panel NISSAN ALMERA N15 1995 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 241 of 1701

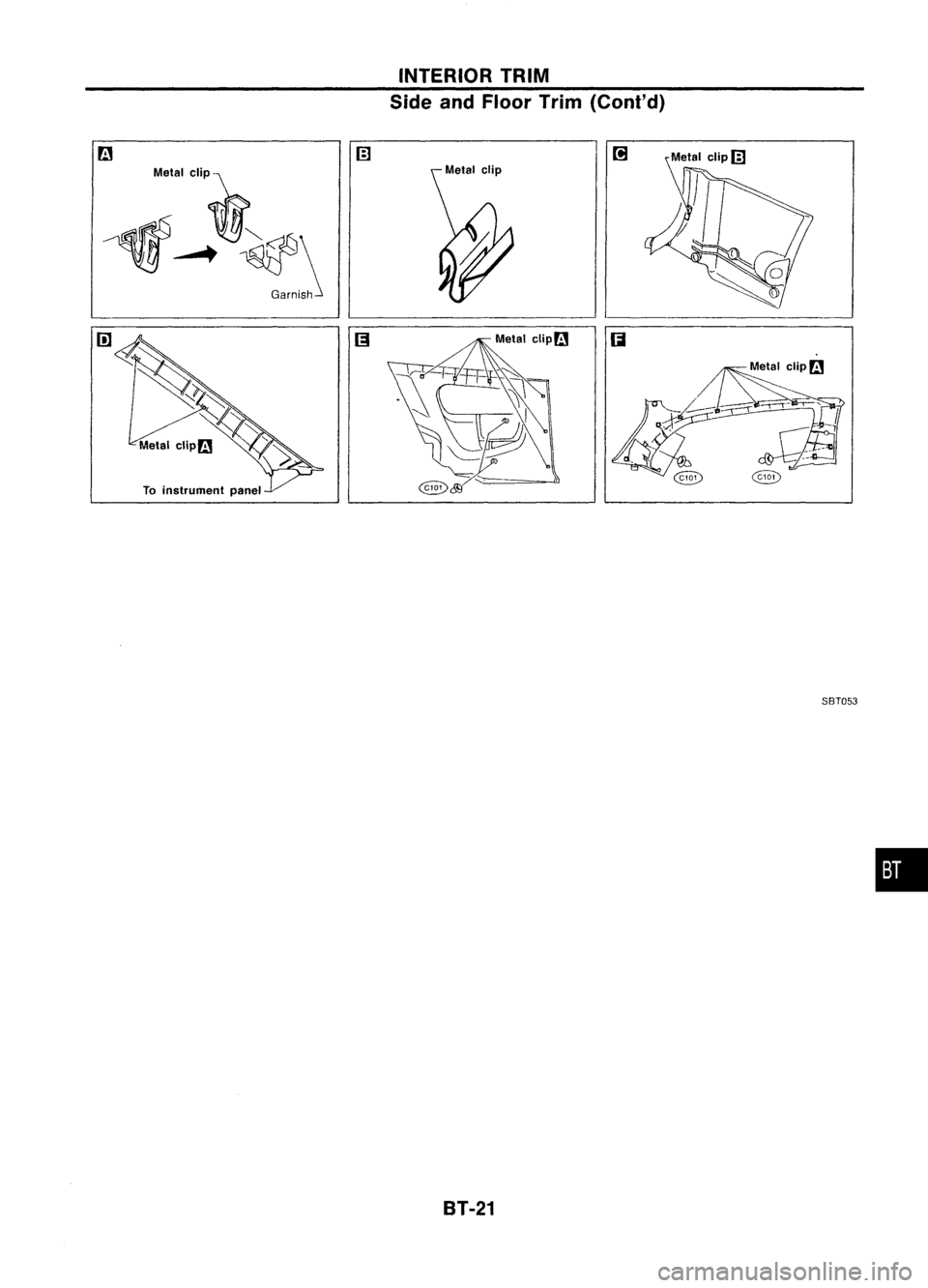

Metalclip

To instrument panel

___________

s~rcN~T~E~R*IO~R~~T~RI~M~~CO':;j;;j),-=====~

d

Floor Trim(Cont d)

