NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 721 of 2898

![NISSAN ALMERA 2001 Service Manual +Clean old grease and abrasive materials off the grease

application area.

SCL815

NOTE:

+Equally apply a coat [approximately 1 mm (0.04 in) thick] of

clutch sleeve grease to withdrawal lever and holder NISSAN ALMERA 2001 Service Manual +Clean old grease and abrasive materials off the grease

application area.

SCL815

NOTE:

+Equally apply a coat [approximately 1 mm (0.04 in) thick] of

clutch sleeve grease to withdrawal lever and holder](/img/5/57348/w960_57348-720.png)

+Clean old grease and abrasive materials off the grease

application area.

SCL815

NOTE:

+Equally apply a coat [approximately 1 mm (0.04 in) thick] of

clutch sleeve grease to withdrawal lever and holder spring

frictional surfaces.

+Apply a coat of clutch sleeve grease to the grooves on contact

surfaces of the withdrawal lever ball pin and inner surface of

release bearing so that grease application, make sure that

grease is flush with grooves.

+Equally apply a thin coat of clutch sleeve grease to release

bearing frictional surface. After grease application, install

release bearing. Wipe off excess grease forced out during

bearing installation. Remove release bearing.

2. Installation is in the reverse order of removal.

CLUTCH RELEASE MECHANISMRS5F50A

Installation (Cont'd)

CL-21

Page 722 of 2898

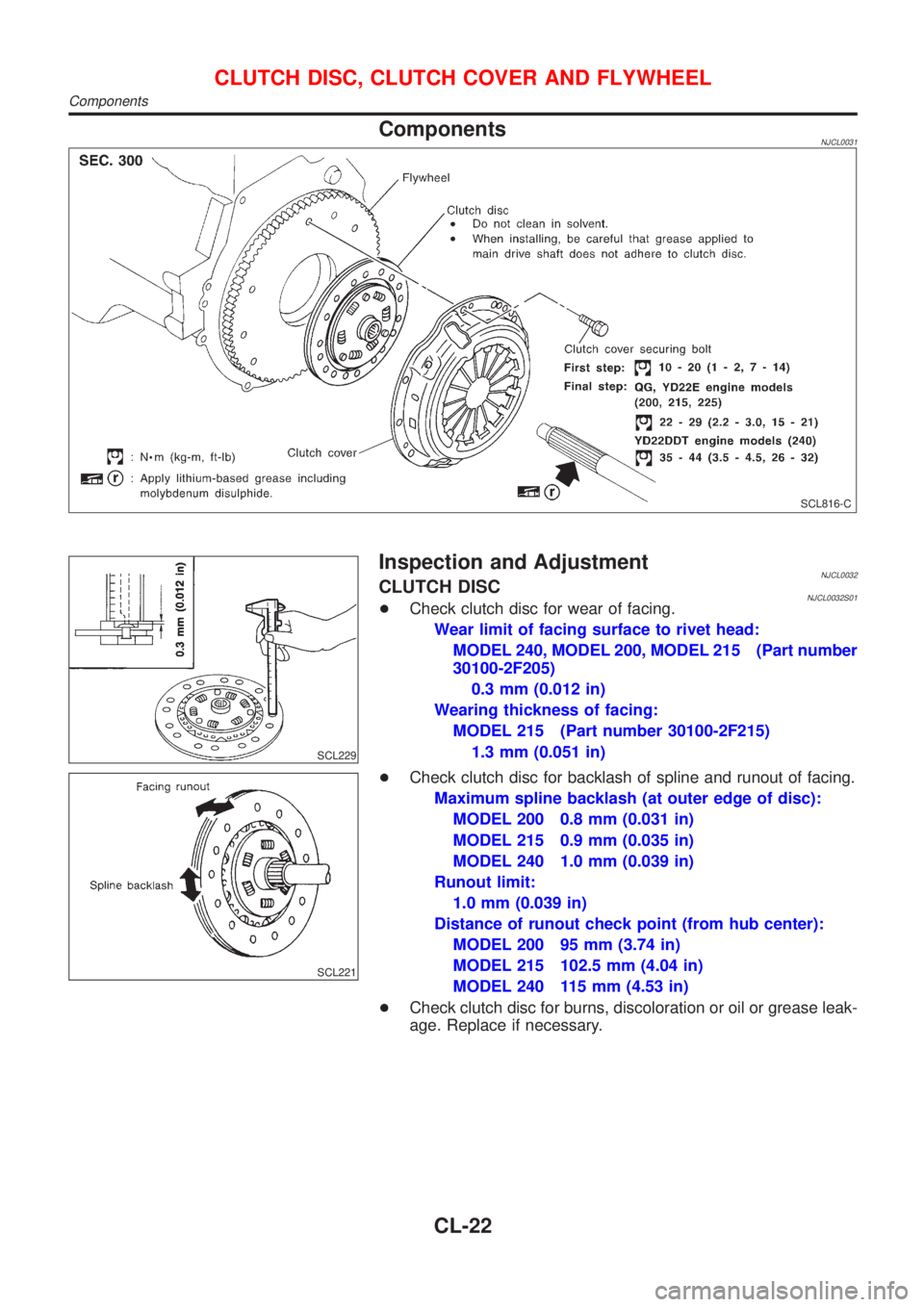

ComponentsNJCL0031

SCL816-C

SCL229

Inspection and AdjustmentNJCL0032CLUTCH DISCNJCL0032S01+Check clutch disc for wear of facing.

