check engine NISSAN ALMERA N15 1995 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 363 of 1701

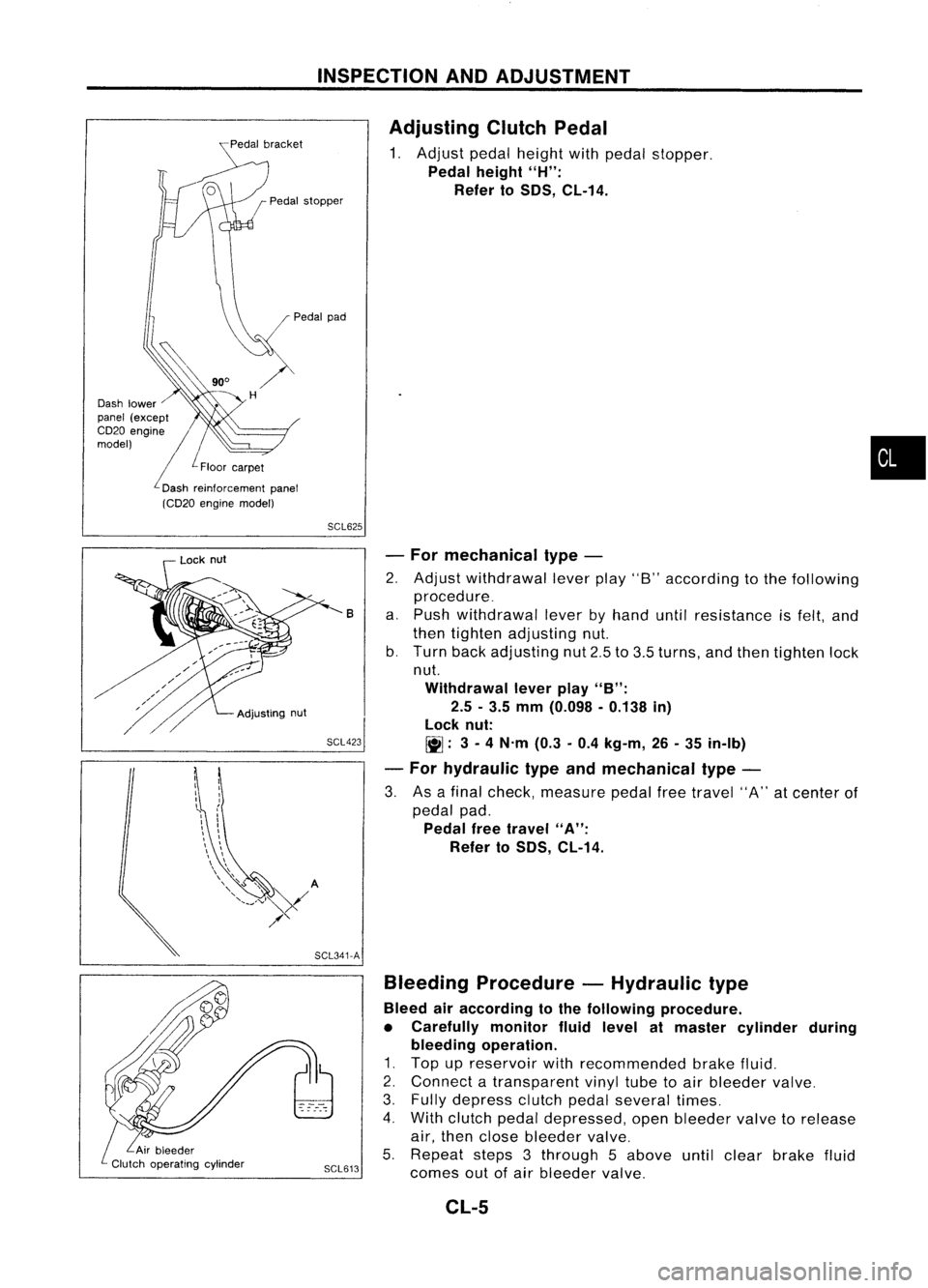

INSPECTIONANDADJUSTMENT

Pedal stopper

Dash lower

panel (except

CD20 engine //

model)

/L

Floor car-pet

L

Dash reinforcement panel

(CD20 engine model)

Adjusting

ClutchPedal

1. Adjust pedalheight withpedal stopper.

Pedal height

"H":

Refer to

50S,

CL-14.

•

SCL625

SCL423 -

For mechanical type-

2. Adjust withdrawal leverplay"8"according tothe following

procedure_

a. Push withdrawal leverbyhand untilresistance isfelt, and

then tighten adjusting nut.

b. Turn backadjusting nut2.5to3.5 turns, andthen tighten lock

nut.

Withdrawal leverplay

"B":

2.5 -3.5 mm (0.098 -0.138 in)

lock nut:

~: 3-

4 N'm (0.3-0.4 kg-m, 26-35 in-Ib)

- For hydraulic typeandmechanical type-

3. Asafinal check, measure pedalfreetravel "A"atcenter of

pedal pad.

Pedal freetravel

"A":

Refer to

50S,

CL-14.

B

Bleeding Procedure -Hydraulic type

Bleed airaccording tothe following procedure.

• Carefully monitorfluidlevel atmaster cylinder during

bleeding operation.

1. Top upreservoir withrecommended brakefluid.

2. Connect atransparent vinyltubetoair bleeder valve.

3. Fully depress clutchpedalseveral times.

4. With clutch pedaldepressed, openbleeder valvetorelease

air, then close bleeder valve.

5. Repeat steps3through 5above untilclear brake fluid

SCL613

comesoutofair bleeder valve.