Side an

1

SBT053

•

8T-21

Page 249 of 1701

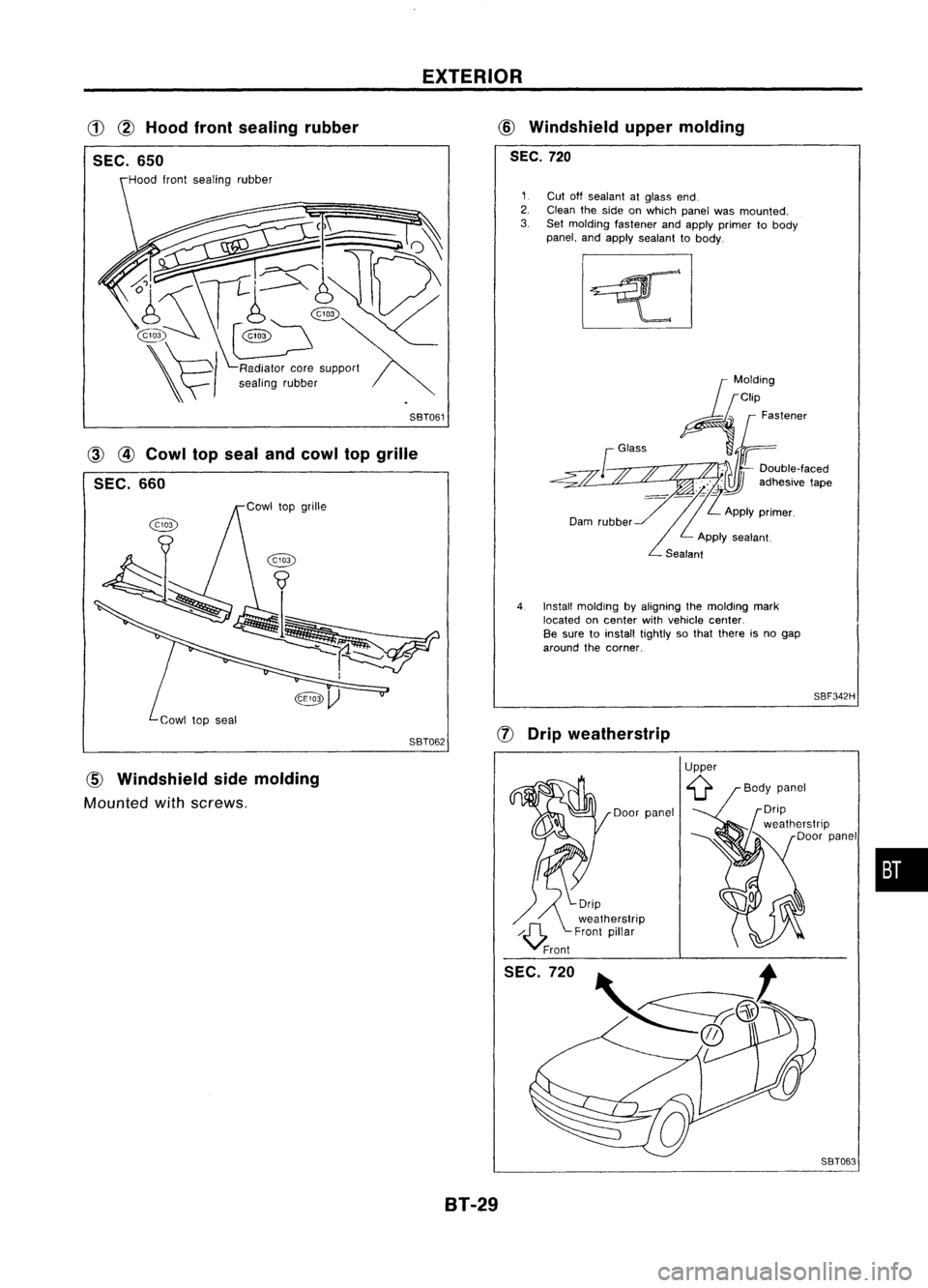

EXTERIOR

CD ~

Hood frontsealing rubber

SEC. 650

CID

Windshield uppermolding

SEC. 720

@lJ

SBF342H

(ID

@

Cowl topseal andcowl topgrille

SEC. 660

1

Cutoffsealant atglass end.

2. Clean theside onwhich panelwasmounted.

3. Setmolding fastener andapply primer tobody

panel, andapply sealant tobody.

4. Install molding byaligning themolding mark

located oncenter withvehicle center.

Be sure toinstall tightly sothat there isno gap

around thecorner.

(f)