Wear limit of facing surface to rivet head:

MODEL 240, MODEL 200, MODEL 215 (Part number

30100-2F205)

0.3 mm (0.012 in)

Wearing thickness of facing:

MODEL 215 (Part number 30100-2F215)

1.3 mm (0.051 in)

SCL221

+Check clutch disc for backlash of spline and runout of facing.

Maximum spline backlash (at outer edge of disc):

MODEL 200 0.8 mm (0.031 in)

MODEL 215 0.9 mm (0.035 in)

MODEL 240 1.0 mm (0.039 in)

Runout limit:

1.0 mm (0.039 in)

Distance of runout check point (from hub center):

MODEL 200 95 mm (3.74 in)

MODEL 215 102.5 mm (4.04 in)

MODEL 240 115 mm (4.53 in)

+Check clutch disc for burns, discoloration or oil or grease leak-

age. Replace if necessary.

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Components

CL-22

Page 723 of 2898

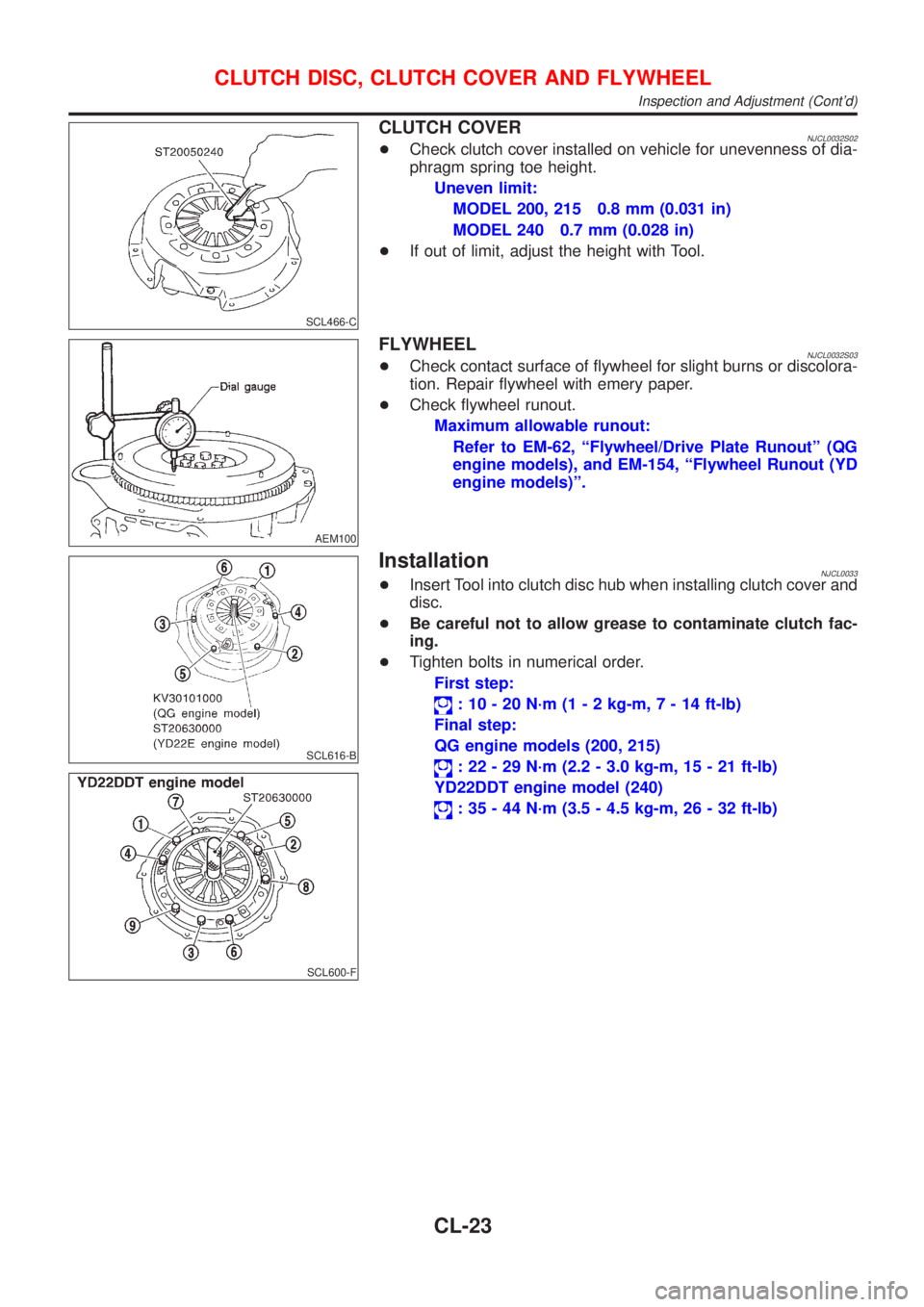

SCL466-C

CLUTCH COVERNJCL0032S02+Check clutch cover installed on vehicle for unevenness of dia-

phragm spring toe height.

Uneven limit:

MODEL 200, 215 0.8 mm (0.031 in)

MODEL 240 0.7 mm (0.028 in)

+If out of limit, adjust the height with Tool.

AEM100

FLYWHEELNJCL0032S03+Check contact surface of flywheel for slight burns or discolora-

tion. Repair flywheel with emery paper.

+Check flywheel runout.

Maximum allowable runout:

Refer to EM-62, ªFlywheel/Drive Plate Runoutº (QG

engine models), and EM-154, ªFlywheel Runout (YD

engine models)º.

