Electric NISSAN ALMERA 2001 Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1235 of 2898

DescriptionNJEC1758SYSTEM DESCRIPTIONNJEC1758S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Idle air

controlIACV-AAC valve Camshaft position sensor (PHASE) Engine speed and cylinder number

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

PNP switch Park/Neutral position

Air conditioner switch Air conditioner operation

Power steering oil pressure switch Power steering load signal

Battery Battery voltage

Vehicle speed sensor Vehicle speed

Cooling fan Cooling fan operation

Electrical load Electrical load signal

This system automatically controls engine idle speed to a specified

level. Idle speed is controlled through fine adjustment of the

amount of air which by-passes the throttle valve via IACV-AAC

valve. The IACV-AAC valve changes the opening of the air by-pass

passage to control the amount of auxiliary air. This valve is actu-

ated by a step motor built into the valve, which moves the valve in

the axial direction in steps corresponding to the ECM output sig-

nals. One step of IACV-AAC valve movement causes the respec-

tive opening of the air by-pass passage. (i.e. when the step

advances, the opening is enlarged.) The opening of the valve is

varied to allow for optimum control of the engine idling speed. The

crankshaft position sensor (POS) detects the actual engine speed

and sends a signal to the ECM. The ECM then controls the step

position of the IACV-AAC valve so that engine speed coincides with

the target value memorized in ECM. The target engine speed is the

lowest speed at which the engine can operate steadily. The opti-

mum value stored in the ECM is determined by taking into consid-

eration various engine conditions, such as during warm up,

deceleration, and engine load (air conditioner, power steering, cool-

ing fan operation and electrical load).

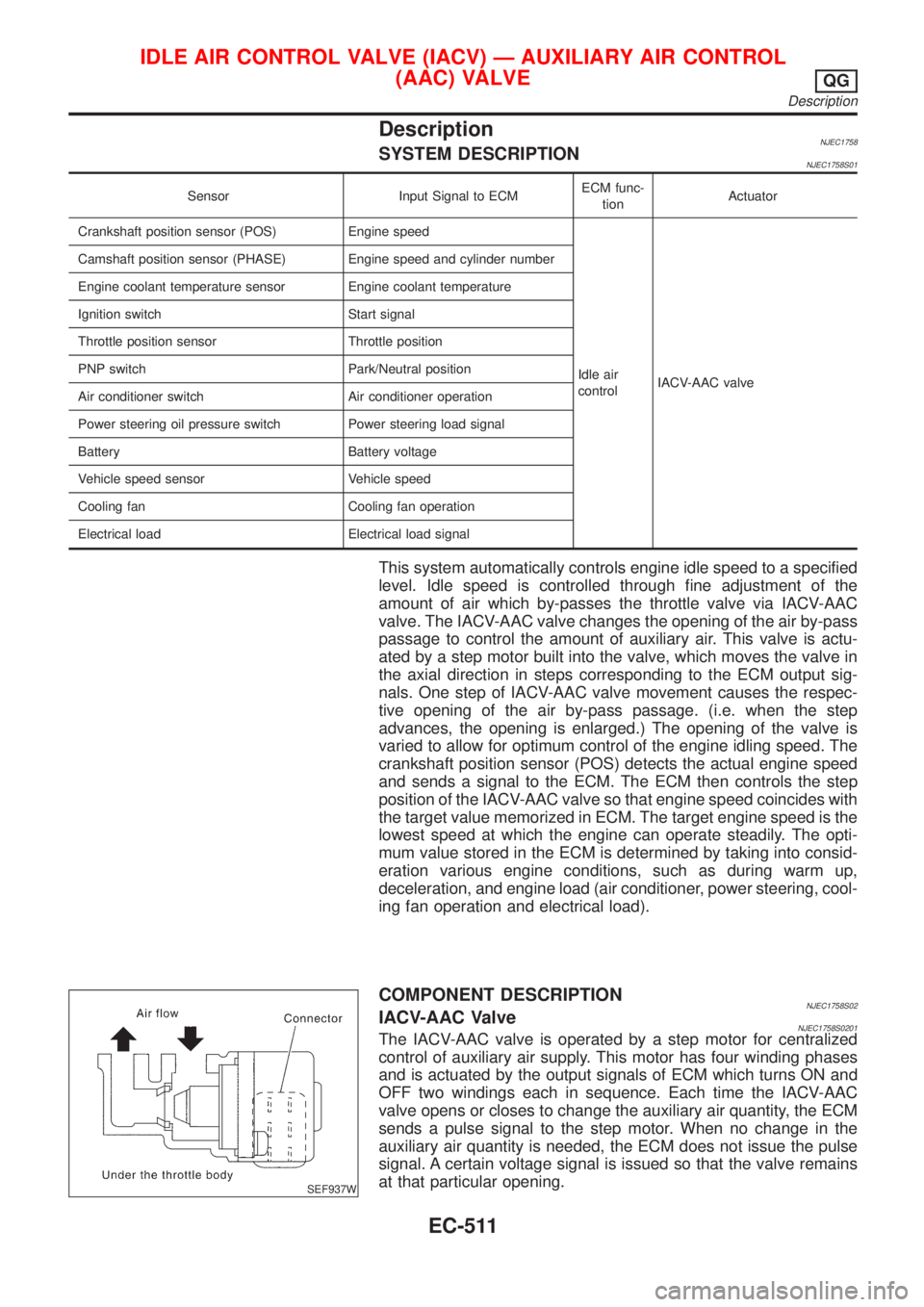

SEF937W

COMPONENT DESCRIPTIONNJEC1758S02IACV-AAC ValveNJEC1758S0201The IACV-AAC valve is operated by a step motor for centralized

control of auxiliary air supply. This motor has four winding phases

and is actuated by the output signals of ECM which turns ON and

OFF two windings each in sequence. Each time the IACV-AAC

valve opens or closes to change the auxiliary air quantity, the ECM

sends a pulse signal to the step motor. When no change in the

auxiliary air quantity is needed, the ECM does not issue the pulse

signal. A certain voltage signal is issued so that the valve remains

at that particular opening.

IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

QG

Description

EC-511

Page 1302 of 2898

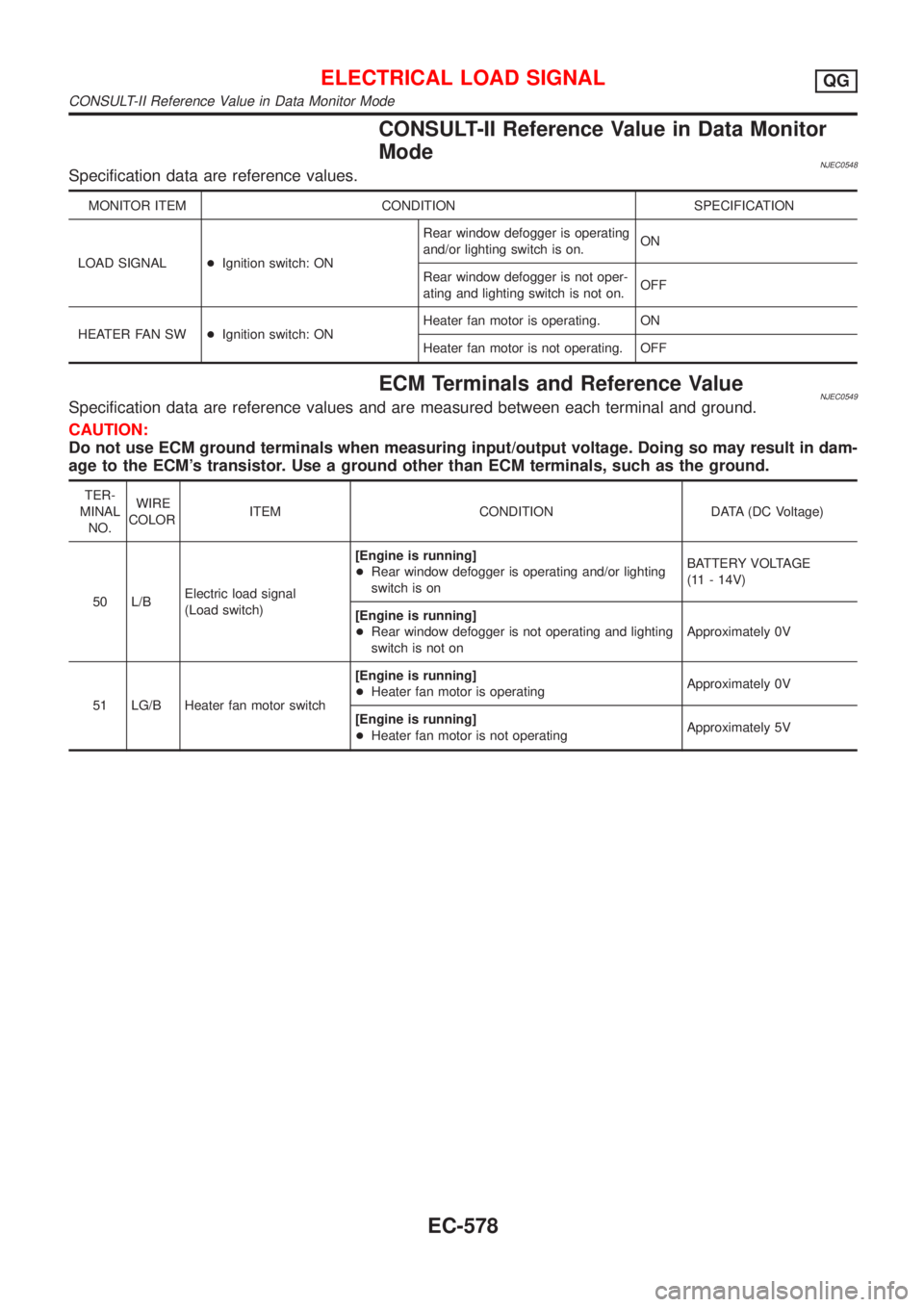

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0548Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

LOAD SIGNAL+Ignition switch: ONRear window defogger is operating

and/or lighting switch is on.ON

Rear window defogger is not oper-

ating and lighting switch is not on.OFF

HEATER FAN SW+Ignition switch: ONHeater fan motor is operating. ON

Heater fan motor is not operating. OFF

ECM Terminals and Reference ValueNJEC0549Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

50 L/BElectric load signal

(Load switch)[Engine is running]

+Rear window defogger is operating and/or lighting

switch is onBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Rear window defogger is not operating and lighting

switch is not onApproximately 0V

51 LG/B Heater fan motor switch[Engine is running]

+Heater fan motor is operatingApproximately 0V

[Engine is running]

