panel NISSAN ALMERA N15 1995 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1523 of 1701

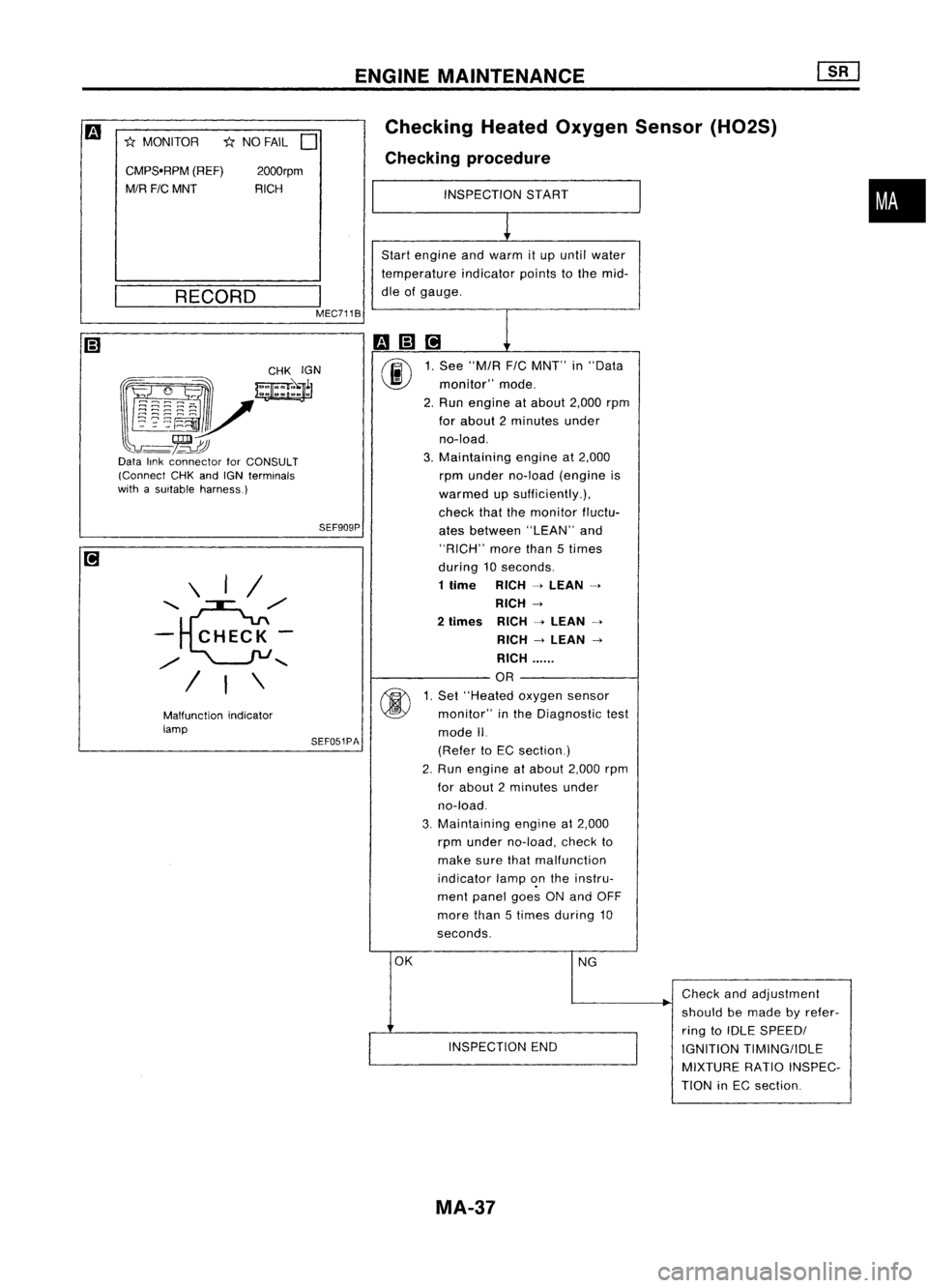

ENGINEMAINTENANCE

SEF051PA SEF909P

*

NO FAIL

D

Malfunction indicator

lamp

•

Checking

HeatedOxygen Sensor(H02S)

Checking procedure

INSPECTION START

1

Start engine andwarm itup until water

temperature indicatorpointstothe mid-

dle ofgauge.

m(;]ri

1

00

1.

See "M/R F/CMNT" in"Data

monitor" mode.

2. Run engine atabout 2,000rpm

for about 2minutes under

no-load.