Drip weatherstrip

58T061

58T062

Cowl

topseal

Hood

frontsealing rubber

CID

Windshield sidemolding

Mounted with

screws,

SEC.720

Door

panel

SBT063

•

8T-29

Page 250 of 1701

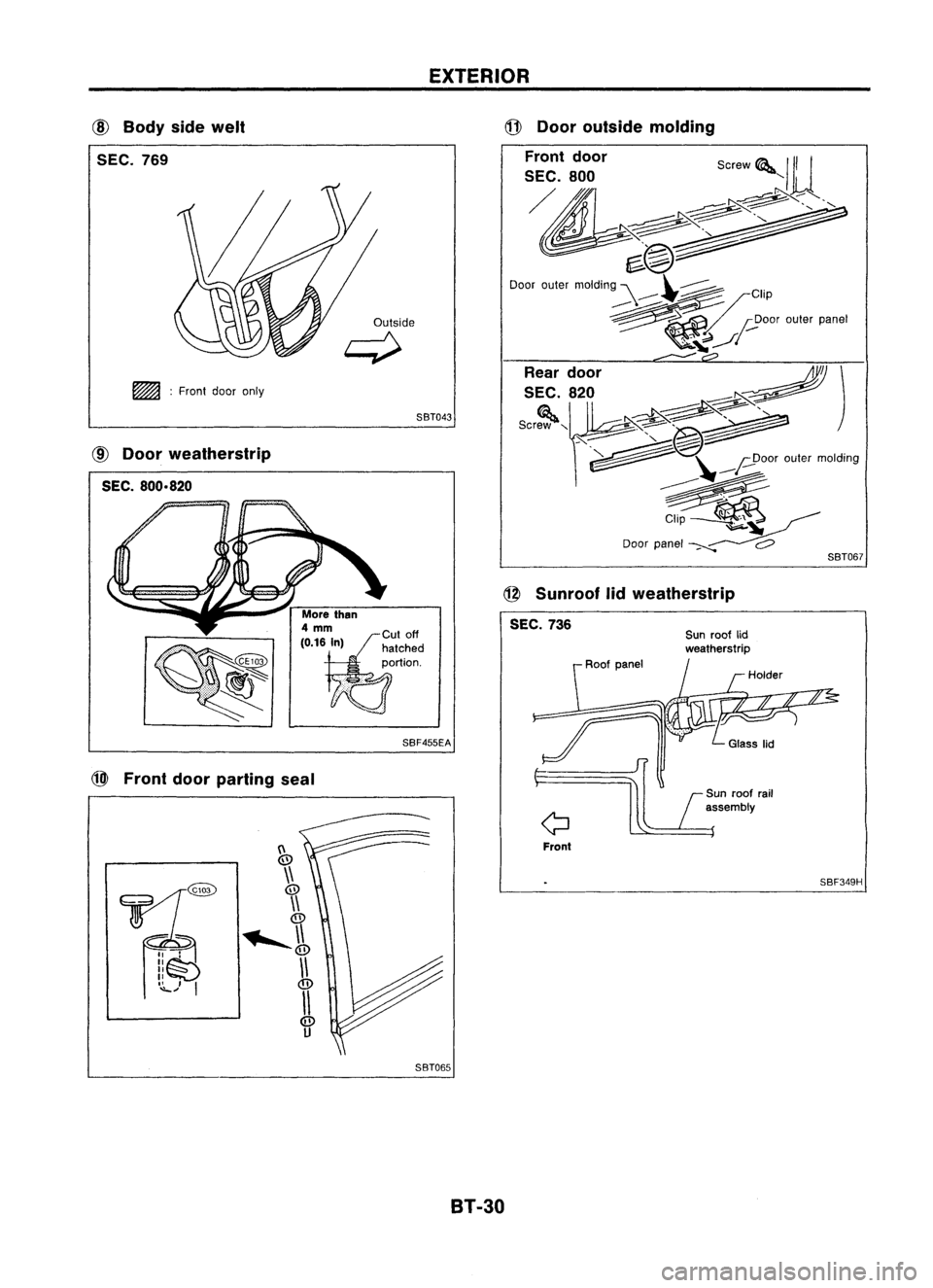

EXTERIOR

r

Sunroof rail

assembly

l

SBF349H

Front

Sun

roof lid

weatherstrip

Roof panel

SBT067

@

Door outside molding

Front door

SEC. 800 Screw'

III

~" g.@~

Door outer molding ~__

~/CIiP

~"..-/f'yoor outerpanel

Rear door ~

c:?

SEC. 820

~J

s,,~,~)

\.~ ~' "',,mold'"

CIIP~~

Door panel --~

~ 0

@

Sunroof lidweath .

S

erstnp

EC.736

SBT043

SBF455EA

d;!)de

(\

@

\\

@

\\

@

.........

\

\

@

\\

@

II

@

u

~~

::€t)£j

I.

II

.~) I

:

Front dooronly

CID

Door weatherstrip

SEC. 800.820

@

Body sidewelt

SEC. 769

@

Front doo .

r parting seal

SBT065

8T-30

Page 259 of 1701

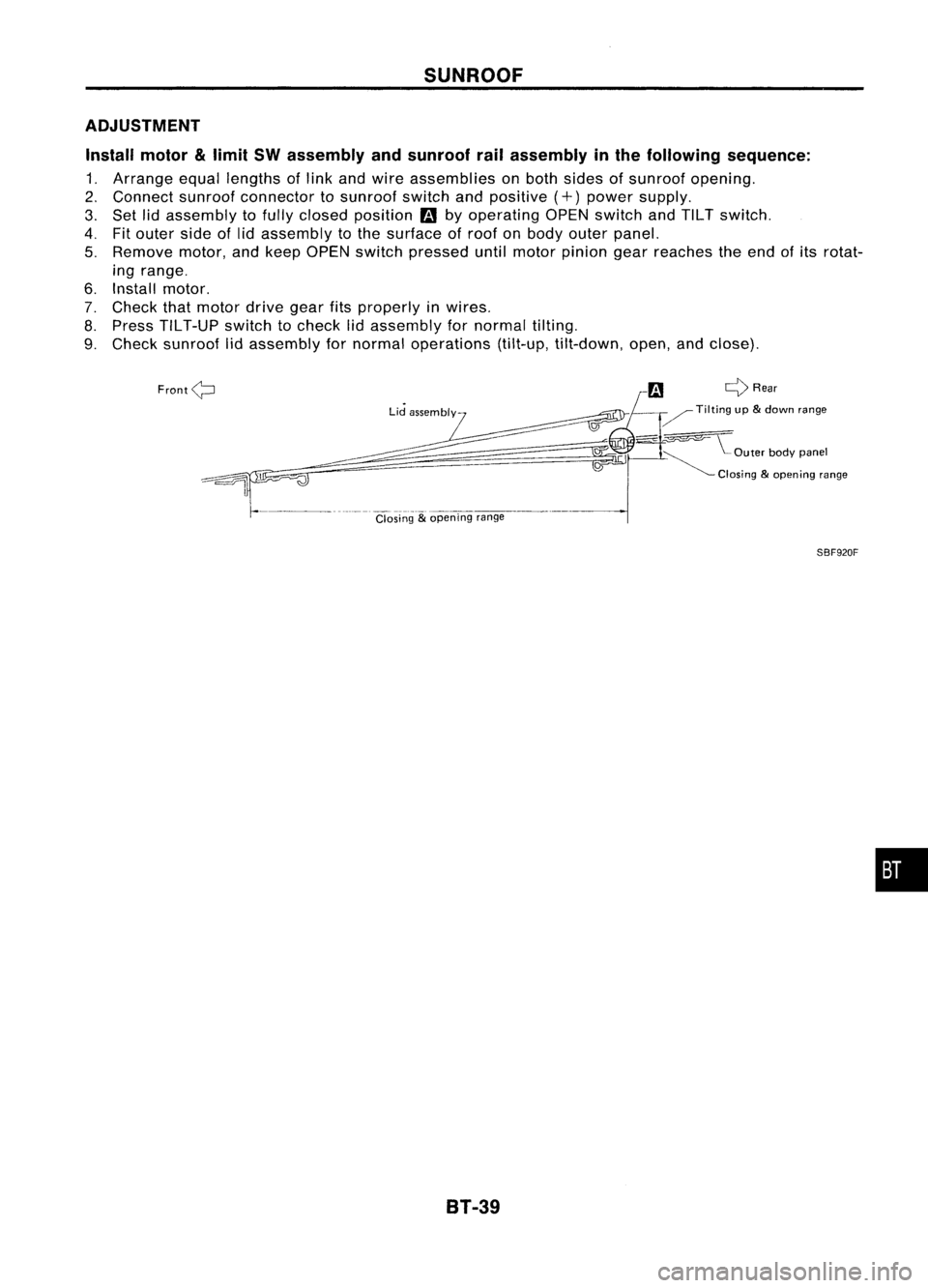

SUNROOF

ADJUSTMENT Install motor

&

limit SWassembly andsunroof railassembly inthe following sequence:

1. Arrange equallengths oflink and wire assemblies onboth sides ofsunroof opening.

2. Connect sunroofconnector tosunroof switchandpositive

(+)

power supply.

