check engine NISSAN ALMERA N15 1995 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 225 of 1701

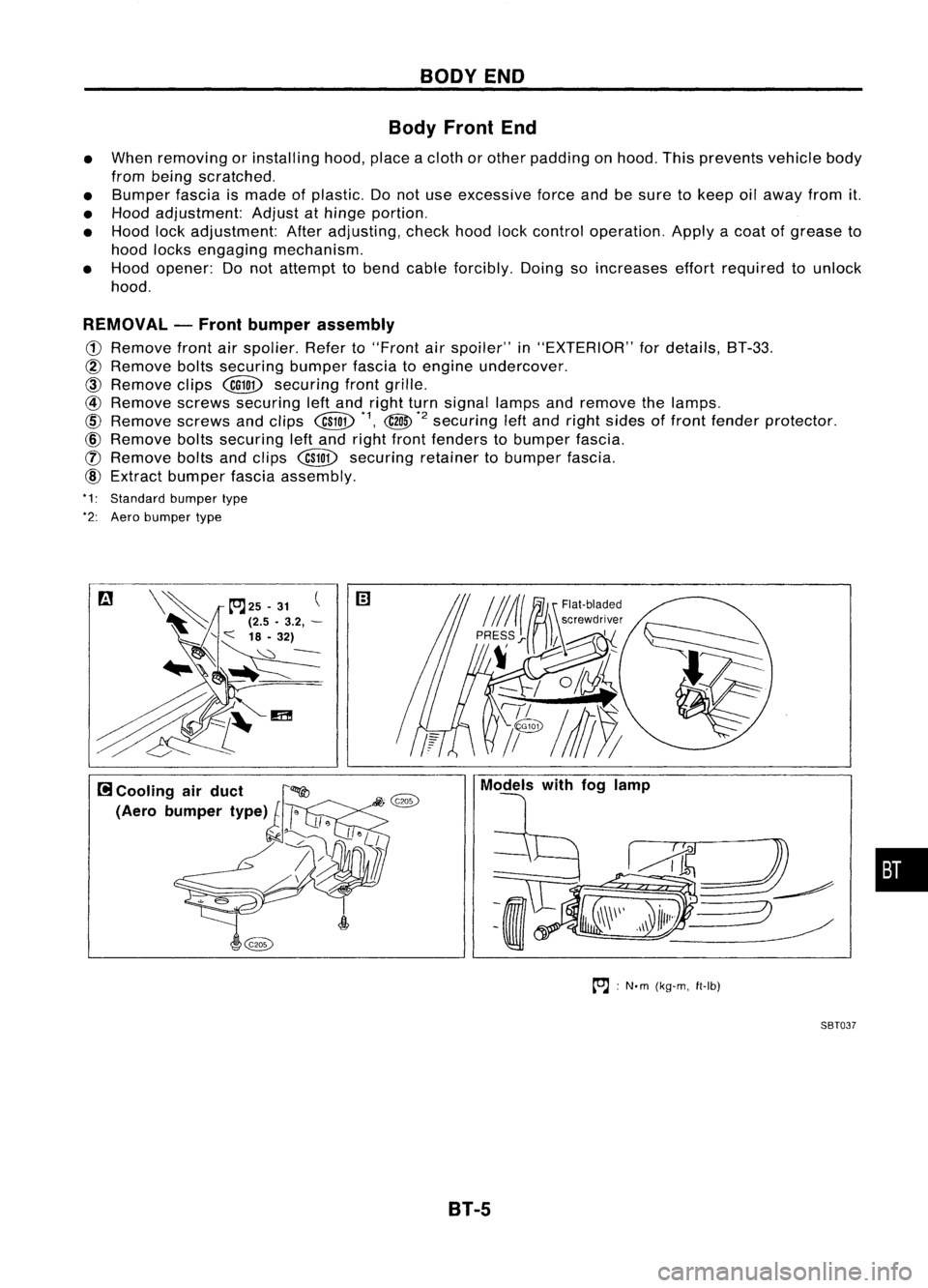

BODYEND

Body Front End

• When removing orinstalling hood,placeacloth orother padding onhood. Thisprevents vehiclebody

from being scratched.

• Bumper fasciaismade ofplastic. Donot use excessive forceandbesure tokeep oilaway fromit.

• Hood adjustment: Adjustathinge portion.

• Hood lockadjustment: Afteradjusting, checkhoodlockcontrol operation. Applyacoat ofgrease to

hood locks engaging mechanism.

• Hood opener: Donot attempt tobend cable forcibly. Doingsoincreases effortrequired tounlock

hood.

REMOVAL -Front bumper assembly

CD

Remove frontairspolier. Referto"Front

air

spoiler" in"EXTERIOR" fordetails, BT-33.

@

Remove boltssecuring bumperfasciatoengine undercover.

CID

Remove clips

@QD

securing frontgrille.

@

Remove screwssecuring leftand right turnsignal lampsandremove thelamps.

@

Remove screwsandclips

@W

*1,

@

*2

securing

leftand right sides offront fender protector.

@)

Remove boltssecuring leftand right front fenders tobumper fascia.

([) Remove boltsandclips

@W

securing retainertobumper fascia.

@)

Extract bumper fasciaassembly.