SCL341-A

Adjusting

nut

Lock

nut

CL-5

Page 372 of 1701

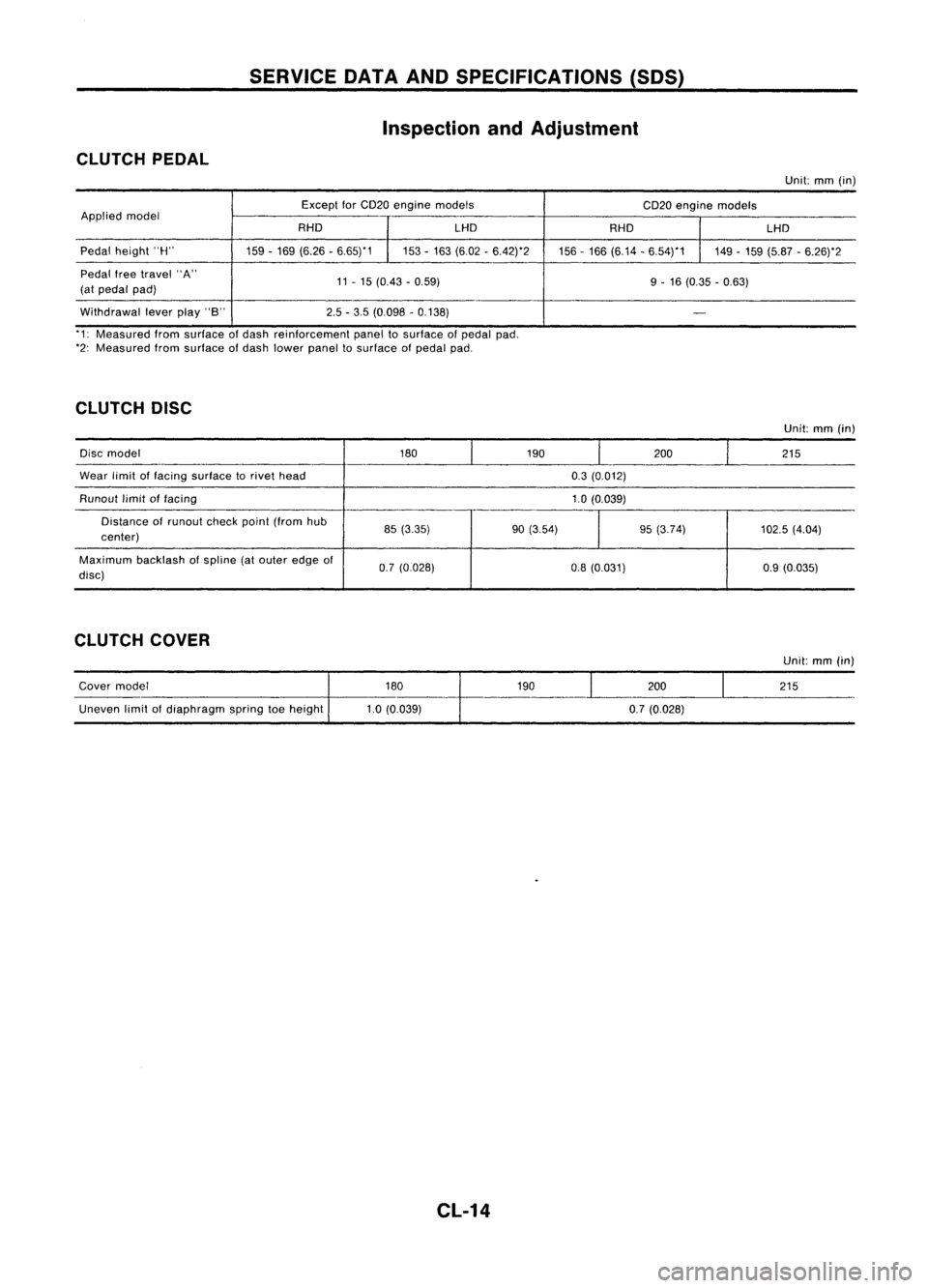

SERVICEDATAANDSPECIFICATIONS (SOS)

Inspection andAdjustment

CLUTCH PEDAL

Unit:mm(in)

Except forCD20 engine models

CD20engine models

Applied model

RHOLHD

RHO LHD

Pedal height "H"

159-169 (6.26 -6.65)'1 153-163 (6.02 -6.42)*2 156-166 (6.14 -6.54)'1

149-159 (5.87 -6.26)'2

Pedal freetravel "A"

11-15 (0.43 -0.59)

9-16 (0.35 -0.63)

(at pedal pad)

Withdrawal leverplay"8" 2.5-3.5 (0.098 -0.138)

-

'1: Measured fromsurface ofdash reinforcement paneltosurface ofpedal pad.

'2: Measured fromsurface ofdash lower paneltosurface ofpedal pad.

CLUTCH DISC

Unit:mm(in)

Disc model

180190

I

200

215

Wear limitoffacing surface torivet head

0.3(0.012)

Runout limitoffacing 1.0(0.039)

Distance ofrunout checkpoint(from hub

85(3.35) 90(3.54)

I

95

(3.74) 102.5(4.04)

center)

Maximum backlashofspline (atouter edgeof

0.7(0.028) 0.8(0.031)

0.9(0.035)

disc)

CLUTCH COVER

Cover model

Uneven limitofdiaphragm springtoeheight 180

1.0 (0.039)

CL-14 190

I

200

0.7 (0.028)

I

Unit:

mm(in)