SCL616-B

SCL600-F

InstallationNJCL0033+Insert Tool into clutch disc hub when installing clutch cover and

disc.

+Be careful not to allow grease to contaminate clutch fac-

ing.

+Tighten bolts in numerical order.

First step:

: 10 - 20 N´m (1 - 2 kg-m,7-14ft-lb)

Final step:

QG engine models (200, 215)

: 22 - 29 N´m (2.2 - 3.0 kg-m, 15 - 21 ft-lb)

YD22DDT engine model (240)

: 35 - 44 N´m (3.5 - 4.5 kg-m, 26 - 32 ft-lb)

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Inspection and Adjustment (Cont'd)

CL-23

Page 724 of 2898

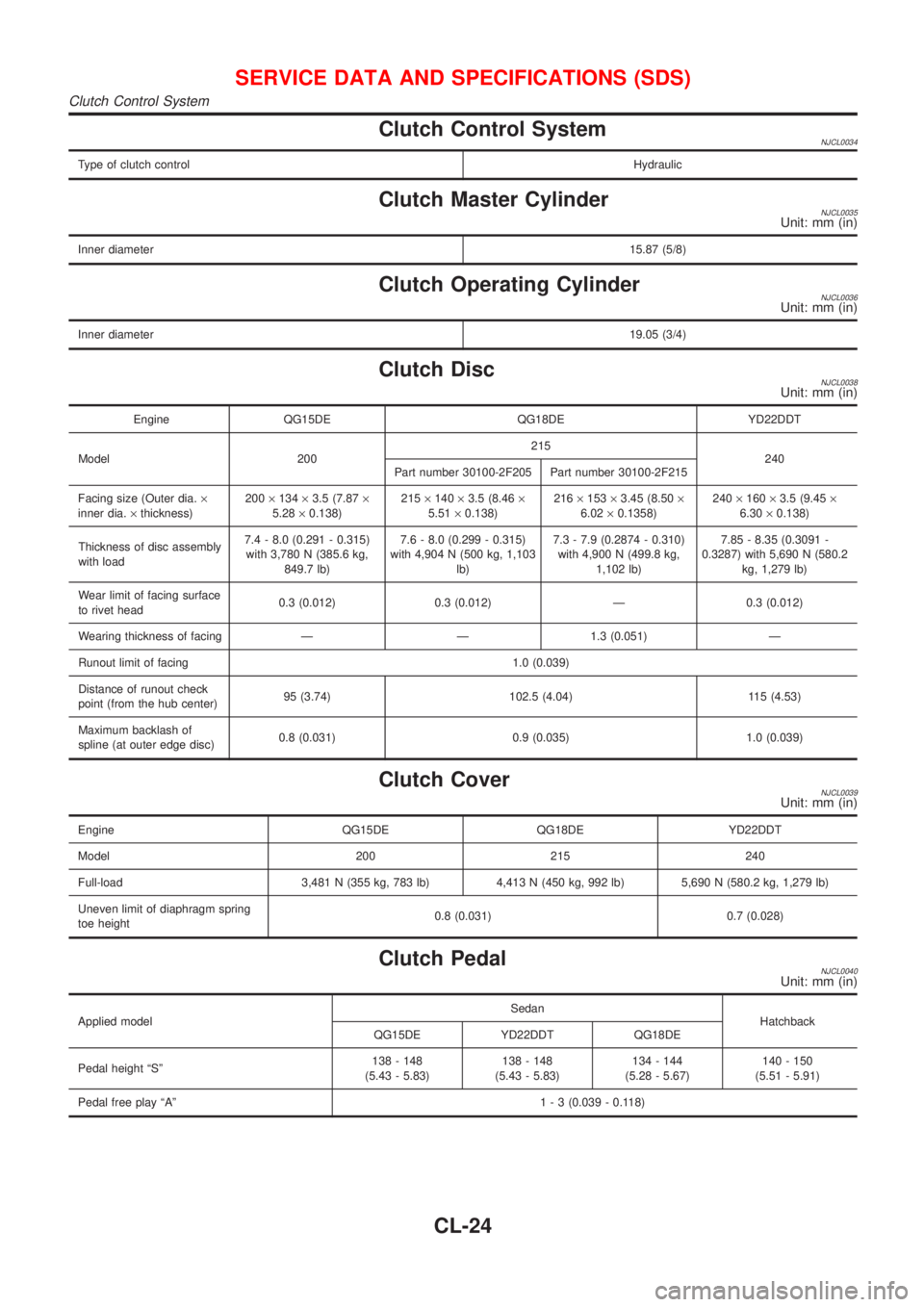

Clutch Control SystemNJCL0034

Type of clutch controlHydraulic

Clutch Master CylinderNJCL0035Unit: mm (in)

Inner diameter15.87 (5/8)

Clutch Operating CylinderNJCL0036Unit: mm (in)

Inner diameter19.05 (3/4)

Clutch DiscNJCL0038Unit: mm (in)

Engine QG15DE QG18DE YD22DDT

Model 200215

240

Part number 30100-2F205 Part number 30100-2F215

Facing size (Outer dia.´

inner dia.´thickness)200´134´3.5 (7.87´

5.28´0.138)215´140´3.5 (8.46´

5.51´0.138)216´153´3.45 (8.50´

6.02´0.1358)240´160´3.5 (9.45´

6.30´0.138)