*1: Standard bumpertype

*2: Aero bumper type

to.J:

N'm (kg-m, ft-Ib)

SBT037

B1-5

•

Page 267 of 1701

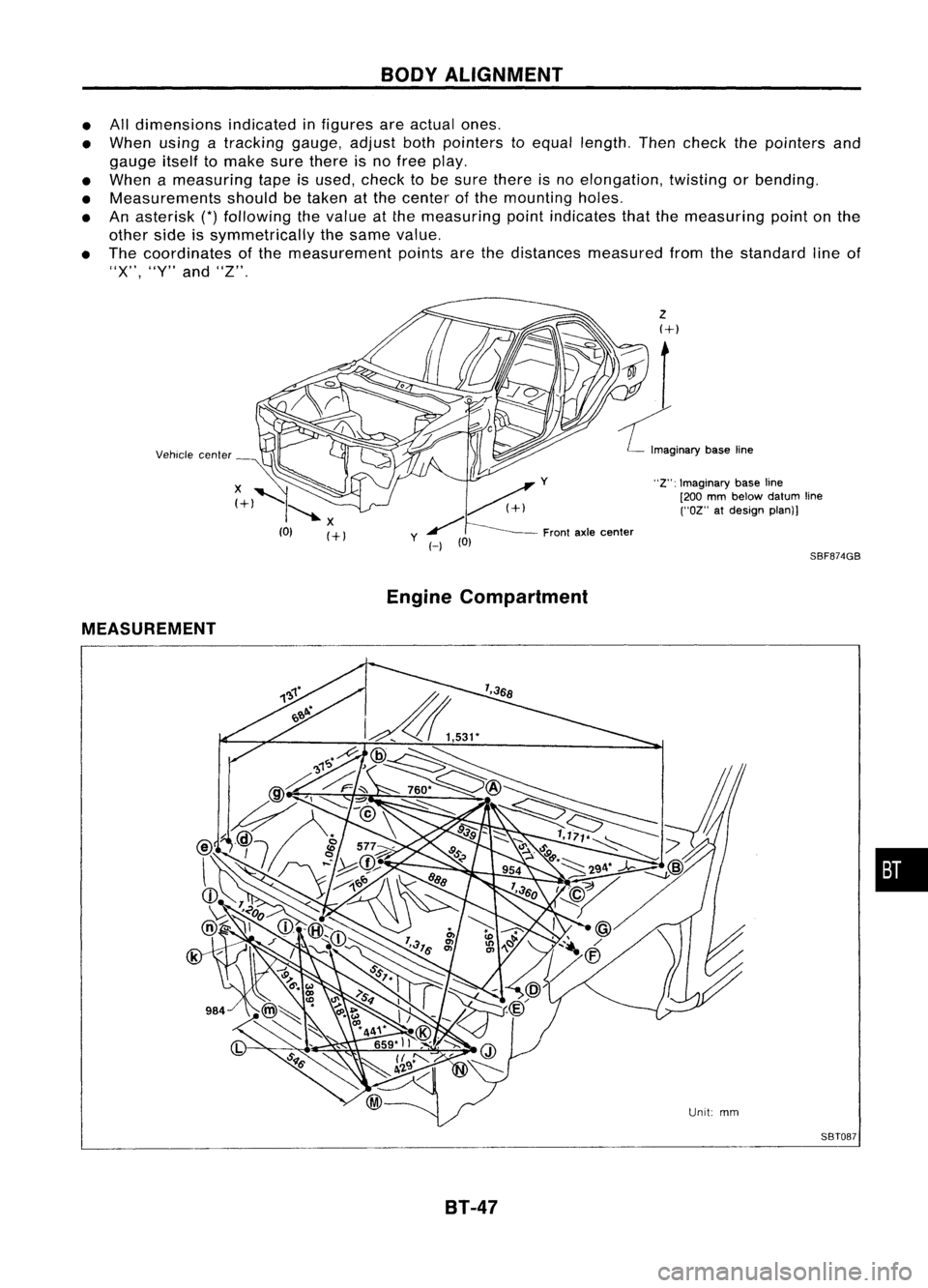

BODYALIGNMENT

• Alldimensions indicatedinfigures areactual ones.

• When usingatracking gauge,adjustbothpointers toequal length. Thencheck thepointers and

gauge itselftomake surethere isno free play.

• When ameasuring tapeisused, check tobe sure there isno elongation, twistingorbending.

• Measurements shouldbetaken atthe center ofthe mounting holes.

• Anasterisk

(*)

following thevalue atthe measuring pointindicates thatthemeasuring pointonthe

other sideissymmetrically thesame value.

• The coordinates ofthe measurement pointsarethedistances measured fromthestandard lineof

"X", "Y"andHZ".

Frontaxlecenter

I

v

~

/

y

H

(0)

2

(+)

~r

L"oo"

b.~

Ii"'

"2": Imaginary baseline

[200 mmbelow datum line

("02" atdesign plan)]

