esp NISSAN ALMERA N15 1995 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 98 of 1701

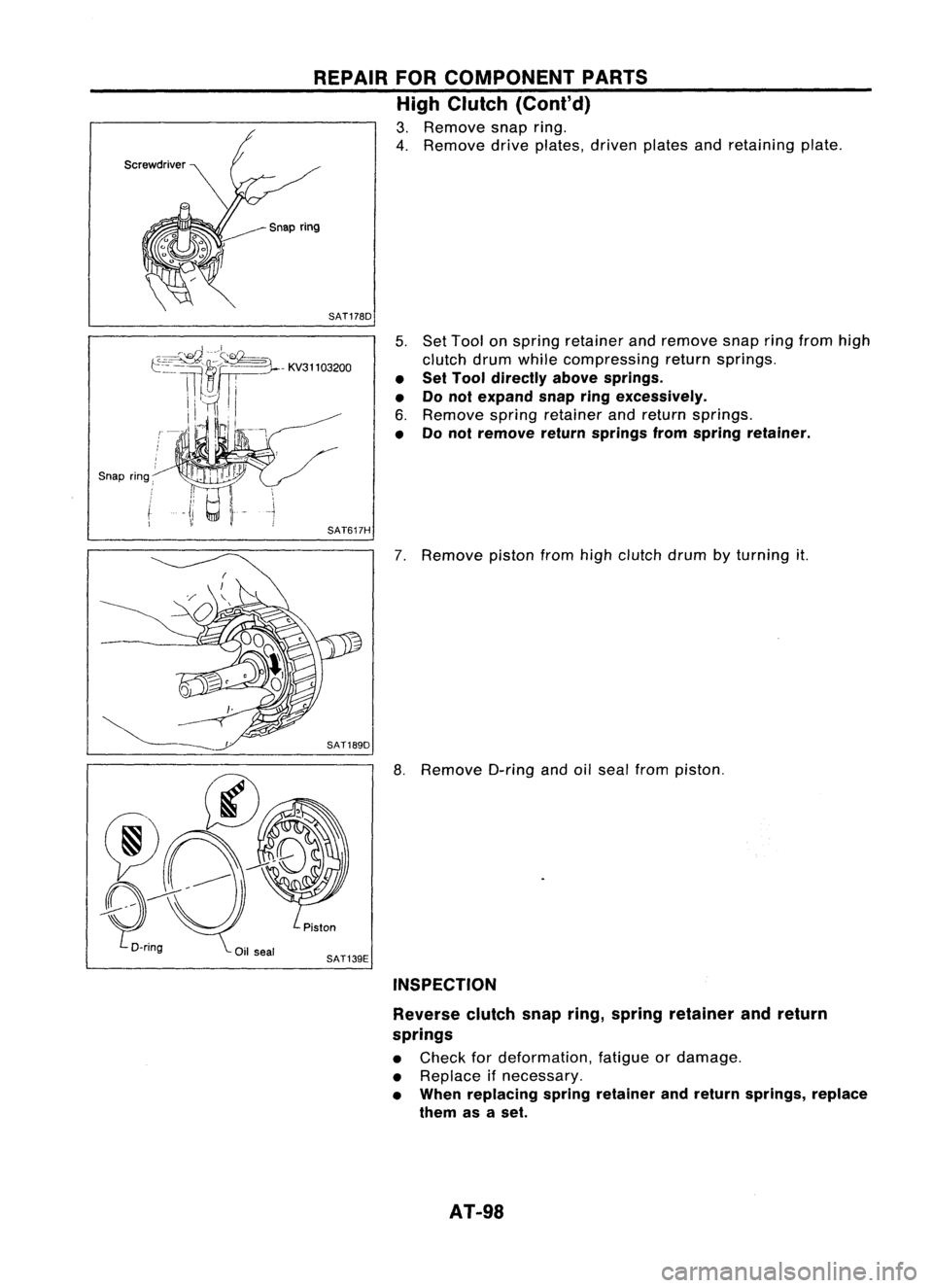

Snapring,

REPAIR

FORCOMPONENT PARTS

High Clutch (Cont'd)

3. Remove snapring.

4. Remove driveplates, drivenplatesandretaining plate.

SAT178D

5.Set Tool onspring retainer andremove snapringfrom high

clutch drumwhile compressing returnsprings.

• Set Tool directly abovesprings.

• Donot expand snap

ring

excessively.

6. Remove springretainer andreturn springs.

• Donot remove returnsprings fromspring retainer.

SAT617H

7.Remove pistonfromhighclutch drumbyturning it.

8. Remove O-ringandoilseal from piston.

SAT139E INSPECTION

Reverse clutchsnapring,spring retainer andreturn

springs

• Check fordeformation, fatigueordamage.

• Replace ifnecessary.

• When replacing springretainer andreturn springs, replace

them asaset.

AT-98

Page 166 of 1701

Vehiclespeed

km/h (MPH)

Gear position

Throttle position

SERVICE

OATAAND SPECIFICATIONS (SOS)

Specifications andAdjustments (Cont'd)

