NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1691 of 1701

POWERSTEERING GEARANDLINKAGE (ModelPR24AC)

Assembly (Cont'd)

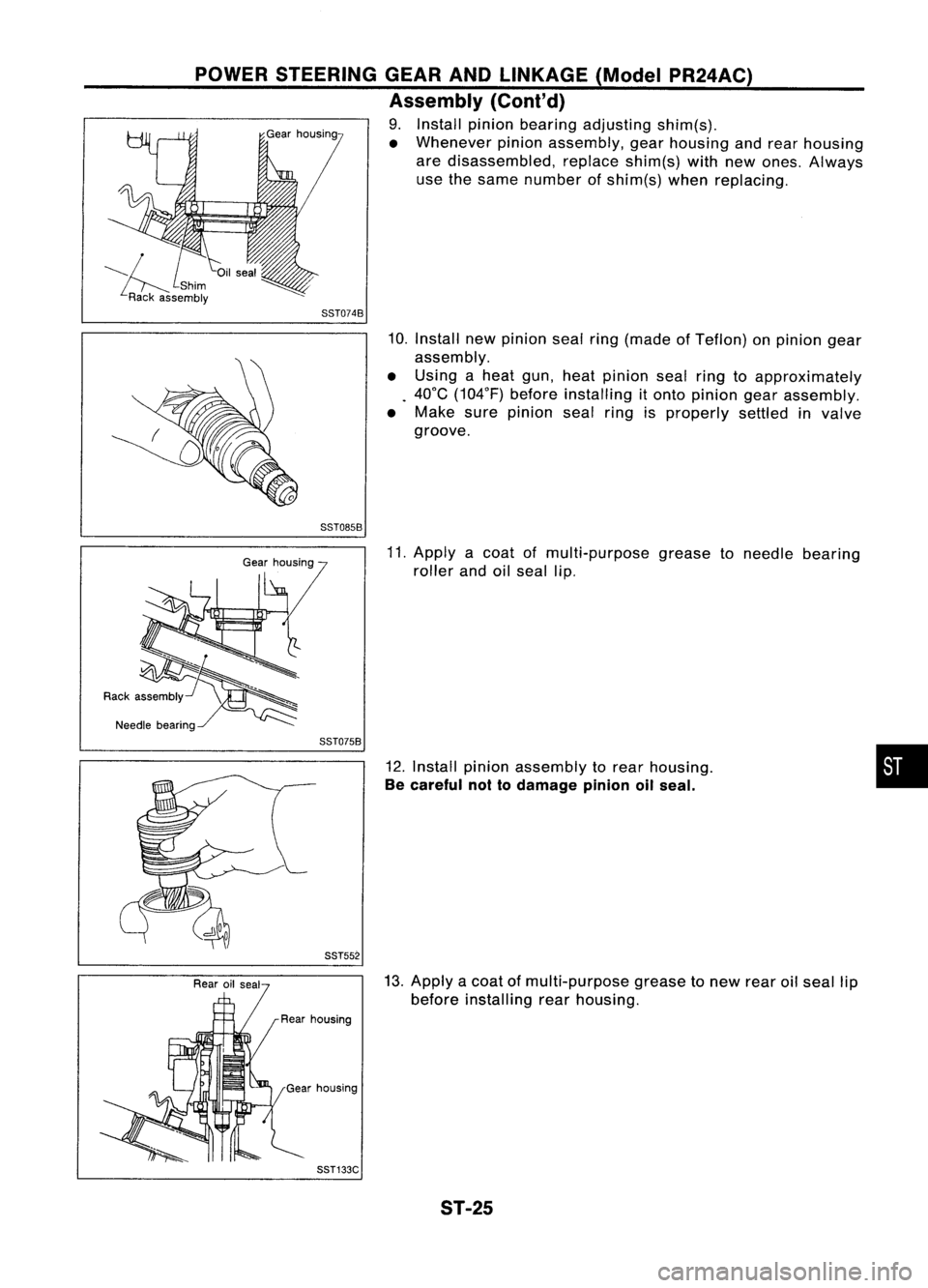

9. Install pinionbearing adjusting shim(s).

• Whenever pinionassembly, gearhousing andrear housing

are disassembled, replaceshim(s)withnewones. Always

use thesame number ofshim(s) whenreplacing.

SST074B

10.Install newpinion sealring(made ofTeflon) onpinion gear

assembly.

• Using aheat gun, heatpinion sealringtoapproximately

. 40°C (104°F) beforeinstalling itonto pinion gearassembly.

• Make surepinion sealringisproperly settledinvalve

groove.

SST085B

11.Apply acoat ofmulti-purpose greasetoneedle bearing

roller andoilseal lip.

SST075B

12.Install pinionassembly torear housing.

Be careful nottodamage pinionoilseal.

SST552

•

13. Apply acoat ofmulti-purpose greasetonew rearoilseal lip

before installing rearhousing.

Gear housing

SST133C ST-25

Page 1692 of 1701

POWERSTEERING GEARANDLINKAGE (ModelPR24AC)

Assembly (Cont'd)

