NISSAN ALMERA N15 1995 Service Manual

ALMERA N15 1995

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57349/w960_57349-0.png

NISSAN ALMERA N15 1995 Service Manual

Page 648 of 1701

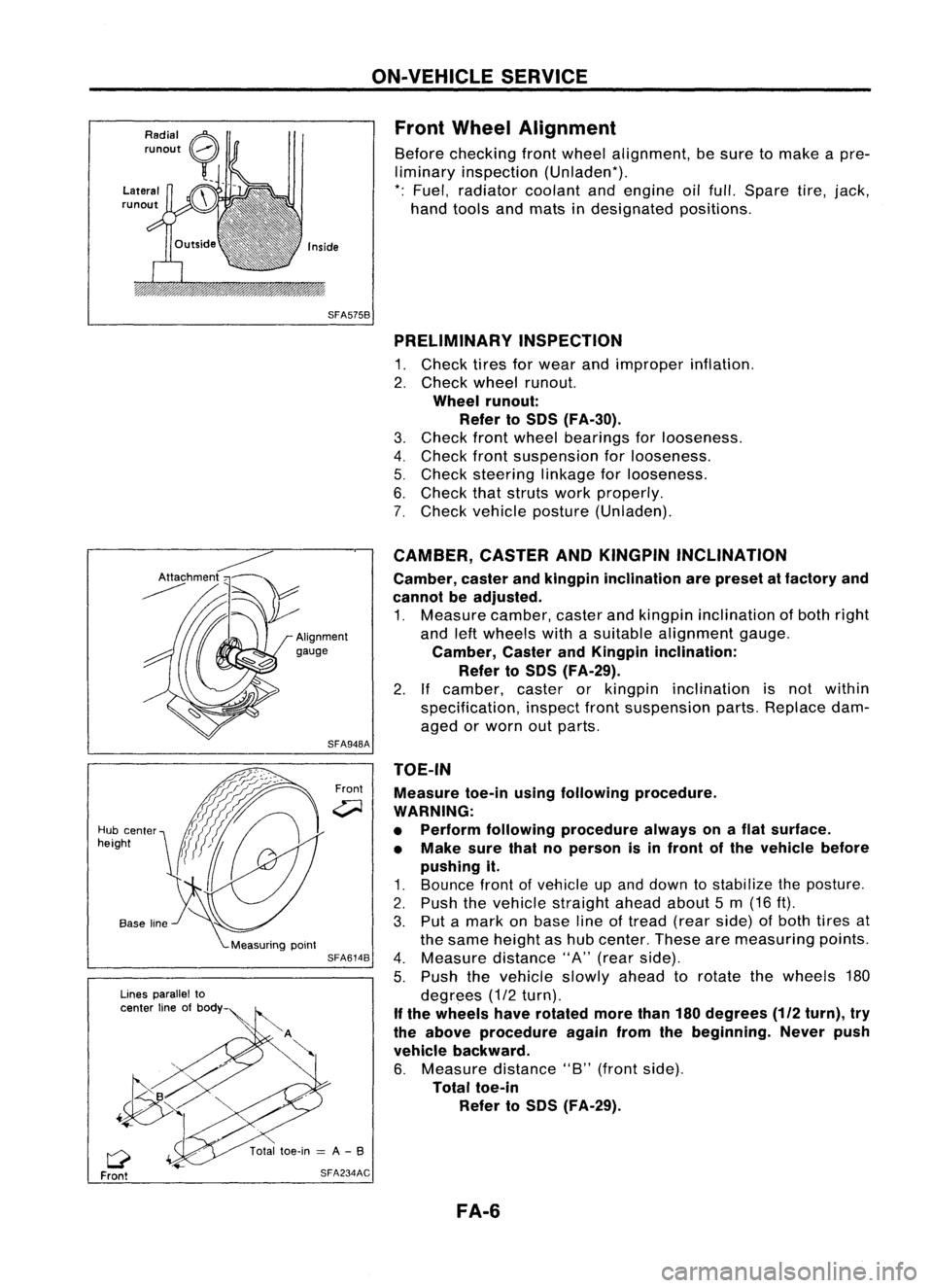

HARNESSLAYOUT

En. R

ENGINE COMPARTMENT RH

gmeoomHarness (Conl'd)

- 0models

C\I

L.L.

