engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 697 of 1701

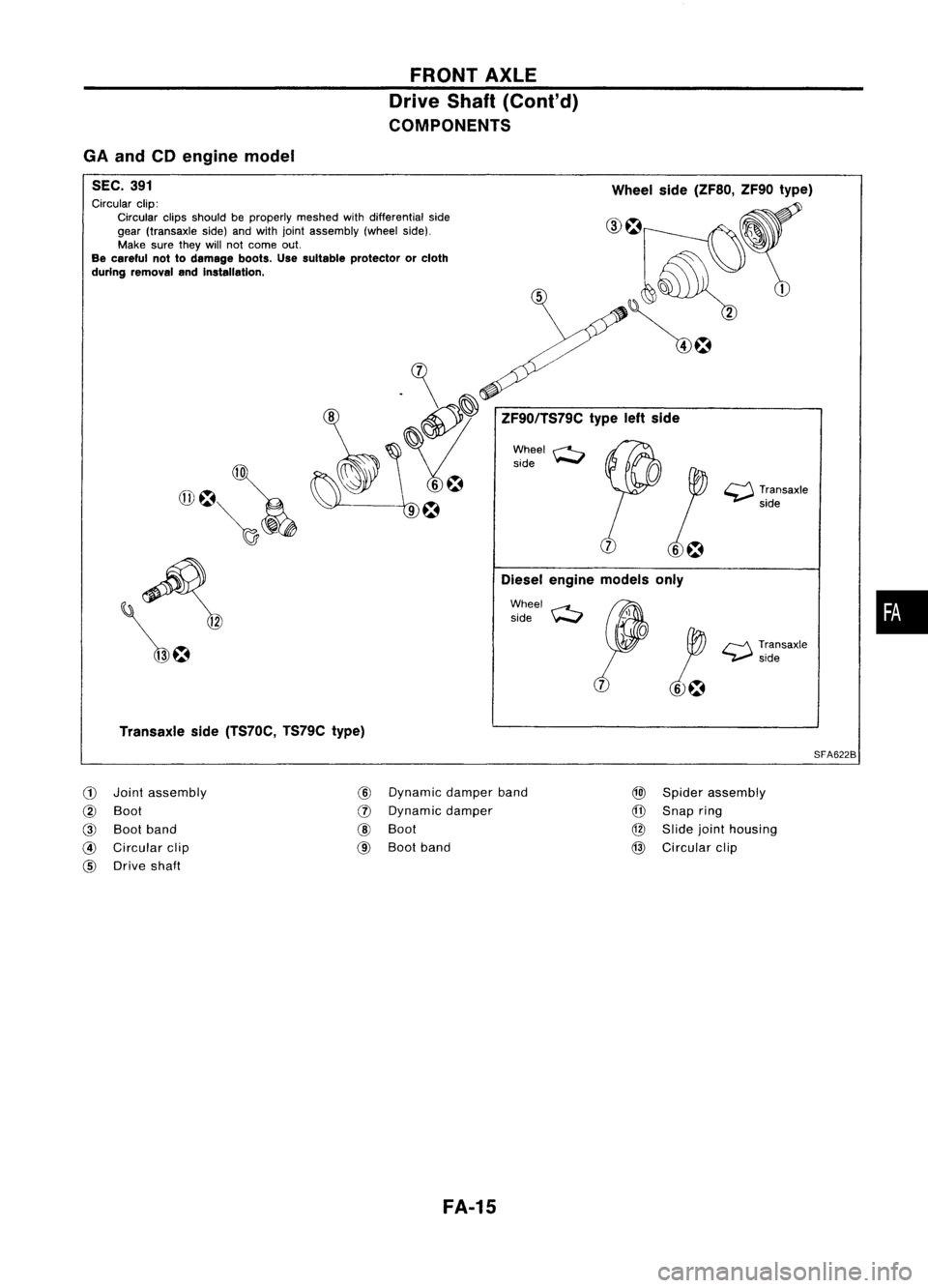

FRONTAXLE

Drive Shaft(Cont'd)

COMPONENTS

ZF90/TS79Ctypeleftside

Diesel engine models only

•

~

Transaxle

side

r-J\

Transaxle

~side

o

p

,~

Wheel

side(ZF80, ZF90type)

Wheel ~

side

Wheel side

8

.~

\~

Circular

clip:

Circular clipsshould beproperly meshedwithdifferential side

gear (transaxle side)andwith joint assembly (wheelside).

Make suretheywillnotcome out.

Be careful nottodamage boots.Usesuitable protector orcloth

during removal andinstallation.

GA

and CDengine model

SEC. 391

Transaxle side(TS70C, TS79Ctype)

SFA622B

CD

Joint

assembly

@

Dynamic damperband

@)

Spider assembly

@

Boot

(J)