Thickness of disc assembly

with load7.4 - 8.0 (0.291 - 0.315)

with 3,780 N (385.6 kg,

849.7 lb)7.6 - 8.0 (0.299 - 0.315)

with 4,904 N (500 kg, 1,103

lb)7.3 - 7.9 (0.2874 - 0.310)

with 4,900 N (499.8 kg,

1,102 lb)7.85 - 8.35 (0.3091 -

0.3287) with 5,690 N (580.2

kg, 1,279 lb)

Wear limit of facing surface

to rivet head0.3 (0.012) 0.3 (0.012) Ð 0.3 (0.012)

Wearing thickness of facing Ð Ð 1.3 (0.051) Ð

Runout limit of facing 1.0 (0.039)

Distance of runout check

point (from the hub center)95 (3.74) 102.5 (4.04) 115 (4.53)

Maximum backlash of

spline (at outer edge disc)0.8 (0.031) 0.9 (0.035) 1.0 (0.039)

Clutch CoverNJCL0039Unit: mm (in)

Engine QG15DE QG18DE YD22DDT

Model 200 215 240

Full-load 3,481 N (355 kg, 783 lb) 4,413 N (450 kg, 992 lb) 5,690 N (580.2 kg, 1,279 lb)

Uneven limit of diaphragm spring

toe height0.8 (0.031) 0.7 (0.028)

Clutch PedalNJCL0040Unit: mm (in)

Applied modelSedan

Hatchback

QG15DE YD22DDT QG18DE

Pedal height ªSº138 - 148

(5.43 - 5.83)138 - 148

(5.43 - 5.83)134 - 144

(5.28 - 5.67)140 - 150

(5.51 - 5.91)

Pedal free play ªAº1 - 3 (0.039 - 0.118)

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutch Control System

CL-24

Page 725 of 2898

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

QG

TROUBLE DIAGNOSIS - INDEX..................................10

Alphabetical & P No. Index for DTC .........................10

PRECAUTIONS.............................................................16

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER².............16

Precautions for On Board Diagnostic (OBD)

System of Engine and A/T.........................................16

Engine Fuel & Emission Control System ..................17

Wiring Diagrams and Trouble Diagnosis ...................19

PREPARATION.............................................................20

Special Service Tools ................................................20

Commercial Service Tools .........................................20

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................21

Engine Control Component Parts Location ...............21

Circuit Diagram ..........................................................25

System Diagram ........................................................29

Vacuum Hose Drawing ..............................................30

System Chart .............................................................31

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................32

Multiport Fuel Injection (MFI) System .......................32

Electronic Ignition (EI) System ..................................34

Air Conditioning Cut Control ......................................35

Fuel Cut Control (at no load & high engine

speed) ........................................................................36

Evaporative Emission System ...................................36

Positive Crankcase Ventilation ..................................39

BASIC SERVICE PROCEDURE...................................40

Fuel Pressure Release ..............................................40

Fuel Pressure Check .................................................40

Fuel Pressure Regulator Check ................................41

Injector .......................................................................41

How to Check Idle Speed and Ignition Timing ..........43

Preparation ................................................................44

Inspection Procedure .................................................47

Idle Air Volume Learning ...........................................57ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................59

Introduction ................................................................59

Two Trip Detection Logic ...........................................59

Emission-related Diagnostic Information ...................60

NATS (Nissan Anti-theft System) ..............................74

Malfunction Indicator (MI) ..........................................74

OBD System Operation Chart (With Euro-OBD

Models Only)..............................................................78

CONSULT-II ...............................................................83

Generic Scan Tool (GST) ..........................................94

TROUBLE DIAGNOSIS - INTRODUCTION..................96

Introduction ................................................................96

Work Flow ..................................................................98

TROUBLE DIAGNOSIS - BASIC INSPECTION.........100

Basic Inspection/Sedan ...........................................100

Basic Inspection/Hatchback.....................................128

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION.............................................................153