w

o

o

«

001

@ @

@

@ @

@ @

N

-Ie

w

~ 0

D

o

«

C\I

EL-276

HEL

156

Page 649 of 1701

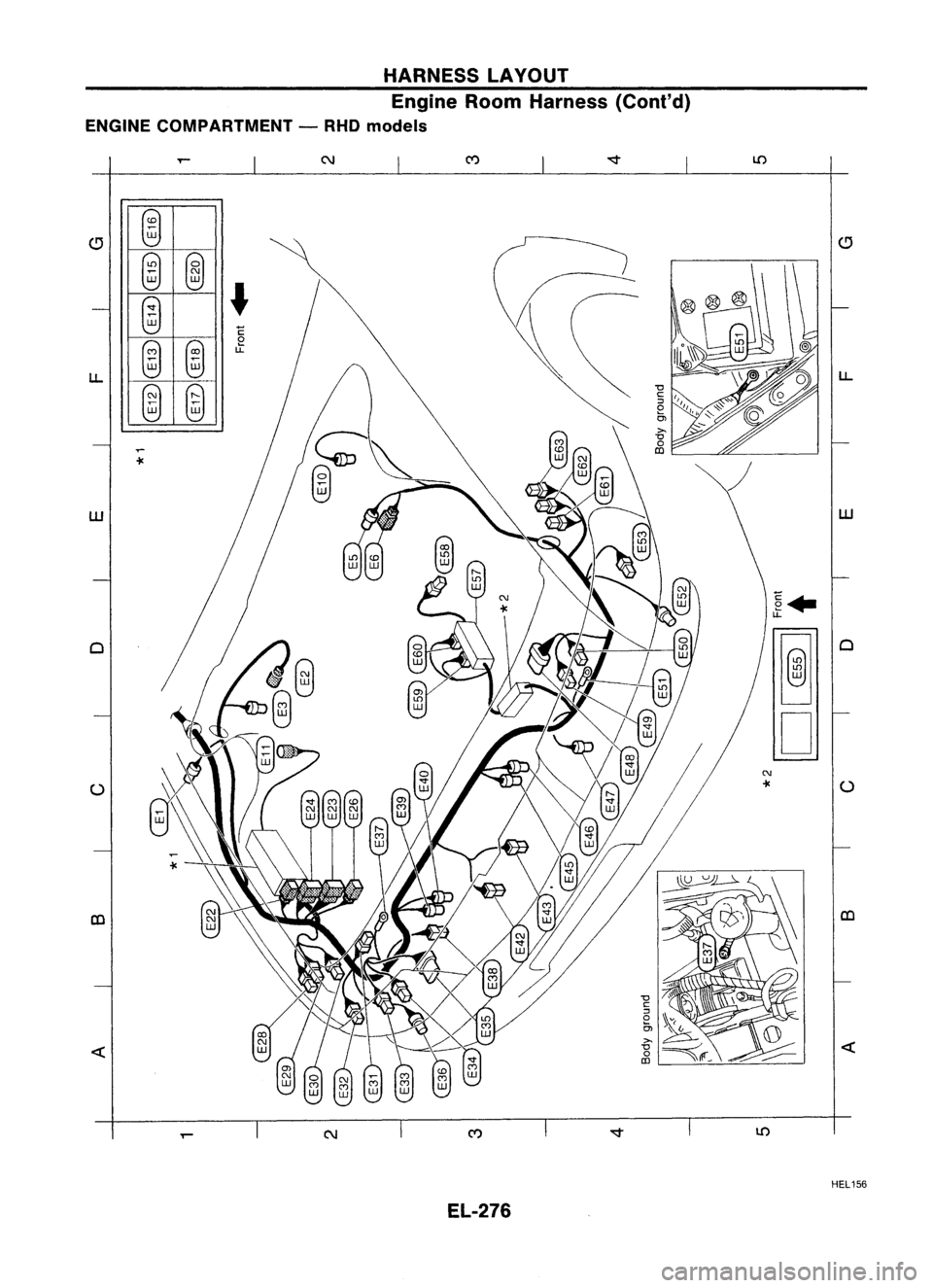

HARNESSLAYOUT

Engine RoomHarness (Conl'd)

c-

o

:;

W

0-

o

:;

W

@@@@@@@@@@ @@@@@@@@@@@@@@@@@

M MMM NMMM M~

««««ucouucoco

~

~~ ~~~~ ~ ~~MM MM ~ ~~

couuuuooowowwoowww

•

c

6>

c

Q)

o

u

Q)

c

"6>

c

Q)

«

CJ

T-

N

(\J

NN

(\J

NN

(\J

CJ

co

U UU

«« «««

(0

ii

co

@@@@@

@

@@@@@@@@@@

C\I

NN

C\l

N

(\J

T-

UOOWWWULL

I

a:

.c

c- ()

S "~

~ (J)

Cii

Qi

c

>

Ol~

"m

-0

c

"5

.a ;:;::

Q)