215

Page 397 of 1701

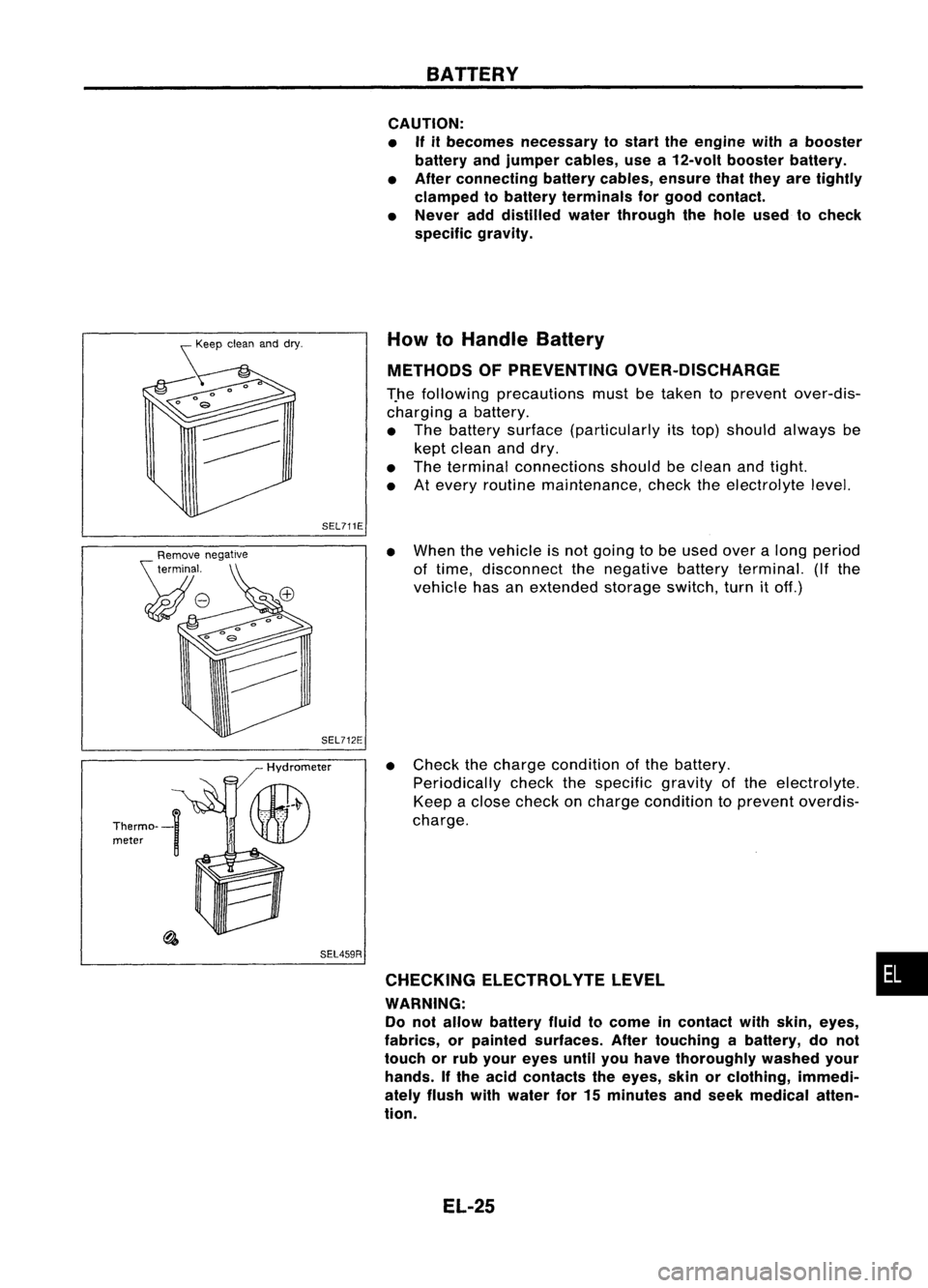

SEL711EBATTERY

CAUTION:

• If

itbecomes necessary tostart theengine withabooster

battery andjumper cables, usea12-volt booster battery.

• After connecting batterycables, ensurethatthey aretightly

clamped tobattery terminals forgood contact.

• Never adddistilled waterthrough thehole used tocheck

specific gravity.

How toHandle Battery

METHODS OFPREVENTING OVER-DISCHARGE

T.he following precautions mustbetaken toprevent over-dis-

charging abattery.

• The battery surface (particularly itstop) should always be

kept clean anddry.

• The terminal connections shouldbeclean andtight.

• Atevery routine maintenance, checktheelectrolyte level.

SEL459R

•

When thevehicle isnot going tobe used overalong period

of time, disconnect thenegative batteryterminal. (Ifthe

vehicle hasanextended storageswitch,turnitoff.)

• Check thecharge condition ofthe battery.

Periodically checkthespecific gravityofthe electrolyte.

Keep aclose check oncharge condition toprevent overdis-

charge.

CHECKING ELECTROLVTELEVEL •

WARNING: Do not allow battery fluidtocome incontact withskin, eyes,

fabrics, orpainted surfaces. Aftertouching abattery, donot

touch orrub your eyes untilyouhave thoroughly washedyour

hands. Ifthe acid contacts theeyes, skinorclothing, immedi-

ately flush withwater for15minutes andseek medical atten-

tion.