Dynamic damper

@

Snap ring

@

Boot band

@

Boot

@

Slide jointhousing

@

Circular clip

@

Boot band

@

Circular clip

@

Drive shaft

FA-15

Page 703 of 1701

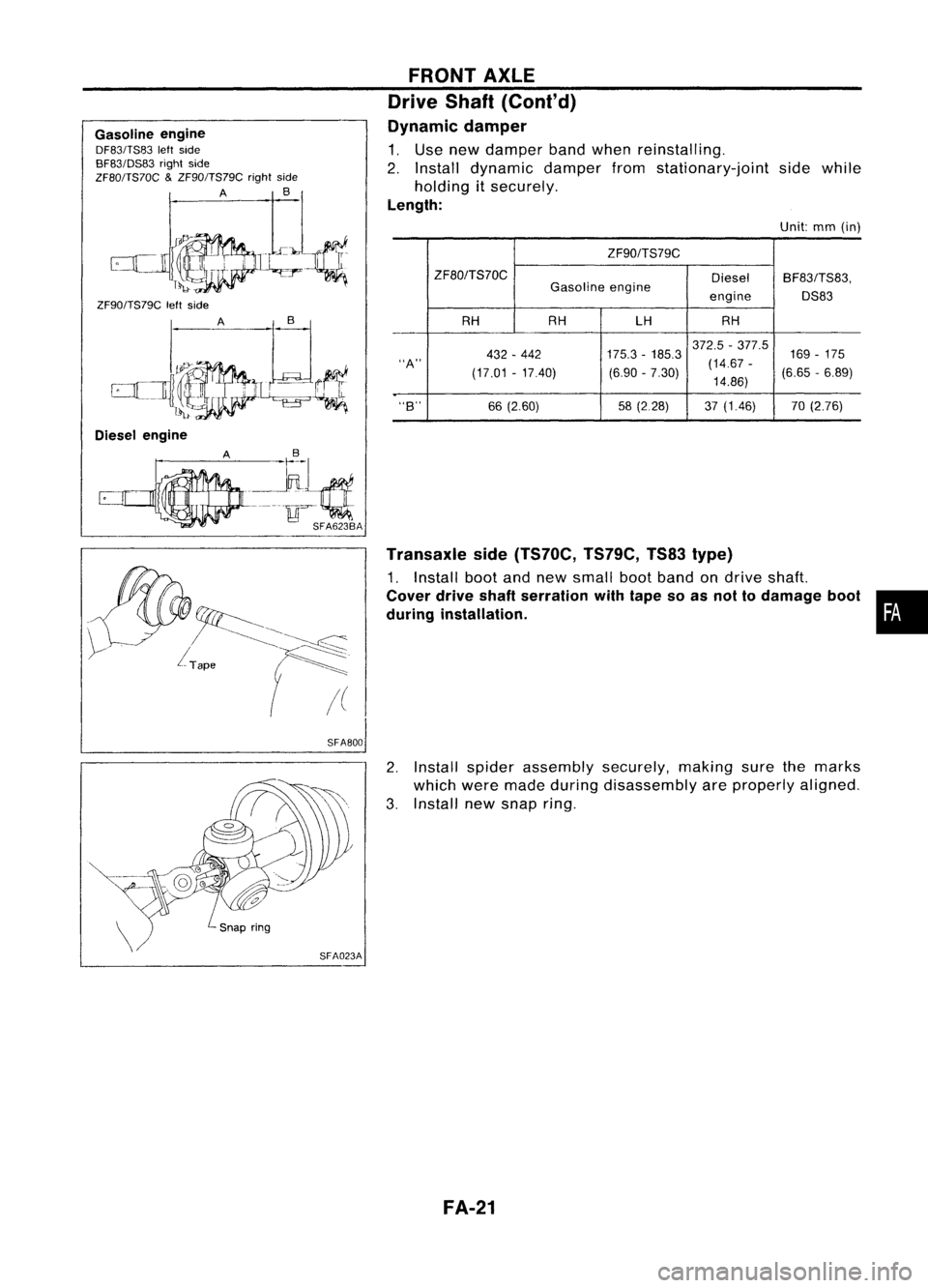

Gasolineengine

DF83/TS83 leftside

BF83/DS83 rightside

ZF80/TS70C

&

ZF90/TS79C rightside

A

B_1

.":JJ.Ci

ZF90/TS79C leftside

SFA800FRONT

AXLE

Drive Shaft(Cont'd)

Dynamic damper

1. Use new damper bandwhen reinstalling.

2. Install dynamic damperfromstationary-joint sidewhile

holding itsecurely.

Length:

Unit:mm(in)

ZF90/TS79C

ZF80/TS70C DieselBF83/TS83,

Gasoline engine

engineDS83

RH RH LHRH

372.5 -377.5

169-175

432 -442 175.3

-185.3

"A"

(17.01-17.40) (6.90

-7.30) (14.67

-

(6.65-6.89)

14.86)

"B"

66(2.60) 58(2.28) 37(1.46) 70(2.76)

Transaxle side(TS70C, TS79C,TS83type)

1. Install bootandnew small bootband ondrive shaft.

Cover driveshaftserration withtape soas not todamage boot•

during installation.

2. Install spider assembly securely.makingsurethemarks

which weremade during disassembly areproperly aligned.