11

-0 ~

i:7i

co

HEL157

EL-277

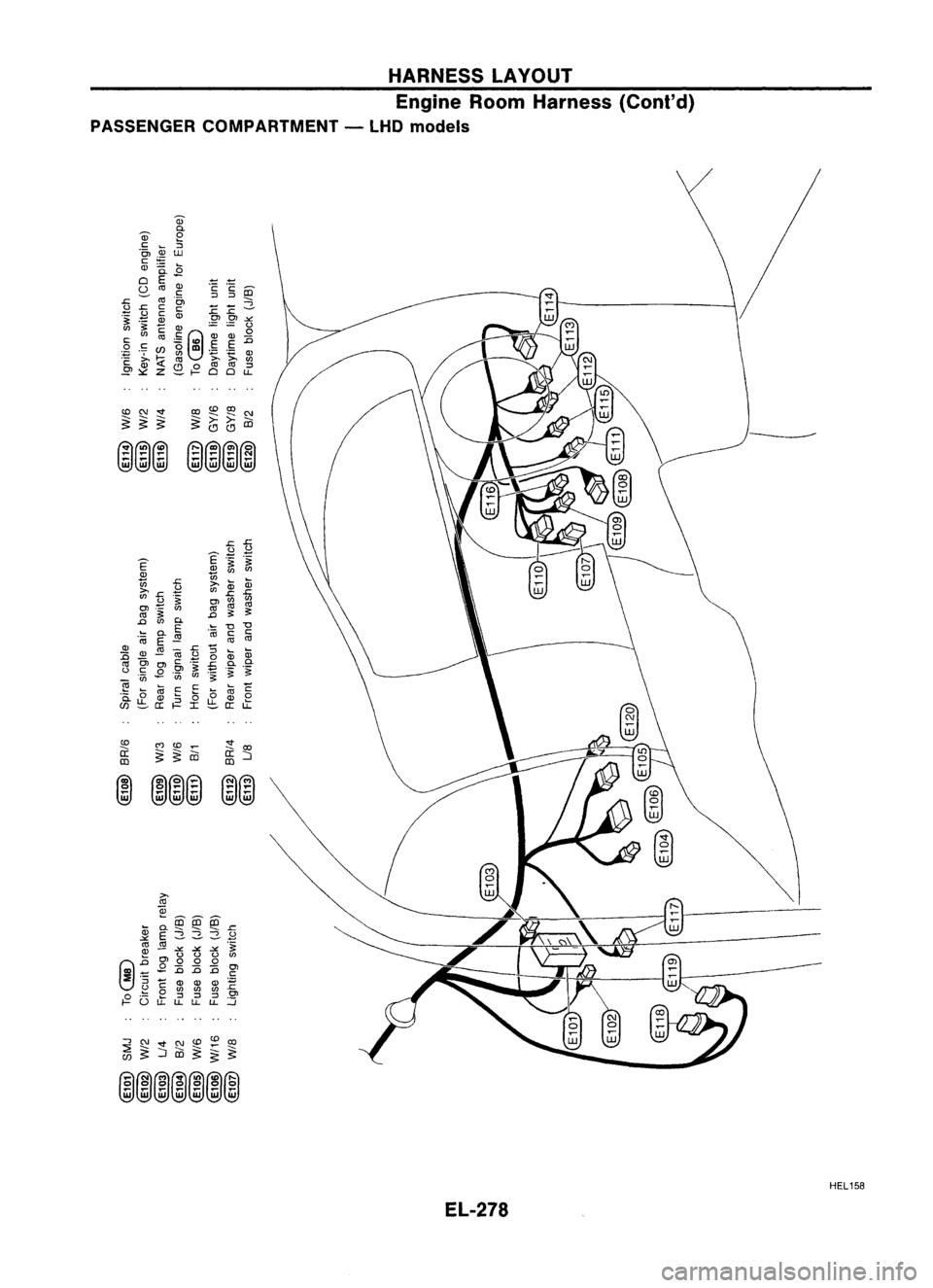

Page 650 of 1701

HARNESSLAYOUT

Engine RoomHarness (Coni'd)

PASSENGER COMPARTMENT -

LHO

models

(0

C\I '

~ ~ ~

~(ID(ID

(0

C')