EL-25

Page 404 of 1701

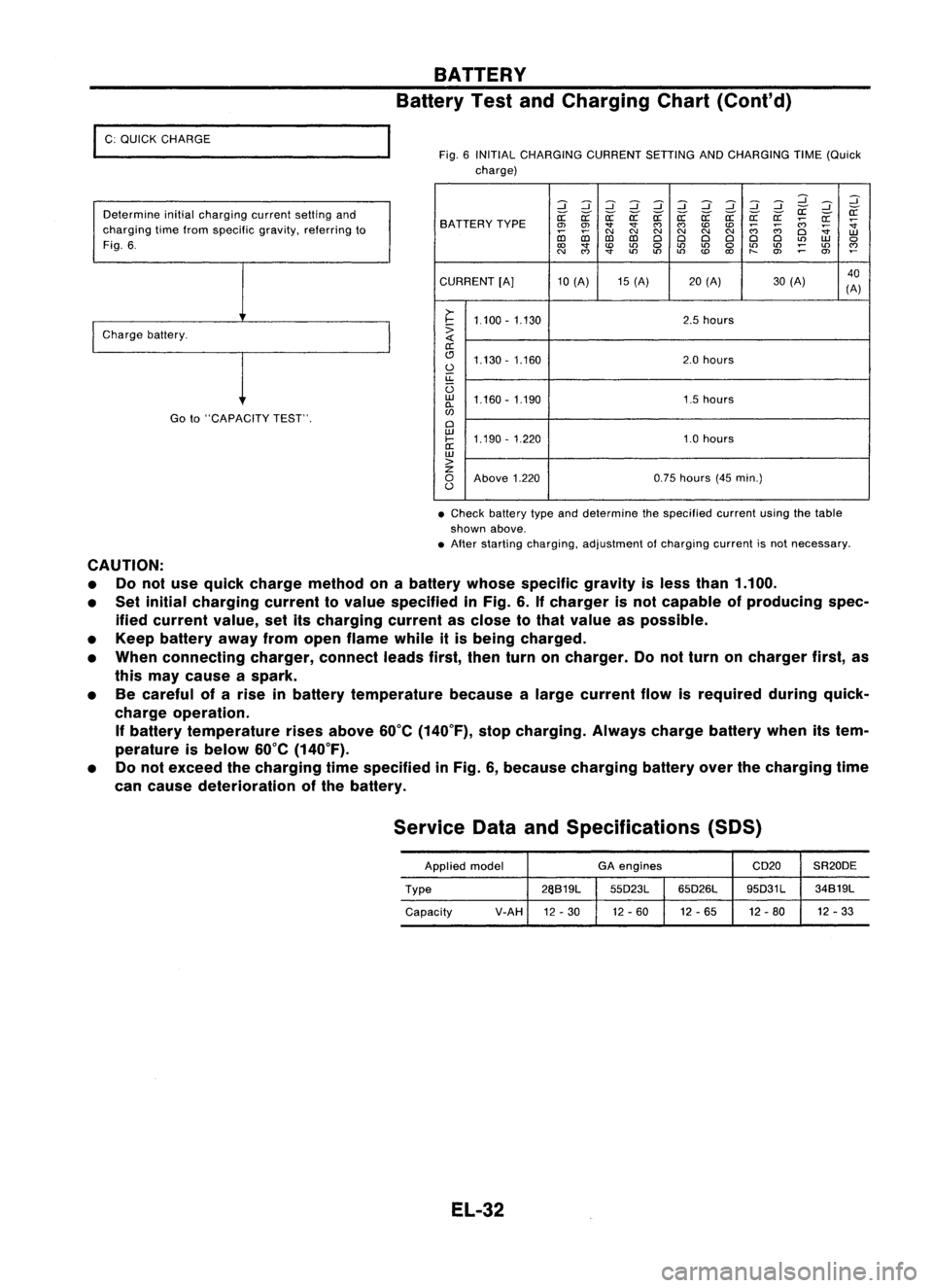

I

C: QUICK CHARGE

Determine initialcharging currentsettingand

charging timefrom specific gravity,referring to

Fig. 6.

I

Charge battery.

Goto"CAPACITY TEST".

BATTERY

Battery TestandCharging Chart(Cont'd)

Fig. 6INITIAL CHARGING CURRENTSETTINGANDCHARGING TIME(Quick

charge)

:::J:::J:::J:::J :::J:::J:::J

d dd

:::J

:::J :::J

~ ~

SA TTERY TYPE

~

~ ~~~~ ~a: a:a:

;;:;

~

~

0>

0>

""

""

C')

C')

CDCD

;;:;

;;:;

~

co co

C\I

N

C\I

N

C\I

N

Cl

W

D:l D:l

ClCl ClCl ClCl

L()

W

0

to

""

CD

L()

0

L()

L()

0

L()

L()

;:

L()

~

N

C')

""

L()

L()L()

CD

to

t-

O>

0>

CURRENT [A]10(A) 15(A) 20(A) 30(A) 40

(A)

>-

I-

1.100 -1.130 2.5

hours

:>

a:

(!J 1.130 -1.160 2.0

hours

0

u::

U

w

1.160 -1.190 1.5hours

0-

w

Cl

w

1.190 -1.220 1.0hours

I-

a:

w

>

z

0

Above 1.220 0.75

hours (45min.)

0

• Check battery typeanddetermine thespecified currentusingthetable

shown above.

• After starting charging, adjustment ofcharging currentisnot necessary.

CAUTION: • Donot use quick charge method onabattery whosespecific gravityisless than 1.100.

• Set initial charging currenttovalue specified inFig. 6.Ifcharger isnot capable ofproducing spec-

ified current value,setitscharging currentasclose tothat value aspossible.

• Keep battery awayfromopen flame whileitis being charged.

• When connecting charger,connectleadsfirst,thenturnoncharger. Donot turn oncharger first,as

this may cause aspark.

• Becareful ofarise inbattery temperature becausealarge current flowisrequired duringquick-

charge operation.

If

battery temperature risesabove 60°C(140°F), stopcharging. Alwayschargebatterywhenitstem-

perature isbelow 60°C(140°F).

• Donot exceed thecharging timespecified inFig. 6,because charging batteryoverthecharging time

can cause deterioration ofthe battery.

Service DataandSpecifications (SOS)

Applied model GA

engines CD20SR20DE

Type 26S19L

55D23L65D26L 95D31L

34S19L

Capacity V-AH

12-30 12

-60 12-65 12-80 12

-33

EL-32

Page 407 of 1701

STARTINGSYSTEM

Trouble Diagnoses

If any abnormality isfound, immediately disconnectbatterynegative terminal.

Starter doesnotstop.

Engine doesnotstart. Replace

magnetic switch.

Does engine turnbycranking? Doesengine turnnormally? Check

ignition/fuel system.

No No

(Turns slowly.)

Check battery asfollows:

OK

Repairstarter motor.

• Charging condition

• Terminal connections

• Terminal corrosion

NG

@

Does starter motorturn? Yes

Doesgearshaft turn? Checkpinionclutch.

No No

Check reduction gear,armature

and gear shaft.

Check fuseandfusible link. Replace.

OK

Check battery asfollows:

@

• Charging condition

• Terminal connections

NG

• Terminal corrosion •

Charge battery.

• Repair connections andcorro-

OK

sian

ofbattery terminals.

Check starting systemwiring.

Repair.

OK

Does magnetic switchoperation No

Replace magnetic switch

sound occur?

Yes

Check condition ofpinion and

OK

Doesstarter turnunder noload Yes

Replace magnetic switch.

ring gear mesh.

byconnecting wiresasfollows?

NG

•

• Adjust pinionmovement.

Repairstarter motor.

• Check pinionmoving mecha-

nism .

• Check ringgear.