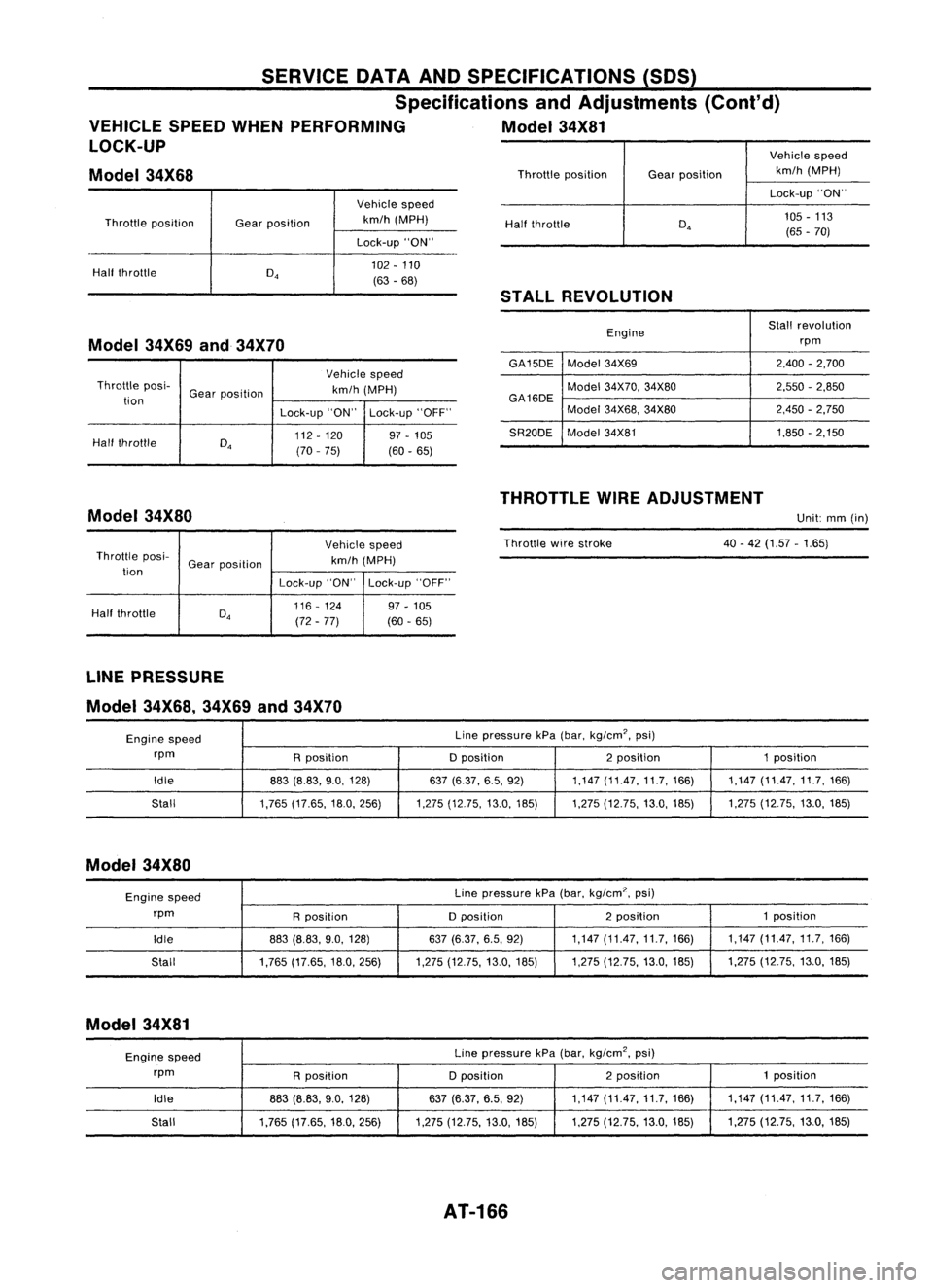

VEHICLE SPEEDWHENPERFORMING Model34X81

LOCK-UP

Model 34X68

Throttle position

Half throttle Gear

position Vehicle

speed

km/h (MPH)

Lock-up "ON"

102 -110

(63 -68)

Half

throttle

STALL REVOLUTION

Lock-up

"ON"

105 -113

(65 -70)

Model 34X69and34X70

Vehiclespeed

Throttle posi-

Gearposition km/h

(MPH)

tion

Lock-up"ON"Lock-up "OFF"

Half throttle

D

4

112

-120 97-105

(70 -75)

(60-65) Engine

Stall

revolution

rpm

GA15DE Model34X69 2,400

-2,700

Model 34X70, 34X80 2,550-2,850

GA16DE Model34X68, 34X80 2,450

-2,750

SR20DE Model

34X81 1,850-2,150

THROTTLE WIREADJUSTMENT

Model 34X80

Unit:mm(in)

Vehicle speed

Throttle posi-

Gearposition km/h

(MPH)

tion Lock-up"ON"Lock-up "OFF"

Half throttle

D

4

116

-124 97-105

(72 -77) (60

-65) Throttle

wirestroke 40-42 (1.57 -1.65)

LINE PRESSURE

Model 34X68, 34X69and34X70

Engine speed Line

pressure kPa(bar, kg/em', psi)

rpm Rposition Dposition 2position 1position

Idle 883(8.83, 9.0,128) 637

(6.37, 6.5,92) 1,147(11.47,11.7,166) 1,147(11.47,11.7,166)

Stall 1,765(17.65, 18.0,256) 1,275(12.75,13.0,185) 1,275(12.75, 13.0,185) 1,275

(12.75,13.0,185)

Model 34X80

Engine speed Line

pressure kPa(bar, kg/em?, psi)

rpm Rposition Dposition 2

position 1position

Idle 883(8.83, 9.0,128) 637(6.37, 6.5,92) 1,147

(11.47,11.7,166) 1,147

(11.47,11.7,166)

Stall 1,765

(17.65, 18.0,256) 1,275(12.75, 13.0,185) 1,275(12.75, 13.0,185) 1,275

(12.75, 13.0,185)

Model 34X81

Engine speed Line

pressure kPa(bar, kg/em', psi)

rpm Rposition Dposition 2position 1

position

Idle 883(8.83, 9.0,128) 637(6.37, 6.5,92) 1,147

(11.47,11.7,166) 1,147

(11.47,11.7,166)

Stall 1,765

(17.65, 18.0,256) 1,275(12.75, 13.0,185) 1,275(12.75, 13.0,185) 1,275

(12.75, 13.0,185)

