panel NISSAN ALMERA N15 1995 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 183 of 1701

REPLACEMENTOPERATIONS

Center Pillar

Sedan

5-door hatchback

________

CORROSIONPROTECTION _

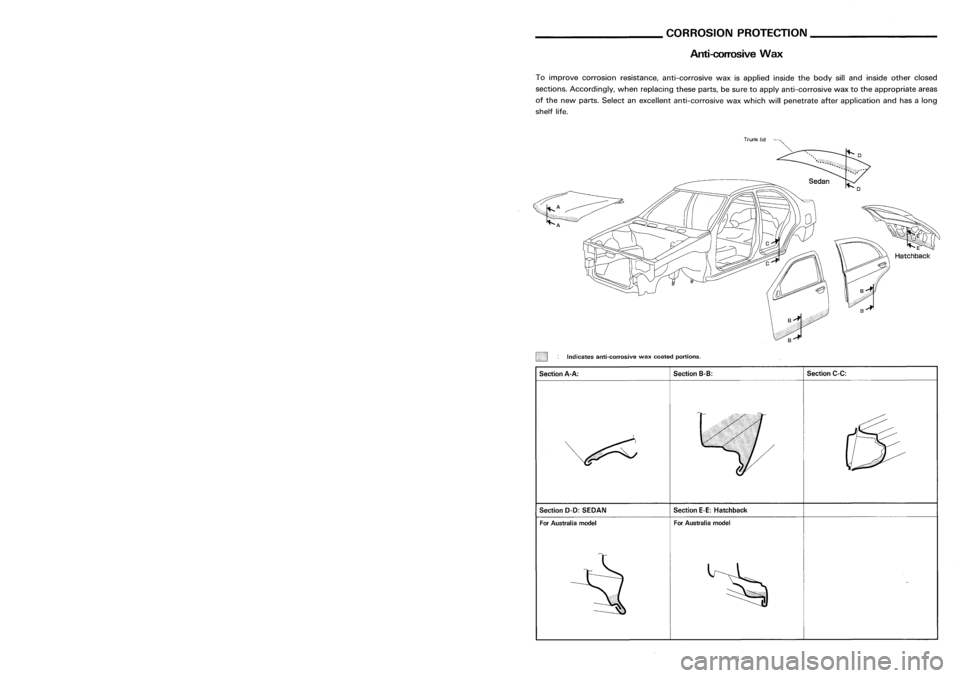

Anti-corrosive Wax

E

Hatchback

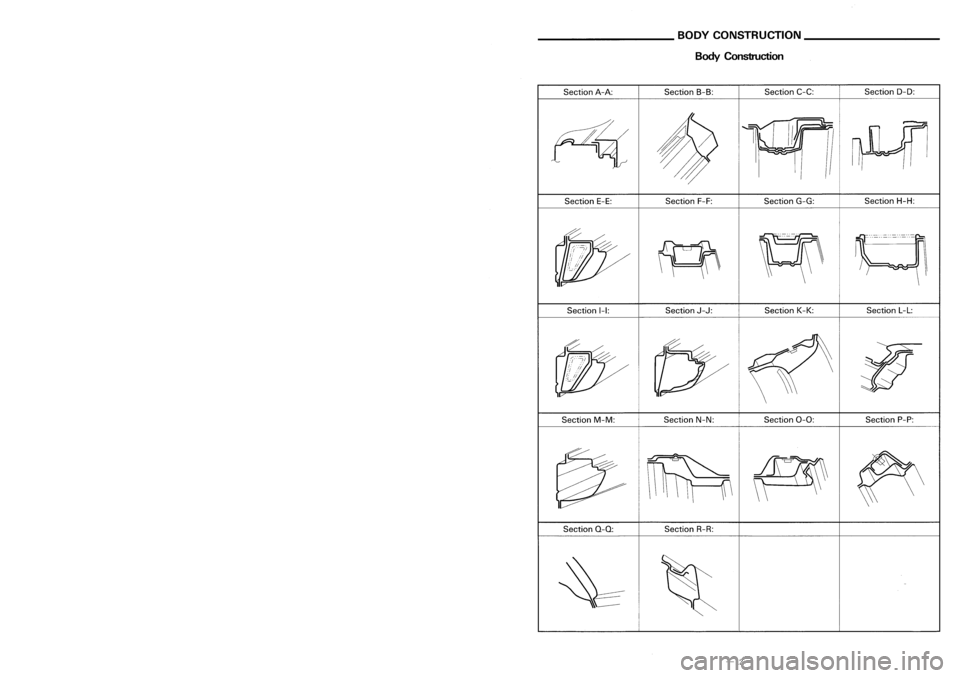

Section C-C:

For Australia model

Section

E-E:Hatchback

Section

8-8:

:

Indicates anti-corrosive waxcoated portions.

A

For Australia model

Section

0-0:SEDAN

Section

A-A:

To

improve corrosion resistance, anti-corrosive waxisapplied insidethebody silland inside otherclosed

sections. Accordingly, whenreplacing theseparts,besure toapply anti-corrosive waxtothe appropriate areas

of the new parts. Select anexcellent anti-corrosive waxwhich willpenetrate afterapplication andhasalong

shelf life.

FR

FR

117

111A

