width NISSAN ALMERA N15 1995 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1218 of 1701

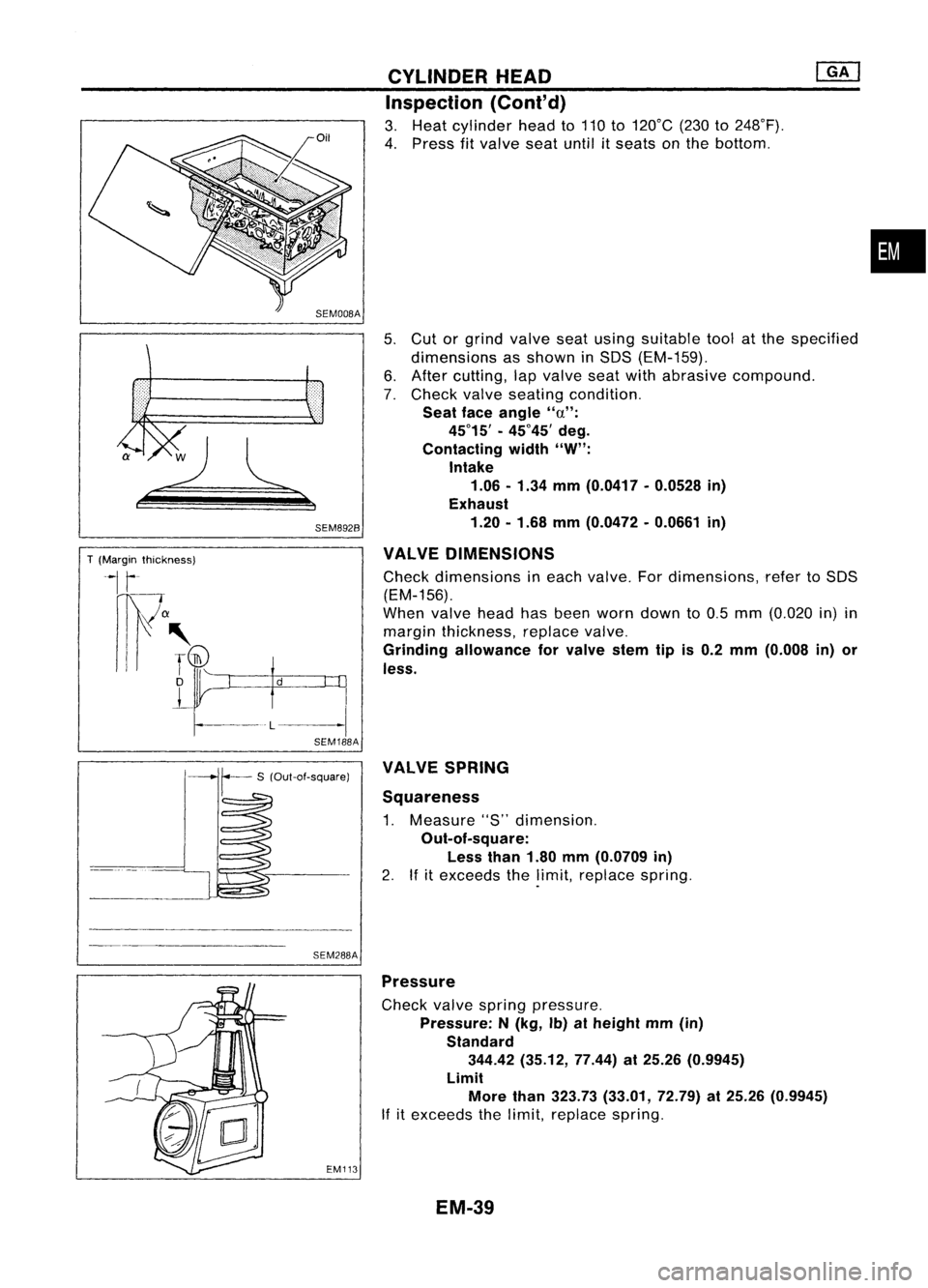

T(Margin thickness)

--1,-

ml

a

III' ~

o

~-

-L

d

SEM8928

I

.\

SEM188A

CYLINDER

HEAD

Inspection (Conl'd)

3. Heat cylinder headto110 to120°C (230to248°F).

4. Press fitvalve seatuntilitseats onthe bottom .

5. Cut orgrind valve seatusing suitable toolatthe specified

dimensions asshown inSOS (EM-159).

6. After cutting, lapvalve seatwithabrasive compound.

7. Check valveseating condition.

Seat faceangle "a":

45°15' -45°45' deg.