AT-166

Page 167 of 1701

SERVICEDATAANDSPECIFICATIONS (SOS)

Specifications andAdjustments (Cont'd)

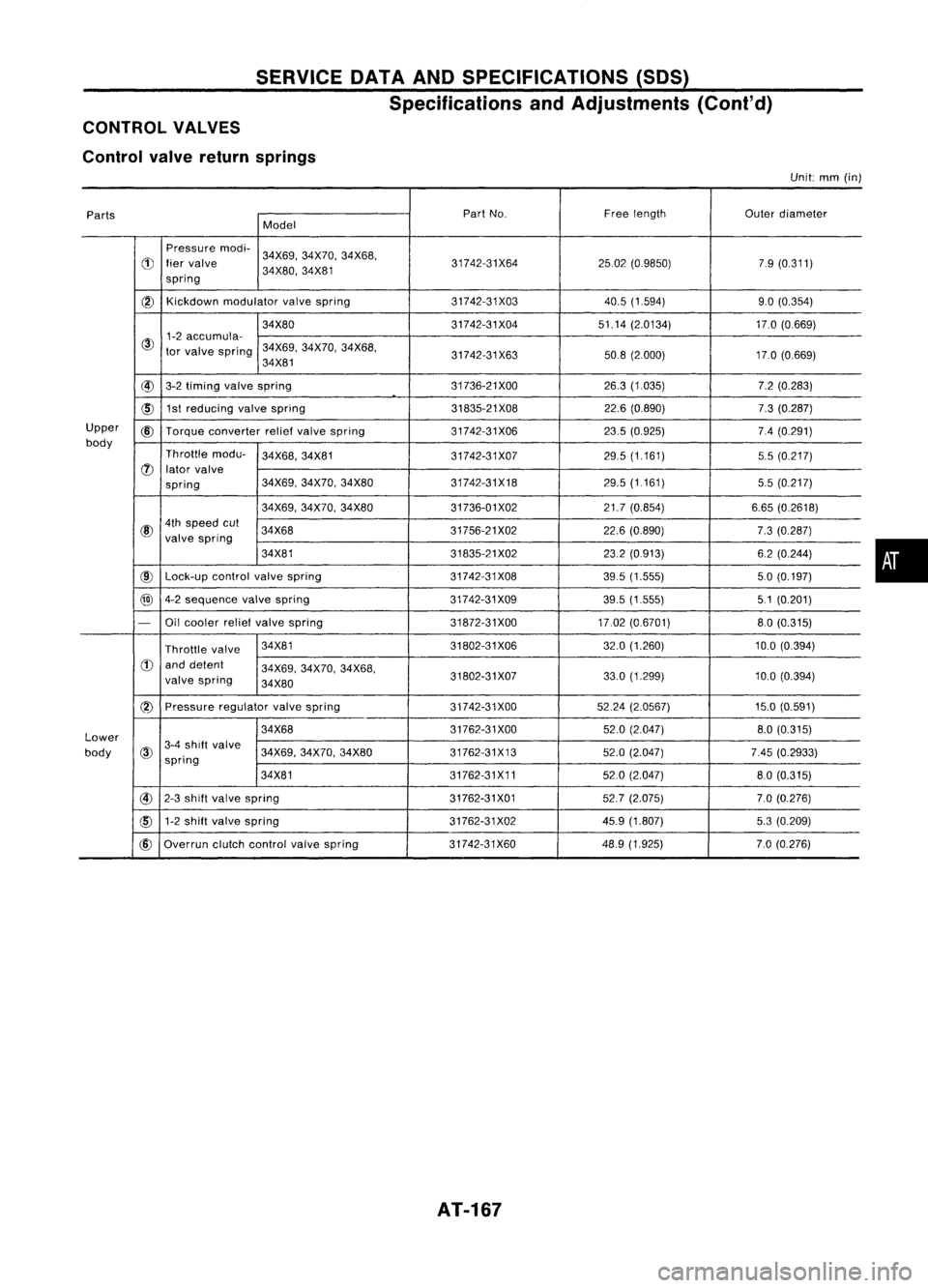

CONTROL VALVES

Control valvereturn springs

Unit:

mm

(in)

Parts Part

No. Freelength

Outerdiameter

Model

Pressure modi-

34X69,34X70, 34X68,

d)

liervalve 31742-31X642502(0.9850) 79(0.311)

spring 34X80,

34X81

@)

Kickdown

modulator valvespring 31742-31X03 40.5(1.594) 9.0(0.354)

34X80 31742-31X0451.14(2.0134) 17.0(0.669)

@

1-2

accumula-

tor valve spring 34X69,

34X70,34X68,

34X81 31742-31X63

50.8(2000) 17.0(0.669)

@

3-2timing valvespring 31736-21

XOO 26.3(1.035) 7.2(0.283)

~ 1st

reducing valvespring 31835-21X0822.6(0.890) 7.3(0.287)

Upper

@

Torque converter reliefvalve spring 31742-31X06 23.5(0.925) 7.4(0.291)

body Throttlemodu-

34X68,34X81

31742-31X07 29.5

(1.161)

5.5(0.217)

(J)

lator valve

spring 34X69,

34X70, 34X80 31742-31X18 29.5(1161)

5.5(0.217)

34X69, 34X70, 34X80 31736-01X02 21.7(0.854) 6.65(0.2618)

@

4th

speed cut

34X68 31756-21X0222.6(0.890)

7.3(0.287)

valve spring

34X81 31835-21X0223.2(0913) 6.2(0.244)

@

Lock-up

controlvalvespring 31742-31X08

39.5(1.555) 50(0.197)

@

4-2sequence valvespring 31742-31X0939.5(1.555) 51(0.201)

-

Oilcooler reliefvalve spring 31872-31XOO17.02(0.6701) 8.0(0.315)