3. Install newsnap ring.

FA-21

Page 706 of 1701

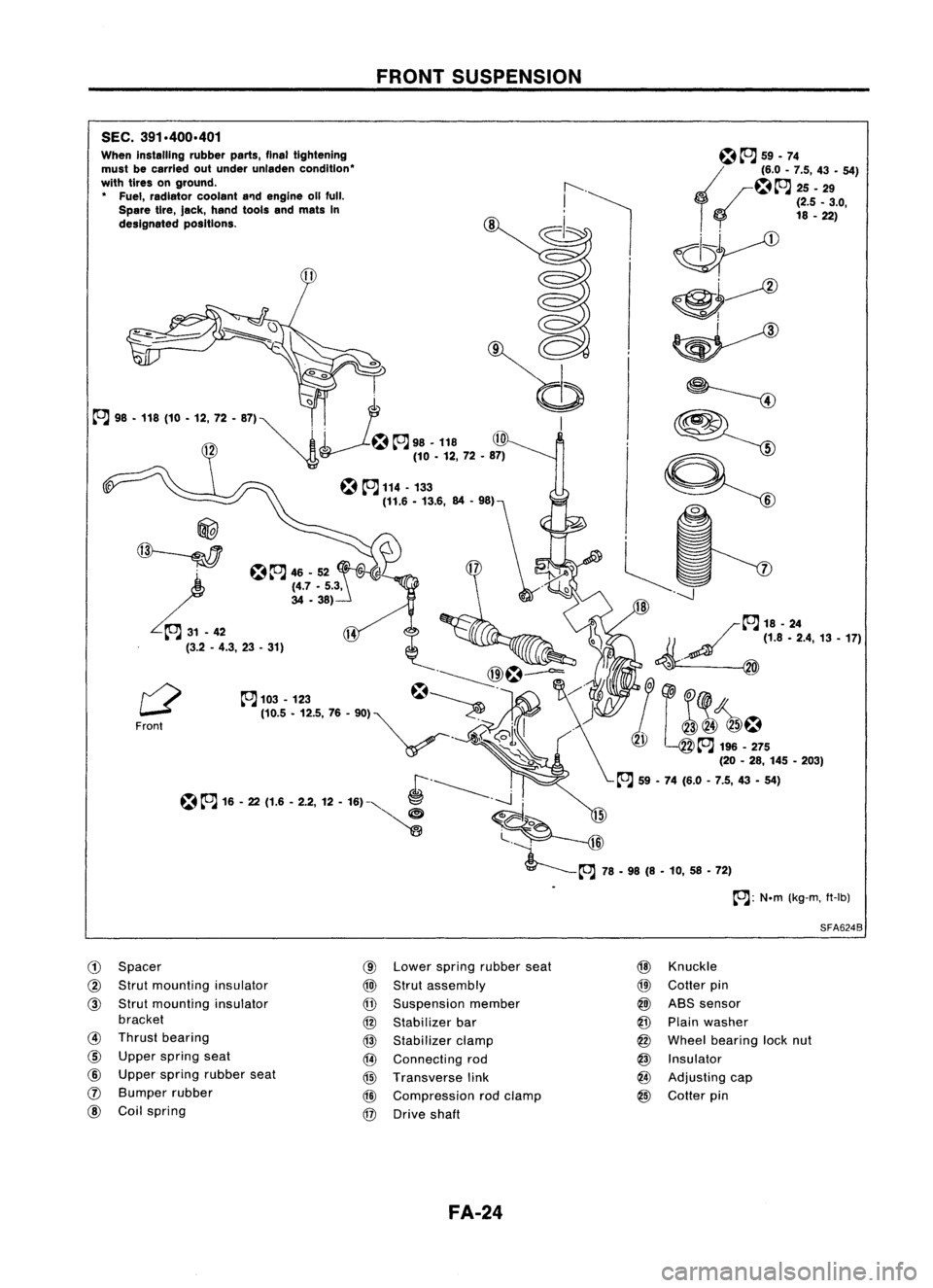

SEC.391.400.401

When installing rubberparts,finaltightening

must becarried outunder unladen condition'

with tires onground.

• Fuel, radiator coolanta'1dengine 011full.

Spare tire,Jack, hand toolsandmats In

designated positions.

@

~

L.~

(3.2-4.3, 23•31)

Front

CD

Spacer

@

Strut mounting insulator

@

Strut mounting insulator

bracket

@

Thrust bearing

@

Upper spring seat

@

Upper spring rubber seat

(J)

Bumper rubber

@

Coilspring

FRONT

SUSPENSION

@

Lower spring rubber seat

@)