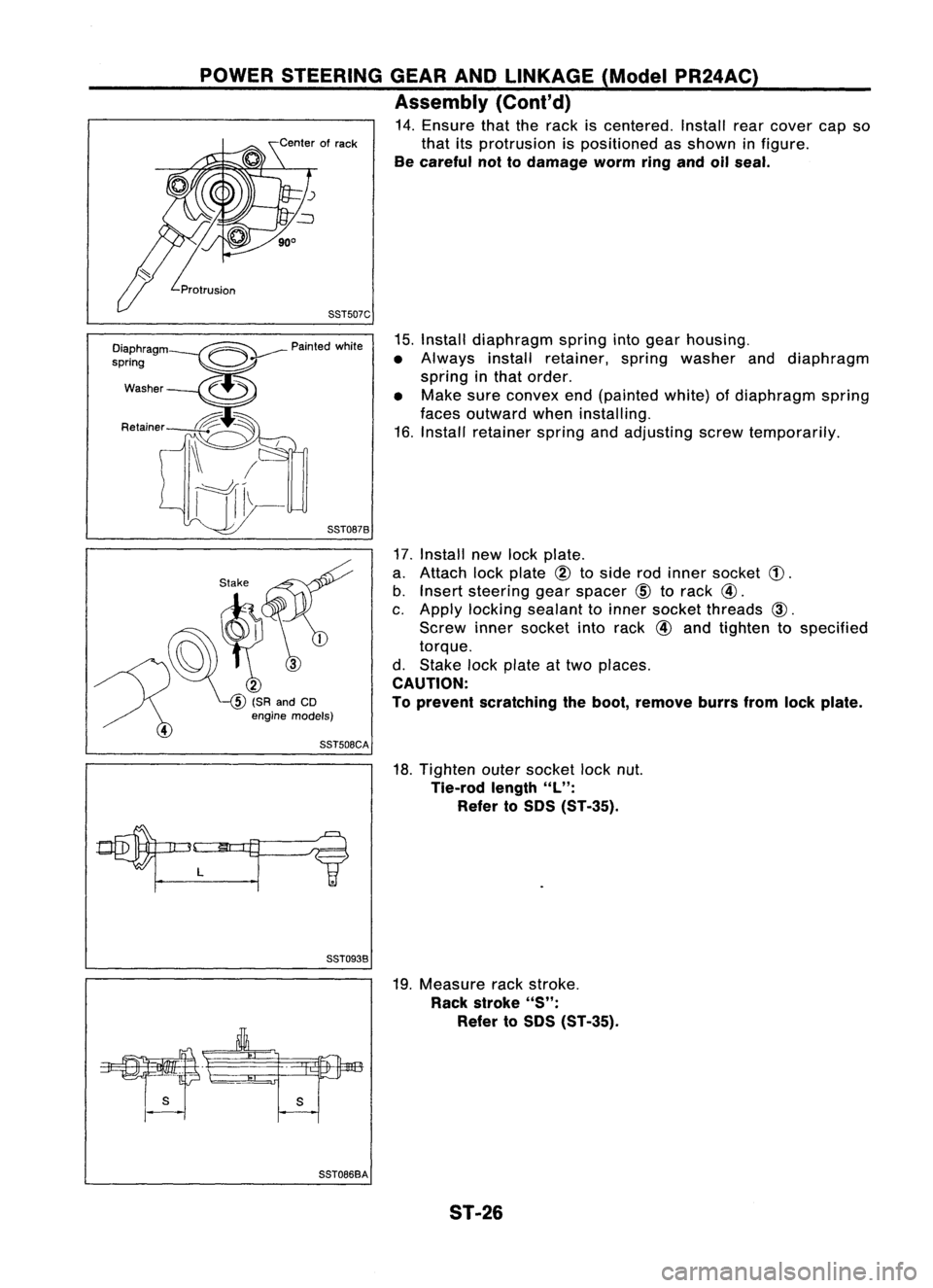

14. Ensure thattherack iscentered. Installrearcover capso

that itsprotrusion ispositioned asshown infigure.

Be careful nottodamage wormringandoilseal.

88T507C

15.Install diaphragm springintogear housing.

• Always installretainer, springwasher anddiaphragm

spring inthat order.

• Make sureconvex end(painted white)ofdiaphragm spring

faces outward wheninstalling.

16. Install retainer springandadjusting screwtemporarily.

88T0878

17.Install newlockplate.

a. Attach lockplate

@

toside rodinner socket

(!).

b. Insert steering gearspacer

CID

torack

@.

c. Apply locking sealant toinner socket threads

CID.

Screw innersocket intorack

@

and tighten tospecified

torque.

d. Stake lockplate attwo places.

CAUTION:

To prevent scratching theboot, remove burrsfromlockplate.

18. Tighten outersocket locknut.

Tie-rod length

"L":

Refer toSOS (ST-35).

88T0938

19.Measure rackstroke.

Rack stroke

"5":

Refer to50S (ST-35).

s

88T0868A ST-26

Page 1693 of 1701

POWERSTEERING GEARANDLINKAGE (ModelPR24AC)

Assembly (Cont'd)