+Heater fan motor is not operatingApproximately 5V

ELECTRICAL LOAD SIGNALQG

CONSULT-II Reference Value in Data Monitor Mode

EC-578

Page 1303 of 2898

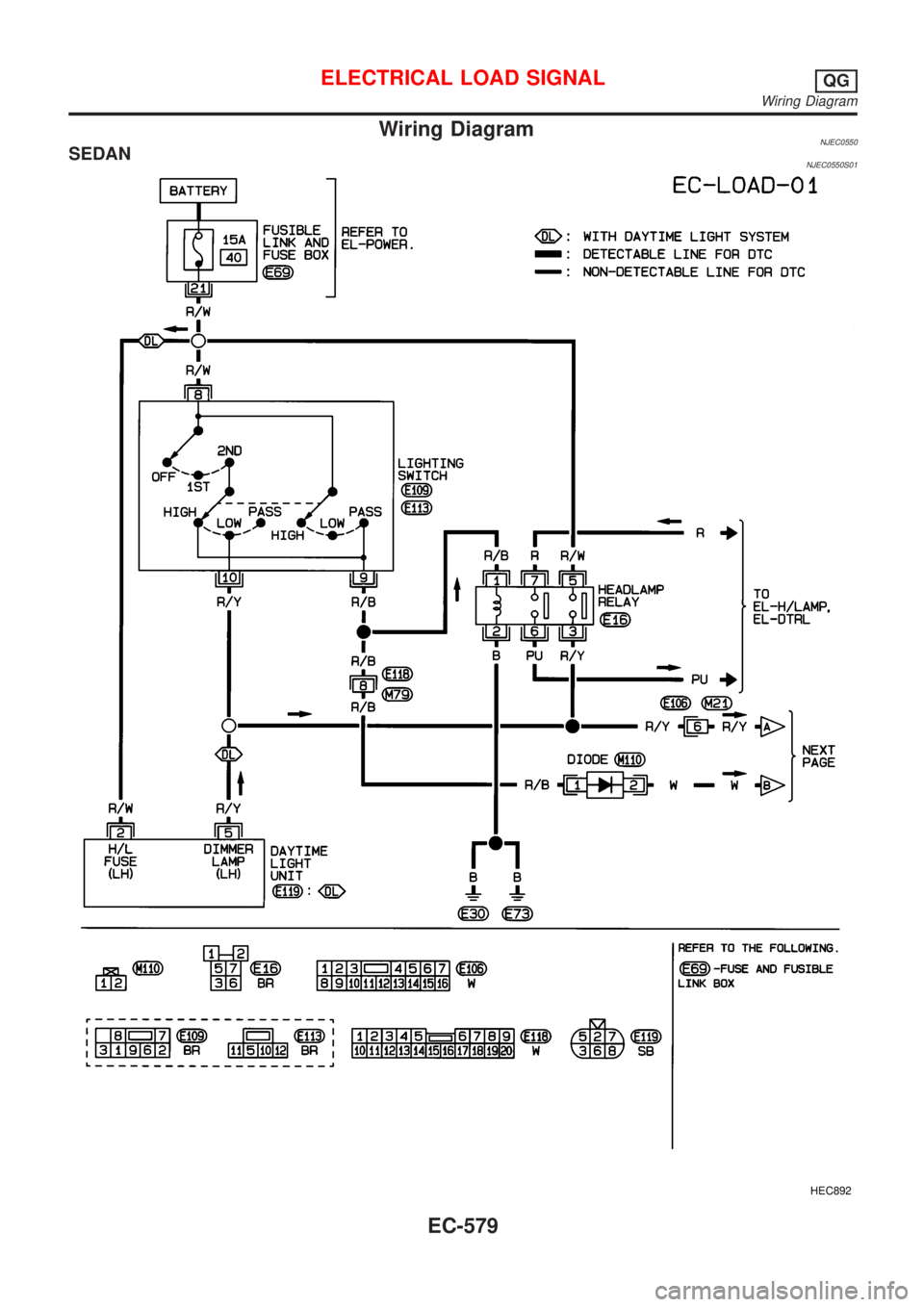

Wiring DiagramNJEC0550SEDANNJEC0550S01

HEC892

ELECTRICAL LOAD SIGNALQG

Wiring Diagram

EC-579