o

117

114

111A

Upper center pillarhinge brace

112

Lower center pillar

hinge brace

112

111

113

113

116 114

.cm.

( Overl apcutt ing)

Seat beltancher

reinforcement

Unit:mm

FR

Service

Joint

2-spot welds 3-spotwelds M.

I.

G plug weld MIG seam weld/

(For 3panels plugweld method )P:

F

weld

• rr= •

A

==-= •

B~

..LLLL

G1J --- ~

-37-

-8-

Page 184 of 1701

Undercoating REPLACEMENT

OPERATIONS

Front Pillar

(Work afterhoodledge reinforcement hasbeen removed.)

116

1lIl..

(Dri pchannel)

an

(Outer)

112

c;;;;?

FR

112

112

116

Unit:mm

<:=i

FR

1lIl..

( Inner)

112

~

113 :::::-----

Service

Joint

~I!!!!!!!!iiii!!!!!i!II :

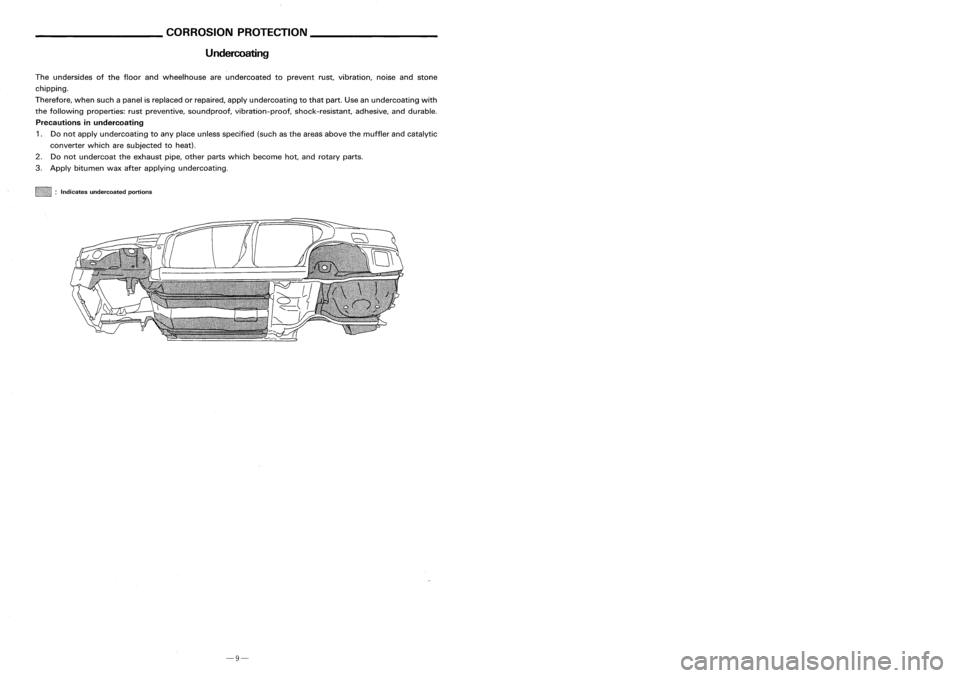

Indicates undercoated portions

The

undersides ofthe floor andwheelhouse areundercoated toprevent rust,vibration, noiseandstone