Strut assembly

@

Suspension member

@

Stabilizer bar

@

Stabilizer clamp

@

Connecting rod

@

Transverse link

@

Compression rodclamp

@

Drive shaft

FA-24

~~

59.74

~~~.~ ::'.4:9- 54)

o

(2.5_3.0,

18 -22)

~

~~

~ ~

9=:

~~

-----J

/~18-24

1/ ~

(1.8.2.4,13.17)

~. @

&1

(@

~ J~!~5

(20-28, 145 •203)

~ 59•74 (6.0 -7.5, 43•54)

SFA624B

@

Knuckle

@

Cotter pin

@)

ABS sensor

@

Plain washer

@

Wheel bearing locknut

@

Insulator

@

Adjusting cap

@

Cotter pin

Page 711 of 1701

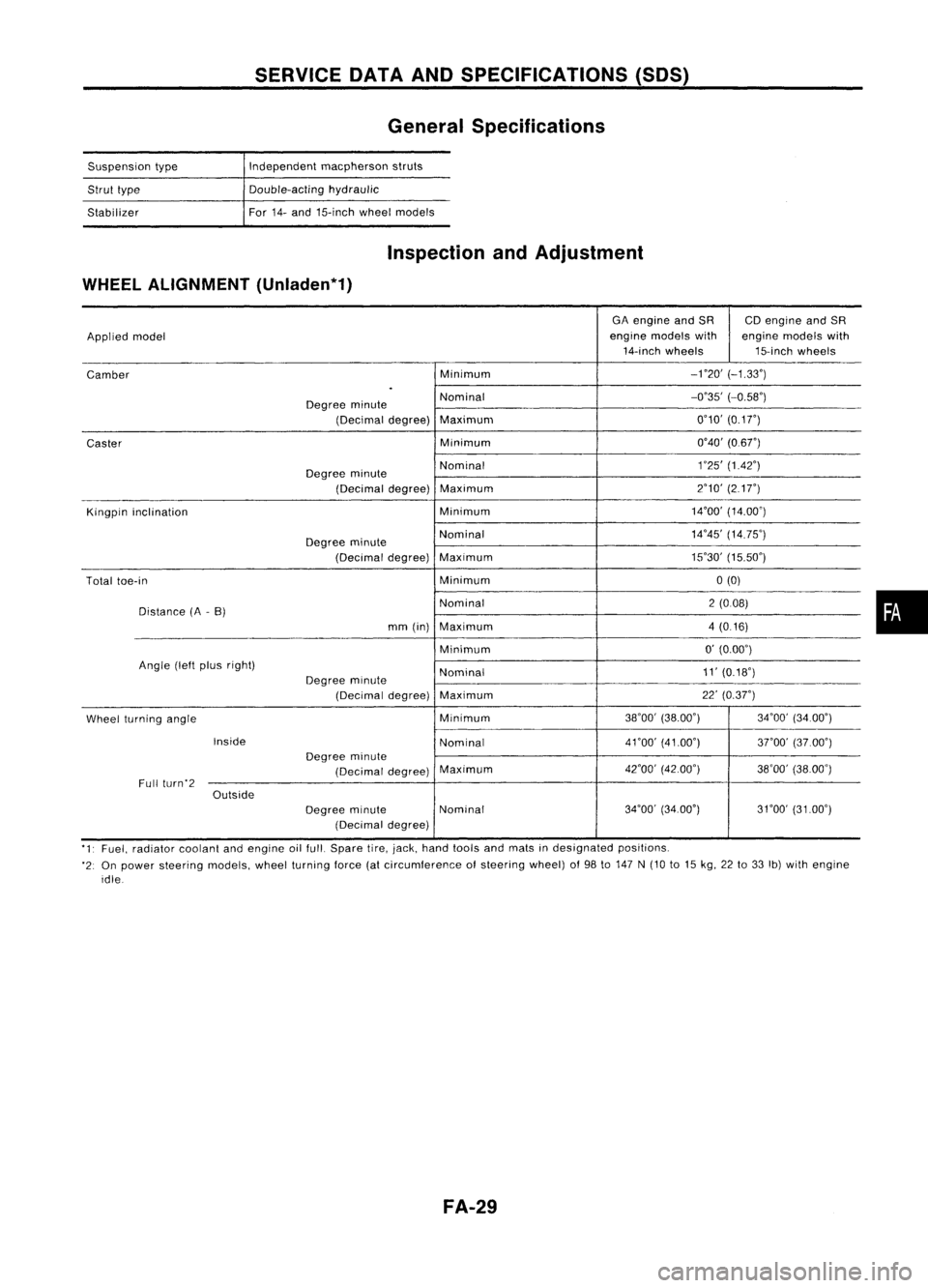

SERVICEDATAANDSPECIFICATIONS (50S)

General Specifications

Suspension type

Strut type

Stabilizer Independent

macpherson struts

Double-acting hydraulic

For 14-and 15-inch wheelmodels

Inspection andAdjustment

WHEEL ALIGNMENT (Unladen*1)

GAengine andSR CDengine andSR

Applied model engine

models with enginemodels with

14-inch wheels 15-inchwheels

Camber Minimum

-no'

(-1.33')

.

Degree minute Nominal

-0'35'

(-0.58')

(Decimal degree)Maximum 0'10'

(0.1

r)

Caster Minimum

0'40'(0.6r)

Degree minute Nominal

1

'25' (1.42')

(Decimal degree)Maximum 2'10'

(217")

Kingpin inclination Minimum14'00'

(14.00')

Degree minute Nominal

14'45'

(14.75')

(Decimal degree)Maximum 15'30'

(15.50')

Total toe-in Minimum0(0)

Distance (A-B) Nominal

2(008)

mm (in) Maximum 4(0.16)