(0

ffi ~~co

(&) OO@)@

HEL158

EL-278

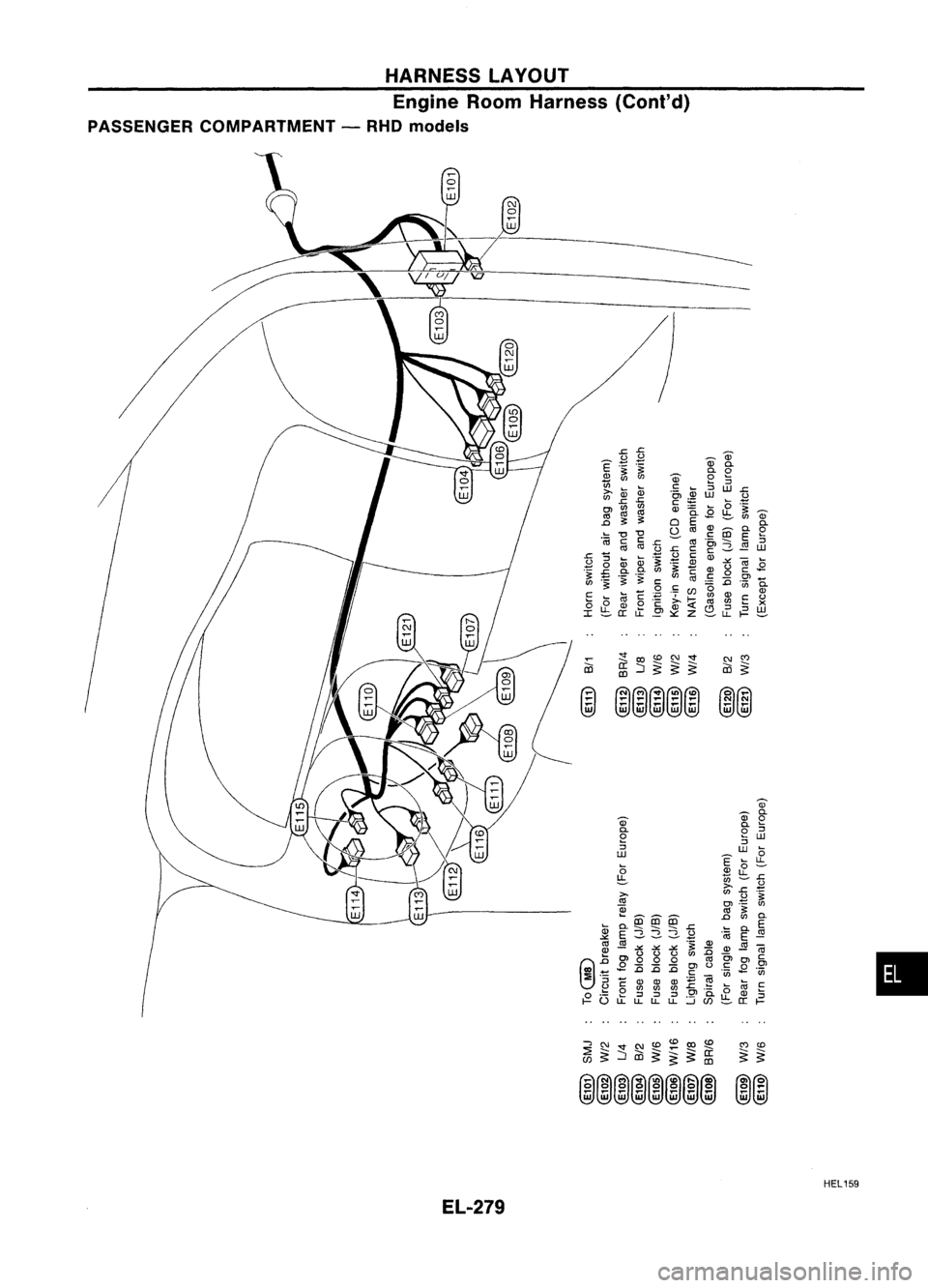

Page 651 of 1701

HARNESSLAYOUr

Engine RoomHarness (Cont'd)

PASSENGER COMPARTMENT -RHO models

•

EL-279

C')

co

~ ~

~~

HEL159

Page 666 of 1701

GAENGINE HARNESS

LAYOUT

Engine Harness

o ~

0.

(])

~w

c:

~~

Ql

"5>

()

x

c:

(])

"~

(])

(/)

~ w

Qi

0

"0

tii

It)

"~

0

::J

~

E

<:

<:

"0

C9

tii

I-

~

c:

0.

Ql

::J

Cll

a.

<:

(])

0

~

Ql

Qi

()

:s

c:

Cll

x

E

"5>

u;

(])

W

Ql

(/)

c:

(/)

a.

m

Ql

Ql

Qi

e

E

"0

ill

0."0

::J

0

0

o

0

ill

0.

E

CD

5

E

(])

~w

t:

0

()

~

x

.E

LL

W

C9

:ii

:-

Z'l

i"'

;'!"

~

EL-294

HEL

167

Page 667 of 1701

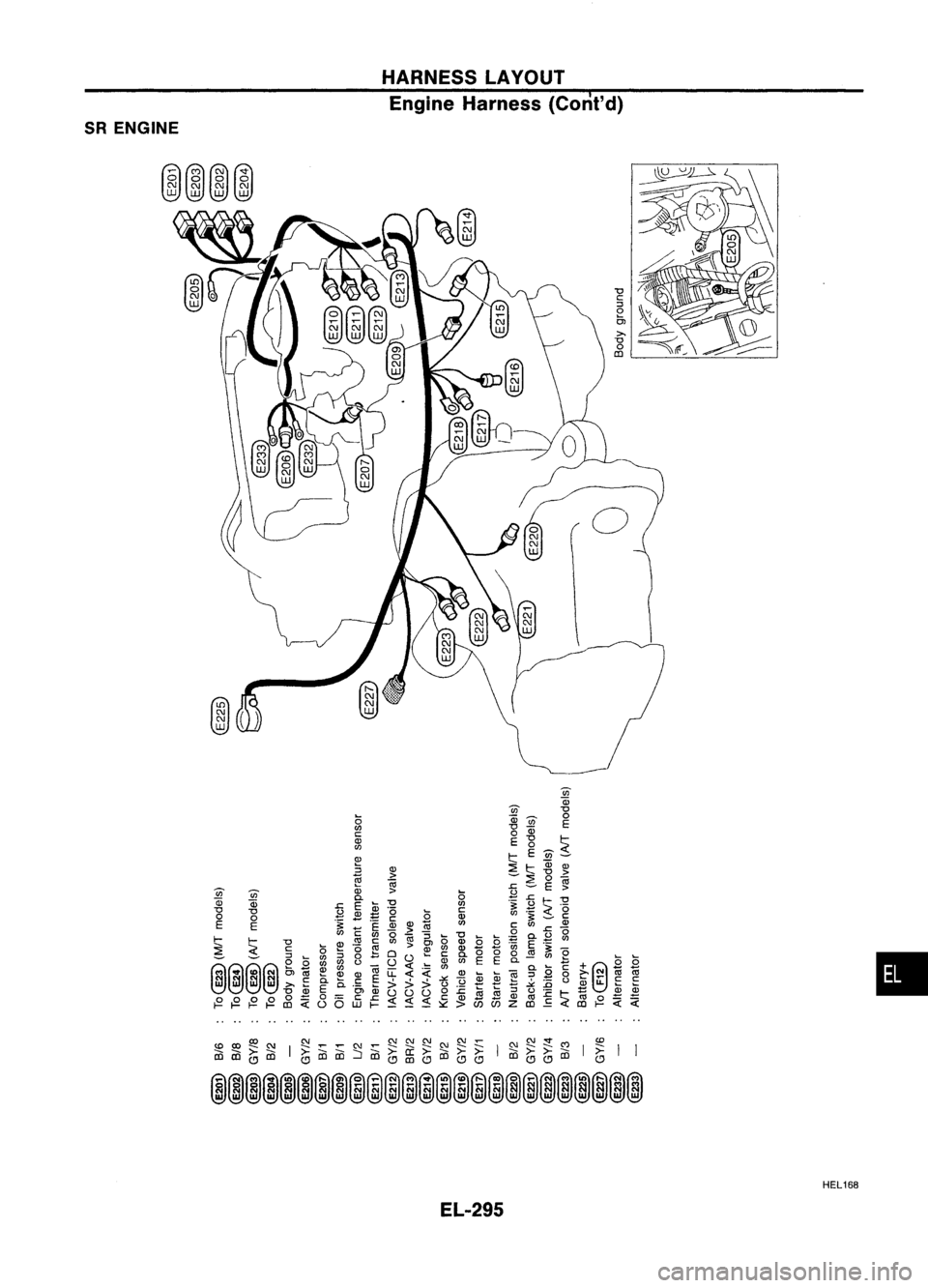

SRENGINE HARNESS

LAYOUT

Engine Harness (Corlt'd)