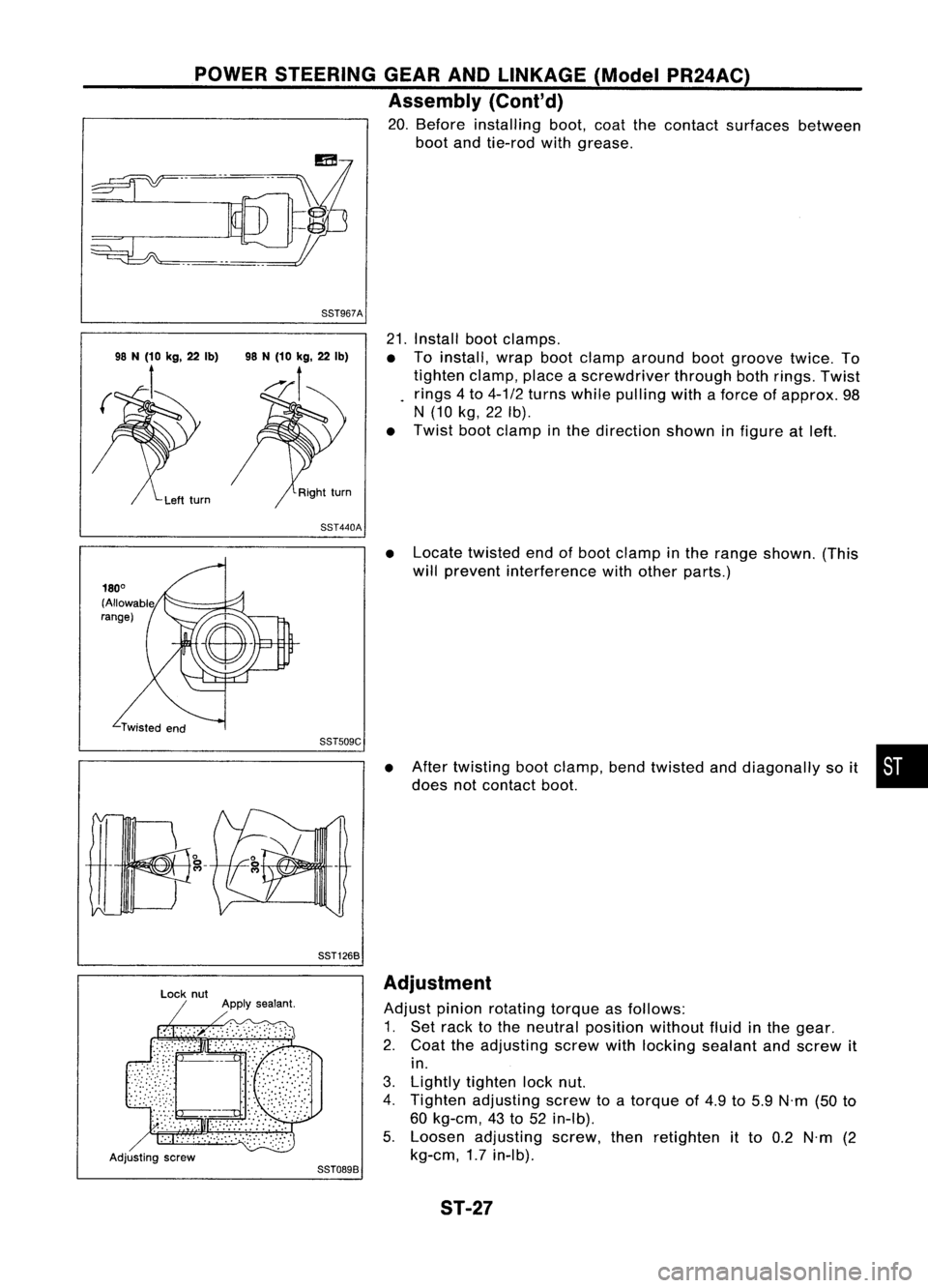

20. Before installing boot,coatthecontact surfaces between

boot andtie-rod withgrease.

88T967A

21.Install bootclamps.

• Toinstall, wrapbootclamp around bootgroove twice.To

tighten clamp,placeascrewdriver throughbothrings. Twist

rings 4to 4-1/2 turns while pulling withaforce ofapprox. 98

N (10 kg,22Ib).

• Twist bootclamp inthe direction showninfigure atleft.

88T440A

•Locate twisted endofboot clamp inthe range shown. (This

will prevent interference withother parts.)

88TS09C

88T1268

•

After twisting bootclamp, bendtwisted anddiagonally soit •

does notcontact boot.

Adjusting screw

88T0898Adjustment

Adjust pinionrotating torqueasfollows:

1. Set rack tothe neutral position withoutfluidinthe gear.

2. Coat theadjusting screwwithlocking sealant andscrew it

in.

3. Lightly tighten locknut.

4. Tighten adjusting screwtoatorque of4.9 to5.9 N'm (50to

60 kg-em, 43to52 in-Ib).

5. Loosen adjusting screw,thenretighten itto 0.2 N'm (2

kg-em, 1.7in-Ib).

ST-27

Page 1694 of 1701

POWERSTEERING GEARANDLINKAGE (ModelPR24AC)

Adjustment (Cont'd)

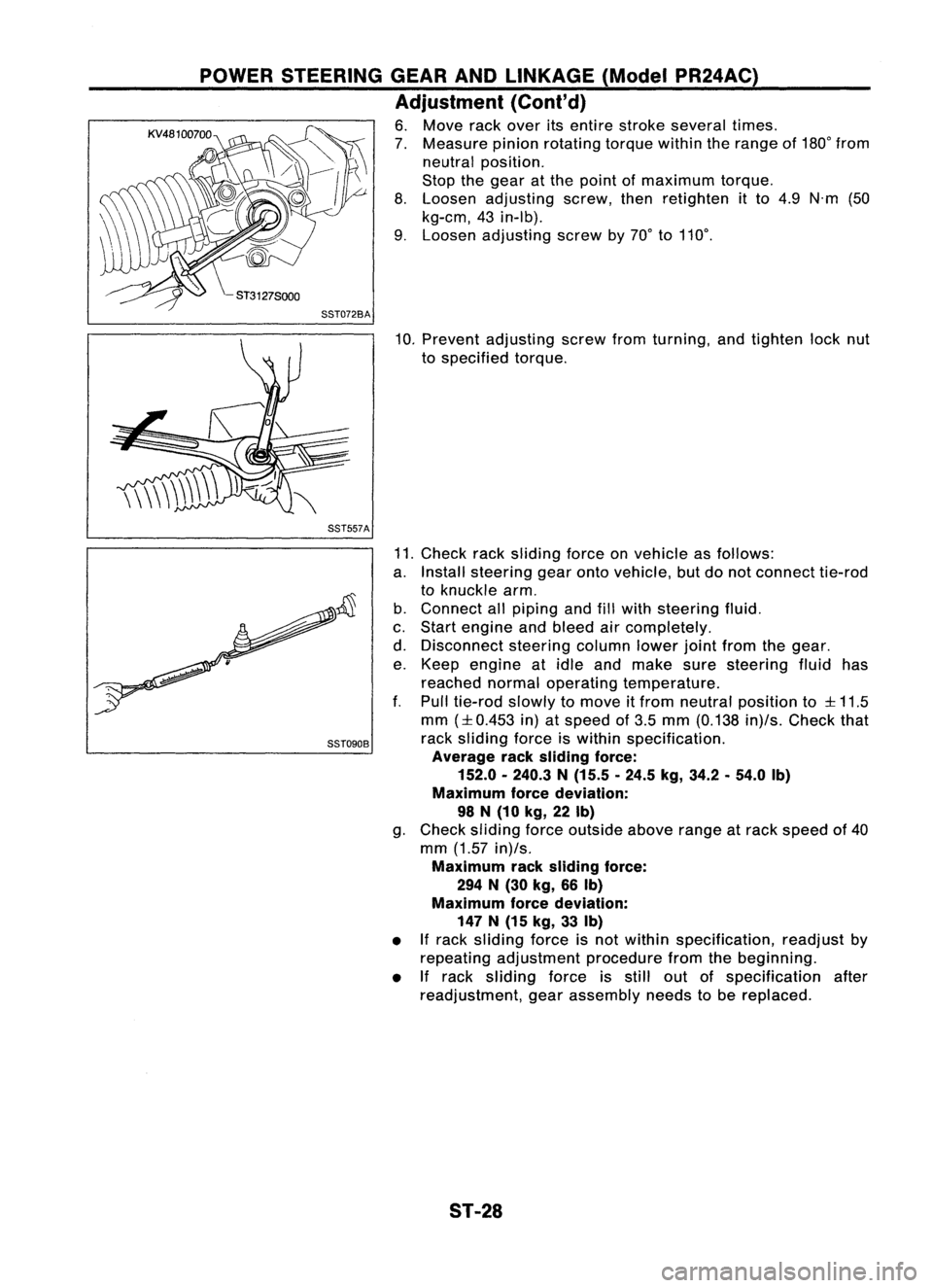

6. Move rackover itsentire stroke several times.

7. Measure pinionrotating torquewithintherange of180° from

neutral position.

