NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 881 of 2898

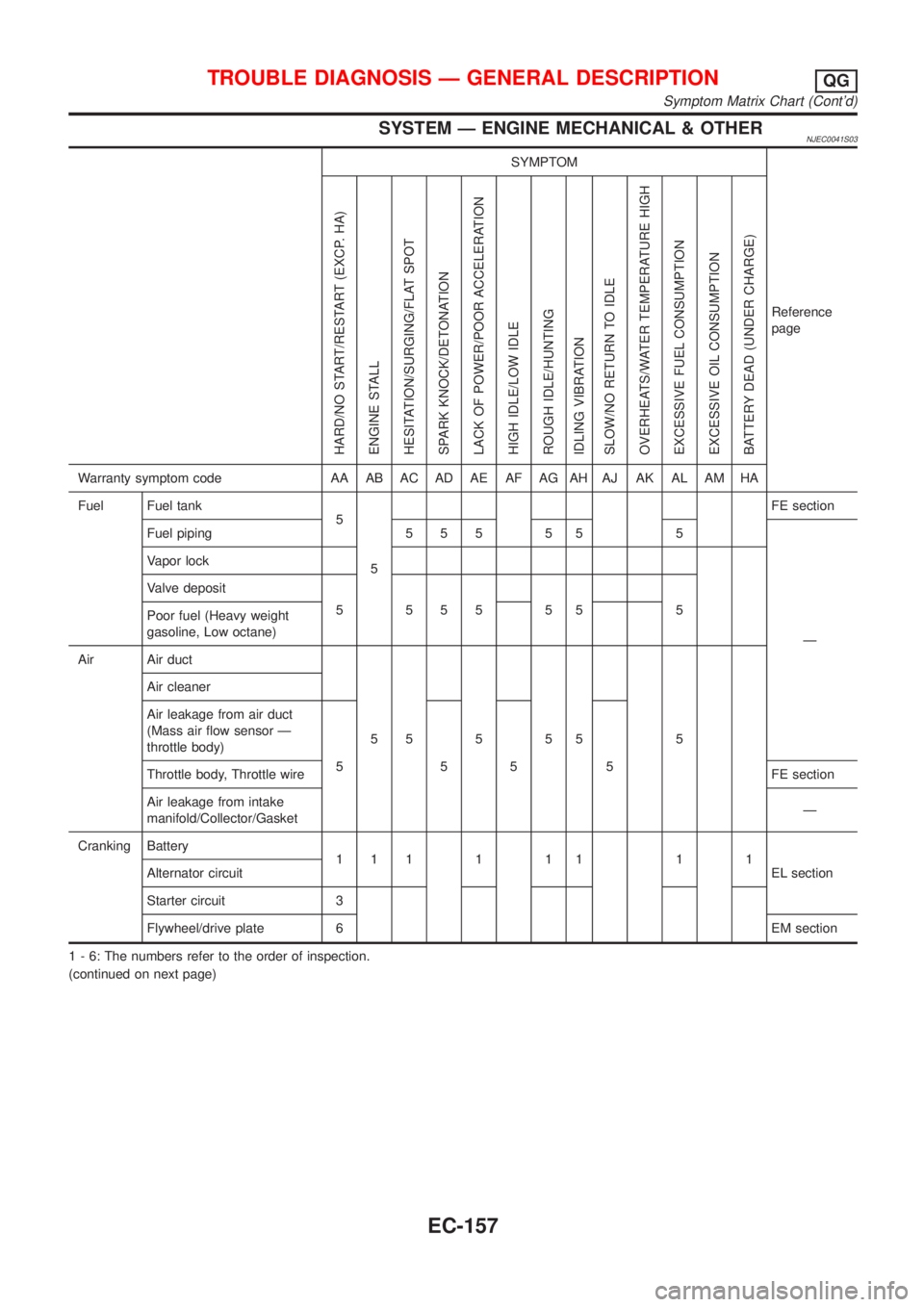

SYSTEM Ð ENGINE MECHANICAL & OTHERNJEC0041S03

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FE section

Fuel piping 5 5 5 5 5 5

Ð Vapor lock

Valve deposit

5 555 55 5

Poor fuel (Heavy weight

gasoline, Low octane)

Air Air duct

55555 5 Air cleaner

Air leakage from air duct

(Mass air flow sensor Ð

throttle body)

5555

Throttle body, Throttle wireFE section

Air leakage from intake

manifold/Collector/GasketÐ

Cranking Battery

111111 11

EL section Alternator circuit

Starter circuit 3

Flywheel/drive plate 6EM section

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Symptom Matrix Chart (Cont'd)