Minimum 0'

(0.00')

Angle (leftplus right)

Nominal 11'

(0.18')

Degree minute

(Decimal degree)Maximum 22'

(0.37")

Wheel turning angle Minimum

38'00'

(38.00') 34'00'(34.00')

Inside Nominal4nO'

(41.00')

3rOO'(37.00')

Degree minute

(Decimal degree)Maximum

42'00'

(42.00')

38'00'(38.00')

Full (urn'2

Outside

Degreeminute Nominal 34'00'

(34.00') 31'00'(3100')

(Decimal degree)

'1' Fuel, radiator coolantandengine oilfull. Spare tire,jack, hand tools andmats indesignated positions.

'2: On power steering models,wheelturning force(atcircumference ofsteering wheel)of98 to147 N(10 to15 kg, 22to33 Ib)with engine

idle

FA-29

•

Page 714 of 1701

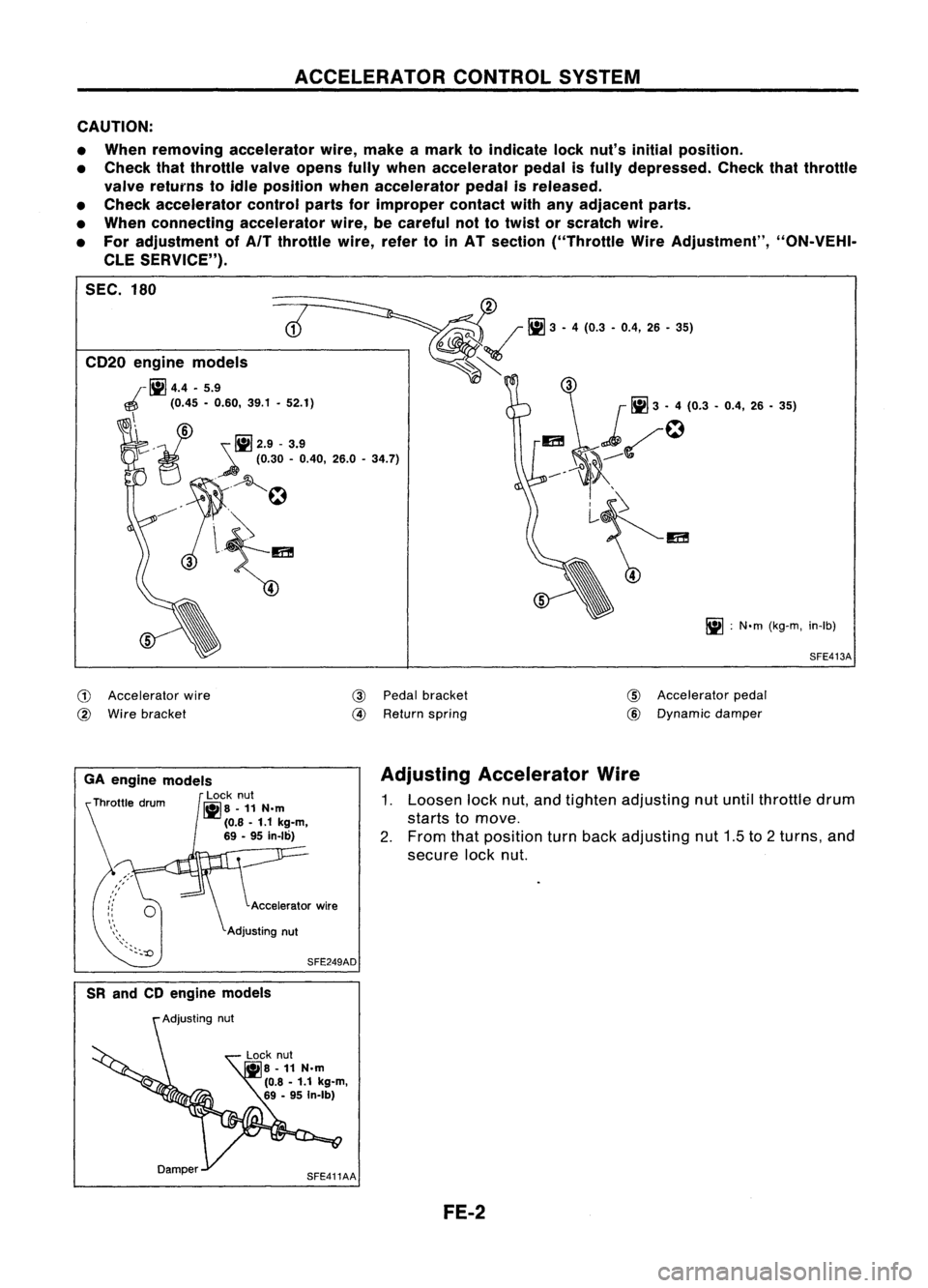

ACCELERATORCONTROLSYSTEM

CAUTION:

• When removing accelerator wire,make amark toindicate locknut's initial position.

• Check thatthrottle valveopens fullywhen accelerator pedalisfUlly depressed. Checkthatthrottle

valve returns toidle position whenaccelerator pedalisreleased.

• Check accelerator controlpartsforimproper contactwithanyadjacent parts.

• When connecting accelerator wire,becareful nottotwist orscratch wire.

• For adjustment ofAfT throttle wire,refertoinAT section ("Throttle WireAdjustment", "ON-VEHI-

CLE SERVICE").

SEC. 180

SFE413A

iii

:

N'm (kg-m, in-Ib)

5

~~

Iii]

3.4 (0.3 .0.4, 26.36)