Stop thegear atthe point ofmaximum torque.

8. Loosen adjusting screw,thenretighten itto 4.9 N'm (50

kg-em, 43in-Ib).

9. Loosen adjusting screwby70° to110°.

SST072BA

10.Prevent adjusting screwfromturning, andtighten locknut

to specified torque.

SST557A

SST090B

11.

Check racksliding forceonvehicle asfollows:

a. Install steering gearontovehicle, butdonot connect tie-rod

to knuckle arm.

b. Connect allpiping andfillwith steering fluid.

c. Start engine andbleed aircompletely.

d. Disconnect steeringcolumnlowerjointfrom thegear.

e. Keep engine atidle and make suresteering fluidhas

reached normaloperating temperature.

f. Pull tie-rod slowlytomove itfrom neutral position to

:l:

11.5

mm

(:l:

0.453 in)atspeed of3.5 mm (0.138 in)/s.Check that

rack sliding forceiswithin specification.

Average racksliding force:

152.0 -240.3 N(15.5 .24.5 kg,34.2.54.0 Ib)

Maximum forcedeviation:

98 N(10 kg,22Ib)

g. Check sliding forceoutside aboverangeatrack speed of40

mm (1.57 in)/s.

Maximum racksliding force:

294 N(30 kg, 66Ib)

Maximum forcedeviation:

147 N(15 kg, 33Ib)

• Ifrack sliding forceisnot within specification, readjustby

repeating adjustment procedurefromthebeginning.

• If

rack sliding forceisstill outofspecification after

readjustment, gearassembly needstobe replaced.

ST-28

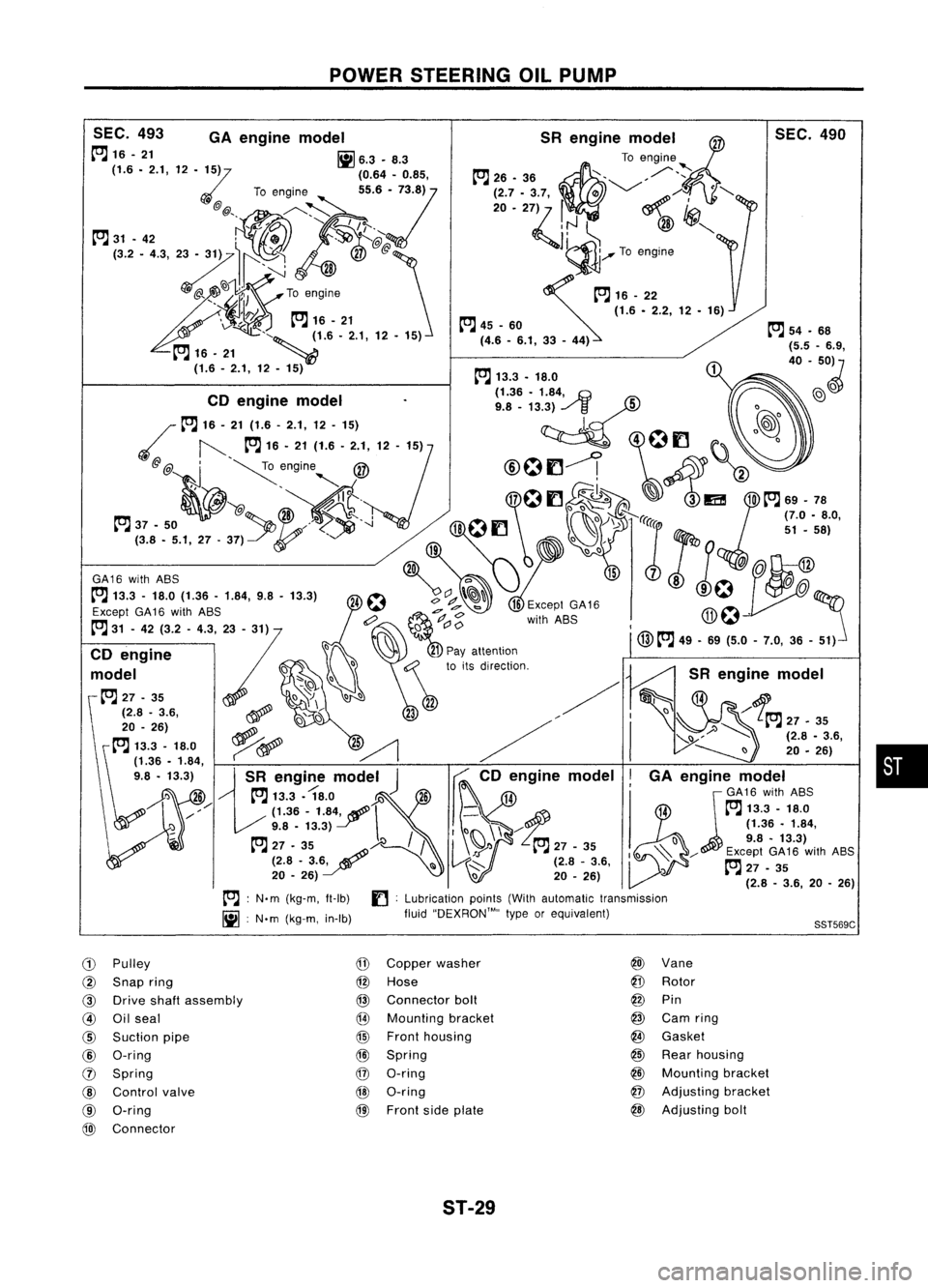

Page 1695 of 1701

POWERSTEERING OILPUMP

•

SST569C

SEC.

490

SR engine model~

To engine

~26. 36~ ,/"~

;~7 ..

':ij m '-/

~/i<> ·"-

~':J ~

@

'CJ!I",

1~ ........To engine

~16_22 (1.6•2.2, 12•16)

~ 45-60

(4.6 -6.1, 33-44)

SEC.

493 GAengine model

~16-21 [ij6.3.8.3

(1.6. 2.1,12

'Z5)

(0.64.0.85,

To engine

55.6:/73.8)

@ @" ./'----~

, "I

/e;..

~ 31•42 ',.., 0

.'$>J

K@

J:

<~~~iX':I~

Toengine

\1f!.7~

Pm

16-21

v. ~-..