chipping.

Therefore, whensuchapanel isreplaced orrepaired, applyundercoating tothat part. Useanundercoating with

the following properties: rustpreventive, soundproof, vibration-proof, shock-resistant, adhesive,anddurable.

Precautions inundercoating

1. Donot apply undercoating toany place unless specified (suchasthe areas above themuffler andcatalytic

converter whicharesubjected toheat).

2. Donot undercoat theexhaust pipe,other partswhich become hot,androtary parts.

3. Apply bitumen waxafter applying undercoating.

2-spotwelds 3-spotwelds

M.I.G plug wel(d For3panels plugweld method )..~:

G(F:~dm

weld/

• rr= •

A

==-=.

B~

.LLLL

GTJ --- ~

-9-

-36-

Page 185 of 1701

REPLACEMENTOPERATIONS

Front SideMember (PartialReplacement)

(Work afterradiator coresupport hasbeen removed.) ________

CORROSIONPROTECTION _

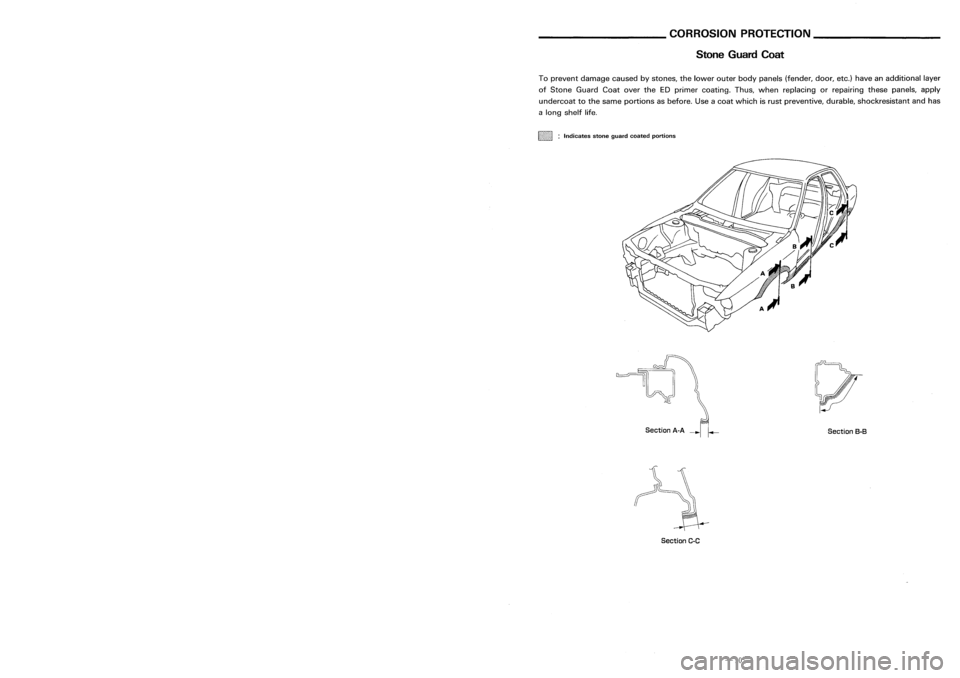

Stone Guard Coat

SectionB-B

Section

A-A

--r':":'

To

prevent damage causedbystones, thelower outerbodypanels (fender, door,etc.)have anadditional layer

of Stone Guard CoatovertheEDprimer coating. Thus,when replacing orrepairing thesepanels, apply

undercoat tothe same portions asbefore. Useacoat which isrust preventive, durable,shockresistant andhas

a long shelf life.