3. Set lidassembly tofully closed position

m

byoperating OPENswitch andTILT switch.

4. Fitouter sideoflid assembly tothe surface ofroof onbody outer panel.

5. Remove motor,andkeep OPEN switch pressed untilmotor pinion gearreaches theend ofits rotat-

ing range.

6. Install motor.

7. Check thatmotor drivegearfitsproperly inwires.

8. Press TILT-UP switchtocheck lidassembly fornormal tilting.

9. Check sunroof lidassembly fornormal operations (tilt-up,tilt-down, open,andclose).

FrontQ

Closing

&

opening range

81-39

ri1

9

Rear

/ Tilting up&down range

- ;:: u~

Outer bodypanel

~ Closing

&

opening range

SBF920F

•

Page 263 of 1701

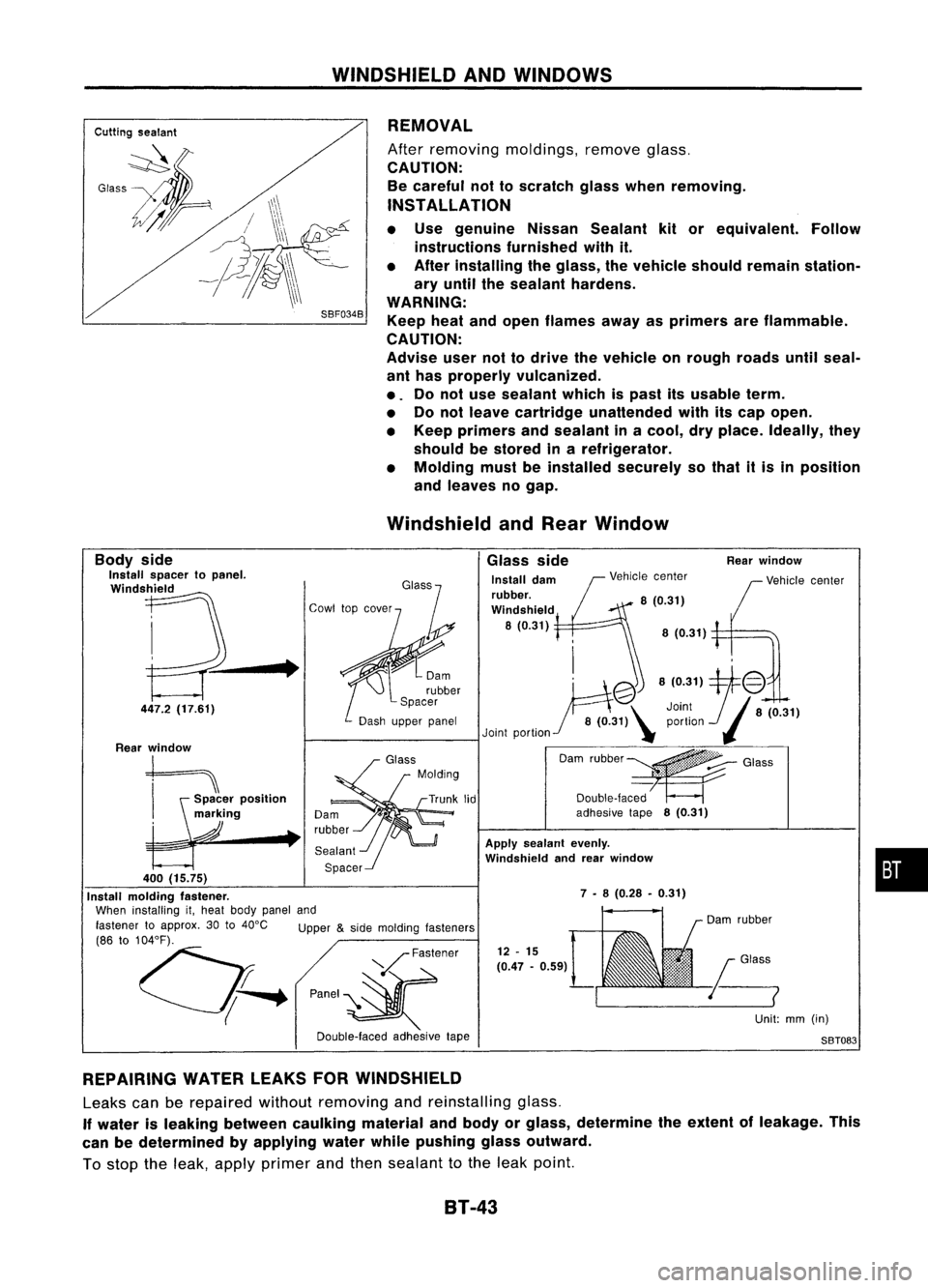

WINDSHIELDANDWINDOWS

Cutting sealant

SBF034BREMOVAL

After removing moldings, removeglass,

CAUTION: Be careful nottoscratch glasswhen removing.

INSTALLATION

• Use genuine NissanSealant kitorequivalent. Follow

instructions furnishedwithit.

• After installing theglass, thevehicle shouldremain station-

ary until thesealant hardens.

WARNING: Keep heatandopen flames awayasprimers areflammable.

CAUTION:

Advise usernottodrive thevehicle onrough roadsuntilseal-

ant has properly vulcanized.

•. Donot use sealant whichispast itsusable term.

• Donot leave cartridge unattended withitscap open.

• Keep primers andsealant inacool, dryplace. Ideally, they

should bestored inarefrigerator.

• Molding mustbeinstalled securely sothat itis in position

and leaves nogap.