Contacting width"W":

Intake

1.06 -1.34 mm(0.0417 -0.0528 in)

Exhaust

1.20 -1.68 mm(0.0472 -0.0661 in)

VALVE DIMENSIONS

Check dimensions ineach valve. Fordimensions, refertoSOS

(EM-156).

When valveheadhasbeen worn down to0.5 mm (0.020 in)in

margin thickness, replacevalve.

Grinding allowance forvalve stemtipis0.2 mm (0.008 in)or

less.

•

SEM288A VALVE

SPRING

Squareness

1. Measure "S"dimension.

Out-of-square: Less than1.80mm(0.0709 in)

2. Ifitexceeds thelimit, replace spring.

EM113

Pressure

Check valvespring pressure.

Pressure: N(kg, Ib)atheight mm(in)

Standard 344.42 (35.12, 77.44)at25.26 (0.9945)

Limit More than323.73 (33.01, 72.79)at25.26 (0.9945)

If itexceeds thelimit, replace spring.

EM-39

Page 1271 of 1701

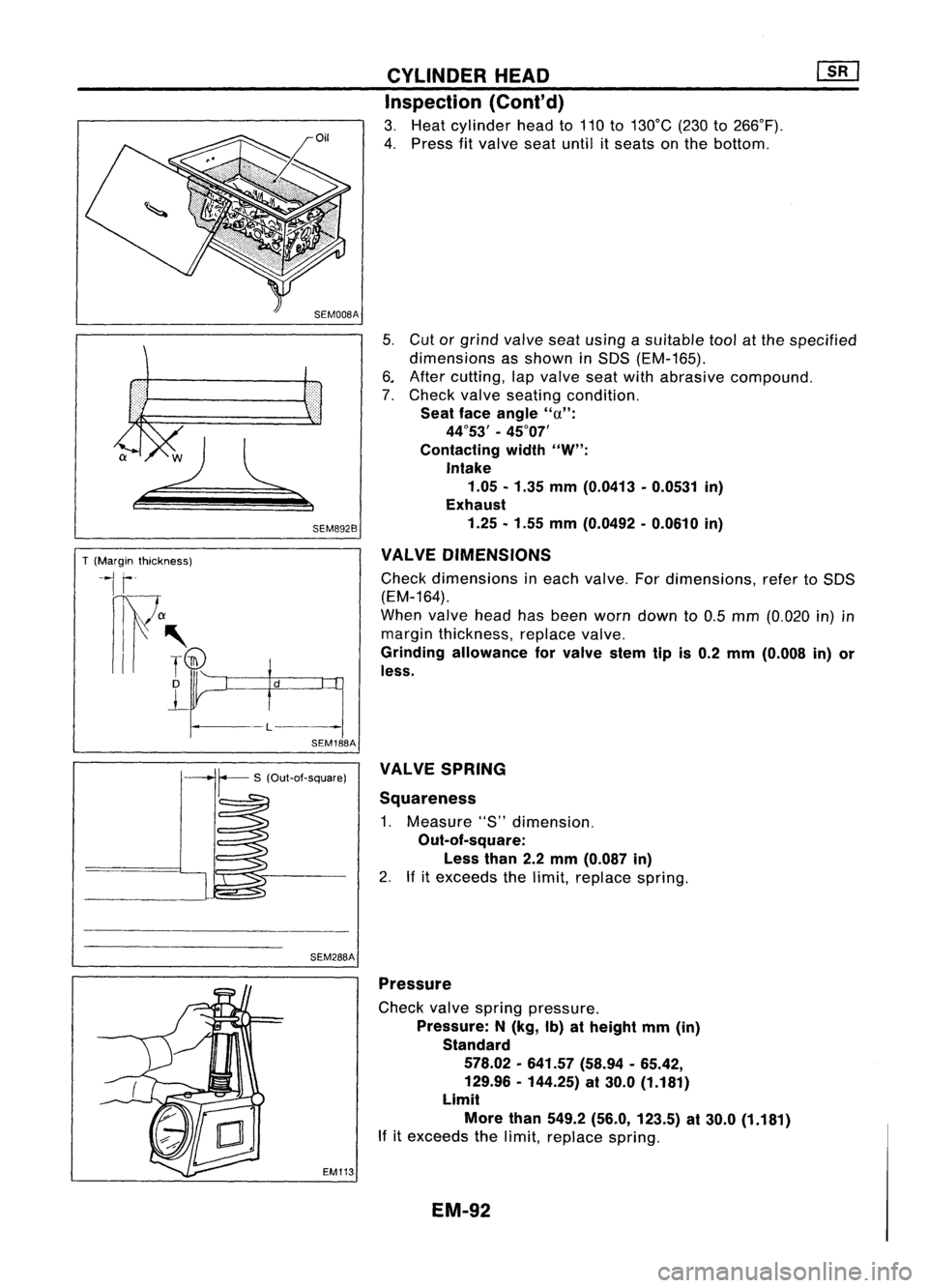

T(Margin thickness)