~mm1111i :

Indicates stoneguard coated portions

114

Patch

118

111

115

114

hoodledge

panel

117

111

Unit:mm

8

Patch

""

"

"

(Thickness: 1mm)

-\

Service

Joint

(This figure showrightfront sidemember)

2-spot welds 3-spotwelds M.1.

Gplug weld MIG seam weld/

(For 3panels plugweld method )P1ID.~irit

F

weld

• rr=

.A=-= .B~

G1J --- ~

Section

C-C

-35- -10-

Page 186 of 1701

BODYCONSTRUCTION _

------------

BodyConsb"uction. REPLACEMENT

OPERATIONS _

------------

Hoodledge(PartialReplacement)

(Work afterradiator coresupport hasbeen removed.)

114AUnit:mm

Before

installing

hoodledge reinforcement.

117

Service

Joint

(This figure showrightsidehoodledge)

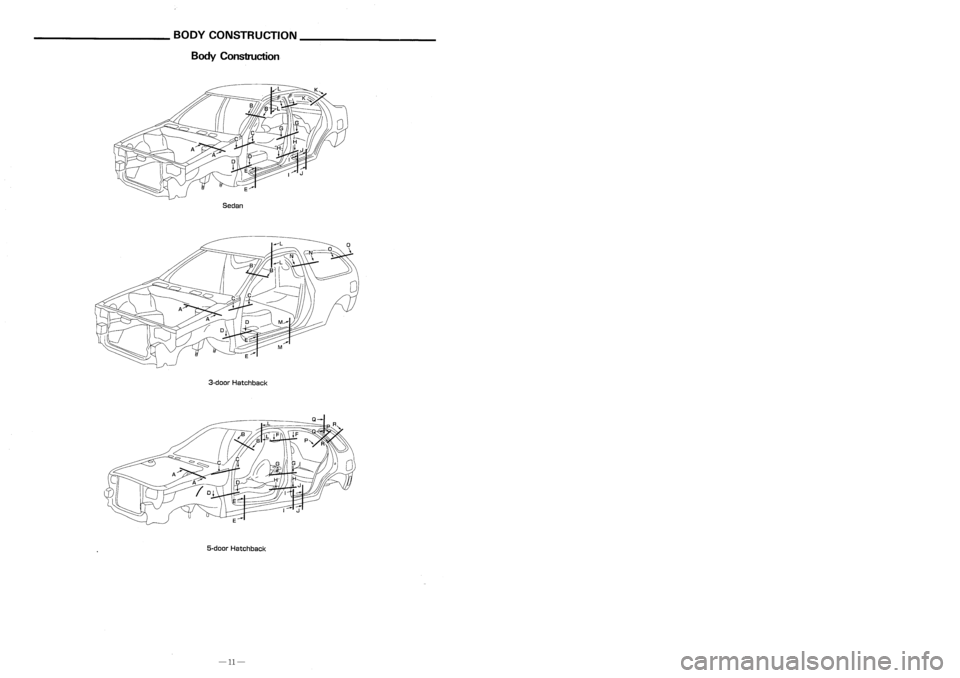

Sedan

3-d oar Hatchback

5-door Hatchback 2-spot

welds 3-spotwelds

M.1.

Gplug weld )

M.I.