MEASUREMENT

SBF874GB

Engine Compartment

SBT087

8T-47

•

Page 275 of 1701

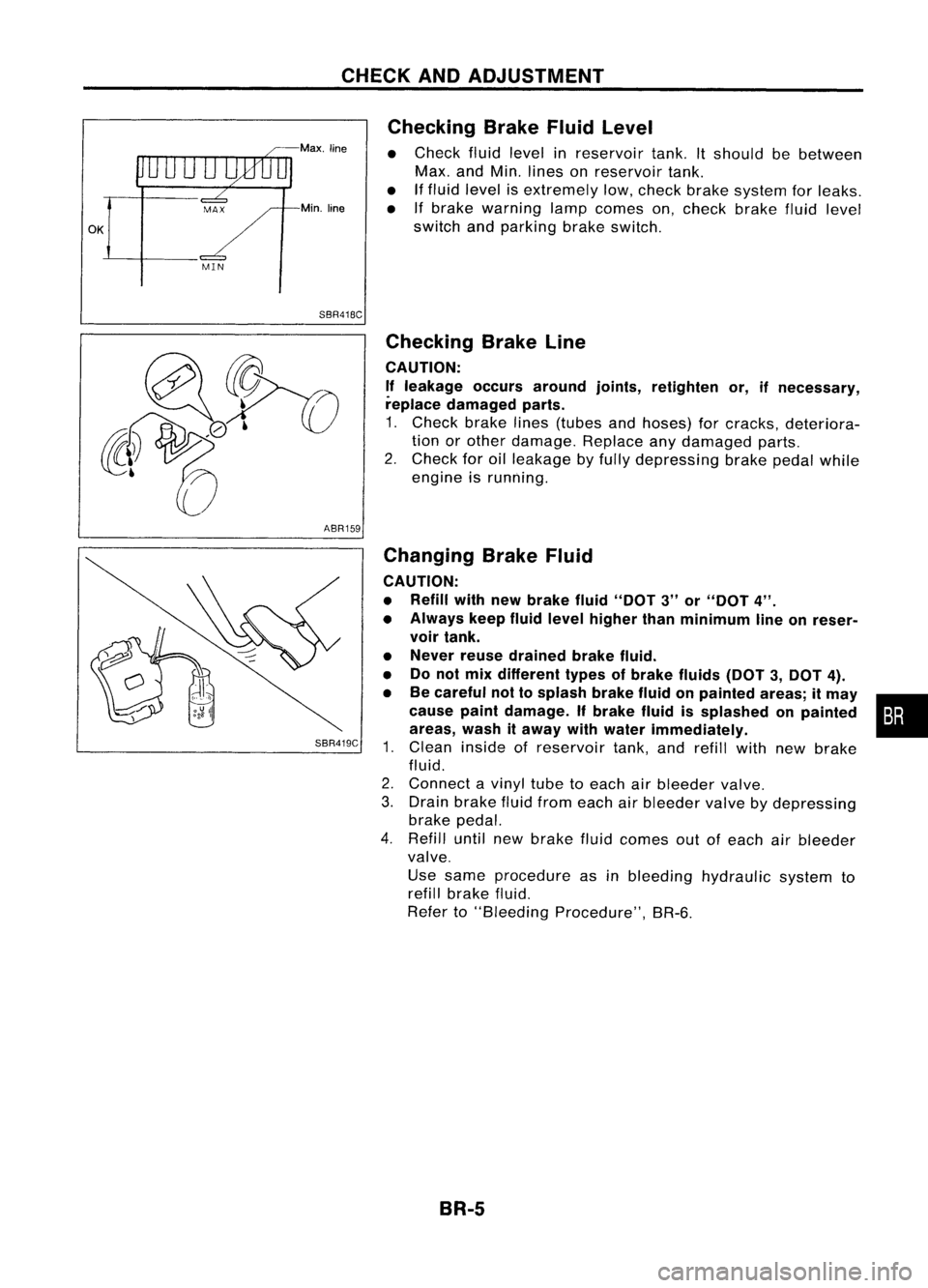

CHECKANDADJUSTMENT

OK

MINMax.

line

Min. line

SBR418C

Checking

BrakeFluidLevel

• Check fluidlevel inreservoir tank.Itshould bebetween

Max. andMin. lines onreservoir tank.

• Iffluid level isextremely low,check brakesystem forleaks.

• Ifbrake warning lampcomes on,check brakefluidlevel

switch andparking brakeswitch.

ABR159

SBR419C

Checking

BrakeLine

CAUTION: If leakage occursaround joints,retighten or,ifnecessary,

replace damaged parts.

1. Check brakelines(tubes andhoses) forcracks, deteriora-

tion orother damage. Replaceanydamaged parts.

2. Check foroilleakage byfully depressing brakepedalwhile

engine isrunning.

Changing BrakeFluid

CAUTION:

• Refill withnewbrake fluid"DOT 3"or"DOT 4".

• Always keepfluidlevel higher thanminimum lineonreser-

voir tank.

• Never reusedrained brakefluid.

• Donot mix different typesofbrake fluids(DOT3,DOT 4).

• Becareful nottosplash brakefluidonpainted areas;itmay •

cause paintdamage. Ifbrake fluidissplashed onpainted :•

areas, washitaway withwater immediately.

1. Clean inside ofreservoir tank,andrefill withnewbrake

fluid.

2. Connect avinyl tubetoeach airbleeder valve.

3. Drain brake fluidfrom each airbleeder valvebydepressing

brake pedal.

4. Refill untilnewbrake fluidcomes outofeach airbleeder

valve.

Use same procedure asinbleeding hydraulic systemto

refill brake fluid.

Refer to"Bleeding Procedure", BR-6.