5

en

c

Ql

en

-g

0

B

~ (5

0

en

E E

EL-295 HEL168

•

Page 668 of 1701

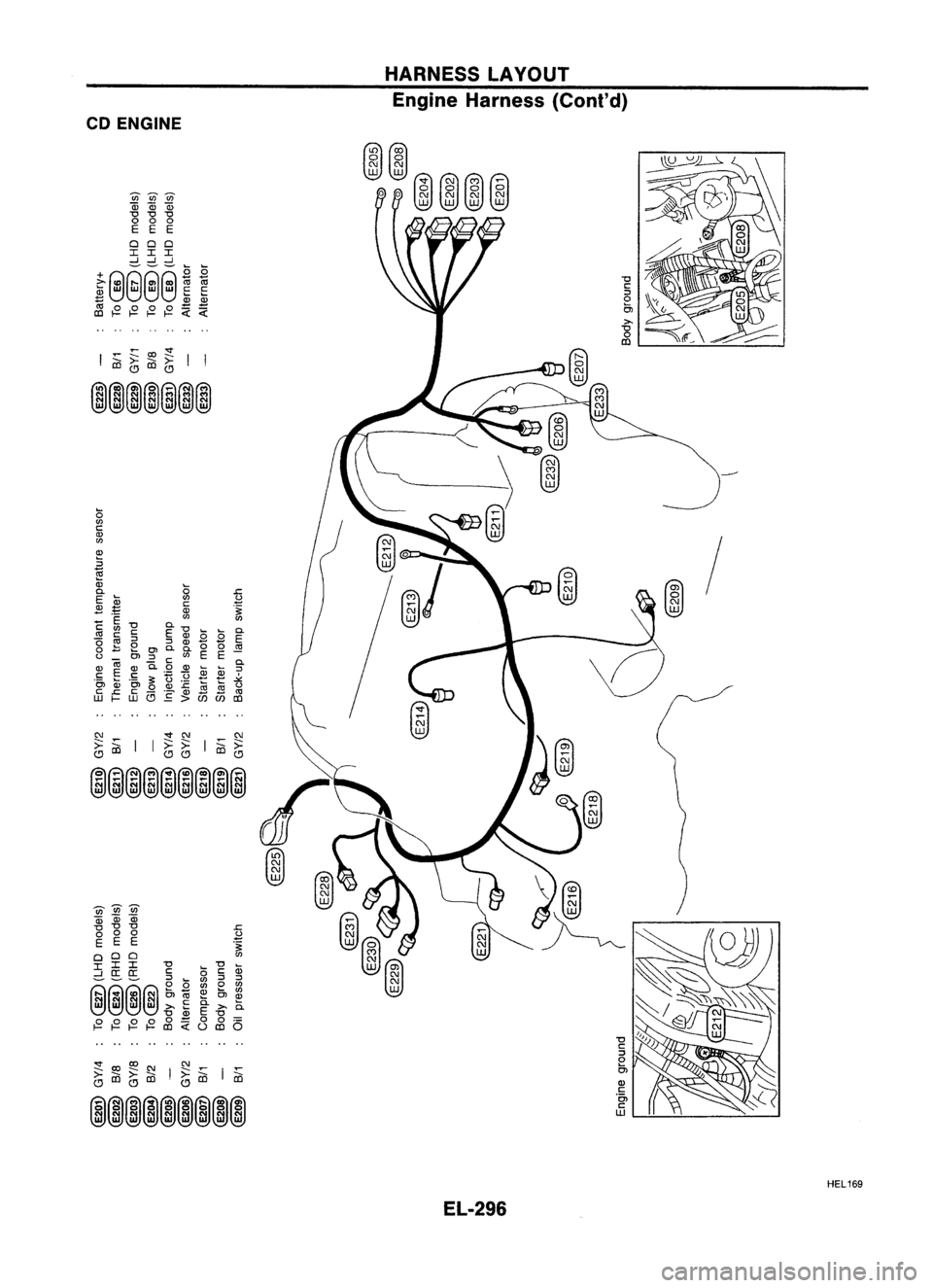

HARNESSLAYOUr

Engine Harness (Cont'd)

CD ENGINE

~

/

"0

C

:>

e

Ol

Q)

c

"5>

c

W

<5

(J)

c

Q)

(J)

~

:>

'@

Q)

c.