Throttle valve 34X81

31802-31X06 32.0(1.260) 10.0(0.394)

d)

anddetent

34X69,34X70, 34X68,

valve spring

34X80 31802-31X07

33.0

(1.299)

10.0(0.394)

(2)

Pressure regulatorvalvespring 31742-31XOO 5224(2.0567) 15.0(0.591)

Lower 34X68

31762-31XOO

52.0(2.047)

8.0(0.315)

body

@

3-4

shift valve

34X69,34X70,34X80 31762-31X13 52.0(2.047) 7.45(0.2933)

spring

34X81 31762-31X1152.0(2.047) 80(0.315)

@

2-3shift valve spring 31762-31X0152.7(2.075) 7.0(0.276)

cID

1-2

shift valve spring 31762-31X0245.9(1.807) 5.3(0.209)

@

Overrun clutchcontrol valvespring 31742-31X60 48.9

(1.925) 7.0(0.276)

AT-167

•

Page 173 of 1701

Sealringclearance

Unit: mm(in)

SERVICE

DATAANDSPECIFICATIONS (SOS)

Specifications andAdjustments (Cont'd)

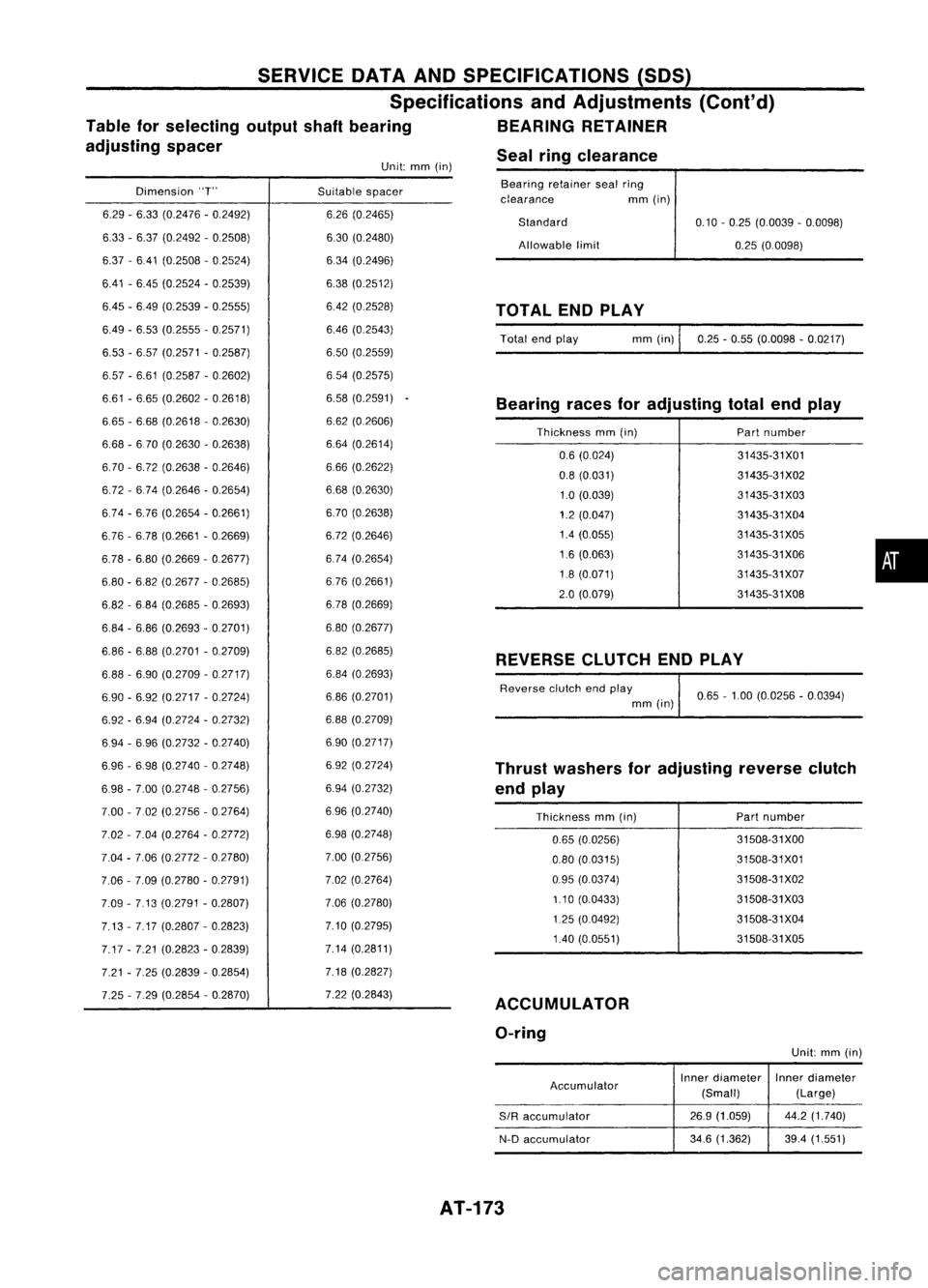

Table forselecting outputshaftbearing BEARINGRETAINER

adjusting spacer

Dimension "T" Suitablespacer Bearing

retainersealring

clearance mm(in)

REVERSE CLUTCHENDPLAY

Bearing

racesforadjusting totalendplay

Thrust washers foradjusting reverseclutch

end play

Thickness mm(in)

•

31435-31X01

31435-31X02

31435-31X03

31435-31X04

31435-31 X05

31435-31X06

31435-31X07

31435-31X08

31508-31XOO

31508-31X01

31508-31 X02

31508-31X03

31508-31X04

31508-31X05

Part

number

Part number

0.65

-1.00 (0.0256 -0.0394)

0.10

-0.25 (0.0039 -0.0098)

0.25 (0.0098)

mm (in)

0.25-0.55 (0.0098 -0.0217)