BR-5

Page 281 of 1701

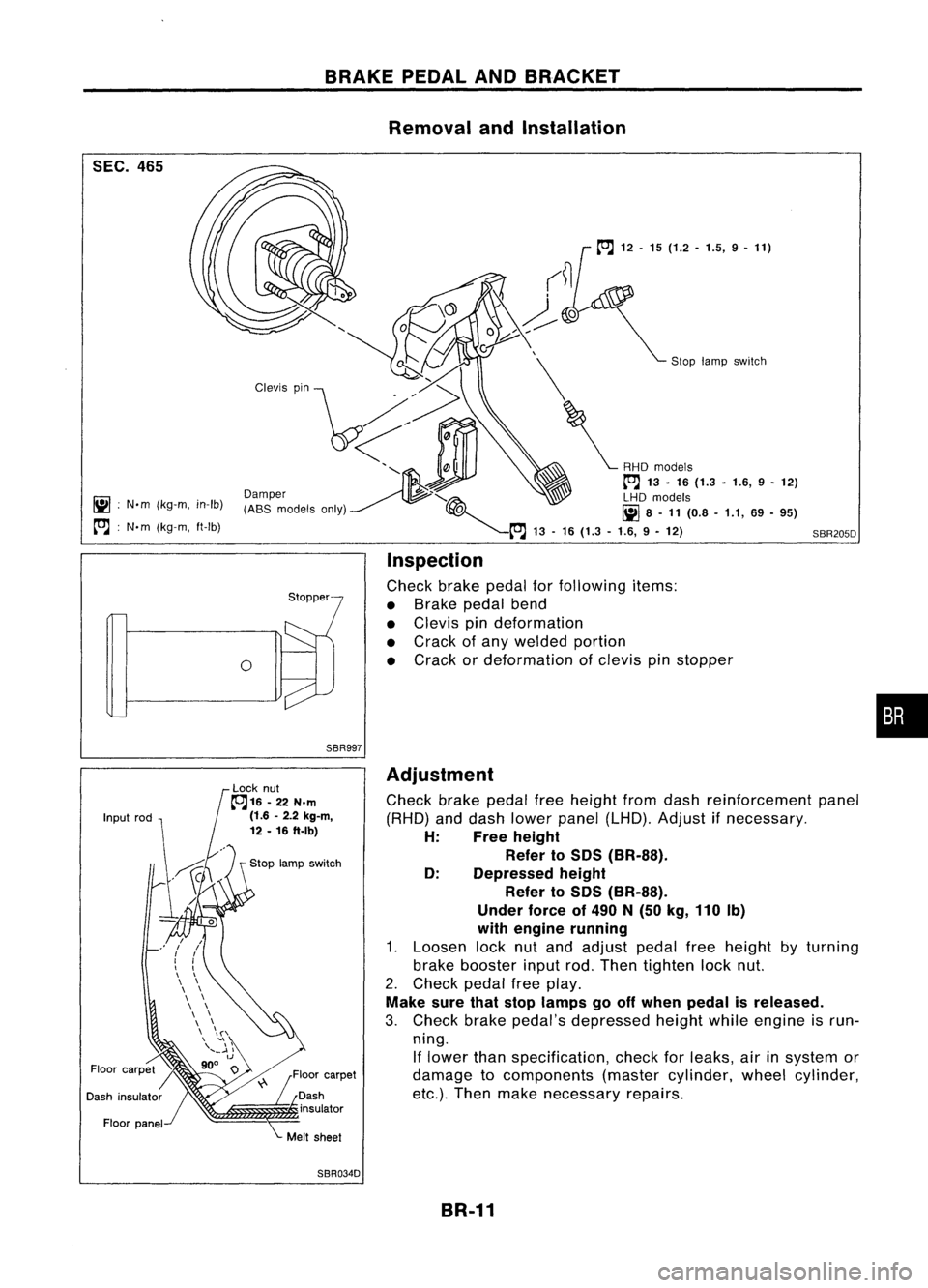

SEC.465

iii :

N'm (kg-m, in-Ib)

~ :N'm (kg-m, ft-Ib)

BRAKE

PEDALANDBRACKET

Removal andInstallation

Sloplamp sWitch

SBR205D

o

Inspection

Check brakepedalforfollowing items:

• Brake pedalbend

• Clevis pindeformation

• Crack ofany welded portion

• Crack ordeformation ofclevis pinstopper

•

SBR997

Adjustment

Check brakepedalfreeheight fromdash reinforcement panel

(RHD) anddash lower panel (LHD). Adjust ifnecessary.

H: Freeheight

Refer to

50S

(BR-SS).

0: Depressed height

Refer to

50S

(BR-SS).

Under forceof

490

N

(50

kg,

110

Ib)

with engine running

1. Loosen locknutand adjust pedalfreeheight byturning

brake booster inputrod.Then tighten locknut.

2. Check pedalfreeplay.

Make surethatstop lamps gooff when pedal isreleased.

3. Check brakepedal's depressed heightwhileengine isrun-

ning. If lower thanspecification, checkforleaks, airinsystem or

damage tocomponents (mastercylinder, wheelcylinder,

etc.). Then make necessary repairs.