~I

r

nw

a

III' ~

D

L

-l

d

SEM892B

SEM188A CYLINDER

HEAD

Inspection (Cont'd)

3. Heat cylinder headto110 to130°C (230to266°F).

4. Press fitvalve seatuntil itseats onthe bottom.

5. Cut orgrind valve seatusing asuitable toolatthe specified

dimensions asshown inSDS (EM-165).

6. After cutting, lapvalve seatwithabrasive compound.

7. Check valveseating condition.

Seat faceangle

"u":

44°53' -45°07'

Contacting width

"W":

Intake 1.05 -1.35 mm(0.0413 -0.0531 in)

Exhaust

1.25 -1.55 mm(0.0492 -0.0610 in)

VALVE DIMENSIONS

Check dimensions ineach valve. Fordimensions, refertoSDS

(EM-164).

When valveheadhasbeen worn down to0.5 mm (0.020 in)in

margin thickness, replacevalve.

Grinding allowance forvalve stemtipis0.2 mm (0.008 in)or

less.

SEM288A VALVE

SPRING

Squareness

1. Measure "S"dimension.

Out-of-square:

Less than2.2mm (0.087 in)

2. Ifitexceeds thelimit, replace spring.

EM113 Pressure

Check valvespring pressure.

Pressure: N(kg, Ib)atheight mm(in)

Standard

578.02 -641.57 (58.94-65.42,

129.96 -144.25) at30.0 (1.181)

Limit

More than549.2 (56.0, 123.5) at30.0 (1.181)

If itexceeds thelimit, replace spring.

EM-92

Page 1315 of 1701

![NISSAN ALMERA N15 1995 User Guide SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsan NISSAN ALMERA N15 1995 User Guide SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsan](/img/5/57349/w960_57349-1314.png)

SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsandmeasure maximum widthof

plastigage. Camshaft bearingclearance:

Limit

0.1 mm (0.004 in)

5. Ifclearance appearstoexceed thelimit, replace camshaft

or cylinder head.

• Which partstobe replaced shouldbedecided uponafter

measuring thediameters ofthe parts concerned.

Assembly

1. Install valvecomponent parts.

Install valvespring withitsnarrow pitchsidetoward cylinder

head side.

• Always installnewvalve oilseals.

Refer tooil seal replacement.

• Before installing oilseal, install valve-spring seat.

• When installing valve,applyengine oilonthe valve stem

and lipofvalve oilseal.

• Check whether thevalve faceisfree from foreign matter.

• Install valvespring retainers onthe intake sideandvalve

rotators onthe exhaust side.

• Valve rotators cannotbedisassembled.

2. Install camshaft andbrackets andtighten bracket nutstothe

specified torqueintwo orthree stages.

Camshaft-bracket nuts:

~: 18-22 N'm (1.8-2.2 kg-m, 13-16 ft-Ib)

• Tighten bracketfromcenter tooutside.

• Apply sealant tobrackets No.1and No.5.

• When installing "brackets, setcamshaft sothat thepinof

camshaft fronthead isuppermost.

• Install newcamshaft oilseals.

Refer tooil seal replacement.

17.5 (0.689)

o

o

13.0

(0.512)

NO.1 journal bracket No.5journal bracket

Unit: mm(in)