SELOO9Z

EL-35

Page 426 of 1701

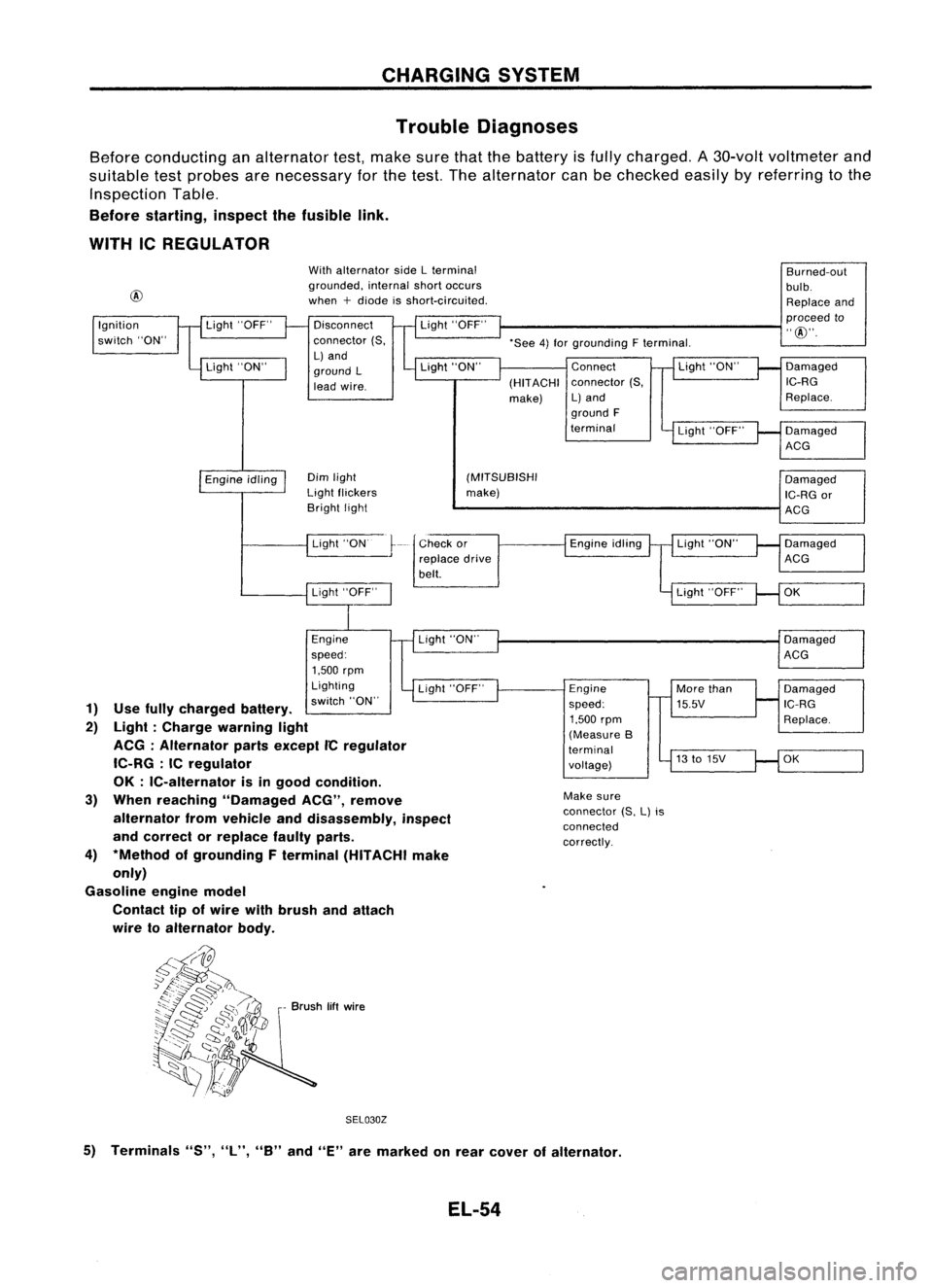

CHARGINGSYSTEM

Trouble Diagnoses

Before conducting analternator test,make surethatthebattery isfully charged. A3D-volt voltmeter and

suitable testprobes arenecessary forthe test. Thealternator canbechecked easilybyreferring tothe

Inspection Table.

Before starting, inspectthefusible link.

WITH IeREGULATOR

Burned-out

bulb.

Replace and

proceed to

"@".

Light "ON"

Light "OFF"

Connect

connector (S,

L) and

ground F

terminal

Engine

speed: 1,500 rpm

(Measure B

terminal

voltage)

Make sure

connector (S,L)is

connected

correctly.

(HITACHI

make)

'See

4)for grounding Fterminal.

(MITSUBISHI

make)

Check or

replace drive

belt.

Light "ON"

Light "OFF"

Disconnect

connector (S,

L) and

ground L

lead wire.

Engine

speed:

1,500 rpm

Lighting

switch "ON"

With

alternator sideLterminal

grounded. internalshortoccurs

when

+

diode isshort-circuited.

Light "ON

Dim

light

Light flickers

Bright light

Light

"ON"

Light

"OFF"

Ignition

switch "ON"

@

1) Use fully charged battery.

2) light: Charge warning light

ACG :Alternator partsexcept I'Cregulator

IC-RG :IC regulator

OK :IC-alternator isingood condition.

3) When reaching "Damaged ACG",remove

alternator fromvehicle anddisassembly, inspect

and correct orreplace faultyparts.

4) *Method ofgrounding Fterminal (HITACHI make

only)

Gasoline enginemodel

Contact tipofwire withbrush andattach

wire toalternator body.

~~~

;;z..'~~.~

~~~/j

S$.~~'

s<(r~, -

Brush liftwire

;;.. ~ Q<:::z"d,l'T7.

~ .. ~ ~-)o,IJ!"-f/

- -~~ C);

0~~/

'~-/i ~-,~

-~j~n

- <::::; -~ \•

'" 1A/-'

SEL030Z

5) Terminals

"S","l","B"

and

"E"

aremarked onrear cover ofalternator.