0.6 (0024)

0.8 (0.031)

1.0 (0.039)

1.2 (0.047)

1.4 (0.055)

1.6 (0.063)

1.8 (0.071)

2.0 (0.079)

0.65 (0.0256)

0.80 (00315)

0.95 (0.0374)

1.10 (0.0433)

1.25 (0.0492)

1.40 (0.0551)

Thickness

mm(in)

Allowable

limit

Standard

Total endplay

Reverse clutchendplay

mm (in)

TOTAL

ENDPLAY

ACCUMULATOR O-ring

6.26

(0.2465)

6.30 (0.2480)

634 (0.2496)

6.38 (0.2512)

6.42 (0.2528)

6.46 (0.2543)

6.50 (0.2559)

654 (0.2575)

6.58 (0.2591)

6.62 (0.2606)

6.64 (0.2614)

6.66 (0.2622)

6.68 (0.2630)

6.70 (0.2638)

6.72 (0.2646)

6.74 (0.2654)

676 (0.2661)

6.78 (0.2669)

6.80 (0.2677)

6.82 (0.2685)

6.84 (0.2693)

6.86 (0.2701)

6.88 (0.2709)

690 (0.2717)

6.92 (0.2724)

6.94 (0.2732)

696 (0.2740)

6.98 (0.2748)

7.00 (0.2756)

7.02 (0.2764)

7.06 (0.2780)

7.10 (0.2795)

7.14 (0.2811)

7.18 (0.2827)

7.22 (0.2843)

6.29

-6.33 (0.2476 -0.2492)

6.33 -6.37 (0.2492 -0.2508)

6.37 -6.41 (0.2508 -0.2524)

6.41 -6.45 (0.2524 -0.2539)

6.45 -6.49 (0.2539 -0.2555)

6.49 -6.53 (0.2555 -0.2571)

6.53 -657 (0.2571 -0.2587)

6.57 -6.61 (0.2587 -0.2602)

6.61 -6.65 (0.2602 -0.2618)

6.65 -668 (0.2618 -0.2630)

6.68 -670 (0.2630 -0.2638)

6.70 -6.72 (0.2638 -0.2646)

6.72 -674 (0.2646 -0.2654)

6.74 -6.76 (0.2654 -0.2661)

6.76 -6.78 (0.2661 -0.2669)

6.78 -6.80 (0.2669 -0.2677)

6.80 -6.82 (0.2677 -0.2685)

6.82 -684 (0.2685 -0.2693)

6.84 -6.86 (0.2693 -0.2701)

6.86 -6.88 (0.2701 -0.2709)

6.88 -6.90 (0.2709 -0.2717)

6.90 -6.92 (0.2717 -0.2724)

6.92 -6.94 (0.2724 -0.2732)

6.94 -696 (0.2732 -0.2740)

6.96 -698 (0.2740 -0.2748)

6.98 -7.00 (0.2748 -0.2756)

7.00 -702 (0.2756 -02764)

7.02 -7.04 (0.2764 -0.2772)

7.04 -7.06 (0.2772 -0.2780)

7.06 -7.09 (0.2780 -0.2791)

7.09 -7.13 (0.2791 -0.2807)

7.13 -7.17 (0.2807 -0.2823)

7.17 -7.21 (0.2823 -0.2839)

7.21 -7.25 (0.2839 -0.2854)

7.25 -7.29 (0.2854 -0.2870)

Unit:mm(in)

Accumulator Inner

diameter Innerdiameter

(Small) (Large)

SIR

accumulator

26.9

(1.059) 44.2(1.740)

N-D accumulator

34.6

(1.362) 39.4(1.551)

AT-173

Page 189 of 1701

__________ PRECAUTIONS _

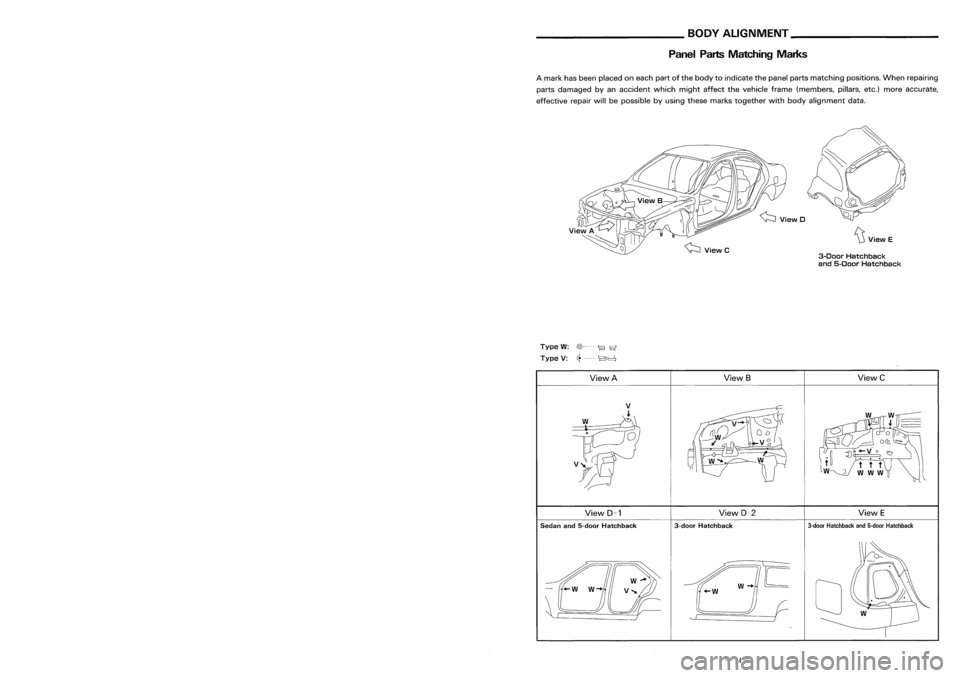

_ BODYALIGNMENT _

Precautions ForHandling HighStrength Steel

PanelPartsMatching Marks

~ViewE

3-Door Hatchback

and 5-Door Hatchback

A

mark hasbeen placed oneach partofthe body toindicate thepanel partsmatching positions.Whenrepairing

parts damaged byan accident whichmightaffectthevehicle frame(members, pillars,etc.)more accurate,

effective repairwillbepossible byusing these marks together wi~hbody alignment data.