3. Maintaining engineat2,000

rpm under no-load (engine is

warmed upsufficiently.),

check thatthemonitor fluctu-

ates between "LEAN"and

"RICH" morethan5times

during 10seconds.

1 time RICH

-4

LEAN

-4

RICH

-4

2

times RICH

-4

LEAN

-4

RICH

-4

LEAN

-4

RICH ......

OR

@

1.

Set "Heated oxygensensor

monitor" inthe Diagnostic test

mode II.

(Refer toEC section)

2. Run engine atabout 2,000rpm

for about 2minutes under

no-load.

3. Maintaining

engineat2,000

rpm under no-load, checkto

make surethatmalfunction

indicator lamp~nthe instru-

ment panel goesONand OFF

more than5times during 10

seconds.

OK NG

.

Check

andadjustment

should bemade byrefer-

ring toIDLE SPEEDI

INSPECTION END

IGNITIONTIMING/IDLE

MIXTURE RATIOINSPEC-

TION inEC section

2000rpm

RICH

\ I/

........ e./

- CHECK-

./

........

/ I\

CMPS.RPM

(REF)

M/R FICMNT

*

MONITOR

__ R_E_C_O_R_D __

I

MEC711B

~~~~:?~;~

~~r

l~~~~V

-~~

Data linkconnector forCONSULT

(Connect CHKandIGN terminals

with asuitable harness.)

MA-37

Page 1538 of 1701

CHASSISANDBODY MAINTENANCE

Checking BodyCorrosion

Visually checkthebody sheet metalpanelforcorrosion, paintdamage (scratches, chipping,rubbing,

etc.) ordamage tothe anti-corrosion materials.Inparticular, checkthefollowing locations.

Hemmed portion

Hood frontend,door lower end,trunk lidrear end, etc.

Panel joint

Side sillofrear fender andcenter pillar,rearwheel housing ofrear fender, aroundstruttower inengine

compartment, etc.

Panel edge

Trunk lidopening, sunroofopening, fenderwheelarch flange,fuelfiller lidflange, around holesinpanel,

etc.

Parts contact

Waist molding, windshield molding,bump.er,etc.

Protectors

Damage orcondition ofmudguard, fenderprotector, chippingprotector, etc.

Anti-corrosion materials

Damage orseparation ofanti-corrosion materialsunderthebody.

Drain holes

Condition ofdrain holes atdoor andside sill.

When repairing corrodedareas,refertothe Corrosion RepairManual.

MA-52

Page 1622 of 1701

PRECAUTION