EL-54

Page 506 of 1701

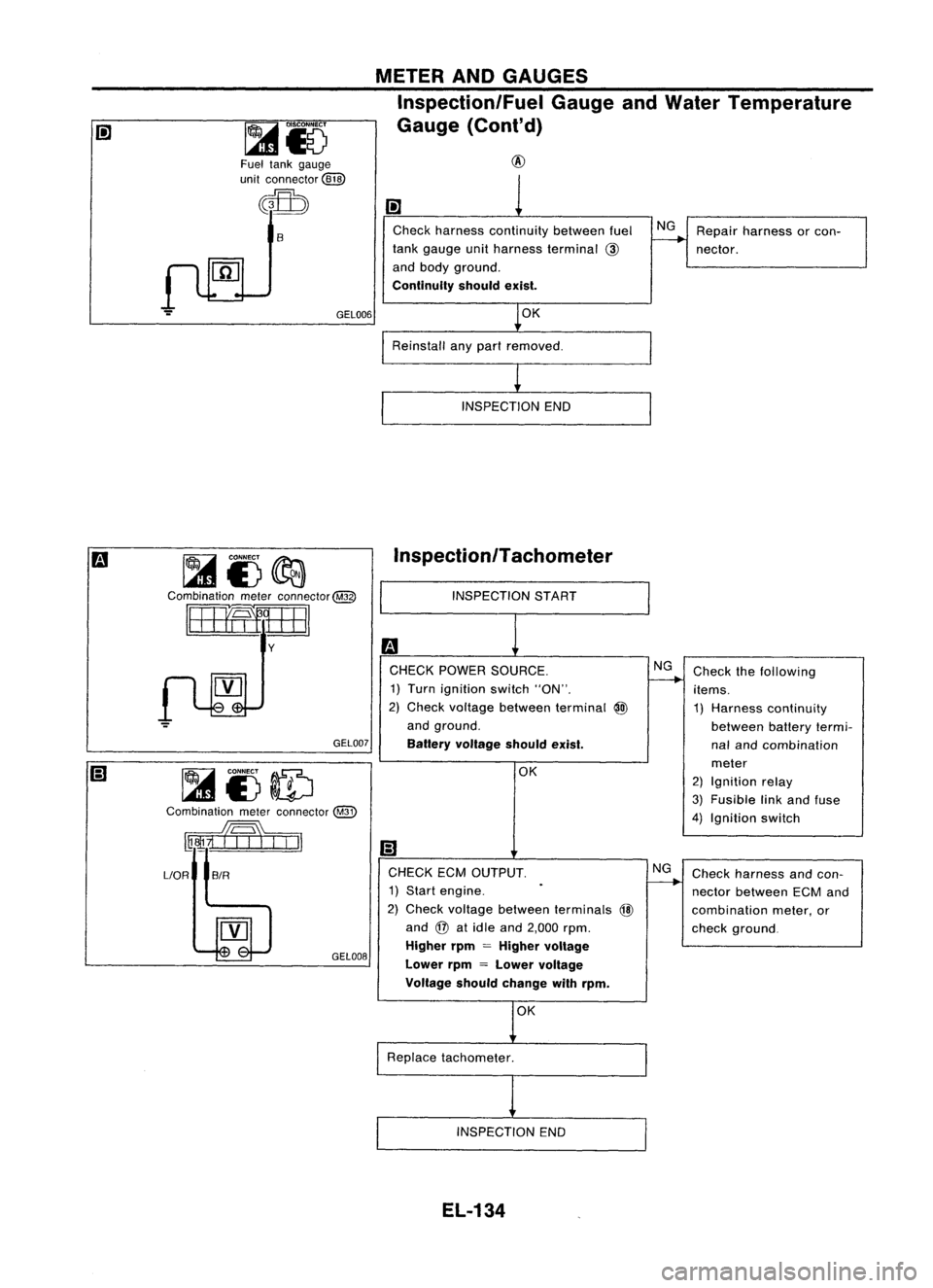

METERANDGAUGES

Inspection/Fuel GaugeandWater Temperature

Gauge (Cont'd)

Fuel tank gauge

unit connector

@W

~

S

GEL006

~i)~

Combination meterconnector@

8mIIEJ

y

GEL007

~i3ID

Combination meterconnector

@

w1i7h:n

Check

harness continuity betweenfuel

tank gauge unitharness terminal

@

and body ground.

Continuity shouldexist.

OK

Reinstall anypart removed.

INSPECTION END

Inspection/Tachometer

INSPECTION START

m

CHECK POWER SOURCE.

1) Turn ignition switch"ON".

2) Check voltage between terminal

@

and ground.

Battery voltage shouldexist.

OK NG

NG

Repair

harness orcon-

nector.

Check thefollowing

items.

1) Harness continuity

between batterytermi-

nal and combination

meter

2) Ignition relay

3) Fusible linkand fuse

4) Ignition switch

LlOR

SIR

GEL008

CHECK

ECMOUTPUT. NG

1) Start engine.

2) Check voltage between terminals

@

and

@

atidle and 2,000 rpm.

Higher rpm

=

Higher voltage

Lower rpm

=

Lower voltage

Voltage shouldchange withrpm.

Replace tachometer.

INSPECTION END

EL-134

Check

harness andcon-

nector between ECMand

combination meter,or

check ground.

Page 523 of 1701

Ohmmeter- + WARNING

LAMPSANDBUZZER

Oil Pressure SwitchCheck

Oil pressure

Continuity

kPa (bar, kg/cm

2,

psi)

More than10-20

NO

Engine

start

(0.10-0.20, 0.1-0.2, 1.4-2.8)

Less than10-20

YES

Engine

stop

(0.10-0.20, 0.1-0.2, 1.4-2.8)

SEL748K

Test lamp 3.4WON

\ ,I

"

/

Ballery

Test lamp 3.4W OFF

~0

CD

Ballery

Gasoline MEL623D

SEL901F

Check

thecontinuity betweentheterminals ofoil pressure

switch andbody ground.

Fuel Warning LampSensor Check

• Itwill take ashort timeforthe bulb tolight.

Diode Check

• Check continuity usinganohmmeter.

• Diode isfunctioning properlyiftest results areasshown in

the figure atleft.