Windshield andRear Window

•

Rear

window

Vehicle center

8 (0.31)

Glass

side

Install dam

rubber.

Windshield

8(0.31)

12 -15

(0.47 -0.59)

Apply

sealant evenly.

Windshield andrear window

7 •8 (0.28 •0.31)

Unit:mm(in)

S8T083

fj

'@8(0.31)1:@

Joint8(0.31)

8 (0.31)\ portion

(J

Joint portion "

O,m ,"bb"~

G,,,,

Double-laced

adhesive tape8(0.31)

V

Fastener

P'""~

Double-laced

adhesive

tape

•

Body

side

Install spacer topanel.

Windshield

447.2 (17.61)

Rear window

t==\

h¥:~'

po"II"

markmg

•

400 (15.75)

Install molding fastener.

When installing it,heat body panel and

fastener toapprox. 30to40°C Upper

&

side molding lasteners

(86 to104°F).

0;-.

REPAIRING WATERLEAKSFORWINDSHIELD

Leaks canberepaired withoutremoving andreinstalling glass.

If water isleaking between caulking materialandbody orglass, determine theextent ofleakage. This

can bedetermined byapplying waterwhilepushing glassoutward.

To stop theleak, apply primer andthen sealant tothe leak point.

81-43

Page 273 of 1701

PRECAUTIONSANDPREPARATION

Precautions

SUPPLEMENTAL RESTRAINTSYSTEM(SRS)"AIRBAG"

(DUAL AIRBAG SYSTEM)

The Supplemental RestraintSystem"AirBag" usedalong with

a seat belt,helps toreduce therisk orseverity ofinjury tothe

driver andfront passenger inafrontal collision. TheSupple-

mental Restraint Systemconsists ofair bag modules (located

in the center ofthe steering wheelandonthe instrument panel

on the passenger side),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoser-

vice thesystem safelyisincluded inthe

RSsection

ofthis Ser-

vice Manual.

WARNING:

• Toavoid rendering theSRS inoperatiYe, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

SUPPLEMENTAL RESTRAINTSYSTEM(SRS)"AIRBAG"

(SINGLE AIRBAG SYSTEM)

The Supplemental RestraintSystem"AirBag" andused along withaseat belt,helps toreduce therisk

or severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists of

an air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoservice thesystem safelyisincluded inthe

RS section

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual.

BR-3

•

Page 280 of 1701

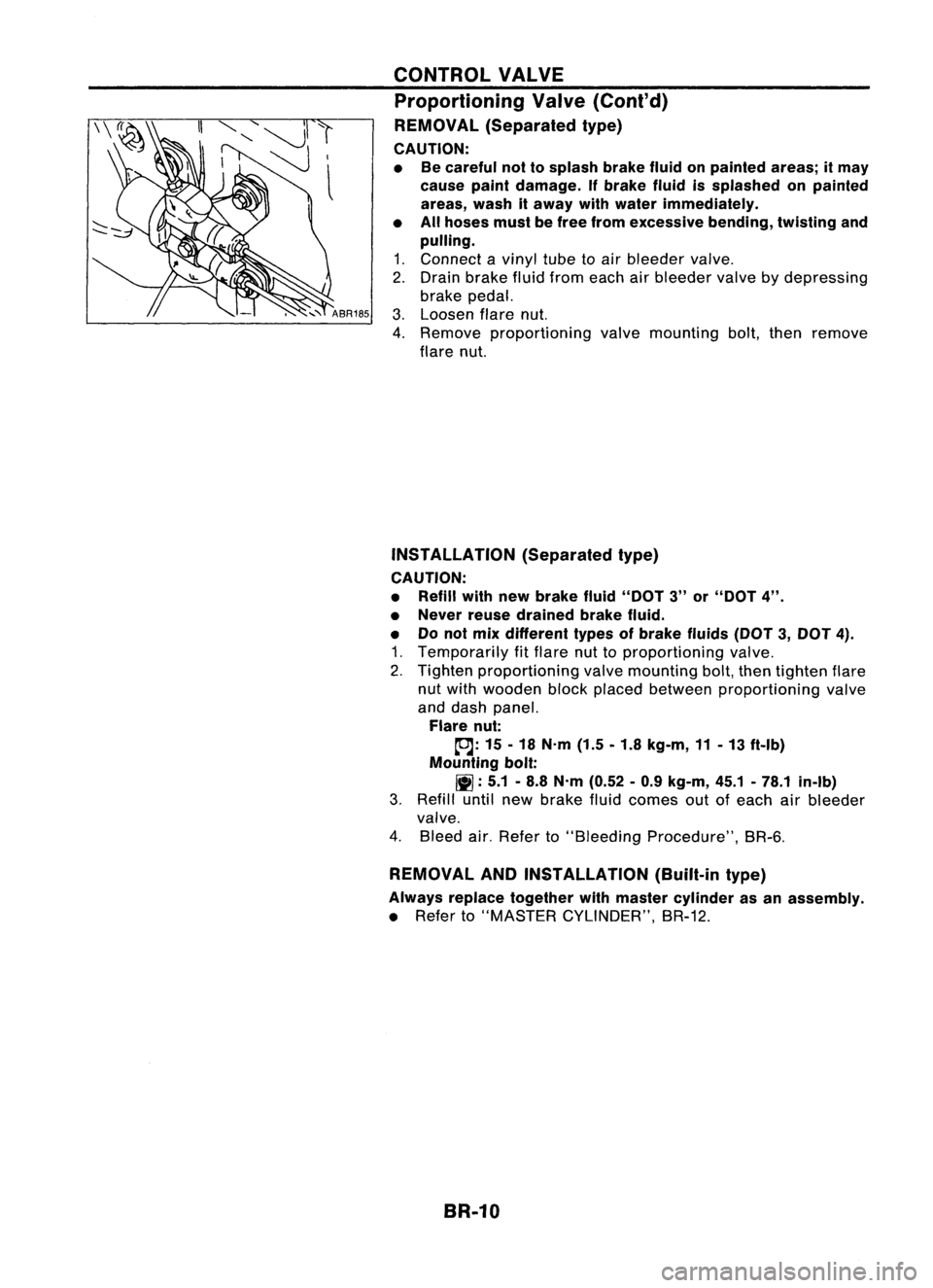

CONTROLVALVE

Proportioning Valve(Cont'd)

REMOVAL (Separated type)

CAUTION:

• Becareful nottosplash brakefluidonpainted areas;itmay

cause paintdamage. Ifbrake fluidissplashed onpainted

areas, washitaway withwater immediately.