, "~ ~1.6'2.1,12•15)

~ 16. 21 _~

(1.6 -2.1, 12. 15) ~

54.68

{5.5 -6.9,

40 -50~

~ 13.3. 18.0

. (1.36•1.84,

.G

@)

0

CD engine model

9.8_13.3) ../

/3

5

0

~ 16-21 (1.6 -2.1, 12-15)

l.~

@@ ,

~engine @

@Of1--! ~

2

" ," I~

.' "@

It. 17

0

f1 ~ ~~ 3lEi! 10~

69-78

37 •50 /,

'-l

18

f1

..>

lei

51•58)

(3.8. 5.1,27.37)

0,

:r:

19

0()

W

~Q

@

GA16

with

ASS

c:>

1578

0.

Except

GA16

with

ASS

,d

e7

b

Except

GA16 ITh~ .

6? ~

<:>

withASS

-J.1;~

~ 31-42 (3.2 -4.3, 23-31) ()

C'

0

I

() @~

49.69 (5.0-7.0,36 -51)

CD engine

:7 ~~

21

Pay attention

d I

f:j

0:\

toits direction.

mo e -'" ()

-~

~ 27-35 \)~

00

22

(2.8 -3.6, ~,~

23

20 _26)

ri /

~ 13.3 -18.0 ~~

2~ /

~1'36 •1.84,

9.8 •13.3)

13R

engi~e

model

J ~

CD engine model

I

') 26 ~

13.3. 18.0

Y.l~6 14

jGA16

with

ASS

/// (1.36-

1.84f \

-\:f

14~

13.3 -18.0

9.8 •13.3)

I() \\"-/

(1.36•1.84,

/ 09.8-13.3)

~ 27.35:~)-e /

I

\~'l ~

27-35

~l)~ / Except

GA16

with

ASS

(2.8 -3.6~ III~..::::-- (2.8-3.6, ~27•35

20 •26) \)20-26) ~ (2.8_3.6, 20_26)

~ :N'm (kg-m, It-Ib)

f]:

Lubrication points(Withautomatic transmission

[ij :

N'm (kg-m, in-Ib) fluid''DEXRON™,, typeorequivalent)

CD

Pulley

@

Copper washer @

Vane

@

Snap ring

@

Hose

@

Rotor

@ Drive shaftassembly

@

Connector boll

@

Pin

@ Oilseal

@

Mounting bracket

@

Carn ring

@

Suction pipe

@

Front housing

@

Gasket

@

O-ring

@l

Spring

@

Rear housing

0

Spring

@

O-ring

@

Mounting bracket

@

Control valve @O-ring

@

Adjusting bracket

@ O-ring

@)

Front sideplate @

Adjusting boll

@)

Connector

ST-29

Page 1696 of 1701

POWERSTEERING OILPUMP

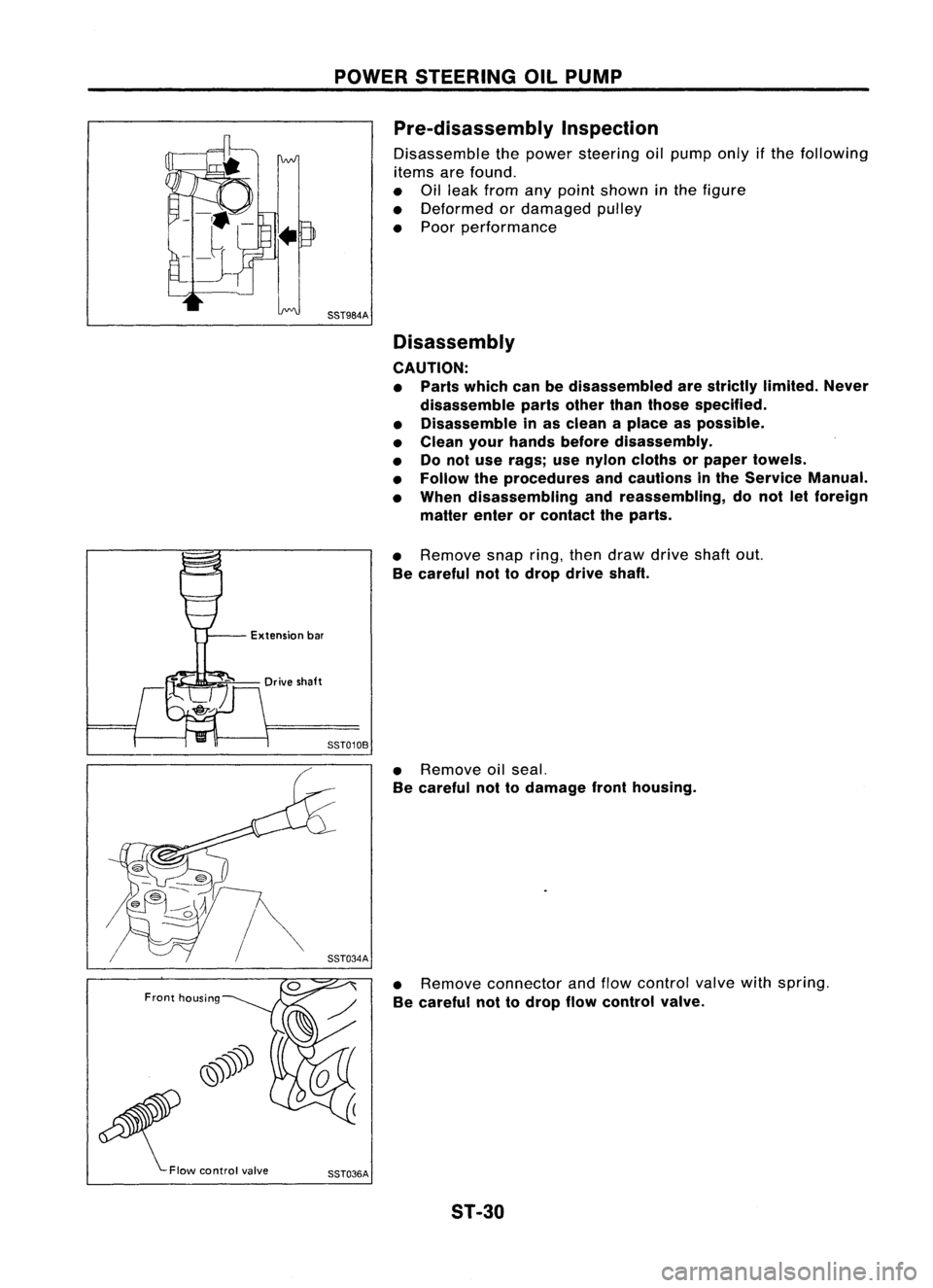

Pre-disassembly Inspection

Disassemble thepower steering oilpump onlyifthe following

items arefound.