DTC Inspection Priority Chart..................................153

Fail-safe Chart .........................................................154

Symptom Matrix Chart .............................................155

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................159

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................161

ECM Terminals and Reference Value .....................164

TROUBLE DIAGNOSIS - SPECIFICATION VALUE..173

Description ...............................................................173

Testing Condition .....................................................173

Inspection Procedure ...............................................173

Diagnostic Procedure ..............................................174

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................177

Description ...............................................................177

Diagnostic Procedure ..............................................177

TROUBLE DIAGNOSIS FOR POWER SUPPLY........178

Main Power Supply and Ground Circuit ..................178

Page 726 of 2898

DTC P0100 MASS AIR FLOW SENSOR (MAFS)......187

Component Description ...........................................187

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................187

ECM Terminals and Reference Value .....................187

On Board Diagnosis Logic.......................................187

Fail-safe Mode .........................................................188

DTC Confirmation Procedure ..................................188

Wiring Diagram ........................................................189

Diagnostic Procedure ..............................................191

Component Inspection .............................................193

DTC P0110 INTAKE AIR TEMPERATURE

SENSOR......................................................................194

Component Description ...........................................194

On Board Diagnosis Logic.......................................195

DTC Confirmation Procedure ..................................195

Wiring Diagram ........................................................196

Diagnostic Procedure ..............................................198

Component Inspection .............................................200

DTC P0115 ENGINE COOLANT TEMPERATURE

SENSOR......................................................................201

Component Description ...........................................201

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................201

On Board Diagnosis Logic.......................................201

Fail-safe Mode .........................................................202

DTC Confirmation Procedure ..................................202

Wiring Diagram ........................................................203

Diagnostic Procedure ..............................................205

Component Inspection .............................................206

DTC P0120 THROTTLE POSITION SENSOR...........207

Component Description ...........................................207

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................207

ECM Terminals and Reference Value .....................208

On Board Diagnosis Logic.......................................208

Fail-safe Mode .........................................................208

DTC Confirmation Procedure ..................................208

Wiring Diagram ........................................................210

Diagnostic Procedure ..............................................212

Component Inspection .............................................214

DTC P0130 HEATED OXYGEN SENSOR 1

(FRONT) (CIRCUIT).....................................................216

Component Description ...........................................216

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................216

ECM Terminals and Reference Value .....................216

On Board Diagnosis Logic.......................................217

DTC Confirmation Procedure ..................................217

Overall Function Check ...........................................218

Wiring Diagram ........................................................219

Diagnostic Procedure ..............................................221Component Inspection .............................................222

DTC P0131 HEATED OXYGEN SENSOR 1

(FRONT) (LEAN SHIFT MONITORING).....................224

Component Description ...........................................224

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................224

ECM Terminals and Reference Value .....................224

On Board Diagnosis Logic.......................................225

DTC Confirmation Procedure ..................................225

Overall Function Check ...........................................226

Diagnostic Procedure ..............................................226

Component Inspection .............................................228

DTC P0132 HEATED OXYGEN SENSOR 1

(FRONT) (RICH SHIFT MONITORING)......................230

Component Description ...........................................230

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................230

ECM Terminals and Reference Value .....................230

On Board Diagnosis Logic.......................................231

DTC Confirmation Procedure ..................................231

Overall Function Check ...........................................232

Diagnostic Procedure ..............................................232

Component Inspection .............................................234

DTC P0133 HEATED OXYGEN SENSOR 1

(FRONT).......................................................................236

Component Description ...........................................236

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................236

ECM Terminals and Reference Value .....................236

On Board Diagnosis Logic.......................................237

DTC Confirmation Procedure ..................................237

Overall Function Check ...........................................238

Wiring Diagram ........................................................239

Diagnostic Procedure ..............................................241

Component Inspection .............................................243

DTC P0134 HEATED OXYGEN SENSOR 1

(FRONT) (HIGH VOLTAGE)........................................245

Component Description ...........................................245

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................245

ECM Terminals and Reference Value .....................245

On Board Diagnosis Logic.......................................246

DTC Confirmation Procedure ..................................246

Wiring Diagram ........................................................247

Diagnostic Procedure ..............................................249

Component Inspection .............................................250

DTC P0135 HEATED OXYGEN SENSOR 1

(FRONT) HEATER.......................................................252

Description ...............................................................252

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................252

ECM Terminals and Reference Value .....................252

CONTENTS(Cont'd)

EC-2

Page 727 of 2898

On Board Diagnosis Logic.......................................252

DTC Confirmation Procedure ..................................253

Wiring Diagram ........................................................254

Diagnostic Procedure ..............................................256

Component Inspection .............................................257

DTC P0137 HEATED OXYGEN SENSOR 2

(REAR) (MIN. VOLTAGE MONITORING)...................258

Component Description ...........................................258

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................258

ECM Terminals and Reference Value .....................258

On Board Diagnosis Logic.......................................258

DTC Confirmation Procedure ..................................259

Overall Function Check ...........................................260

Wiring Diagram ........................................................261

Diagnostic Procedure ..............................................263

Component Inspection .............................................265

DTC P0138 HEATED OXYGEN SENSOR 2

(REAR) (MAX. VOLTAGE MONITORING).................267

Component Description ...........................................267

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................267

ECM Terminals and Reference Value .....................267

On Board Diagnosis Logic.......................................267

DTC Confirmation Procedure ..................................268

Overall Function Check ...........................................269

Wiring Diagram ........................................................270

Diagnostic Procedure ..............................................272

Component Inspection .............................................273

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR).........................................................................275

Component Description ...........................................275

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................275

ECM Terminals and Reference Value .....................275

On Board Diagnosis Logic.......................................275

DTC Confirmation Procedure ..................................276

Overall Function Check ...........................................277

Wiring Diagram ........................................................278

Diagnostic Procedure ..............................................280

Component Inspection .............................................282

DTC P0140 HEATED OXYGEN SENSOR 2

(REAR) (HIGH VOLTAGE)..........................................284

Component Description ...........................................284

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................284

ECM Terminals and Reference Value .....................284

On Board Diagnosis Logic.......................................284

DTC Confirmation Procedure ..................................285

Overall Function Check ...........................................285

Wiring Diagram ........................................................286

Diagnostic Procedure ..............................................288Component Inspection .............................................289