• Allhoses mustbefree from excessive bending,twistingand

pulling.

1. Connect avinyl tubetoair bleeder valve.

2. Drain brake fluidfrom each airbleeder valvebydepressing

brake pedal.

3. Loosen flarenut.

4. Remove proportioning valvemounting bolt,then remove

flare nut.

INSTAllATION (Separatedtype)

CAUTION:

• Refill withnewbrake fluid"DOT 3"or"DOT 4".

• Never reusedrained brakefluid.

• Donot mix different typesofbrake fluids(DOT3,DOT 4).

1. Temporarily fitflare nuttoproportioning valve.

2. Tighten proportioning valvemounting bolt,then tighten flare

nut with wooden blockplaced between proportioning valve

and dash panel.

Flare nut:

tDJ:

15-18 N'm (1.5-1.8 kg-m, 11-13 ft-Ib)

Mounting bolt:

11]:

5.1-8.8 N'm (0.52 -0.9 kg-m, 45.1-78.1 in-Ib)

3. Refill untilnewbrake fluidcomes outofeach airbleeder

valve.

4. Bleed air.Refer to"Bleeding Procedure", BR-6.

REMOVAL ANDINSTAllATION (Built-intype)

Always replace together withmaster cylinder asan assembly.

• Refer to"MASTER CYLINDER", BR-12.

BR-10

Page 281 of 1701

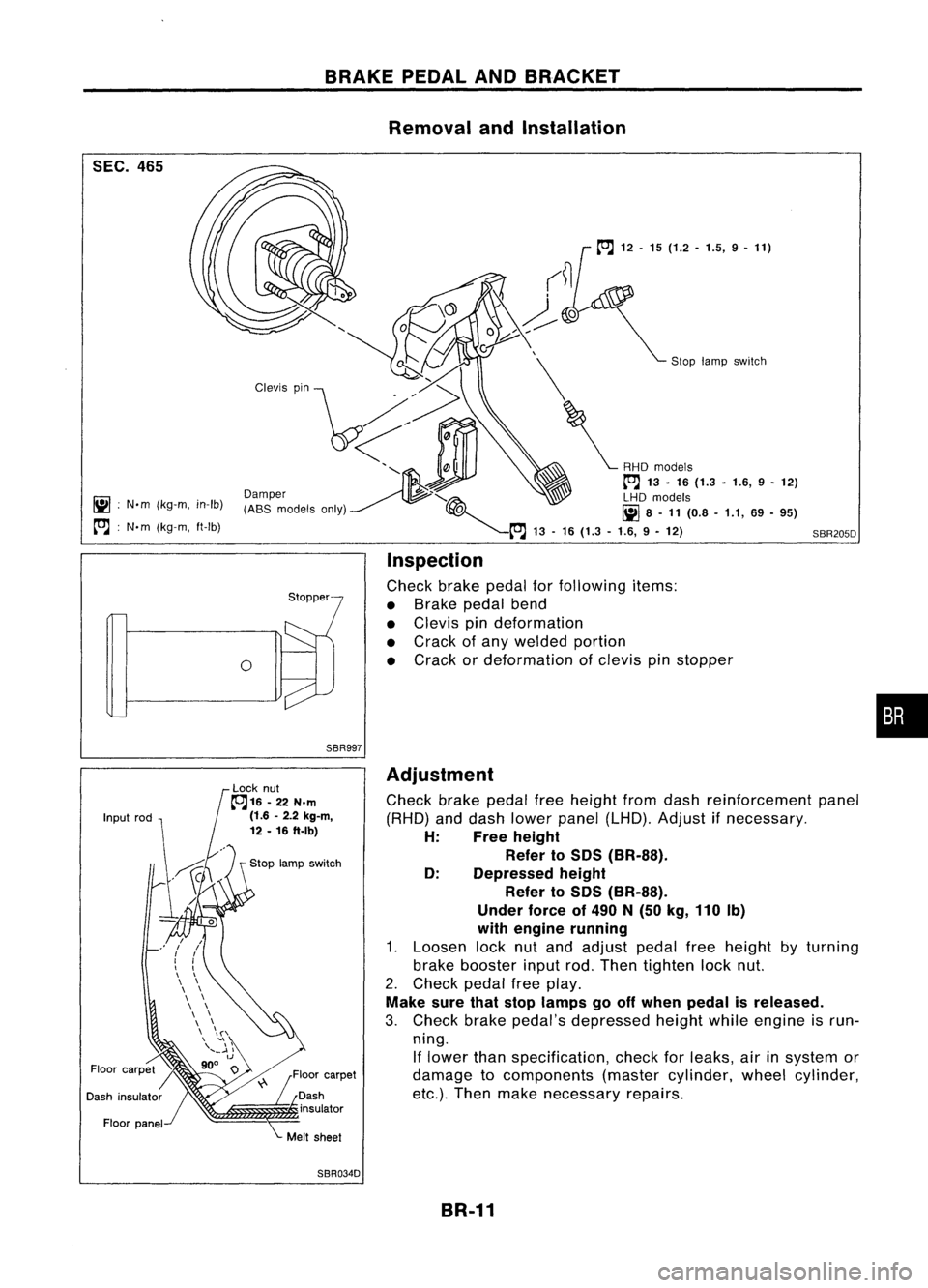

SEC.465

iii :

N'm (kg-m, in-Ib)

~ :N'm (kg-m, ft-Ib)

BRAKE

PEDALANDBRACKET

Removal andInstallation

Sloplamp sWitch

SBR205D

o

Inspection

Check brakepedalforfollowing items:

• Brake pedalbend

• Clevis pindeformation

• Crack ofany welded portion

• Crack ordeformation ofclevis pinstopper

•

SBR997

Adjustment

Check brakepedalfreeheight fromdash reinforcement panel

(RHD) anddash lower panel (LHD). Adjust ifnecessary.