Gseam weld/

(For 3panels plugweld method. Pointweld

· r

.A~ .B~

.an.F

-34-

-11-

Page 187 of 1701

REPLACEMENTOPERATIONS _

------------

RadiatorCoreSupport (PartialReplacement) BODY

CONSTRUCTION _

-----------

BodyConstruction

\

Section

L-L:

Section P-P:

Section

D-D:

Section H-H:

Section K-K:

Section

C-C:

Section G-G:

Section 0-0:

Section

J-J:

Section

F-F:

Section

8-8:

. Section N-N:

Section

I-I:

Section

E-E:

Section

A-A:

Section M-M:

_1

FR

(

e

4orll3 *

indicates thatthere isan equivalent wel~ing.portion

with thesame dimensions onthe opposite Side.

o

*

e

3

or 112

FR

Service

Joint

Section

0-0:

Section

R-R:

2-spot welds 3-spotwelds

M.1.Gplug weld )M.I.Gseam weld/

(Point weld

For 3panels plugweld m.ethod

· r ·

A

=='*= •

B

===:=

.an

F

-33- -12-

Page 188 of 1701

Description

_________

BODYALIGNMENT _

Body Center Marks ________

REPLACEMENTOPERATIONS _

SYMBOLS FORCUITING AND

WELDING/BRAZING OPERATIONS

..J

3-spot welds

(3-panel overlapping portions)

2-SDOt

welds

(2-panel overlapping portions)

••••

2-spot

welds

0000

3-spot

welds

Spot

weld

Brazing

Soldering

(ItIlI)

M.LG. seamweld/

Point weld

Saw

cutor

air chisel cut

•

•

•

M.LG. plugweld

-

The

indentification ofthe cutting andthewelding/brazing symbolsusedthroughout thisguide isgiven inthe

following pages

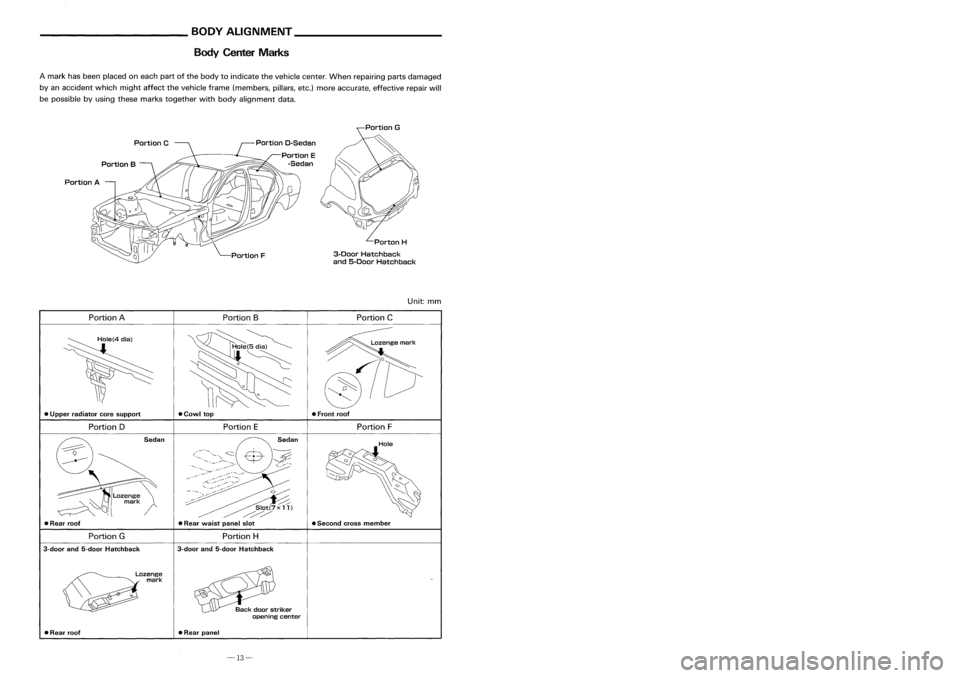

Portion F

Portion

C

Unit:

mm

Porton

H

3-Door Hatchback

and 5-Door Hatchback

• Front roof

• Second crossmember

Portion

D-Sedan

Portion E

-Sedan

Portion F

Portion E

Portion

8

Portion

G

~

Slot(7X 11)

/~/

• Rear waist panelslot

•

Cowl top

Portion

BPortion

C

Hole(4

dial

Portion

A

Portion D

Portion

A

• Rear roof

•

Upper radiator coresupport

A

mark hasbeen placed oneach partofthe body toindicate thevehicle center.Whenrepairing partsdamaged

by an accident whichmightaffectthevehicle frame(members, pillars,etc.)more accurate, effectiverepairwill

be possible byusing these marks together withbody alignment data.