EC-157

Page 882 of 2898

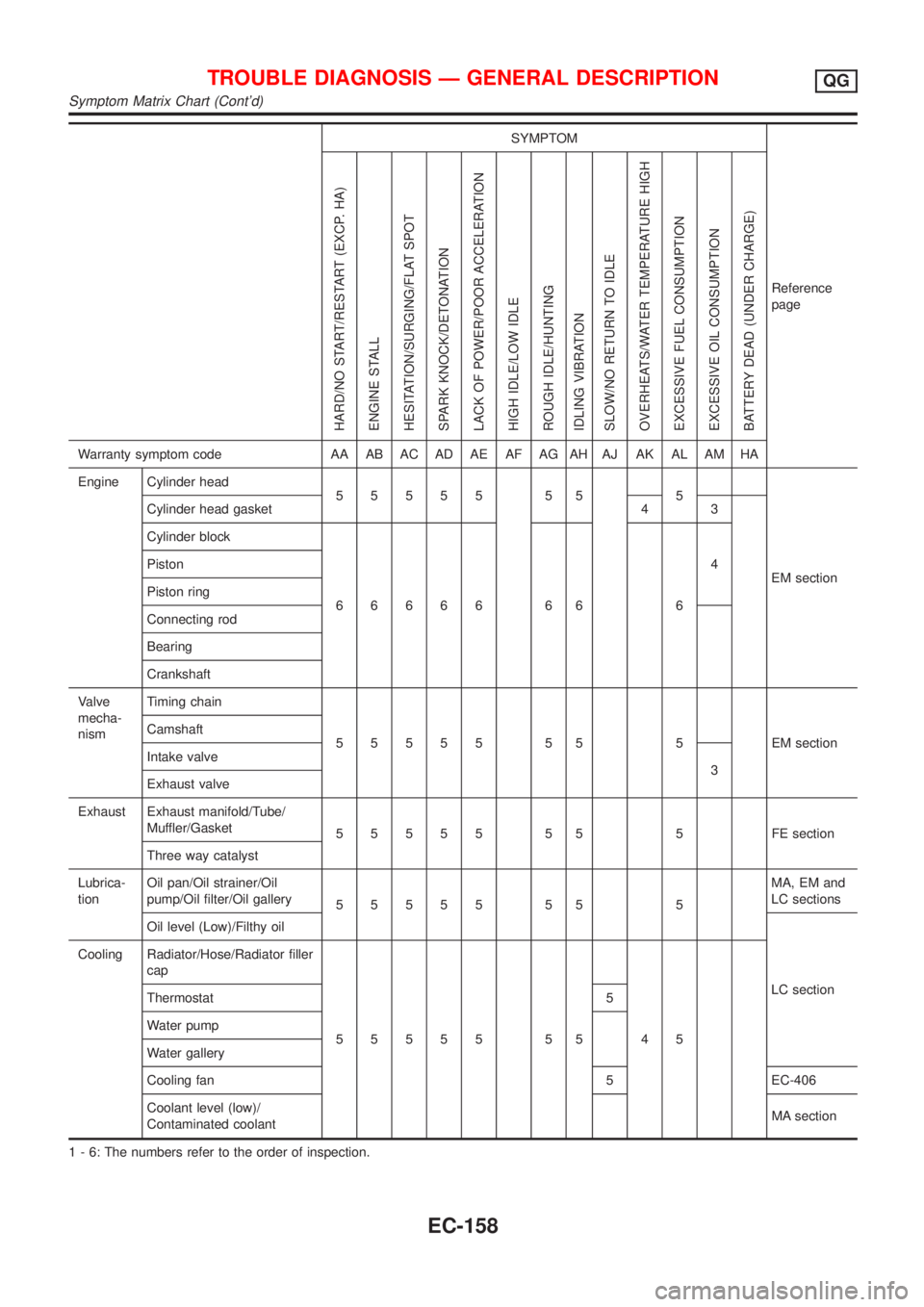

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine Cylinder head

55555 55 5

EM section Cylinder head gasket 4 3

Cylinder block

66666 66 64 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mecha-

nismTiming chain

55555 55 5 EMsection Camshaft

Intake valve

3

Exhaust valve

Exhaust Exhaust manifold/Tube/

Muffler/Gasket

55555 55 5 FEsection

Three way catalyst

Lubrica-

tionOil pan/Oil strainer/Oil

pump/Oil filter/Oil gallery

55555 55 5MA, EM and

LC sections

Oil level (Low)/Filthy oil

LC section Cooling Radiator/Hose/Radiator filler

cap

55555 55 45 Thermostat 5

Water pump

Water gallery

Cooling fan 5 EC-406

Coolant level (low)/

Contaminated coolantMA section

1 - 6: The numbers refer to the order of inspection.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Symptom Matrix Chart (Cont'd)

EC-158

Page 883 of 2898

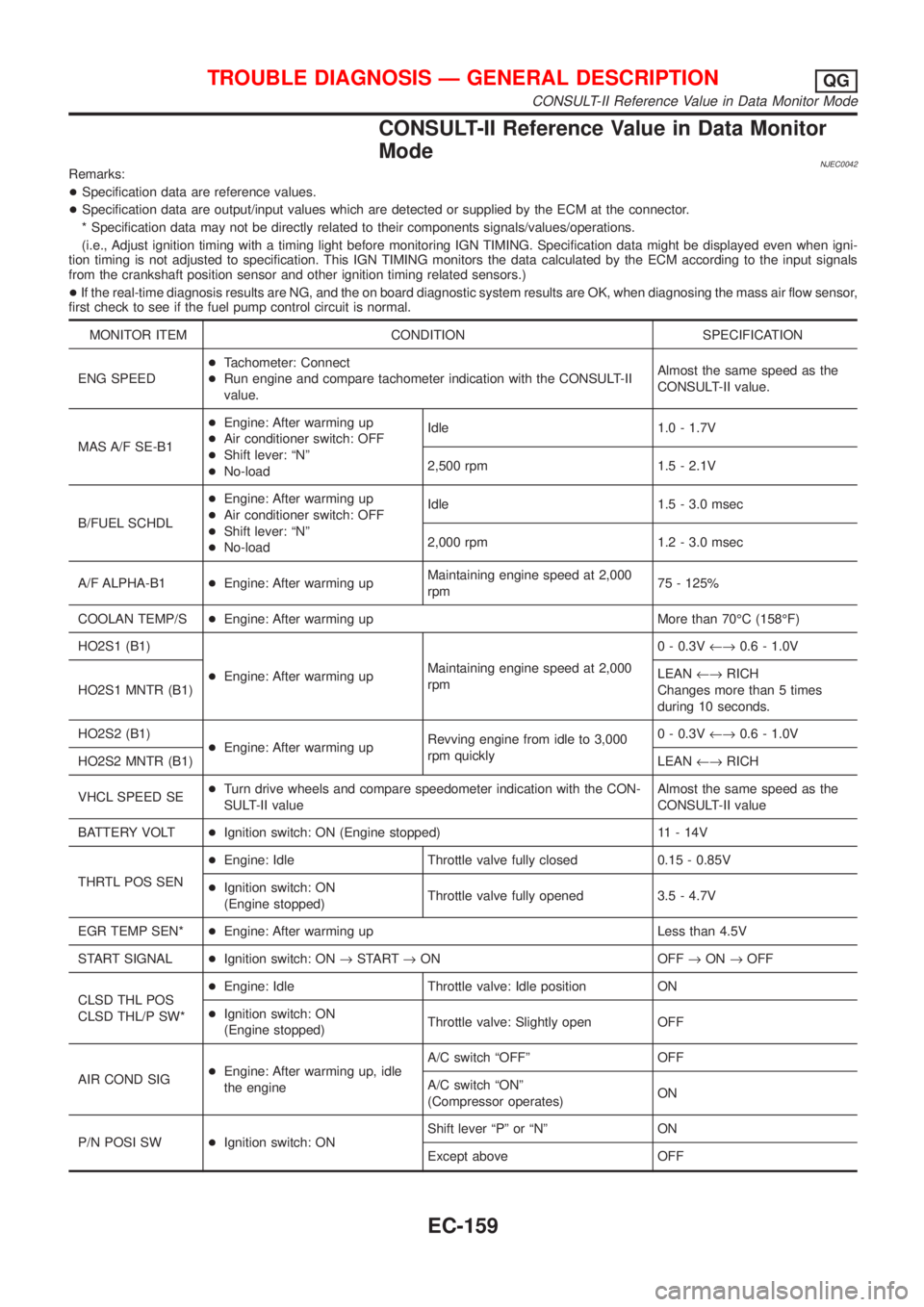

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0042Remarks:

+Specification data are reference values.

+Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

(i.e., Adjust ignition timing with a timing light before monitoring IGN TIMING. Specification data might be displayed even when igni-

tion timing is not adjusted to specification. This IGN TIMING monitors the data calculated by the ECM according to the input signals

from the crankshaft position sensor and other ignition timing related sensors.)

+If the real-time diagnosis results are NG, and the on board diagnostic system results are OK, when diagnosing the mass air flow sensor,

first check to see if the fuel pump control circuit is normal.

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value.

MAS A/F SE-B1+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ªNº

+No-loadIdle 1.0 - 1.7V

2,500 rpm 1.5 - 2.1V

B/FUEL SCHDL+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ªNº

+No-loadIdle 1.5 - 3.0 msec

2,000 rpm 1.2 - 3.0 msec

A/F ALPHA-B1+Engine: After warming upMaintaining engine speed at 2,000

rpm75 - 125%

COOLAN TEMP/S+Engine: After warming up More than 70ÉC (158ÉF)

HO2S1 (B1)

+Engine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V¨0.6 - 1.0V

HO2S1 MNTR (B1)LEAN¨RICH

Changes more than 5 times

during 10 seconds.

HO2S2 (B1)

+Engine: After warming upRevving engine from idle to 3,000

rpm quickly0 - 0.3V¨0.6 - 1.0V

HO2S2 MNTR (B1)LEAN¨RICH

VHCL SPEED SE+Turn drive wheels and compare speedometer indication with the CON-

SULT-II valueAlmost the same speed as the

CONSULT-II value

BATTERY VOLT+Ignition switch: ON (Engine stopped) 11 - 14V

THRTL POS SEN+Engine: Idle Throttle valve fully closed 0.15 - 0.85V

+Ignition switch: ON

(Engine stopped)Throttle valve fully opened 3.5 - 4.7V

EGR TEMP SEN*+Engine: After warming up Less than 4.5V

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

CLSD THL POS

CLSD THL/P SW*+Engine: Idle Throttle valve: Idle position ON

+Ignition switch: ON

(Engine stopped)Throttle valve: Slightly open OFF

AIR COND SIG+Engine: After warming up, idle

the engineA/C switch ªOFFº OFF

A/C switch ªONº

(Compressor operates)ON

P/N POSI SW+Ignition switch: ONShift lever ªPº or ªNº ON

Except above OFF

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

CONSULT-II Reference Value in Data Monitor Mode

EC-159

Page 884 of 2898

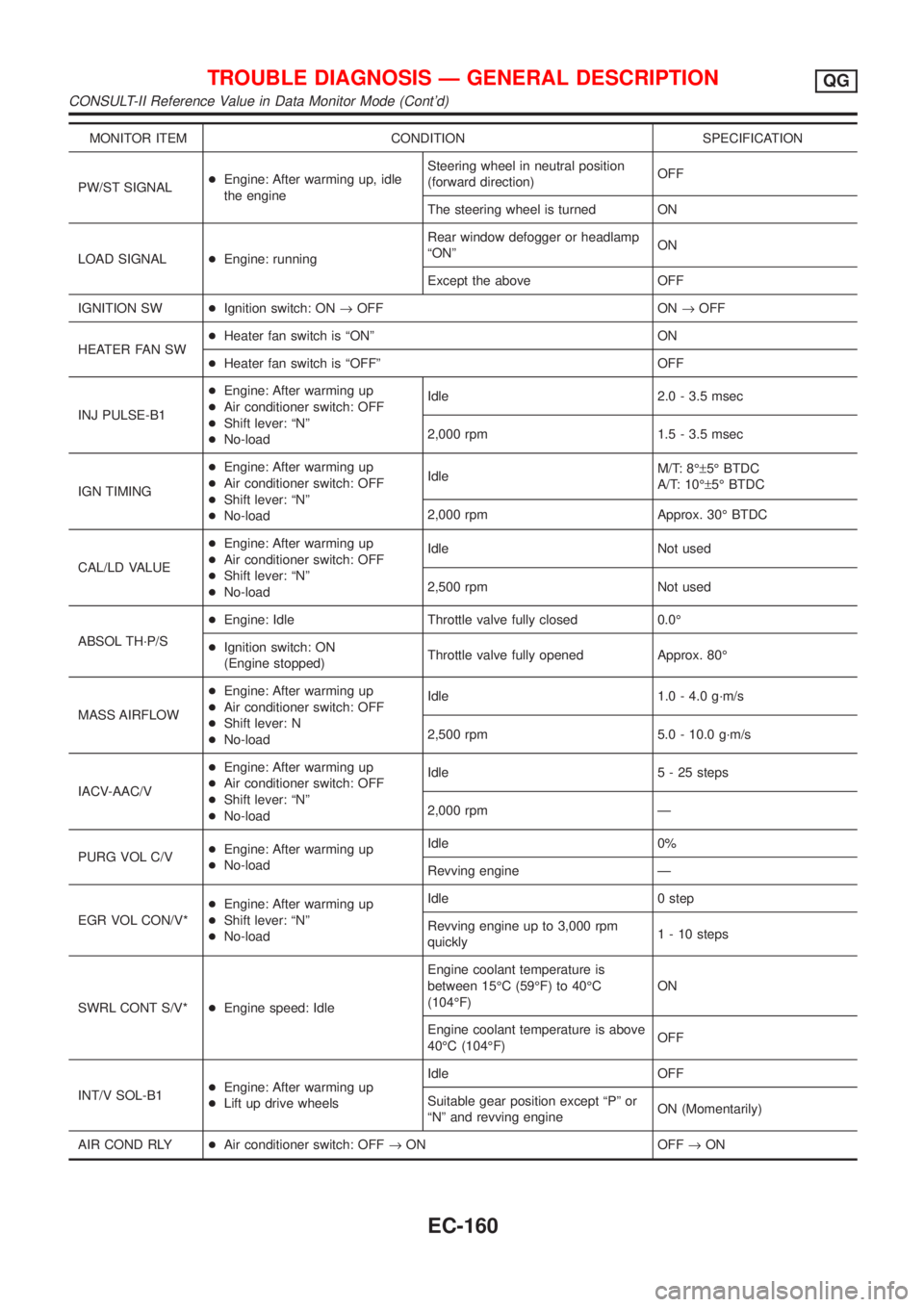

MONITOR ITEM CONDITION SPECIFICATION

PW/ST SIGNAL+Engine: After warming up, idle

the engineSteering wheel in neutral position

(forward direction)OFF

The steering wheel is turned ON