NOTE:

Specification mayvary depending onthe type oftester. Before

performing thisinspection, besure torefer tothe instruction

manual forthe tester tobe used.

• Diodes forwarning lampsarebuilt intothecombination

meter printed circuit.

Refer to"Combination Meter"(EL-127).

Warning BuzzerUnit

• Seat beltwarning lampiscontrolled bythe warning buzzer

unit.

Refer to"Warning Buzzer"(EL-152).

EL-151

•

Page 623 of 1701

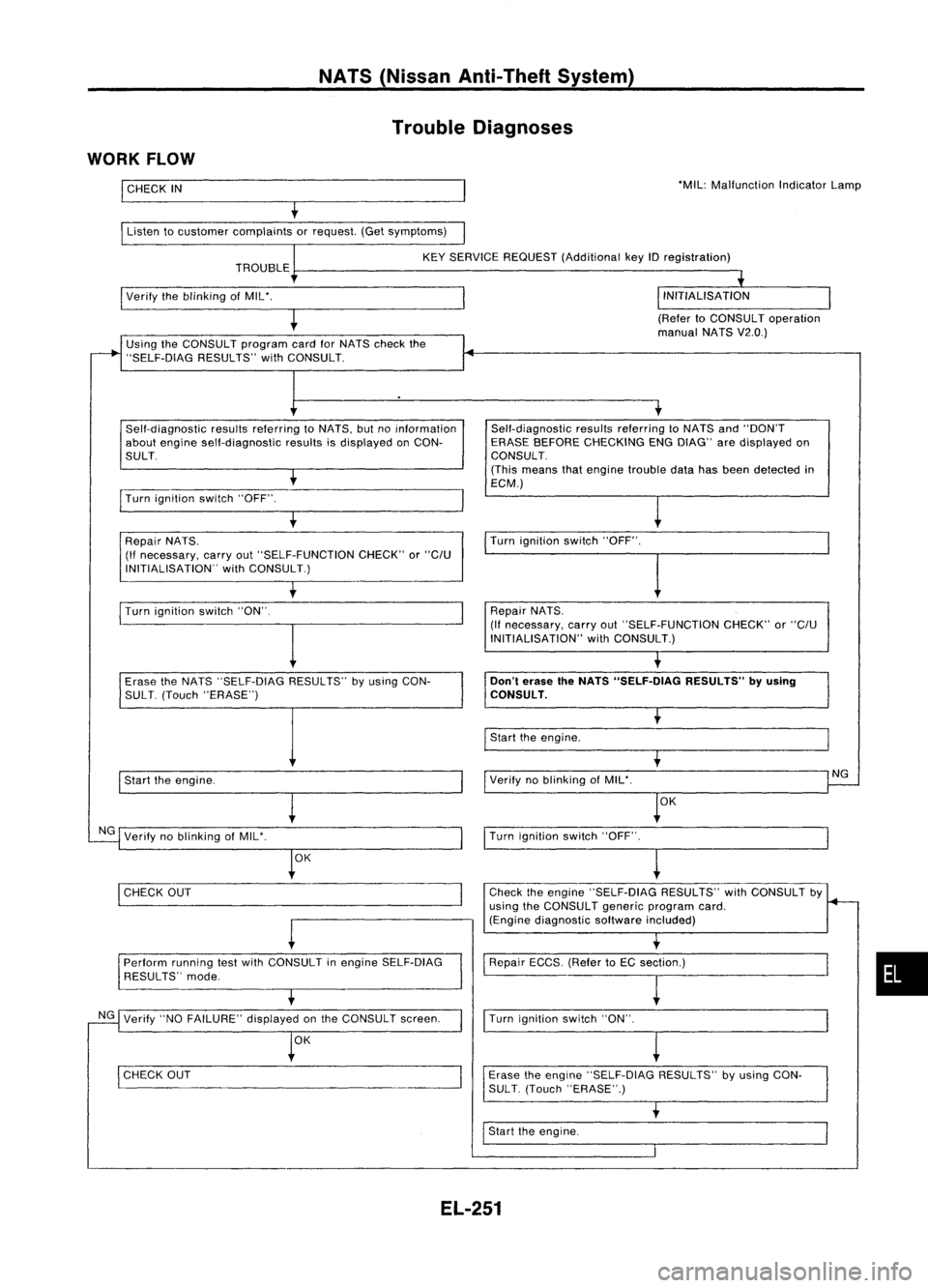

NATS(Nissan Anti-Theft System)

Trouble Diagnoses

WORK FLOW

I

CHECK

IN

Listen tocustomer complaints orrequest. (Getsymptoms) 'MIL:

Malfunction IndicatorLamp

KEY SERVICE REQUEST (Additional keyIDregistration)

TROUBLE

I

Verify theblinking ofMIL'.

(RefertoCONSULT operation

manual NATSV2.0.)

Using theCONSULT programcardforNATS check the

"SELF-DiAG RESULTS"withCONSULT.

Self-diagnostic resultsreferring toNATS, butnoinformation

about engine self-diagnostic resultsisdisplayed onCON-

SULT.

I

Turn ignition switch"OFF".

t

Repair NATS.

(If necessary, carryout"SELF-FUNCTION CHECK"or

"C/U

INITIALISATION" withCONSULT.) Self-diagnostic

resultsreferring toNATS and"DON'T

ERASE BEFORE CHECKING ENGDIAG" aredisplayed on

CONSULT.

(This means thatengine trouble datahasbeen detected in

ECM.)

Turn ignition switch"OFF".

I

Turn ignition switch"ON".

I

Repair

NATS.

(If necessary, carryout"SELF-FUNCTION CHECK"or

"C/U

INITIALISATION" withCONSULT.)

Erase theNATS "SELF-DIAG RESULTS"byusing CON-

SUL T.(Touch "ERASE")

I

Start theengine.

NG Verify noblinking ofMIL'.

OK

I

CHECK OUT

-

Perform runningtestwith CONSULT inengine SELF-DiAG

RESULTS" mode.

NG Verify "NOFAILURE" displayedonthe CONSULT screen.