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt, helps toreduce therisk or

severity ofinjury tothe driver andfront passenger inafrontal collision. TheSupplemental Restraint

System consists ofair bag modules (locatedinthe center ofthe steering wheelandonthe instrument

panel onthe passenger side),adiagnosis sensorunit,warning lamp,wiring harness andspiral cable.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt, helps toreduce therisk or

severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists ofan

air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual.

RS-2

Page 1628 of 1701

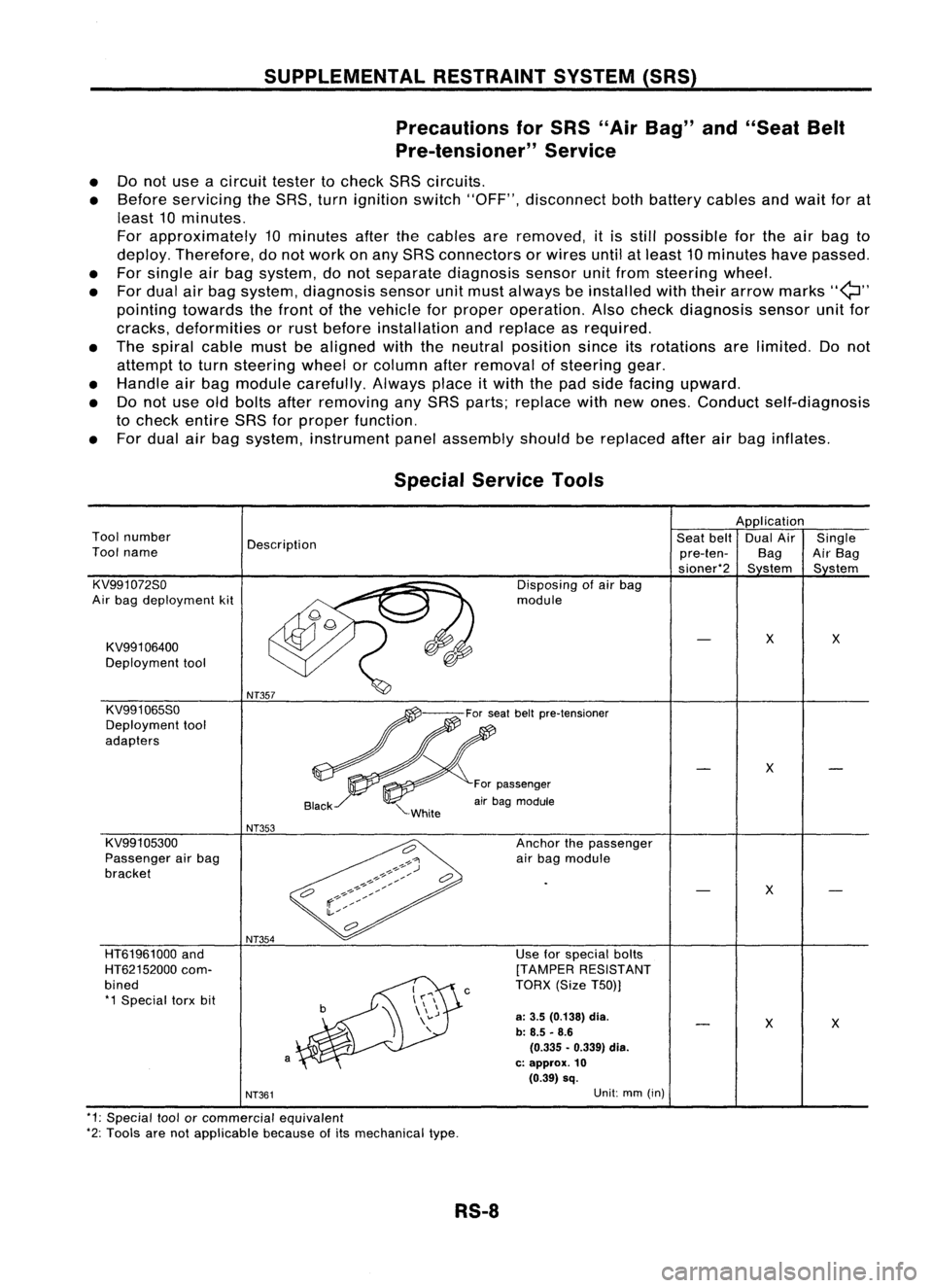

SUPPLEMENTALRESTRAINTSYSTEM(SRS)

Precautions forSRS "AirBag" and"Seat Belt

Pre-tensioner" Service

• Donot use acircuit testertocheck SRScircuits.

• Before servicing theSRS. turnignition switch"OFF", disconnect bothbattery cablesandwait forat

least 10minutes.

For approximately 10minutes afterthecables areremoved, itis still possible forthe airbag to

deploy. Therefore, donot work onany SRS connectors orwires untilatleast 10minutes havepassed.

• For single airbag system, donot separate diagnosis sensorunitfrom steering wheel.

• For dual airbag system. diagnosis sensorunitmust always beinstalled withtheir arrow marks

"Q"

pointing towards thefront ofthe vehicle forproper operation. Alsocheck diagnosis sensorunitfor

cracks. deformities orrust before installation andreplace asrequired.

• The spiral cablemustbealigned withtheneutral position sinceitsrotations arelimited. Donot

attempt toturn steering wheelorcolumn afterremoval ofsteering gear.

• Handle airbag module carefully. Alwaysplaceitwith thepad side facing upward.

• Donot use oldbolts afterremoving anySRS parts; replace withnewones. Conduct self-diagnosis

to check entire SRSforproper function.

• For dual airbag system, instrument panelassembly shouldbereplaced afterairbag inflates.

X

X

Use

forspecial bolts

[TAMPER RESISTANT

TORX (SizeT50))

a:

3.5 (0.138)

dia.

b: 8.5 -8.6

(0.335 •0.339) dia.

c: approx.

10

(0.39) sq.

c