LOAD SIGNAL+Engine: runningRear window defogger or headlamp

ªONºON

Except the above OFF

IGNITION SW+Ignition switch: ON®OFF ON®OFF

HEATER FAN SW+Heater fan switch is ªONº ON

+Heater fan switch is ªOFFº OFF

INJ PULSE-B1+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ªNº

+No-loadIdle 2.0 - 3.5 msec

2,000 rpm 1.5 - 3.5 msec

IGN TIMING+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ªNº

+No-loadIdleM/T: 8ɱ5É BTDC

A/T: 10ɱ5É BTDC

2,000 rpm Approx. 30É BTDC

CAL/LD VALUE+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ªNº

+No-loadIdle Not used

2,500 rpm Not used

ABSOL TH´P/S+Engine: Idle Throttle valve fully closed 0.0É

+Ignition switch: ON

(Engine stopped)Throttle valve fully opened Approx. 80É

MASS AIRFLOW+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: N

+No-loadIdle 1.0 - 4.0 g´m/s

2,500 rpm 5.0 - 10.0 g´m/s

IACV-AAC/V+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ªNº

+No-loadIdle 5 - 25 steps

2,000 rpm Ð

PURG VOL C/V+Engine: After warming up

+No-loadIdle 0%

Revving engine Ð

EGR VOL CON/V*+Engine: After warming up

+Shift lever: ªNº

+No-loadIdle 0 step

Revving engine up to 3,000 rpm

quickly1 - 10 steps

SWRL CONT S/V*+Engine speed: IdleEngine coolant temperature is

between 15ÉC (59ÉF) to 40ÉC

(104ÉF)ON

Engine coolant temperature is above

40ÉC (104ÉF)OFF

INT/V SOL-B1+Engine: After warming up

+Lift up drive wheelsIdle OFF

Suitable gear position except ªPº or

ªNº and revving engineON (Momentarily)

AIR COND RLY+Air conditioner switch: OFF®ON OFF®ON

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-160

Page 885 of 2898

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLY+Ignition switch is turned to ON (Operates for 1 second)

+Engine running and cranking

+When engine is stopped (stops in 1.5 seconds)ON

+Except as shown above OFF

COOLING FAN+After warming up engine, idle

the engine.

+Air conditioner switch: OFFEngine coolant temperature is 99ÉC

(210ÉF) or lessOFF

Engine coolant temperature is 100ÉC

(212ÉF) or moreON

HO2S1 HTR (B1)+Engine speed: Below 3,200 rpm ON

+Engine speed: Above 3,200 rpm OFF

HO2S2 HTR (B1)+Engine speedBelow 3,600 rpm [After driving for 2

minutes at a speed of 70 km/h (43

MPH) or more]ON

Above 3,600 rpm OFF

+Ignition switch ON (Engine stopped) OFF

TRVL AFTER MI+Ignition switch: ONVehicle has traveled after MI has

turned ON.0 - 65,535 km

(0 - 40,723 mile)

*: If so equipped

Major Sensor Reference Graph in Data Monitor

Mode

NJEC0043The following are the major sensor reference graphs in ªDATA MONITORº mode.