Page 1304 of 2898

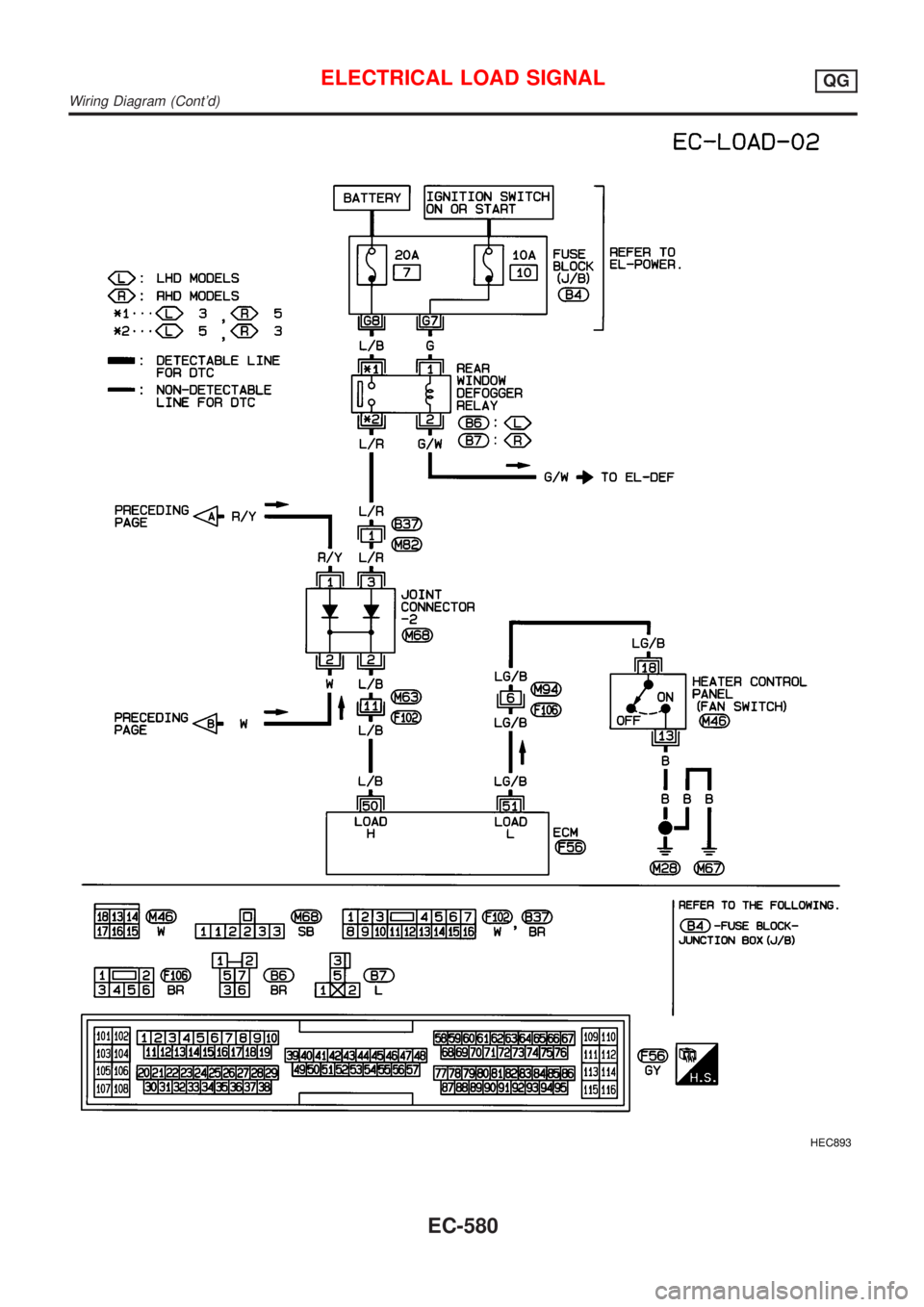

HEC893

ELECTRICAL LOAD SIGNALQG

Wiring Diagram (Cont'd)

EC-580

Page 1305 of 2898

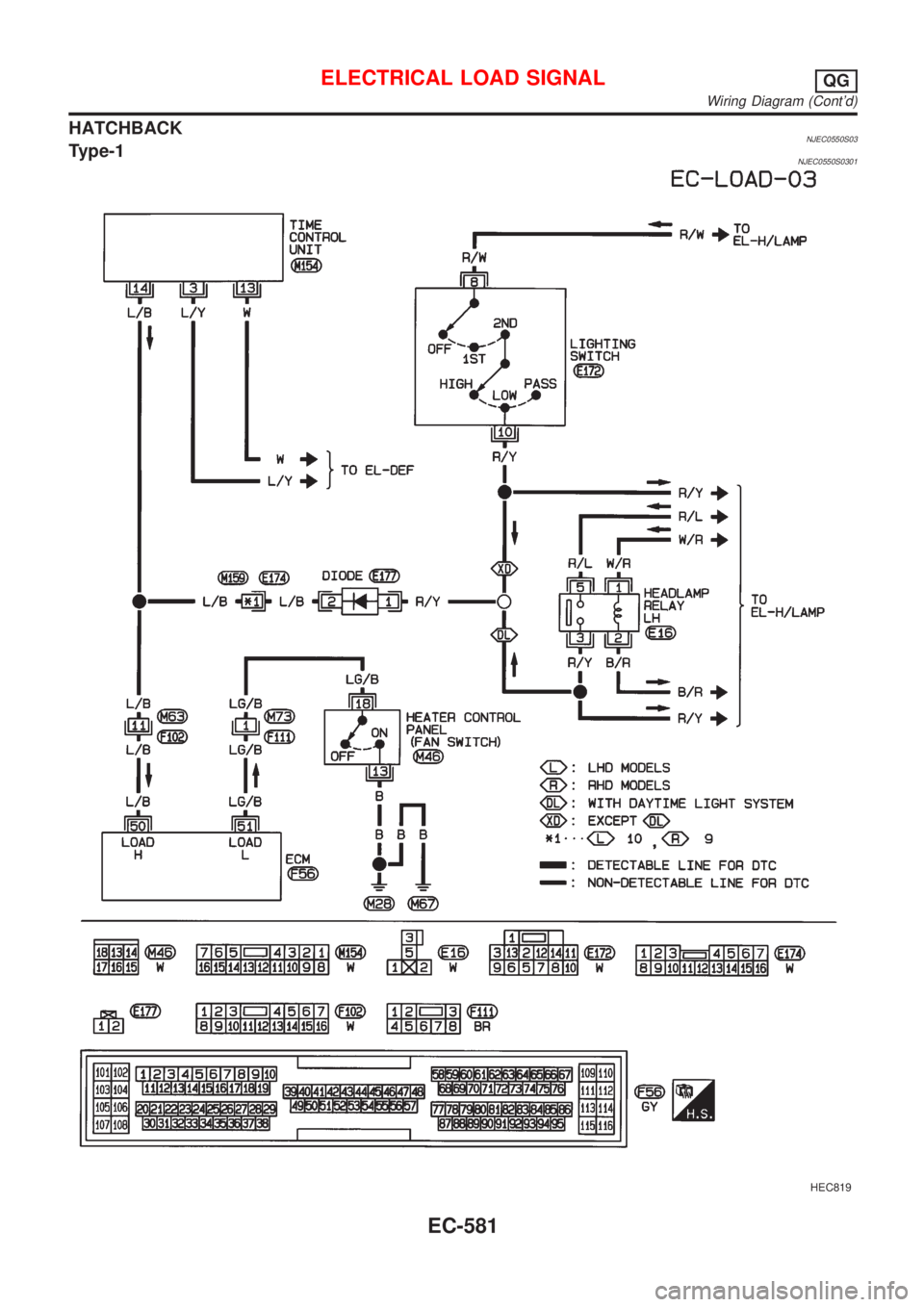

HATCHBACKNJEC0550S03Type-1NJEC0550S0301

HEC819

ELECTRICAL LOAD SIGNALQG

Wiring Diagram (Cont'd)