~~~

5

CD20

engine models

r

1iI4.4 •5.9

~ (0.45-0.60, 39.1•52.1)

\i

v'

!il2.9-3.9

~ (0.30-0.40, 26.0-34.7)

7C

A~

~'

.

.

~

3l~

,

G)

Accelerator wire

@

Wire bracket

@

Pedal bracket

@

Return spring

CID

Accelerator pedal

@

Dynamic

damper

SFE249AD

GA

engine models

Locknut

~8 -11N.m

(0.8 -1.1 kg-m,

69 -95 in-Ib)

Adjusting

Accelerator Wire

1. Loosen locknut,andtighten adjusting nutuntil throttle drum

starts tomove.

2. From thatposition turnback adjusting nut1.5to2turns, and

secure locknut.

SR and CDengine models

Lock nut

• 8-11 N.m

(0.8 -1.1 kg-m,

69 -95 In-Ib)

SFE411AA FE-2

Page 715 of 1701

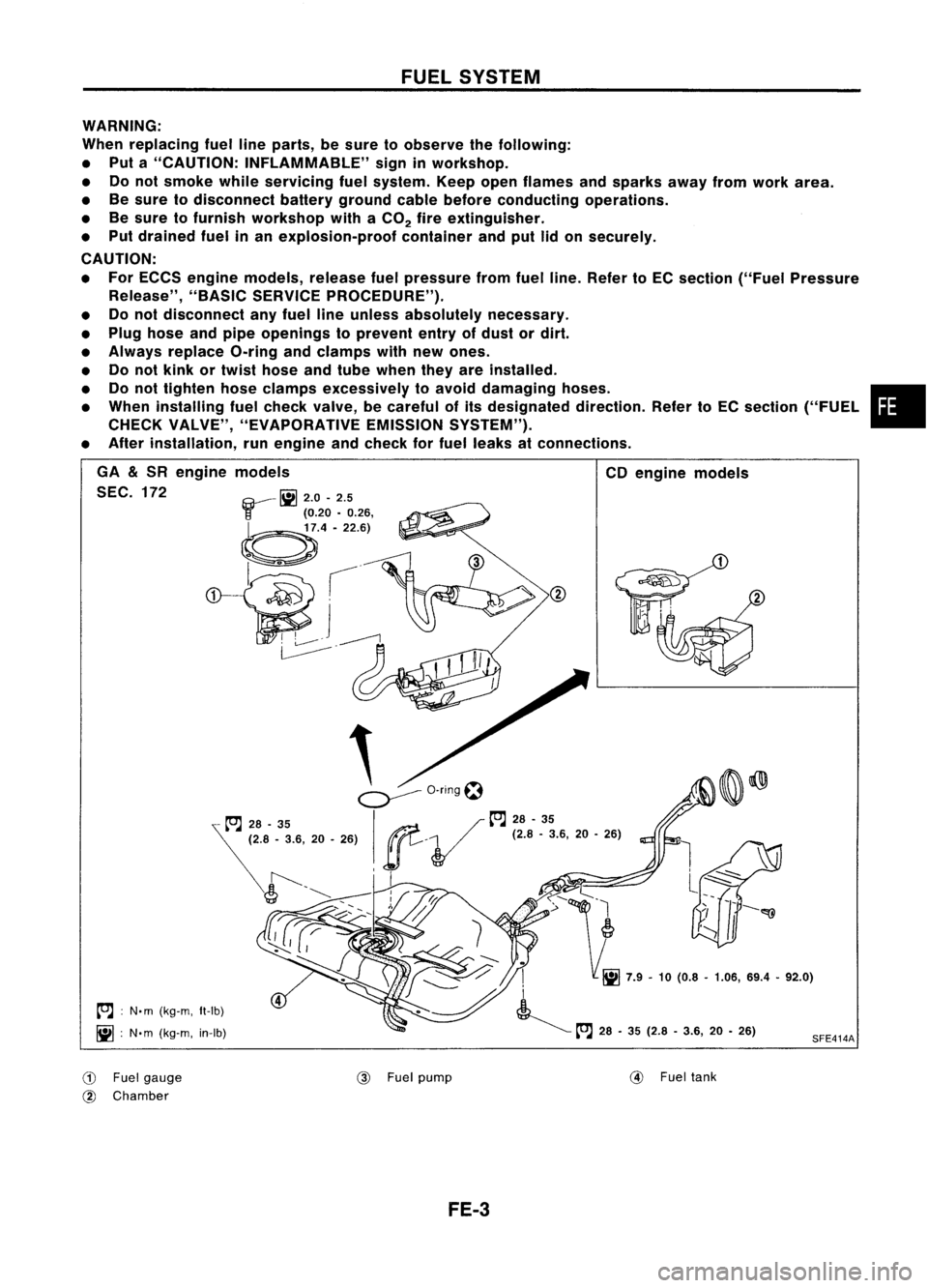

FUELSYSTEM

WARNING:

When replacing fuellineparts, besure toobserve thefollowing:

• Put a"CAUTION: INFLAMMABLE" signinworkshop.

• Donot smoke whileservicing fuelsystem. Keepopenflames andsparks awayfromwork area.

• Besure todisconnect batterygroundcablebefore conducting operations.

• Besure tofurnish workshop withaCO

2

fireextinguisher.

• Put drained fuelinan explosion-proof containerandputlidon securely.

CAUTION:

• For ECCS engine models, releasefuelpressure fromfuelline. Refer toEC section ("FuelPressure

Release", "BASICSERVICE PROCEDURE").

• Donot disconnect anyfuel lineunless absolutely necessary.

• Plug hose andpipe openings toprevent entryofdust ordirt.

• Always replace O-ringandclamps withnewones.

• Donot kink ortwist hose andtube when theyareinstalled.

• Donot tighten hoseclamps excessively toavoid damaging hoses. •

• When installing fuelcheck valve, becareful ofits designated direction.RefertoEC section ("FUEL

CHECK VALVE", "EVAPORATIVE EMISSIONSYSTEM").

• After installation, runengine andcheck forfuel leaks atconnections.

SFE414A

CD

engine models

.

I

i

~ tt'.J

28•35 (2.8 -3.6, 20•26)

,

.

~o-nngt:1

...,/ tt'.J

28-35

ge.

V

(2.'.3.6, 20•26)

, I

GA

&

SR engine models

SEC. 172 ~

2.0-2.5

r

(0.20•0.26,

~.4'22.6)

~ .---£l

~I

~j~

~.

tt'.J :

N. m (kg-m, It-Ib)

iii :

N'm (kg-m, in-Ib)

