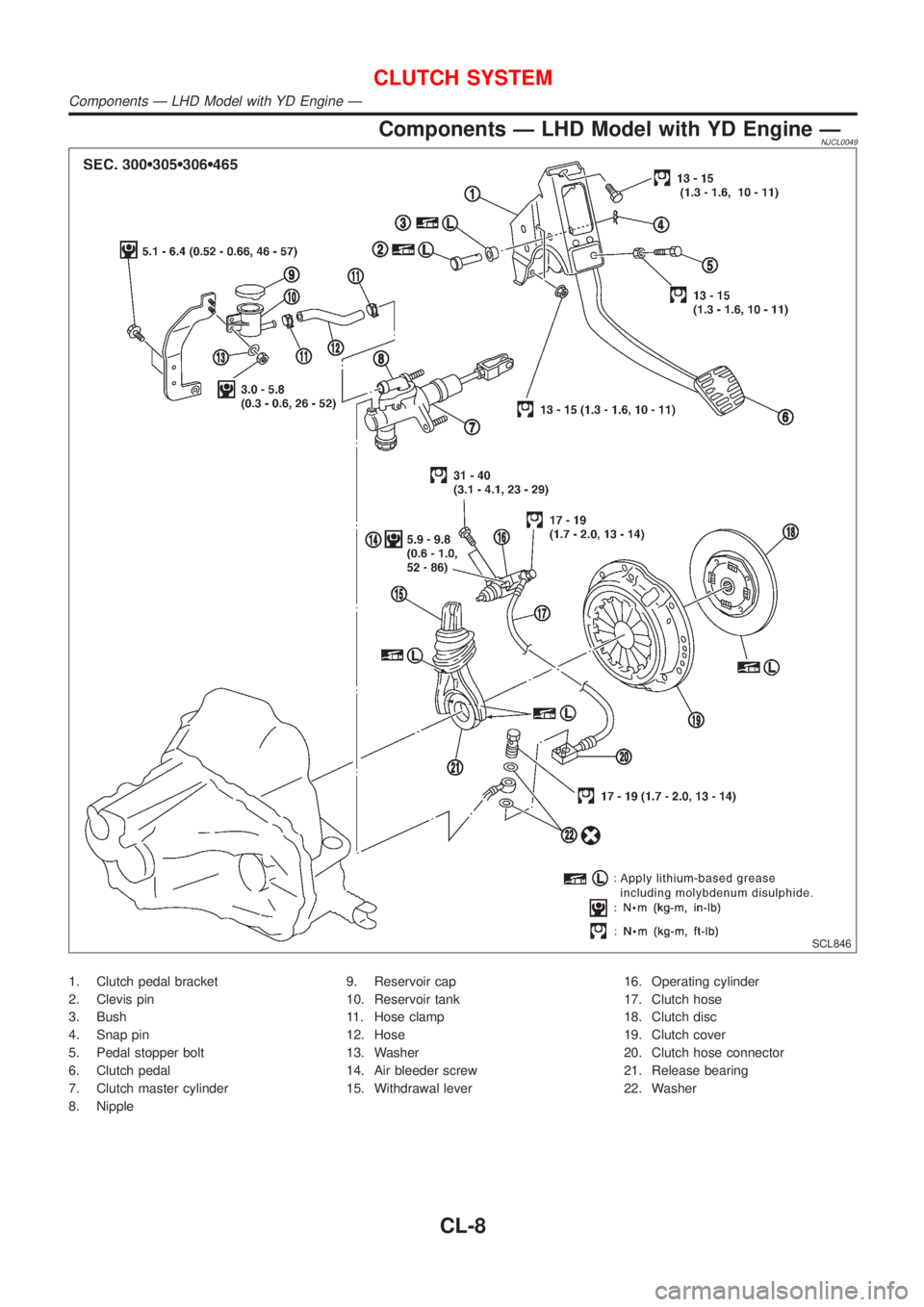

Components Ð LHD Model with YD Engine ÐNJCL0049

SCL846

1. Clutch pedal bracket

2. Clevis pin

3. Bush

4. Snap pin

5. Pedal stopper bolt

6. Clutch pedal

7. Clutch master cylinder

8. Nipple9. Reservoir cap

10. Reservoir tank

11. Hose clamp

12. Hose

13. Washer

14. Air bleeder screw

15. Withdrawal lever16. Operating cylinder

17. Clutch hose

18. Clutch disc

19. Clutch cover

20. Clutch hose connector

21. Release bearing

22. Washer

CLUTCH SYSTEM

Components Ð LHD Model with YD Engine Ð

CL-8

Page 709 of 2898

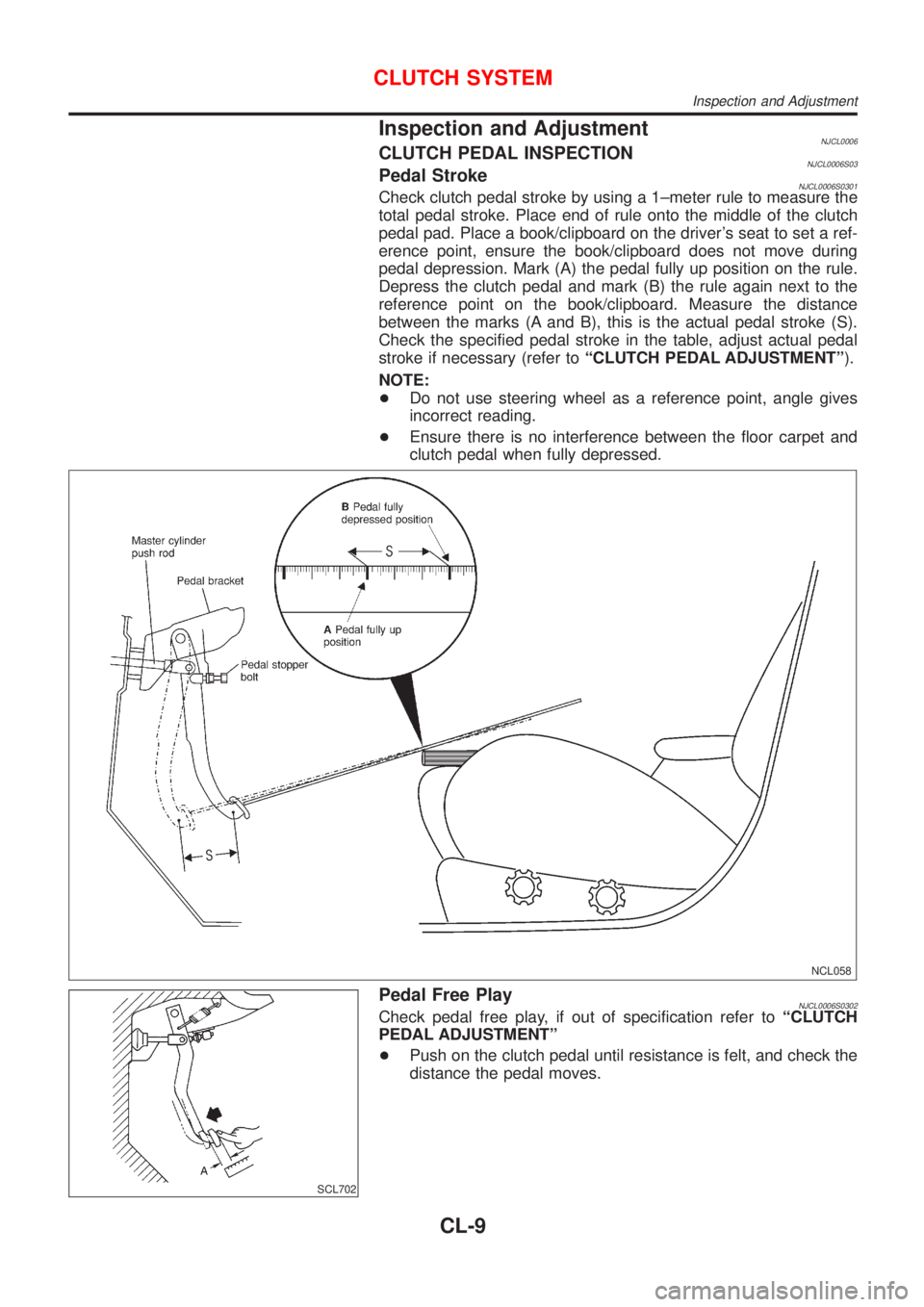

Inspection and AdjustmentNJCL0006CLUTCH PEDAL INSPECTIONNJCL0006S03Pedal StrokeNJCL0006S0301Check clutch pedal stroke by using a 1±meter rule to measure the

total pedal stroke. Place end of rule onto the middle of the clutch

pedal pad. Place a book/clipboard on the driver's seat to set a ref-

erence point, ensure the book/clipboard does not move during

pedal depression. Mark (A) the pedal fully up position on the rule.

Depress the clutch pedal and mark (B) the rule again next to the

reference point on the book/clipboard. Measure the distance

between the marks (A and B), this is the actual pedal stroke (S).

Check the specified pedal stroke in the table, adjust actual pedal

stroke if necessary (refer toªCLUTCH PEDAL ADJUSTMENTº).

NOTE:

+Do not use steering wheel as a reference point, angle gives

incorrect reading.

+Ensure there is no interference between the floor carpet and

clutch pedal when fully depressed.