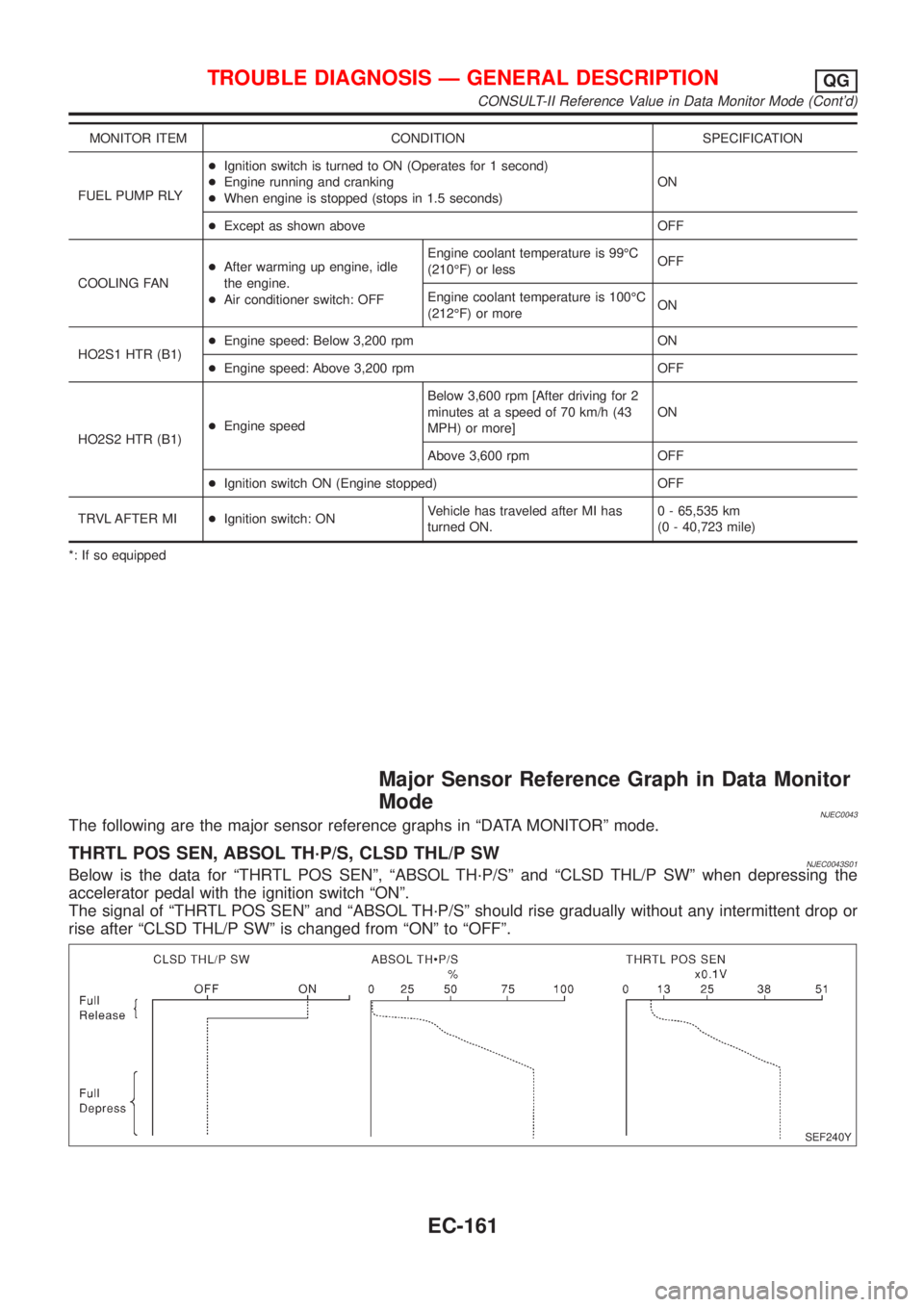

THRTL POS SEN, ABSOL TH´P/S, CLSD THL/P SWNJEC0043S01Below is the data for ªTHRTL POS SENº, ªABSOL TH´P/Sº and ªCLSD THL/P SWº when depressing the

accelerator pedal with the ignition switch ªONº.

The signal of ªTHRTL POS SENº and ªABSOL TH´P/Sº should rise gradually without any intermittent drop or

rise after ªCLSD THL/P SWº is changed from ªONº to ªOFFº.