EC-581

Page 1306 of 2898

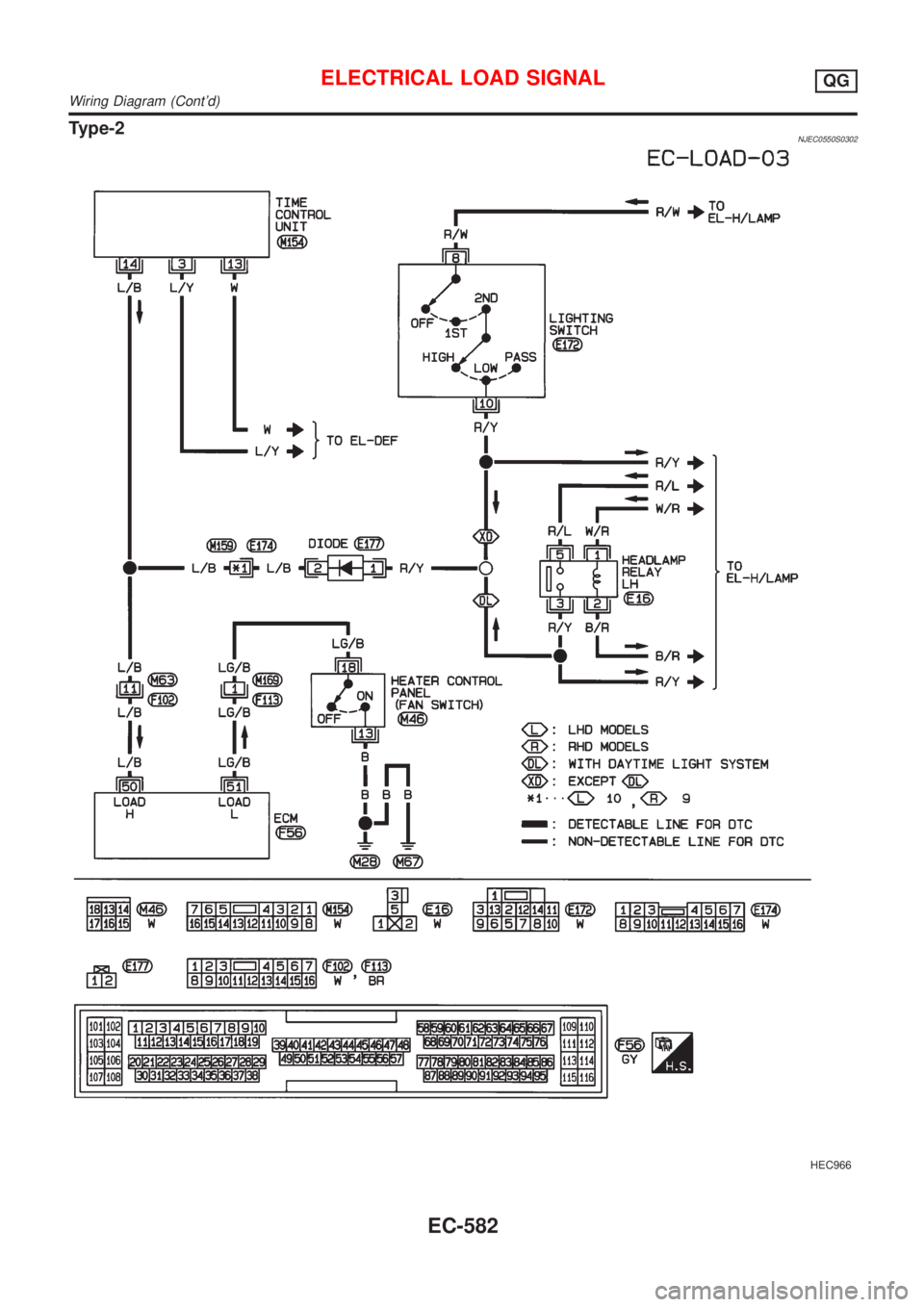

Type-2NJEC0550S0302

HEC966

ELECTRICAL LOAD SIGNALQG

Wiring Diagram (Cont'd)