SBR034D BR-11

Page 285 of 1701

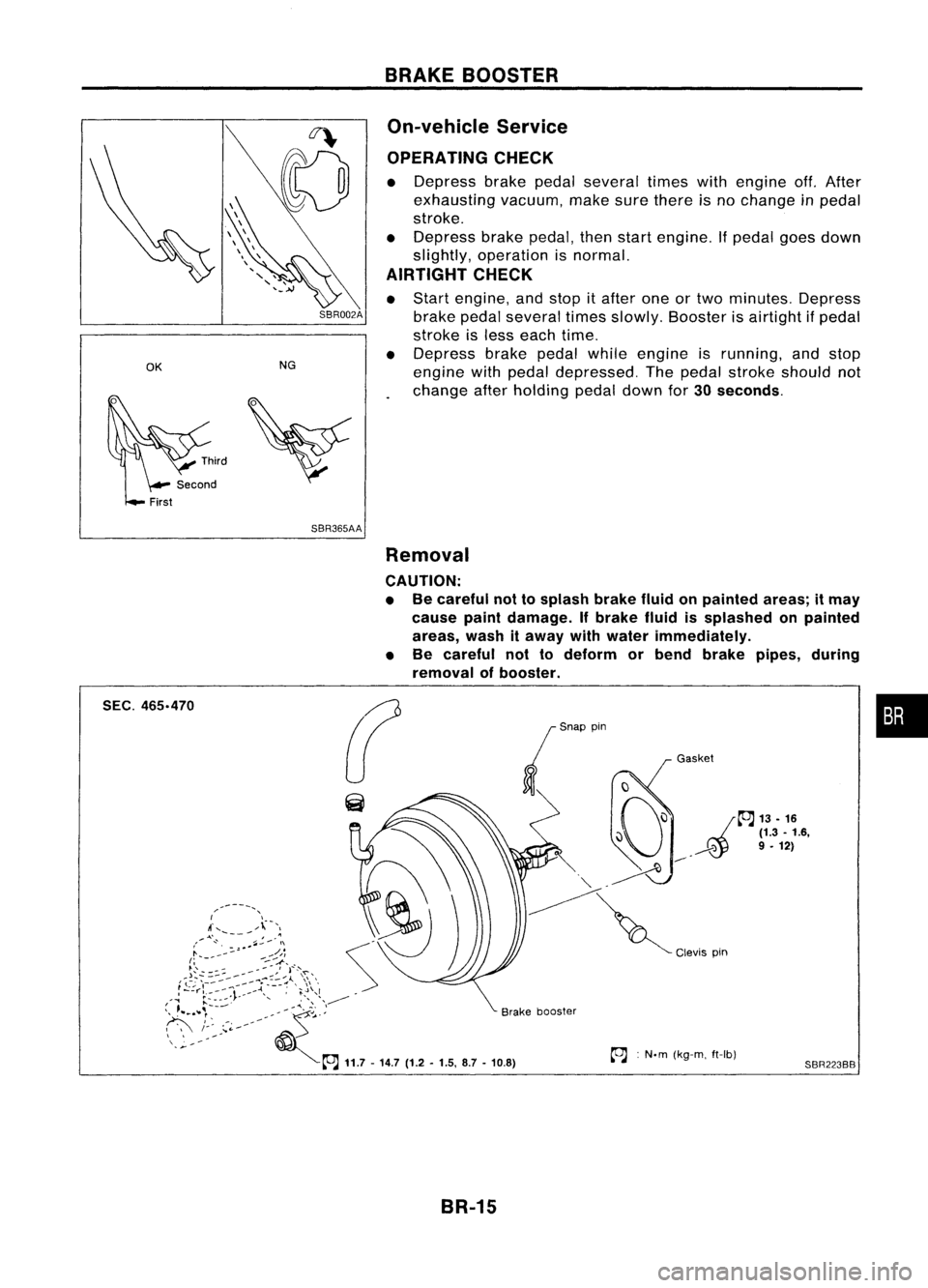

OKNGBRAKE

BOOSTER

On-vehicle Service

OPERATING CHECK

• Depress brakepedalseveral timeswithengine off.After

exhausting vacuum,makesurethere isno change inpedal

stroke.

• Depress brakepedal, thenstart engine. Ifpedal goesdown

slightly, operation isnormal.

AIRTIGHT CHECK

• Start engine, andstop itafter oneortwo minutes. Depress

SBR002A

brakepedalseveral timesslowly. Booster isairtight ifpedal

stroke isless each time.

• Depress brakepedalwhileengine isrunning, andstop

engine withpedal depressed. Thepedal stroke should not

change afterholding pedaldownfor

30seconds.

SBR365AA Removal

CAUTION:

• Becareful nottosplash brakefluidonpainted areas;itmay

cause paintdamage. Ifbrake fluidissplashed onpainted

areas, washitaway withwater immediately.

• Be careful nottodeform orbend brake pipes, during

removal ofbooster.

SEC.

465.470

BR-15Gasket

~ :N.m (kg-m. ft-Ib)