~

"~

c ~

tIl

C

g ~

u

Q)

Oi

c

E

"5>

Q;

c

.c

W

I-

HEL169

EL-296

Page 684 of 1701

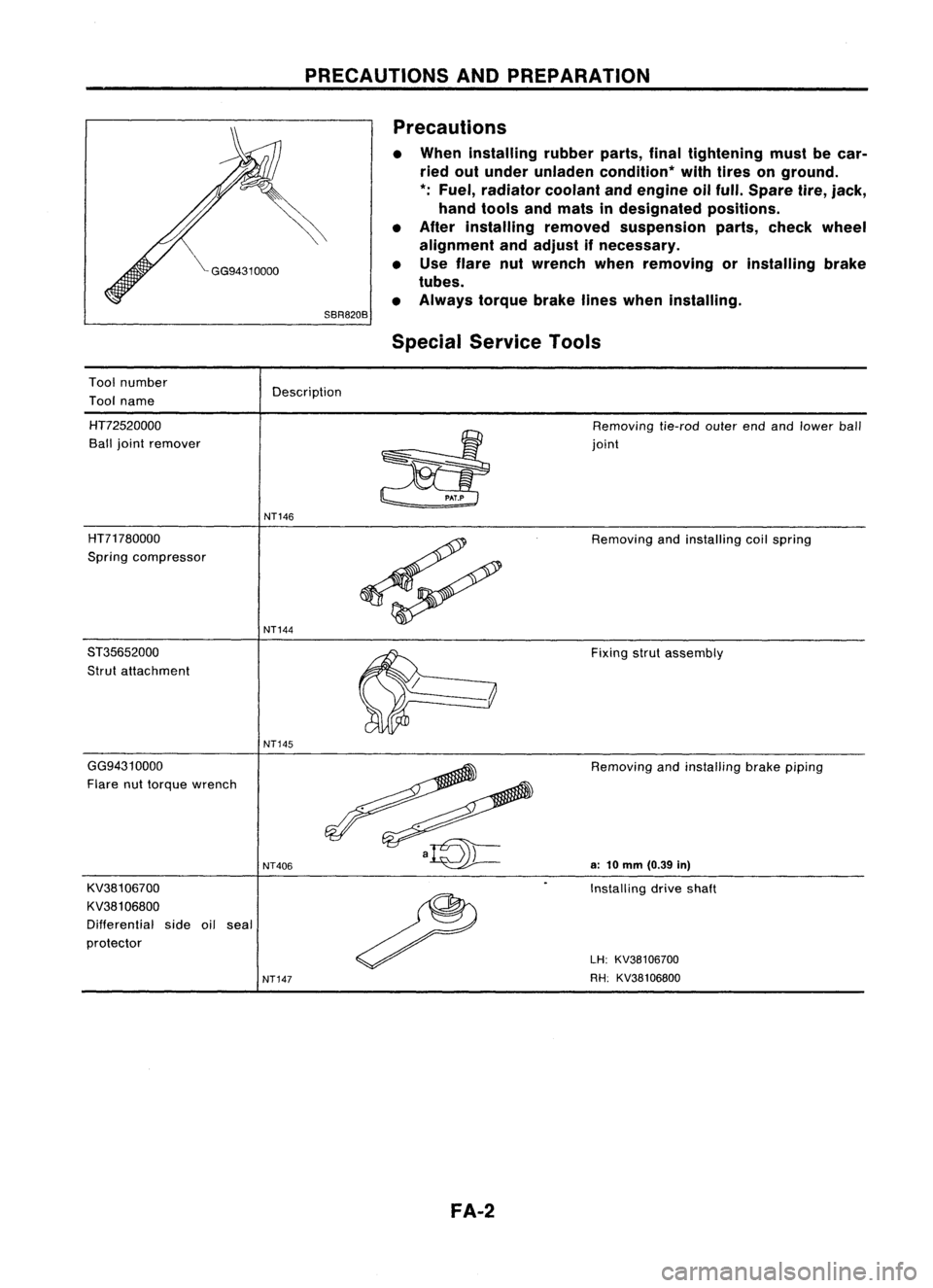

PRECAUTIONSANDPREPARATION

Precautions

• When installing rubberparts,finaltightening mustbecar-

ried outunder unladen condition* withtires onground.

*: Fuel, radiator coolantandengine oilfull. Spare tire,

jack,

hand tools andmats indesignated positions.

• After installing removedsuspension parts,check wheel

alignment andadjust ifnecessary.

• Use flare nutwrench whenremoving orinstalling brake

tubes.

• Always torquebrakelineswhen installing.

Tool number

Tool name

SBR820B

Special Service Tools

Description

HT72520000

Ball joint remover Removing

tie-rodouterendandlower ball

joint

NT146

HT71780000

Spring compressor

ST35652000

Strut attachment

NT144

Removing

andinstalling coilspring

Fixing strutassembly

NT145

GG94310000

Flare nuttorque wrench

KV38106700

KV381 06800

Differential sideoilseal

protector

NT406

NT147

FA-2

Removing

andinstalling brakepiping

a:

10mm (0.39 in)