SEF240Y

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-161

Page 886 of 2898

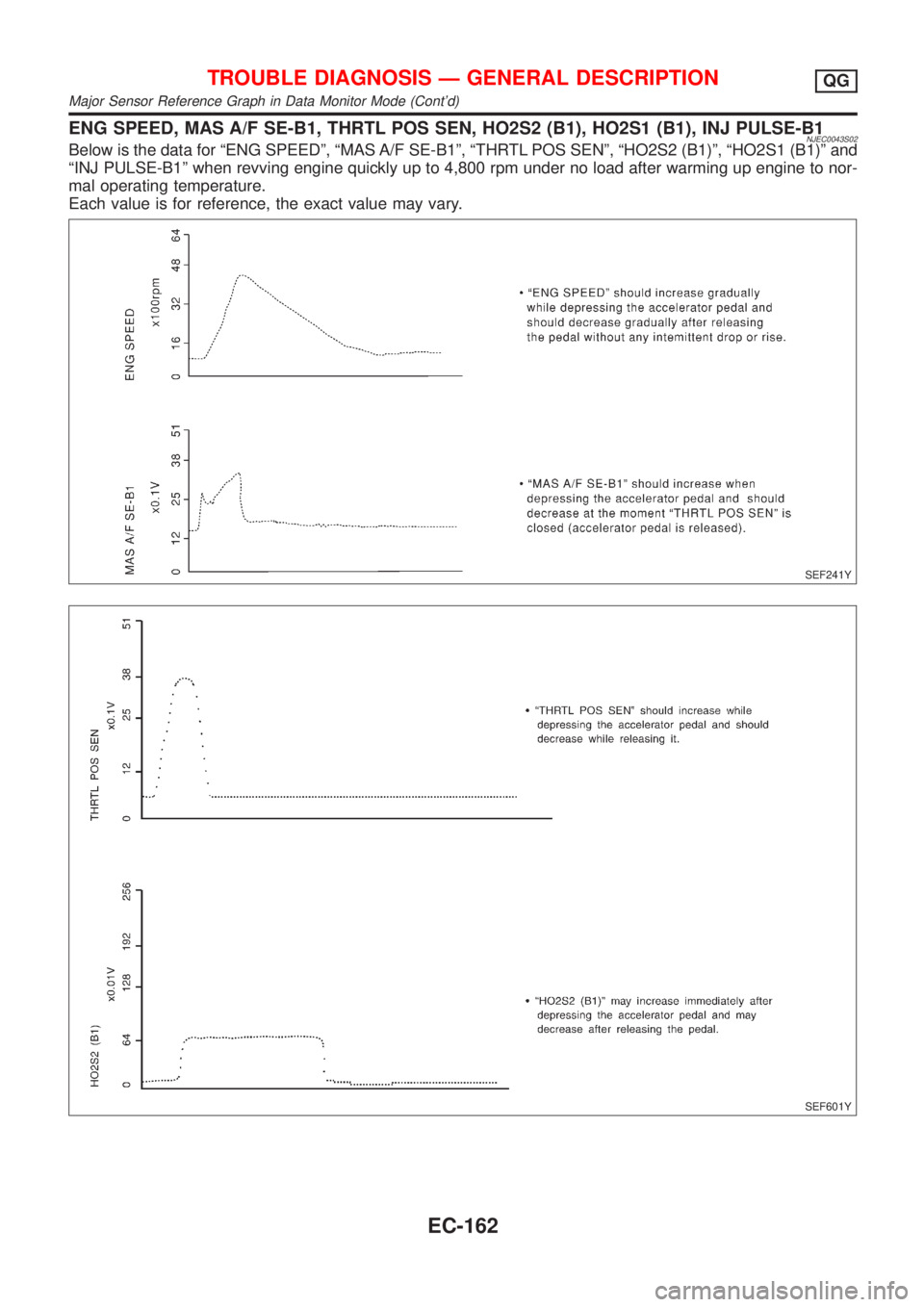

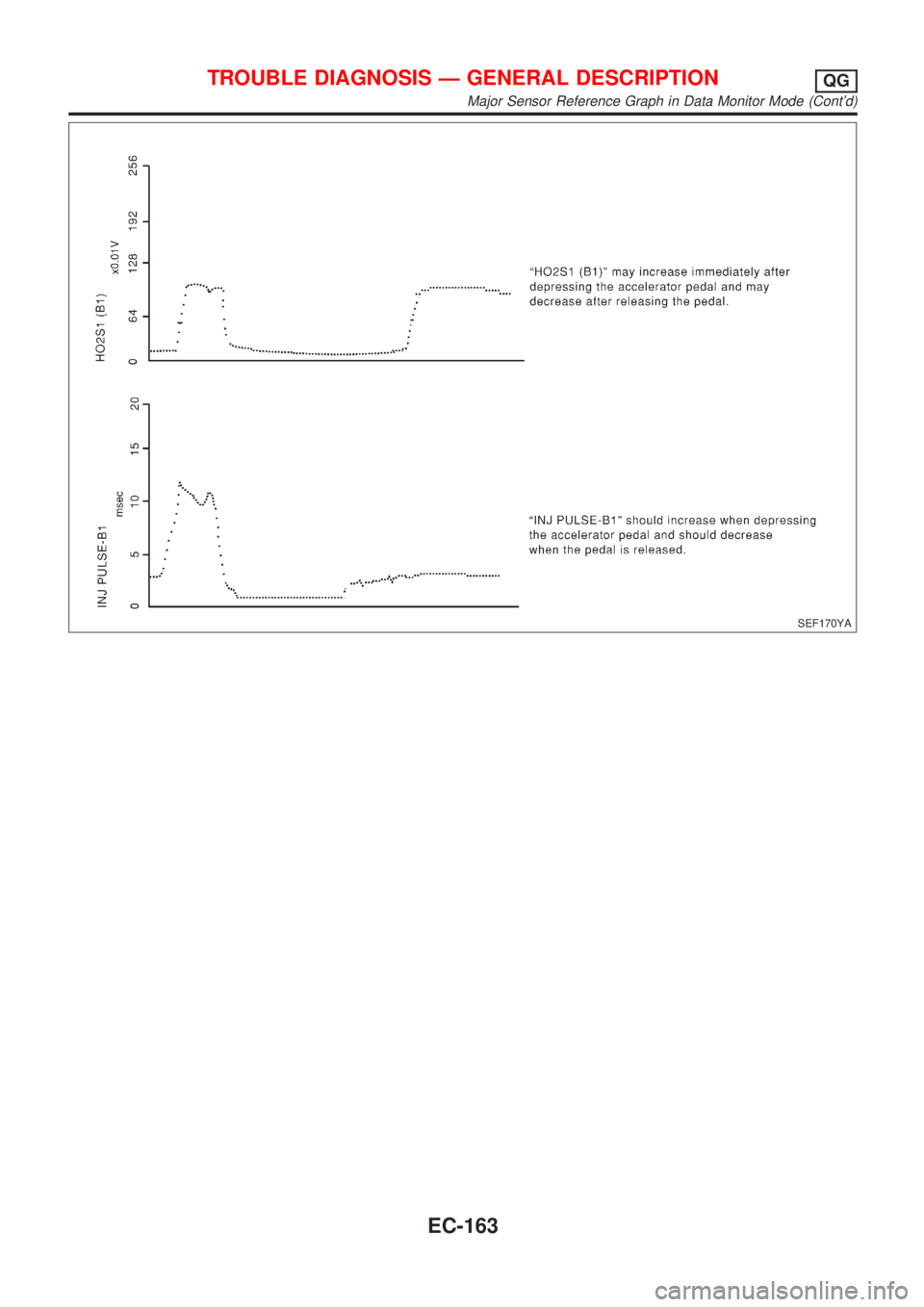

ENG SPEED, MAS A/F SE-B1, THRTL POS SEN, HO2S2 (B1), HO2S1 (B1), INJ PULSE-B1NJEC0043S02Below is the data for ªENG SPEEDº, ªMAS A/F SE-B1º, ªTHRTL POS SENº, ªHO2S2 (B1)º, ªHO2S1 (B1)º and

ªINJ PULSE-B1º when revving engine quickly up to 4,800 rpm under no load after warming up engine to nor-

mal operating temperature.

Each value is for reference, the exact value may vary.

SEF241Y

SEF601Y

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Major Sensor Reference Graph in Data Monitor Mode (Cont'd)

EC-162

Page 887 of 2898

SEF170YA

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Major Sensor Reference Graph in Data Monitor Mode (Cont'd)