NCL058

SCL702

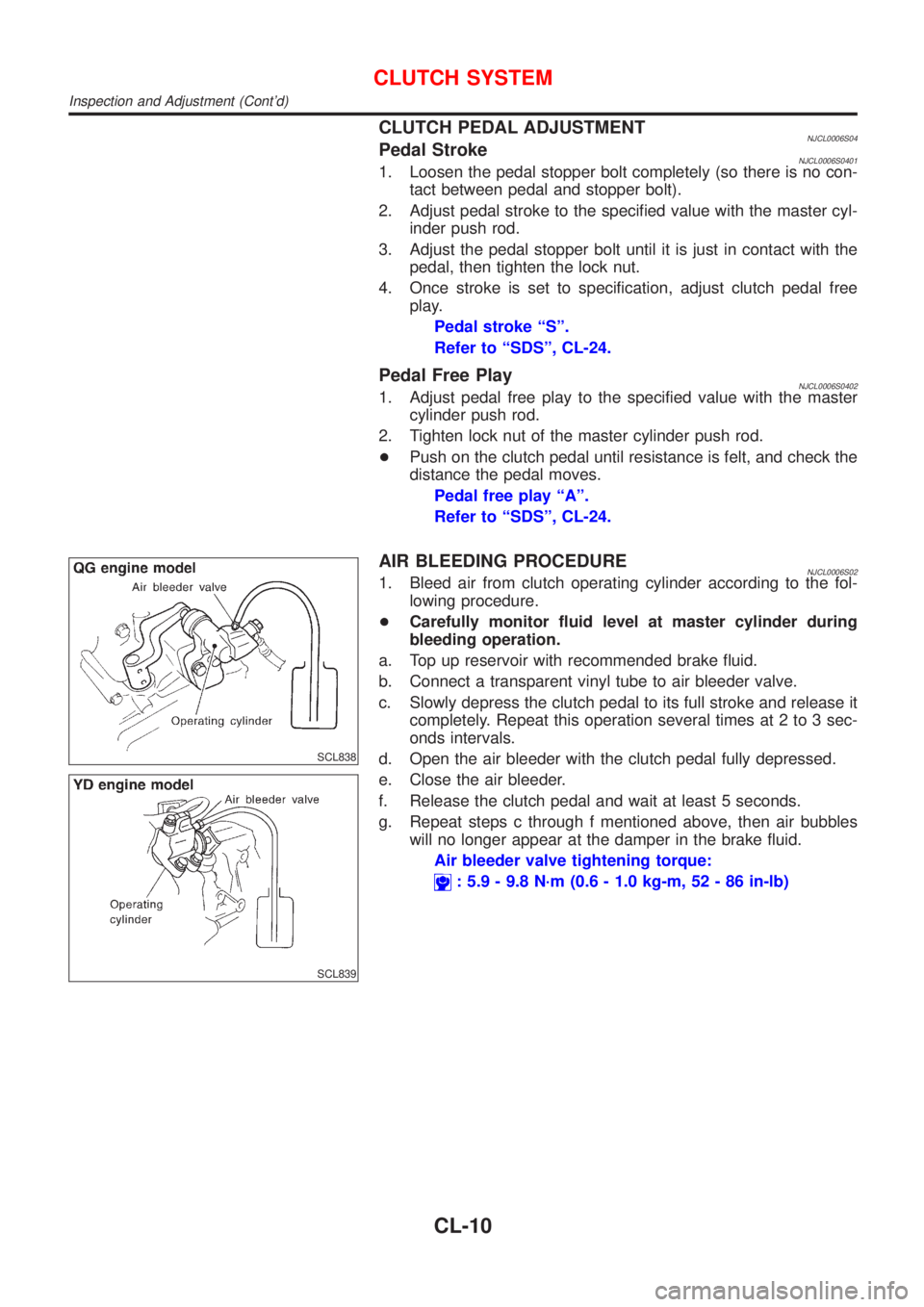

Pedal Free PlayNJCL0006S0302Check pedal free play, if out of specification refer toªCLUTCH

PEDAL ADJUSTMENTº

+Push on the clutch pedal until resistance is felt, and check the

distance the pedal moves.

CLUTCH SYSTEM

Inspection and Adjustment

CL-9

Page 710 of 2898

CLUTCH PEDAL ADJUSTMENTNJCL0006S04Pedal StrokeNJCL0006S04011. Loosen the pedal stopper bolt completely (so there is no con-

tact between pedal and stopper bolt).

2. Adjust pedal stroke to the specified value with the master cyl-

inder push rod.

3. Adjust the pedal stopper bolt until it is just in contact with the

pedal, then tighten the lock nut.

4. Once stroke is set to specification, adjust clutch pedal free

play.

Pedal stroke ªSº.

Refer to ªSDSº, CL-24.

Pedal Free PlayNJCL0006S04021. Adjust pedal free play to the specified value with the master

cylinder push rod.

2. Tighten lock nut of the master cylinder push rod.

+Push on the clutch pedal until resistance is felt, and check the

distance the pedal moves.

Pedal free play ªAº.

Refer to ªSDSº, CL-24.

SCL838

SCL839

AIR BLEEDING PROCEDURENJCL0006S021. Bleed air from clutch operating cylinder according to the fol-

lowing procedure.

+Carefully monitor fluid level at master cylinder during

bleeding operation.

a. Top up reservoir with recommended brake fluid.

b. Connect a transparent vinyl tube to air bleeder valve.

c. Slowly depress the clutch pedal to its full stroke and release it

completely. Repeat this operation several times at 2 to 3 sec-

onds intervals.

d. Open the air bleeder with the clutch pedal fully depressed.

e. Close the air bleeder.

f. Release the clutch pedal and wait at least 5 seconds.

g. Repeat steps c through f mentioned above, then air bubbles

will no longer appear at the damper in the brake fluid.

Air bleeder valve tightening torque:

: 5.9 - 9.8 N´m (0.6 - 1.0 kg-m, 52 - 86 in-lb)

CLUTCH SYSTEM

Inspection and Adjustment (Cont'd)

CL-10