H: Freeheight

Refer to

50S

(BR-SS).

0: Depressed height

Refer to

50S

(BR-SS).

Under forceof

490

N

(50

kg,

110

Ib)

with engine running

1. Loosen locknutand adjust pedalfreeheight byturning

brake booster inputrod.Then tighten locknut.

2. Check pedalfreeplay.

Make surethatstop lamps gooff when pedal isreleased.

3. Check brakepedal's depressed heightwhileengine isrun-

ning. If lower thanspecification, checkforleaks, airinsystem or

damage tocomponents (mastercylinder, wheelcylinder,

etc.). Then make necessary repairs.

SBR034D BR-11

Page 286 of 1701

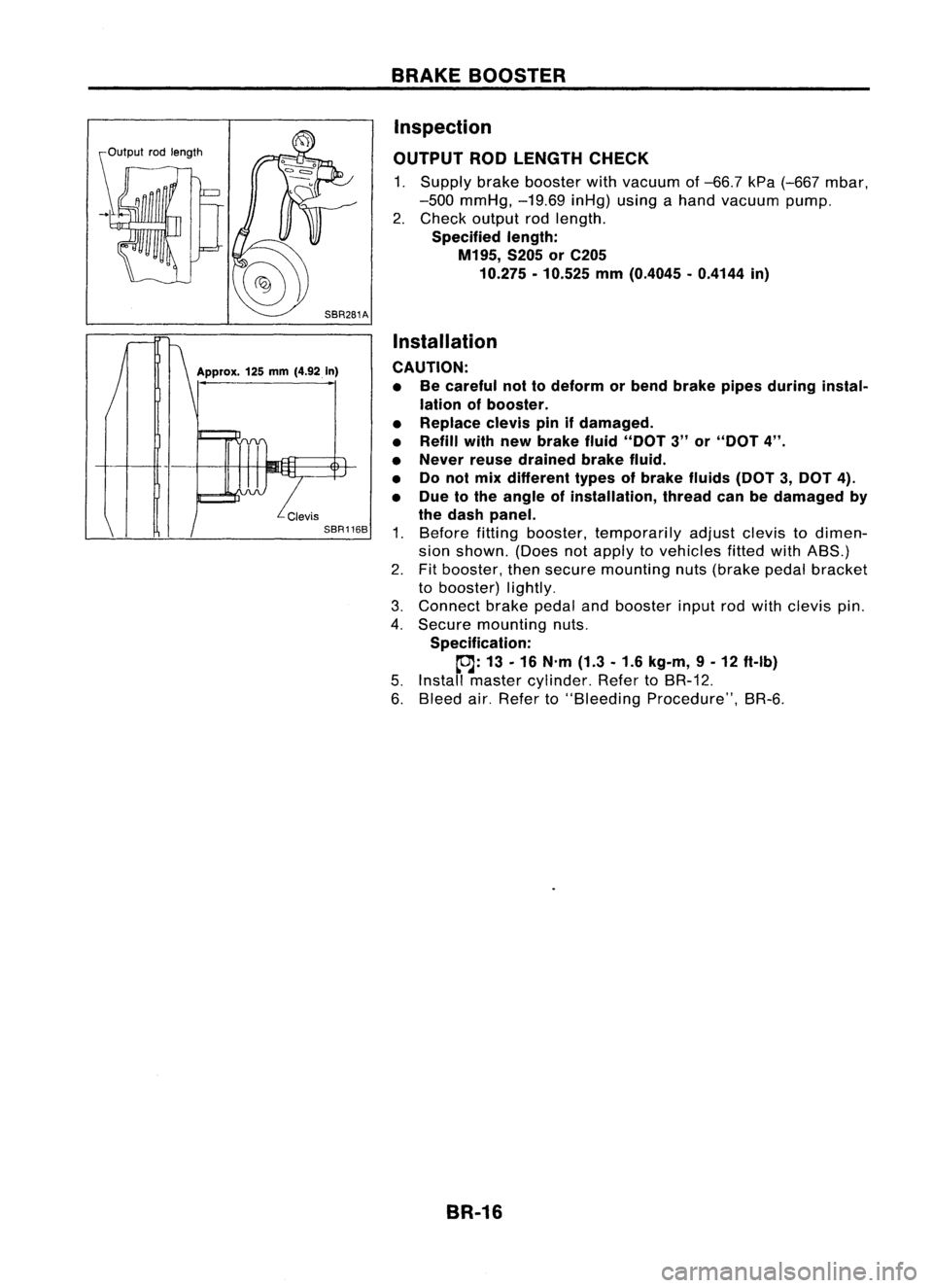

Approx.125mm (4.92 In) BRAKE

BOOSTER

Inspection

OUTPUT RODLENGTH CHECK

1. Supply brakebooster withvacuum of-66.7 kPa(-667 mbar,

-500 mmHg, -19.69inHg)usingahand vacuum pump.

2. Check output rodlength.

Specified length:

M195, S205orC205

10.275 -10.525 mm(0.4045 -0.4144 in)

Installation

CAUTION: • Becareful nottodeform orbend brake pipesduring instal-

lation ofbooster.

• Replace clevispinifdamaged.

• Refill withnewbrake fluid"DOT 3"or"DOT 4".

• Never reusedrained brakefluid.

• Donol mix different typesofbrake fluids(DOT3,DOT 4).