SBR223BB

•

Page 288 of 1701

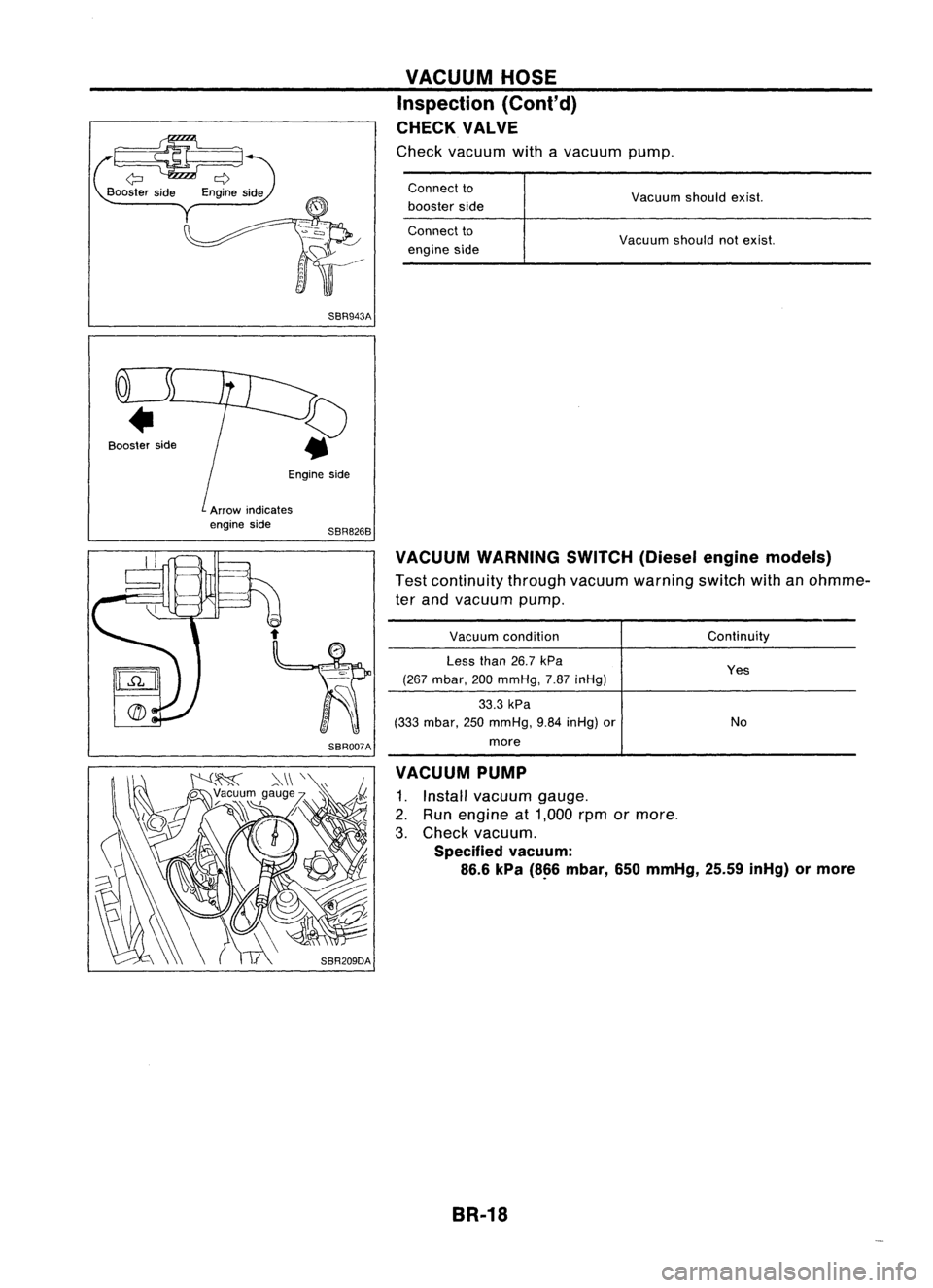

VACUUMHOSE

Inspection (Cont'd)

CHECK VALVE

Check vacuum withavacuum pump.

~

Booster side

SBR943A

Connect

to

booster side

Connect to

engine side Vacuum

shouldexist.

Vacuum shouldnotexist.

Engine side

VACUUM WARNING SWITCH(Dieselenginemodels)

Test continuity throughvacuum warning switchwithanohmme-

ter and vacuum pump.

Booster

side

Arrowindicates

engine side

SBR826B

SBR007A

Vacuum

condition

Less than26.7kPa

(267 mbar, 200mmHg, 7.87inHg)

33.3 kPa

(333 mbar, 250mmHg, 9.84inHg) or

more Continuity

Yes

No

VACUUM PUMP

1. Install vacuum gauge.

2. Run engine at1,000 rpmormore.

3. Check vacuum.

Specified vacuum:

86.6 kPa

(8~6

mbar, 650mmHg, 25.59inHg) ormore

BR-18

Page 307 of 1701

Togglelever

Stopper

Front

V

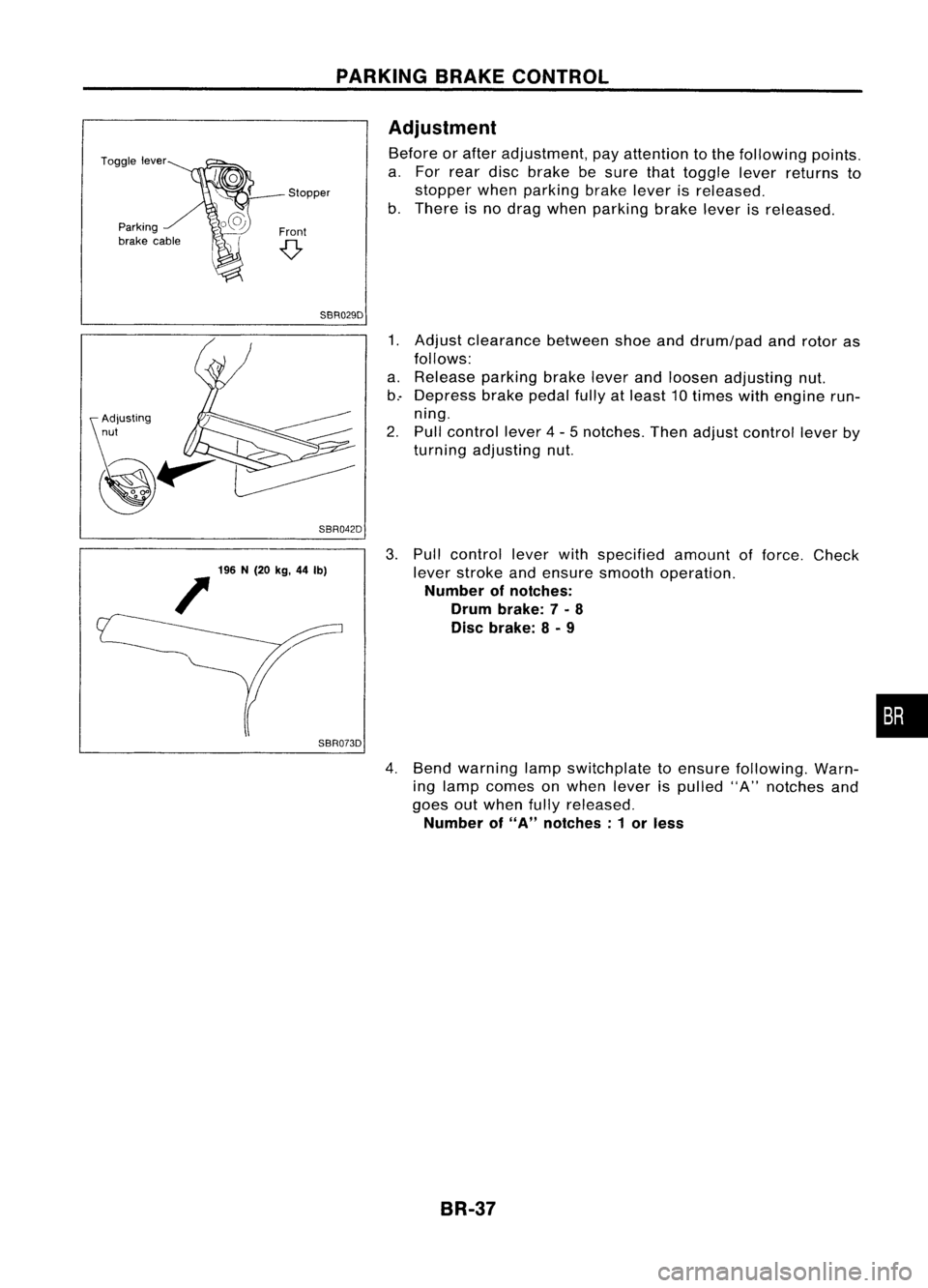

PARKING

BRAKECONTROL

Adjustment

Before orafter adjustment, payattention tothe following points.

a. For rear discbrake besure thattoggle leverreturns to

stopper whenparking brakeleverisreleased.

b. There isno drag when parking brakeleverisreleased.

SBR029D

SBR042D

1.

Adjust clearance betweenshoeanddrum/pad androtor as

follows:

a. Release parkingbrakeleverandloosen adjusting nut.

b.- Depress brakepedalfullyatleast 10times withengine run-

ning.

2. Pull control lever4-5 notches. Thenadjust control leverby

turning adjusting nut.

196 N(20 kg,44Ib)

/

SBR073D

3.

Pull control leverwithspecified amountofforce. Check

lever stroke andensure smooth operation.

Number ofnotches:

Drum brake: 7-

8

Disc brake: 8-

9

4. Bend warning lampswitchplate toensure following. Warn-

ing lamp comes onwhen leverispulled "A"notches and

goes outwhen fullyreleased.

Number of

"A"

notches: 1or less

BR-37

•

Page 323 of 1701

.=J

MPH

-~s::~

~~

___ --- warnin:1

TROUBLE

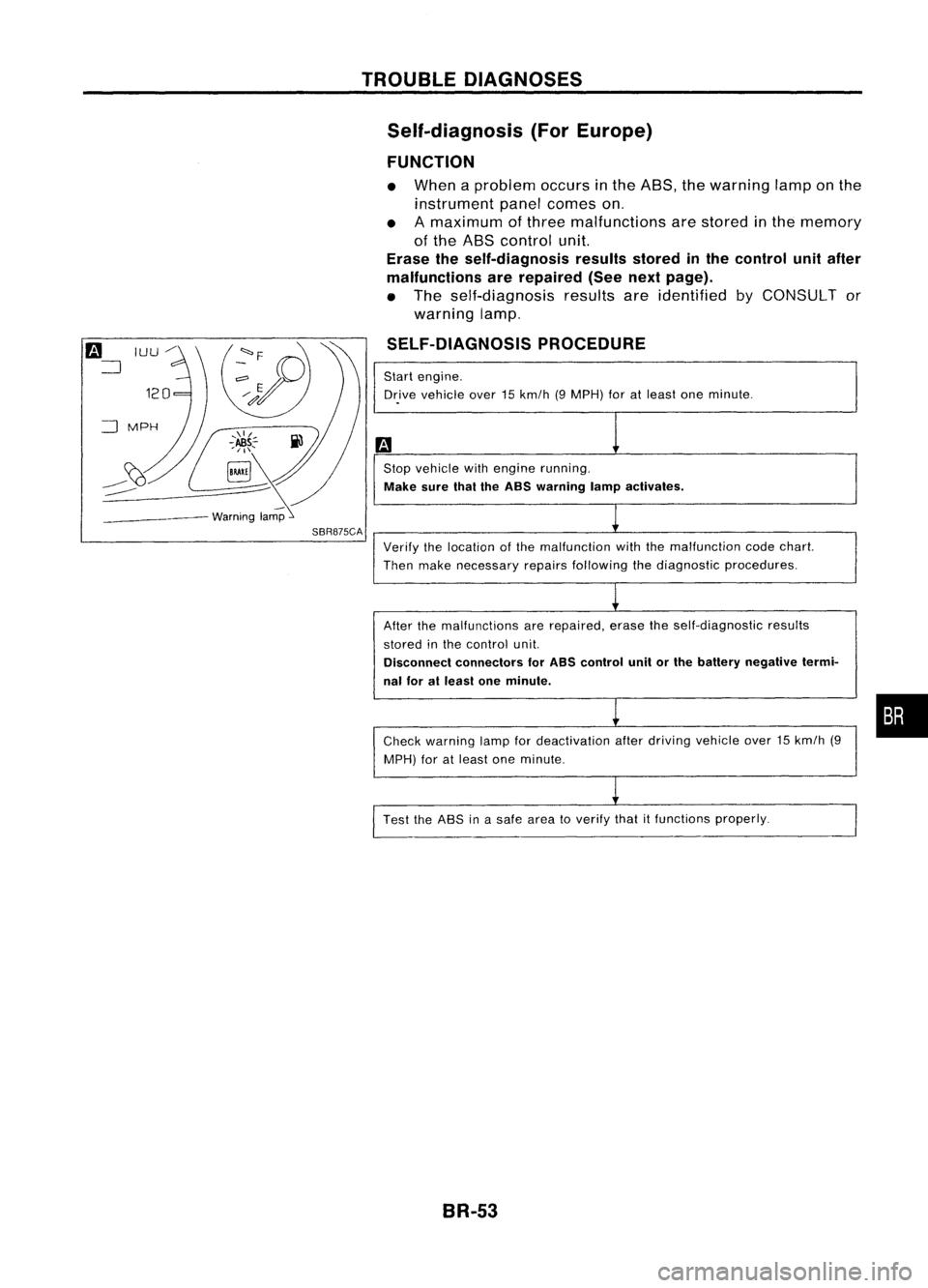

DIAGNOSES

Self-diagnosis (ForEurope)

FUNCTION

• When aproblem occursinthe ABS, thewarning lamponthe

instrument panelcomes on.