CD

Fuelgauge

@ Chamber @

Fuelpump

@

Fueltank

FE-3

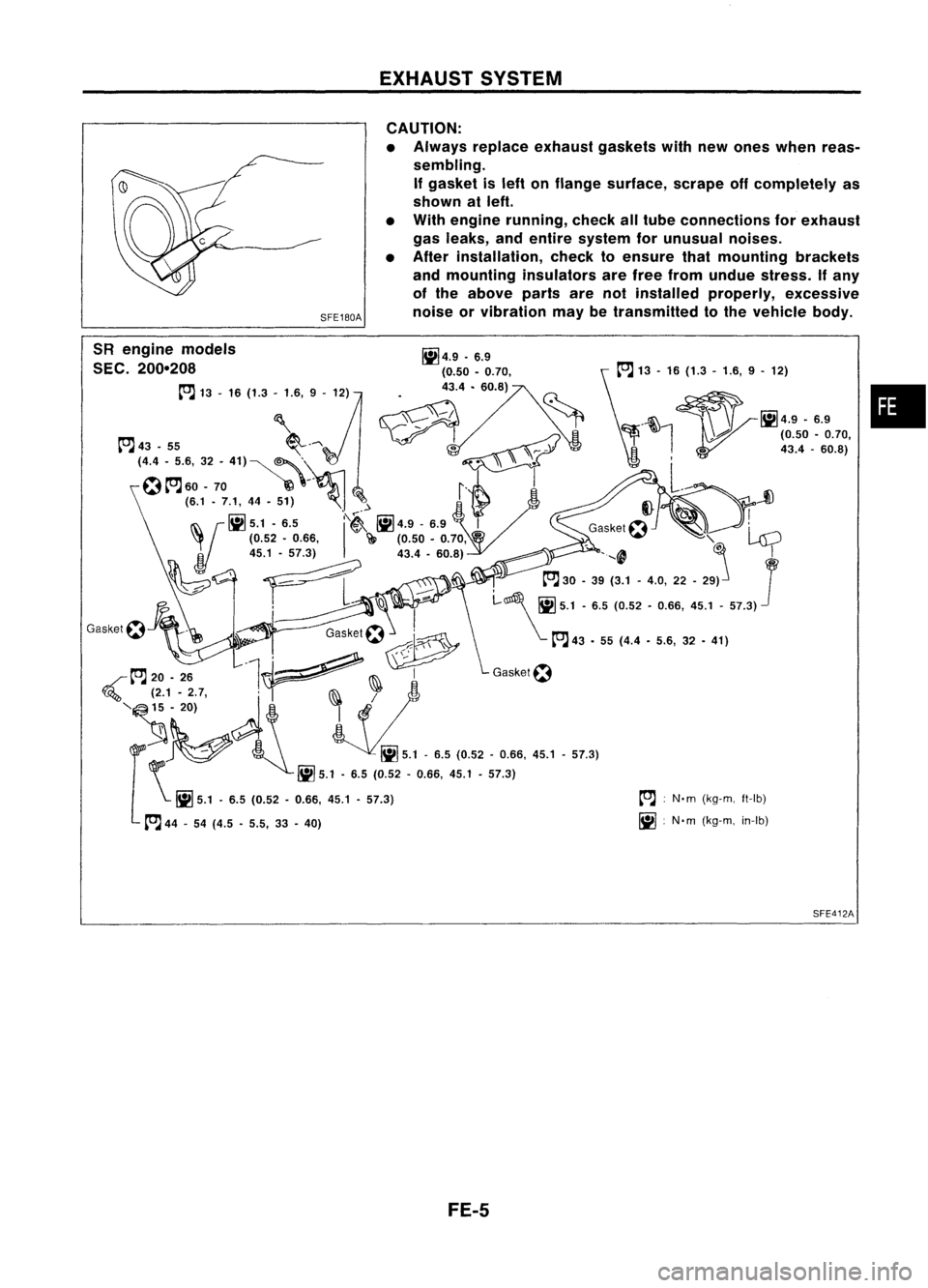

Page 717 of 1701

SFE180A

SR engine models

SEC. 200-208

toJ

13-16 (1.3 -1.6, 9-12)

EXHAUST

SYSTEM

CAUTION:

• Always replace exhaust gasketswithnewones when reas-

sembling. If gasket isleft onflange surface, scrapeoffcompletely as

shown atleft.

• With engine running, checkalltube connections forexhaust

gas leaks, andentire system forunusual noises.

• After installation, checktoensure thatmounting brackets

and mounting insulators arefree from undue stress.

If

any

of the above partsarenotinstalled properly, excessive

noise orvibration maybetransmitted tothe vehicle body.

GaSket~

toJ:

N'm (kg-m, ft-Ib)

~ :N'm (kg-m, in-Ib)

SFE412A

FE-5

•

Page 718 of 1701

![NISSAN ALMERA N15 1995 Service Manual EXHAUSTSYSTEM

C1 tOJ

28•33 (2.9 -3.4, 21-25)

Ii]

4.9•6.9

(0.50 •0.70, 43.4•60.8)

L~tCJ

43-55

(4.4 •5.6,

32 •41)

~~

! ~

C1tOJ

28-33 ~~

(2.9 •3.4, 20.7 •24.3)

i

Gasket

C1

b ~

NISSAN ALMERA N15 1995 Service Manual EXHAUSTSYSTEM

C1 tOJ

28•33 (2.9 -3.4, 21-25)

Ii]

4.9•6.9

(0.50 •0.70, 43.4•60.8)

L~tCJ

43-55

(4.4 •5.6,

32 •41)

~~

! ~

C1tOJ

28-33 ~~

(2.9 •3.4, 20.7 •24.3)

i

Gasket

C1

b ~](/img/5/57349/w960_57349-717.png)