SEM676D

EM-136

Page 1344 of 1701

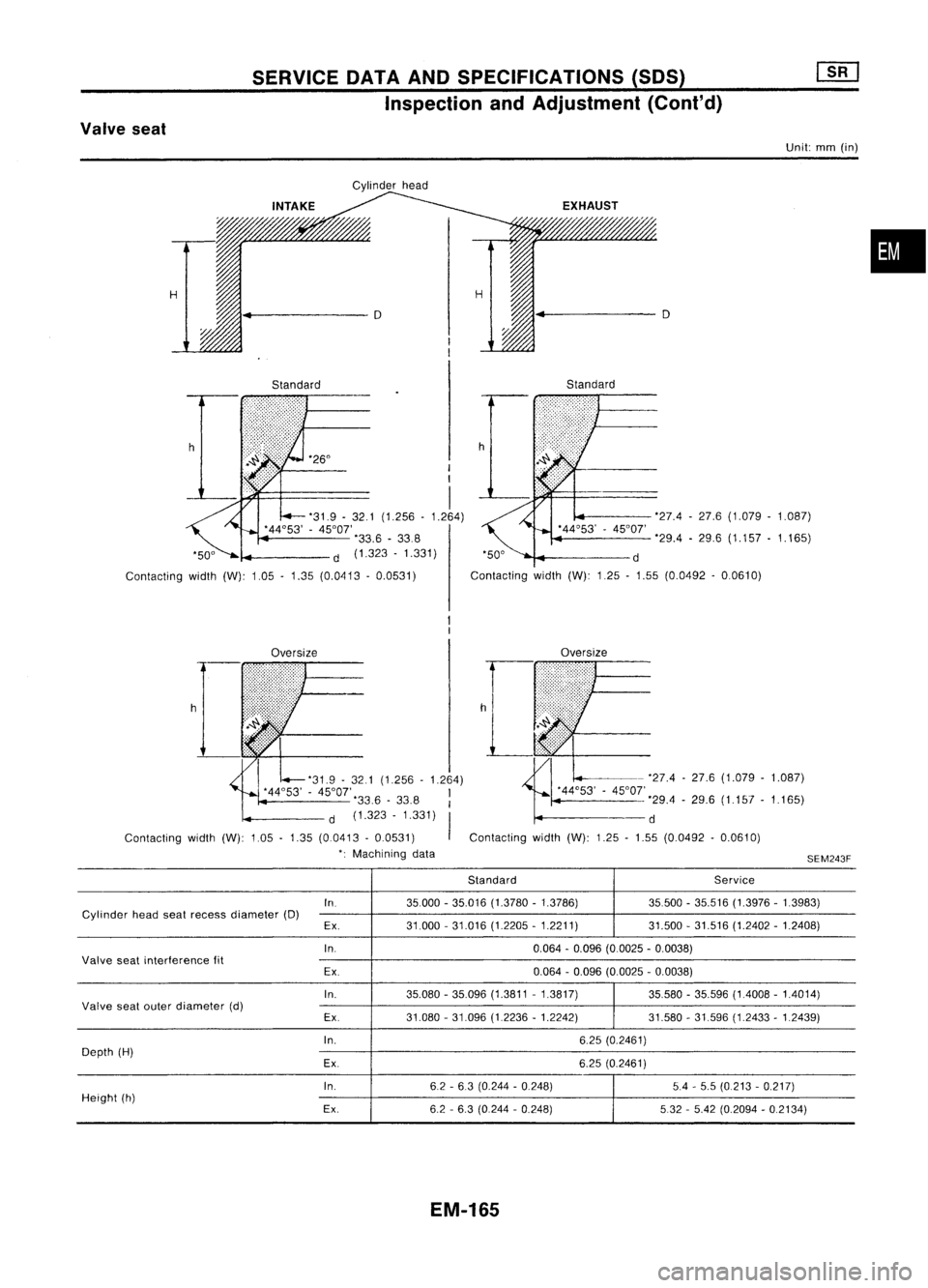

SERVICEDATAANDSPECIFICATIONS (SOS)

Inspection andAdjustment (Cont'd)

Valve seat

Unit:mm(in)

Cylinder head

•

H H

4

D D

Standard Standard

h '26°

I

I

I

'31.9 -32.1 (1.256 -1.264)

'44°53' -45°01'

'33.6-338

d (1.323 -1.331)

Contacting width(W):1.05-1.35 (0.0413 -0.0531) '27.4

-27.6 (1.079 -1.087)

'29.4 -29.6 (1.157 -1.165)

'50° d

Contacting width(W):125-1.55 (0.0492 -0.0610)

Oversize Oversize

'31.9 -321 (1.256 -1.264)

'44°53' -45°01', I

33.6 -33.8 I

d (1.323 -1.331)

I

Contacting width(W):1.05-1.35 (00413 -0.0531)

': Machining data h

-'27.4 -27.6 (1.079 -1.087)

'44°53' -45°01'

'29.4-29.6 (1.157 -1.165)

d

Contacting width(W):1.25-1.55 (0.0492 -0.0610)

SEM243F

Standard Service

In. 35000-35.016 (1.3780 -1.3786) 35500-35.516 (1.3976 -1.3983)

Cylinder headseatrecess diameter (D)

Ex. 31.000

-31.016 (1.2205 -1.2211) 31.500-31.516 (1.2402 -1.2408)

In. 0.064-0.096 (0.0025 -0.0038)

Valve seatinterference fit

Ex. 0.064

-0.096 (0.0025 -0.0038)

In. 35.080-35.096 (1.3811 -1.3817) 35.580-35.596 (1.4008 -1.4014)

Valve seatouter diameter (d)