Portion G

3-door and5-door Hatchback

Lozenge

mark

Portion

H

3-door and5-door Hatchback Sealing

• Rear roof •

Rear panel

-13- -32-

Page 189 of 1701

__________ PRECAUTIONS _

_ BODYALIGNMENT _

Precautions ForHandling HighStrength Steel

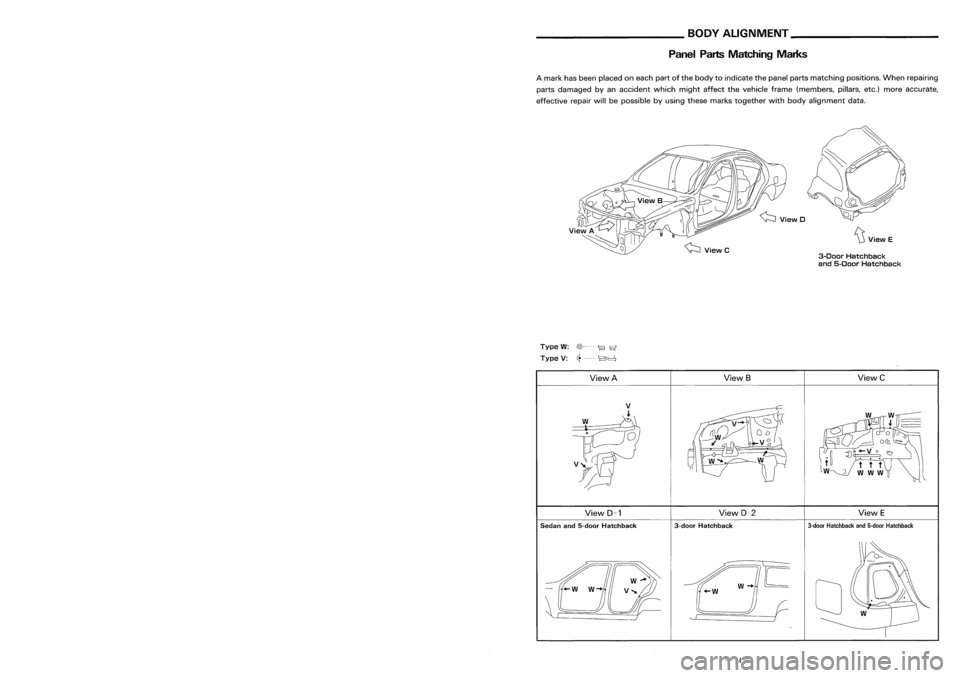

PanelPartsMatching Marks

~ViewE

3-Door Hatchback

and 5-Door Hatchback

A

mark hasbeen placed oneach partofthe body toindicate thepanel partsmatching positions.Whenrepairing

parts damaged byan accident whichmightaffectthevehicle frame(members, pillars,etc.)more accurate,

effective repairwillbepossible byusing these marks together wi~hbody alignment data.

Welding

current

Pressure

Unit:mrr

(C•

Thickness

(t)

Minimum pitch(

Q )

0.6 (0.024)

I

10 (0.39)

orover

0.8 (0.031) 12(0.47)

orover

1.0 (0.039) 18(0.71)

orover

1.2 (0.047) 20(0.79)

orover

1.6 (0.063) 27(1.06)

orover

~71) 31

11.221

orover

•

Follow established specifications forthe

appropriate pressurelevel,current leveland

weld time.

• Follow thespecifications forthe proper

welding pitch.

• After welding, weldingstrength mustbe

tested.