Welding

current

Pressure

Unit:mrr

(C•

Thickness

(t)

Minimum pitch(

Q )

0.6 (0.024)

I

10 (0.39)

orover

0.8 (0.031) 12(0.47)

orover

1.0 (0.039) 18(0.71)

orover

1.2 (0.047) 20(0.79)

orover

1.6 (0.063) 27(1.06)

orover

~71) 31

11.221

orover

•

Follow established specifications forthe

appropriate pressurelevel,current leveland

weld time.

• Follow thespecifications forthe proper

welding pitch.

• After welding, weldingstrength mustbe

tested.

J

Type

W:

@----- ~

Et

Type V:~----- ~

View A ViewS

ViewC

View D-1 View

D-2

ViewE

Sedan and5-door Hatchback 3-door

Hatchback

3-door

Hatchback and5-door Hatchback

/w-..IE

+-W

II (-

'- r )

o

-31- -14-

Page 191 of 1701

__________ PRECAUTIONS ___________

BODYALIGNMENT _

Precautions ForHandling HighStregth Steel Engine

Compartment

__ MEASURMENT POINTS__

Unit:mm

Front side

SBT088

Traction direction: ...

Not

recommended

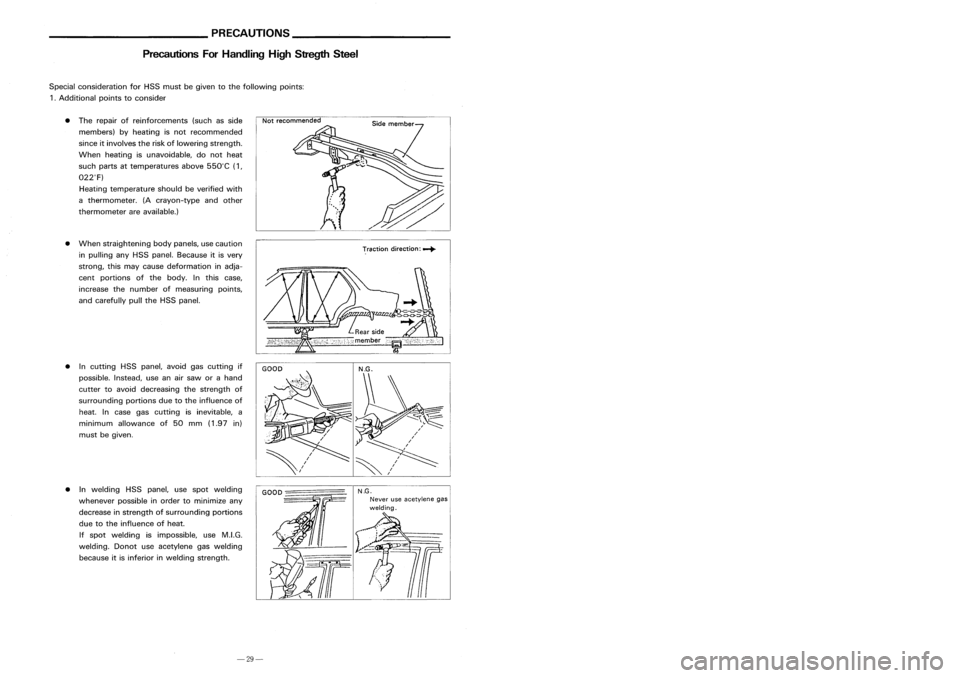

• The repair ofreinforcements (suchasside

members) byheating isnot recommended

since itinvolves theriskoflowering strength.

When heating isunavoidable, donot heat

such parts attemperatures above550°C (1,

022°F)

Heating temperature shouldbeverified with

a thermometer. (Acrayon-type andother

thermometer areavailable.)

• When straightening bodypanels, usecaution

in pulling anyHSS panel. Because itis very

strong, thismay cause deformation inadja-

cent portions ofthe body. Inthis case,

increase thenumber ofmeasuring points,

and carefully pulltheHSS panel.

Special

consideration forHSS must begiven tothe following points:

1 .Additional pointstoconsider

• Incutting HSSpanel, avoidgascutting if

possible. Instead,useanairsaw orahand

cutter toavoid decreasing thestrength of

surrounding portionsduetothe influence of

heat. Incase gascutting isinevitable, a

minimum allowance of50 mm (1.97 in)

must begiven.

SBT090

Radiator

coresupport lower

•

(b)

11

dia.

SBT094

• Inwelding HSSpanel, usespot welding

whenever possibleinorder tominimize any

decrease instrength ofsurrounding portions

due tothe influence ofheat.

If spot welding isimpossible, useM.LG.

welding. Donotuseacetylene gaswelding

because itis inferior inwelding strength.

GOOD

-================

N.G.

Never useacetylene .gas

welding.

Radiator

coresupport uppercenter

SBT091

-29-

-16-

Page 204 of 1701

__________ PRECAUTIONS ___________

BODYALIGNMENT _

Precautions ForHandling HighStregth Steel Engine

Compartment

__ MEASURMENT POINTS__

Unit:mm

Front side

SBT088

Traction direction: ...

Not

recommended

• The repair ofreinforcements (suchasside

members) byheating isnot recommended

since itinvolves theriskoflowering strength.