OK

I

CHECK OUT

Don't

erase theNATS "SELF.DlAG RESULTS"byusing

CONSULT.

I

Start theengine.

Verify noblinking ofMIL'.

OK

I

Turn ignition switch"OFF".

~

Check theengine "SELF-DiAG RESULTS"withCONSULT by

using theCONSULT genericprogram card.

(Engine diagnostic softwareincluded)

Repair ECCS.(RefertoEC section.)

I

Turn ignition switch"ON".

Erase theengine "SELF-DIAG RESULTS"byusing CON-

SUL T.(Touch "ERASE".)

I

Start theengine.

NG

•

EL-251

Page 626 of 1701

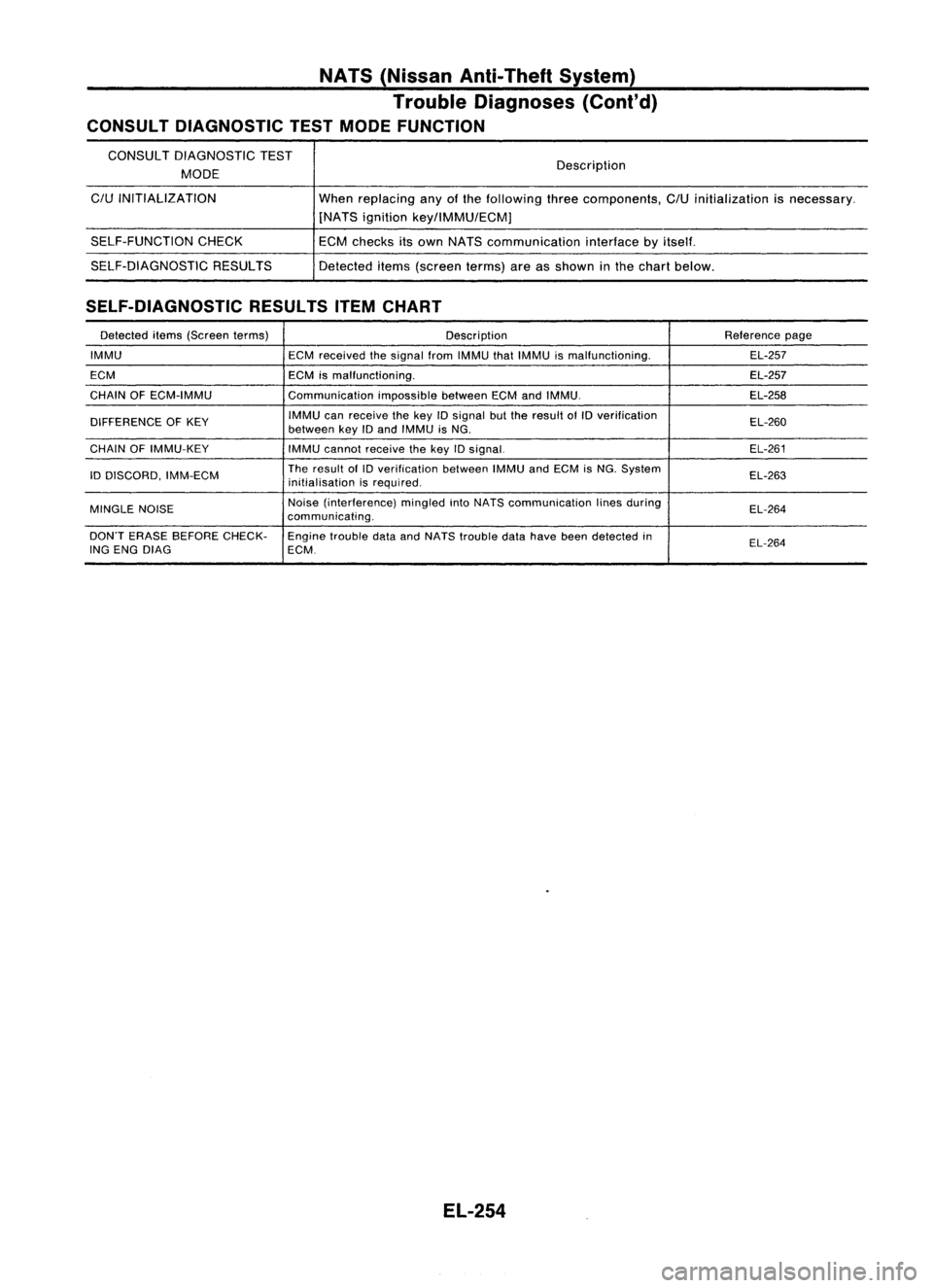

NATS(Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

CONSULT DIAGNOSTIC TESTMODE FUNCTION

CONSULT DIAGNOSTIC TEST

MODE

C/U

INITIALIZATION

SELF-FUNCTION CHECK

SELF-DIAGNOSTIC RESULTS Description

When replacing anyofthe following threecomponents,

C/U

initialization isnecessary.

[NATS ignition key/lMMU/ECMj

ECM checks itsown NATS communication interfacebyitself.

Detected items(screen terms)areasshown inthe chart below.

SELF-DIAGNOSTIC RESULTSITEMCHART

Detected items(Screen terms) Description Reference

page

IMMU ECMreceived thesignal fromIMMU thatIMMU ismalfunctioning. EL-257

ECM ECMismalfunctioning. EL-257

CHAIN OFECM-IMMU CommunicationimpossiblebetweenECMandIMMU. EL-258

DIFFERENCE OFKEY IMMU

canreceive thekey

10

signal butthe result ofID verification

EL-260

between keyIDand IMMU isNG.

CHAIN OFIMMU-KEY

IMMUcannot receive thekey IDsignal. EL-261

ID DISCORD, IMM-ECM The

result of

10

verification betweenIMMUandECM isNG. System

EL-263

initialisation isrequired.

MINGLE NOISE Noise

(interference) mingledintoNATS communication linesduring

EL-264

communicating.

DON'T ERASE BEFORE CHECK-

Enginetrouble dataandNATS trouble datahave beendetected in

EL-264

ING ENG DIAG ECM.

EL-254