NT354

a

HT61961000

and

HT62152000 com-

bined *1 Special torxbit

Special

Service Tools

Application

Tool number

Description Seat

belt DualAir Single

Tool name

pre-ten-BagAirBag

sioner*2 Sstem Sstem

KV991072So Disposingofair bag

Air bag deployment kit module

KV991 06400

X

X

Deployment tool

KV991065So

Deployment tool

adapters

X

For passenger

air bag module

NT353

KV991 05300 Anchorthepassenger

Passenger airbag

airbag module

bracket

X

NT361

Unit:

mm(in)

*1: Special toolorcommercial equivalent

*2: Tools arenotapplicable becauseofits mechanical type.

RS-8

Page 1631 of 1701

SUPPLEMENTALRESTRAINTSYSTEM(SRS)

Visually checkSRScomponents

Diagnosis sensorunit

Check diagnosis sensorunitand bracket fordents, cracks

or deformities.

Check connectors fordamage, andterminals fordeformi-

ties.

Air bag module andsteering wheel

Remove airbag module fromsteering wheelorinstrument

panel. Check harness coverandconnectors fordamage,

terminals fordeformities, andharness forbinding.

Install driversideairbag module tosteering wheeltocheck

fit or alignment withthewheel.

Check steering wheelforexcessive freeplay.

For dual airbag system, installpassenger sideairbag

module toinstrument paneltocheck fitor alignment withthe

instrument panel.

Maintenance

Items

1. Check "AIRBAG" warning lampoperation

After turning ignition keyto"ON" position, "AIRBAG"

warning lampilluminates. The"AIR BAG" warning lamp

will turn offafter about 7seconds ifno malfunction is

detected. If any ofthe following airbag warning lampconditions

occur, immediately checktheairbag system. RefertoRS-32

and 43for details.

The warning lampdoesnotilluminate whentheignition

switch isturned "ON".

The warning lampdoesnotturn offabout 7seconds after

the ignition switchisturned "ON".

The warning lampturns offabout 7seconds aftertheigni-

tion switch isturned "ON",butitturns onorflashes again.

•

MRS115A

•

•

2. (1)

•

•

(2)

•

•

•

•

(3) Spiral cable

• Check spiralcablefordents, cracks, ordeformities.