DTC P0141 HEATED OXYGEN SENSOR 2

HEATER (REAR).........................................................291

Description ...............................................................291

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................291

ECM Terminals and Reference Value .....................291

On Board Diagnosis Logic.......................................292

DTC Confirmation Procedure ..................................292

Wiring Diagram ........................................................293

Diagnostic Procedure ..............................................295

Component Inspection .............................................296

DTC P0171 FUEL INJECTION SYSTEM

FUNCTION (LEAN SIDE)............................................297

On Board Diagnosis Logic.......................................297

DTC Confirmation Procedure ..................................297

Wiring Diagram ........................................................299

Diagnostic Procedure ..............................................301

DTC P0172 FUEL INJECTION SYSTEM

FUNCTION (RICH SIDE).............................................305

On Board Diagnosis Logic.......................................305

DTC Confirmation Procedure ..................................305

Wiring Diagram ........................................................307

Diagnostic Procedure ..............................................309

DTC P0180 FUEL TANK TEMPERATURE

SENSOR (WHERE FITTED)........................................313

Component Description ...........................................313

On Board Diagnosis Logic.......................................313

DTC Confirmation Procedure ..................................313

Wiring Diagram ........................................................315

Diagnostic Procedure ..............................................316

Component Inspection .............................................317

DTC P0300 - P0304 NO.4-1CYLINDER

MISFIRE, MULTIPLE CYLINDER MISFIRE...............318

On Board Diagnosis Logic.......................................318

DTC Confirmation Procedure ..................................318

Diagnostic Procedure ..............................................319

DTC P0325 KNOCK SENSOR (KS)...........................324

Component Description ...........................................324

ECM Terminals and Reference Value .....................324

On Board Diagnosis Logic.......................................324

DTC Confirmation Procedure ..................................324

Wiring Diagram ........................................................325

Diagnostic Procedure ..............................................326

Component Inspection .............................................327

DTC P0335 CRANKSHAFT POSITION SENSOR

(POS)............................................................................328

Component Description ...........................................328

ECM Terminals and Reference Value .....................328

On Board Diagnosis Logic.......................................329

DTC Confirmation Procedure ..................................329

Wiring Diagram ........................................................330

CONTENTS(Cont'd)

EC-3

Page 728 of 2898

Diagnostic Procedure ..............................................332

Component Inspection .............................................334

DTC P0340 CAMSHAFT POSITION SENSOR

(CMPS) (PHASE).........................................................335

Component Description ...........................................335

ECM Terminals and Reference Value .....................335

On Board Diagnosis Logic.......................................336

DTC Confirmation Procedure ..................................336

Wiring Diagram ........................................................337

Diagnostic Procedure ..............................................339

Component Inspection .............................................342

DTC P0400 EGR FUNCTION (CLOSED) (WHERE

FITTED)........................................................................343

Description ...............................................................343

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................344

ECM Terminals and Reference Value .....................344

On Board Diagnosis Logic.......................................344

DTC Confirmation Procedure ..................................345

Wiring Diagram ........................................................347

Diagnostic Procedure ..............................................349

Component Inspection .............................................351

DTC P0403 EGR VOLUME CONTROL VALVE

(CIRCUIT).....................................................................352

Description ...............................................................352

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................353

ECM Terminals and Reference Value .....................353

On Board Diagnosis Logic.......................................353

DTC Confirmation Procedure ..................................353

Wiring Diagram ........................................................355

Diagnostic Procedure ..............................................357

Component Inspection .............................................358

DTC P0420 THREE WAY CATALYST FUNCTION...359

On Board Diagnosis Logic.......................................359

DTC Confirmation Procedure ..................................359

Overall Function Check ...........................................360

Diagnostic Procedure ..............................................360

DTC P0443 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE (CIRCUIT).................364

Description ...............................................................364

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................364

ECM Terminals and Reference Value .....................365

On Board Diagnosis Logic.......................................365

DTC Confirmation Procedure ..................................365

Wiring Diagram ........................................................366

Diagnostic Procedure ..............................................368

Component Inspection .............................................369

DTC P0500 VEHICLE SPEED SENSOR (VSS).........370

Component Description ...........................................370

ECM Terminals and Reference Value .....................370On Board Diagnosis Logic.......................................370

DTC Confirmation Procedure ..................................370

Wiring Diagram ........................................................372

Diagnostic Procedure ..............................................375

DTC P0505 IDLE AIR CONTROL VALVE (IACV) -

AUXILIARY AIR CONTROL (AAC) VALVE...............376

Description ...............................................................376

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................377

ECM Terminals and Reference Value .....................377

On Board Diagnosis Logic.......................................377

DTC Confirmation Procedure ..................................377

Wiring Diagram ........................................................378

Diagnostic Procedure ..............................................380

Component Inspection .............................................384

DTC P0510 CLOSED THROTTLE POSITION

SWITCH (WHERE FITTED).........................................385

Component Description ...........................................385

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................385

ECM Terminals and Reference Value .....................385

On Board Diagnosis Logic.......................................385

DTC Confirmation Procedure ..................................385

Overall Function Check ...........................................386

Wiring Diagram ........................................................387

Diagnostic Procedure ..............................................388

Component Inspection .............................................389

DTC P0605 ECM.........................................................391

Component Description ...........................................391

On Board Diagnosis Logic.......................................391

DTC Confirmation Procedure ..................................391

Diagnostic Procedure ..............................................392

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE......................................................393

Component Description ...........................................393

Operation .................................................................393

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................393

ECM Terminals and Reference Value .....................393

On Board Diagnosis Logic.......................................393

DTC Confirmation Procedure ..................................394

Wiring Diagram ........................................................395

Diagnostic Procedure ..............................................397

Component Inspection .............................................398

DTC P1131 SWIRL CONTROL VALVE SOLENOID

VALVE (CIRCUIT) (WHERE FITTED).........................399

Description ...............................................................399

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................399

ECM Terminals and Reference Value .....................400

Component Description ...........................................400

On Board Diagnosis Logic.......................................400

CONTENTS(Cont'd)