EC-163

Page 888 of 2898

SEF553Y

JEF096Y

SEF097Y

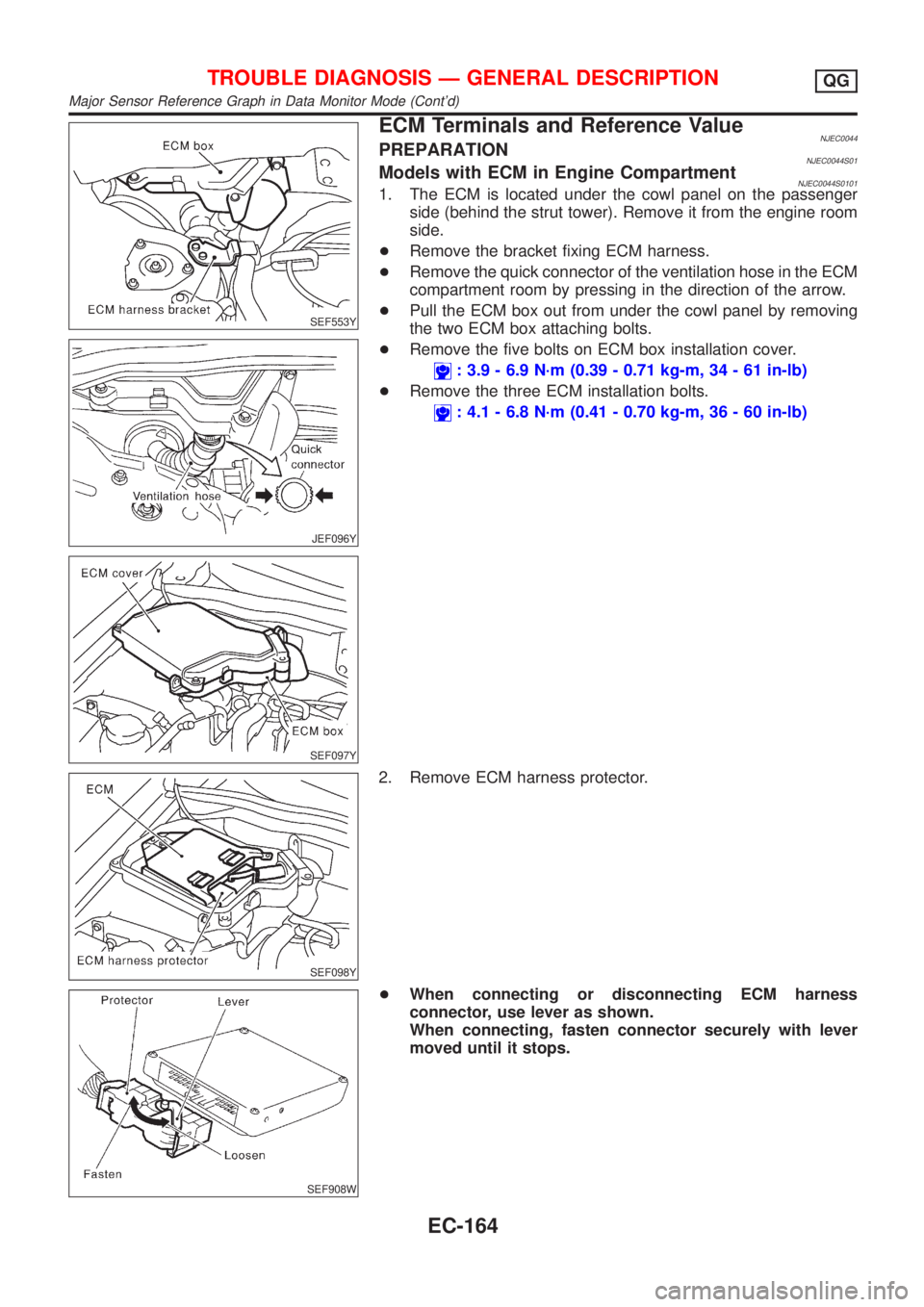

ECM Terminals and Reference ValueNJEC0044PREPARATIONNJEC0044S01Models with ECM in Engine CompartmentNJEC0044S01011. The ECM is located under the cowl panel on the passenger

side (behind the strut tower). Remove it from the engine room

side.

+Remove the bracket fixing ECM harness.

+Remove the quick connector of the ventilation hose in the ECM

compartment room by pressing in the direction of the arrow.

+Pull the ECM box out from under the cowl panel by removing

the two ECM box attaching bolts.

+Remove the five bolts on ECM box installation cover.

: 3.9 - 6.9 N´m (0.39 - 0.71 kg-m, 34 - 61 in-lb)

+Remove the three ECM installation bolts.

: 4.1 - 6.8 N´m (0.41 - 0.70 kg-m, 36 - 60 in-lb)

SEF098Y

2. Remove ECM harness protector.

SEF908W

+When connecting or disconnecting ECM harness

connector, use lever as shown.

When connecting, fasten connector securely with lever

moved until it stops.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Major Sensor Reference Graph in Data Monitor Mode (Cont'd)

EC-164

Page 889 of 2898

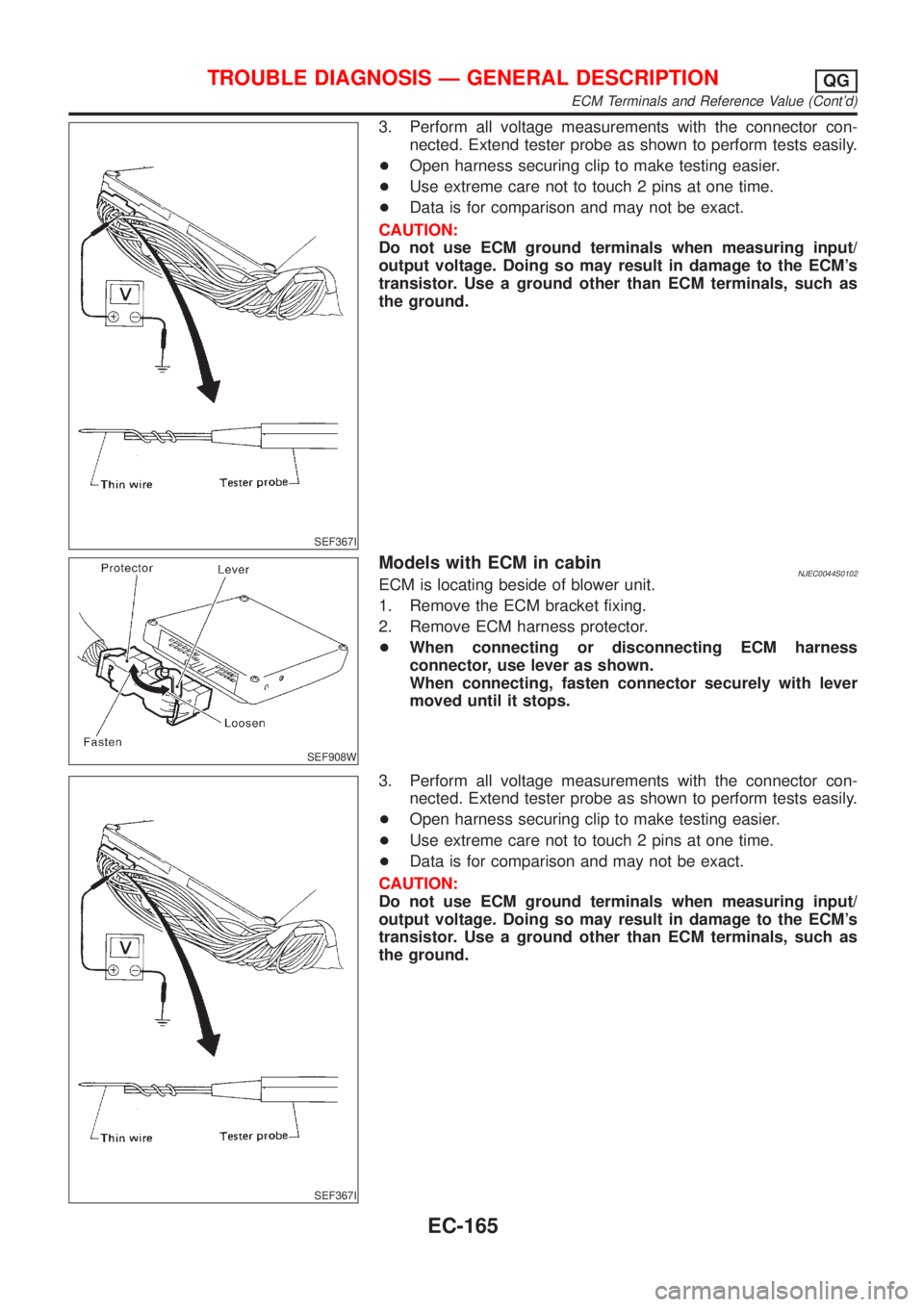

SEF367I

3. Perform all voltage measurements with the connector con-

nected. Extend tester probe as shown to perform tests easily.