Ex.31.080-31.096 (1.2236 -1.2242) 31.580-31.596 (1.2433 -1.2439)

In. 6.25(0.2461)

Depth (H)

Ex. 6.25(0.2461)

In. 62-63 (0.244 -0.248) 5.4-5.5 (0.213 -0.217)

Height (h)

Ex.6.2-6.3 (0.244 -0.248) 532-5.42 (0.2094 -0.2134)

EM-165

Page 1349 of 1701

SEM685D

#5

#4 ~

~il hole #3~~ \)

#2 ~~'

#1~~~ ~~

L2 ~~

Engine front~

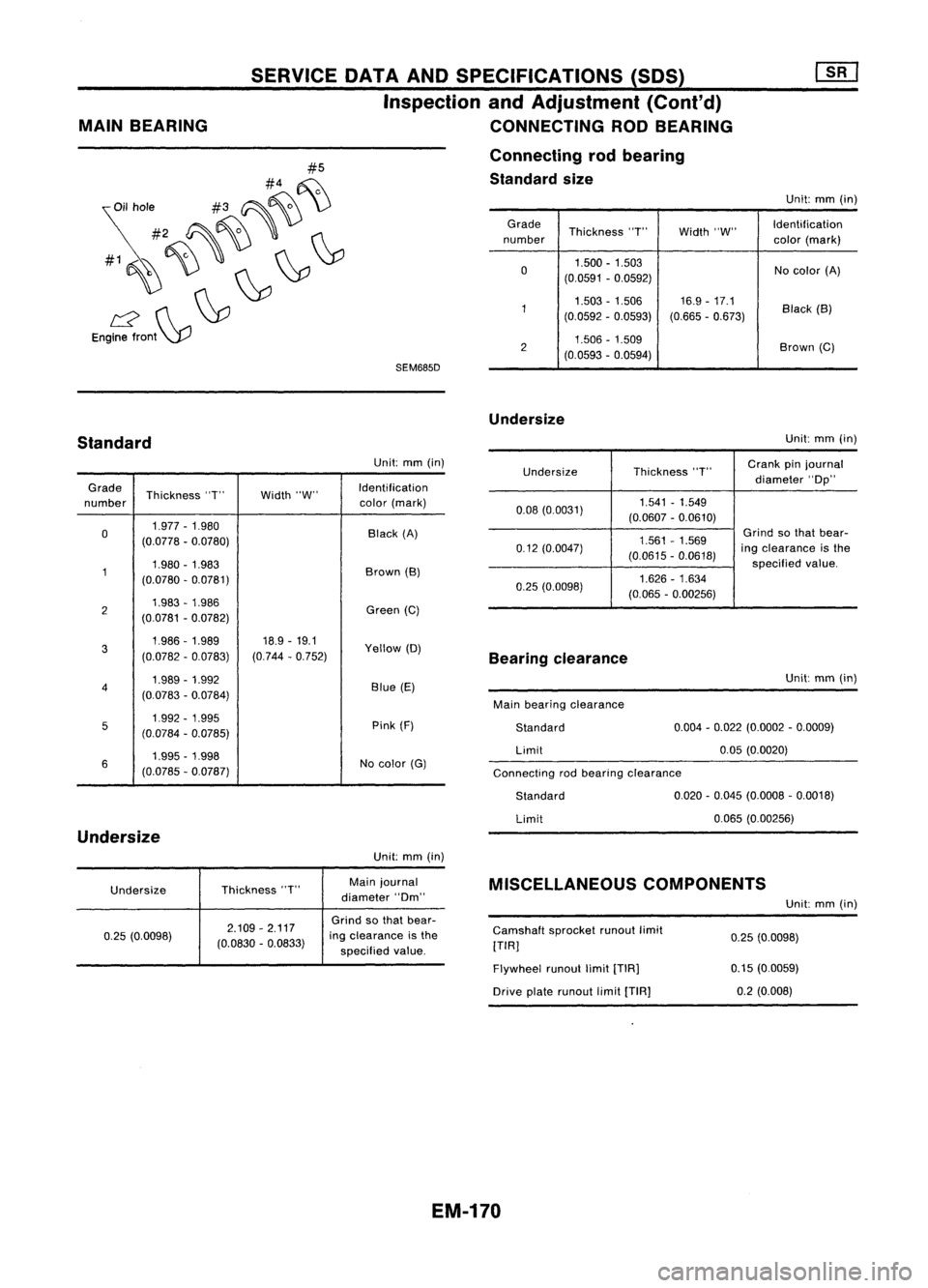

MAIN

BEARING SERVICE

DATAANDSPECIFICATIONS (SOS)

Inspection andAdjustment (Cont'd)