EC-4

Page 729 of 2898

DTC Confirmation Procedure ..................................400

Wiring Diagram ........................................................402

Diagnostic Procedure ..............................................403

Component Inspection .............................................404

DTC P1217 OVERHEAT (COOLING SYSTEM).........406

System Description ..................................................406

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................406

ECM Terminals and Reference Value .....................407

On Board Diagnosis Logic.......................................407

Overall Function Check ...........................................408

Wiring Diagram ........................................................409

Diagnostic Procedure ..............................................410

Main 12 Causes of Overheating..............................416

Component Inspection .............................................416

DTC P1401 EGR TEMPERATURE SENSOR

(WHERE FITTED)........................................................418

Component Description ...........................................418

On Board Diagnosis Logic.......................................418

DTC Confirmation Procedure ..................................418

Wiring Diagram ........................................................421

Diagnostic Procedure ..............................................423

Component Inspection .............................................424

DTC P1402 EGR FUNCTION (OPEN) (WHERE

FITTED)........................................................................425

Description ...............................................................425

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................426

ECM Terminals and Reference Value .....................426

On Board Diagnosis Logic.......................................426

DTC Confirmation Procedure ..................................427

Wiring Diagram ........................................................429

Diagnostic Procedure ..............................................431

Component Inspection .............................................432

DTC P1605 A/T DIAGNOSIS COMMUNICATION

LINE.............................................................................434

System Description ..................................................434

ECM Terminals and Reference Value .....................434

On Board Diagnosis Logic.......................................434

DTC Confirmation Procedure ..................................434

Wiring Diagram ........................................................435

Diagnostic Procedure ..............................................436

DTC P1706 PARK/NEUTRAL POSITION (PNP)

SWITCH.......................................................................437

Component Description ...........................................437

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................437

ECM Terminals and Reference Value .....................437

On Board Diagnosis Logic.......................................437

DTC Confirmation Procedure ..................................437

Overall Function Check ...........................................438

Wiring Diagram ........................................................439Diagnostic Procedure ..............................................440

INTAKE AIR TEMPERATURE SENSOR....................442

Component Description ...........................................442

Wiring Diagram ........................................................444

Diagnostic Procedure ..............................................446

Component Inspection .............................................448

HEATED OXYGEN SENSOR 1 (FRONT)...................450

Component Description ...........................................450

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................450

ECM Terminals and Reference Value .....................450

Wiring Diagram ........................................................451

Diagnostic Procedure ..............................................453

Component Inspection .............................................455

HEATED OXYGEN SENSOR 1 HEATER (FRONT)...457

Description ...............................................................457

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................457

ECM Terminals and Reference Value .....................457

Wiring Diagram ........................................................458

Diagnostic Procedure ..............................................460

Component Inspection .............................................461

HEATED OXYGEN SENSOR 2 (REAR).....................462

Component Description ...........................................462

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................462

ECM Terminals and Reference Value .....................462

Wiring Diagram ........................................................463

Diagnostic Procedure ..............................................465

Component Inspection .............................................467

HEATED OXYGEN SENSOR 2 HEATER (REAR).....469

Description ...............................................................469

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................469

ECM Terminals and Reference Value .....................469

Wiring Diagram ........................................................470

Diagnostic Procedure ..............................................472

Component Inspection .............................................474

SWIRL CONTROL VALVE CONTROL SYSTEM

(WHERE FITTED)........................................................475

Description ...............................................................475

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................475

ECM Terminals and Reference Value .....................476

Component Description ...........................................476

Wiring Diagram ........................................................477

Diagnostic Procedure ..............................................478

Component Inspection .............................................482

CRANKSHAFT POSITION SENSOR (POS)...............484

Component Description ...........................................484

ECM Terminals and Reference Value .....................484

Wiring Diagram ........................................................485

CONTENTS(Cont'd)

EC-5

Page 730 of 2898

Diagnostic Procedure ..............................................487

Component Inspection .............................................490

EGR VOLUME CONTROL SYSTEM (WHERE

FITTED)........................................................................491

Description ...............................................................491

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................492

ECM Terminals and Reference Value .....................493

Wiring Diagram ........................................................494

Diagnostic Procedure ..............................................496

Component Inspection .............................................501

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE......................................................503

Description ...............................................................503

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................503

ECM Terminals and Reference Value .....................504

Wiring Diagram ........................................................505

Diagnostic Procedure ..............................................507

Component Inspection .............................................510

IDLE AIR CONTROL VALVE (IACV) - AUXILIARY

AIR CONTROL............................................................ 511

Description ............................................................... 511

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................512

ECM Terminals and Reference Value .....................512

Wiring Diagram ........................................................513

Diagnostic Procedure ..............................................515

Component Inspection .............................................519

CLOSED THROTTLE POSITION SWITCH

(WHERE FITTED)........................................................520

Component Description ...........................................520

ECM Terminals and Reference Value .....................520

Wiring Diagram ........................................................521

Diagnostic Procedure ..............................................522

Component Inspection .............................................525

INTAKE VALVE TIMING CONTROL SOLENOID

VALVE..........................................................................526

Component Description ...........................................526

Operation .................................................................526

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................526

ECM Terminals and Reference Value .....................526

Wiring Diagram ........................................................527

Diagnostic Procedure ..............................................529

Component Inspection .............................................531

A/T COMMUNICATION LINE......................................532

System Description ..................................................532

Wiring Diagram ........................................................533

Diagnostic Procedure ..............................................534

PARK/NEUTRAL POSITION (PNP) SWITCH............536

Component Description ...........................................536CONSULT-II Reference Value in Data Monitor