J

Type

W:

@----- ~

Et

Type V:~----- ~

View A ViewS

ViewC

View D-1 View

D-2

ViewE

Sedan and5-door Hatchback 3-door

Hatchback

3-door

Hatchback and5-door Hatchback

/w-..IE

+-W

II (-

'- r )

o

-31- -14-

Page 190 of 1701

__________ BODYALIGNMENT _

_ PRECAUTIONS _

Description PrecautionsForHandling HighStrength Steel

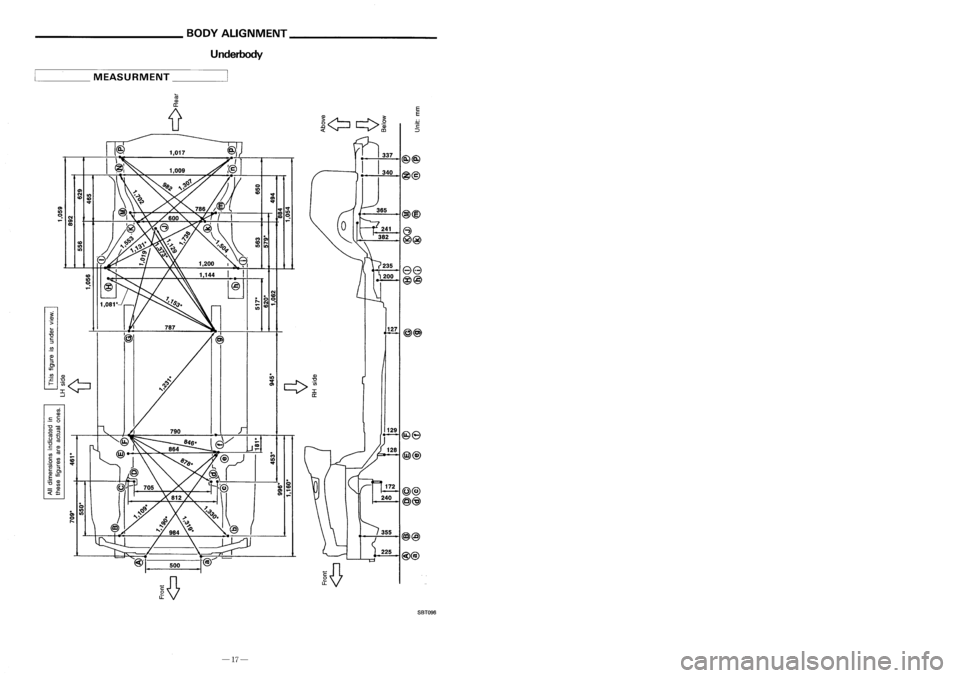

• Alldimensions indicatedinfigures areactual ones.

• When usingatracking gauge,adjustbothpointers toequal length. Thencheck thepointers andgauge

itself tomake surethere isno free play.

• When ameasuring tapeisused, check tobe sure there isno elongation, twistingorbending.

• Measurements shouldbetaken atthe center ofthe mounting holes.

• Anasterisk

(*)

following thevalue atthe measuring pointindicates thatthemeasuring pointonthe other

side issymmetrically thesame value.

• The coordinates ofthe measurement pointsarethe distances measured fromthestandard lineof"X", "V"

and "Z".

EngineCompartment

D=2T+3(mm)

D=2T+O.12 (in)

•

The electrode tipdiameter mustbereformed

properly according tothe panels thickness.

•

The spot ungget onHSS panel isharder than

that ofan ordinary steelpanel.

Therefore, forspot cutting HSSpanel, ahigh

torque drillofalow speed (1,000 to1,200

rpm) maybeused tomaintain itsdurability

and facilitate theoperation.

• HSS panels withatensile strength of785 to981 N/mm

2

(80to100 kg/mm

2,

114to142 klb/sq in),

used asreinforcement inthe door guard barand inthe bumper, istoo high intensile strength touse

for general repairs.Whenthesepanels aredamaged, theouter panels alsosustain consequential

damage; therefore, thesepanels arenever remedied withoutreplacing thedoor assembly orbumper

assembly.