Installing driveshaft

LH: KV38106700

RH: KV38106800

Page 686 of 1701

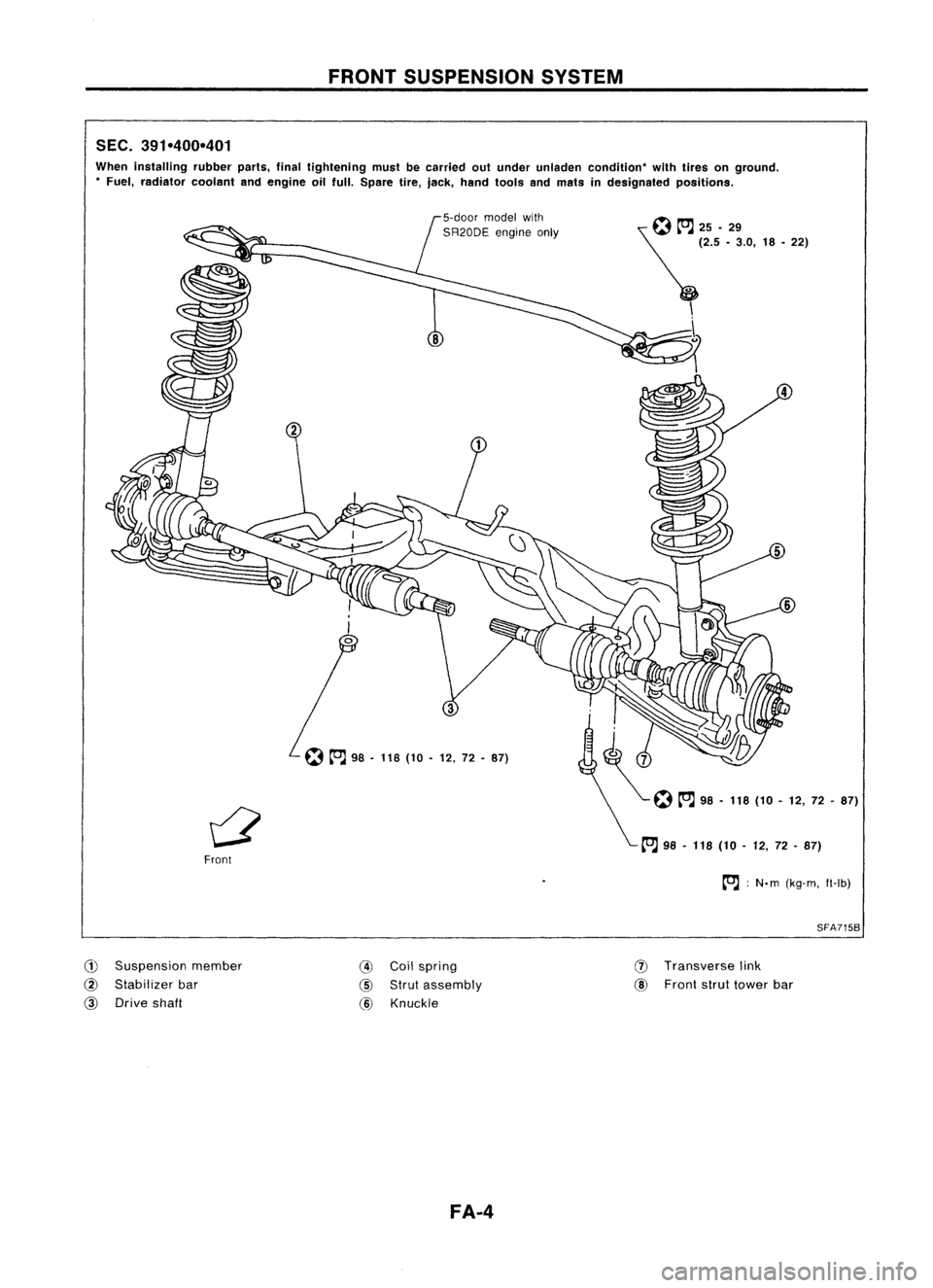

FRONTSUSPENSION SYSTEM

SEC. 391-400-401

When installing rubberparts,finaltightening mustbecarried outunder unladen condition" withtires onground .

• Fuel, radiator coolantandengine oilfull. Spare tire,jack, hand tools andmats indesignated positions.

~~25.29

~ (2.5•3.0, 18•22)

\ \

...

5

~ 98•118 (10•12, 72•87)

Front

to.J:

N. m (kg-m, ft-Ib)

SFA715B

CD

Suspension member

@

Stabilizer bar

@

Drive shaft

@

Coilspring

@

Strut assembly

@

Knuckle

FA-4

(J)