Mode ........................................................................536

ECM Terminals and Reference Value .....................536

Wiring Diagram ........................................................537

Diagnostic Procedure ..............................................538

INJECTOR...................................................................541

Component Description ...........................................541

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................541

ECM Terminals and Reference Value .....................541

Wiring Diagram ........................................................542

Diagnostic Procedure ..............................................544

Component Inspection .............................................546

IGNITION SIGNAL.......................................................547

Component Description ...........................................547

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................547

ECM Terminals and Reference Value .....................547

Wiring Diagram ........................................................548

Diagnostic Procedure ..............................................551

Component Inspection .............................................555

START SIGNAL...........................................................557

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................557

ECM Terminals and Reference Value .....................557

Wiring Diagram ........................................................558

Diagnostic Procedure ..............................................559

FUEL PUMP.................................................................561

System Description ..................................................561

Component Description ...........................................561

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................561

ECM Terminals and Reference Value .....................562

Wiring Diagram ........................................................563

Diagnostic Procedure ..............................................564

Component Inspection .............................................566

POWER STEERING OIL PRESSURE SWITCH.........567

Component Description ...........................................567

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................567

ECM Terminals and Reference Value .....................567

Wiring Diagram ........................................................568

Diagnostic Procedure ..............................................569

Component Inspection .............................................570

REFRIGERANT PRESSURE SENSOR......................572

Description ...............................................................572

ECM Terminals and Reference Value .....................572

Wiring Diagram ........................................................573

Diagnostic Procedure ..............................................575

ELECTRICAL LOAD SIGNAL.....................................578

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................578

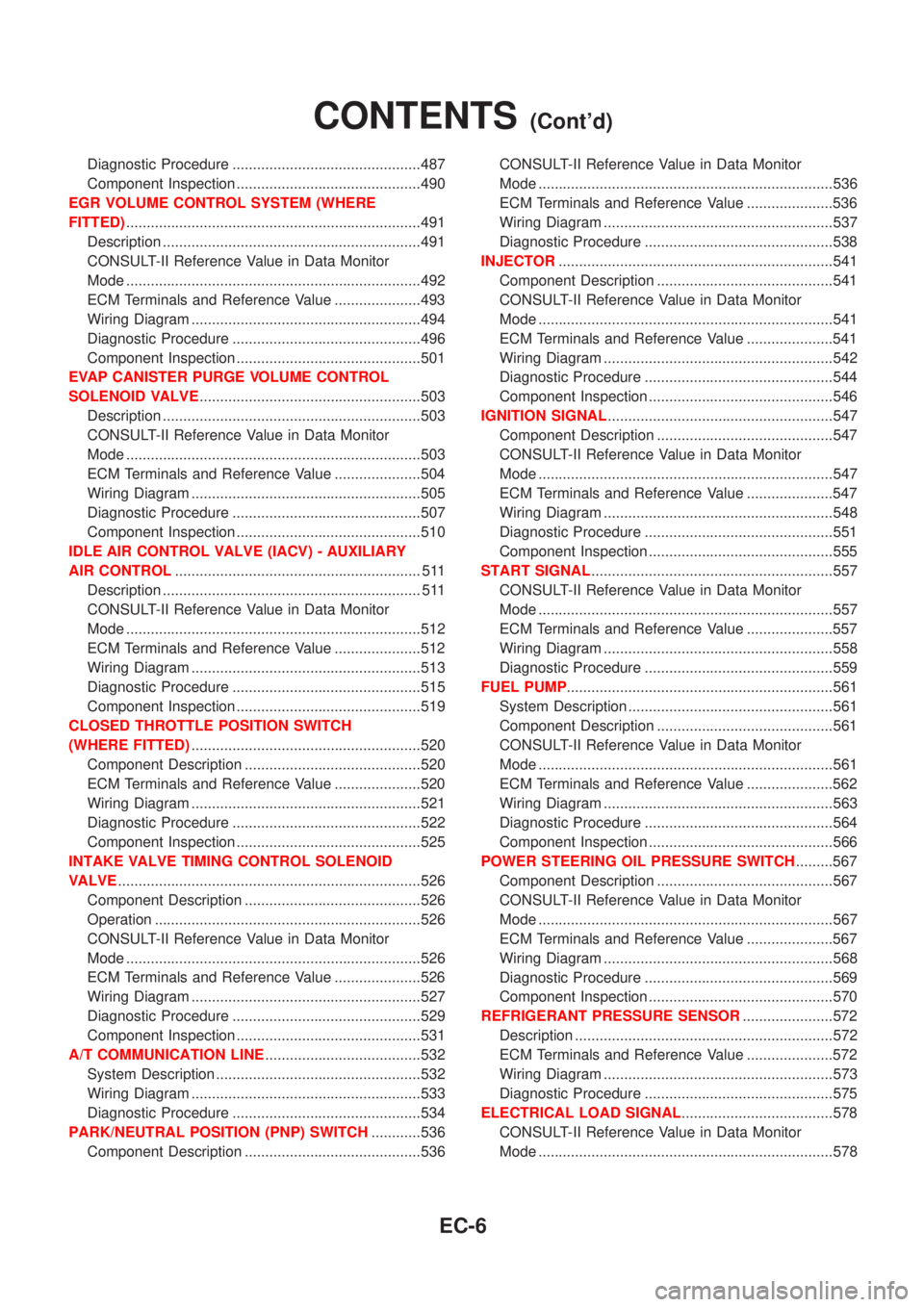

CONTENTS(Cont'd)

EC-6