2. Precautions inspot welding

This work should beperformed understandard workconditions. However,workcontrol mustbeexercised

as folloows:

SBF8?4GB

"Z":

Imaginary baseline

[200 mmbelow datum line

("OZ" atdesign plan)]

Front axlecenter

/

y (_)

(0)

Incorrect

Incorrect

Correct

D==Tip+diameter

T

,::=T====p=la::t_e=-=-_t_h=i_C=k=_n=_e_s=s= __,-- ~

• The panel surfaces mustbefitted toeach

other, leaving nogaps.

____

MEASURMENT _

SBT08?

-15- -30-

Page 191 of 1701

__________ PRECAUTIONS ___________

BODYALIGNMENT _

Precautions ForHandling HighStregth Steel Engine

Compartment

__ MEASURMENT POINTS__

Unit:mm

Front side

SBT088

Traction direction: ...

Not

recommended

• The repair ofreinforcements (suchasside

members) byheating isnot recommended

since itinvolves theriskoflowering strength.

When heating isunavoidable, donot heat

such parts attemperatures above550°C (1,

022°F)

Heating temperature shouldbeverified with

a thermometer. (Acrayon-type andother

thermometer areavailable.)

• When straightening bodypanels, usecaution

in pulling anyHSS panel. Because itis very

strong, thismay cause deformation inadja-

cent portions ofthe body. Inthis case,

increase thenumber ofmeasuring points,

and carefully pulltheHSS panel.

Special

consideration forHSS must begiven tothe following points:

1 .Additional pointstoconsider

• Incutting HSSpanel, avoidgascutting if

possible. Instead,useanairsaw orahand

cutter toavoid decreasing thestrength of

surrounding portionsduetothe influence of

heat. Incase gascutting isinevitable, a

minimum allowance of50 mm (1.97 in)

must begiven.

SBT090

Radiator

coresupport lower

•

(b)

11

dia.

SBT094

• Inwelding HSSpanel, usespot welding

whenever possibleinorder tominimize any

decrease instrength ofsurrounding portions

due tothe influence ofheat.

If spot welding isimpossible, useM.LG.

welding. Donotuseacetylene gaswelding

because itis inferior inwelding strength.

GOOD

-================

N.G.

Never useacetylene .gas

welding.

Radiator

coresupport uppercenter

SBT091

-29-

-16-

Page 192 of 1701

__________ BODYALIGNMENT ___________

PRECAUTIONS _

Underbody Precautions

ForHandling HighStrength Steel

• InNissan vehicles, HSSplates of373 N/mm

2

(38kg/mm

2,

54klb/sq in)(NP130) aremost commonly

utilized, andthose withatensile strength of785 to981 N/mm

2

(80to100 kg/mm

2,

114to142 klb/sq

in) (NP150) areused onlyonparts requiring muchmorestrength.

HIGH

STRENGTH STEEL(HSS)USED INNISSAN VEHICLES

High

strength steelhasbeen usedforbody panels inorder toreduce vehicle weight.

Accordingly, precautionsinrepairing automotive bodiesmadeofhigh strength steelaredescribed below:

Tensile strength Nissan designation Major

applicable parts

• Side member

373N/mm

2

•

Hoodledge

(38 kg/mm

2,

54klb/sq in) NP130

•

Pillar

• Hood

.Trunk lidouter

785-981 N/mm

2

•Bumper reinforcement

(80-100 kg/mm

2

NP150

114-142 klb/sqin) •

Door guard beam

E

E

127

@>@)

235

~200

ee

@@

o

It)

CD

N

.. CD

.. 00

~ N~

It)

CD

CD

It)

C!.

~

CD

It)

It)

en

N

It)

CD CD

IIIlI:t'

(ij

Q)

er:

iJ

--------

en

It)

C!.

N

~ en

co

____

MEASURMENT _

..

o

.. It)

0)

It)

o

I'

..

.. 0

CD CD

en~

0) .,

~

129

@8

@@

@)@)

225

SBT096

-17- -28-