• Check connectors andprotective tapefordamage.

• Check steering wheelfornoise, binding orheavy operation. •

(4) Main harness andairbag harness (Fordual airbag system

only)

• Check connectors forpoor connections, damage,andtermi-

nals fordeformities.

• Check harnesses forbinding, chafingorcut.

CAUTION: Replace previously usedscrews withnewones.

RS-11

Page 1632 of 1701

SUPPLEMENTALRESTRAINTSYSTEM(SRS)

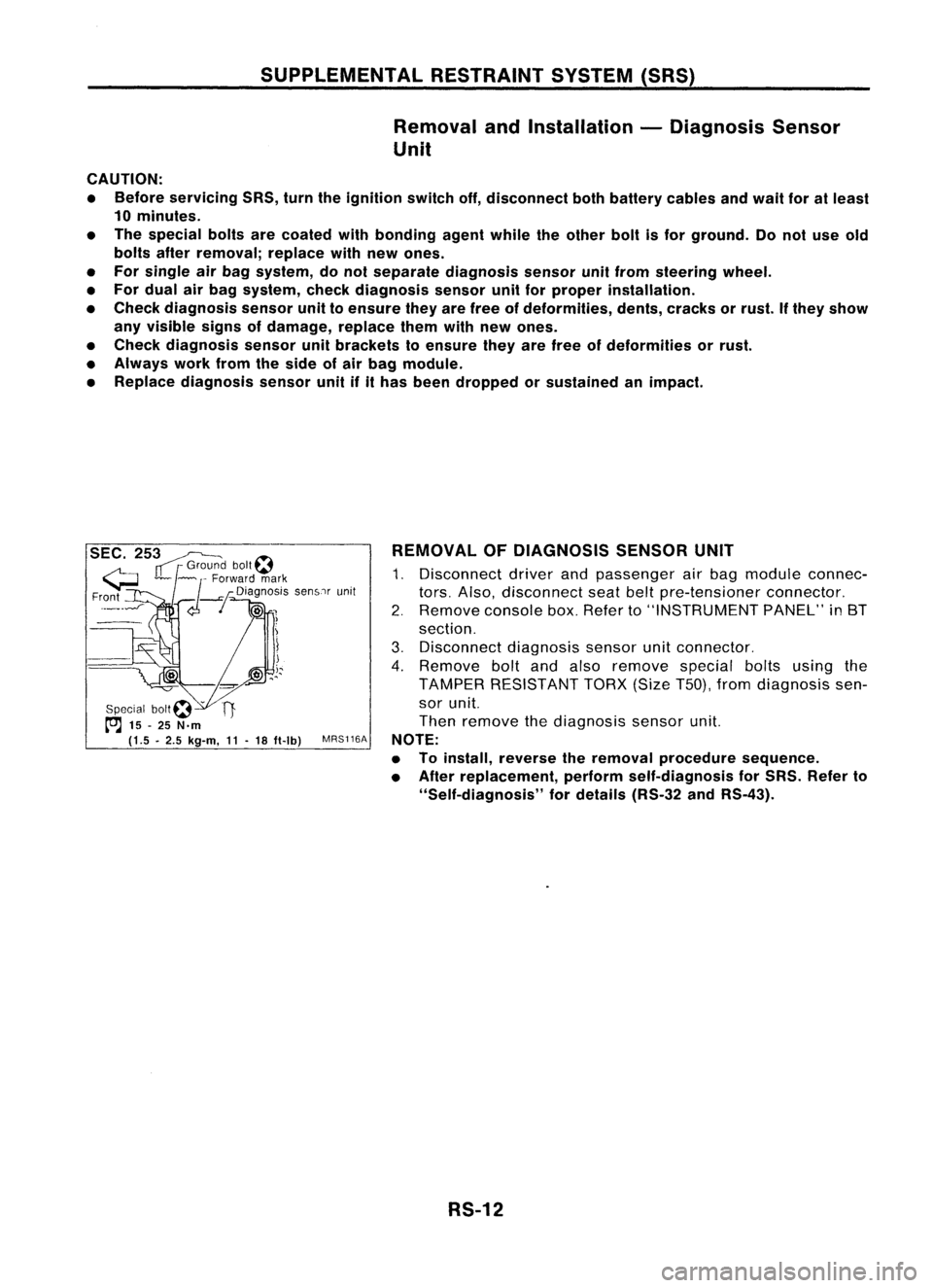

Removal andInstallation -Diagnosis Sensor

Unit

CAUTION:

• Before servicing SRS,turntheignition switchoff,disconnect bothbattery cablesandwait foratleast

10 minutes.

• The special boltsarecoated withbonding agentwhiletheother boltisfor ground. Donot use old

bolts afterremoval; replacewithnewones.

• For single airbag system, donot separate diagnosis sensorunitfrom steering wheel.

• For dual airbag system, checkdiagnosis sensorunitforproper installation.

• Check diagnosis sensorunittoensure theyarefree ofdeformities, dents,cracks orrust. Ifthey show

any visible signsofdamage, replacethemwithnewones.

• Check diagnosis sensorunitbrackets toensure theyarefree ofdeformities orrust.

• Always workfromtheside ofair bag module.

• Replace diagnosis sensorunitifithas been dropped orsustained animpact.

SEC. 253~

IT

r

Grou~? bolt~

G ~~ ~

Forward mark

Fr?nt

_--I

d--!

Dia~no:iS senSlrunit

!

Special bOIt~ -

t"'J

15-25 N.m

(1.5 •2.5 kg-m,

11-

18 ft-Ib)

MRS116A REMOVAL

OFDIAGNOSIS SENSORUNIT

1. Disconnect driverandpassenger airbag module connec-

tors. Also, disconnect seatbeltpre-tensioner connector.

2. Remove consolebox.Refer to"INSTRUMENT PANEL"in8T

section.

3. Disconnect diagnosissensorunitconnector.

4. Remove boltandalso remove specialboltsusing the

TAMPER RESISTANT TORX(SizeT50),fromdiagnosis sen-

sor unit.

Then remove thediagnosis sensorunit.

NOTE:

• Toinstall, reverse theremoval procedure sequence.

• After replacement, performself-diagnosis forSRS. Refer to

"Self-diagnosis" fordetails (RS-32andRS-43).

RS-12

Page 1636 of 1701