• Amaximum ofthree malfunctions arestored inthe memory

of the ABS control unit.

Erase theself-diagnosis resultsstoredinthe control unitafter

malfunctions arerepaired (Seenextpage).

• The self-diagnosis resultsareidentified byCONSULT or

warning lamp.

SELF-DIAGNOSIS PROCEDURE

Start engine.

Dr.ive vehicle over15km/h (9MPH) foratleast oneminute .

Stop vehicle withengine running.

Make surethaitheASS warning lampactivates.

SBR875CA

Verifythelocation ofthe malfunction withthemalfunction codechart.

Then make necessary repairsfollowing thediagnostic procedures.

After themalfunctions arerepaired, erasetheself-diagnostic results

stored inthe control unit.

Disconnect connectors forASS control unitorthe battery negative termi-

nal foratleast oneminute.

Check warning lampfordeactivation afterdriving vehicle over15km/h (9

MPH) foratleast oneminute.

Test theASS inasafe area toverify thatitfunctions properly.

BR-53

•

Page 329 of 1701

![NISSAN ALMERA N15 1995 User Guide TROUBLEDIAGNOSES

Ii)

NISSAN

CONSULT

EE940.

I

~

I

START

I

SUB

MODE

,

SEF253Q

@]

~

SELECT

SYSTEM

0

ENGINE

AfT

AIRBAG ABS

IVMS

SBR104D

@]

I~

SELECT DIAGMODE

01

I

SELF-DIAG

RESULTS NISSAN ALMERA N15 1995 User Guide TROUBLEDIAGNOSES

Ii)

NISSAN

CONSULT

EE940.

I

~

I

START

I

SUB

MODE

,

SEF253Q

@]

~

SELECT

SYSTEM

0

ENGINE

AfT

AIRBAG ABS

IVMS

SBR104D

@]

I~

SELECT DIAGMODE

01

I

SELF-DIAG

RESULTS](/img/5/57349/w960_57349-328.png)

TROUBLEDIAGNOSES

Ii)

NISSAN

CONSULT

EE940.

I

~

I

START

I

SUB

MODE

,

SEF253Q

@]

~

SELECT

SYSTEM

0

ENGINE

AfT

AIRBAG ABS

IVMS

SBR104D

@]

I~

SELECT DIAGMODE

01

I

SELF-DIAG

RESULTS

,

I

DATA

MONITOR

I

I

ACTIVE

TEST

I

ECU

PART NUMBER

I

I

SST412B

II

•SELF-DiAG RESULTS.

0

FAILURE DETECTED

TIME

FR RH SENSOR

0

[OPEN)

ERASE

II

PRINT

SBR950C CONSULT

Inspection Procedure

SELF-DIAGNOSIS PROCEDURE

m

1) Turn ignition switchOFF.

2) Connect CONSULT toData LinkCon-

nector forCONSULT.

1) Start engine.

2) Drive vehicle over30km/h (20MPH)

for atleast oneminute.

.

r

(;)

1)Stop vehicle withengine running

and touch "START" onCON-

SUL Tscreen.

• Program

card

AE950: ForAustralia

EE940: ExceptAustralia

(!]

2)Touch "ASS".

lP]

3)Touch "SELF-DIAG RESULTS".

• The screen showsthedetected mal-

function andthetimes ofignition

switch ONand OFF after itoccurred.

Make thenecessary repairsfollowing

the diagnostic procedures.

II

After themalfunctions arerepaired,

erase theself-diagnostic resultsstored

in the control unitbytouching

"ERASE".

Check warning lampfordeactivation

after driving vehicle over30km/h (20

MPH) foratleast oneminute.

Test theASS inasafe area toverify

that itfunctions properly.

Note: "SELF.DlAG RESULTS"screenshowsthedetected malfunction and

the times ofignition switchONand OFF after

it

occurred.

BR-59

•

Page 352 of 1701

TROUBLEDIAGNOSES

Diagnostic Procedure8

CONTROL UNIT

(Malfunction codeNo.71)

Carry outself-diagnosis aftererasing

self-diagnostic results,BR-56.

Does warning lampindicate codeNo.

71 again?

No

Inspect thesystem according tothe

code No. Yes

Replace controlunit.

Brake pedal Diagnostic

Procedure9

SYMPTOM: Pedalvibration andnoise

No

Does thesymptom appearwhenelectri-

SAT797A

calequipment switches(suchashead-

lamp) areoperated?

1.

Apply brake.

2. Start engine.

3. Does thesymptom appearonlywhen

engine isstarted?

No

Yes

Check wheelsensor shieldgrou.nd

secured withcontrol unitmounting bolt.

Refer toBR-41. Yes

Carryoutself-diagnosis.

Refer toBR-53 (Europe)

or BR-56 (Except

Europe).

Go to

Ii1

inDiagnostic

Procedure 11,BR-83.

OK

Check control unitpinterminals for

damage orthe connection ofcontrol

unit harness connector.

Reconnect controlunitharness connec-

tor. Then retest.

Note: ABSmayoperate andcause vibration underanyofthe

following conditions.

• Applying brakegradually whenshifting oroperating clutch.

• Low friction (slippery) road.

• High speed cornering.

• Driving overbumps andpotholes.

• Engine speedisover 5,000 rpmwith vehicle stopped.

BR-82