EC-582

Page 1307 of 2898

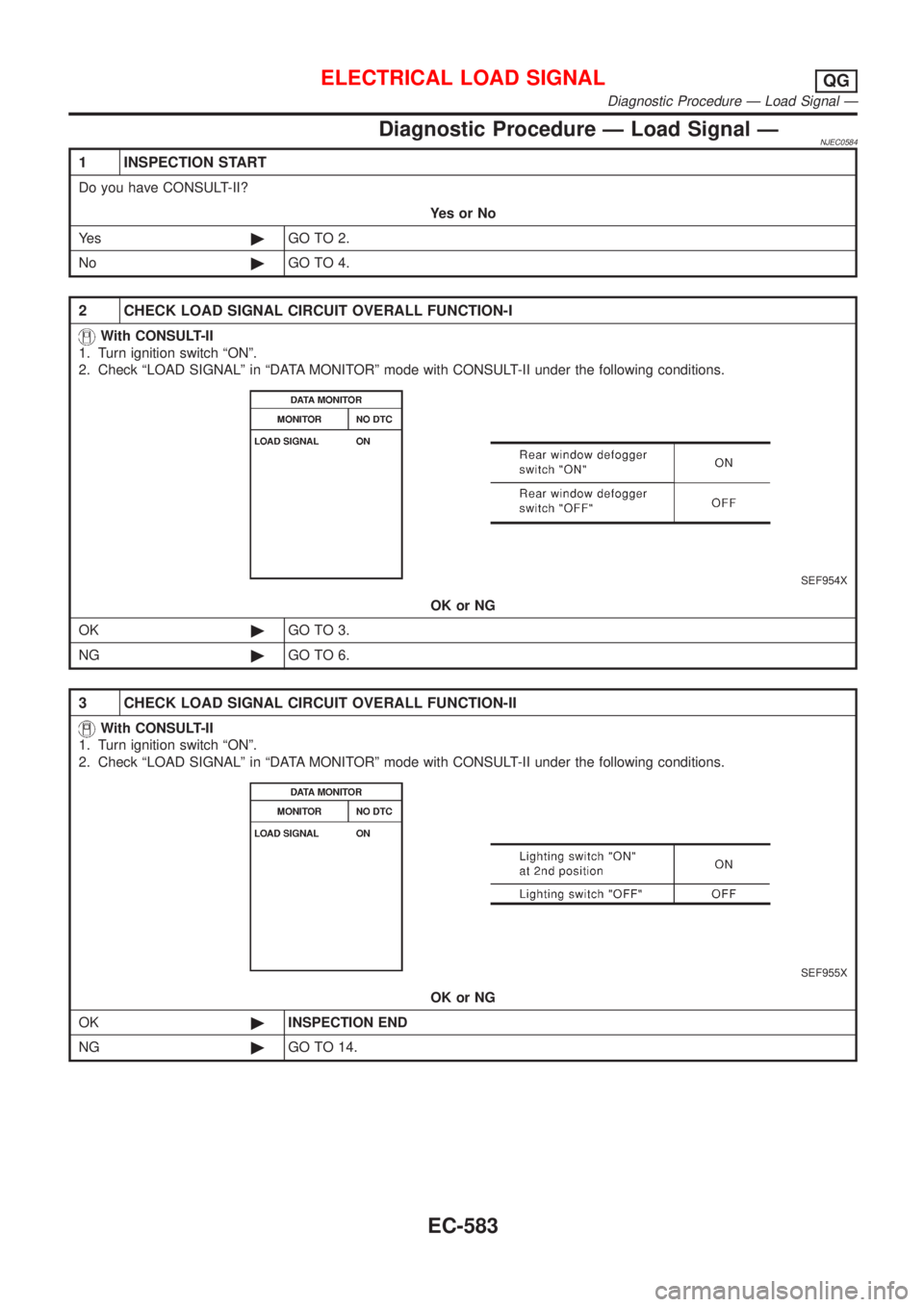

Diagnostic Procedure Ð Load Signal ÐNJEC0584

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 4.

2 CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-I

With CONSULT-II

1. Turn ignition switch ªONº.

2. Check ªLOAD SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF954X

OK or NG

OK©GO TO 3.

NG©GO TO 6.

3 CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

With CONSULT-II

1. Turn ignition switch ªONº.

2. Check ªLOAD SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF955X

OK or NG

OK©INSPECTION END

NG©GO TO 14.