When heating isunavoidable, donot heat

such parts attemperatures above550°C (1,

022°F)

Heating temperature shouldbeverified with

a thermometer. (Acrayon-type andother

thermometer areavailable.)

• When straightening bodypanels, usecaution

in pulling anyHSS panel. Because itis very

strong, thismay cause deformation inadja-

cent portions ofthe body. Inthis case,

increase thenumber ofmeasuring points,

and carefully pulltheHSS panel.

Special

consideration forHSS must begiven tothe following points:

1 .Additional pointstoconsider

• Incutting HSSpanel, avoidgascutting if

possible. Instead,useanairsaw orahand

cutter toavoid decreasing thestrength of

surrounding portionsduetothe influence of

heat. Incase gascutting isinevitable, a

minimum allowance of50 mm (1.97 in)

must begiven.

SBT090

Radiator

coresupport lower

•

(b)

11

dia.

SBT094

• Inwelding HSSpanel, usespot welding

whenever possibleinorder tominimize any

decrease instrength ofsurrounding portions

due tothe influence ofheat.

If spot welding isimpossible, useM.LG.

welding. Donotuseacetylene gaswelding

because itis inferior inwelding strength.

GOOD

-================

N.G.

Never useacetylene .gas

welding.

Radiator

coresupport uppercenter

SBT091

-29-

-16-

Page 206 of 1701

__________ PRECAUTIONS _

_ BODYALIGNMENT _

Precautions ForHandling HighStrength Steel

PanelPartsMatching Marks

~ViewE

3-Door Hatchback

and 5-Door Hatchback

A

mark hasbeen placed oneach partofthe body toindicate thepanel partsmatching positions.Whenrepairing

parts damaged byan accident whichmightaffectthevehicle frame(members, pillars,etc.)more accurate,

effective repairwillbepossible byusing these marks together wi~hbody alignment data.

Welding

current

Pressure

Unit:mrr

(C•

Thickness

(t)

Minimum pitch(

Q )

0.6 (0.024)

I

10 (0.39)

orover

0.8 (0.031) 12(0.47)

orover

1.0 (0.039) 18(0.71)

orover

1.2 (0.047) 20(0.79)

orover

1.6 (0.063) 27(1.06)

orover

~71) 31

11.221

orover

•

Follow established specifications forthe

appropriate pressurelevel,current leveland

weld time.

• Follow thespecifications forthe proper

welding pitch.

• After welding, weldingstrength mustbe

tested.

J

Type

W:

@----- ~

Et

Type V:~----- ~

View A ViewS

ViewC

View D-1 View

D-2

ViewE

Sedan and5-door Hatchback 3-door

Hatchback

3-door

Hatchback and5-door Hatchback

/w-..IE

+-W

II (-

'- r )