SUPPLEMENTALRESTRAINTSYSTEM(SRS)

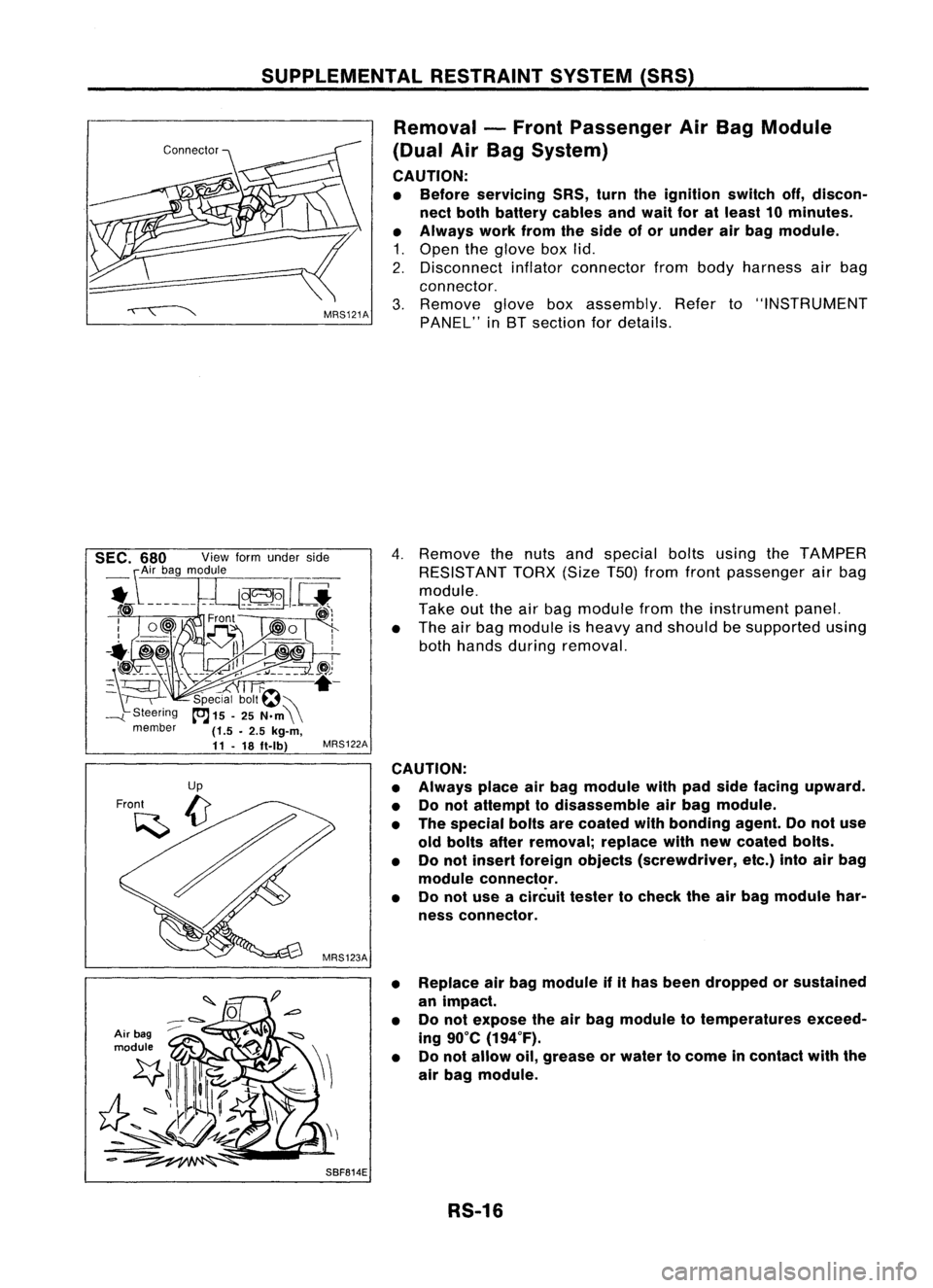

Removal -Front Passenger AirBag Module

(Dual AirBag System)

CAUTION:

• Before servicing SRS,turntheignition switchoff,discon-

nect both battery cablesandwait foratleast 10minutes.

• Always workfromtheside ofor under airbag module.

1. Open theglove boxlid.

2. Disconnect inflatorconnector frombody harness airbag

connector.

3. Remove gloveboxassembly. Referto"INSTRUMENT

PANEL" inBT section fordetails.

Air bag

module

4.

Remove thenuts andspecial boltsusing theTAMPER

RESISTANT TORX(SizeT50jfrom front passenger airbag

module.

Take outtheairbag module fromtheinstrument panel.

• The airbag module isheavy andshould besupported using

both hands during removal.

MRS122A

CAUTION:

• Always placeairbag module withpadside facing upward.

• Donot attempt todisassemble airbag module.

• The special boltsarecoated withbonding agent.Donot use

old bolts afterremoval; replacewithnewcoated bolts.

• Donot insert foreign objects (screwdriver, etc.)intoairbag

module connector.

• Donot use acircuit testertocheck theairbag module har-

ness connector.

• Replace airbag module ifithas been dropped orsustained

an impact.

• Donot expose theairbag module totemperatures exceed-

ing 90°C (194°F).

• Donot allow oil,grease orwater tocome incontact withthe

air bag module.

SBF814E RS-16

Page 1660 of 1701

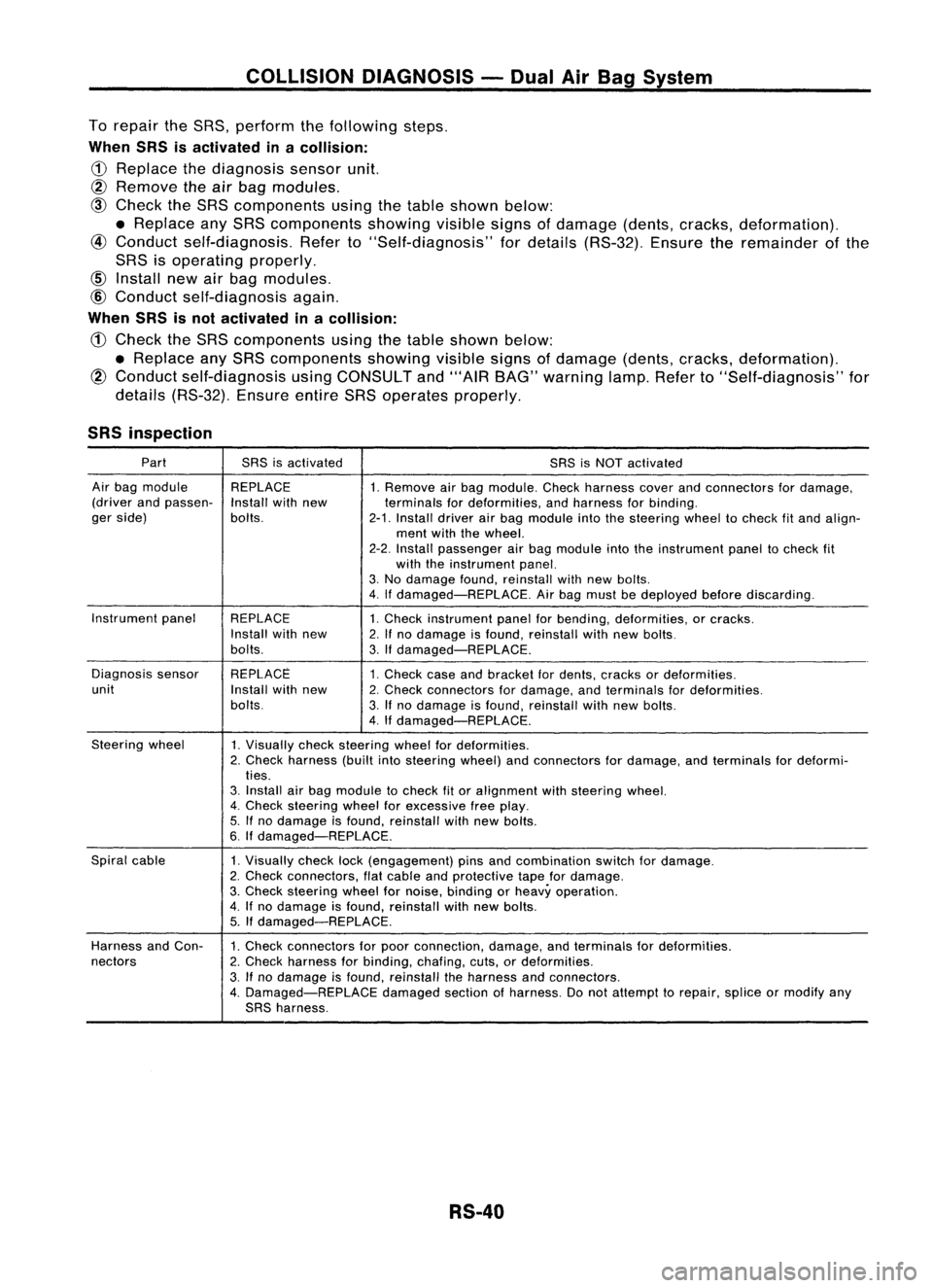

COLLISIONDIAGNOSIS -Dual AirBag System

To repair theSRS, perform thefollowing steps.

When SRSisactivated inacollision:

CD

Replace thediagnosis sensorunit.

@ Remove

theairbag modules.

@

Check theSRS components usingthetable shown below:

• Replace anySRS components showing

visible

signsofdamage (dents,cracks, deformation).

@

Conduct self-diagnosis. Referto"Self-diagnosis" fordetails (RS-32). Ensuretheremainder ofthe

SRS isoperating properly.

@

Conduct self-diagnosis again.

When SRSisnot activated inacollision:

CD

Check theSRS components usingthetable shown below:

• Replace anySRS components showingvisiblesignsofdamage (dents,cracks, deformation).

@

Conduct self-diagnosis usingCONSULT and"'AIR BAG" warning lamp.Referto"Self-diagnosis" for

details (RS-32). EnsureentireSRSoperates properly.

SRS inspection

Part SRSisactivated

SRSisNOT activated

Air bag module REPLACE

1.Remove airbag module. Checkharness coverandconnectors fordamage,

(driver andpassen-

Installwithnew terminalsfordeformities, andharness forbinding.

ger side) bolts.

2-1.Install driverairbag module intothesteering wheeltocheck fitand align-

ment withthewheel.

2-2. Install passenger airbag module intotheinstrument paneltocheck fit

with theinstrument panel.

3. No damage found,reinstall withnewbolts.

4. Ifdamaged-REPLACE. Airbag must bedeployed beforediscarding.

Instrument panel

REPLACE 1.Check instrument panelforbending, deformities, orcracks.

Install withnew

2.Ifno damage isfound, reinstall withnewbolts.

bolts. 3.Ifdamaged-REPLACE.

Diagnosis sensor REPLACE

1.Check caseandbracket fordents, cracks ordeformities.

unit Installwithnew

2.Check connectors fordamage, andterminals fordeformities.

bolts. 3.Ifno damage isfound, reinstall withnewbolts.

4. Ifdamaged-REPLACE.

Steering wheel

1.Visually checksteering wheelfordeformities.

2. Check harness (builtintosteering wheel)andconnectors fordamage, andterminals fordeformi-

ties.

3. Install airbag module tocheck fitor alignment withsteering wheel.

4. Check steering wheelforexcessive freeplay.

5. Ifno damage isfound, reinstall withnewbolts.

6. Ifdamaged-REPLACE.

Spiral cable

1.Visually checklock(engagement) pinsandcombination switchfordamage.

2. Check connectors, flatcable andprotective tapefordamage.

3. Check steering wheelfornoise, binding orheavy operation.

4. Ifno damage isfound, reinstall withnew bolts.

5. Ifdamaged-REPLACE.

Harness andCon-

1.Check connectors forpoor connection, damage,andterminals fordeformities.

nectors 2.Check harness forbinding, chafing,cuts,ordeformities.

3. Ifno damage isfound, reinstall theharness andconnectors.