ELECTRICAL LOAD SIGNALQG

Diagnostic Procedure Ð Load Signal Ð

EC-583

Page 1308 of 2898

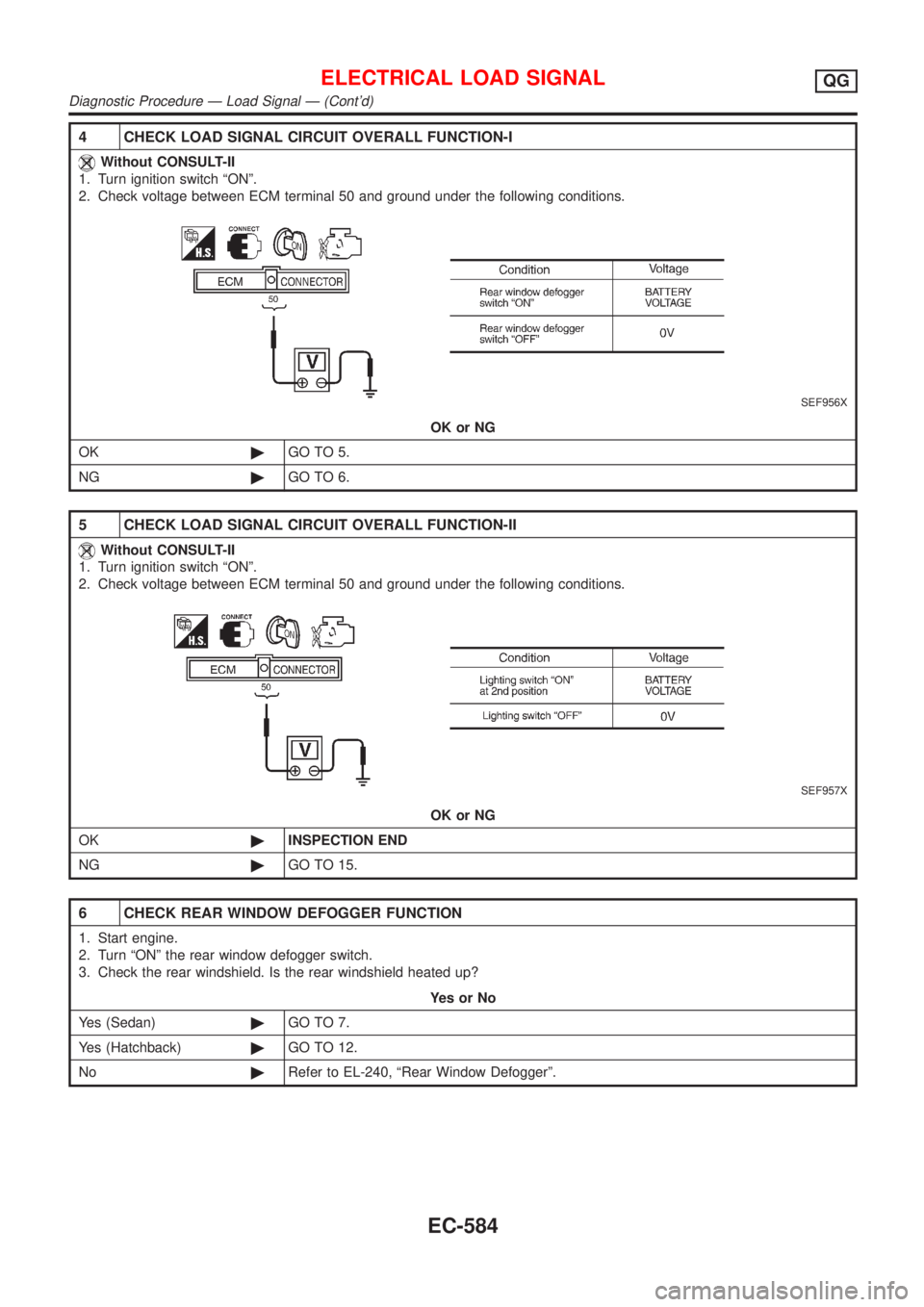

4 CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-I

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 50 and ground under the following conditions.

SEF956X

OK or NG

OK©GO TO 5.

NG©GO TO 6.

5 CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 50 and ground under the following conditions.

SEF957X

OK or NG

OK©INSPECTION END

NG©GO TO 15.

6 CHECK REAR WINDOW DEFOGGER FUNCTION

1. Start engine.

2. Turn ªONº the rear window defogger switch.

3. Check the rear windshield. Is the rear windshield heated up?

YesorNo

Yes (Sedan)©GO TO 7.

Yes (Hatchback)©GO TO 12.

No©Refer to EL-240, ªRear Window Defoggerº.

ELECTRICAL LOAD SIGNALQG

Diagnostic Procedure Ð Load Signal Ð (Cont'd)

EC-584

Page 1309 of 2898

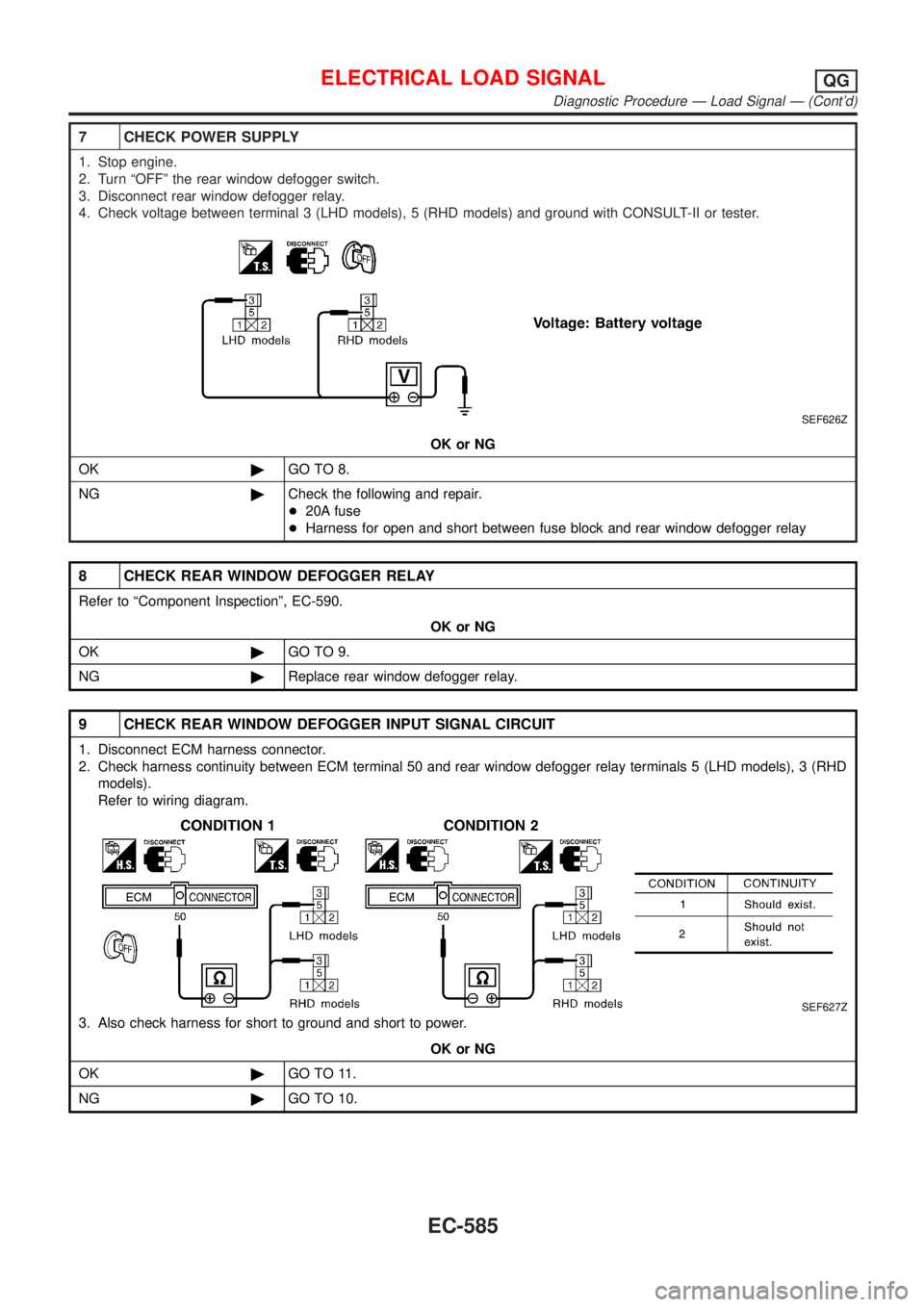

7 CHECK POWER SUPPLY

1. Stop engine.

2. Turn ªOFFº the rear window defogger switch.

3. Disconnect rear window defogger relay.

4. Check voltage between terminal 3 (LHD models), 5 (RHD models) and ground with CONSULT-II or tester.

SEF626Z

OK or NG

OK©GO TO 8.