• Due tothe angle ofinstallation, threadcanbedamaged by

the dash panel.

1. Before fittingbooster, temporarily adjustclevistodimen-

sion shown. (Doesnotapply tovehicles fittedwithABS.)

2. Fitbooster, thensecure mounting nuts(brake pedalbracket

to booster) lightly.

3. Connect brakepedalandbooster inputrodwith clevis pin.

4. Secure mounting nuts.

Specification:

~: 13-16 N'm (1.3-1.6 kg-m, 9-12 ft-Ib)

5. Install master cylinder. RefertoBR-12.

6. Bleed air.Refer to"Bleeding Procedure", BR-6.

BR-16

Page 323 of 1701

.=J

MPH

-~s::~

~~

___ --- warnin:1

TROUBLE

DIAGNOSES

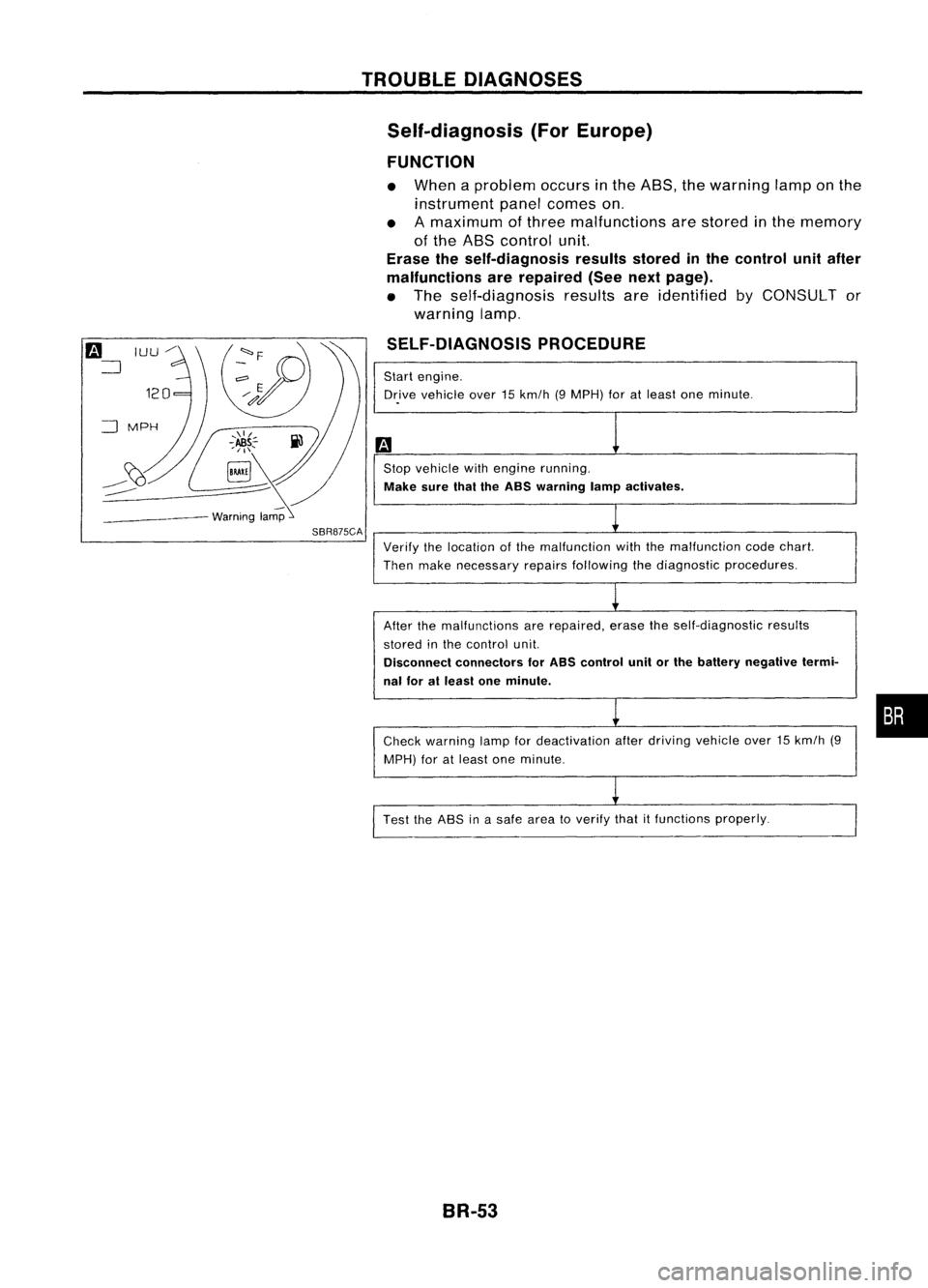

Self-diagnosis (ForEurope)

FUNCTION

• When aproblem occursinthe ABS, thewarning lamponthe

instrument panelcomes on.

• Amaximum ofthree malfunctions arestored inthe memory

of the ABS control unit.

Erase theself-diagnosis resultsstoredinthe control unitafter

malfunctions arerepaired (Seenextpage).

• The self-diagnosis resultsareidentified byCONSULT or

warning lamp.

SELF-DIAGNOSIS PROCEDURE

Start engine.

Dr.ive vehicle over15km/h (9MPH) foratleast oneminute .

Stop vehicle withengine running.

Make surethaitheASS warning lampactivates.

SBR875CA

Verifythelocation ofthe malfunction withthemalfunction codechart.

Then make necessary repairsfollowing thediagnostic procedures.

After themalfunctions arerepaired, erasetheself-diagnostic results

stored inthe control unit.

Disconnect connectors forASS control unitorthe battery negative termi-

nal foratleast oneminute.

Check warning lampfordeactivation afterdriving vehicle over15km/h (9

MPH) foratleast oneminute.

Test theASS inasafe area toverify thatitfunctions properly.

BR-53

•