CONNECTING RODBEARING

Connecting rodbearing

Standard size

Unit:mm(in)

Grade Thickness"T"Width"W" Identification

number color(mark)

0 1.500

-1.503

Nocolor (A)

(0.0591 -0.0592)

1 1.503

-1.506 16.9-17.1

Black(B)

(0.0592 -0.0593) (0.665-0.673)

2 1.506

-1.509

Brown(C)

(0.0593 -0.0594)

Undersize

Standard

Unit:

mm(in)

Connecting rodbearing clearance

Undersize

Thickness

"T"

Crank

pinjournal

diameter "Op"

0.08 (0.0031) 1.541

-1.549

(0.0607 -0.0610)

1.561 -1.569

Grind

sothat bear-

0.12 (0.0047)

(0.0615-0.0618)

ing

clearance isthe

specified value.

0.25 (0.0098) 1.626

-1.634

(0.065 -0.00256)

Unit:

mm(in)

Grade Thickness "T"Width"W" Identification

number color

(mark)

0 1.977

-1.980

Black(A)

(0.0778 -0.0780)

1 1.980

-1.983

Brown(B)

(0.0780 -0.0781)

2 1.983

-1.986

Green(C)

(0.0781 -0.0782)

3 1.986-1.989

18.9-19.1

Yellow(D)

(0.0782 -0.0783) (0.744

-0.752)

4 1.989

-1.992

Blue(E)

(0.0783 -0.0784)

5 1.992

-1.995

Pink(F)

(0.0784 -0.0785)

6 1.995

-1.998

Nocolor (G)

(0.0785 -0.Q787)

Undersize

Unit:mm(in)

Bearing

clearance

Main bearing clearance

Standard

Limit

Standard

Limit Unit:

mm(in)

0.004 -0.022 (0.0002 -0.0009)

0.05 (0.0020)

0.020 -0.045 (0.0008 -0.0018)

0.065 (0.00256)

Undersize Thickness

"T" Main

journal

diameter "Om"

MISCELLANEOUS

COMPONENTS

Unit:mm(in)

0.25 (0.0098) 2.109

-2.117

(0.0830 -0.0833)

Grind

sothat bear-

ing clearance isthe

specified value. Camshaft

sprocketrunoutlimit

[TIR]

Flywheel runoutlimit[TIR]

Drive platerunout limit[TIA]

0.25

(0.0098)

0.15 (0.0059)

0.2 (0.008)