Transverse link

@

Front struttower bar

Page 688 of 1701

ON-VEHICLESERVICE

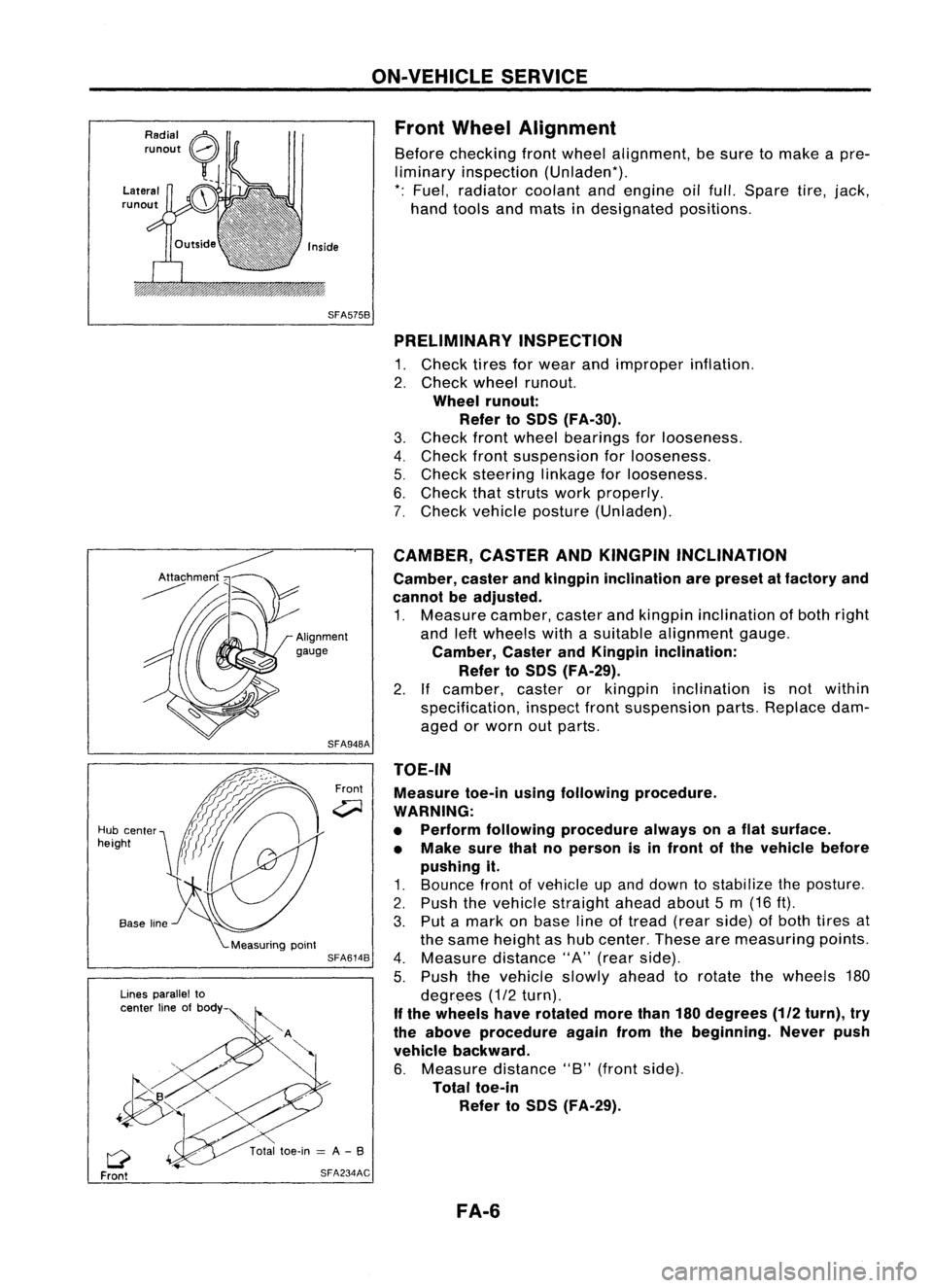

Front Wheel Alignment

Before checking frontwheel alignment, besure tomake apre-

liminary inspection (Unladen*).

*: Fuel, radiator coolantandengine oilfull. Spare tire,jack,

hand tools andmats indesignated positions.

SFA575B PRELIMINARY INSPECTION

1. Check tiresforwear andimproper inflation.

2. Check wheelrunout.

Wheel runout:

Refer toSOS (FA-30).

3. Check frontwheel bearings forlooseness.

4. Check frontsuspension forlooseness.

5. Check steering linkageforlooseness.

6. Check thatstruts workproperly.

7. Check vehicle posture (Unladen).

TOE-IN Measure toe-inusingfollowing procedure.

WARNING:

• Perform following procedure alwaysonaflat surface.

• Make surethatnoperson isin front ofthe vehicle before

pushing it.

1. Bounce frontofvehicle upand down tostabilize theposture.

2. Push thevehicle straight aheadabout5m (16 ft).

3. Put amark onbase lineoftread (rearside) ofboth tires at

the same height ashub center. Thesearemeasuring points.

4. Measure distance"A"(rear side).

5. Push thevehicle slowlyaheadtorotate thewheels 180

degrees (1/2turn).

If the wheels haverotated morethan180degrees

(112

turn), try

the above procedure againfromthebeginning. Neverpush

vehicle backward.

6. Measure distance"B"(front side).

Total toe-in

Refer toSOS (FA-29).

CAMBER,

CASTERANDKINGPIN INCLINATION

Camber, casterandkingpin inclination arepreset atfactory and

cannot beadjusted.

1. Measure camber,casterandkingpin inclination ofboth right

and leftwheels withasuitable alignment gauge.

Camber, CasterandKingpin inclination:

Refer toSOS (FA-29).

2. Ifcamber, casterorkingpin inclination isnot within

specification, inspectfrontsuspension parts.Replace dam-

aged orworn outparts.

Front

SFA948A

SFA614B

SFA234AC

Lines

parallel to

center lineofbody

Q

Front

Hub

center

height

FA-6

![NISSAN ALMERA N15 1995 Service Manual GAENGINE HARNESS

LAYOUT

Engine Harness

o ~

0.

(])

~w

c:

~~

Ql

"5>

()

x

c:

(])

"~

(])

(/)

~ w

Qi

0

"0

tii

It)

"~

0

::J

~

E

<:

<:

"0

C9

tii

I-

~

c:

0 NISSAN ALMERA N15 1995 Service Manual GAENGINE HARNESS

LAYOUT

Engine Harness

o ~

0.

(])

~w

c:

~~

Ql

"5>

()

x

c:

(])

"~

(])

(/)

~ w

Qi

0

"0

tii

It)

"~

0

::J

~

E

<:

<:

"0

C9

tii

I-

~

c:

0](/img/5/57349/w960_57349-665.png)