+Open harness securing clip to make testing easier.

+Use extreme care not to touch 2 pins at one time.

+Data is for comparison and may not be exact.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

SEF908W

Models with ECM in cabinNJEC0044S0102ECM is locating beside of blower unit.

1. Remove the ECM bracket fixing.

2. Remove ECM harness protector.

+When connecting or disconnecting ECM harness

connector, use lever as shown.

When connecting, fasten connector securely with lever

moved until it stops.

SEF367I

3. Perform all voltage measurements with the connector con-

nected. Extend tester probe as shown to perform tests easily.

+Open harness securing clip to make testing easier.

+Use extreme care not to touch 2 pins at one time.

+Data is for comparison and may not be exact.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

ECM Terminals and Reference Value (Cont'd)

EC-165

Page 890 of 2898

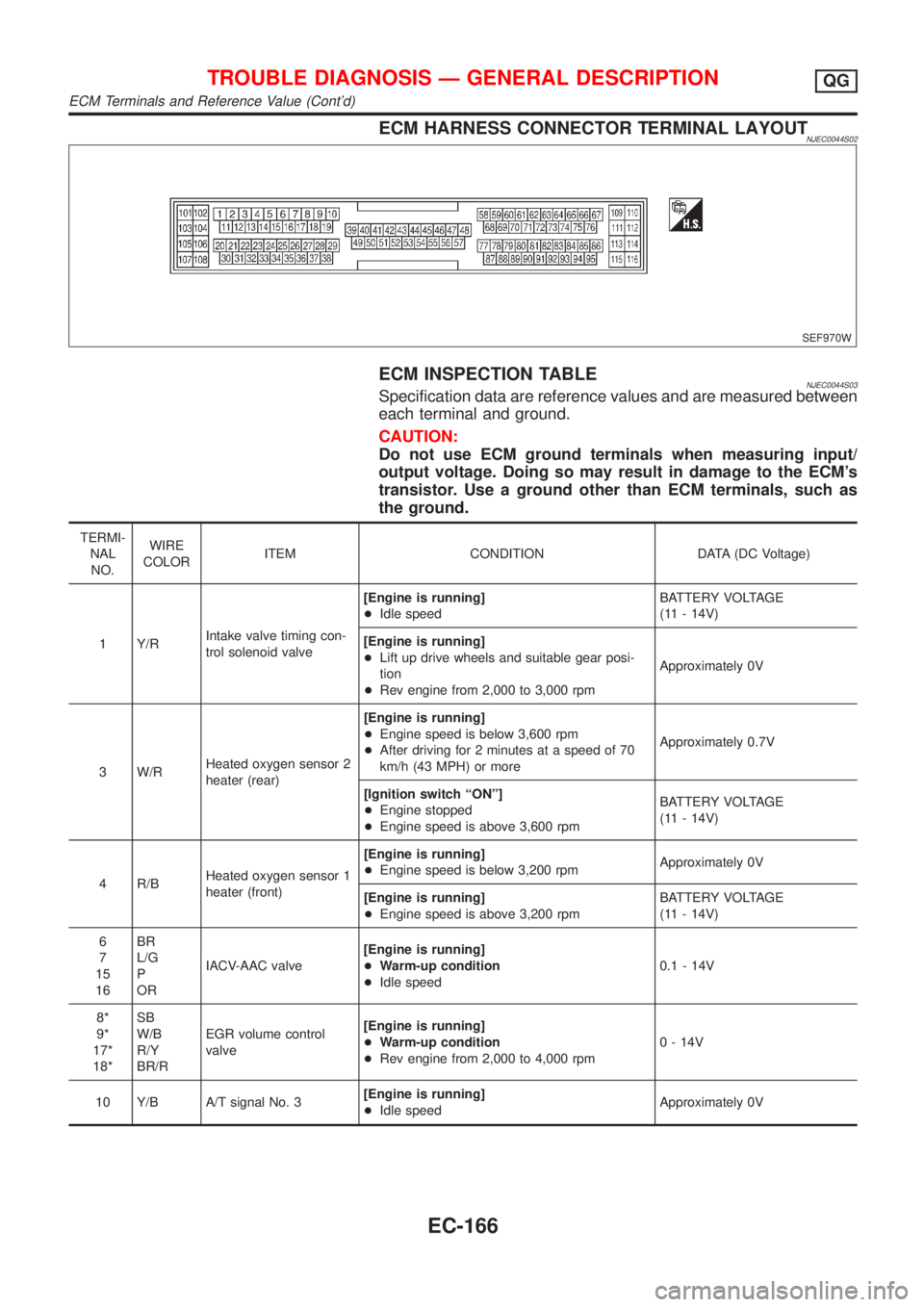

ECM HARNESS CONNECTOR TERMINAL LAYOUTNJEC0044S02

SEF970W

ECM INSPECTION TABLENJEC0044S03Specification data are reference values and are measured between

each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

1 Y/RIntake valve timing con-

trol solenoid valve[Engine is running]

+Idle speedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Lift up drive wheels and suitable gear posi-

tion

+Rev engine from 2,000 to 3,000 rpmApproximately 0V

3 W/RHeated oxygen sensor 2

heater (rear)[Engine is running]

+Engine speed is below 3,600 rpm

+After driving for 2 minutes at a speed of 70

km/h (43 MPH) or moreApproximately 0.7V

[Ignition switch ªONº]

+Engine stopped

+Engine speed is above 3,600 rpmBATTERY VOLTAGE

(11 - 14V)

4 R/BHeated oxygen sensor 1

heater (front)[Engine is running]

+Engine speed is below 3,200 rpmApproximately 0V

[Engine is running]

+Engine speed is above 3,200 rpmBATTERY VOLTAGE

(11 - 14V)

6

7

15

16BR

L/G

P

ORIACV-AAC valve[Engine is running]

+Warm-up condition

+Idle speed0.1 - 14V

8*

9*

17*

18*SB

W/B

R/Y

BR/REGR volume control

valve[Engine is running]

+Warm-up condition

+Rev engine from 2,000 to 4,000 rpm0 - 14V

10 Y/B A/T signal No. 3[Engine is running]

+Idle speedApproximately 0V

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

ECM Terminals and Reference Value (Cont'd)

EC-166