EM-170

Page 1354 of 1701

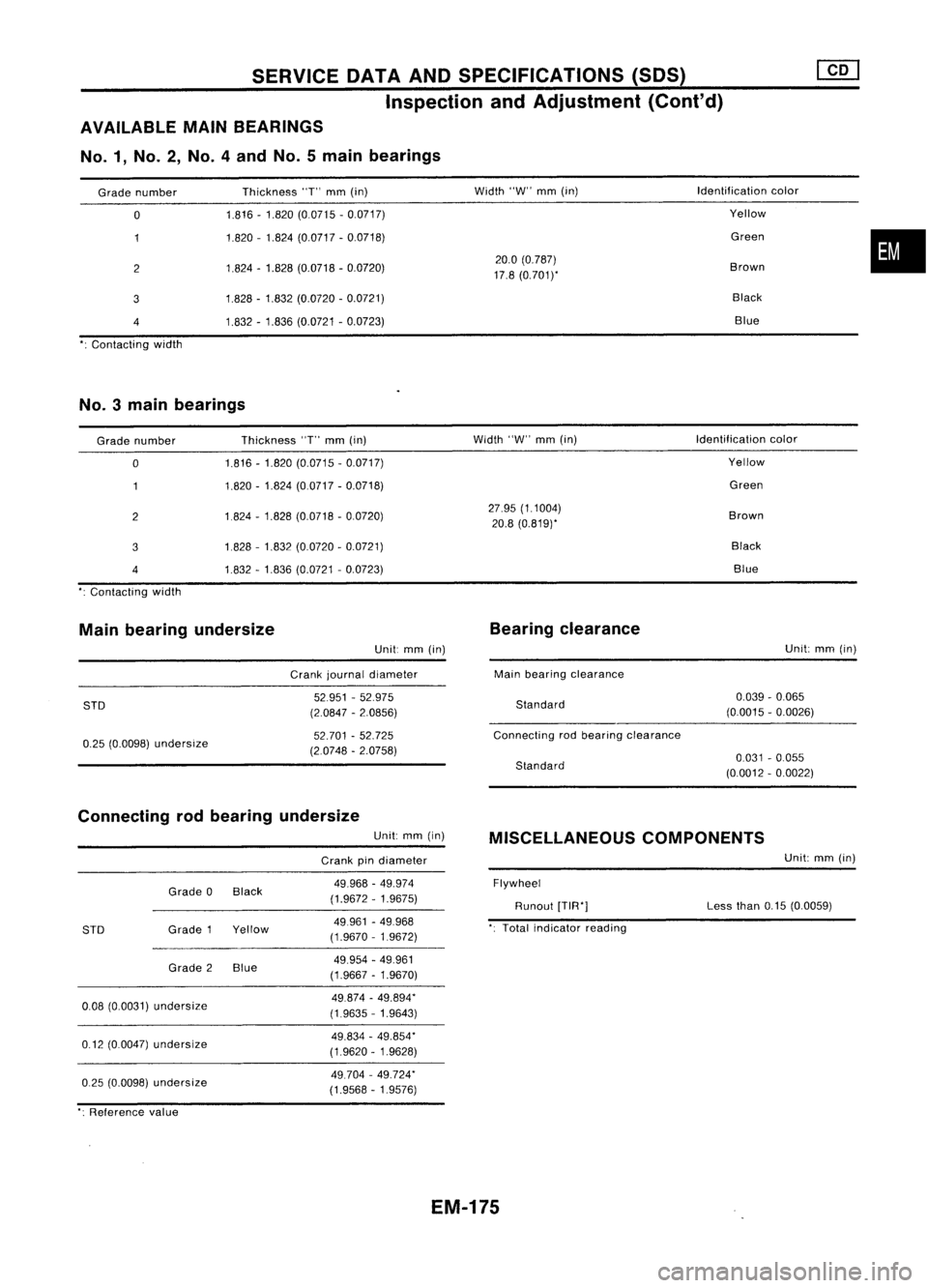

SERVICEOATAAND SPECIFICATIONS (SOS)

Inspection andAdjustment (Cont'd)

AVAILABLE MAINBEARINGS

No.1, No.2, No.4andNo.5main bearings

Grade number

o

2

3

4

Contacting width Thickness

"T"

mm

(in)

1.816 -1.820 (0.0715 -0.0717)

1.820 -1.824 (0.0717 -0.0718)

1.824 -1.828 (0.0718 -0.0720)

1.828 -1.832 (0.0720 -0.0721)

1.832 -1.836 (0.0721 -0.0723)

Width

"W"

mm

(in)

20.0 (0.787)

17.8 (0.7011'

Identification

color

Yellow

Green

Brown Black Blue

•

No.3 mainbearings

Grade number

o

2

3

4

Contacting width Thickness

"T"

mm

(in)

1.816 -1.820 (0.0715 -0.0717)

1.820 -1.824 (0.0717 -0.0718)

1.824 -1.828 (0.0718 -0.0720)

1828 -1.832 (0.0720 -0.0721)

1.832 -1.836 (0.0721 -0.0723)

Width

"W"

mm

(in)

27.95 (1.1004)

20.8 (0.819)'

Identification

color

Yellow

Green

Brown BlackBlue

Main bearing undersize

Unit:

mm

(in)

Crank journal diameter

Bearing

clearance

Main bearing clearance Unit:

mm

(in)

STD

0.25 (0.0098)

undersize

52951

-52.975

(2.0847 -2.0856)

52.701 -52.725

(2.0748 -2.0758)

Standard

Connecting rodbearing clearance

Standard

0.039

-0.065

(0.0015 -0.0026)

0.031 -0.055

(0.0012 -0.0022)

Connecting rodbearing undersize

Unit:

mm

(in)

Crank pindiameter

MISCELLANEOUS

COMPONENTS

Unit:

mm

(in)

0.25 (0.0098)

undersize

0.08

(0.0031)

undersize

0.12 (0.0047)

undersize

STD

Grade

0Black

Grade 1Yellow

Grade 2Blue

49.968

-49.974

(1.9672 -1.9675)

49961 -49.968

(1.9670 -1.9672)

49.954 -49.961

(1.9667 -1.9670)

49.874 -49.894"

(1.9635 -1.9643)

49.834 -49.854"

(1.9620 -1.9628)

49.704 -49.724"

(1.9568 -1.9576)

Flywheel

Runout

[TIR"]

Total indicator reading Less

than

0.15(0.0059)