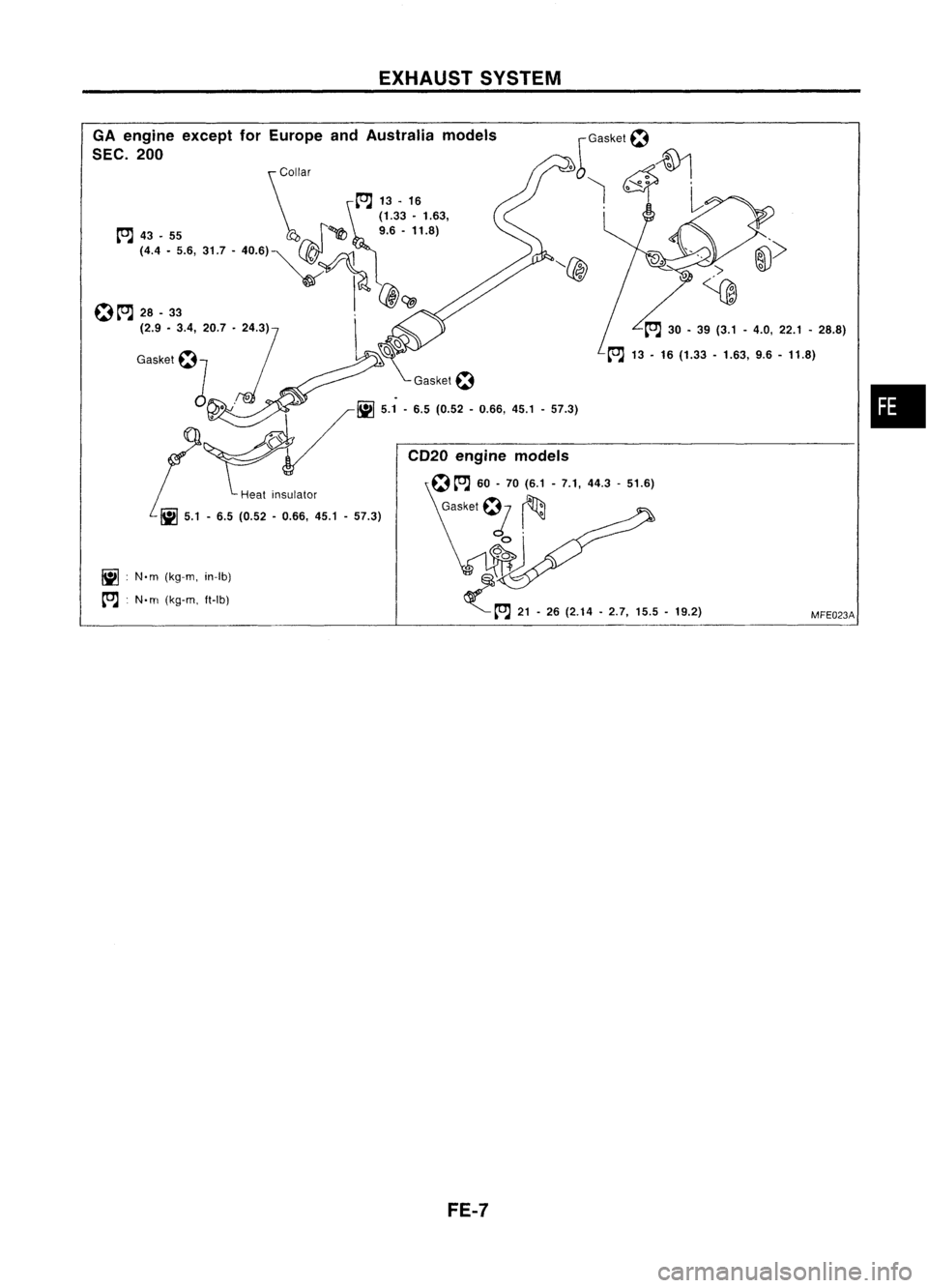

EXHAUSTSYSTEM

C1 tOJ

28•33 (2.9 -3.4, 21-25)

Ii]

4.9•6.9

(0.50 •0.70, 43.4•60.8)

L~tCJ

43-55

(4.4 •5.6,

32 •41)

~~

! ~

C1tOJ

28-33 ~~

(2.9 •3.4, 20.7 •24.3)

i

Gasket

C1

b ~

-~r~

5.1•6.5

V

(0.52•0.66,

45.1 •57.3)

Heat insulator

II]

5.1•6.5 (0.52 •0.66, 45.1•57.3)

GA

engine forEurope models

models

tOJ

13. 16(1.3 •1.6, 9.12)

Ii]

5.1•6.5

(0.52 -0.66, 45.1•57.3)

Ii]

5.1-6.5

(0.52 -0.66,

45.1 -57.3)

GA

engine forAustralia

SEC. 200-208

tCJ

43-55 Collar

(4.4 -5.6,

32 -41)

~ :N'm (kg-m, in-Ib)

tCJ :

N.m (kg-m, fl.lb) -

Among Europe model!l, onlyGA16DE engine model

has aheat insulator onthe exhaust fronttube,

MFE024A

FE-6

Page 719 of 1701

EXHAUSTSYSTEM

•

MFE023A

to.J

30-39 (3.1 -4.0, 22.1 -28.8)

~ 13-16 (1.33 -1.63, 9.6-11.8)

iii :

N'm (kg-m, in-Ib)

~ :N'm (kg-m, ft-Ib)

\ollar

8~

13-16

(1.33 -1.63,

~ 43_55 ~9.6-11.8)

(4.4.5.6,31.7' 40'6)'~~

o

to.J

28-33 \

{J)f:::@

(2.9 -3.4, 20.7 -124.3)

~~

Gasket

0

1 ".~

Gasket

0

v' •

. . . .v. ~

5.1-6.5 (0.52 -0.66,45.1 -57.3)

I~'''~ CD20engine models

. 0

to.J

60-70 (6.1 -7.1, 44.3 -51.6)

Heat Insulator ~~

• Gasket~ :

iii

5.1-6.5 (0.52 -0.66, 45.1-57.3)

7

r

o

GA

engine exceptforEurope andAustralia models

SEC. 200

FE-7

Page 720 of 1701

ENGINECONTROL SYSTEM

SECTION

EC

CONTENTS

•

PRECAUTIONS ANDPREPARATION

4

Special Service Tools 4

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System) 7

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System) 7

GA,SR

PRECAUTIONS ANDPREPARATION

8

Engine Fuel

&

Emission ControlSystem 8

Precautions forECCS Trouble Diagnosis of

Engine 9

Precautions 9

ENGINE ANDEMISSION CONTROLOVERALL

SYSTEM 11

Circuit Diagram -Except forAustralia 11

Circuit Diagram -For Australia 12

System Diagram -GA 14DE, GA16DE for

Europe andIsrael 13

System Diagram -GA15DE 14

System Diagram -GA 16DE except for

Europe, IsraelandAustralia 15

System Diagram -GA 16DE forAustralia 16

ECCS Component PartsLocation -GA 14DE,

GA 16DE forEurope andIsrael 17

ECCS Component PartsLocation -GA15DE 18

ECCS Component PartsLocation -GA 16DE

except forEurope, IsraelandAustralia 19

ECCS Component PartsLocation -GA 16DE

for Austral ia 20

ECCS Component PartsLocation 21

Vacuum HoseDrawing 22

c=

~

GA

ENGINE

ANDEMISSION BASICCONTROL

SYSTEM DESCRiPTION 23

System Chart.. 23

Multiport FuelInjection (MFI)System 24

Distributor Ignition(01)System 27

Air Conditioning CutControl 28

Fuel CutControl (atnoload &high engine

speed) 28

EVAPORATIVE EMISSIONSYSTEM

29

Inspection 29

POSITIVE CRANKCASE VENTILATION 31

Description 31

Inspection 32

BASIC SERVICE PROCEDURE 33

Fuel Pressure Release 33

Fuel Pressure Check 33

Fuel Pressure Regulator Check 33

Injector Removal andInstallation 34

Idle Speed/lgnition Timing/ldleMixtureRatio

Adjustment ,35

ON-BOARD DIAGNOSTIC SYSTEMDESCRIPTION .44

Malfunction IndicatorLamp(MIL) 44

CONSULT .48

TROUBLE DIAGNOSIS -General Description

58

Introduction 58

Work Flow 59

Description forWork Flow 60

Diagnostic Worksheet 61

Diagnostic TroubleCode(DTC) Chart 62

Fail-Safe Chart 64

Basic Inspection 65

Fast IdleCam (FIC) Inspection and

Adjustment -For Europe andIsrael 68

Fast IdleCam (FIC) Inspection and

Adjustment -Except forEurope andIsrael. 68

Symptom MatrixChart 71