o

-31- -14-

Page 223 of 1701

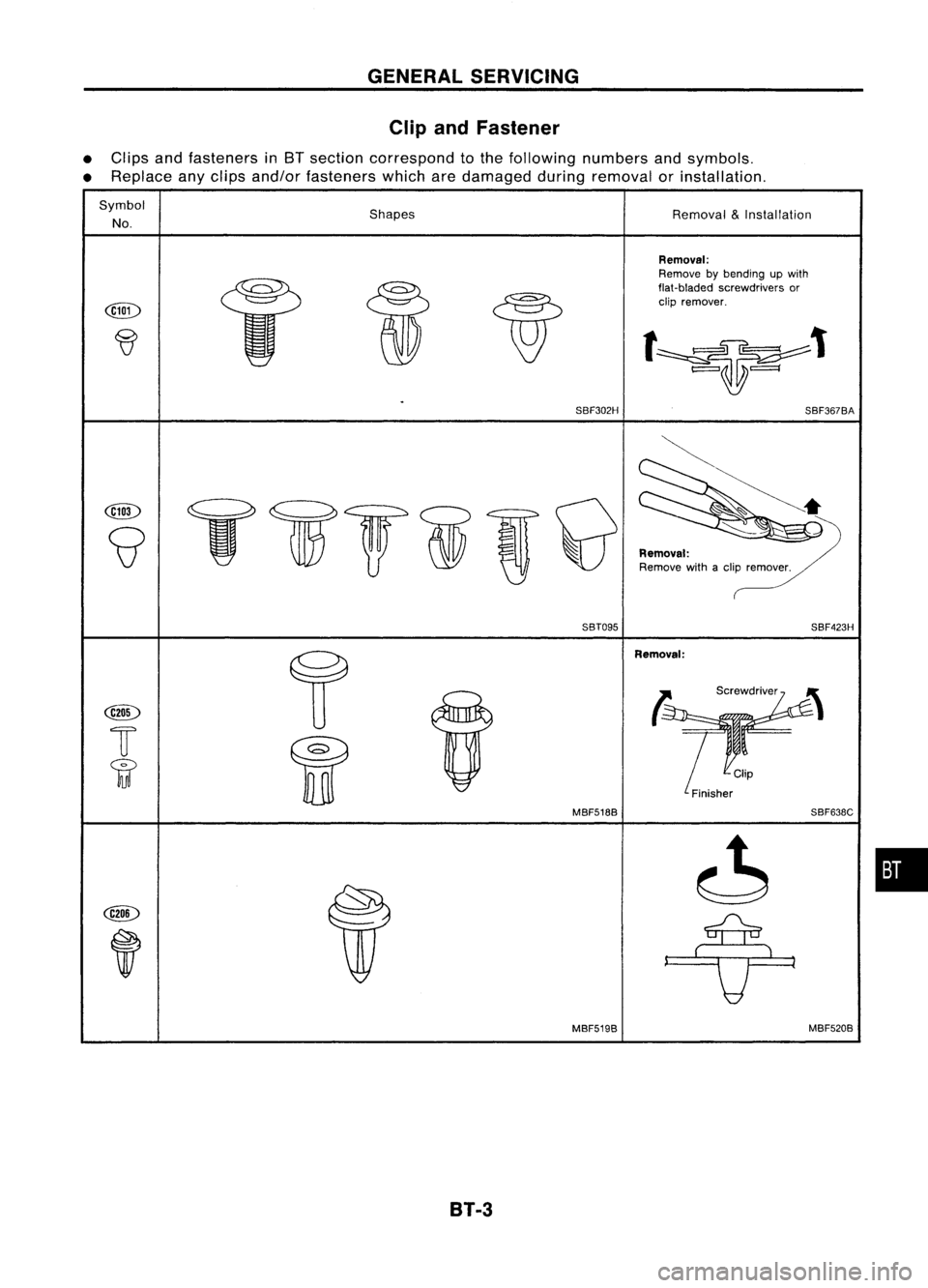

GENERALSERVICING

Clip andFastener

Removal

&

Installation

Shapes

•

Clips andfasteners inBT section correspond tothe following numbersandsymbols.

• Replace anyclips and/or fasteners whicharedamaged duringremoval orinstallation.

Symbol

No.

Removal:

Remove bybending upwith

flat -bladed screwdrivers or

clip remover.

SBF302H SBF367BA

@D

T1f1f~,Q

9

Removal:

Remove withaclip remover.

SBT095 SBF423H

f

Removal:

@ID

~s""ru'

u

w

l1!

y

Finisher

MBF518B SBF638C

•

@D

,

MBF519BMBF520B

81-3

Page 254 of 1701

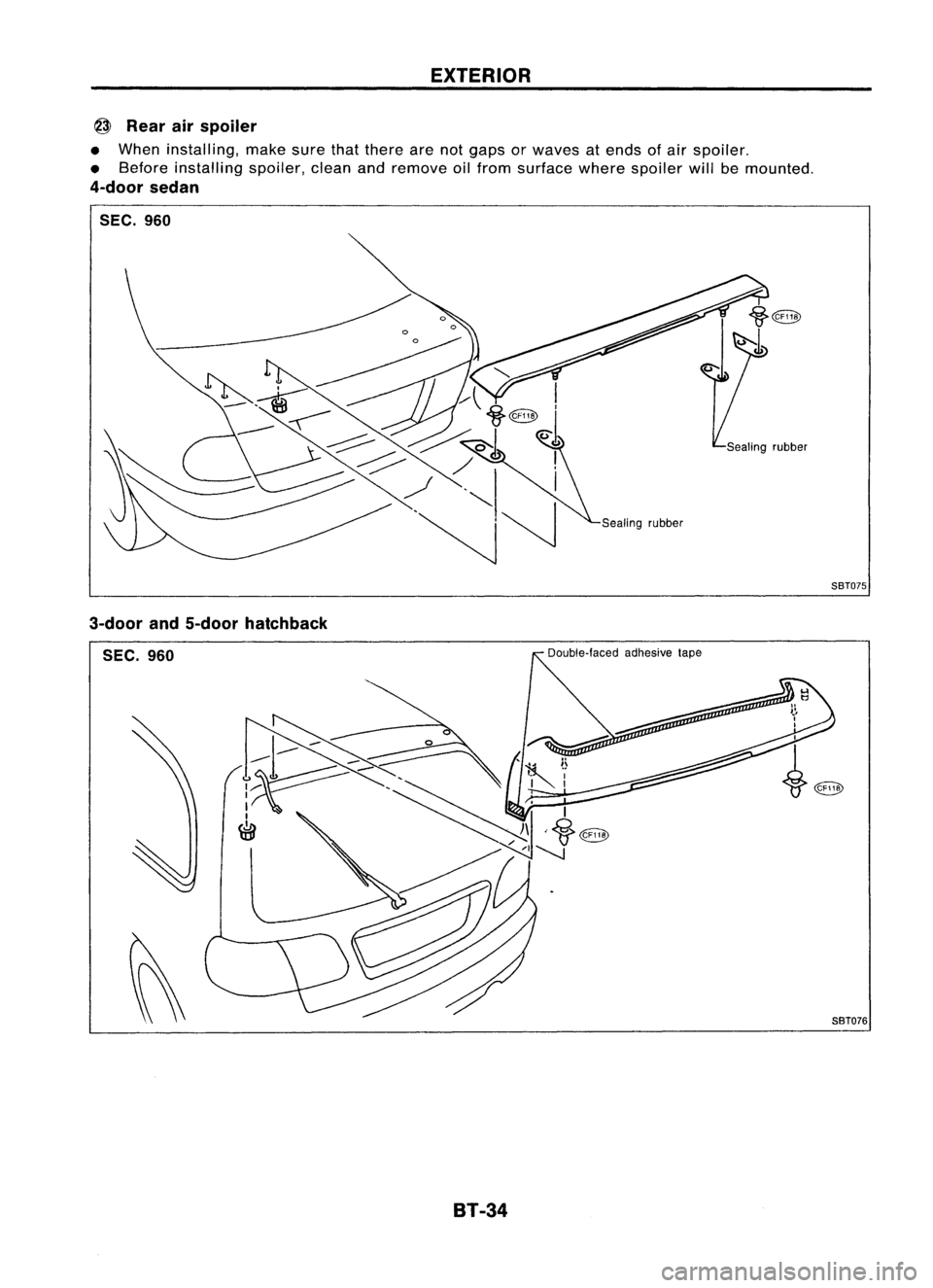

EXTERIOR

@

Rear airspoiler

• When installing, makesurethatthere arenotgaps orwaves atends ofair spoiler.

• Before installing spoiler,cleanandremove oilfrom surface wherespoiler willbemounted.

4-door sedan

SEC. 960

Sealingrubber

SBT075

3-door and5-door hatchback

SEC. 960

8T-34

Double-laced

adhesivelape

SBT076