NG©Check the following and repair.

+20A fuse

+Harness for open and short between fuse block and rear window defogger relay

8 CHECK REAR WINDOW DEFOGGER RELAY

Refer to ªComponent Inspectionº, EC-590.

OK or NG

OK©GO TO 9.

NG©Replace rear window defogger relay.

9 CHECK REAR WINDOW DEFOGGER INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 50 and rear window defogger relay terminals 5 (LHD models), 3 (RHD

models).

Refer to wiring diagram.

SEF627Z

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 11.

NG©GO TO 10.

ELECTRICAL LOAD SIGNALQG

Diagnostic Procedure Ð Load Signal Ð (Cont'd)

EC-585

Page 1311 of 2898

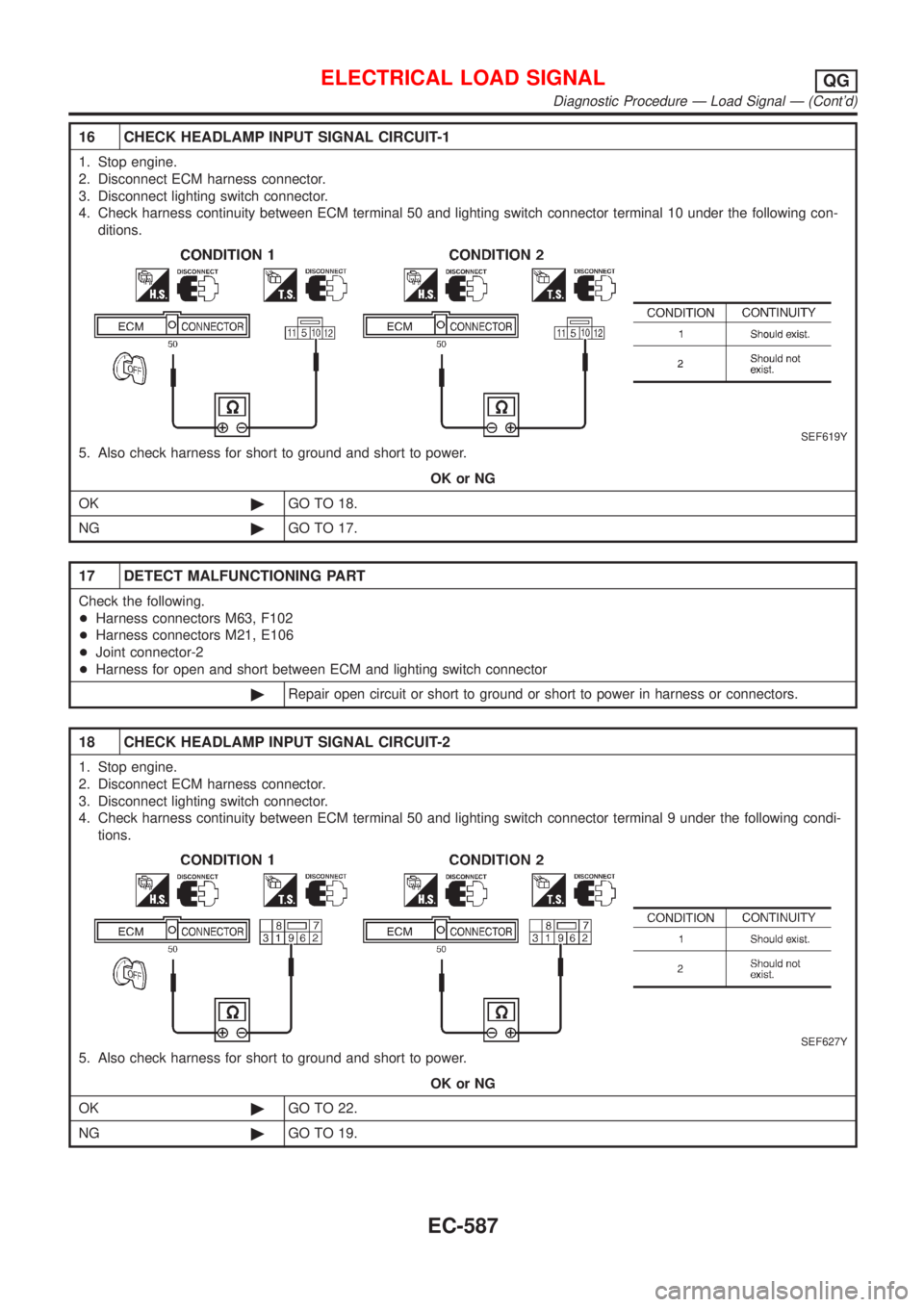

16 CHECK HEADLAMP INPUT SIGNAL CIRCUIT-1

1. Stop engine.

2. Disconnect ECM harness connector.

3. Disconnect lighting switch connector.

4. Check harness continuity between ECM terminal 50 and lighting switch connector terminal 10 under the following con-

ditions.

SEF619Y

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 18.

NG©GO TO 17.

17 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M63, F102

+Harness connectors M21, E106

+Joint connector-2

+Harness for open and short between ECM and lighting switch connector

©Repair open circuit or short to ground or short to power in harness or connectors.

18 CHECK HEADLAMP INPUT SIGNAL CIRCUIT-2

1. Stop engine.

2. Disconnect ECM harness connector.

3. Disconnect lighting switch connector.

4. Check harness continuity between ECM terminal 50 and lighting switch connector terminal 9 under the following condi-

tions.

SEF627Y

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 22.

NG©GO TO 19.

ELECTRICAL LOAD SIGNALQG

Diagnostic Procedure Ð Load Signal Ð (Cont'd)

EC-587