• Oilleak from anypoint shown inthe figure

• Deformed ordamaged pulley

• Poor performance

SST984A Disassembly

CAUTION: • Parts which canbedisassembled arestrictly limited. Never

disassemble partsother thanthose specified.

• Disassemble inas clean aplace aspossible.

• Clean yourhands before disassembly.

• Donot use rags; usenylon cloths orpaper towels.

• Follow theprocedures andcautions inthe Service Manual.

• When disassembling andreassembling, donot letforeign

matter enterorcontact theparts.

Front housing Extension

bar

•

Remove snapring,thendraw drive shaftout.

Be careful nottodrop drive shaft.

SST010B

•Remove oilseal.

Be careful nottodamage fronthousing.

• Remove connector andflow control valvewithspring.

Be careful nottodrop flowcontrol valve.

SST036A 5T-30

Page 1697 of 1701

POWERSTEERING OILPUMP

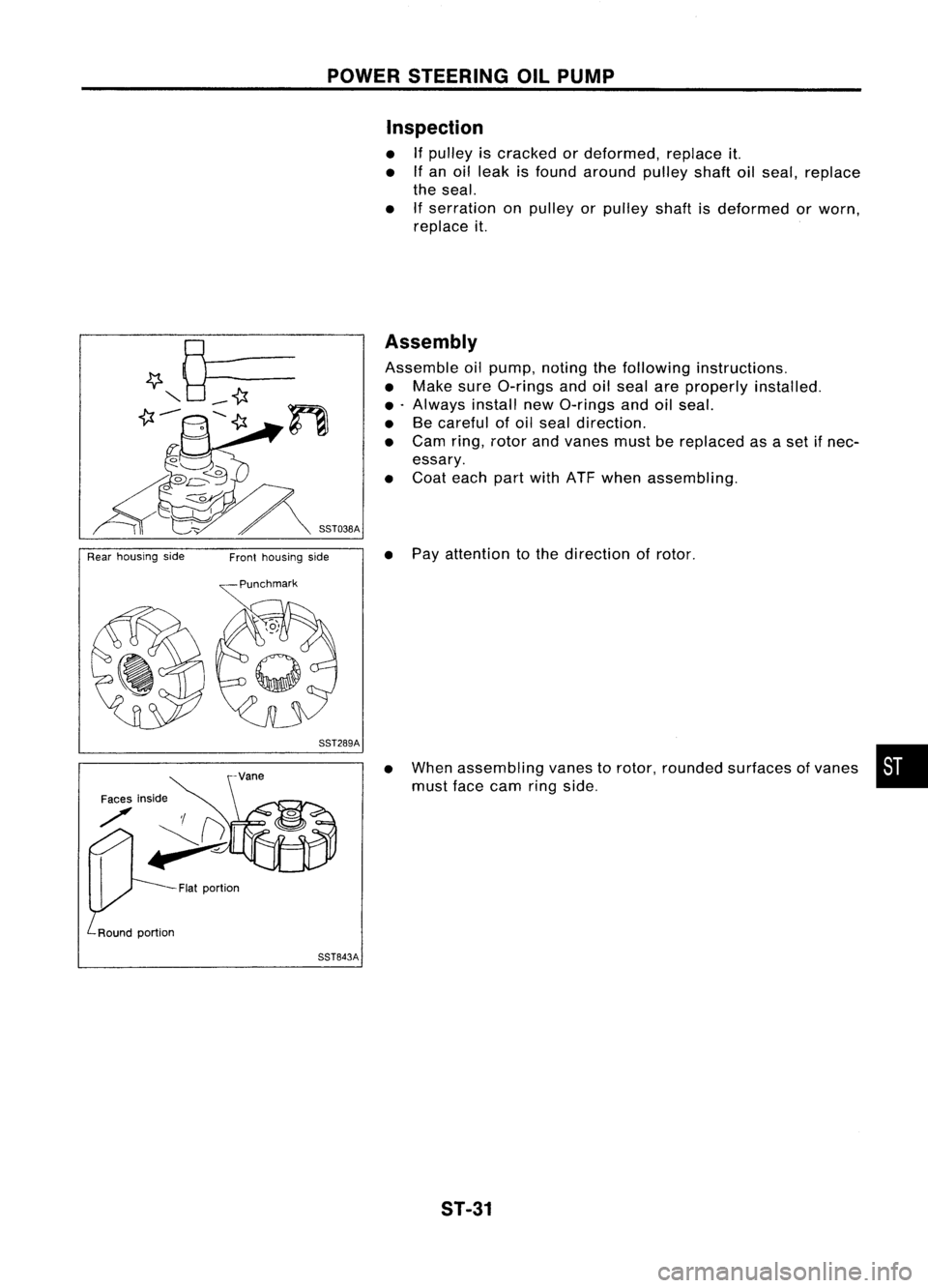

Inspection

• Ifpulley iscracked ordeformed, replaceit.

• Ifan oil leak isfound around pulleyshaftoilseal, replace

the seal.

• Ifserration onpulley orpulley shaftisdeformed orworn,

replace it.

Rear housing side

Fronthousing side

Assembly

Assemble oilpump, notingthefollowing instructions.

• Make sureO-rings andoilseal areproperly installed.

• .Always installnewO-rings andoilseal.

• Becareful ofoil seal direction.

• Cam ring,rotor andvanes mustbereplaced asaset ifnec-

essary.

• Coat each partwith ATFwhen assembling.

• Pay attention tothe direction ofrotor.

SST289A

Faces inside

./' 'I(}

~

Flatportion

SST843A

•

When assembling vanestorotor, rounded surfaces ofvanes •

must facecam ringside.