": Reference value

EM-175

Page 1393 of 1701

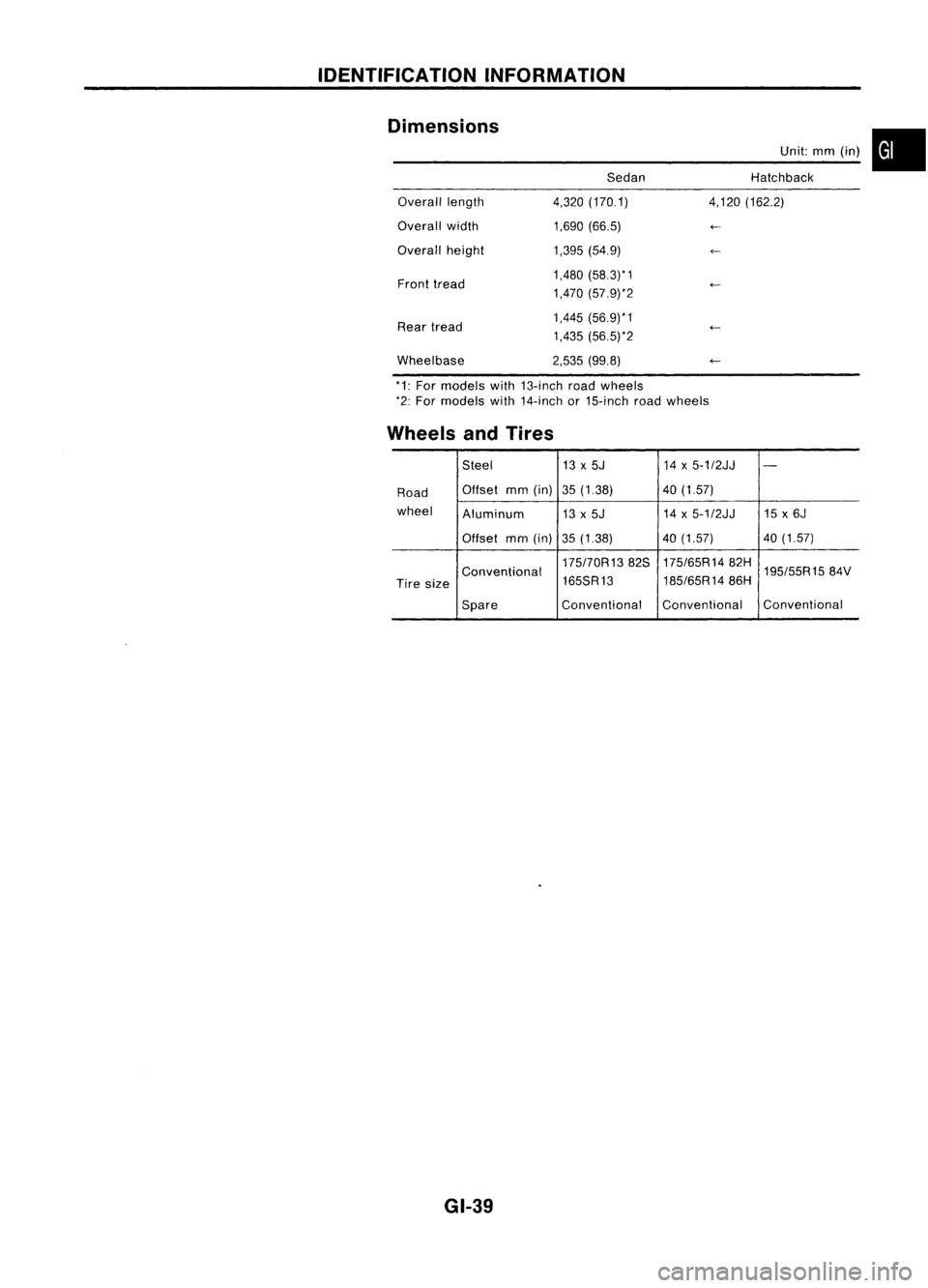

IDENTIFICATIONINFORMATION

Dimensions SedanUnit:

mm(in) •

Hatchback

Overall length

Overall width

Overall height

Front tread

Rear tread

Wheelbase 4,320

(170.1)

1,690 (66.5)

1,395 (54.9)

1,480 (58.3)* 1

1,470 (57.9)*2

1,445 (56.9)*1

1,435 (56.5)*2

2,535 (99.8) 4,120

(162.2)

*1: For models with13-inch roadwheels

*2: For models with14-inch or15-inch roadwheels

Wheels andTires

Steel 13x5J 14x5-1/2JJ

-

Road Offset

mm(in) 35(1.38) 40(1.57)

wheel Aluminum 13x5J 14

x5-1/2JJ 15x6J

Offset mm(in)

35(1.38) 40

(1.57) 40(1.57)

175170R1382S 175/65R1482H

195/55R1584V

Conventional

185/65R1486H

Tire size 165SR13

Spare Conventional

Conventional Conventional

GI-39