4. Damaged-REPLACE damagedsectionofharness. Donot attempt torepair, spliceormodify any

SRS harness.

RS-40

Page 1668 of 1701

PRECAUTIONSANDPREPARATION

Precautions

SUPPLEMENTAL RESTRAINTSYSTEM(SRS)"AIRBAG"

(Dual AirBag System)

The Supplemental RestraintSystem"AirBag" usedalong withaseat belt,helps toreduce therisk or

severity ofinjury tothe driver andfront passenger inafrontal collision. TheSupplemental Restraint

System consists ofair bag modules (locatedinthe center ofthe steering wheelandonthe instrument

panel onthe passenger side),adiagnosis sensorunit,warning lamp,wiring harness andspiral cable.

Information necessarytoservice thesystem safelyisincluded inthe

RSsection

ofthis Service Manual.

WARNING: • Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

SUPPLEMENTAL RESTRAINTSYSTEM(SRS)"AIRBAG"

(Single AirBag System)

The Supplemental RestraintSystem"AirBag" andused along withaseat belt,helps toreduce therisk

or severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists of

an air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoservice thesystem safelyisincluded inthe

RS section

ofthis Service Manual.

WARNING: • Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual.

STEERINGSYSTEM

• Before disassembly, thoroughlycleantheoutside ofthe unit.

• Disassembly shouldbedone inaclean workarea. Itis important toprevent theinternal partsfrom

becoming contaminated bydirt orother foreign matter.

• Place disassembled partsinorder, onaparts rack,fore"asier andproper assembly.

• Use nylon cloths orpaper towels toclean theparts; common shopragscanleave lintthat might

interfere withtheir operation.

• Before inspection orreassembly, carefullycleanallparts withageneral purpose, non-flammable

solvent.

• Before assembly, applyacoat ofrecommended ATF*tohydraulic parts.Vaseline maybeapplied to

O-rings andseals. Donot use any grease.

• Replace allgaskets, sealsandO-rings. Avoiddamaging O-rings,sealsandgaskets duringinstalla-

tion. Perform functional testswhenever designated.

*:

Automatic transmission fluid

ST-2