ST-31

Page 1698 of 1701

POWERSTEERING OILPUMP

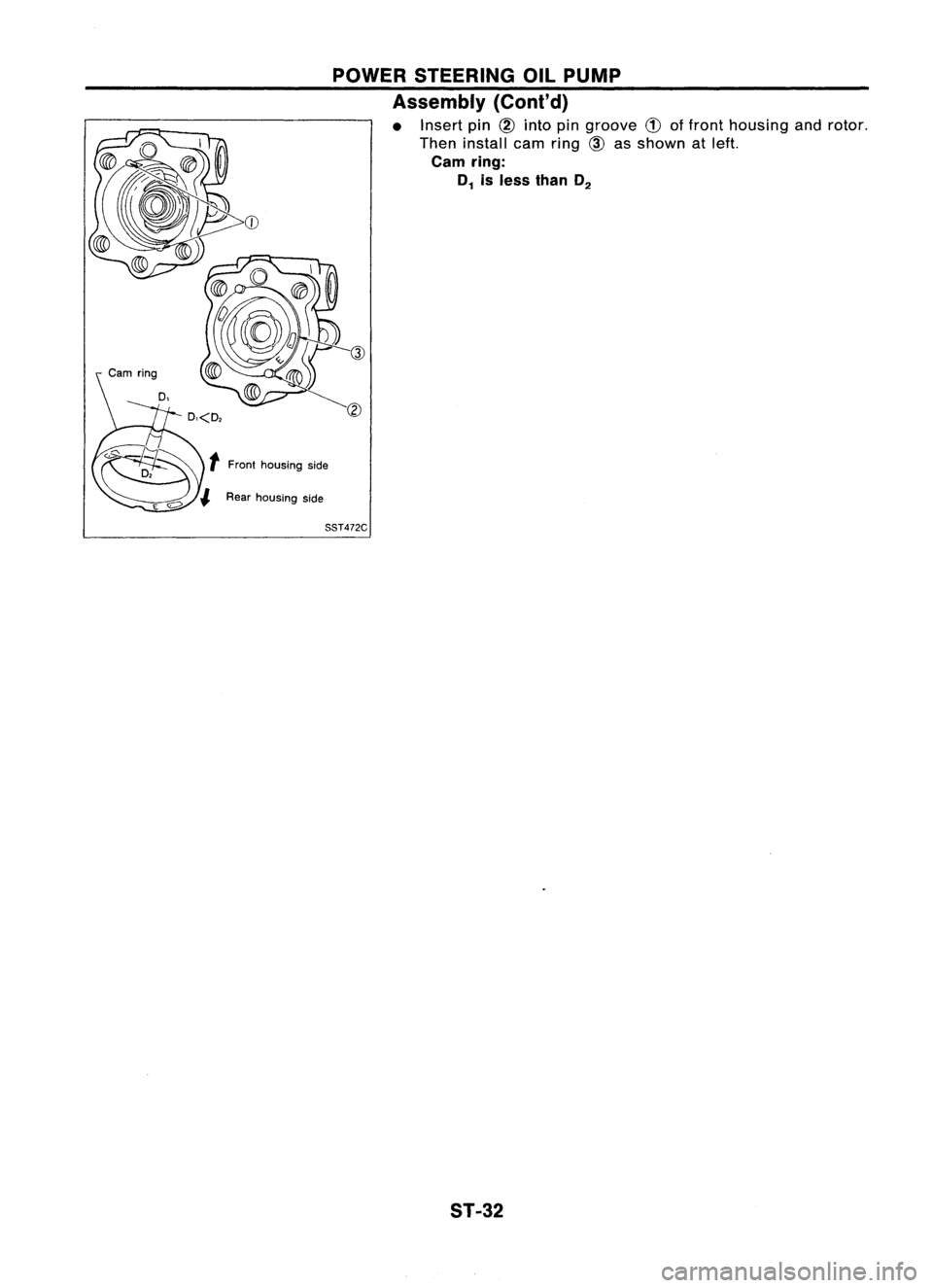

Assembly (Cont'd)

• Insert pin

CID

into pingroove

CD

offront housing androtor.

Then install earnring

CID

asshown atleft.

earn ring:

D

1

isless than D

2

SST472C

ST-32

Page 1699 of 1701

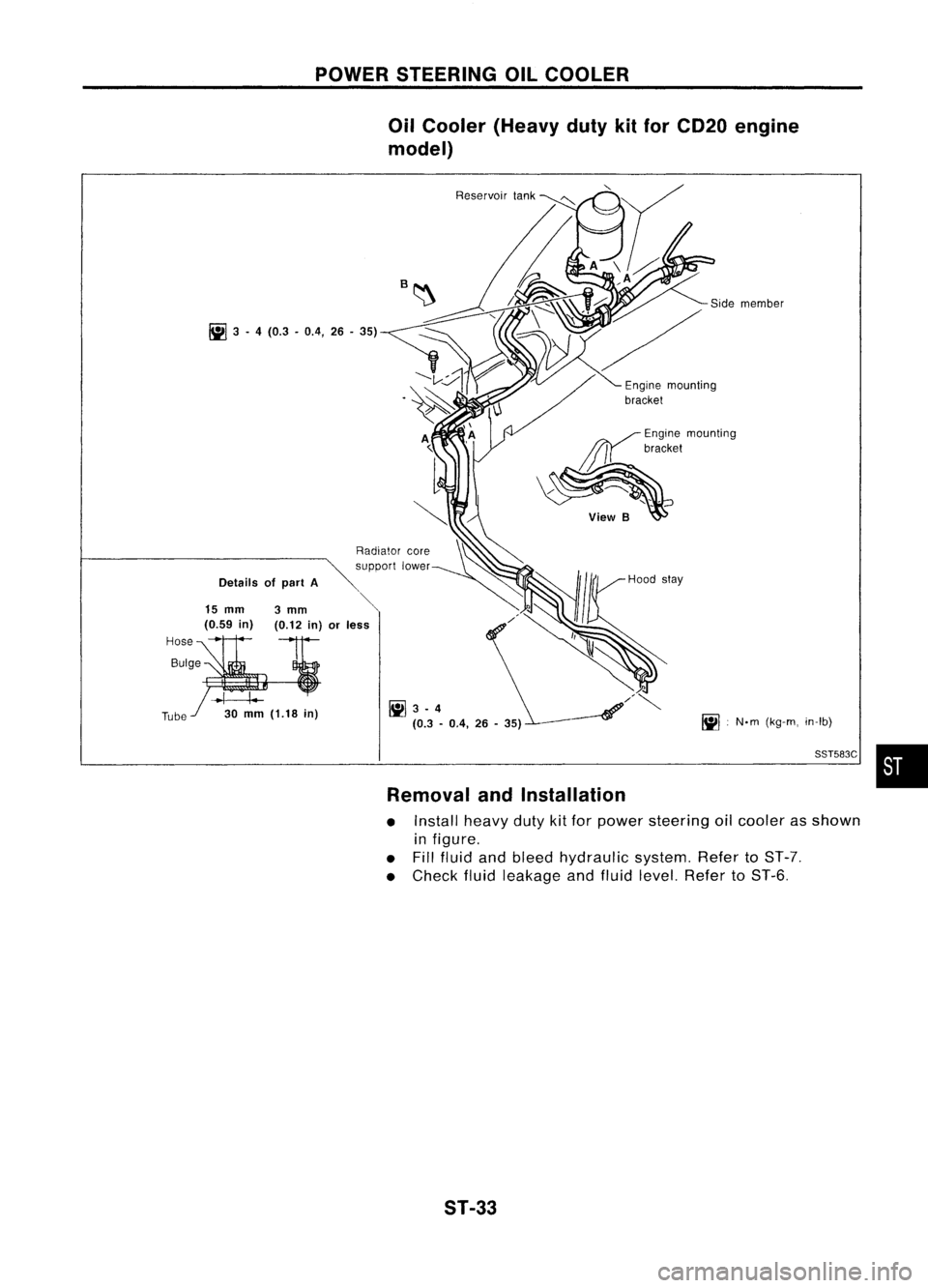

POWERSTEERING OILCOOLER

Oil Cooler (Heavy dutykitfor CD20 engine

model)

Removal andInstallation

• Install heavydutykitfor power steering oilcooler asshown

in figure.

• Fill fluid andbleed hydraulic system.RefertoST-7.

• Check fluidleakage andfluid level. Refer toST-6.

Hose

Bulge

Tube

~

3-4 (0.3 -0.4, 26-35)

Details ofpart A

15

mm

3

mm

(0.59 in) (0.12in)orless

.1 I-

30

mm

(1.18

in)

Reservoir

lank

~ 3-4

(0.3 -0.4, 26-35)

~

Enginemounting

/~bracket

\~ ~~eWB~

~•N.m (kg-m, in-Ib)

SST583C

•

ST-33

Page 1700 of 1701

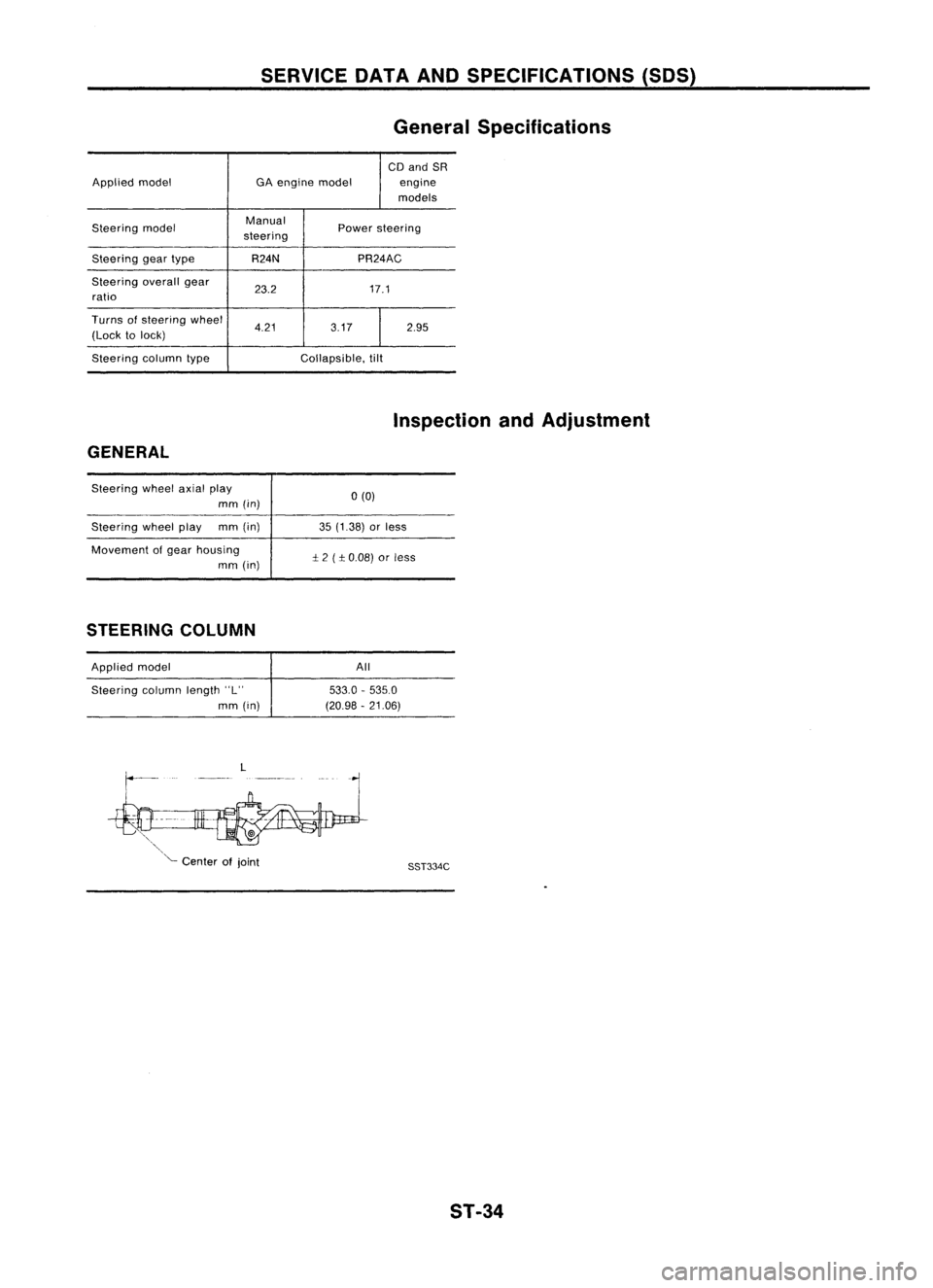

SERVICEDATAANDSPECIFICATIONS (SOS)

General Specifications

CD and SR

Applied model GAengine model engine

models

Steering model Manual

Powersteering

steering

Steering geartype R24N PR24AC

Steering overallgear

23.2 17.1

ratio

Turns ofsteering wheel

4.21 3.172.95

(Lock tolock)

Steering columntype Collapsible,tilt

Inspection andAdjustment

GENERAL

Steering wheelaxialplay

mm (in)

Steering wheelplay mm(in)

Movement ofgear housing

mm (in)

STEERING COLUMN

Applied model

Steering columnlength"L"

mm (in)

L

'"

'- Center ofjoint 0(0)

35 (1.38) orless

:!:

2 (

:!:

0.08) orless

All

533.0 -535.0

(20.98 -21.06)

SST334C

ST-34